Determining the Print Quality Due to Deformation of the Halftone Dots in Flexography

Abstract

:1. Introduction

2. Tone Reproduction in Flexography

- Decrease the line ruling on the printing plate. This increases the minimum dot size on the printing plate and thus optimizes the ratio to the cell size of the anilox roller. The print quality is generally reduced;

- Use an anilox roller of a higher line count, if available. This leads to a smaller cell opening size and hence a better adjustment to the minimum size of the dot;

- Increase the size of the minimum dot by using a “bump-up” curve in the prepress. This means keeping the same line ruling of the polymer plate, which also reduces the tonal range on printouts;

- Apply advanced hybrid screening technologies that, via a different approach, allow better reproduction of highlight tones [20].

3. Methods

4. Results

4.1. The Influence of a Print Run on the Dot Deformation

4.1.1. Analysis of Dot Coverages

4.1.2. Analysis of the Uniformity of the Ink Density and Dot Sharpness

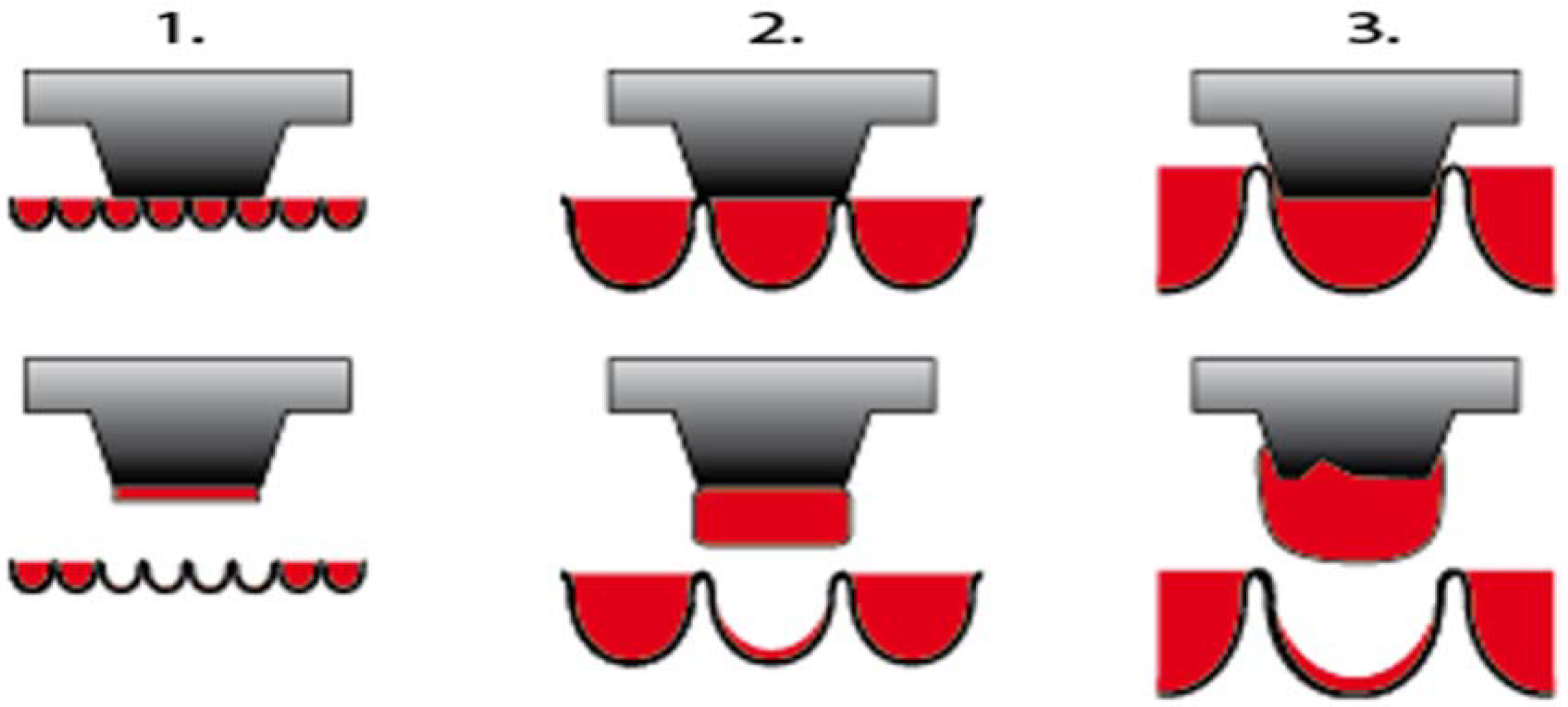

4.2. Dot Deformation Caused by Incorrect Printing Settings

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Crouch, J.P. Flexography Primer; Graphic Arts Technical Foundation: Pittsburgh, PA, USA, 1998. [Google Scholar]

- Johnson, J.; Andersson, C.; Lestelius, M.; Jarnstrom, L.; Ratto, P.; Blohm, E. Some properties of flexographic printing plates and aspects of print quality. Appita Technol. Innov. Manuf. Environ. 2009, 62, 371–378. [Google Scholar]

- Liu, X.; Guthrie, J.; Bryant, C. A study of the processing of flexographic solid-sheet photopolymer printing plates. Surf. Coat. Int. Part B Coat. Trans. 2002, 85, 313–319. [Google Scholar] [CrossRef]

- Theohari, S.; Fraggedakis, E.; Tsimis, D.; Mandis, D. Effect of Paper Properties on Print Quality by Flexographic Method. In Proceedings of the 46th Annual International Conference on Graphic Arts and Media Technology, Athens, Greece, 25–29 May 2014. [Google Scholar]

- Laurent, G. Measurement and Prediction Procedures for Printability in Flexography (MP3 Flexo); Royal Institute of Technology: Stockholm, Sweden, 2002. [Google Scholar]

