Featured Application

This manuscript studies the feasibility of combining anaerobic digestion with high temperature and pressure treatments to reduce the final amount of digestate requiring disposal and to produce a material with higher added value. However, thermal treatments present high energy demand and installation costs. This research is a preliminary study performed to evaluate different process configurations and establish strategies for reducing the thermal demand of the combined approach.

Abstract

Anaerobic digestion is a biological process with wide application for the treatment of high organic-containing streams. The production of biogas and the lack of oxygen requirements are the main energetic advantages of this process. However, the digested stream may not readily find a final disposal outlet under certain circumstances. The present manuscript analyzed the feasibility of valorizing digestate by the hydrothermal carbonization (HTC) process. A hypothetical plant treating cattle manure and cheese whey as co-substrate (25% v/w, wet weight) was studied. The global performance was evaluated using available data reported in the literature. The best configuration was digestion as a first stage with the subsequent treatment of digestate in an HTC unit. The treatment of manure as sole substrate reported a value of 752 m3/d of biogas which could be increased to 1076 m3/d (43% increase) when coupling an HTC unit for digestate post-treatment and the introduction of the co-substrate. However, the high energy demand of the combined configurations indicated, as the best alternative, the valorization of just a fraction (15%) of digestate to provide the benefits of enhancing biogas production. This configuration presented a much better energy performance than the thermal hydrolysis pre-treatment of manure. The increase in biogas production does not compensate for the high energy demand of the pre-treatment unit. However, several technical factors still need further research to make this alternative a reality, as it is the handling and pumping of high solid slurries that significantly affects the energy demand of the thermal treatment units and the possible toxicity of hydrochar when used in a biological process.

1. Introduction

High temperature and pressure treatments are technologies useful for converting organic materials leading to their stabilization and accumulation of carbon content. Hydrothermal carbonization is performed in high-pressure reactors where the increase in temperature causes a disruption of bonds and the formation of entirely different compounds where carbon is accumulated in a solid form. The process involves a series of reactions such as hydrolysis, dehydration and decarboxylation, where gaseous and water-soluble products are released, in addition to water itself and a solid char [1]. The water generated in the process seems to become a problem for large-scale implementation of this technology due to the high volume needed if the substrate has a low moisture content. In addition, a liquid by-product stream is derived from the process, with high organic content and low energetic value. Some authors have proposed the recirculation of this process water into consecutive batches to reduce water consumption of the hydrothermal carbonization (HTC) technology [2], but if wastes already contain high humidity, this option would be unsuitable.

Thermal hydrolysis is an alternative technology where high temperature and pressure conditions are applied. This technology has been implemented as a pre-treatment of sewage sludge before anaerobic digestion. This way, the biodegradability of the substrate is increased and bioreactor performance enhanced. Several reports have evaluated the benefits of thermal hydrolysis, studying the temperature range (120–170 °C) [3,4,5], the effect on solubilization and different types of substrates [6,7,8,9] along with the effect on methane production. An increase in organic matter recalcitrance with the severity of the process has been demonstrated [10,11,12], which may adversely affect the outcome of a subsequent digestion step.

The benefits of any of these processes are mainly associated with the reduction attained in the amount of waste and the capacity to stabilize an organic material that otherwise could cause pollution problems related to its uncontrolled degradation and offensive odor. However, the energy demand of these thermal treatments and high installation costs of running these systems under high pressure makes it imperative to find ways to increase efficiency and attain lower installation costs. There are different commercial technologies available, widely used in sewage sludge pre-treatment, including technologies developed by Cambi, Veolia Water Technologies, Haarslev, DMT Environmental Technology and Eliquo Water and Energy BV [13,14,15,16,17]. There are many reports published of experimental work in the scientific literature [5,18,19,20,21], but the number of manuscripts dealing with large-scale results is much lower. The study of Oosterhuis and co-workers [22] presents results from a pilot plant at the Hengelo Wastewater Treatment Plant, The Netherlands, indicating a significant reduction in volatile solid removal. A full-scale study was described by Kepp and co-workers [23] after three years operating a thermal hydrolysis plant located in Hamar, Norway. These authors indicated a great conversion into biogas of the organic matter contained in sludge and a pathogen-free digestate.

The analysis performed by Liu and Smith [24] in the United Kingdom used data from 66 conventional wastewater treatment plants (WWTP), six of them with thermal pre-treatment units followed by conventional mesophilic digestion. Data were recorded daily for periods of 2–7 years. They indicated similar biogas yields from mesophilic digestion after sludge pre-treatment, whereas higher biogas production was attained if the digestion stage proceeded under thermophilic conditions. Even though this finding may seem disappointing, the decrease in the amount of sludge obtained still gives a positive balance. Other benefits should also be added regarding the safety of the product and improvements in the rheological properties of digestate (lower viscosity and improved dewaterability) [19,25]. Other studies focus on energy evaluations dealing with global process performance, indicating that the energy demand of the additional equipment associated with the thermal hydrolysis unit may be higher than the energy derived from digestion enhancement [26,27]. This disadvantage may be offset by a much lower amount of sludge needing final disposal [28], along with a lower volume of reactor required to treat the pre-treated sludge. Therefore, it is of great importance to analyze the performance of the complete process since additional benefits, including synergies associated with the improvement of the global thermal balance, may be attained [29]. Additionally, the application of thermal treatments to other processes also dealing with the treatment of wastes should be explored as a way for increasing global efficiency using, in this case, the wide experience attained in sludge pre-treatment.

Reports regarding the performance of thermal hydrolysis of agricultural, animal wastes or organic wastes usually deal with small-scale experimental work [6,30,31,32]. Results reported by Şenol et al. [33] indicated an increase in biogas production which can be double the value obtained from fresh lignocellulosic substrate. Conditions tested in their study evaluated the temperature in a range of 100–180 °C at a duration of 10–120 min. However, other authors have reported a decrease in digestion performance with the severity of the thermal pre-treatment, indicating the formation of recalcitrant compounds such as furfural and 5-hydroxy methyl furfurals [34,35] and the accumulation of recalcitrant structures with an increasing pre-treatment severity [10].

The HTC process retains similarities with thermal hydrolysis regarding the severe treatment conditions of both techniques. In the latter, the temperature is controlled to avoid the accumulation of excessive recalcitrant compounds because the subsequent treatment stage will be a biological process. Thus HTC can be interpreted as a further severe treatment where conditions are set to maintain the transformation of the feedstock into complex compounds with high carbon content. Ro et al. [36] found that the duration of this process did not have a significant effect on the fixed carbon content of the remaining material, but on the contrary, the increase in temperature had an inverse effect on solid yield and, to a lesser extent, in the energy content.

The solid product derived from HTC, also known as hydrochar, has been demonstrated to attain benefits when added as a supplement in anaerobic digestion and composting, similar to those reported by biochar obtained from pyrolysis processes [37,38,39,40,41,42]. Other reports have also demonstrated that char may act as an active compound, improving nutrient management in crops [43,44]. Given these features, the coupling of HTC processes and anaerobic digestion leads to additional improvements associated with the enhancement in organic degradation and reactor productivity. Additionally, the process water derived from the HTC may also be used as a substrate in the digestion stage, thus eliminating the problems derived with the final disposal of this high organic content fraction. There are several reports in the literature reporting the biogas potential of this HTC liquid stream [39,45,46].

The present manuscript aims to assess the energy demand of the HTC process integrated into a conventional digestion plant treating cattle manure. Results obtained are compared with those derived from the hypothetical pre-treatment of the same material under thermal hydrolysis. Co-digestion was also considered to increase the amount of energy available in the treatment plant. Cheese whey was selected as the co-substrate due to its high carbohydrate content and being readily degradable.

2. Materials and Methods

2.1. Description of Scenarios

Scenarios considered the valorization of cattle manure and cheese whey as a readily degradable co-substrate to improve digestion performance. The energy performance of the system was evaluated, assuming that the process water obtained from the HTC unit is also used as a substrate for the anaerobic reactor. Hydrochar derived from hydrothermal processing of digested manure is used as a fuel to obtain energy from combustion. The use of this char as a supplement in the digestion process and its addition as an active carbon compound during digestate composting was also evaluated.

