Development and Validation of an ICP-AES Method for the Determination of Toxic and Nutrient Metals in Candies: Application for the Analysis of Different Samples from the Greek Market

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Instrumentation

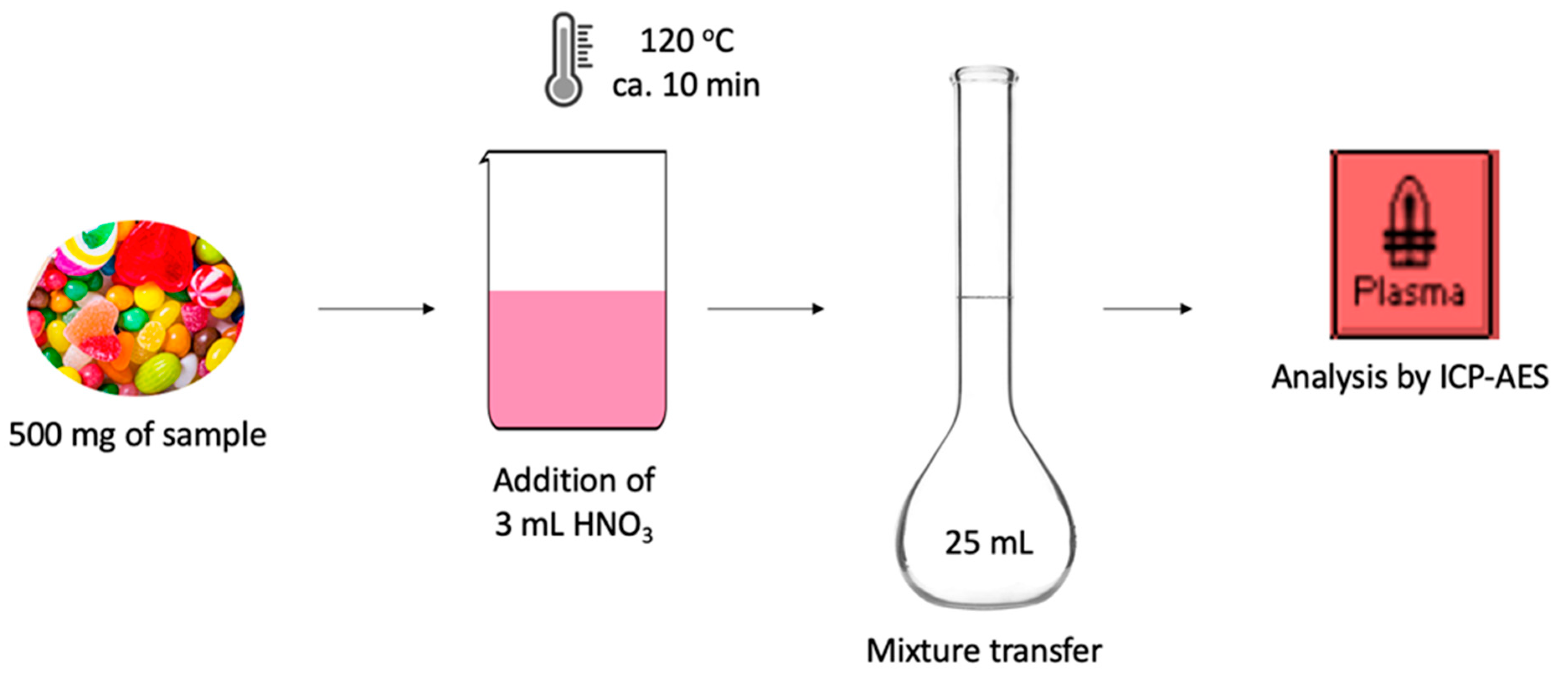

2.3. Sample Collection and Preparation

2.4. Method Validation

3. Results and Discussion

3.1. Dissolution Procedures

3.2. Figures of Merit

3.3. Analysis of Samples

3.4. Comparison with Other Studies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Miller-Ihli, N.J. Trace Element Determinations in Foods and Biological Samples Using Inductively Coupled Plasma Atomic Emission Spectrometry and Flame Atomic Absorption Spectrometry. J. Agric. Food Chem. 1996, 44, 2675–2679. [Google Scholar] [CrossRef]

- Momen, A.A.; Zachariadis, G.A.; Anthemidis, A.N.; Stratis, J.A. Use of fractional factorial design for optimization of digestion procedures followed by multi-element determination of essential and non-essential elements in nuts using ICP-OES technique. Talanta 2007, 71, 443–451. [Google Scholar] [CrossRef] [PubMed]

