Quantitative Description for Sand Void Fabric with the Principle of Stereology

Abstract

:1. Introduction

2. Existing Theories of the Void Fabric Tensors

3. Novel Void Fabric Tensors Definitions

3.1. Definition of Void Fabric

3.2. A Novel Definition of 2D Void Fabric

4. Novel Void Fabric Tensors Definitions

4.1. Orthotropic Void Fabrics

4.2. Transversely Isotropic Void Fabrics

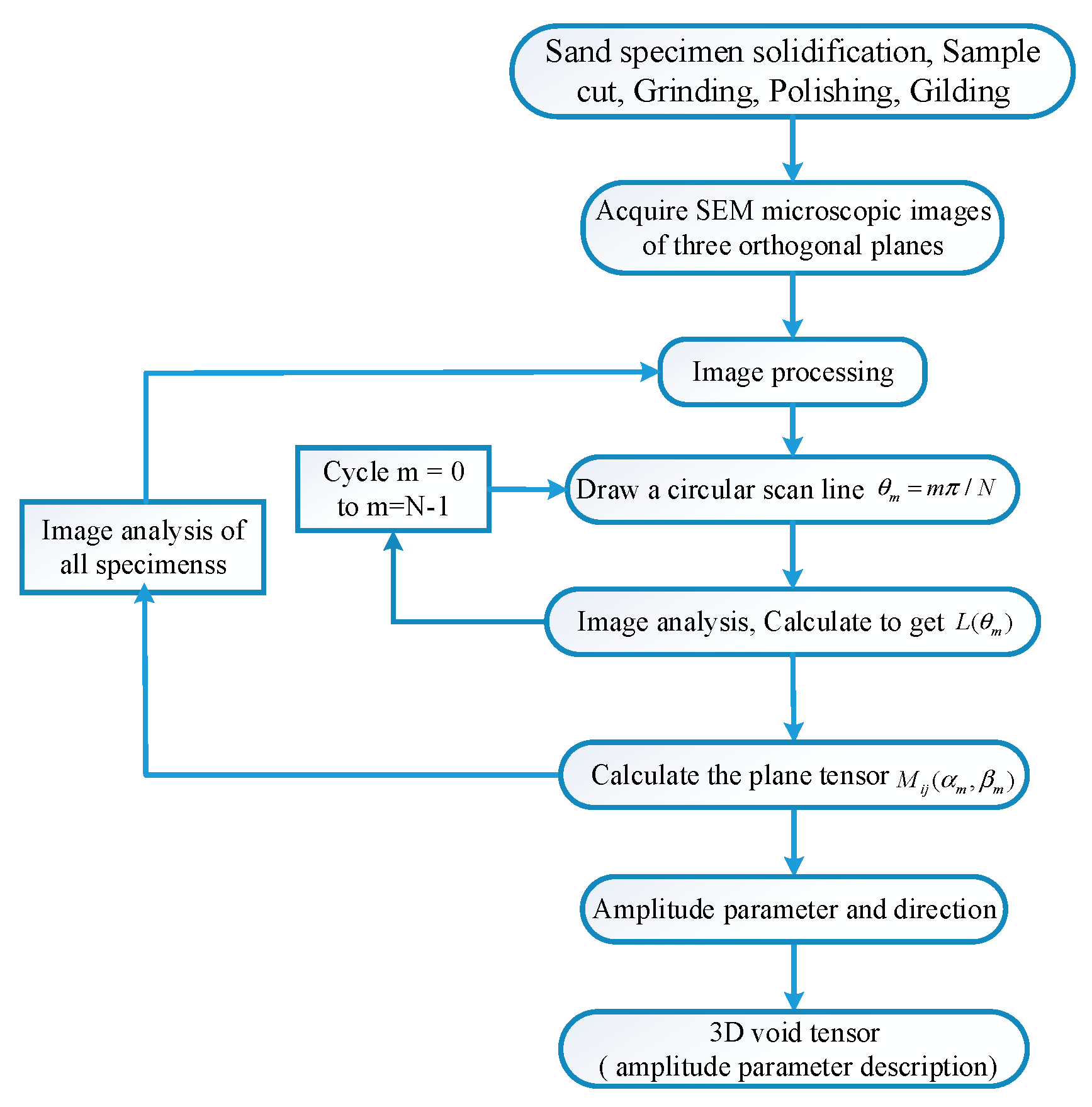

5. Image Analysis of Void Fabric

5.1. Analysis Procedure and Method

5.2. Parallel Scan Line Analysis Method

5.3. Analysis Method with Annular Scan Line

6. Determination and Application Analysis of Void Fabric

6.1. The Fabric of Orthogonal Plane Determined by Experiment

6.2. Application of Orthogonal Fabric

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, X.S.; Dafalias, Y.F. Anisotropic Critical State Theory: Role of Fabric. J. Eng. Mech. 2012, 138, 263–275. [Google Scholar] [CrossRef]

