Nondestructive Tomographic Imaging of Rust with Rapid THz Time-Domain Spectroscopy

Abstract

:1. Introduction

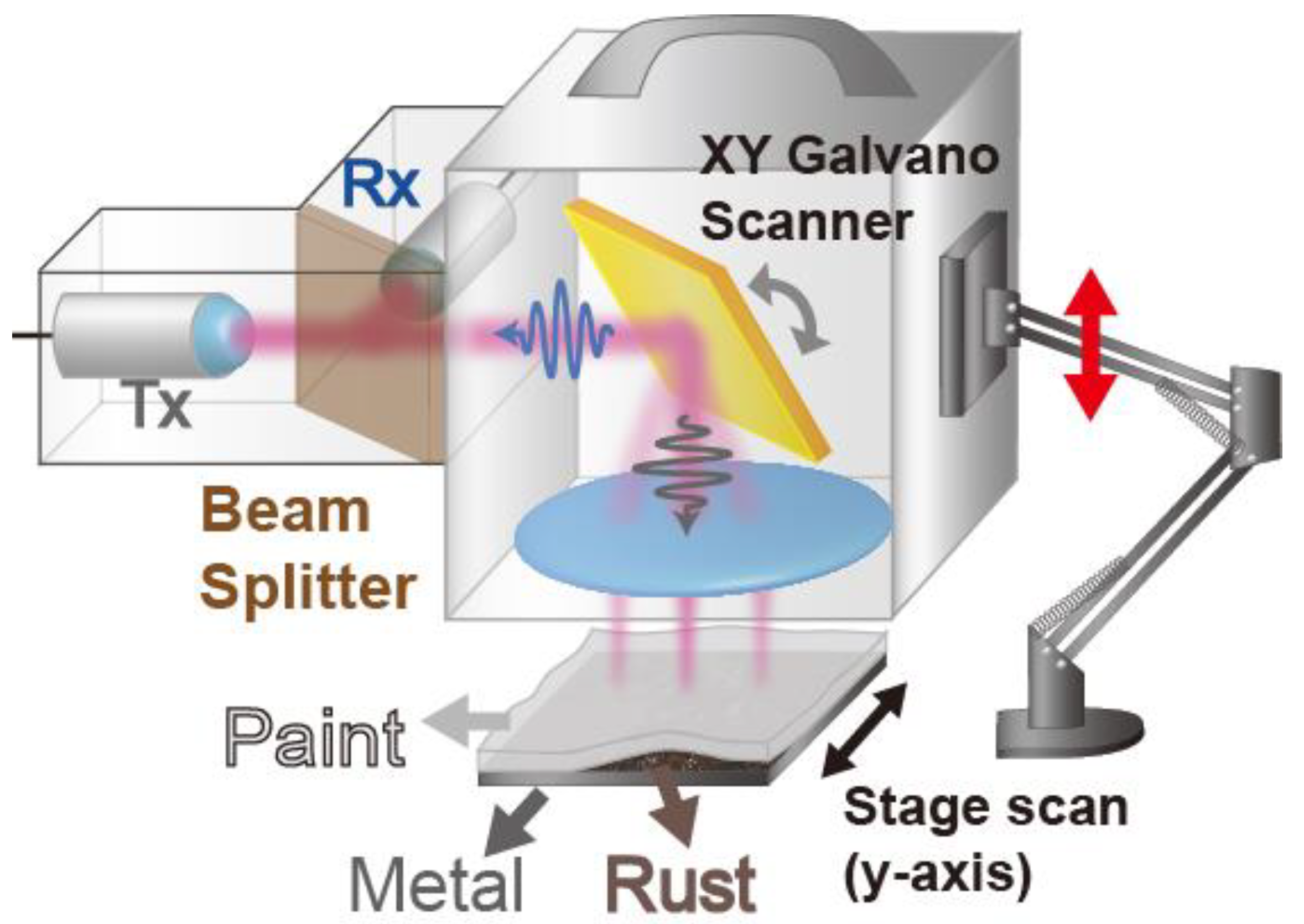

2. Experimental Setup

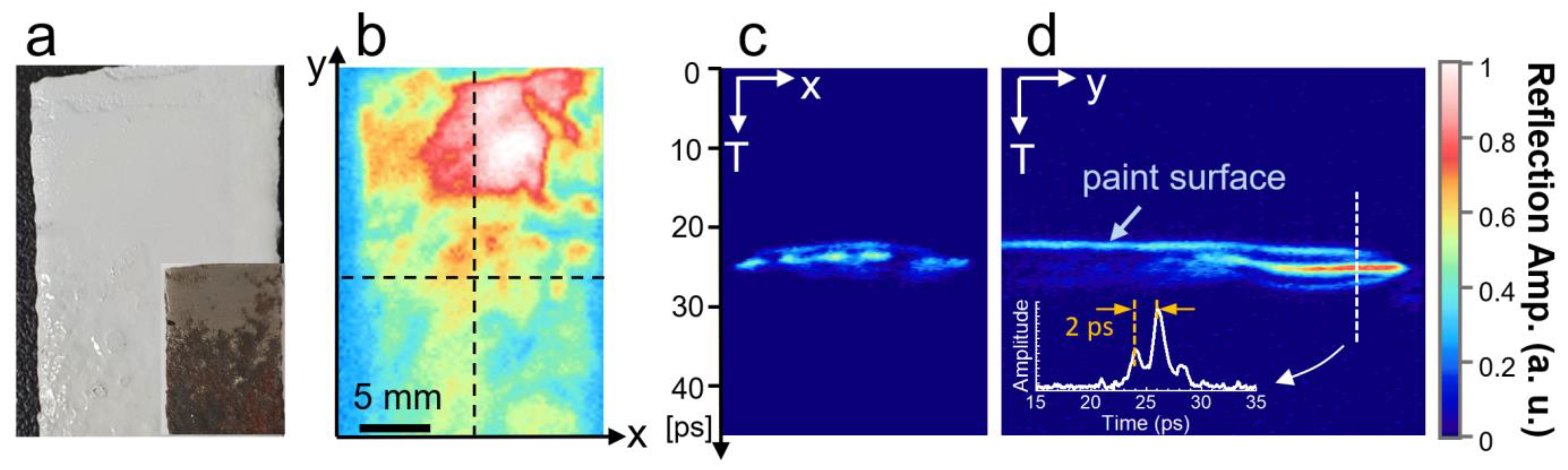

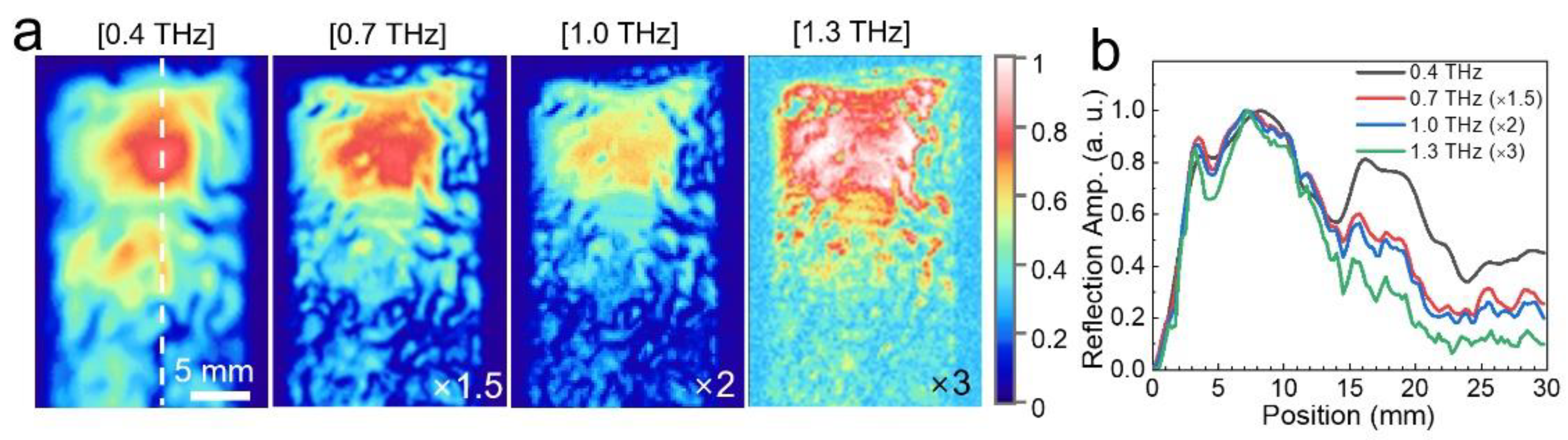

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shaw, B.; Kelly, R. What is corrosion? Electrochem. Soc. Interface 2006, 15, 24. [Google Scholar] [CrossRef]

- El-Meligi, A. Corrosion Preventive Strategies as a Crucial Need for Decreasing Environmental Pollution and Saving Economics. Re. Pat. Corr. Sci. 2010, 2, 22–33. [Google Scholar] [CrossRef] [Green Version]

- Hansson, C.M. The impact of corrosion on society. Metall. Mater. Trans. 2011, 42, 2952–2962. [Google Scholar] [CrossRef]