- Birghila, S.; Dobrinas, S.; Stanciu, G.; Soceanu, A. Determination of major and minor elements in milk through ICP-AES. Environ. Eng. Manag. J. 2008, 7, 805–808. [Google Scholar] [CrossRef]

- Kim, K.C.; Park, Y.B.; Lee, M.J.; Kim, J.B.; Huh, J.W.; Kim, D.H.; Lee, J.B.; Kim, J.C. Levels of heavy metals in candy packages and candies likely to be consumed by small children. Food Res. Int. 2008, 41, 411–418. [Google Scholar] [CrossRef]

- de Moura, S.C.S.R.; Berling, C.L.; Garcia, A.O.; Queiroz, M.B.; Alvim, I.D.; Hubinger, M.D. Release of anthocyanins from the hibiscus extract encapsulated by ionic gelation and application of microparticles in jelly candy. Food Res. Int. 2019, 121, 542–552. [Google Scholar] [CrossRef]

- Cano-Lamadrid, M.; Calín-Sánchez, Á.; Clemente-Villalba, J.; Hernández, F.; Carbonell-Barrachina, Á.A.; Sendra, E.; Wojdyło, A. Quality parameters and consumer acceptance of jelly candies based on pomegranate juice “mollar de elche”. Foods 2020, 9, 516. [Google Scholar] [CrossRef] [Green Version]

- Mutlu, C.; Tontul, S.A.; Erbaş, M. Production of a minimally processed jelly candy for children using honey instead of sugar. LWT 2018, 93, 499–505. [Google Scholar] [CrossRef]

- Manousi, N.; Zachariadis, G.A. Development and application of an ICP-AES method for the determination of nutrient and toxic elements in savory snack products after autoclave dissolution. Separations 2020, 7, 66. [Google Scholar] [CrossRef]

- Nardi, E.P.; Evangelista, F.S.; Tormen, L.; Saint-Pierre, T.D.; Curtius, A.J.; de Souza, S.S.; Barbosa, F., Jr. The use of inductively coupled plasma mass spectrometry (ICP-MS) for the determination of toxic and essential elements in different types of food samples. Food Chem. 2009, 112, 727–732. [Google Scholar] [CrossRef]

- Melai, V.; Giovannini, A.; Chiumiento, F.; Bellocci, M.; Migliorati, G. Occurrence of metals in vegetables and fruits from areas near landfill in Southern Italy and implications for human exposure. Int. J. Food Contam. 2018, 5, 8. [Google Scholar] [CrossRef]

- Momen, A.A.; Zachariadis, G.A.; Anthemidis, A.N.; Stratis, J.A. Investigation of four digestion procedures for multi-element determination of toxic and nutrient elements in legumes by inductively coupled plasma-optical emission spectrometry. Anal. Chim. Acta 2006, 565, 81–88. [Google Scholar] [CrossRef]

- El-Sayed, E.M.; Hamed, A.M.; Badran, S.M.; Mostafa, A.A. A survey of selected essential and heavy metals in milk from different regions of Egypt using ICP-AES. Food Addit. Contam. Part B Surveill. 2011, 4, 294–298. [Google Scholar] [CrossRef] [PubMed]

- Terol, A.; Paredes, E.; Maestre, S.E.; Prats, S.; Todolí, J.L. Alcohol and metal determination in alcoholic beverages through high-temperature liquid-chromatography coupled to an inductively coupled plasma atomic emission spectrometer. J. Chromatogr. A 2011, 1218, 3439–3446. [Google Scholar] [CrossRef]

- Karasakal, A. Determination of Trace and Major Elements in Vegan Milk and Oils by ICP-OES After Microwave Digestion. Biol. Trace Elem. Res. 2020, 197, 683–693. [Google Scholar] [CrossRef] [PubMed]

- Srinuttrakul, W.; Busamongkol, A. Elemental analysis of brown rice by inductively coupled plasma atomic emission spectrometry and instrumental neutron activation analysis. Energy Procedia 2014, 56, 85–91. [Google Scholar] [CrossRef] [Green Version]

- Sneddon, E.J.; Hardaway, C.J.; Sneddon, J.; Boggavarapu, K.; Tate, A.S.; Tidwell, S.L.; Gary, D.P.; Douvris, C. Determination of selected metals in rice and cereal by inductively coupled plasma-optical emission spectrometry (ICP-OES). Microchem. J. 2017, 134, 9–12. [Google Scholar] [CrossRef]