- Zhao, J.; Guo, N. Unique critical state characteristics in granular media considering fabric anisotropy. Géotechnique 2013, 63, 695–704. [Google Scholar] [CrossRef] [Green Version]

- Sadrekarimi, A.; Olson, S.M. Residual State of Sands. J. Geotech. Geoenviron. Eng. 2014, 140, 04013045. [Google Scholar] [CrossRef]

- Chow, J.K.; Li, Z.; Wang, Y.-H. Comprehensive microstructural characterizations of 1-D consolidated kaolinite samples with fabric tensors and pore elongation factors. Eng. Geol. 2019, 248, 22–33. [Google Scholar] [CrossRef]

- Sun, Q.; Zheng, J.; He, H.; Li, Z. Characterizing Fabric Anisotropy of Air-Pluviated Sands. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 92, p. 01003. [Google Scholar]

- Zheng, J.; Hryciw, R.D. Cross-anisotropic fabric of sands by wavelet-based simulation of human cognition. Soils Found. 2018, 58, 1028–1041. [Google Scholar] [CrossRef]

- Hu, N.; Yu, H.-S.; Yang, D.-S.; Zhuang, P.-Z. Constitutive modelling of granular materials using a contact normal-based fabric tensor. Acta Geotech. 2019, 15, 1125–1151. [Google Scholar] [CrossRef] [Green Version]

- Weihua, Z.; Chenggang, Z.; Yinping, Z. Study on pore fabric, dilatancy, dissipation function and yield function for sand. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 794. [Google Scholar] [CrossRef]

- Zhao, C.-F.; Kruyt, N.P. An evolution law for fabric anisotropy and its application in micromechanical modelling of granular materials. Int. J. Solids Struct. 2020, 196–197, 53–66. [Google Scholar] [CrossRef]

- Oda, M.; Koishikawa, I. Anisotropic fabric of sands. Soils Found. 1977, 17, 71–77. [Google Scholar]

- Tobita, Y.; Yanagisawa, E. Contact Tensor in Constitutive Model for Granular Materials. In Studies in Applied Mechanics; Elsevier: Amsterdam, The Netherlands, 1988; Volume 20, pp. 263–270. [Google Scholar]

- Clara, J.; Edward, A.; Gioacchino, V.; Hugues, T. Estimation of Separating Planes between Touching 3D Objects Using Power Watershed. In Proceedings of the International Symposium on Mathematical Morphology, Uppsala, Sweden, 27–29 May 2013; Springer: Berlin/Heidelberg, Germany, 2013; Volume 11, pp. 452–463. [Google Scholar]

- Wiebicke, M.; Andò, E.; Herle, I.; Viggiani, G. On the metrology of interparticle contacts in sand from x-ray tomography images. Meas. Sci. Technol. 2017, 28, 124007. [Google Scholar] [CrossRef]

- Li, X.F.; Huang, M.S.; Qian, J.G. Failure criterion of anisotropic sand with the method of macro-micro incorporation. Chin. J. Rock Mech. Eng. 2010, 29, 1885–1892. [Google Scholar]

- Huang, M.S.; Li, X.F.; Qian, J.G. On strain localization of anisotropic sands. Chin. J. Geotech. Eng. 2012, 34, 1885–1892. [Google Scholar]

- Li, X.F.; Kong, L.; Huang, M.S. Property-dependent plastic potential theory for geomaterials. Chin. J. Geotech. Eng. 2013, 35, 1722–1729. [Google Scholar]

- Oda, M. Fabrics and Their Effects on the Deformation Behaviors of Sand. Ph.D. Thesis, Tokyo University, Tokyo, Japan, 1975. [Google Scholar]