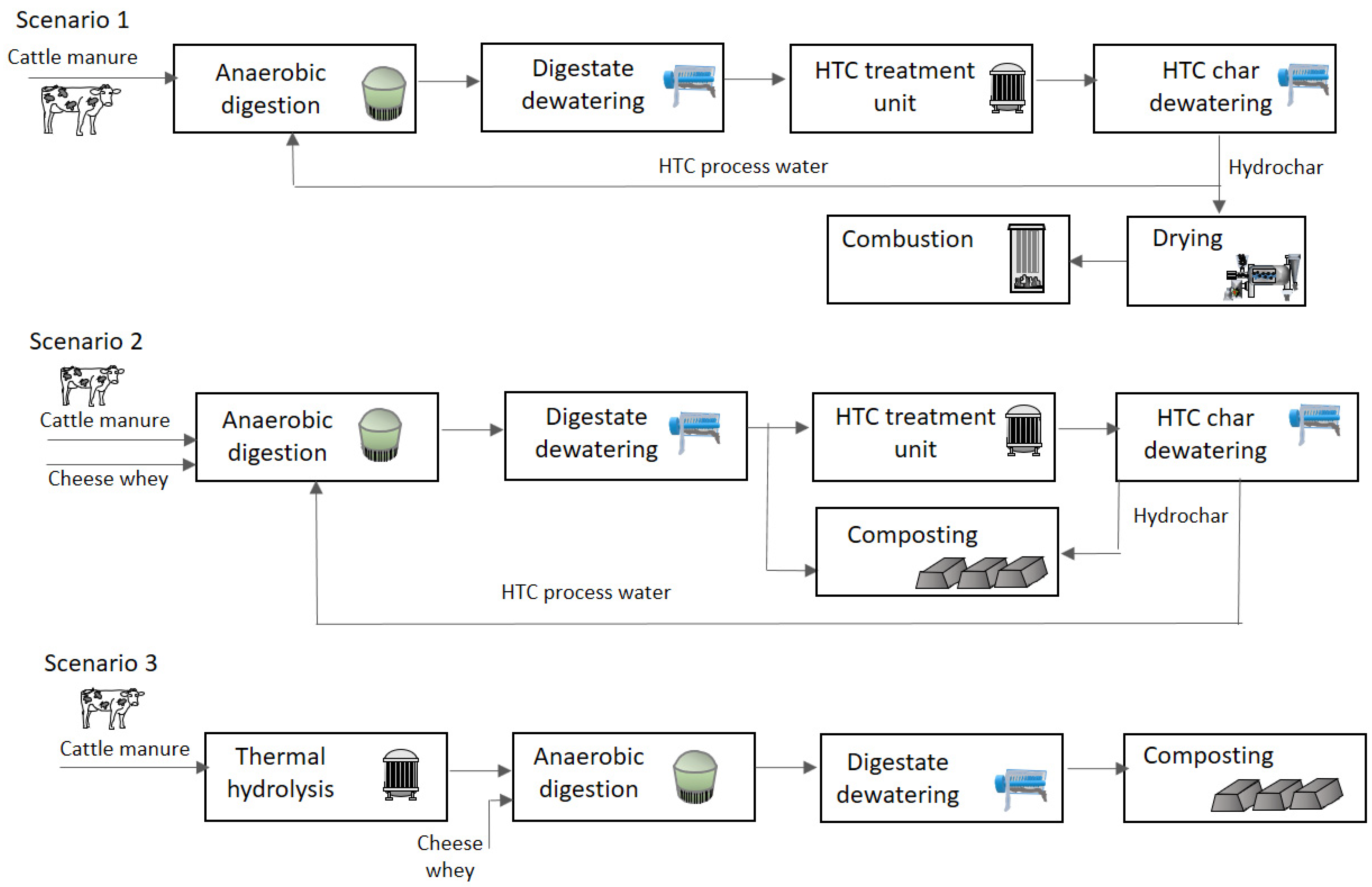

Three scenarios were studied. Scenario 1 involves the digestion of manure as a single substrate in the first stage, with the second stage being an HTC process for treating the digested material. The thermally-treated slurry is then separated to obtain hydrochar to be used as fuel in a combustion process. The HTC process water is returned to the anaerobic reactor for treatment and degradation of the organic compounds. In this same scenario, the expected enhancement in performance is analyzed when a fraction of char is added to supplement the digestion process.

Scenario 2 considers the effect of adding a co-substrate to the digestion system keeping the previous configuration of Scenario 1. It also evaluates the thermal demand associated with the treatment by HTC of a fraction of digestate to obtain the amount of hydrochar needed for the digestion process and for the composting stage to produce an active compost supplemented with carbon-enriched material.

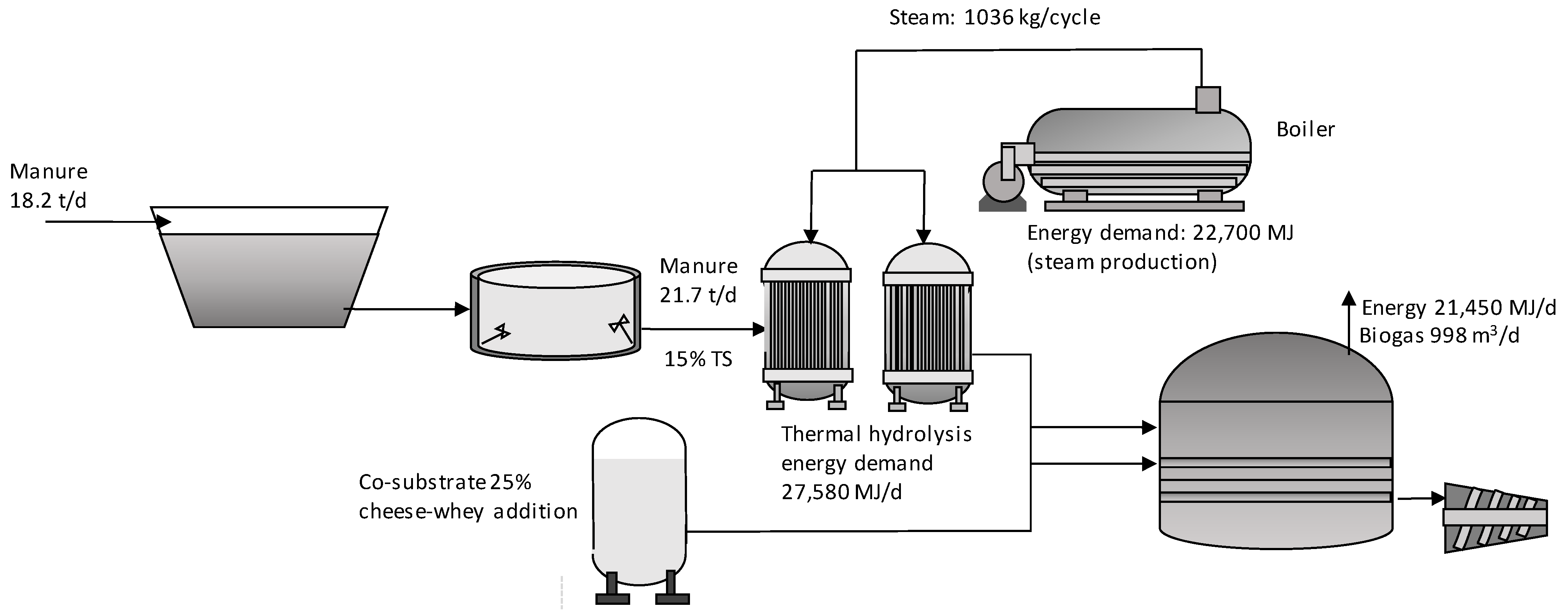

Scenario 3 considers thermal hydrolysis as a pre-treatment stage followed by anaerobic digestion. The hydrolyzed material obtained is then co-digested in the anaerobic reactor with cheese whey as co-substrate. Biogas is valorized in a combined heat and power system (CHP) for producing heat and electricity. A boiler is also considered in all scenarios for supplying the energy demand for the thermal treatments. Figure 1 shows a simplified representation of the different scenarios.

Figure 1.

Representation of the three different scenarios showing the main process stages. Cattle manure is the primary substrate, with cheese whey added as co-substrate.

2.2. Assumptions of Substrate Characteristics

Cattle manure was assumed to be the primary feedstock of the integrated plant, considering that it contains straw, which is a common practice in many farms where manure is collected with straw used as bedding. The total solid (TS) content was 178.8 g/kg with a volatile solid (VS) percentage of 84.8%, assuming average values reported by Gómez et al. [47] and Otero et al. [48]. The methane yield was 163.3 mL/g VS, also derived from the average values of these references.

Cheese whey characteristics were those taken from Fernández et al. [49], considering a TS content of 33.1 g/L and VS content of 91%, for a concentrated stream derived from ultrafiltration process. Methane yields were those reported by Bertin et al. [50]. A value of 316.5 mL CH4/g VS for cheese whey was obtained as an average. This value was derived from their co-digestion experiments assuming no synergistic effects. Co-digestion with cattle manure yielded values between 151 and 320 mL CH4/g VS for mixtures containing a VS percentage of cheese whey between 25 and 82%, in accordance with Bertin et al. [50].

The waste treatment facility receives manure from livestock farms with a herd of 300 cows. It was assumed that an animal of 1400 pounds would produce 54 kg/cow d of feces and urine with an average solid content of 120 g TS/kg. Straw used as bedding material was considered to have a TS content of 650 g/kg. Straw was also contained in animal feces after manure collecting operations. Thus the total amount of the mixture was 18,200 kg/d.

Manure was then mixed with process water to optimize the solid content required for the reactor working under wet configuration. This configuration was assumed based on the reports indicated by different authors where a decrease in methane production was observed when increasing the solid content [51,52]. The process water comes from dewatering operations of the digested slurry, where a solid material and a liquid-rich ammonium stream are obtained. The total solid content achieved for the feed mixture is 10% after the addition of process water.

2.3. Detailed Plant Description

The waste treatment plant is assumed to contain a waste reception area for manure and a separate tank for storing the co-substrate. The mass of material to be held was equivalent to 15 days’ treatment capacity. Thus, the volume of the storage zone is 382 m3. The volume of the storage tank for the co-substrate was also estimated from the same assumptions considering the proportion of co-substrate applied in the feeding mixture.

A mixture tank is dedicated to homogenizing manure with process water to reach the desired solid content. The tank was furnished with two mixers and chopper pumps for avoiding clogging problems when feeding the anaerobic reactor. The anaerobic digester was considered to run under a hydraulic retention time of 40 days at mesophilic conditions. Storage of biogas is assumed to take place at the head of the reactor, with a headspace of 30%. Table 1 provides the main plant parameters and characteristics.

Table 1.

Characteristics of the digestion treatment plant.

Biogas produced is assumed to be derived exclusively from volatile solids of the feedstock. Inorganic material remains constant during the process, thus accumulating in the digested slurry. Estimations of biogas production and thermal energy needs of the anaerobic reactor were based on González et al. [53].

Equation (1) was used to estimate biogas production (m3/d) expected from the substrate:

Biogas = (Fv × VSinlet × SMP)/(1000 × %CH4),

The daily amount of biogas produced is estimated from the volumetric flow (Fv, m3/d) of the digester feeding stream and the concentration of volatile solid of this stream (VSinlet, g/L). The specific methane production (SMP, expressed as (L CH4/kg VS)) of each substrate is used for estimating the global amount of gas produced. The composition of methane in biogas is represented by %CH4 and assumed to be 60%. The lower heating value (LHV, 35.8 MJ/m3) of methane was used to estimate biogas energy content. Biogas produced is assumed to be valorized in a combined heat and power unit (CHP) with an electrical efficiency of 34% [54].

