1. Introduction

Controllers for HEVs powertrains and speeds can be included model-free or model-based. Model-free controllers are mostly used with heuristic, fuzzy, neuro, AI, or human virtual and augmented reality. The use of model-free methods will be presented in the next part of this study. Model-based controllers can be used with a conventional adaptive PID,

H2,

H∞, or sliding mode. However, all conventional control methods cannot include the real-time dynamic constraints of the vehicle physical limits, the surrounding obstacles, and the environment (road and weather) conditions. Therefore, a MPC with horizon state and open loop control prediction subject to dynamic constraints are mainly used to control as real-time the HEV speeds and torques. Due to the limit size of this paper, we have reviewed some of the most recent research of MPC applications for HEVs. In this paper, vehicle dynamic formulas and calculations are referred to the reference [

1].

A recent modelling and control of the dual clutch transmission for HEVs are presented in [

2], in which a new controller was designed for synchronizing the dual clutch transmission (DCT) with higher performances and lower fuel consumption. Another MPC for an autonomous driving vehicle is developed in [

3], in which the MPC was used to drive the HEV to exactly track the given feasible trajectories. Moreover, a controller for a hybrid dual clutch transmission powertrain for a HEV is introduced in [

4], in which the ICE and EM were driven by a DCT powertrain. A MPC for a HEV with linear parameters and a varying model is presented in [

5], in which the MPC controller was designed to improve the fuel economy of the power-split HEV.

A MPC for a HEV is necessary not only to control the torque and speed, but also to control the gas emission and improve the fuel economy. The authors of [

6] developed a MPC with a multi-objective function for HEVs for fuel economy and exhaust emission and collision detection as well as to optimize the vehicle speed and engine torque. A new MPC design for HEVs with adaptive cruise of autonomous electric vehicles was presented in [

7]. A hybrid MPC to optimize the HEV mode selection was introduced in [

8], in which the vehicle thermal management was controlled by this MPC subject to decision-making algorithms. Fuel economy and lower emission were also controlled by a MPC with outer approximation and semi-convex cut generation, as presented in [

9].

Due to the recent world commitment to limit the increase in global warming and stop using fossil fuels, plug-in and the pure electric vehicles are expanding. MPC algorithms are also being developed to control the plug-in hybrid vehicle (PHEV), as shown in [

10]. In this study, a non-linear MPC is designed to control the torque-split and to optimize fuel management. The authors of [

11] also present a data-based scenario MPC framework to optimize power consumption.

Non-linear model predictive control (NMPC) has been widely used due to the rapid increase in computer capacity and speeds. Computers now can calculate a real-time solution from complex non-linear functions. Therefore, the authors of [

12] provide a MPC for the non-linear energy management of the power split HEV. Energy efficiency management for HEVs is now also extended in communication among vehicles, as shown in [

13], in which a MPC framework is proposed to generate the optimal torque and velocity by connecting the information from vehicle to vehicle.

The authors of [

14] reviewed the latest model-based controllers in the market to assess the improvement of energy management for HEVs, and, in this study, the MPC was used to calculate optimal energy, torque, and speed. Since a MPC is a model-based algorithm, difficulties will arise when there are existing mismatches between the model and the plant or the plant uncertainties. These mismatches and uncertainties may lead to the instability of the controller. Robust model predictive control (RMPC) algorithms are, therefore, developed to deal to these uncertainties. The authors of [

15] present a new method using matrix inequalities based on RMPC for HEVs considering the external disturbances, the time varying delays, and the model uncertainties. The authors of [

16] introduce a real-time NMPC for the energy management of HEVs using sequential quadratic programing.

