Resurgence of a Nation’s Radiation Science Driven by Its Nuclear Industry Needs

Abstract

:1. Introduction

2. Review of Established Capabilities

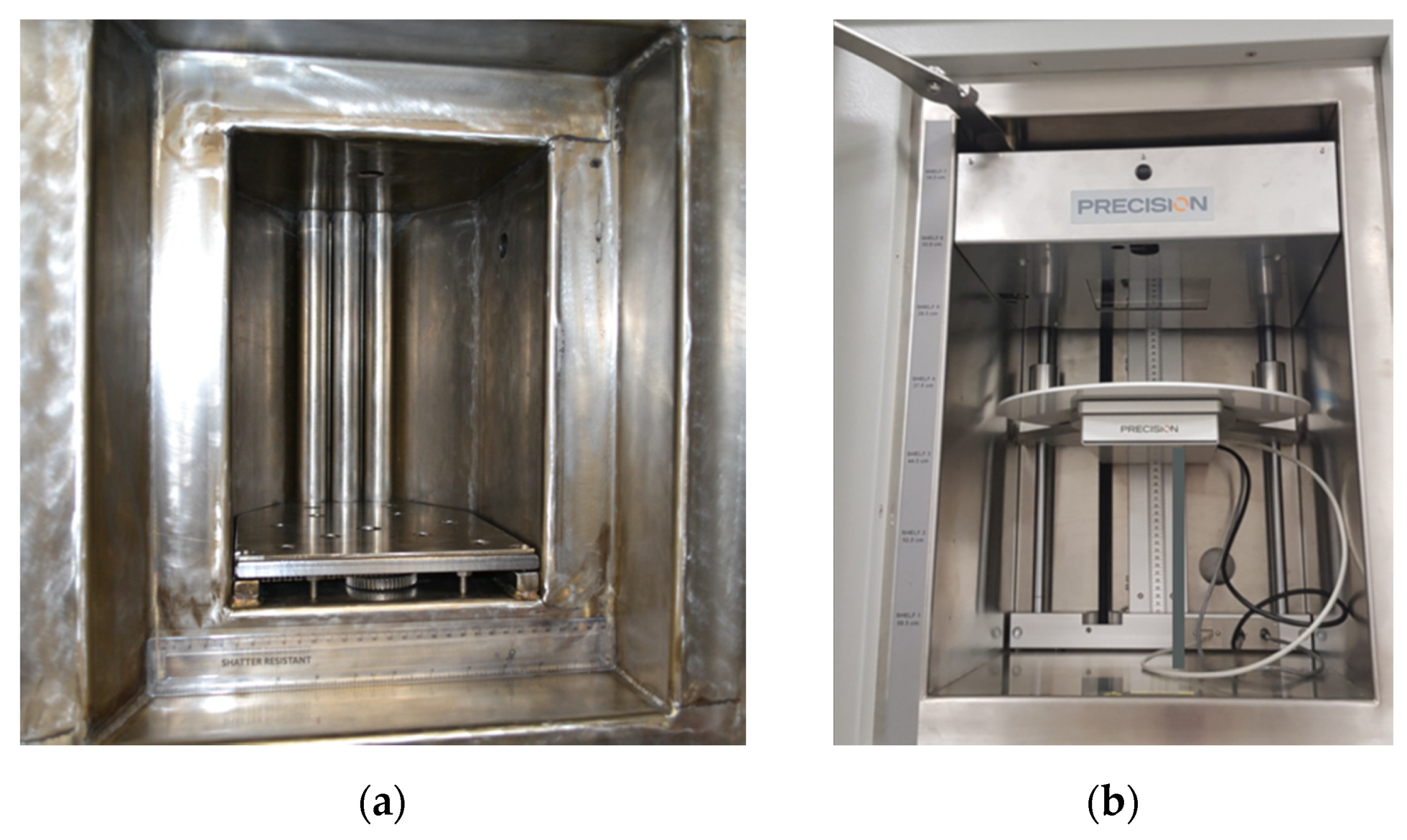

2.1. Gamma and X-ray Irradiators

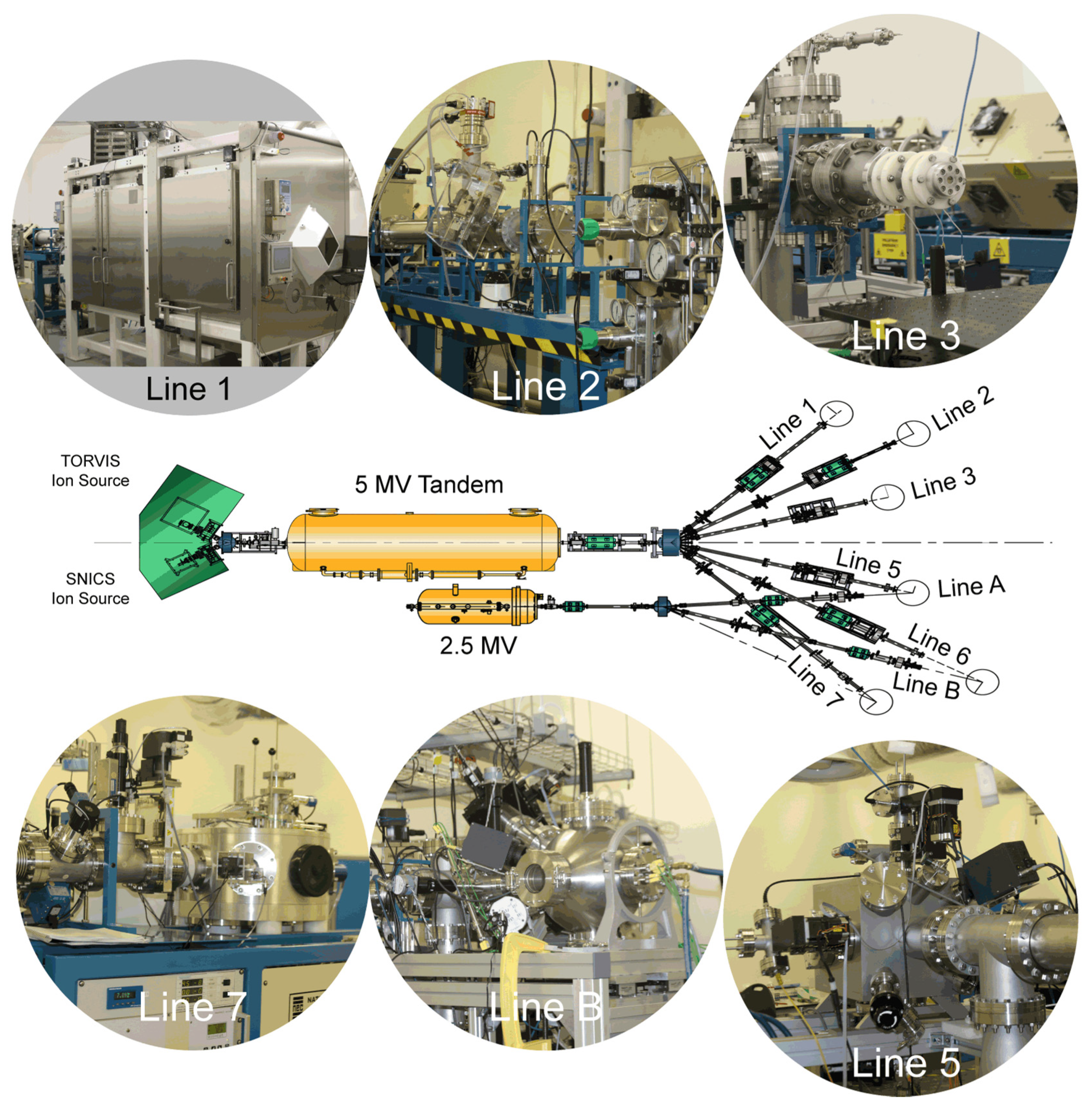

2.2. Accelerator Systems

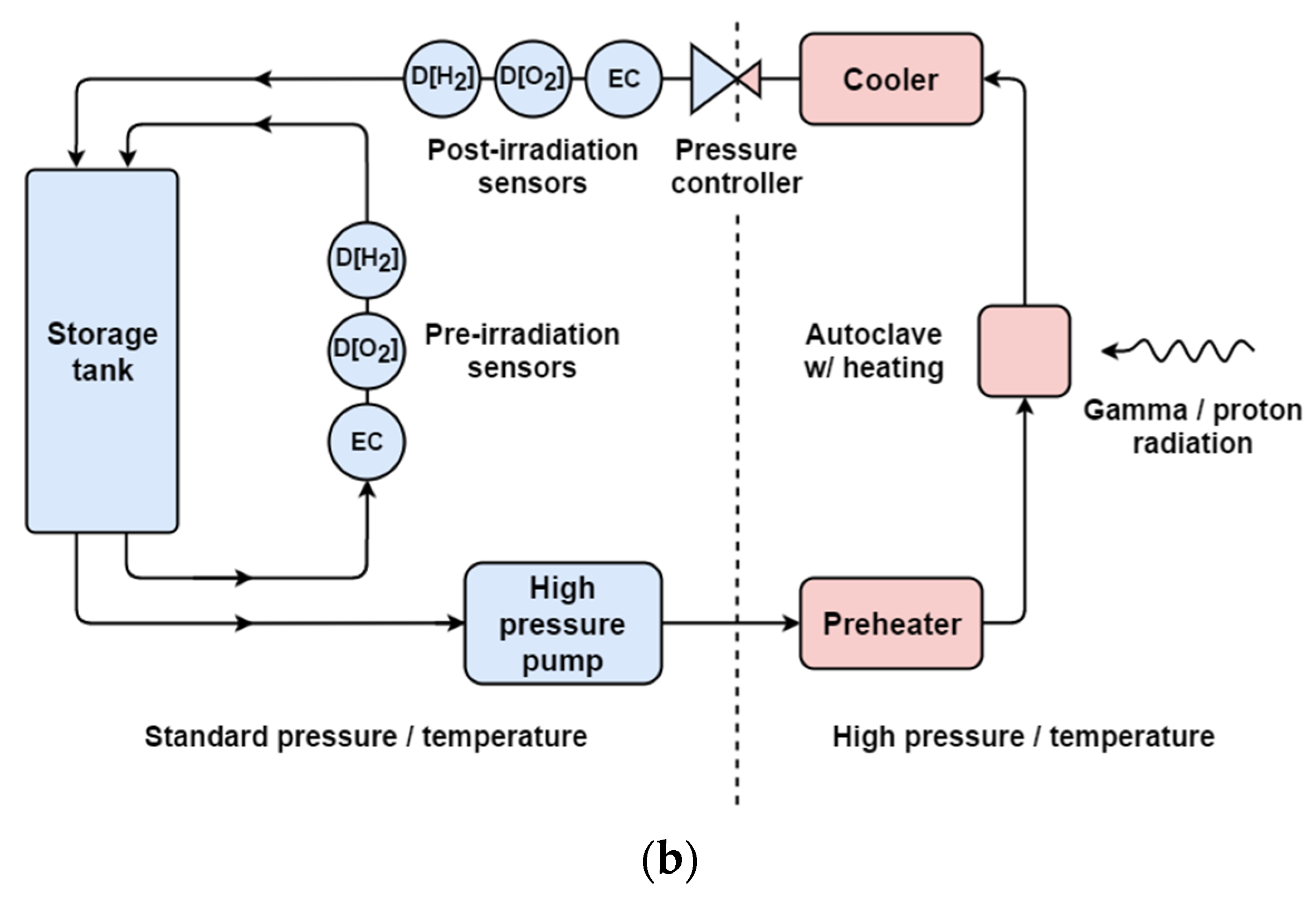