The thermal energy demand of the digestion reactor was estimated for winter conditions to consider the worst-case scenario. The influent stream was assumed to be at 8 °C, and the temperature of the reactor was set at 37 °C. The heating needs of the digester were calculated based on Equation (2) considering a 12% increase due to thermal losses [53]:

where Thermaldig (kJ/d) is the thermal energy demand of the anaerobic reactor for increasing the temperature of the feeding stream (Tfeed, °C) to the temperature of the digestion (Tdigestion, °C). The mass of the feeding stream was assumed to be conformed of water (mwater, kg/d) and solids (msolid, kg/d) derived from the organic waste. The specific heat capacity (cp, kJ/kg K) was assumed to be kept constant with changes in temperature, considering a value of 4.2176 kJ/kg K for water (cp_water) and 1.5 kJ/kg K for solids (cp_solid) based on data reported by Nyakuma et al. [55] for lignocellulosic material.

Thermaldig = 1.12 × (mwater × cp_water + msolid × cp_solid) × (Tdigestion − Tfeed)

The digestate is subsequently sent for dewatering prior to HTC treatment. A value of 30% TS was assumed for this process. The HTC unit worked under batch conditions with loading, reaction and unloading operations carried out in a single day in two consecutive cycles. The process conditions were set at 200 °C (15.5 bar) for 1 h duration. The energy balance for this system was estimated considering the enthalpy of the sludge stream and steam injection and that of the final conditions under adiabatic approximation [56]. The energy demand of the boiler was calculated using an efficiency value of 85.7% for energy conversion [57]. Thermal energy recovery after the HTC system was achieved by considering the use of flash steam equipment. The amount of energy contained in the flash gas was obtained from the flash steam calculator available at [58]. The energy demand for heating the reactor unit was calculated based on assumptions found in Lucian et al. [59], where a 1.5 m3 tank volume requires 1550 kJ/K.

The resulting slurry from HTC was dewatered at 40% solid content. The HTC process water was sent back to the digestion process for further treatment. Assumptions for the HTC process were based on data reported in the literature, described as follows.

Methane yield from the process water was 105.5 mL CH4/g COD added using average values reported by De la Rubia et al. [60] and Ferrentino et al. [39], considering a chemical oxygen demand (COD) concentration for HTC process water of 98.7 g COD/L. These values were considered for the case of HTC liquid fraction derived from manure digestate, keeping this assumption also for the co-digestion case with cheese whey. Data derived by Marin-Batista et al. [61] from processing cow manure under HTC, gives higher values for the methane yield (246.5 mL CH4/g VS; average data from the two experimental set-ups) of the liquid fraction but a much lower VS content for the process water (23.8 g VS/L, average data), therefore, leading to similar results.

Performance of the HTC process was obtained from data reported by Parmar and Ross [62], Ferrentino et al. [39] and Wu et al. [63]. A hydrochar yield of 78.7% was considered. Liquid and gas yields were 15.1 and 6.2%, respectively. This high hydrochar value was justified based on the high mineral content of the digested material and the high solid content of the digestate submitted to the thermal treatment. Other authors reported lower yields of char, but these values were derived from fresh material, a higher HTC process temperature and lower solid content of the waste slurry [64,65,66].

The energy demand for hydrochar drying was calculated using a value of 2296 kJ/kg for water heat vaporization at 85 °C and assuming an efficiency of 80% in drying operation. The higher heating value (HHV) of hydrochar was supposed to be 15.7 MJ/kg based on data reported by Parmar and Ross [62]. The lower heating value (LHV) was estimated considering the ultimate analysis also reported by these authors leading to a value of 14.8 MJ/kg. LHV of digested material was estimated using elemental composition data reported by Otero et al. [48], considering ash content to be equivalent to that of inorganic solids contained in the original feed and using the equation proposed by Sheng et al. [67] for estimating HHV of biomass from elemental analysis.

Composting degradation rate was calculated based on the mineralization rate reported by Kulikowska and Bernat [68] with values of 0.06 d−1 for the first-order kinetic constant. The initial organic matter was estimated, assuming VS to be equivalent to OM content and estimating the total amount of solids present in the stream to be composed of char, TS from digestate and wood chips. The addition of wood chips was assumed at a weight ratio of 1:1 (TS content of 50%) and degradation of this material was disregarded. A recovery rate of 90% for wood chips was used for calculating the final amount of compost.

3. Results

3.1. Scenario 1

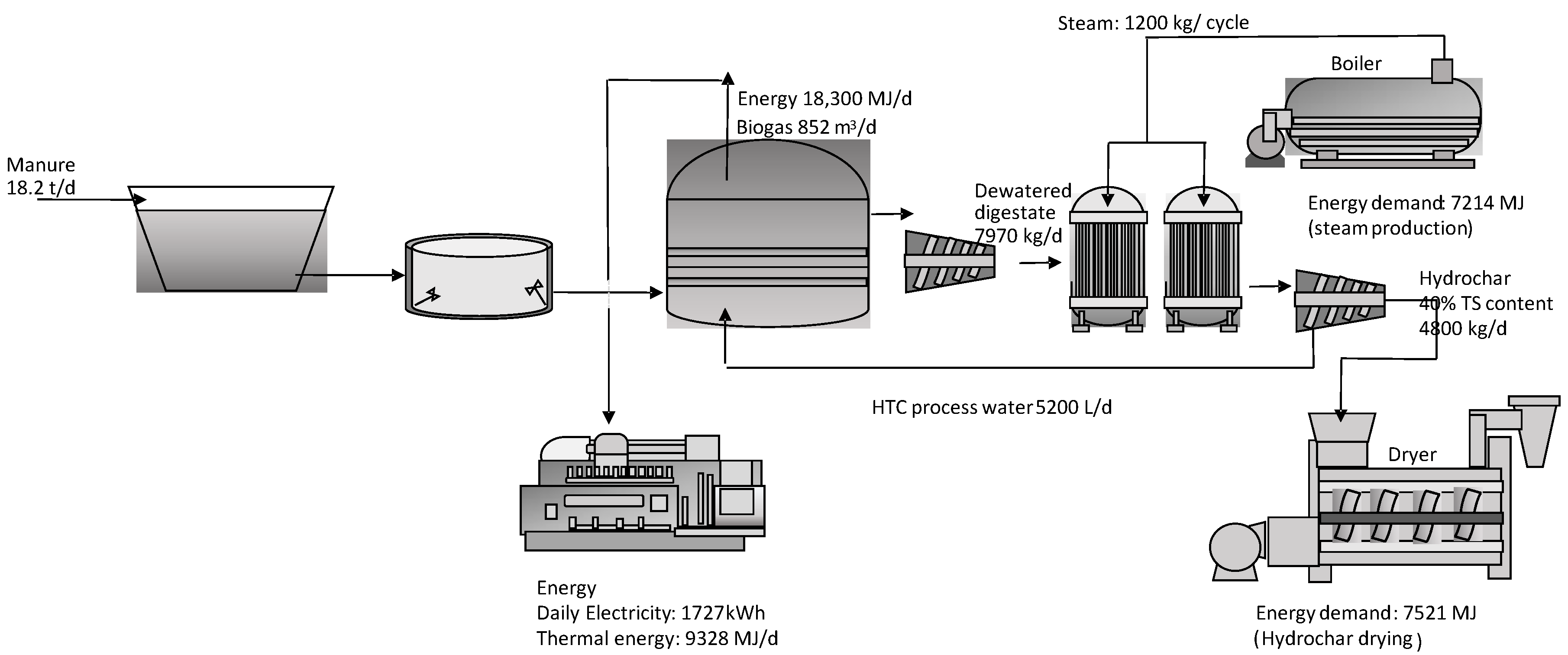

Assumptions made for Scenario 1 considered the feeding material to be diluted at a 10% TS to avoid problems regarding floating straw and forming a scum layer on the top of the reactor. The biogas production expected for this system is 752 m3/d, if only manure is fed into the reactor. The addition of process water from the HTC system would lead to 852 m3/d, representing a 13% increase in gas production, which is almost incidental considering the requirements of installing such a high-pressure system. This low increment is due to the low methane yield of the HTC process water. Table 2 presents the values of the main parameters studied for the different scenarios and Figure 2 provides an outline of the process with main streams represented. The energy content in biogas was estimated considering a methane composition of 60% and the LHV of this gas. The digester thermal demand was calculated by considering the incoming substrate and disregarding the sensible enthalpy of the HTC process water.

Table 2.

Main calculated parameters of the integrated system: anaerobic digestion and HTC.

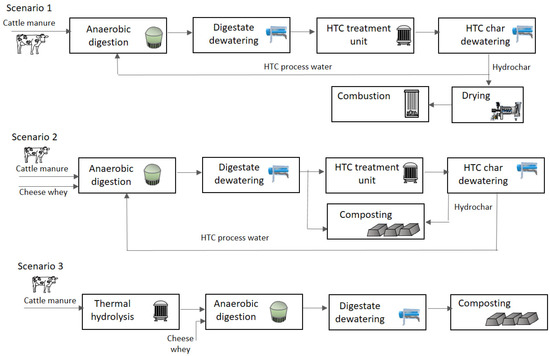

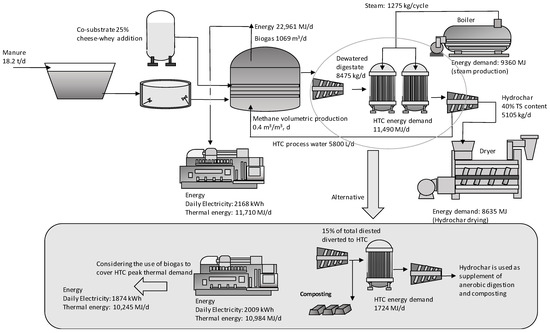

Figure 2.

Representation of the main treatment stages in Scenario 1 (anaerobic digestion and subsequent HTC treatment of the whole digestate stream).