The use of a MPC for pure electric vehicles is also mentioned in [

17] regarding full battery consumption and road slope condition. The authors of [

18] presented a decentralized MPC of plug-in electric vehicles charged based on the alternative direction method of multipliers. A real-time control for HEVs, longitudinal tracking, jaw movement, dual-mode power split, and minimizing energy were presented by the authors of [

19,

20,

21,

22,

23,

24,

25,

26,

27,

28]. However, none of the recent MPC methods mentioned is concerned with the MPC with softened constraints. The MPC is always subject to many strict constraints on states, outputs, and inputs; therefore, the MPC may not find a feasible solution and it may become unstable. Since the MPC is a real-time optimizer, any failure solution cannot be tolerated. We propose to convert some physical strict constraints into softened constraints, while adding some large penalty values into the MPC objective function. In this way, we can increase the stability and the robustness of the system dealing with uncertainties and some initial conditions, which may lead the input to violate output constraints.

The layout of this paper is as following:

Section 2 presents the modelling of the parallel HEV;

Section 3 introduces the design of the MPC;

Section 4 develops the MPC algorithms with softened constraints;

Section 5 illustrates the simulations of the MPC for the HEV; and

Section 6 is the conclusion.

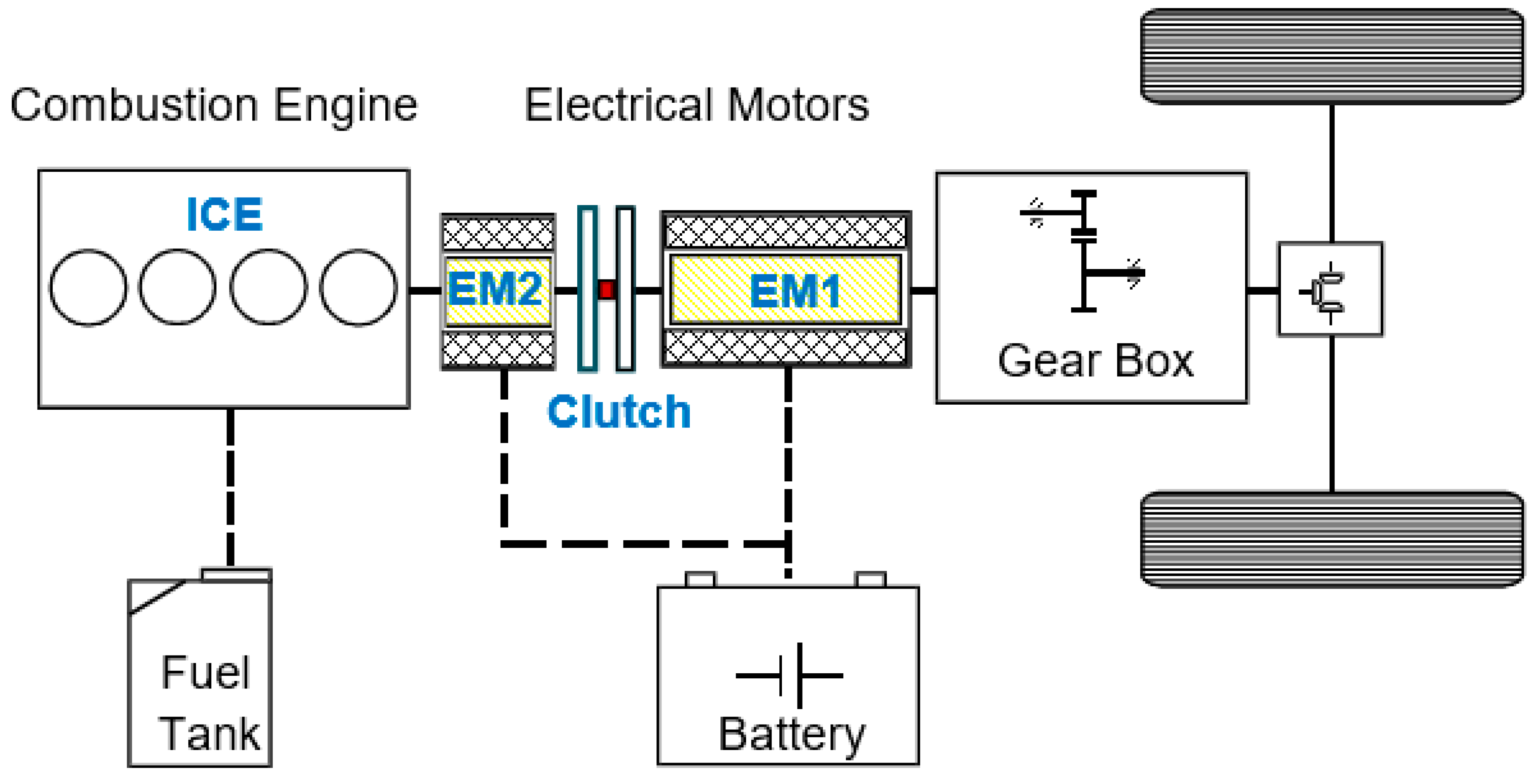

2. Modelling of the Parallel HEV

In parallel hybrid electric vehicles, both combustion engine and main electric motor are installed in parallel and work in independent configurations. The vehicle can run and switch in four driving modes: pure main electric motor (EV1) at a low speed and/or low load; pure combustion engine (EV2) at a high speed and/or high load; both main electric motor and combustion engine (EV3) at a very high and/or very high load; and a combination of the main electric motor, generator motor, and combustion engine (EV4) at extreme high speed and/or load. In 2021, Hyundai introduced a new version of Sonata Hybrid, the middle size family passenger HEV that combines updated technologies for a typical parallel electric vehicle, as shown in

Figure 1.