- Valdec, D.; Miljković, P.; Auguštin, B. The influence of printing substrate properties on color characterization in flexography according to the ISO specifications. Tech. J. 2017, 11, 73–77. [Google Scholar]

- Kipphan, H. Handbook of Print Media: Technologies and Production Methods; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Izdebska-Podsiadły, J. Effect of Plasma Surface Modification on Print Quality of Biodegradable PLA Films. Appl. Sci. 2021, 11, 8245. [Google Scholar] [CrossRef]

- Bould, D.; Claypole, T.; Bohan, M.; Gethin, D. Deformation of flexographic printing plates. In Proceedings of the 56th TAGA Technical Conference, TAGA, San Antonio, TX, USA, 18–21 April 2004; pp. 146–162. [Google Scholar]

- Anderson, J.; Schlotthauer, E. Kodak’s Flat Top Dots: The Effect of Flexo Dot Shape on Plate Stress and Wear; Eastman Kodak Company Rochester: New York, NY, USA, 2010. [Google Scholar]

- Valdec, D.; Zjakić, I.; Milković, M. The influence of variable parameters of flexographic printing on dot geometry of pre-printed printing substrate. Tech. Gaz. 2013, 20, 659–667. [Google Scholar]

- Konyukhov, V.Y.; Komarova, L.Y.; Rekus, I. The Changing of Deformation Properties of Flexo Plates in the Process of Swelling in Solvents. Trans. Tech. Publ. 2021, 1031, 75–79. [Google Scholar] [CrossRef]

- Bould, D.; Claypole, T.; Bohan, M. An investigation into plate deformation in flexographic printing. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2004, 218, 1499–1511. [Google Scholar] [CrossRef]

- Gilbert, E.D.; Lee, F. Flexographic plate technology: Conventional solvent plates versus digital solvent plates. J. Ind. Technol. 2008, 24, 1–7. [Google Scholar]

- Liu, X.; Guthrie, J. A review of flexographic printing plate development. Surf. Coat. Int. Part B Coat. Trans. 2003, 86, 91–99. [Google Scholar] [CrossRef]

- Gooran, S. Hybrid Halftoning, a useful method for flexography. J. Imaging Sci. Technol. 2005, 49, 85–95. [Google Scholar]

- Mahovic Poljacek, S.; Tomasegovic, T.; Cigula, T.; Gojo, M.; Milcic, D. Formation of the printing elements in the photopolymer material used in flexography. Trans. Tech. Publ. 2014, 611, 883–891. [Google Scholar] [CrossRef]