The digested material is dehydrated at 30% TS content, assuming that inorganic solids remain constant during the biological process. Therefore, the mass of solids treated in the HTC is 2392 kg/d. This material is loaded into the reactor under batch operating conditions. Thus loading and unloading operations need to be coupled with the continuous production of sludge. For this reason, two HTC units were assumed with a reaction working time of 1 h and a steam injection time of 45 min. The discharge of the HTC system should allow the production of flash steam for energy recovery, whereas the charge and unloading of the reactor tank were assumed to take place in 3 h for each operation, needing two reactors for completing the cycle to treat the whole digested stream derived from the fermentation. If the total dehydrated sludge produced in a single day is to be treated in these thermal units, the boiler needs to provide the whole steam demand associated with the HTC treatment system for a 90 min period distributed in two cycles.

The amount of steam added to the HTC process, considering that adiabatic conditions are reached for saturated water at 200 °C (15 bar) would be 1200 kg/batch with a steam flow of 1602 kg/h. The steam flow is provided by a boiler for a daily period of 90 min. The energy needed for producing the steam flow is then 5380 MJ/h, as estimated for 85.7% boiler efficiency. The energy demand associated with heating was 1932 MJ for the two working reactors with 5.5 m3 of volume. This value is to be added to the energy demand of the boiler, finally accounting for the HTC system already needing 57% of the energy produced from biogas. Thus the recovery of thermal energy is imperative to increase process feasibility.

If the production of flash steam from the HTC reactor is considered and conditions of saturated water are assumed, then the amount of flash steam to be produced from the two cycles would be 993.4 kg/d at 1.3 bar. If 85% of the energy can be recovered, then 2268 MJ/d are now available to cover some of the thermal demand of the plant. An additional amount of energy can also be recovered from the cooling of the HTC process water. For a flow of 5200 L/d of HTC process water, an additional 977 MJ/d can be obtained as thermal energy. However, this latter energy is of lower quality since it is derived from cooling a liquid stream from 90 to 40 °C. This heat can be recovered by mixing the hot process water stream with the fresh manure slurry to increase thus its temperature.

Valorizing hydrochar by combustion is a process requiring the drying of this material and, therefore, increasing the energy demand of the global process. The energy needed for drying was calculated assuming a water content of 60% in the dewatered hydrochar. Thus the thermal energy needed for attaining a 10% moisture content was 797.2 kWh per ton of water evaporated, translating into 7521 MJ/d of energy to dry this material.

The valorization of hydrochar by combustion is necessary to cover the high energy demand of the process. However, alternative uses of hydrochar have been proposed. The use of char as an active supplement in organic fertilizers, the production of activated carbon, or its use as an adsorbent to remove bacterial pathogens are some examples [69,70,71]. However, the high energy demand of the global process necessitates a reliance on fossil fuels which translates into higher operational costs and negative effects associated with CO2 fossil fuel emissions. Based on assumptions regarding the LHV of hydrochar, the energy in this material would be 27,974 MJ/d. This amount is enough to cover the thermal demand of the HTC process and drying. Therefore, there is no need for diverting biogas to produce heat, as this fuel can be fully valorized for electricity production, which yields 1728 kWhe per day.

If the combined digestion and HTC system is compared with the single production of biogas from manure, then only 33% of energy is recovered. This calculation was made for biogas being the only fuel susceptible of valorization. The value was calculated as the ratio between the energy contained in biogas and that of fresh manure as well as considering data reported by Toufiq Reza et al. [72], with an HHV of 19.1 MJ/kg (free ash manure) reported along with the ultimate analysis for this material. Evidently, the direct combustion of either manure or digestate can be performed, but in the first case, no gaseous fuel is obtained capable of valorization in a CHP unit. If digestate is directly used as fuel, then assuming values reported by Otero et al. [48] for digestate composition, the LHV of digested manure would be 11.4 MJ/kg, which translates into 27,340 MJ/d energy. The energy demand for drying would be 15,251 MJ/d after dewatering this material to a solid content of 30% (as in the previous case). This quantity can be easily provided by the combustion of the digestate if 85% of heat recovery is obtained from combustion. However, this strategy does not account for benefits regarding the production of hydrochar and positive effects associated with its application as it would be the use of char as a supplement in the same digestion process for producing active fertilizers. Arauzo et al. [73] studied the combustion characteristics of digested material and the pyrochar and hydrochar obtained from the thermal processing of digestate, and reported better combustion characteristics for digestate and pyrochar, whereas hydrochar presented a poor combustion scenario.

Several authors have reported digestion enhancement when char is added as carbon conductive material to the anaerobic process [74,75,76], indicating that the presence of this external material serves as electrons’ transport leading to an innovative pathway for improving performance [77]. Ren et al. [78] reported that the addition of hydrochar favored methane production rate thanks to the abundance of surface oxygen-containing functional groups. Therefore, adding char back to the digestion process would provide an additional benefit for energy recovery regarding the greater biogas production expected.

A dose of 10 g/L was evaluated by Chiappero et al. [79], reporting an increase in biogas yield up to 22%. This same dose was tested by Martínez et al. [80] when digesting citrus waste. Sun et al. [81] reported doses between 2–10 g/L with an average enhancement in methane yields of 47% under mesophilic conditions. Higher doses were tested by Sánchez et al. [75]—50 g/L in a single application to the reactor—and by Quintana-Najera et al. [82]—(30 g/L)—under biochemical methane potential (BMP) tests reporting no detriments in the fermentation. Other doses reported per mass of substrate are those tested by Cai et al. [83], with values between 0.5–2.5 g char/g substrate. A low amount would be assumed to avoid penalizing energy recovery from hydrochar combustion in the hypothetical case here studied.

The addition of char supplement to the digester will consider a dose of 5 g/L of hydrochar with a 15% increase in methane yield. Under this assumption, the biogas production is increased to 958 m3/d, but the solid balance is hardly affected. This is explained because the system experiences a low increase in digestate concentration associated with char addition, but the enhancement in volatile solid removal offsets this effect. Thus the global energy balance is further improved when a small fraction of char is supplemented to the digester. The amount of energy now available from the combustion of char would be 26,400 MJ/d, and the energy demand for hydrochar drying is scarcely increased.

The energy balance leads to positive results regarding the valorization of the material by transforming it into biogas and heat derived from hydrochar combustion. Similar results have been also reported by Mayer et al. [84] indicating that a cascade approach integrating digestion and HTC is the best option for dealing with organic wastes, but a responsible energy source needs to be supplemented to cover the high energy demand of the HTC process. Heidari et al. [85] reported the performance of HTC and digestion as a combined approach for treating organic wastes. These authors also brought out the same conclusion regarding the better energy efficiency of this alternative when the moisture content in the waste stream is high.

However, this analysis is obviating the high installation costs of such thermal hydrotreatment requiring specialist vessels to support the high pressure associated with harsh conditions and install a high-pressure boiler to provide the necessary steam. Pyrolysis of the digestate would be also an alternative treatment for obtaining energy. However, in this latter case, the drying of the dewatered slurry would need an excessive amount of heat. The pyrochar produced would be much lower because this process has a lower char yield against that of hydrothermal carbonization [86]. Therefore, oil and gas products from pyrolysis would also be used for covering the thermal demand for drying and to keep running the pyrolysis unit [53].