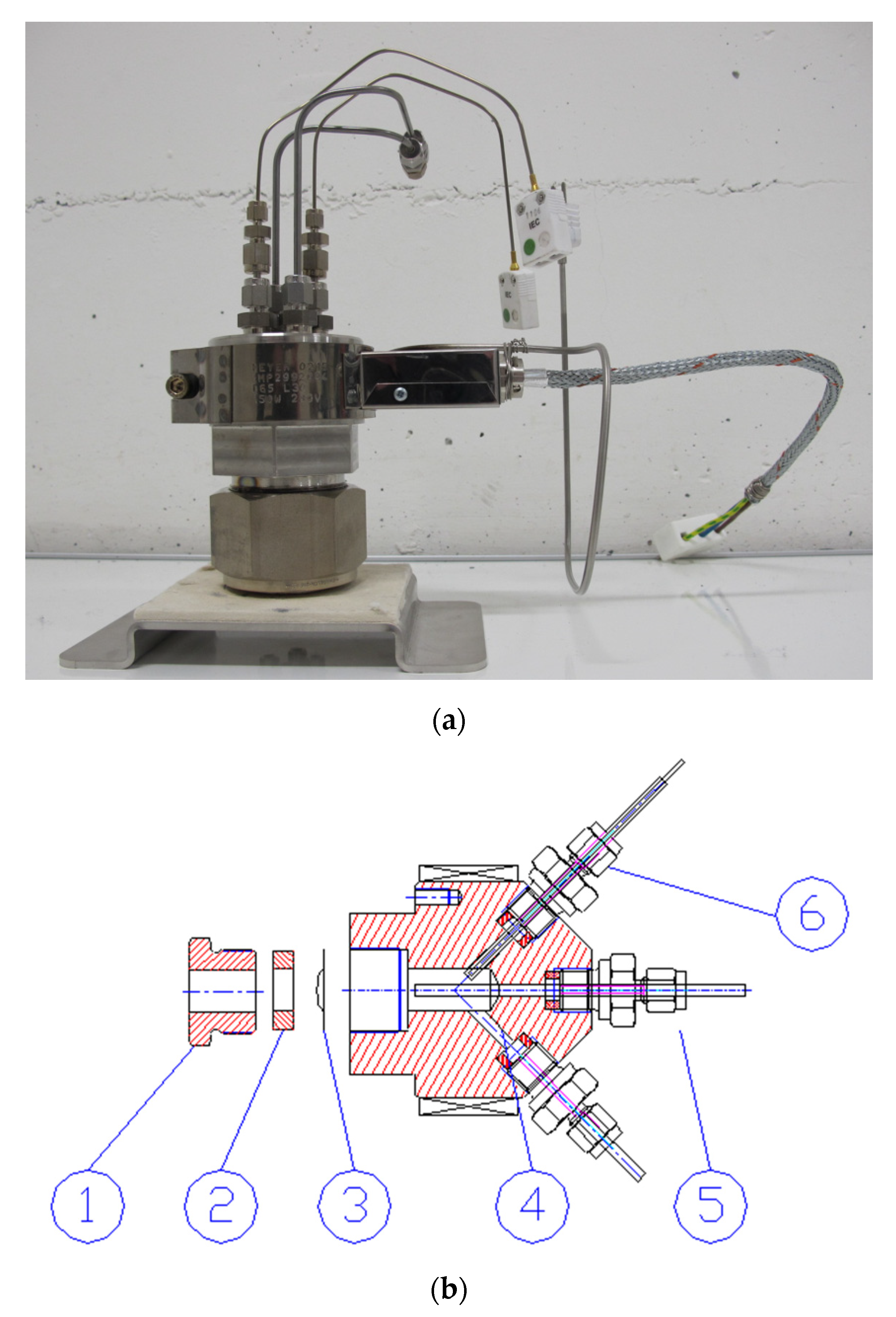

2.3. Recirculation Loop

2.4. Stand-Alone Analytical Equipment

3. Exemplar Results

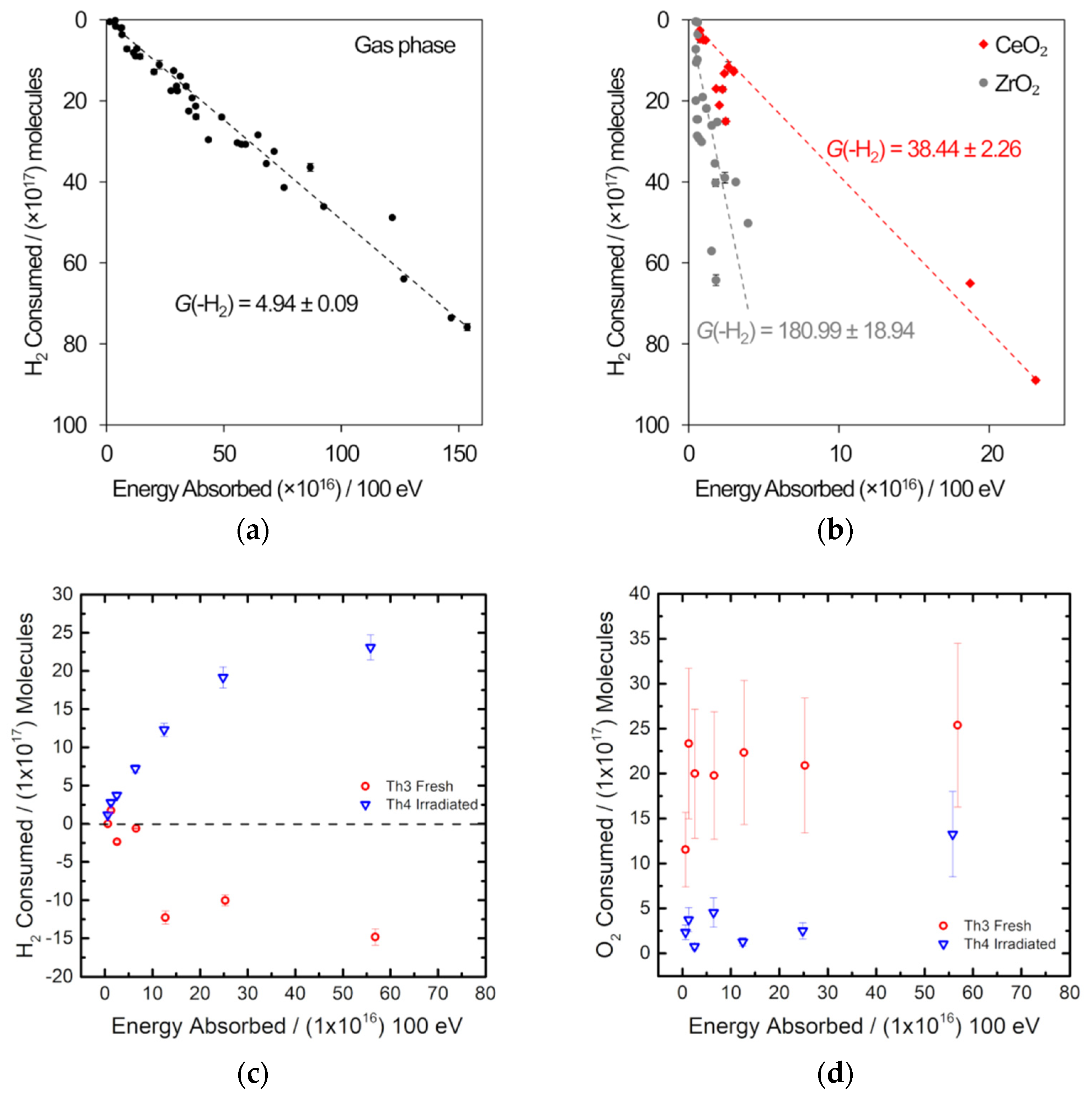

3.1. Sensing of Gases Produced by Radiolysis

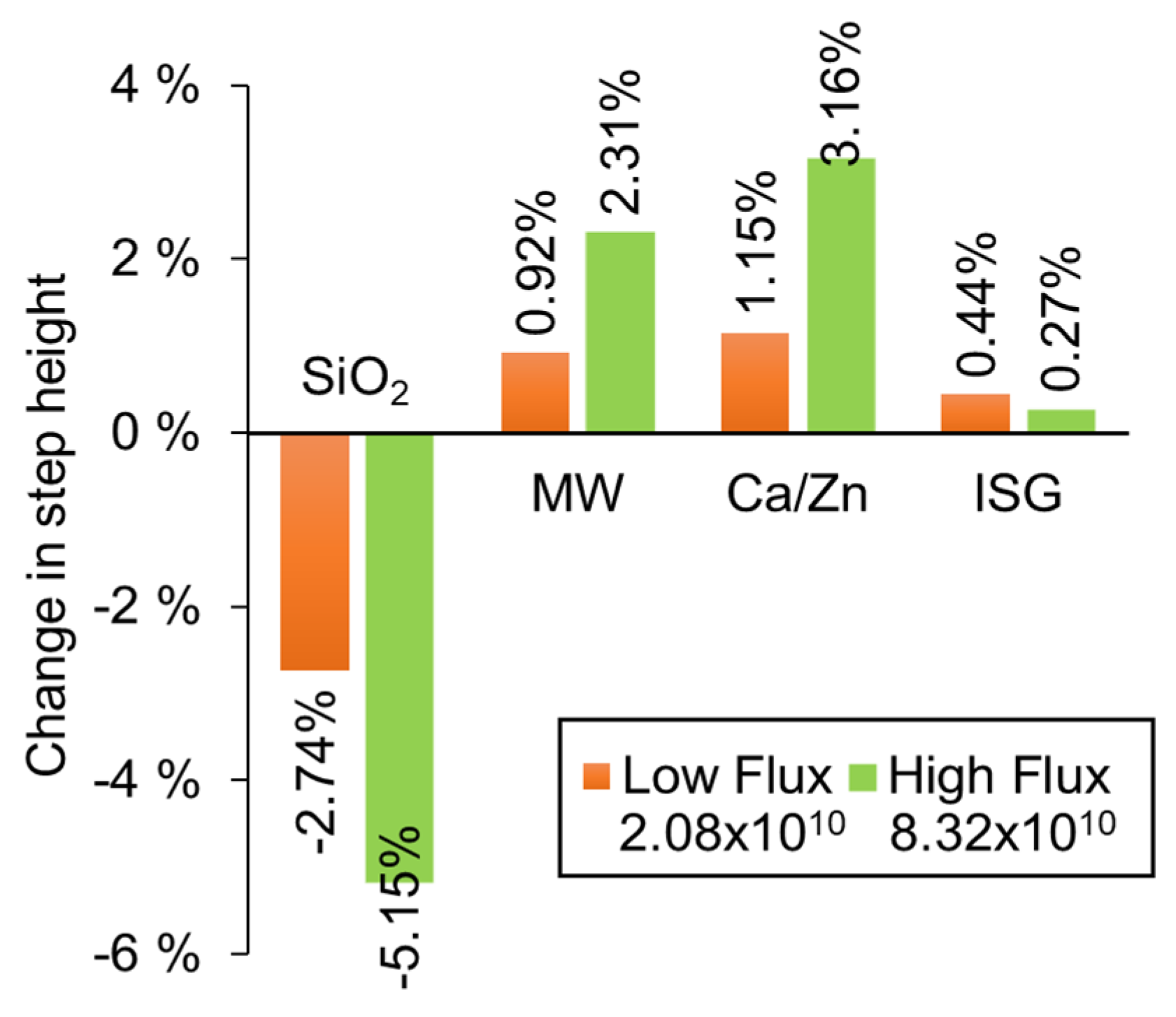

3.2. Materials Chemistry for Nuclear Waste Immobilisation