- Naozuka, J.; Carvalho Vieira, E.; Nascimento, A.N.; Oliveira, P.V. Elemental analysis of nuts and seeds by axially viewed ICP OES. Food Chem. 2011, 124, 1667–1672. [Google Scholar] [CrossRef]

- Velimirović, D.S.; Mitić, S.S.; Tošić, S.B.; Kaličanin, B.M.; Pavlović, A.N.; Mitić, M.N. Levels of major and minor elements in some commercial fruit juices available in Serbia. Trop. J. Pharm. Res. 2013, 12, 805–811. [Google Scholar] [CrossRef] [Green Version]

- Paz, S.; Rubio, C.; Frías, I.; Revert, C.; Hardisson, A. Toxic metals (Al, Cd, Pb and Hg) in the most consumed edible seaweeds in Europe. Chemosphere 2019, 218, 879–884. [Google Scholar] [CrossRef]

- Paz, S.; Rubio, C.; Frías, I.; Luis-gonzález, G.; Gutiérrez, Á.J. Human exposure assessment to macro- and trace elements in the most consumed edible seaweeds in Europe. Environ. Sci. Pollut. Res. 2019, 26, 36478–36485. [Google Scholar] [CrossRef]

- Orisakwe, O.E.; Igweze, Z.N.; Udowelle, N.A. Candy consumption may add to the body burden of lead and cadmium of children in Nigeria. Environ. Sci. Pollut. Res. 2019, 26, 1921–1931. [Google Scholar] [CrossRef]

- Devi, P.; Bajala, V.; Garg, V.K.; Mor, S.; Ravindra, K. Heavy metal content in various types of candies and their daily dietary intake by children. Environ. Monit. Assess. 2016, 188, 86. [Google Scholar] [CrossRef] [PubMed]

- Alampanos, V.; Kabir, A.; Furton, K.G.; Roje, Ž.; Vrček, I.V.; Samanidou, V. Fabric phase sorptive extraction combined with high-performance-liquid chromatography-photodiode array analysis for the determination of seven parabens in human breast tissues: Application to cancerous and non-cancerous samples. J. Chromatogr. A 2020, 1630, 461530. [Google Scholar] [CrossRef] [PubMed]

- Ioannidou, M.D.; Zachariadis, G.A.; Anthemidis, A.N.; Stratis, J.A. Direct determination of toxic trace metals in honey and sugars using inductively coupled plasma atomic emission spectrometry. Talanta 2005, 65, 92–97. [Google Scholar] [CrossRef] [PubMed]

- Dahiya, S.; Karpe, R.; Hegde, A.G.; Sharma, R.M. Lead, cadmium and nickel in chocolates and candies from suburban areas of Mumbai, India. J. Food Compos. Anal. 2005, 18, 517–522. [Google Scholar] [CrossRef]

| RF Generator | 40 MHz |

| Radiofrequency incident power | 1300 W |

| Auxiliary argon gas flow rate | 0.6 L min−1 |

| Plasma argon gas flow rate | 15.0 L min−1 |

| Nebulizer argon gas flow rate | 0.85 L min−1 |

| Sample aspiration flow rate | 2.5 mL min−1 |

| Digestion Mixture | Digestion Temperature (°C) | Approximate Digestion Time (min) | Observation for Hard Candies | Observation for Jellies |

|---|---|---|---|---|

| 5 mL conc. HNO3 | Room temperature | 60 | Clear solution | Partial dissolution |

| 5 mL conc. HNO3 | Room temperature | 120 | Clear solution | Clear solution |

| 5 mL conc. H2O2 | Room temperature | 60 | Clear colored solution | Partial dissolution |

| 5 mL conc. H2O2 | Room temperature | 120 | Clear colored solution | Clear colored solution |

| 3 mL conc. HNO3 2 mL conc. H2O2 | Room temperature | 30 | Clear solution | Partial dissolution |

| 3 mL conc. HNO3 2 mL conc. H2O2 | Room temperature | 60 | Clear solution | Clear solution |

| 5 mL H2O | 100 | 20 | Clear colored solution | Clear colored solution |

| 3 mL conc. HNO3 | 120 | <10 | Clear solution | Clear solution |

| 5 mL conc. HNO3 | 120 | <10 | Clear solution | Clear solution |

| 3 mL conc. HNO3 2 mL conc. H2O2 | 120 | <10 | Clear solution | Clear solution |