3.2. Scenario 2

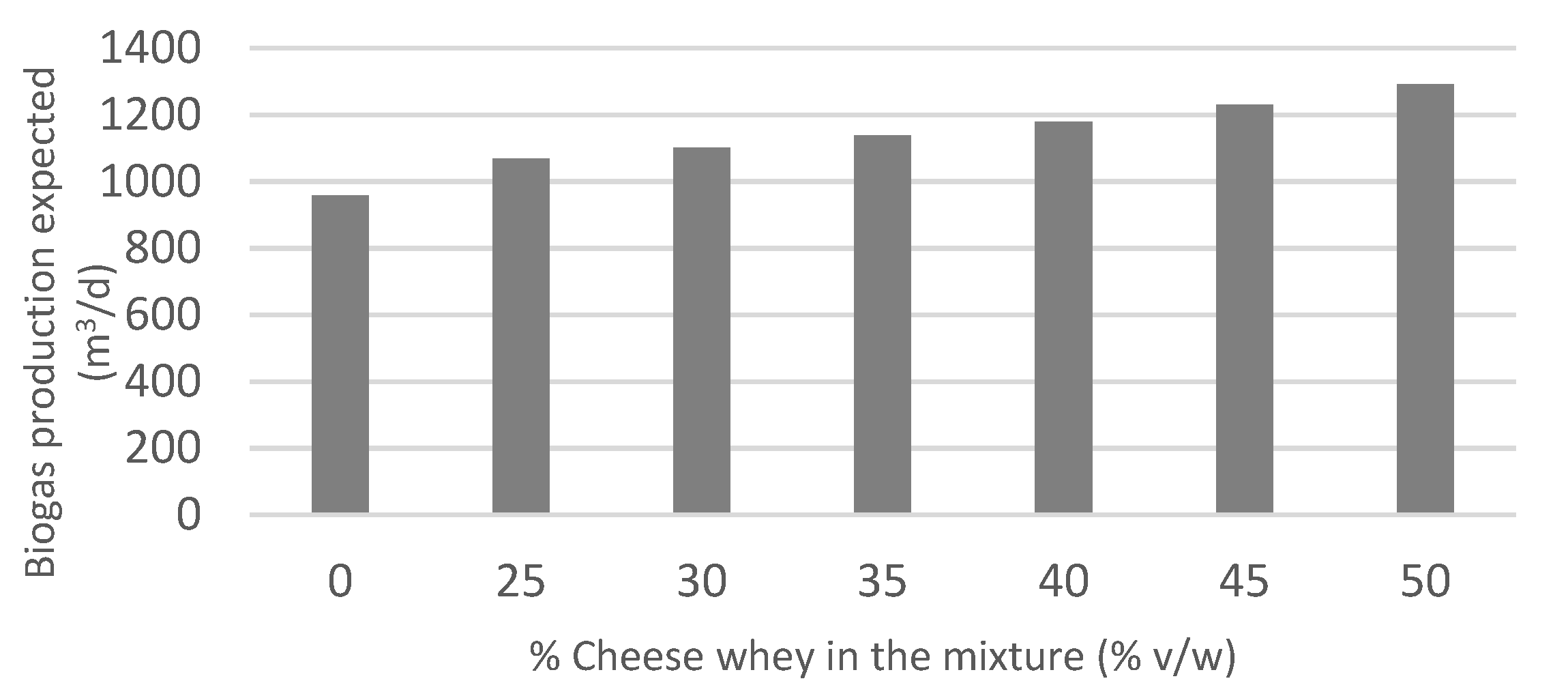

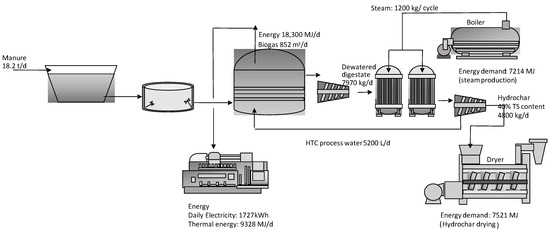

The addition of a co-substrate would increase the amount of biogas available in the system and, therefore, benefit the process’s feasibility by increasing revenues derived from biogas valorization. If a variable amount of co-substrate is added from 25 to 50%, then the amount of biogas produced can be estimated based on biochemical methane potential (BMP) data reported by Bertin et al. [50], considering that the total solid content of the feed is kept constant at 10% by the addition of process water from digestate dewatering operations. The addition of the co-substrate in a 25% mass percentage causes a moderate increase in biogas production (11%) due to the low solid content of the cheese whey stream here considered. Doubling this quantity to 50% causes just a 34% increase if compared with the case of no co-substrate addition (see Figure 3). Thus the advantage of adding a high methane yield co-substrates is lost by the low organic load of the stream here considered (TS content values based on data reported by Fernández et al. [49]).

Figure 3.

Daily biogas production obtained from the addition of different co-substrate proportions to the mixture (the mixture is composed of cheese whey and cattle manure). The value of 0 in the graph stands for the baseline case where no co-substrate addition is implemented. Substrate addition was made as a percentage representing volumetric addition of cheese whey to the global mass of the feeding mixture.

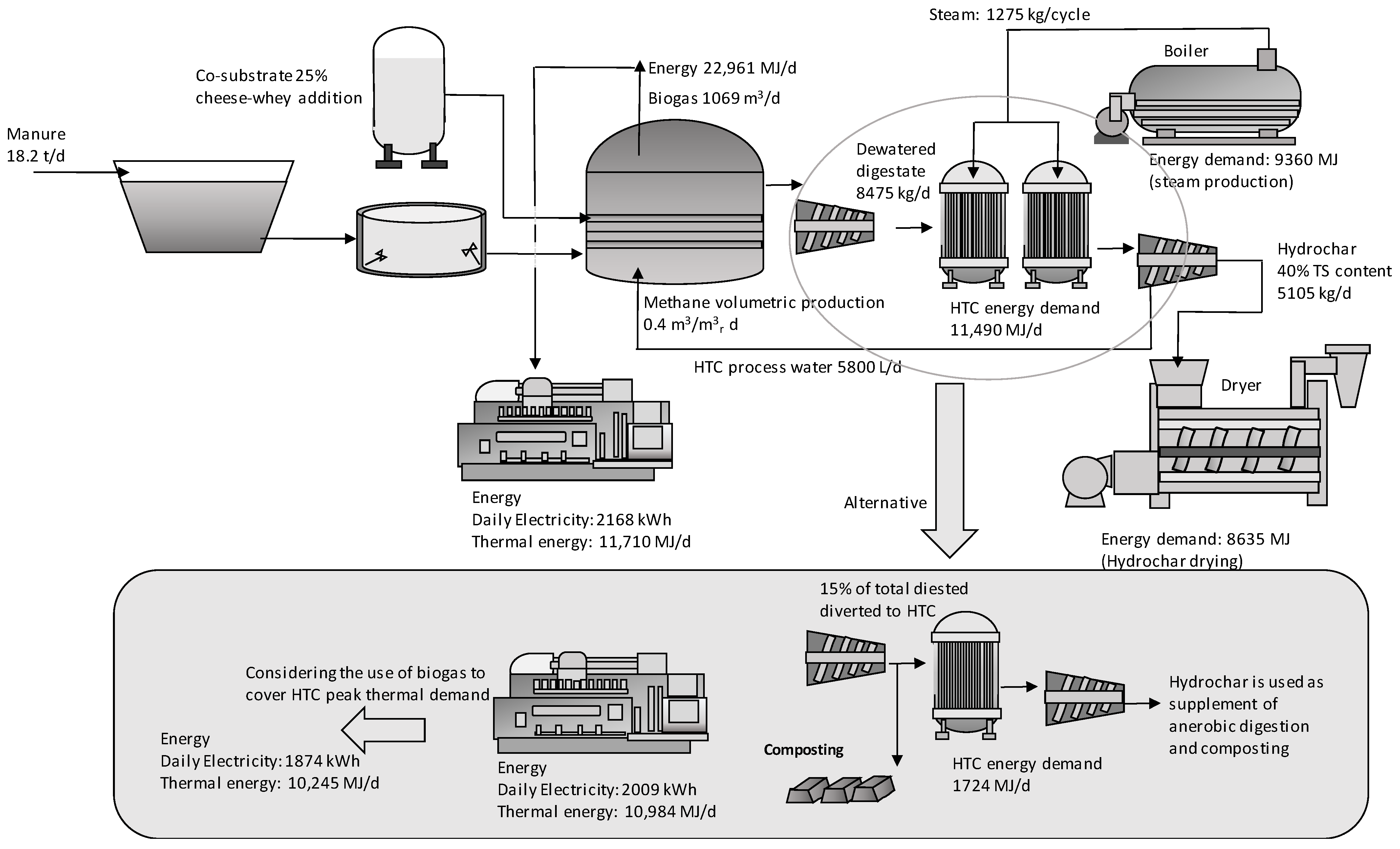

The high content in volatile solids of the co-substrate and its high biodegradability scarcely affect the system’s solid balance (Figure 4). Thus, adding this carbon-rich source was estimated to increase the mass of digested solids in the range of 4 to 11%. The assumption considered additive effects in methane production disregarding synergistic effects, which would lead to better results due to the higher gas obtained and lower volume of digestate needing final disposal. Different authors have widely reported synergistic effects when evaluating mixtures of manures and carbon-rich content substrates [87,88,89,90]. Therefore, the remaining amount of solids in the digested slurry should not be significantly affected.

Figure 4.

Representation of the main treatment stages in Scenario 2 (anaerobic digestion and subsequent HTC treatment). Cheese whey is added as co-substrate in a 25% w/w (wet weight proportion). The figure represents the main parameters of mass and energy balance when all the digestate is sent to HTC treatment, and as an alternative when only a fraction is treated by HTC (gray-colored).

Keeping the conservative assumption of no synergies, then it is evident that adding a low organic content co-substrate for attaining just a 34% gas improvement may not be worthwhile, given the additional investments necessary for transporting and storing the co-substrate. Other authors have reported the use of more concentrated whey streams, as it is the case of Gonzalez-Piedra et al. [91] with a TS content of 134.87 g/L or Hallaji et al. [92] reporting a solid content of cheese whey of 84.3 g TS/L. The availability of such type of material will highly enhance biogas production.

Another important fact is that the valorization process assumes that the only valuable product (hydrochar) is used for heat production. This strategy is justified by the need to supply the thermal demand to the whole process. However, if heat is obtained in excess, this energy has a low market price. Other valorization options are more attractive, including producing high-quality compost enriched with hydrochar or applying other thermal processes capable of producing higher valuable biofuels, such as gasification or pyrolysis. Digestate can also be valorized for attaining the recovery of nutrients [93], as it would be the use of digestate liquid fraction as media for ethanol production [94] or for producing biofertilizers based on the use of plant growth promoting rhizobacterium (PGPR) [95]. Digestate can also be transformed into methanol and hydrogen via gasification and posterior syngas conversion by water gas shift reaction [96]. Other processes consider the treatment of the recalcitrant carbon fraction of digestate, or of the remaining straw, to be further transformed into ethanol via fermentation [97,98]. There is a wide range of possibilities for valorizing digestates as reported by Wang and Lee [99] but the economic feasibility of these alternatives may currently prevent its commercial application.

The assumptions of variable addition of the amount of cheese whey need the local availability of significant amounts of this co-substrate in the vicinity. Thus, a value of 25% addition would imply having available a daily volume of 6 m3/d, and this quantity is increased to 18.2 m3/d if the assumption of 50% volumetric addition is considered. This latter value would be unreasonable since cheese whey finds valorization in other production sectors as it is in the production of food and pharmaceutical compounds for recovering nutrients, lactose and lactic acid [100]. Keeping the first assumption of 25% co-substrate addition and considering again that the whole digestate stream is submitted to hydrotreatment (8.5 t/d), then the volumetric flow of HTC process water generated would be 5700 L/d. This stream would account for additional biogas production, translating into a global amount of 1076 m3/d (representing an increase of 42% compared with the single digestion of manure). Results derived from Scenario 2 calculations are shown in Table 3.

Table 3.

Main calculated parameters of the integrated system: anaerobic digestion and HTC Scenario 2. Manure and cheese whey (25% v/w) used as substrate.

HTC process water presents a low methane yield, as reported by different authors [39,60]. In addition, calculations considered that the total HTC water derived from dewatering operations has the same characteristics as those reported from experimental results found in the literature. However, industrial application of this system requires high-pressure steam injection, causing a dilution effect and probably resulting in a liquid stream with lower COD content, and lower methane potential if estimated per volumetric flow. Thus, this stream may cause a dilution of the reaction system rather than creating a real benefit regarding significant additional performance. Therefore, the direct addition to the reactor of this stream will cause an increase of the reactor working volume of 16.7%. The reactor productivity measured as the volume of methane produced per unit of reactor volume is also decreased from 0.42 to 0.40 m3 CH4/m3r d when adding the HTC process water. Using the HTC process water to adjust the TS content of substrate to 10% will result in an increase in the organic loading of the system. Thus the daily production of biogas will be kept constant, but now the reactor volumetric productivity is increased to a value of 0.47 m3 CH4/m3r d.