3.3. Applications of Radiation Science to Healthcare

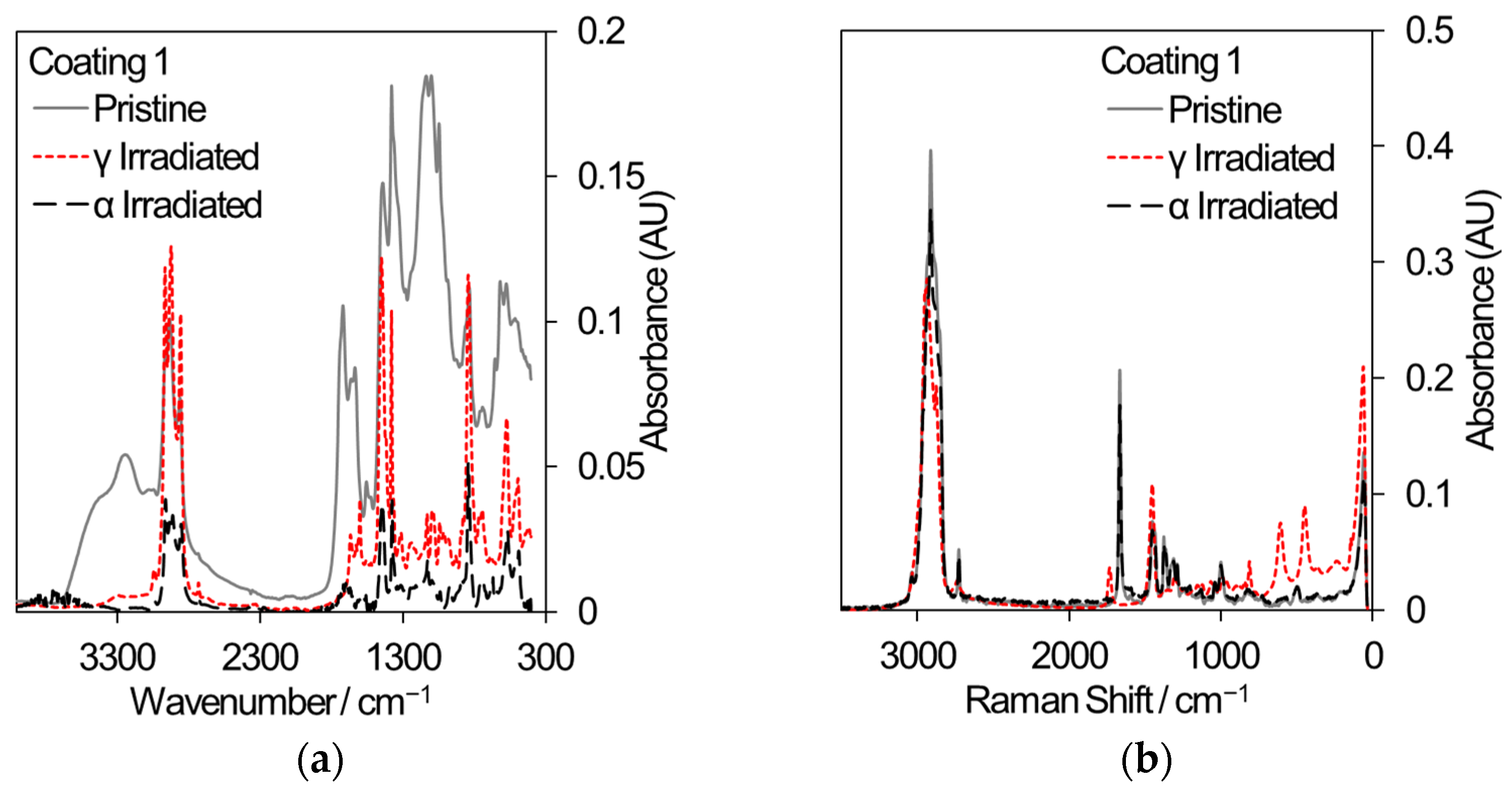

3.4. Commerical Polymeric Materials of Interest to the Nuclear Industry

3.5. Applications of the Re-Circulation Loop

3.5.1. Radiation Chemistry in LWRs

3.5.2. Gamma Radiation-Induced Corrosion

4. New and Emerging Capabilities