- Valdec, D.; Miljković, P.; Čerepinko, D. The Impact of Top Dot Shapes of the Printing Plate on Dot Formation in Flexography. Tech. Gaz. 2018, 25, 596–602. [Google Scholar]

- Havenko, S.; Ohirko, M.; Ryvak, P.; Kotmalova, O. Determining the Factors That Affect the Quality of Test Prints at Flexographic Printing. East.-Eur. J. Enterp. Technol. 2020, 2, 53–63. [Google Scholar] [CrossRef]

- Yung-Cheng, H.; Hui-Wen, C.; Yuan-Hao, C.; Shu-Yu, C.; Sing, N.V. Flexible Hybrid Screening Solutions for Flexography. IEEE 2008, 6, 393–397. [Google Scholar]

- Bohan, M.; Townsend, P.; Hamblyn, S.; Claypole, T.; Gethin, D. Evaluation of pressures in flexographic printing. TAGA 2003, 1998, 311–321. [Google Scholar]

- Fetsko, J.M.; Walker, W.C. Measurements of ink transfer in printing coated paper. Am. Ink. Maker 1955, 33, 38–42. [Google Scholar]

- Yusof, M.; Claypole, T.; Gethin, D.; Zaidi, A.A. Application of finite elements on non-linear deformation of flexographic photopolymer printing plate. In Proceedings of the World Congress on Engineering, London, UK, 2–4 July 2008; Volume 2, pp. 1–5. [Google Scholar]

- Bould, D.; Claypole, T.; Bohan, M. An experimental investigation into flexographic printing plates. J. Graph. Technol. 2004, 1, 1–8. [Google Scholar]

- Bould, D.C.; Hamblyn, S.M.; Gethin, D.T.; Claypole, T.C. Effect of impression pressure and anilox specification on solid and halftone density. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 699–709. [Google Scholar] [CrossRef]

- Harper, C. Aniloks line screen–stabilizer of the ink film. Flexo Grav. Asia 2005, 4, 14–15. [Google Scholar]

- Valdec, D.; Hajdek, K.; Majnarić, I.; Čerepinko, D. Influence of Printing Substrate on Quality of Line and Text Reproduction in Flexography. Appl. Sci. 2021, 11, 7827. [Google Scholar] [CrossRef]

- Novaković, D.; Dedijer, S.; Mahović Poljaček, S. A model for improving the flexographic printing plate making process. Tech. Gaz. 2010, 17, 403–410. [Google Scholar]

- Tse, M.-K. PIAS-IITM–A High-Performance Portable Tool for Print Quality Analysis Anytime, Anywhere; Quality Engineering Associates (QEA), Inc.: Billerica, MA, USA, 2007; pp. 1–4. [Google Scholar]

- Wolin, D.; Johnson, K.; Kipman, Y. The importance of objective analysis in image quality evaluation. In NIP & Digital Fabrication Conference, 1998 International Conference on Digital Printing Technologie; Society for Imaging Science and Technology: Springfield, VA, USA, 1998; pp. 603–606. [Google Scholar]

- Valdec, D.; Čerepinko, D.; Tomiša, M. An analytical approach for determining the mechanical dot gain of AM and FM screen technology. Tech. J. 2015, 9, 446–450. [Google Scholar]

- Fleming, P.D.; Cawthorne, J.E.; Mehta, F.; Halwawala, S.; Joyce, M.K. Interpretation of dot fidelity of ink jet dots based on image analysis. J. Imaging Sci. Technol. 2003, 47, 394–399. [Google Scholar]

- Galton, D. A study of the effects of the process parameters on the flexographic printing problem “dot bridging”—Part II: Experimental design and print contrast/density. Pigment Resin Technol. 2005, 34, 94–100. [Google Scholar] [CrossRef]

- Miljković, P.; Valdec, D.; Matijević, M. The impact of printing substrate on dot deformation in flexography. Tech. Gaz. 2018, 25, 509–515. [Google Scholar]