The system was proven to provide enough thermal energy to sustain the process by the use of the whole hydrochar as fuel. However, hydrochar has multiple applications, thus burning to produce just thermal energy seems inadequate. A similar analysis of this scenario was performed for the case of 25% addition of co-substrate. The evaluation only considered char production to supply the amount of material to be used as a supplement in the digestion process and in composting to attain the conversion of digestate into active compost enriched with hydrochar. Compared with transforming the whole digestate into hydrochar, the thermal demand of the HTC process is 11,490 MJ/d. However, if this option is disregarded in preference of treating just a fraction of digestate, then the energy demand is considerably decreased but the benefits of greater biogas production are retained.

The amount of digestate to be treated by HTC to produce hydrochar needed in biological processes was estimated. The amount of digestate to be treated by HTC is then reduced to 15% of the total digestate stream. Thus, the volume of HTC water was also reduced, affecting the total amount of biogas produced. However, given the low methane yield of this stream, the effect is irrelevant. The volume of biogas produced under this assumption is 990 m3/d, whereas this value was 1076 m3/d when the whole digestate stream was treated by the HTC system. The more significant benefit comes from the much lower demand for energy associated with the HTC, which is 1724 MJ/d. In addition, since hydrochar would be used as a supplement in biological processes, the drying step after dewatering is unnecessary, reducing the thermal energy demand of the whole process.

If biogas is used as fuel in a CHP system, electricity and thermal energy are produced simultaneously. For an electrical efficiency of 34% and a thermal efficiency of 51%, the energy recovered as heat (10,984 MJ/d) can clearly compensate for the thermal demand of the process. However, one additional consideration that should be carefully evaluated is that HTC operates under batch conditions. Given the small amount of digestate to be treated, then only one single reactor can be used for the process. The reactor would receive the total mass of steam to be injected in a single cycle. If an injection flow of 10 kg/min is considered, which is equivalent to a steam injection time of 38 min, then the hourly demand of the HTC unit rises to 2700 MJ/h while the engine can produce a flow of 458 MJ/h as maximum.

A fraction of biogas must be sent to the boiler to cover the thermal demand of the process. This feature results in a lower production of electricity because of the thermal needs associated with the peak demand imposed by the batch HTC process, decreasing the global efficiency. However, even if this inefficiency is considered, the energy available for the engine will be 19,826 MJ/d (which is 93% of the total amount produced). The thermal demand can be thus met by the engine and a recovery boiler capable of using engine exhaust gases and biogas as fuel. The thermal energy produced from the engine under this configuration will be 10,236 MJ/d with a daily electricity output of 1920 kWh

The thermal demand of the digester is scarcely affected, amounting to 4390 MJ/d. Therefore, as schematized, the combined treatment can cover the thermal demand of the biological process and that of the HTC system. The main advantage of this configuration is the elimination of fossil fuels to provide the energy needed by the thermal conversion unit, while the use of hydrochar as a supplement in the biological process avoids the need for material drying. However, the capacity of the treatment system should be carefully evaluated. Final disposal of the composted material is still necessary. The compost generated accounts for 2.8 t/d, a value calculated by the use of the first-order kinetic degradation constant suggested by Kulikowska and Bernat [68] (0.06 d−1), and initial organic matter content of 238 g OM/kg DM obtained from the ratio of VS present in digestate.

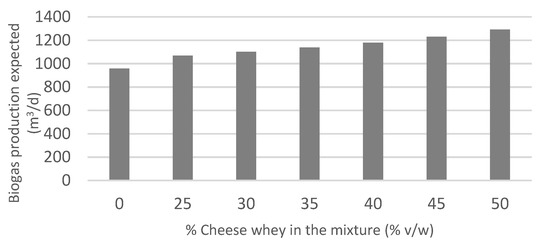

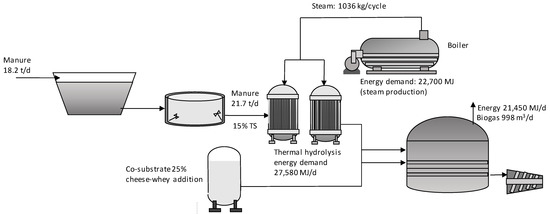

3.3. Scenario 3

The thermal hydrolysis of the whole incoming stream of manure may improve the degradability of the substrate, mainly given by the high lignocellulosic content of this type of material. There are several reports regarding the treatment of different substrates under thermal hydrolysis [20,101,102]. Alkaline pre-treatment seems to guarantee better solubilization performance at lower temperatures [103]. However, operational constraints associated with the handling of this type of stream and the subsequent stage for neutralizing the final material do not make this alternative an attractive technology. Different authors have reported enhancements in methane yield from 10 to 30% when evaluating thermal hydrolysis of cow manure [104,105,106], however, better values were obtained for swine manure, doubling the methane yield attributable to the application of thermal pre-treatment [31,107]. If a conservative value is selected for evaluating the thermal hydrolysis of cattle manure in the present scenario, then a 20% enhancement in methane yield can be considered.

The mass flow of the manure stream to be treated will account for 21,700 kg/d if the system is run at 15% TS content. Two thermal hydrolysis reactors with a working volume of 5.1 m3 operating under batch conditions (3 cycles each) would be needed. Based on technical data reported by García-Cascallana et al. [27], a steam injection time of 15 min was assumed with a 20 min duration for the hydrolysis process. Using these assumptions, the steam flow needed would account for 3750 kg/h for a total period of 1.5 h (derived from the summation of the six operating cycles). The energy to produce this steam flow is 22,700 MJ, with a boiler efficiency of 85.7%. However, the energy needed for heating the hydrolysis reactor should also be added (4920 MJ). Thus, it is clear that the energy necessary for running this type of system is excessive. Table 4 shows results obtained from Scenario 3.

Table 4.

Main calculated parameters of the integrated system: thermal hydrolysis and anaerobic digestion, Scenario 3. Hydrolyzed manure and cheese whey (25% v/w) used as substrate.

The enhancement considered 20% increase in methane yield, which translates into 3230 MJ/d. The additional energy obtained from the digestion of hydrolyzed manure is much lower than the amount needed to run the whole process (see Figure 5). A deficit of 24,350 MJ is the result of installing such a technology (value estimated considering the treatment of manure as a single substrate). Even if a higher biogas enhancement is assumed, then the extra energy obtained will be consumed in running the thermal pre-treatment. Liu et al. [31] came to the same conclusion when evaluating thermal pre-treatment of different wastes (food wastes, swine manure and sewage sludge). These authors tested mesophilic and thermophilic digestion of the hydrolyzed wastes indicating that the increased energy benefits by thermal hydrolysis did not cover the energy demand of the pre-treatment.

Figure 5.

Representation of the main treatment stages in Scenario 3 (thermal hydrolysis and anaerobic digestion of hydrolyzed manure). Cheese whey is used also as co-substrate in this scenario.

If heat recovery from flash steam is considered, then a portion of this energy can be recovered, reducing the energy deficiency. If this is the case, for the given operating conditions and using the flash steam calculator [58], the energy contained in flash steam will be 8042 MJ. Under similar assumptions for estimating the energy recovery for the previous scenarios, an 85% recovery capacity will lead to 6840 MJ available, which is still far from the deficit associated with the thermal treatment.

Additional energy is recovered from cooling the pretreated slurry to the digester temperature. Considering that the incoming stream to the digester should be at 37 °C and also taking into account that process water is added to adjust solid content to 10%, then an additional amount of energy would be available through the heat exchanger dedicated to this aim. This recovery is considered to contain low-quality energy if water is used as a transfer fluid. Thus the energy obtained from cooling the slurry to a temperature of 55 °C will be available for other uses, and this quantity is 4885 MJ/d.

The slurry stream is mixed with cheese whey (25% (v/w) addition—keeping the co-digestion assumption also for this case) and process water (attaining a volumetric flow of 32.5 m3/d). If the mixture of these streams takes place by directly combining the hot slurry stream with the other influents to adjust solid content, then a final temperature of the mixture of 46 °C is reached. This value comes from assuming a cheese whey temperature of 15 °C and a process water temperature of 35 °C. The final temperature reached can cover digester thermal demand, including losses associated with digester walls. Thus the heat demand of the digester is eliminated. However, this energy recovery is insufficient to cover the demand of the whole system.

For the present scenario, a feed solid content of 15% TS was set. However, this solid concentration adversely affects the capacity of this fluid to be pumped. Low-solid content sludge behaves as a pseudoplastic fluid, but at high-solids content (with TS values in the range of 7–15%), thixotropic behavior is exhibited [108]. Sludge viscosity increases significantly with an increase in total solid content, but on the contrary, decreases with the increase in shear rate. Thus, future aspects being considered are the actual feasibility of applying thermal treatments as either a pre-treatment or post-treatment stage, when pumping capacity and slurry handling becomes a challenging task with an increase in the solid content.

Scenario 2 evaluating thermal post-treatment of digestate considered that a slurry stream dewatered at 30% TS content is submitted to HTC treatment. However, loading and unloading operations for this system will set severe constraints regarding the handling of this stream with such a high TS value. Comparing these two scenarios at similar TS values, (it should be borne in mind that thermal hydrolysis units can handle sludge streams between 12.5 and 16% for CambiTM Process and 20% for the ExelisTM process [109]), then the amount of energy needed for running the HTC unit will rise to 25,365 MJ which makes the process unfeasible. If this same configuration is evaluated when only a fraction of the digestate is submitted to hydrotreatment, 3800 MJ will be needed. Further research is needed to find optimal configurations and evaluate the plant’s electrical demand once the solid content of the slurry is established. Another relevant factor is the possible toxicity of hydrochar material when used in biological processes, just as it has already been reported for biochar [110]. Table 5 summarizes benefits and disbenefits of the three scenarios evaluated, being coincident in the need of finding a practical solution to the energy demand associated with the thermal treatment.

Table 5.

Strengths and weaknesses of each scenario evaluated considering the use of digestion for producing biogas and the introduction of thermal treatment for digestate valorization (Scenario 1 and 2) or as a pre-treatment (Scenario 3).