| 5 mL conc. HNO3 2 mL conc. H2O2 | 120 | <10 | Clear solution | Clear solution |

| Element | Emission Line (nm) | Matrix | ||

|---|---|---|---|---|

| Aqueous | 2% w/v Glucose | Standard Addition Curve | ||

| Ag | 328.068 | 249 ± 0.2 (0.9999) | 228 ± 0.8 (0.9999) | 236 ± 1 (0.9999) |

| Ba | 233.527 | 19.5 ± 0.1 (0.9999) | 17.6 ± 0.2 (0.9999) | 18.0 ± 0.01 (0.9999) |

| Bi | 223.061 | 3.47 ± 0.08 (0.9994) | 3.36 ± 0.03 (0.9999) | 3.19 ± 0.05 (0.9998) |

| Ca | 396.847 | 29,057 ± 50 (0.9998) | 26,864 ± 83 (0.9998) | 27,142 ± 41 (0.9999) |

| Cd | 226.502 | 15.6 ± 0.03 (0.9999) | 14.2 ± 0.1 (0.9999) | 14.1 ± 0.01 (0.9999) |

| Co | 238.892 | 23.8 ± 0.1 (0.9999) | 22.9 ± 0.1 (0.9999) | 23.9 ± 0.02 (0.9999) |

| Cr | 357.869 | 1004 ± 4 (0.9999) | 926 ± 1 (0.9999) | 997 ± 4 (0.9999) |

| Cu | 324.752 | 1449 ± 11 (0.9999) | 1382 ± 0.2 (0.9999) | 1530 ± 2 (0.9999) |

| Fe | 238.204 | 37.7 ± 0.4 (0.9999) | 35.5 ± 0.1 (0.9999) | 34.3 ± 0.1 (0.9999) |

| Mg | 280.271 | 895 ± 13 (0.9994) | 807 ± 15 (0.9995) | 843 ± 7 (0.9993) |

| Mn | 257.610 | 419 ± 5 (0.9998) | 385 ± 6 (0.9997) | 416 ± 2 (0.9998) |

| Ni | 232.003 | 6.69 ± 0.03 (0.9997) | 6.26 ± 0.07 (0.9998) | 6.22 ± 0.02 (0.9998) |

| Pb | 217.000 | 1.01 ± 0.02 (0.9997) | 0.96 ± 0.01 (0.9997) | 0.95 ± 0.03 (0.9991) |

| Zn | 213.857 | 12.8 ± 0.5 (0.9999) | 13.0 ± 0.6 (0.9979) | 12.1 ± 0.6 (0.9998) |

| Element | Emission Line (nm) | Regression Lines | R2 | LOD (mg kg−1) | LOQ (mg kg−1) | Upper Limit of Calibration Curve (mg kg−1) |