4.1. Automated, Reaptable Experiments

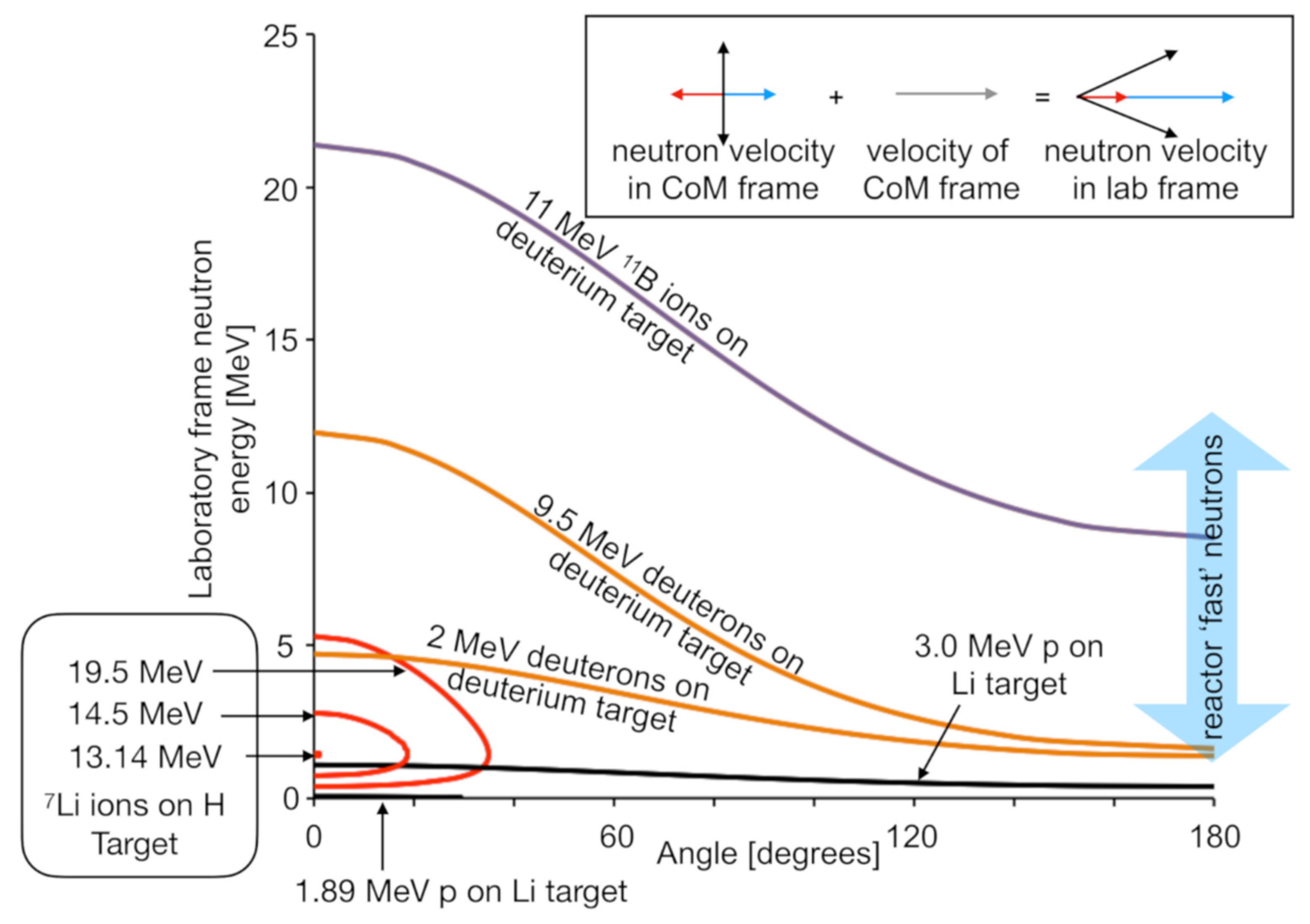

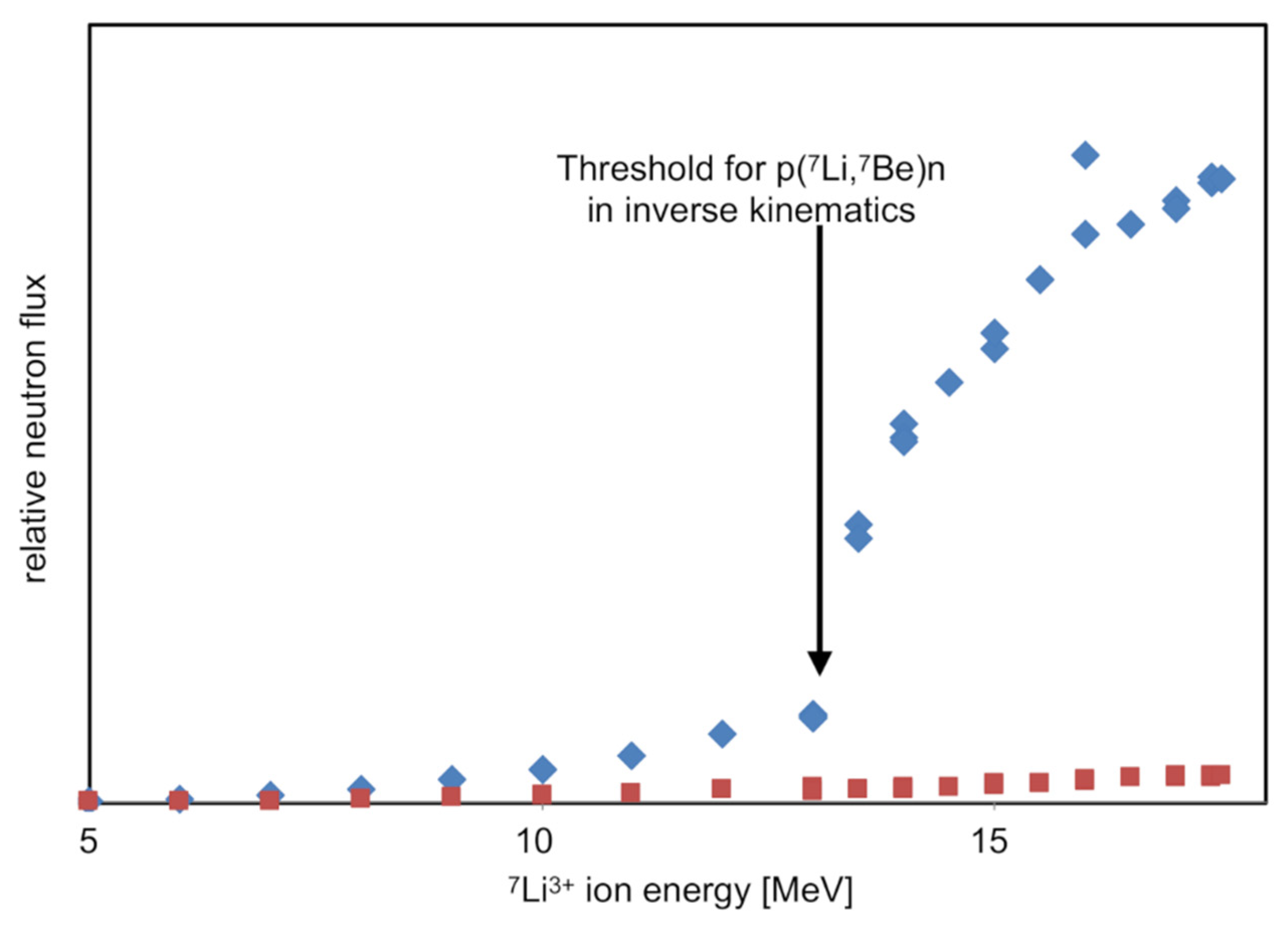

4.2. Variable-Energy Neutron Beams

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ayres, G.P. An Overview of Thirty Years of Operation of Calder Hall; British Nuclear Fuels Ltd.: Daresbury, UK, 1986; ISSN 03682595. [Google Scholar]

- World Nuclear Association Information Library. Nuclear Development in the United Kingdom Appendix 1. 2016. Available online: https://www.world-nuclear.org/information-library/country-profiles/countries-t-z/appendices/nuclear-development-in-the-united-kingdom.aspx (accessed on 25 October 2021).