4. Conclusions

The energy assessment of high temperature and pressure systems was evaluated considering different scenarios where anaerobic digestion of the material was integrated to recover energy as biogas. The hydrothermal treatment of digestate was the best performing option when contemplating the thermal demand associated with this process. The treatment of the whole digestate under the HTC process resulted in high thermal demand. Yet, even in this case, the energy requirement could be fully provided by the use of the hydrochar as fuel in the same process, thus providing thermal energy for steam production and heat for hydrochar drying. In addition, the mass and energy calculations here performed demonstrated that the HTC process can be operated without the need for supplementary fossil fuels, solely using the energy contained in the incoming waste.

The most favorable case was co-digestion which significantly increased the biogas productivity of the digester, even with the use of a low organic content stream as with cheese whey herein considered. The partial treatment of digestate by HTC allows hydrochar to be used as a supplement in the digestion process and as an additive if composting of digestate is selected as the final stabilization stage. This configuration increases biogas production and secures full coverage of the thermal demand, given that the HTC unit now has a significantly lower volume. Additionally, the use of hydrochar in the biological process eliminates the drying step, thus reducing the thermal demand of the whole treatment sequence.

When conventional thermal hydrolysis was evaluated as a pre-treatment stage before the digestion process, then the size and number of reactor units dedicated to this aim present a high thermal demand. Even though heat recovery was considered and the digester heat demand was eliminated in this configuration, the energy surplus obtained from this strategy does not compensate for the comparatively high demand of the thermal process.

Author Contributions

Conceptualization, R.G. and J.G.-C.; methodology, D.C.-P.; validation, A.A.-P., R.G. and R.S.; formal analysis, X.G.; investigation, A.A.-P. and M.E.; resources, X.G.; data curation, M.E. and A.A.-P.; writing—original draft preparation, X.G.; writing—review and editing, R.G. and R.S.; visualization, J.G.-C.; supervision, X.G.; project administration, X.G.; funding acquisition, X.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by FGULEM, grant number NT55-2018.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hoekman, S.K.; Broch, A.; Robbins, C. Hydrothermal carbonization (HTC) of lignocellulosic biomass. Energy Fuels 2011, 25, 1802–1810. [Google Scholar] [CrossRef]

- Kambo, H.S.; Minaret, J.; Dutta, A. Process water from the hydrothermal carbonization of biomass: A waste or a valuable product? Waste Biomass Valorization 2018, 9, 1181–1189. [Google Scholar] [CrossRef]

- Choi, J.M.; Han, S.K.; Lee, C.Y. Enhancement of methane production in anaerobic digestion of sewage sludge by thermal hydrolysis pretreatment. Bioresour. Technol. 2018, 259, 207–213. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Yi, H.; Li, H.; Guo, X.; Xiao, B. Effects of thermal and thermal-alkaline pretreatments on continuous anaerobic sludge digestion: Performance, energy balance and, enhancement mechanism. Renew. Energy 2020, 147, 2409–2416. [Google Scholar] [CrossRef]

- Hong, E.H.; Park, J.G.; Lee, B.; Shi, W.Q.; Jun, H.B. Improvement of Waste Dehydrated Sludge for Anaerobic Digestion through High-Temperature and High-Pressure Solubilization. Energies 2020, 13, 88. [Google Scholar] [CrossRef] [Green Version]

- Cuetos, M.J.; Gómez, X.; Otero, M.; Morán, A. Anaerobic digestion and co-digestion of slaughterhouse waste (SHW): Influence of heat and pressure pre-treatment in biogas yield. Waste Manag. 2010, 30, 1780–1789. [Google Scholar] [CrossRef]

- Phothilangka, P.; Schoen, M.A.; Huber, M.; Luchetta, P.; Winkler, T.; Wett, B. Prediction of thermal hydrolysis pretreatment on anaerobic digestion of waste activated sludge. Water Sci. Technol. 2008, 58, 1467–1473. [Google Scholar] [CrossRef] [PubMed]

- Song, S.; Jiang, M.; Yao, J.; Liu, H.; Dai, X. Anaerobic digestion of spectinomycin mycelial residues pretreated by thermal hydrolysis: Removal of spectinomycin and enhancement of biogas production. Environ. Sci. Pollut. Res. 2020, 27, 39297–39307. [Google Scholar] [CrossRef]

- Zhang, D.; Santha, H.; Pallansch, K.; Novak, J.T.; Wang, Z.W. Repurposing pre-pasteurization as an in situ thermal hydrolysis pretreatment process for enhancing anaerobic digestion of municipal sludge: A horizontal comparison between temperature-phased and standalone thermophilic or mesophilic anaerobic digestion. Environ. Sci. Water Res. Technol. 2020, 6, 3316–3325. [Google Scholar] [CrossRef]

- Martínez, E.J.; Gil, M.V.; Rosas, J.G.; Moreno, R.; Mateos, R.; Morán, A.; Gómez, X. Application of thermal analysis for evaluating the digestion of microwave pre-treated sewage sludge. J. Therm. Anal. Calorim. 2017, 127, 1209–1219. [Google Scholar] [CrossRef]

- Toutian, V.; Barjenbruch, M.; Unger, T.; Loderer, C.; Remy, C. Effect of temperature on biogas yield increase and formation of refractory COD during thermal hydrolysis of waste activated sludge. Water Res. 2020, 171, 115383. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; An, Z.; Strawn, M.; Broderick, T.; Khunjar, W.; Wang, Z.W. Understanding the formation of recalcitrant dissolved organic nitrogen as a result of thermal hydrolysis and anaerobic digestion of municipal sludge. Environ. Sci. Water Res. Technol. 2021, 7, 335–345. [Google Scholar] [CrossRef]

- How Does Thermal Hydrolysis Work?—Cambi—World Leader in Thermal Hydrolysis. Available online: https://www.cambi.com/what-we-do/thermal-hydrolysis/how-does-thermal-hydrolysis-work/ (accessed on 10 August 2021).

- Available online: https://www.veoliawatertech.com/en/expertise/municipal-market/biosolidsbioenergy/biothelys-batch-thermal-hydrolysis (accessed on 18 August 2021).

- Thermal Hydrolysis Process. Available online: https://haarslev.com/industries/environmental/municipal/thermal-hydrolysis-process/ (accessed on 18 August 2021).

- Available online: https://www.veoliawatertechnologies.com/en/products/exelys (accessed on 18 August 2021).

- DMT|TurboTec Thermal Hydrolosis|DMT Environmental Technology. Available online: https://www.dmt-et.com/products/turbotec/ (accessed on 2 September 2021).

- Bonmati, A.; Flotats, X.; Mateu, L.; Campos, E. Study of thermal hydrolysis as a pretreatment to mesophilic anaerobic digestion of pig slurry. Water Sci. Technol. 2001, 44, 109–116. [Google Scholar] [CrossRef]

- Zhou, Y.; Takaoka, M.; Wang, W.; Liu, X.; Oshita, K. Effect of thermal hydrolysis pre-treatment on anaerobic digestion of municipal biowaste: A pilot scale study in China. J. Biosci. Bioeng. 2013, 116, 101–105. [Google Scholar] [CrossRef]

- Ferrentino, R.; Merzari, F.; Fiori, L.; Andreottola, G. Biochemical methane potential tests to evaluate anaerobic digestion enhancement by thermal hydrolysis pretreatment. BioEnergy Res. 2019, 12, 722–732. [Google Scholar] [CrossRef]

- Nava-Valente, N.; Del Ángel-Coronel, O.A.; Atenodoro-Alonso, J.; López-Escobar, L.A. Effect of thermal and acid pre-treatment on increasing organic loading rate of anaerobic digestion of coffee pulp for biogas production. Biomass Conv. Bioref. 2021, 1–14. [Google Scholar] [CrossRef]

- Oosterhuis, M.; Ringoot, D.; Hendriks, A.; Roeleveld, P. Thermal hydrolysis of waste activated sludge at Hengelo wastewater treatment plant, The Netherlands. Water Sci. Technol. 2014, 70, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Kepp, U.; Machenbach, I.; Weisz, N.; Solheim, O.E. Enhanced stabilisation of sewage sludge through thermal hydrolysis-three years of experience with full scale plant. Water Sci. Technol. 2000, 42, 89–96. [Google Scholar] [CrossRef]

- Liu, J.; Smith, S.R. A multi-level biogas model to optimise the energy balance of full-scale sewage sludge conventional and THP anaerobic digestion. Renew. Energy 2020, 159, 756–766. [Google Scholar] [CrossRef]

- Feng, G.; Liu, L.; Tan, W. Effect of thermal hydrolysis on rheological behavior of municipal sludge. Ind. Eng. Chem. Res. 2014, 53, 11185–11192. [Google Scholar] [CrossRef]

- García-Cascallana, J.; Borge-Díez, D.; Gómez, X. Enhancing the efficiency of thermal hydrolysis process in wastewater treatment plants by the use of steam accumulation. Int. J. Environ. Sci. Technol. 2019, 16, 3403–3418. [Google Scholar] [CrossRef]

- García-Cascallana, J.; Gómez, X.; Martinez, E.J. Thermal Hydrolysis of Sewage Sludge: A Case Study of a WWTP in Burgos, Spain. Appl. Sci. 2021, 11, 964. [Google Scholar] [CrossRef]

- Taboada-Santos, A.; Lema, J.M.; Carballa, M. Energetic and economic assessment of sludge thermal hydrolysis in novel wastewater treatment plant configurations. Waste Manag. 2019, 92, 30–38. [Google Scholar] [CrossRef]

- Palma-Heredia, D.; Poch, M.; Cugueró-Escofet, M.À. Implementation of a decision support system for sewage sludge management. Sustainability 2020, 12, 9089. [Google Scholar] [CrossRef]

- Ferreira, L.C.; Nilse, P.J.; Fdz-Polanco, F.; Pérez-Elvira, S.I. Biomethane potential of wheal straw: Influence of particle size, water impregnation and thermal hydrolysis. Chem. Eng. J. 2014, 242, 254–259. [Google Scholar] [CrossRef]