|---|---|---|---|---|---|---|

| Ag | 328.068 | y = 249x + 477 | 0.9999 | 0.04 | 0.12 | 500 |

| Ba | 233.527 | y = 19.5x + 25.5 | 0.9999 | 0.08 | 0.28 | 500 |

| Bi | 223.061 | y = 3.47x + 3.82 | 0.9994 | 1.32 | 4.39 | 125 |

| Ca | 396.847 | y = 29,057x + 58,815 | 0.9998 | 0.28 | 0.92 | 2000 |

| Cd | 226.502 | y = 15.6x − 8.77 | 0.9999 | 0.51 | 1.69 | 500 |

| Co | 238.892 | y = 23.8x − 43.2 | 0.9999 | 0.36 | 1.19 | 500 |

| Cr | 357.869 | y = 1004x − 2082 | 0.9999 | 0.05 | 0.15 | 500 |

| Cu | 324.752 | y = 1449x − 1311 | 0.9999 | 1.00 | 3.30 | 500 |

| Fe | 238.204 | y = 37.7x + 33.0 | 0.9999 | 0.43 | 1.44 | 500 |

| Mg | 280.271 | y = 895x + 4923 | 0.9994 | 0.13 | 0.43 | 2000 |

| Mn | 257.610 | y = 419x + 1463 | 0.9998 | 0.16 | 0.53 | 500 |

| Ni | 232.003 | y = 6.69x + 0.54 | 0.9997 | 0.46 | 1.54 | 125 |

| Pb | 217.000 | y = 1.01x + 7.09 | 0.9997 | 2.25 | 7.50 | 125 |

| Zn | 213.857 | y = 12.8x + 275 | 0.9999 | 0.16 | 0.55 | 125 |

| Element | Added (mg kg−1) | Candy | Jelly | ||||

|---|---|---|---|---|---|---|---|

| Found (mg kg−1) | RR% | RSD% | Found (mg kg−1) | RR% | RSD% | ||

| Ag | 0 | ND | - | - | ND | - | - |

| 25 | 20.2 ± 0.2 | 80.8 | 1.0 | 21.8 ± 0.4 | 87.2 | 1.8 | |

| 100 | 83.5 ± 0.5 | 83.5 | 0.6 | 88.7 ± 0.6 | 88.7 | 0.7 | |

| 500 | 405 ± 2 | 81.0 | 0.5 | 423 ± 9 | 84.6 | 2.1 | |

| Ba | 0 | ND | - | - | ND | - | - |

| 25 | 21.0 ± 0.1 | 84.0 | 0.5 | 21.9 ± 0.5 | 87.6 | 2.3 | |

| 100 | 80.9 ± 0.5 | 80.9 | 0.6 | 83.9 ± 0.3 | 83.9 | 0.4 | |

| 500 | 401 ± 2 | 80.2 | 0.5 | 406 ± 9 | 81.2 | 2.2 | |

| Bi | 0 | 1.91 ± 0.12 | - | 6.3 | 2.33 ± 0.19 | - | 8.2 |

| 25 | 24.7 ± 1.9 | 91.2 | 7.7 | 29.6 ± 0.6 | 109.1 | 2.0 | |

| 100 | 106 ± 4 | 104.1 | 3.7 | 117 ± 0.1 | 114.7 | 0.1 | |

| 500 | 561 ± 2 | 111.8 | 0.4 | 584 ± 5 | 116.6 | 0.9 | |

| Ca | 0 | 14.6 ± 1.0 | - | 6.8 | 17.9 ± 1.2 | - | 6.7 |

| 25 | 38.3 ± 0.9 | 94.8 | 2.3 | 40.4 ± 1.1 | 90.0 | 2.7 | |

| 100 | 101 ± 1 | 86.4 | 1.0 | 136 ± 1 | 118.1 | 0.7 | |

| 500 | 435 ± 5 | 86.8 | 1.1 | 470 ± 2 | 90.4 | 0.4 | |

| Cd | 0 | ND | - | - | ND | - | - |

| 25 | 22.5 ± 0.3 | 90.0 | 1.3 | 23.0 ± 2.0 | 92.0 | 8.7 | |

| 100 | 90.3 ± 1.1 | 90.3 | 1.2 | 92.0 ± 0.4 | 92.0 | 0.4 | |

| 500 | 433 ± 2 | 86.6 | 0.5 | 443 ± 6 | 88.6 | 1.4 | |

| Co | 0 | ND | - | - | ND | - | - |

| 25 | 22.9 ± 0.2 | 91.6 | 0.9 | 23.5 ± 0.1 | 94.0 | 0.4 | |

| 100 | 89.5 ± 0.2 | 89.5 | 0.2 | 91.8 ± 0.5 | 91.8 | 0.5 | |

| 500 | 447 ± 1 | 89.4 | 0.2 | 461 ± 7 | 92.2 | 1.5 | |

| Cr | 0 | 0.31 ± 0.03 | - | 9.7 | 0.15 ± 0.01 | - | 6.7 |