- Żołek-Tryznowska, Z.; Rombel, M.; Petriaszwili, G.; Dedijer, S.; Kašiković, N. Influence of Some Flexographic Printing Process Conditions on the Optical Density and Tonal Value Increase of Overprinted Plastic Films. Coatings 2020, 10, 816. [Google Scholar] [CrossRef]

| Plate-Making Process Specification | |

|---|---|

| Ctp device | Hell HelioFlex F1200 (LAMS technology) |

| Resolution | 2540 dpi |

| Photopolymer type | Flint nyloflex ACE, 62 shore A |

| Plate thickness | 1.14 mm |

| Base layer thickness | 0.125 mm |

| Line ruling | 133 lines per inch (lpi) |

| Screening type | Conventional AM, round dot shape |

| Printing Specifications | |

| Flexo printing machine | Nilpeter FA-17 |

| Printing speed | 120 m/min |

| Process flexo inks | UV FoilStar LM yellow, magenta, cyan, black |

| White flexo ink | LightStar UV Opaque White Foil FCM ED405700 |

| UV curing | UV Lamp-Mercury Wavelength, 600 WPI output power (watts per inch) |

| Printing width | 450 mm |

| Plate mounting tape | 3M E315, 0.38 mm thickness |

| Print run | 500,000 labels (experiment 1); 200,000 labels (experiment 2) |

| Anilox Roller Specifications | |

| Cyan | 440 c/cm (1020 cpi); 4.0 cm3/m2 |

| Magenta | 440 c/cm (1020 cpi); 3.0 cm3/m2 |

| Yellow | 440 c/cm (1020 cpi); 3.0 cm3/m2 |

| Black | 340 c/cm (860 cpi); 5.7 cm3/m2 |

| White | 120 c/cm (300 cpi); 8.6 cm3/m2 |

| Printing Substrate Specifications | |

| Experiment 1 | High shrinkage 45 μm transparency Polyvinyl Chloride (PVC) shrink film for label printing; thickness: 45 μm; hardness: soft; shrinkage: 45–53% |

| Experiment 2 | Transparent 40 μm Biaxially Oriented Polypropylene (BOPP) film; thickness: 40 μm |