- House of Lords Select Committee on Science and Technology. Report of Inquiry into Nuclear Research and Development (R&D) Capabilities in the UK. 2011. Available online: https://publications.parliament.uk/pa/ld201012/ldselect/ldsctech/221/22102.htm (accessed on 3 September 2021).

- UK Public General Acts. Energy Act 2004; Part 1: The Civil Nuclear Industry. 2004. Available online: https://www.legislation.gov.uk/ukpga/2004/20/contents (accessed on 3 September 2021).

- Nuclear Decommissioning Authority Corporate Report. Dalton Cumbrian Facility: 10 Years of Collaboration. 18 September 2017. Available online: https://www.gov.uk/government/publications/dalton-cumbrian-facility-celebrating-a-10-year-journey-to-success/dalton-cumbrian-facility-10-years-of-collaboration (accessed on 3 September 2021).

- UK Government Department for Business, Energy & Industrial Strategy; Nuclear Innovation and Research Office. UK Nuclear Fission R&D Catalogue: Facilities, Equipment and Capabilities, 1st ed.; Nuclear Innovation and Research Office: Warrington, UK, 2021.

- Leay, L.; Bower, W.; Horne, G.; Wady, P.; Baidak, A.; Pottinger, M.; Nancekievill, M.; Smith, A.; Watson, S.; Green, P.; et al. Development of irradiation capabilities to address the challenges of the nuclear industry. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2015, 343, 62–69. [Google Scholar] [CrossRef]

- Hauser, T.; Daniel, R.; Norton, G.; Schroeder, J. High current He− injector for tandem accelerators. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2006, 249, 932–934. [Google Scholar] [CrossRef]

- Norton, G.A. Multi cathode SNICS ion source. In Proceedings of the 25th Symposium of North Eastern Accelerator Personnel, Santa Fe, NM, USA, 16–19 October 1991; Benson, J., Rowton, L., Tesmer, J., Darling, R., Eds.; World Scientific: Singapore, 1992; p. 29. [Google Scholar]

- Zinkle, S.; Was, G. Materials challenges in nuclear energy. Acta Mater. 2013, 61, 735–758. [Google Scholar] [CrossRef]

- Gilbert, M.; Dudarev, S.; Zheng, S.; Packer, L.; Sublet, J.-C. An integrated model for materials in a fusion power plant: Transmutation, gas production, and helium embrittlement under neutron irradiation. Nucl. Fusion 2012, 52. [Google Scholar] [CrossRef] [Green Version]

- Wiss, T.; Hiernaut, J.-P.; Roudil, D.; Colle, J.-Y.; Maugeri, E.; Talip, Z.; Janssen, A.; Rondinella, V.; Konings, R.J.; Matzke, H.-J.; et al. Evolution of spent nuclear fuel in dry storage conditions for millennia and beyond. J. Nucl. Mater. 2014, 451, 198–206. [Google Scholar] [CrossRef]

- Wady, P.; Draude, A.; Shubeita, S.; Smith, A.; Mason, N.; Pimblott, S.; Jimenez-Melero, E. Accelerated radiation damage test facility using a 5 MV tandem ion accelerator. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2016, 806, 109–116. [Google Scholar] [CrossRef]

- Ipatova, I.; Harrison, R.; Wady, P.; Shubeita, S.; Terentyev, D.; Donnelly, S.; Jimenez-Melero, E. Structural defect accumulation in tungsten and tungsten-5wt.% tantalum under incremental proton damage. J. Nucl. Mater. 2018, 501, 329–335. [Google Scholar] [CrossRef]

- Ipatova, I.; Wady, P.; Shubeita, S.; Barcellini, C.; Impagnatiello, A.; Jimenez-Melero, E. Radiation-induced void formation and ordering in Ta-W alloys. J. Nucl. Mater. 2017, 495, 343–350. [Google Scholar] [CrossRef]

- Fernández-Caballero, A.; Bousser, E.; Shubeita, S.; Wady, P.; Gu, Y.; Krishna, R.; Gorley, M.; Nguyen-Manh, D.; Mummery, P.; Pickering, E. High-dose ion irradiation damage in Fe28Ni28Mn26Cr18 characterised by TEM and depth-sensing nanoindentation. Nucl. Mater. Energy 2021, 28, 101028. [Google Scholar] [CrossRef]

- Impagnatiello, A.; Shubeita, S.; Wady, P.; Ipatova, I.; Dawson, H.; Barcellini, C.; Jimenez-Melero, E. Monolayer-thick TiO precipitation in V-4Cr-4Ti alloy induced by proton irradiation. Scr. Mater. 2017, 130, 174–177. [Google Scholar] [CrossRef] [Green Version]

- Spencer, R.P.; Patterson, E.A. Observations of fatigue crack behaviour in proton-irradiated 304 stainless steel. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 2120–2132. [Google Scholar] [CrossRef]

- Thomas, R.; Lunt, D.; Atkinson, M.; da Fonseca, J.Q.; Preuss, M.; Barton, F.; O’Hanlon, J.; Frankel, P. Characterisation of irradiation enhanced strain localisation in a zirconium alloy. Materialia 2019, 5, 100248. [Google Scholar] [CrossRef]

- Bowden, D.; Ward, J.; Middleburgh, S.; Shubeita, S.D.M.; Zapata-Solvas, E.; Lapauw, T.; Vleugels, J.; Lambrinou, K.; Lee, W.; Preuss, M.; et al. The stability of irradiation-induced defects in Zr3AlC2, Nb4AlC3 and (Zr0.5, Ti0.5)3AlC2 MAX phase-based ceramics. Acta Mater. 2019, 183, 24–35. [Google Scholar] [CrossRef]

- Ward, J.; Bowden, D.; Stewart, D.; Barsoum, M.W.; Frankel, P.; Preuss, M. Influence of proton-irradiation temperature on the damage accumulation in Ti3SiC2 and Ti3AlC2. Scr. Mater. 2019, 165, 98–102. [Google Scholar] [CrossRef] [Green Version]