| 25 | 24.1 ± 0.3 | 95.2 | 1.2 | 25.5 ± 0.3 | 101.4 | 1.2 | |

| 100 | 96.6 ± 2.3 | 96.3 | 2.4 | 99.4 ± 1.2 | 99.3 | 1.2 | |

| 500 | 511 ± 1 | 102.0 | 0.2 | 513 ± 4 | 102.6 | 0.8 | |

| Cu | 0 | ND | - | - | ND | - | - |

| 25 | 23.6 ± 0.7 | 94.4 | 3.0 | 23.9 ± 0.6 | 95.6 | 2.5 | |

| 100 | 105 ± 3 | 105.0 | 2.9 | 105 ± 1 | 105.0 | 1.0 | |

| 500 | 548 ± 4 | 109.6 | 0.7 | 542 ± 3 | 108.4 | 0.6 | |

| Fe | 0 | 1.91 ± 0.12 | - | 6.3 | ND | - | - |

| 25 | 26.6 ± 0.4 | 98.8 | 1.5 | 23.6 ± 0.3 | 94.4 | 1.3 | |

| 100 | 94.3 ± 6.0 | 92.4 | 6.4 | 91.1 ± 0.8 | 91.1 | 0.9 | |

| 500 | 446 ± 7 | 88.8 | 1.6 | 433 ± 3 | 86.6 | 0.7 | |

| Mg | 0 | 7.46 ± 0.65 | - | 8.7 | 2.11 ± 0.15 | - | 7.1 |

| 25 | 29.9 ± 0.4 | 89.8 | 1.3 | 31.2 ± 1.0 | 116.4 | 3.2 | |

| 100 | 96.0 ± 0.4 | 88.5 | 0.4 | 99.5 ± 1.0 | 97.4 | 1.0 | |

| 500 | 408 ± 1 | 80.1 | 0.2 | 424 ± 9 | 84.4 | 2.1 | |

| Mn | 0 | ND | - | - | ND | - | - |

| 25 | 21.5 ± 0.5 | 86.0 | 2.3 | 22.4 ± 0.6 | 89.6 | 2.7 | |

| 100 | 91.1 ± 0.7 | 91.1 | 0.8 | 93.8 ± 0.8 | 93.8 | 0.9 | |

| 500 | 433 ± 1 | 86.6 | 0.2 | 444 ± 7 | 88.8 | 1.6 | |

| Ni | 0 | ND | - | - | ND | - | - |

| 25 | 20.7 ± 1.5 | 82.8 | 7.2 | 21.7 ± 0.9 | 86.8 | 4.1 | |

| 100 | 105 ± 0.2 | 105.0 | 0.2 | 108 ± 2 | 108.0 | 1.9 | |

| 500 | 433 ± 1 | 86.6 | 0.2 | 444 ± 7 | 88.8 | 1.6 | |

| Pb | 0 | ND | - | - | ND | - | - |

| 25 | 20.0 ± 1.8 | 80.0 | 9.0 | 21.4 ± 1.9 | 85.6 | 8.9 | |

| 100 | 103 ± 5 | 103.0 | 4.9 | 94 ± 4 | 94.0 | 4.3 | |

| 500 | 552 ± 4 | 110.4 | 0.7 | 574 ± 3 | 114.8 | 0.5 | |

| Zn | 0 | ND | - | - | ND | - | - |

| 25 | 20.1 ± 0.3 | 80.4 | 1.5 | 21.9 ± 0.2 | 87.6 | 0.9 | |

| 100 | 118 ± 0.4 | 118.0 | 0.3 | 119 ± 1 | 119.0 | 0.8 | |

| 500 | 514 ± 3 | 102.8 | 0.6 | 546 ± 8 | 109.2 | 1.5 | |

| Element | JS-1 | JS-2 | JS-3 | JS-4 | JS-5 | JS-6 | JS-7 | JS-8 |

|---|---|---|---|---|---|---|---|---|

| Ba (mg kg−1) | <LOD | <LOD | <LOD | <LOD | <LOD | <LOD | 4.03 ± 0.14 | <LOD |

| Bi (mg kg−1) | 1.28 ± 0.02 | <LOD | <LOD | 2.33 ± 0.19 | 1.97 ± 0.05 | 1.33 ± 0.12 | <LOD | 1.74 ± 0.12 |

| Ca (mg kg−1) | 3.73 ± 0.25 | 2.52 ± 0.13 | 14.50 ± 0.01 | 17.9 ± 1.2 | 19.1 ± 1.5 | 6.42 ± 0.42 | 1183 ± 98 | 26.5 ± 2.1 |

| Cr (mg kg−1) | 0.78 ± 0.02 | 0.53 ± 0.03 | 0.38 ± 0.06 | 0.15 ± 0.01 | 0.45 ± 0.01 | 0.38 ± 0.04 | 0.46 ± 0.06 | 0.36 ± 0.05 |

| Fe (mg kg−1) | 4.88 ± 0.12 | 1.95 ± 0.07 | <LOD | <LOD | <LOD | <LOD | 2.16 ± 0.22 | 6.24 ± 0.24 |

| Mg (mg kg−1) | 0.71 ± 0.05 | 3.20 ± 0.12 | 1.29 ± 0.15 | 2.11 ± 0.15 | 4.66 ± 0.15 | 3.47 ± 0.11 | 463 ± 4 | 8.87 ± 0.28 |