This parallel HEV consists of one internal combustion engine (ICE) with four cylinders with multiple point injection, a volume of 2.4 litters, a maximum power of 156 kW at 6000 rpm, and a peak torque of 265 Nm; one electric motor starter (EM2) with a maximum power of 8 kW and a maximum torque of 43 Nm; the main electric motor (EM1) with a maximum power of 35 kW and a maximum torque of 205 Nm; the battery HEV Li-ion with a capacity of 6.1 Ah; a transmission gearbox with fully automated 6 speeds; and a friction clutch engagement. The vehicle curb weight is 1569 kg. This Sonata Hybrid vehicle is used to simulate our system modelling and test the new MPC scheme with softened constraints.

The schematic architecture of the 2021 Hyundai Sonata Hybrid in

Figure 1 can be modelled with a simple drivetrain and is shown in

Figure 2. The first part of this mechanical structure consists of an internal combustion engine (ICE) and the electric starter/generator motor (EM2) can be grouped into one inertia

, including the left clutch disk, the sharp 1, EM2, and ICE.

is modelled as one rigid inertia.

and

are the torques on the ICE and EM2, respectively.

and

are the angular position and the velocity of the sharp 1, respectively. Similarly,

is modelled as the lumped rigid inertia of the main electric motor EM1 and the right clutch disk.

and

are the angular position and velocity of the sharp 2, respectively. The third powertrain part connecting the gearbox and the vehicle’s driven wheels can be modelled by a gear ratio

via a torsional spring and damper with

,

, and

as the stiffness, damping, and acceleration coefficient, respectively, of which the acceleration has not been studied before. The third part, the lumped inertia

, consists of the rest of the vehicle, including the gearbox, differential gear, shaft 3, and the driven wheels.

and

are the angular position and velocity of shaft 3, respectively.

is the rolling radius of the vehicle’s wheels.

In this paper, all vehicle dynamic formulas and constraints were taken from the technical book in [

1]. The vehicle resistance torque is the approximation of the air density

, air drag coefficient

, the vehicle crossing area

, the wheel rolling radius

, vehicle friction resistant coefficient

, natural gravity

, vehicle mass

, and the polynomial coefficients of

,

and

The vehicle rolling resistance torque

can be calculated as:

In Equation (1), the additional road conditions, such as the road dynamics, the road increase, and other environment conditions, can be added as disturbances that lead to some reduction of or increase in the vehicle rolling resistance torque. Changes of vehicle velocity, depending on the road conditions as well as the vehicle dynamic constraints between the vehicle speed and vehicle steering wheel, are referred to in [

1].