- Leidheiser, H., Jr. Corrosion of Painted Metals A Review. Corrosion 1982, 38, 374–383. [Google Scholar] [CrossRef]

- Morcillo, M. Soluble salts: Their effect on premature degradation of anticorrosive paints. Prog. Org. Coat. 1999, 36, 137–147. [Google Scholar] [CrossRef]

- Chico, B.; Morcillo, M. The effects of soluble salts at the metal/paint interface: Advances in knowledge. Port. Electrochim. Acta 2006, 24, 191–206. [Google Scholar]

- Rifai, D.; Abdalla, A.N.; Ali, K.; Razali, R. Giant magnetoresistance sensors: A review on structures and non-destructive eddy current testing applications. Sensors 2016, 16, 298. [Google Scholar] [CrossRef] [Green Version]

- Si, D.; Gao, B.; Guo, W.; Yan, Y.; Tian, G.Y.; Yin, Y. Variational mode decomposition linked wavelet method for EMAT denoise with large lift-off effect. NDT E Int. 2019, 107, 102149. [Google Scholar] [CrossRef]

- Wu, R.; Zhang, H.; Yang, R.; Chen, W.; Chen, G. Nondestructive Testing for Corrosion Evaluation of Metal under Coating. J. Sens. 2021, 2021. [Google Scholar] [CrossRef]

- Kawase, K.; Ogawa, Y.; Watanabe, Y.; Inoue, H. Non-destructive terahertz imaging of illicit drugs using spectral fingerprints. Opt. Express 2003, 11, 2549–2554. [Google Scholar] [CrossRef] [Green Version]

- Federici, J.F.; Schulkin, B.; Huang, F.; Gary, D.; Barat, R.; Oliveira, F.; Zimdars, D. THz imaging and sensing for security applications—Explosives, weapons and drugs. Semicond. Sci. Technol. 2005, 20, S266–S280. [Google Scholar] [CrossRef]

- Shen, Y.C.; Lo, T.; Taday, P.F.; Cole, B.E.; Tribe, W.R.; Kemp, M.C. Detection and identification of explosives using terahertz pulsed spectroscopic imaging. Appl. Phys. Lett. 2005, 86, 1–3. [Google Scholar] [CrossRef] [Green Version]

- Zhong, H.; Xu, J.; Xie, X.; Yuan, T.; Reightler, R.; Madaras, E.; Zhang, X.C. Nondestructive defect identification with terahertz time-of-flight tomography. IEEE Sens. J. 2005, 5, 203–207. [Google Scholar] [CrossRef]

- Karpowicz, N.; Redo, A.; Zhong, H.; Li, X.; Xu, J.; Zhang, X.C. Continuous-wave terahertz imaging for non-destructive testing applications. In Proceedings of the Joint 30th International Conference on Infrared and Millimeter Waves and 13th International Conference on Terahertz Electronics, Williamsburg, VA, USA, 19–23 September 2005. [Google Scholar]

- Schirmer, M.; Fujio, M.; Minami, M.; Miura, J.; Araki, T.; Yasui, T. Biomedical applications of a real-time terahertz color scanner. Biomed. Opt. Express 2010, 1, 354–366. [Google Scholar] [CrossRef] [Green Version]

- Kawase, K.; Shibuya, T.; Hayashi, S.; Suizu, K. THz imaging techniques for nondestructive inspections. Comptes Rendus Phys. 2010, 11, 510–518. [Google Scholar] [CrossRef]

- Jin, K.H.; Kim, Y.-G.; Cho, S.H.; Ye, J.C.; Yee, D.-S. High-speed terahertz reflection three-dimensional imaging for nondestructive evaluation. Opt. Express 2012, 20, 25432–25440. [Google Scholar] [CrossRef] [PubMed]

- Park, S.H.; Jang, J.W.; Kim, H.S. Non-destructive evaluation of the hidden voids in integrated circuit packages using terahertz time-domain spectroscopy. J. Micromech. Microeng. 2015, 25, 095007. [Google Scholar] [CrossRef]

- Park, S.J.; Yoon, S.A.N.; Ahn, Y.H. Dielectric constant measurements of thin films and liquids using terahertz metamaterials. RSC Adv. 2016, 6, 69381–69386. [Google Scholar] [CrossRef]

- Fan, S.; Li, T.; Zhou, J.; Liu, X.; Liu, X.; Qi, H.; Mu, Z. Terahertz non-destructive imaging of cracks and cracking in structures of cement-based materials. AIP Adv. 2017, 7, 115202. [Google Scholar] [CrossRef] [Green Version]