| Element | CS-1 | CS-2 | CS-3 | CS-4 | CS-5 | CS-6 | LS-1 | LS-2 |

|---|---|---|---|---|---|---|---|---|

| Bi (mg kg−1) | 3.15 ± 0.21 | 1.91 ± 0.12 | 3.06 ± 0.04 | 2.68 ± 0.43 | <LOD | 1.38 ± 0.02 | <LOD | 4.03 ± 0.19 |

| Ca (mg kg−1) | 10.5 ± 0.7 | 14.6 ± 1.0 | 7.55 ± 0.81 | 5.93 ± 0.10 | 26.3 ± 1.8 | 9.76 ± 0.34 | 2.64 ± 0.19 | 5.10 ± 0.14 |

| Cr (mg kg−1) | 0.29 ± 0.02 | 0.31 ± 0.03 | 0.36 ± 0.01 | 0.15 ± 0.01 | 0.33 ± 0.03 | 0.32 ± 0.02 | 0.29 ± 0.01 | 0.19 ± 0.07 |

| Fe (mg kg−1) | 3.15 ± 0.21 | 1.91 ± 0.12 | 3.06 ± 0.04 | 2.68 ± 0.43 | <LOD | 1.38 ± 0.02 | <LOD | 4.03 ± 0.19 |

| Mg (mg kg−1) | 3.32 ± 0.22 | 7.46 ± 0.65 | 3.23 ± 0.07 | 2.00 ± 0.44 | 3.73 ± 0.9 | 1.93 ± 0.08 | 0.71 ± 0.01 | 2.37 ± 0.25 |

| Analytes | Samples | Instrumental Technique 1 | Digestion Mixture | Digestion Time | Relative Recovery (%) | Precision (RSD %) | LODs | Ref. |

|---|---|---|---|---|---|---|---|---|

| Cd, Cr, Co, Cu, Mn, Pb, Zn | Candy packages and candies (lollipops, chocolates, chewing gums, jellies) | ICP-AES | Na2CO3 and NaOH | 1 h | 98.5–103.2 | <2.4 | 9.8–36.8 μg L−1 | [4] |

| Cd, Cr, Ni, Pb, Zn | Candies and chocolates consumed in Nigeria | AAS | 9 mL HNO3 and 3 mL HClO4 | >18 h | >95 | <4 | 0.005 ppm | [21] |

| Cd, Ni, Pb, Zn | Milk-, cocoa- and sugar-based candies | FAAS | 25 mL of HNO3 and HClO4 (9:1) | NA 2 | NA | NA | NA | [22] |

| Cd, Ni, Pb | Chocolates and candies from Mumbai, India | AAS | HNO3:HClO4 (3:1) | 16 h | >85 | ±2 | NA | [25] |

| Ag, Ba, Bi, Ca, Cd, Co, Cr, Cu, Fe, Mg, Mn, Ni, Pb and Zn | Jellies, candies and lollipops from Greece | ICP-AES | 3 mL HNO3 | 10 min | 80.1–119.1 | <9.0 | 0.04–2.25 mg kg−1 | This study |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manousi, N.; Zachariadis, G.A. Development and Validation of an ICP-AES Method for the Determination of Toxic and Nutrient Metals in Candies: Application for the Analysis of Different Samples from the Greek Market. Appl. Sci. 2021, 11, 10599. https://doi.org/10.3390/app112210599

Manousi N, Zachariadis GA. Development and Validation of an ICP-AES Method for the Determination of Toxic and Nutrient Metals in Candies: Application for the Analysis of Different Samples from the Greek Market. Applied Sciences. 2021; 11(22):10599. https://doi.org/10.3390/app112210599

Chicago/Turabian StyleManousi, Natalia, and George A. Zachariadis. 2021. "Development and Validation of an ICP-AES Method for the Determination of Toxic and Nutrient Metals in Candies: Application for the Analysis of Different Samples from the Greek Market" Applied Sciences 11, no. 22: 10599. https://doi.org/10.3390/app112210599

APA StyleManousi, N., & Zachariadis, G. A. (2021). Development and Validation of an ICP-AES Method for the Determination of Toxic and Nutrient Metals in Candies: Application for the Analysis of Different Samples from the Greek Market. Applied Sciences, 11(22), 10599. https://doi.org/10.3390/app112210599