| Halftone Dots No. | First Good Print | 100,000th Print | 500,000th Print | |||

|---|---|---|---|---|---|---|

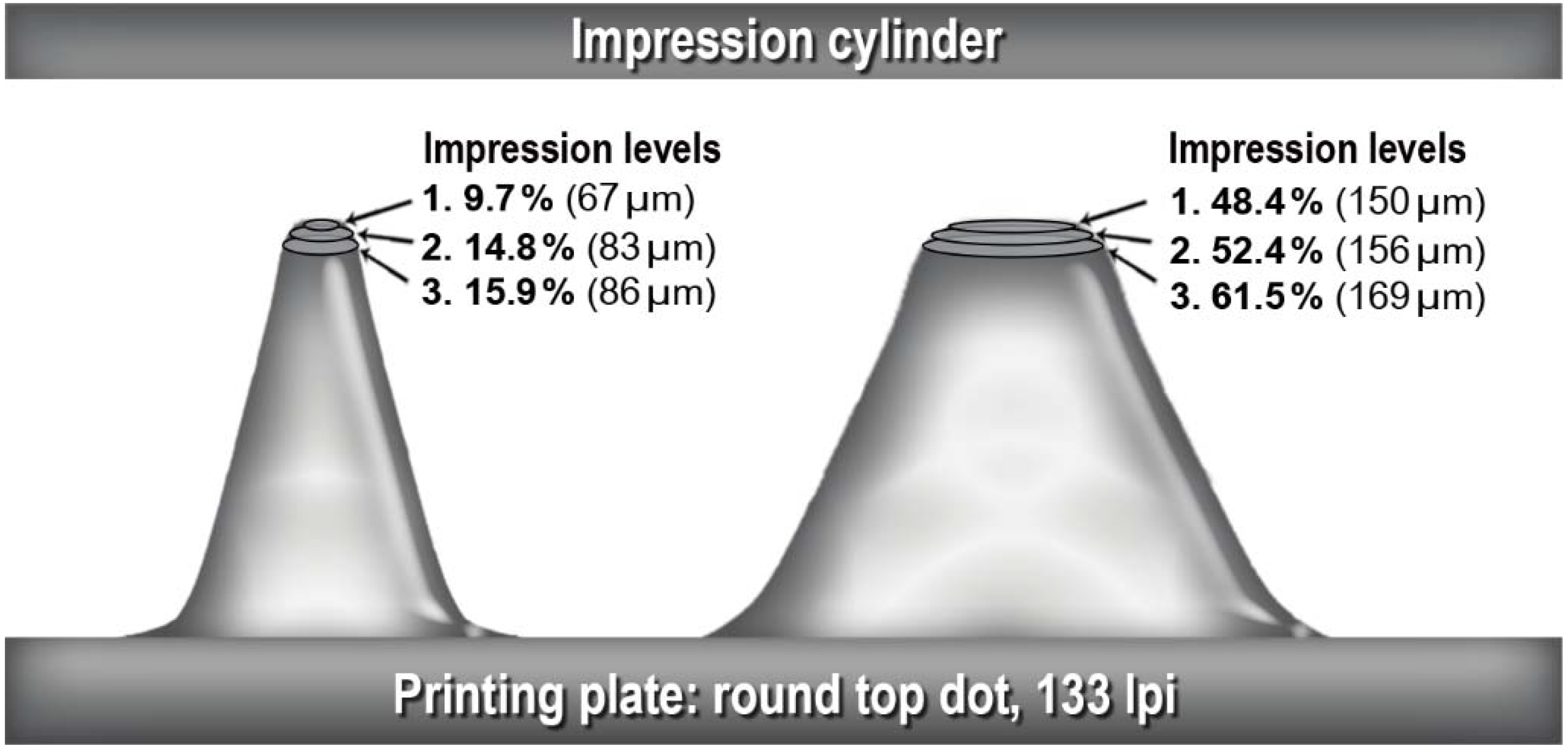

| 1 | 161 | 55.8 | 166 | 59.3 | 180 | 69.7 |

| 2 | 150 | 48.4 | 156 | 52.4 | 169 | 61.5 |

| 3 | 118 | 30 | 127 | 34.7 | 135 | 39.2 |

| 4 | 83 | 14.8 | 96 | 19.8 | 101 | 21.9 |

| 5 | 67 | 9.7 | 83 | 14.8 | 86 | 15.9 |

| Plate Line Screen 133 lpi (52 L/cm) | |||||

|---|---|---|---|---|---|

| Plate Dot (%) | 1% | 2% | 3% | 4% | 5% |

| Plate Dot Diameter (μm) | 22 | 30 | 37 | 43 | 48 |

| Anilox Roller Praxair Proline 60° | |||||

| Anilox Line Count (cpi) | 1120 | 800 | 650 | 600 | 500 |

| Anilox Line Count (c/cm) | 440 | 315 | 260 | 240 | 200 |

| Anilox Cell Size (μm) | 21 | 33 | 39 | 42 | 50 |

| Anilox Cell Opening (μm) | 18 | 29 | 35 | 38 | 45 |

| Anilox Cell Wall (μm) | 3 | 4 | 4 | 4 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valdec, D.; Hajdek, K.; Vragović, L.; Geček, R. Determining the Print Quality Due to Deformation of the Halftone Dots in Flexography. Appl. Sci. 2021, 11, 10601. https://doi.org/10.3390/app112210601

Valdec D, Hajdek K, Vragović L, Geček R. Determining the Print Quality Due to Deformation of the Halftone Dots in Flexography. Applied Sciences. 2021; 11(22):10601. https://doi.org/10.3390/app112210601

Chicago/Turabian StyleValdec, Dean, Krunoslav Hajdek, Lucia Vragović, and Robert Geček. 2021. "Determining the Print Quality Due to Deformation of the Halftone Dots in Flexography" Applied Sciences 11, no. 22: 10601. https://doi.org/10.3390/app112210601

APA StyleValdec, D., Hajdek, K., Vragović, L., & Geček, R. (2021). Determining the Print Quality Due to Deformation of the Halftone Dots in Flexography. Applied Sciences, 11(22), 10601. https://doi.org/10.3390/app112210601