- Bhatia, S.K.; Soliman, A.F. Frequency distribution of void ratio of granular materials determined by an image analyzer. Soils Found. 1990, 30, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Bagi, K. Stress and strain in granular assemblies. Mech. Mater. 1996, 22, 165–177. [Google Scholar] [CrossRef]

- Li, X.; Li, X.S. Micro-macro quantification of the internal structure of granular materials. J. Eng. Mech. 2009, 135, 641–656. [Google Scholar] [CrossRef]

- Fu, P.; Dafalias, Y.F. Relationship between void- and contact normal-based fabric tensors for 2D idealized granular materials. Int. J. Solids Struct. 2015, 63, 68–81. [Google Scholar] [CrossRef]

- Hilliard, J.E. Determination of Structural Anisotropy. In Stereology, Proceedings of the Second International Congress for Stereology, Chicago, IL, USA, 8–13 April 1967; Springer: Singapore, 1967; Volume 1, pp. 219–227. [Google Scholar] [CrossRef]

- Kanatani, K.-I. Stereological determination of structural anisotropy. Int. J. Eng. Sci. 1984, 22, 531–546. [Google Scholar] [CrossRef]

- Ken-Ichi, K. Procedures for stereological estimation of structural anisotropy. Int. J. Eng. Sci. 1985, 23, 587–598. [Google Scholar] [CrossRef]

- Ken-Ichi, K. Distribution of directional data and fabric tensors. Int. J. Eng. Sci. 1984, 22, 149–164. [Google Scholar] [CrossRef]

- Kuo, C.Y.; Frost, J.D.; Chameau, J.L.A. Image analysis determination of stereology based fabric tensors. Geotechnique 1998, 48, 515–525. [Google Scholar] [CrossRef]

- Shiva, P.K.K.; Gong, G.B.; Fan, L.; Charles, K.S.; Moy, C.K.; Villalobos, F. Effects of preparation methods on inherent fabric anisotropy and packing density of reconstituted sand. Cogent Eng. 2018, 5, 1533363. [Google Scholar]

- Ghedia, R.; O’Sullivan, C. Quantifying void fabric using a scan-line approach. Comput. Geotech. 2012, 41, 1–12. [Google Scholar] [CrossRef]

- Theocharis, A.I.; Vairaktaris, E.; Dafalias, Y.F. Scan line void fabric anisotropy tensors of granular media. Granul. Matter 2017, 19, 68. [Google Scholar] [CrossRef]

- Li, X.F.; Wang, Q.; Liu, J.F.; Wu, W.; Meng, F.C. Quantitative description of microscopic fabric based on sand particle shapes. China J. Highw. Transp. 2016, 29, 29–36. [Google Scholar]

- Li, X.F.; He, Y.Q.; Liu, J.F.; He, W.G. Quantitative analysis of amplitude parameters for orthotropic fabric sand. Rock Soil Mech. 2017, 38, 3619–3626. [Google Scholar]

- Li, X.F.; He, Y.Q.; Meng, F.C. Image analysis of sand void rabric basedstereology principleon. J. Tongji Univ. Nat. Sci. 2017, 45, 323–329. [Google Scholar]

- Li, X.F.; Wang, X.; Yuan, Q. Quantitative determining the crack fabric of rock. Chin. J. Rock Mech. Eng. 2015, 34, 2355–2361. [Google Scholar]

- Li, X.F.; Wang, Q.; Wang, X. Determination of mesoscopic crack fabric for rock on plan. J. Zhejiang Univ. Eng. Sci. 2016, 50, 2037–2044. [Google Scholar]

- Tobita, Y. A Micromechanical Study on Constitutive Models of Granular Materials. Ph.D. Thesis, Tohoku University, Sendai, Japan, 1987. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Ma, Z.; Meng, F. Quantitative Description for Sand Void Fabric with the Principle of Stereology. Appl. Sci. 2021, 11, 11158. https://doi.org/10.3390/app112311158

Li X, Ma Z, Meng F. Quantitative Description for Sand Void Fabric with the Principle of Stereology. Applied Sciences. 2021; 11(23):11158. https://doi.org/10.3390/app112311158

Chicago/Turabian StyleLi, Xuefeng, Zhigang Ma, and Fanchao Meng. 2021. "Quantitative Description for Sand Void Fabric with the Principle of Stereology" Applied Sciences 11, no. 23: 11158. https://doi.org/10.3390/app112311158