- Park, S.J.; Kim, A.R.; Hong, J.T.; Park, J.Y.; Lee, S.; Ahn, Y.H. Crystallization Kinetics of Lead Halide Perovskite Film Monitored by In Situ Terahertz Spectroscopy. J. Phys. Chem. 2017, 8, 401–406. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.S.; Sung, H.C.; Roy, B.; Kim, S.; Ahn, Y.H. Humidity sensing using THz metamaterial with silk protein fibroin. Opt. Express 2018, 26, 33575–33581. [Google Scholar] [CrossRef]

- Ahi, K.; Shahbazmohamadi, S.; Asadizanjani, N. Quality control and authentication of packaged integrated circuits using enhanced-spatial-resolution terahertz time-domain spectroscopy and imaging. Opt. Lasers Eng. 2018, 104, 274–284. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Ren, J.J.; Li, L.J.; Gu, J.; Zhang, D.D. THz imaging technique for nondestructive analysis of debonding defects in ceramic matrix composites based on multiple echoes and feature fusion. Opt. Express 2020, 28, 19901–19915. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.S.; Ha, N.Y.; Park, J.Y.; Lee, S.; Kim, D.S.; Ahn, Y.H. Phonon-Polaritons in Lead Halide Perovskite Film Hybridized with THz Metamaterials. Nano Lett. 2020, 20, 6690–6696. [Google Scholar] [CrossRef] [PubMed]

- Bartels, A.; Cerna, R.; Kistner, C.; Thoma, A.; Hudert, F.; Janke, C.; Dekorsy, T. Ultrafast time-domain spectroscopy based on high-speed asynchronous optical sampling. Rev. Sci. Instrum. 2007, 78, 035107. [Google Scholar] [CrossRef] [Green Version]

- Wilk, R.; Hochrein, T.; Koch, M.; Mei, M.; Holzwarth, R. OSCAT: Novel technique for time-resolved experiments without moveable optical delay lines. J. Infrared Millim. Terahertz Waves 2011, 32, 596–602. [Google Scholar] [CrossRef]

- Yim, J.H.; Kim, S.Y.; Kim, Y.; Cho, S.; Kim, J.; Ahn, Y.H. Rapid 3d-imaging of semiconductor chips using thz time-of-flight technique. Appl. Sci. 2021, 11, 4770. [Google Scholar] [CrossRef]

- Kong, D.Y.; Wu, X.J.; Wang, B.; Gao, Y.; Dai, J.; Wang, L.; Ruan, C.J.; Miao, J.G. High resolution continuous wave terahertz spectroscopy on solid-state samples with coherent detection. Opt. Express 2018, 26, 17964–17976. [Google Scholar] [CrossRef]

- Komatsu, M.; Sato, R.; Mizuno, M.; Fukunaga, K.; Ohki, Y. Feasibility study on terahertz imaging of corrosion on a cable metal shield. Jpn. J. Appl. Phys. 2012, 51, 122405. [Google Scholar] [CrossRef]

- Wu, D.B.; Zhao, H.; Liu, H.L.; Zhao, K.; Sun, Q. THz spectrum of iron corrosion products. In Proceedings of the Selected Photoelectronic Technology Committee Conferences, China, China, 1 August 2014. [Google Scholar]

- Fuse, N.; Sugae, K. Non-destructive terahertz imaging of alkali products in coated steels with cathodic disbanding. Prog. Org. Coat. 2019, 137, 105334. [Google Scholar] [CrossRef]

- Fuse, N.; Fukuchi, T.; Takahashi, T.; Mizuno, M.; Fukunaga, K. Evaluation of applicability of noncontact analysis methods todetect rust regions in coated steel plates. IEEE Trans. Terahertz Sci. Technol. 2012, 2, 242–249. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.S.; Baik, S.Y.; Lee, J.W.; Kim, J.; Ahn, Y.H. Nondestructive Tomographic Imaging of Rust with Rapid THz Time-Domain Spectroscopy. Appl. Sci. 2021, 11, 10594. https://doi.org/10.3390/app112210594

Kim HS, Baik SY, Lee JW, Kim J, Ahn YH. Nondestructive Tomographic Imaging of Rust with Rapid THz Time-Domain Spectroscopy. Applied Sciences. 2021; 11(22):10594. https://doi.org/10.3390/app112210594

Chicago/Turabian StyleKim, Hwan Sik, Seung Yeob Baik, Joong Wook Lee, Jangsun Kim, and Yeong Hwan Ahn. 2021. "Nondestructive Tomographic Imaging of Rust with Rapid THz Time-Domain Spectroscopy" Applied Sciences 11, no. 22: 10594. https://doi.org/10.3390/app112210594