At a low speed of less than 40 km/h, the clutch is open, and only the main electric motor EM1 propels the HEV. The contribution of some other exponential coefficients is small and can be ignored. The vehicle rolling resistance torque at a low speed can be simplified as:

where

is the initial resistance constant of air drag and rolling friction.

is a linear coefficient that depends on the gear ratio.

On the first part, the torque applied is:

This torque can be calculated as:

where

is the torque from ICE;

is the torque from motor ME2; and

is the torque from the clutch.

When the clutch is locked, the clutch torque

is the maximum static clutch friction:

where

is the clutch radius;

is the normal force; and

µS is the clutch friction coefficient.

When the clutch is in the transitional period,

, the clutch torque is:

where

is the clutch slipping coefficient.

On the second part, the torque applied on the main motor ME1 is:

The sum of inertias is calculated as:

The torque changing is calculated as:

The balance of torque

is calculated as:

where

is the transmission efficiency of the gearbox and the differential gear.

The above torque equations can be transformed to the following dynamic equations:

The angular acceleration of the shaft 1 is calculated as:

where

is the shaft 1 friction coefficient.

The angular acceleration of the shaft 2 is calculated as:

where

is the shaft 2 friction coefficient.

Finally, the angular acceleration of the shaft 3 is calculated as:

where

is the shaft 3 friction coefficient.

The jerk on the drivetrain is calculated as:

The torque generated on the main motor is calculated as:

where

is the main motor torque;

is the motor constant,

(Nm/A);

is the electromotive force (EMF) constant,

;

is the resistance;

is the voltage supply; and

is the angular velocity.

Now we proceed and transform all the above equations into a first order linear system as:

If we put the space vector as

, the input variables as

for the torque on the combustion engine (ICE), the input voltage for motor EM1 and EM2, torque on clutch, and the initial air-drag load, a linear space state of the vehicle dynamics system can be expressed as:

The linear first order state space model in Equation (24) can be used to form the MPC algorithms in the next part. The system in Equation (24) includes acceleration and jerk , which can be used to simulate and regulate the HEV driving comfortability.

When the HEV runs in a low speed of less than 40km/h, only the main motor EM1 is activated. Considering the inputs of

,

, and

, and the state variables of

and

, then the above linear system can be simplified as:

where the states

, inputs

, outputs

. The output

is the unmeasured torque at shaft 3. In this equation,

is the torsional rigidity,

, and

is the twist angle,

.

is the rigidity modulus.

is the shaft length.

is the lumped inertia moment,

.

When the HEV runs in a high speed greater than 40 km/h, the starter motor EM2 activates the combustion engine ICE while the friction clutch is still open, the state equations of the first part can be written as:

where

is the additional coefficient for starting motor EM2 as a compensation load for the starting period. The linear state space system in the first part is:

where

,

, and

. The output

is the unmeasured torque at shaft 1.

3. Model Predictive Control for the HEV

A MPC is an open loop, infinite horizon prediction, and optimization subject to dynamic constraints. The continuous first order linear space state equation in Equation (24) can be discretized into time intervals with a discrete

and

k + 1 =

k + Δ

t (

is the computer scanning speed or the time sampling interval). Now, the continuous time form in Equation (24) can be discretized into:

which is subject to the states, inputs, outputs, and the input increase constraints

A MPC calculates the open loop input and output prediction horizon. For the calculation simplicity, we assumed the input prediction length is always equal to the output prediction length, or

. The objective function of the MPC for the HEV is:

By substituting

, Equation (31) can be transformed as

subject to the linear matrices inequality (LMI),

, where the column vector

is the optimization vector,

, and

H,

F,

Y,

G,

W,

E are obtained from

Q,

R and in (9) as only the optimizer vector

U is needed, the term involving

Y is usually removed from (10). The optimization problem (10) is a quadratic program (QP). The MPC optimizer will calculate the optimal input vector

subject to the hard constraints of the inputs,

, and

; of the outputs

, and

; and of the input increments

. But only the first input increment,

, is taken into the implementation. Then, the optimizer will update the outputs and states variables with the new update input and repeat the calculation for the next time interval. Therefore, the MPC is also called as the receding time horizon control. A diagram control system for this NMPC is shown in

Figure 3.