- Schofield, J.; Reiff, S.C.; Pimblott, S.; LaVerne, J.A. Radiolytic hydrogen generation at silicon carbide–water interfaces. J. Nucl. Mater. 2016, 469, 43–50. [Google Scholar] [CrossRef] [Green Version]

- Jones, L. The Radiation Chemistry of Gases at the Interface with Ceramic Oxides. Ph.D. Thesis, The University of Manchester, Manchester, UK, 2015. [Google Scholar]

- Leay, L.; Potts, A.; Donoclift, T. Geopolymers from fly ash and their gamma irradiation. Mater. Lett. 2018, 227, 240–242. [Google Scholar] [CrossRef]

- Potts, A.; Leay, L. Evidence for pore water composition controlling carbonate morphology in concrete and the further effect of gamma radiation. Constr. Build. Mater. 2021, 275, 122049. [Google Scholar] [CrossRef]

- Potts, A.; Butcher, E.; Cann, G.; Leay, L. Long term effects of gamma irradiation on in-service concrete structures. J. Nucl. Mater. 2021, 548, 152868. [Google Scholar] [CrossRef]

- Barr, L. Radiation Effects on Novel Polymeric Encapsulants. Ph.D. Thesis, The University of Manchester, Manchester, UK, 2015. [Google Scholar]

- Wady, P.; Wasilewski, A.; Brock, L.; Edge, R.; Baidak, A.; McBride, C.; Leay, L.; Griffiths, A.; Vallés, C. Effect of ionising radiation on the mechanical and structural properties of 3D printed plastics. Addit. Manuf. 2019, 31, 100907. [Google Scholar] [CrossRef]

- Horne, G. An Experimental and Computational Investigation into the Radiolysis of PUREX Solvent Systems. Ph.D. Thesis, The University of Manchester, Manchester, UK, 2015. [Google Scholar]

- Rautiyal, P.; Gupta, G.; Edge, R.; Leay, L.; Daubney, A.; Patel, M.; Jones, A.; Bingham, P. Gamma irradiation-induced defects in borosilicate glasses for high-level radioactive waste immobilisation. J. Nucl. Mater. 2020, 544, 152702. [Google Scholar] [CrossRef]

- Unisense H2 MICROSENSOR. Available online: http://www.unisense.com/H2/ (accessed on 30 September 2020).

- O’Leary, M.; Baidak, A.; Barnes, M.; Donoclift, T.; Emerson, C.; Figueira, C.; Fox, O.J.L.; Kleppe, A.; McCulloch, A.; Messer, D.M.; et al. First Observation of Radiolytic Bubble Formation in Unstirred Nano-powder Sludges and a Consistent Model Thereof. Sci. Rep. 2021, in press. [Google Scholar]

- Haschke, J.M.; Allen, T.H. Interactions of Plutonium Dioxide with Water and Oxygen-Hydrogen Mixtures; LA-13537-MS; Los Alamos National Laboratory: Los Alamos, NM, USA, 1999.

- Morales, L.A. Preliminary Report on the Recombination Rates of Hydrogen and Oxygen over Pure and Impure Plutonium Oxides; LA-UR-98-5022; Los Alamos National Laboratory: Los Alamos, NM, USA, 1998.

- Messer, D. Radiolytic Recombination of H2, O2 and N2 over PuO2 Surrogate Materials. Ph.D. Thesis, The University of Manchester, Manchester, UK, 2021. [Google Scholar]

- Short, R. Phase Separation and Crystallisation in UK HLW Vitrified Products. Proced. Mater. Sci. 2014, 7, 93–100. [Google Scholar] [CrossRef] [Green Version]

- Gin, S.; Abdelouas, A.; Criscenti, L.; Ebert, W.; Ferrand, K.; Geisler, T.; Harrison, M.; Inagaki, Y.; Mitsui, S.; Mueller, K.; et al. An international initiative on long-term behavior of high-level nuclear waste glass. Mater. Today 2013, 16, 243–248. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Ziegler, M.; Biersack, J. SRIM—The stopping and range of ions in matter. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2010, 268, 1818–1823. [Google Scholar] [CrossRef] [Green Version]

- Eernisse, E.P. Compaction of ion-implanted fused silica. J. Appl. Phys. 1974, 45, 167–174. [Google Scholar] [CrossRef]

- Snoeks, E.; Weber, T.P.; Cacciato, A.; Polman, A. MeV ion irradiation-induced creation and relaxation of mechanical stress in silica. J. Appl. Phys. 1995, 78, 4723–4732. [Google Scholar] [CrossRef]

- Brongersma, M.L.; Snoeks, E.; van Dillen, T.; Polman, A. Origin of MeV ion irradiation-induced stress changes in SiO2. J. Appl. Phys. 2000, 88, 59–64. [Google Scholar] [CrossRef]

- Guo, X.; Gin, S.; Lei, P.; Yao, T.; Liu, H.; Schreiber, D.K.; Ngo, D.; Viswanathan, G.; Li, T.; Kim, S.H.; et al. Self-accelerated corrosion of nuclear waste forms at material interfaces. Nat. Mater. 2020, 19, 310–316. [Google Scholar] [CrossRef]

- Omenn, G.S.; Goodman, G.E.; Thornquist, M.D.; Balmes, J.R.; Cullen, M.; Glass, A.G.; Keogh, J.P.; Meyskens, F.L.; Valanis, B.G.; Williams, J.H.; et al. Effects of a Combination of Beta Carotene and Vitamin A on Lung Cancer and Cardiovascular Disease. N. Engl. J. Med. 1996, 334, 1150–1155. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Boehm, F.; Edge, R.; Truscott, T.G.; Witt, C. A dramatic effect of oxygen on protection of human cells against γ-radiation by lycopene. FEBS Lett. 2016, 590, 1086–1093. [Google Scholar] [CrossRef] [Green Version]

- Boehm, F.; Edge, R.; Truscott, T.G. Anti- and pro-oxidative mechanisms comparing the macular carotenoids zeaxanthin and lutein with other dietary carotenoids—A singlet oxygen, free-radical in vitro and ex vivo study. Photochem. Photobiol. Sci. 2020, 19, 1001–1008. [Google Scholar] [CrossRef] [PubMed]

- Bonnefont-Rousselot, D. Gamma radiolysis as a tool to study lipoprotein oxidation mechanisms. Biochimie 2004, 86, 903–911. [Google Scholar] [CrossRef] [PubMed]

- Buxton, G.V.; Greenstock, C.L.; Helman, W.P.; Ross, A.B. Critical Review of rate constants for reactions of hydrated electrons, hydrogen atoms and hydroxyl radicals (•OH/•O−) in Aqueous Solution. J. Phys. Chem. Ref. Data 1988, 17, 513–886. [Google Scholar] [CrossRef] [Green Version]

- Donoclift, T.; Edge, R.; Unsworth, T.; Warren, K.; Jenkins, A.; Ostle, L. Radiation Tolerance Studies of Commercial Strippa ble Coatings and Fixatives used for Decontamination. In Proceedings of the Waste Management Conference, Phoenix, AZ, USA, 18–22 March 2018; p. 18642. [Google Scholar]

- Butarbutar, S.L.; Sanguanmith, S.; Meesungnoen, J.; Sunaryo, G.R.; Jay-Gerin, J.-P. Calculation of the Yields for the Primary Species Formed from the Radiolysis of Liquid Water by Fast Neutrons at Temperatures between 25–350 °C. Radiat. Res. 2014, 181, 659–665. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Spinks, J.W.T.; Woods, R.J. An Introduction to Radiation Chemistry, 3rd ed.; Wiley-Blackwell: Hoboken, NJ, USA, 1990. [Google Scholar]

- Ashmore, C.B.; Sims, H.E.; Tait, P.K.; Walters, W.S. The Measurement of Water Radiolysis Product Yields at High Temperature and Pressure; Progress Report AEAT—1278; AEA Technology: Didcot, UK, 1997. [Google Scholar]

- Sterniczuk, M.; Yakabuskie, P.A.; Wren, J.C.; Jacob, J.A.; Bartels, D.M. Low LET radiolysis escape yields for reducing radicals and H2 in pressurized high temperature water. Radiat. Phys. Chem. 2016, 121, 35–42. [Google Scholar] [CrossRef] [Green Version]

- Sanguanmith, S.; Muroya, Y.; Meesungnoen, J.; Lin, M.; Katsumura, Y.; Kohan, L.M.; Guzonas, D.; Stuart, C.; Jay-Gerin, J.-P. Low-linear energy transfer radiolysis of liquid water at elevated temperatures up to 350 °C: Monte-Carlo simulations. Chem. Phys. Lett. 2011, 508, 224–230. [Google Scholar] [CrossRef]

- Pimblott, S.M.; LaVerne, J.A. Effects of Track Structure on the Ion Radiolysis of the Fricke Dosimeter. J. Phys. Chem. A 2002, 106, 9420–9427. [Google Scholar] [CrossRef]

- Horne, G.P.; Donoclift, T.A.; Sims, H.E.; Orr, R.M.; Pimblott, S.M. Multi-Scale Modeling of the Gamma Radiolysis of Nitrate Solutions. J. Phys. Chem. B 2016, 120, 11781–11789. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rishel, D.; Kammenzind, B. The role of gamma radiation on Zircaloy-4 corrosion. In Proceedings of the Zirconium in the Nuclear Industry: 18th International Symposium, Hilton Head, SC, USA, 15–19 May 2016; Comstock, R., Motta, A., Eds.; ASTM International: West Conshohocken, PA, USA, 2018; pp. 555–595. [Google Scholar] [CrossRef]

- Rishel, D.M.; Eklund, K.L.; Kammenzind, B.F.; Limbäck, M.; Kammenzind, B.; Dean, S.W. In situ EIS Measurements of Irradiated Zircaloy-4 Post-Transition Corrosion Kinetic Behavior. J. ASTM Int. 2008, 5, 326–359. [Google Scholar] [CrossRef]

- Chan, C.M. Project E1: Effect of gamma irradiation on Zirconium alloy corrosion. In Understanding Hydrogen Pickup Mechanism: MUZIC-3 Advanced Materials Characterization and Testing; EPRI Report No. 3002020953; Electric Power Research Institute, Inc.: Palo Alto, CA, USA, 2021; pp. 4-3–4-13. [Google Scholar]

- Polin, C.; Wardlow, N.; McQuaid, H.; Orr, P.; Villagomez-Bernabe, B.; Figueira, C.; Alexander, G.; Srigengan, S.; Brun, E.; Gilles, M.; et al. A novel experimental approach to investigate radiolysis processes in liquid samples using collimated radiation sources. Rev. Sci. Instrum. 2015, 86, 035106. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- LaVerne, J.A.; Schuler, R.H. Radiation chemical studies with heavy ions: Oxidation of ferrous ion in the Fricke dosimeter. J. Phys. Chem. 1987, 91, 5770–5776. [Google Scholar] [CrossRef]

- Jonah, C.D.; Spinks, J.W.T.; Woods, R.J. Introduction to Radiation Chemistry. Radiat. Res. 1990, 124, 378. [Google Scholar] [CrossRef]

- Lebois, M.; Wilson, J.; Halipré, P.; Leniau, B.; Matea, I.; Oberstedt, A.; Verney, D. Development of a kinematically focused neutron source with the p(7Li,n)7Be inverse reaction. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2014, 735, 145–151. [Google Scholar] [CrossRef]

- JANIS—Renderer. 2021. Available online: https://www.oecd-nea.org/janisweb/book/protons/O16/MT28 (accessed on 29 August 2021).

- Eschneider, U.; Ehälg, R. The Impact of Neutrons in Clinical Proton Therapy. Front. Oncol. 2015, 5, 235. [Google Scholar] [CrossRef]

| Component | MW | Ca/Zn | ISG |

|---|---|---|---|

| SiO2 | 61.75 | 56.10 | 56.18 |

| B2O3 | 21.88 | 21.51 | 17.34 |

| Na2O | 11.05 | 11.48 | 12.17 |

| Li2O | 5.33 | 2.92 | - |

| ZnO | - | 6.03 | - |

| CaO | - | 1.94 | 4.98 |

| ZrO2 | - | - | 3.27 |

| Penetration Depth (μm) | 5.68 | 6.40 | 6.75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leay, L.; Baidak, A.; Anderson, C.; Chan, C.M.; Daubney, A.; Donoclift, T.; Draper, G.; Edge, R.; Hobbs, J.; Jones, L.; et al. Resurgence of a Nation’s Radiation Science Driven by Its Nuclear Industry Needs. Appl. Sci. 2021, 11, 11081. https://doi.org/10.3390/app112311081

Leay L, Baidak A, Anderson C, Chan CM, Daubney A, Donoclift T, Draper G, Edge R, Hobbs J, Jones L, et al. Resurgence of a Nation’s Radiation Science Driven by Its Nuclear Industry Needs. Applied Sciences. 2021; 11(23):11081. https://doi.org/10.3390/app112311081

Chicago/Turabian StyleLeay, Laura, Aliaksandr Baidak, Christopher Anderson, Choen May Chan, Aaron Daubney, Thomas Donoclift, Gemma Draper, Ruth Edge, Jeff Hobbs, Luke Jones, and et al. 2021. "Resurgence of a Nation’s Radiation Science Driven by Its Nuclear Industry Needs" Applied Sciences 11, no. 23: 11081. https://doi.org/10.3390/app112311081

APA StyleLeay, L., Baidak, A., Anderson, C., Chan, C. M., Daubney, A., Donoclift, T., Draper, G., Edge, R., Hobbs, J., Jones, L., Mason, N. J. S., Messer, D., O’Leary, M., Orr, R., Pimblott, S. M., de Moraes Shubeita, S., Smith, A. D., Steele, H., Wady, P., & Currell, F. (2021). Resurgence of a Nation’s Radiation Science Driven by Its Nuclear Industry Needs. Applied Sciences, 11(23), 11081. https://doi.org/10.3390/app112311081