The MPC scheme for the HEV in

Figure 3 calculates the real-time optimal control action,

, and feeds into the vehicle dynamic equations and updates the current states, inputs, and outputs. The updated states, inputs, and outputs will feedback and compare to the reference desired trajectory data for generating the next optimal control action,

, in the next interval.

When the system is non-linear and has a general derivative nonlinear form, it is calculated as:

where

x is the state variables and

u is the inputs. The non-linear equation in (33) can be approximated in a Taylor series at referenced positions of

for

, so that:

where

and

are the Jacobian function calculating approximation of

and

, respectively, moving around the referenced positions

.

Substituting Equation (34) for

, we can obtain an approximation linear form in continuous time

:

The linearized system in Equation (35) can be used as the linear system in Equation (24) for the MPC calculation. However, the MPC real-time optimal control action must be fed into the original non-linear system in Equation (33) for the updated states, outputs, and inputs.

4. The MPC with Softened Constraints for the HEV

The conventional MPC objective function in Equation (31) subject to the constraints in Equation (30) regarding states, outputs, inputs, and input increase may deal with so many hard constraints. The MPC optimizer may not find out a solution that satisfies all constraints. Thus, we considered to widen the MPC feasibility by converting some possible hard constraints from Equation (30) into softened constraints to increase the possibility of finding a solution. The new MPC scheme subject to the softened constraints has the following form:

subject to

where

is assigned as big values as a weighting factor (

), and

is the constraints penalty terms (

) added into the MPC objective function.

and

are the corresponding matrix of the hard constraints.

The new items in Equation (37) are softened constraints selected from hard constraints in , and , , for ,

, and , for , , and , for , , , , , where, , , and ; and is the additional penalty matrix (generally and assign to small values). In this new MPC scheme, the penalty term of the softened constraints is added into the objective function with the positive definite and symmetric matrix . This term penalizes the violations of constraints and, where possible, the free constrained solution is returned.

This MPC calculates the new optimization vector

and the new MPC computational algorithms are:

subject to

, where

is the new optimization input vector;

;

; and the matrices for inequality constraints

H,

F,

G,

W, and

E are obtained from Equation (38),

with ,

with , and with .

To illustrate the ability of this controller, we test the two MPC schemes in Equations (31) and (36) by the following simple example as considering the non-linear system shown below:

It is assumed that the system in Equation (39) is subjected to the hard state and input constraints

and

. The linearized approximation of this system in (35) is:

, in which

and

. The weighting matrices are chosen as

. The weighting matrices for softened constraints are chosen as

and

. It is assumed that the system is starting form an initial state position,

.

Figure 4 shows the performance of two NMPC schemes: this initial state position,

x0, does not lead to any violation of states and input (

and

). In this

, the solutions of the two control schemes are always available. We can see that the NMPC with a softened state approaches the asymptotic point faster than the hard constraints. It means that, if we somehow loosen some of the constraints, the optimizer can generate easier optimal inputs and the system will be more stable.

It is interesting to see in

Figure 4 that both schemes have

and

, which almost reach the hard constraint of

. These states still have not violated the state constraints but selecting other initial positions

may lead to state and input violations.

If we select

, this initial condition will lead to the violations of the state and the input constraints as

and

. These violations will make the RMPC with hard constraints infeasible. Meanwhile, the RMPC scheme with softened constraints is still running well and it is still easy to find optimal input solutions, as shown in

Figure 5. After a very short transitional period, the fully constrained solution is returned, or there is no more constrained violation.

The new MPC scheme with softened constraints for the HEV will be further analyzed and simulated in the next section.