- Liu, X.; Lee, C.; Kim, J.Y. Thermal hydrolysis pre-treatment combined with anaerobic digestion for energy recovery from organic wastes. J. Mater. Cycles Waste Manag. 2020, 22, 1370–1381. [Google Scholar] [CrossRef]

- Khan, M.U.; Ahring, B.K. Anaerobic digestion of digested manure fibers: Influence of thermal and alkaline thermal pretreatment on the biogas yield. BioEnergy Res. 2021, 14, 891–900. [Google Scholar] [CrossRef]

- Şenol, H.; Açıkel, Ü.; Demir, S.; Oda, V. Anaerobic digestion of cattle manure, corn silage and sugar beet pulp mixtures after thermal pretreatment and kinetic modeling study. Fuel 2020, 263, 116651. [Google Scholar] [CrossRef]

- Ahmed, B.; Aboudi, K.; Tyagi, V.K.; Álvarez-Gallego, C.J.; Fernández-Güelfo, L.A.; Romero-García, L.I.; Kazmi, A.A. Improvement of anaerobic digestion of lignocellulosic biomass by hydrothermal pretreatment. Appl. Sci. 2019, 9, 3853. [Google Scholar] [CrossRef] [Green Version]

- Ghimire, N.; Bakke, R.; Bergland, W.H. Mesophilic Anaerobic Digestion of Hydrothermally Pretreated Lignocellulosic Biomass (Norway Spruce (Picea abies)). Processes 2021, 9, 190. [Google Scholar] [CrossRef]

- Ro, K.S.; Flora, J.R.; Bae, S.; Libra, J.A.; Berge, N.D.; Álvarez-Murillo, A.; Li, L. Properties of animal-manure-based hydrochars and predictions using published models. ACS Sustain. Chem. Eng. 2017, 5, 7317–7324. [Google Scholar] [CrossRef]

- Xu, J.; Mustafa, A.M.; Lin, H.; Choe, U.Y.; Sheng, K. Effect of hydrochar on anaerobic digestion of dead pig carcass after hydrothermal pretreatment. Waste Manag. 2018, 78, 849–856. [Google Scholar] [CrossRef]

- Arenas, C.B.; Meredith, W.; Snape, C.E.; Gómez, X.; González, J.F.; Martinez, E.J. Effect of char addition on anaerobic digestion of animal by-products: Evaluating biogas production and process performance. Environ. Sci. Pollut. Res. 2020, 27, 24387–24399. [Google Scholar] [CrossRef] [PubMed]

- Ferrentino, R.; Merzari, F.; Fiori, L.; Andreottola, G. Coupling hydrothermal carbonization with anaerobic digestion for sewage sludge treatment: Influence of HTC liquor and hydrochar on biomethane production. Energies 2020, 13, 6262. [Google Scholar] [CrossRef]

- Chaher, N.E.H.; Chakchouk, M.; Engler, N.; Nassour, A.; Nelles, M.; Hamdi, M. Optimization of food waste and biochar in-vessel co-composting. Sustainability 2020, 12, 1356. [Google Scholar] [CrossRef] [Green Version]

- Hagemann, N.; Kammann, C.I.; Schmidt, H.P.; Kappler, A.; Behrens, S. Nitrate capture and slow release in biochar amended compost and soil. PLoS ONE 2017, 12, e0171214. [Google Scholar] [CrossRef]

- Scrinzi, D.; Andreottola, G.; Fiori, L. Composting Hydrochar-OFMSW Digestate Mixtures: Design of Bioreactors and Preliminary Experimental Results. Appl. Sci. 2021, 11, 1496. [Google Scholar] [CrossRef]

- Adjuik, T.; Rodjom, A.M.; Miller, K.E.; Reza, M.T.M.; Davis, S.C. Application of hydrochar, digestate, and synthetic fertilizer to a miscanthus X giganteus crop: Implications for biomass and greenhouse gas emissions. Appl. Sci. 2020, 10, 8953. [Google Scholar] [CrossRef]

- Paz-Ferreiro, J.; Álvarez-Calvo, M.L.; Figueiredo, C.C.D.; Mendez, A.M.; Gascó, G. Effect of Biochar and Hydrochar on Forms of Aluminium in an Acidic Soil. Appl. Sci. 2020, 10, 7843. [Google Scholar] [CrossRef]

- Pagés-Díaz, J.; Huiliñir, C. Valorization of the liquid fraction of co-hydrothermal carbonization of mixed biomass by anaerobic digestion: Effect of the substrate to inoculum ratio and hydrochar addition. Bioresour. Technol. 2020, 317, 123989. [Google Scholar] [CrossRef] [PubMed]

- Usman, M.; Shi, Z.; Ren, S.; Ngo, H.H.; Luo, G.; Zhang, S. Hydrochar promoted anaerobic digestion of hydrothermal liquefaction wastewater: Focusing on the organic degradation and microbial community. Chem. Eng. J. 2020, 399, 125766. [Google Scholar] [CrossRef]

- Gómez, X.; Diaz, M.C.; Cooper, M.; Blanco, D.; Morán, A.; Snape, C.E. Study of biological stabilization processes of cattle and poultry manure by thermogravimetric analysis and 13C NMR. Chemosphere 2007, 68, 1889–1897. [Google Scholar] [CrossRef] [PubMed]

- Otero, M.; Lobato, A.; Cuetos, M.J.; Sánchez, M.E.; Gómez, X. Digestion of cattle manure: Thermogravimetric kinetic analysis for the evaluation of organic matter conversion. Bioresour. Technol. 2011, 102, 3404–3410. [Google Scholar] [CrossRef] [PubMed]

- Fernández, C.; Cuetos, M.J.; Martínez, E.J.; Gómez, X. Thermophilic anaerobic digestion of cheese whey: Coupling H2 and CH4 production. Biomass Bioenergy 2015, 81, 55–62. [Google Scholar] [CrossRef]

- Bertin, L.; Grilli, S.; Spagni, A.; Fava, F. Innovative two-stage anaerobic process for effective codigestion of cheese whey and cattle manure. Bioresour. Technol. 2013, 128, 779–783. [Google Scholar] [CrossRef] [PubMed]

- Jansson, A.T.; Patinvoh, R.J.; Sárvári Horváth, I.; Taherzadeh, M.J. Dry anaerobic digestion of food and paper industry wastes at different solid contents. Fermentation 2019, 5, 40. [Google Scholar] [CrossRef] [Green Version]

- González, R.; Blanco, D.; García-Cascallana, J.; Carrillo-Peña, D.; Gómez, X. Anaerobic Co-Digestion of Sheep Manure and Waste from a Potato Processing Factory: Techno-Economic Analysis. Fermentation 2021, 7, 235. [Google Scholar] [CrossRef]

- González, R.; González, J.; Rosas, J.G.; Smith, R.; Gómez, X. Biochar and energy production: Valorizing swine manure through coupling co-digestion and pyrolysis. C 2020, 6, 43. [Google Scholar] [CrossRef]

- Available online: https://www.wolf-ps.de/fileadmin/WPS/Broschueren/WOLF_PS_CHP_solutions_with_added_value_EN.pdf (accessed on 18 September 2021).

- Nyakuma, B.B.; Johari, A.; Ahmad, A.; Abdullah, T.A.T. Comparative analysis of the calorific fuel properties of Empty Fruit Bunch Fiber and Briquette. Energy Procedia 2014, 52, 466–473. [Google Scholar] [CrossRef] [Green Version]

- Aragón-Briceño, C.I.; Ross, A.B.; Camargo-Valero, M.A. Mass and energy integration study of hydrothermal carbonization with anaerobic digestion of sewage sludge. Renew. Energy 2021, 167, 473–483. [Google Scholar] [CrossRef]

- Available online: https://www4.eere.energy.gov/manufacturing/tech_deployment/amo_steam_tool/equipBoiler (accessed on 18 September 2021).

- Available online: https://www4.eere.energy.gov/manufacturing/tech_deployment/amo_steam_tool/equipFlashtank (accessed on 18 September 2021).

- Lucian, M.; Volpe, M.; Merzari, F.; Wüst, D.; Kruse, A.; Andreottola, G.; Fiori, L. Hydrothermal carbonization coupled with anaerobic digestion for the valorization of the organic fraction of municipal solid waste. Bioresour. Technol. 2020, 314, 123734. [Google Scholar] [CrossRef] [PubMed]

- De la Rubia, M.A.; Villamil, J.A.; Rodriguez, J.J.; Mohedano, A.F. Effect of inoculum source and initial concentration on the anaerobic digestion of the liquid fraction from hydrothermal carbonisation of sewage sludge. Renew. Energy 2018, 127, 697–704. [Google Scholar] [CrossRef]

- Marin-Batista, J.D.; Villamil, J.A.; Qaramaleki, S.V.; Coronella, C.J.; Mohedano, A.F.; de la Rubia, M.A. Energy valorization of cow manure by hydrothermal carbonization and anaerobic digestion. Renew. Energy 2020, 160, 623–632. [Google Scholar] [CrossRef]

- Parmar, K.R.; Ross, A.B. Integration of hydrothermal carbonisation with anaerobic digestion; Opportunities for valorisation of digestate. Energies 2019, 12, 1586. [Google Scholar] [CrossRef] [Green Version]

- Wu, K.; Zhang, X.; Yuan, Q. Effects of process parameters on the distribution characteristics of inorganic nutrients from hydrothermal carbonization of cattle manure. J. Environ. Manag. 2018, 209, 328–335. [Google Scholar] [CrossRef]

- Reza, M.T.; Mumme, J.; Ebert, A. Characterization of hydrochar obtained from hydrothermal carbonization of wheat straw digestate. Biomass Convers. Biorefinery 2015, 5, 425–435. [Google Scholar] [CrossRef]

- Wu, K.; Gao, Y.; Zhu, G.; Zhu, J.; Yuan, Q.; Chen, Y.; Cai, M.; Feng, L. 342. Characterization of dairy manure hydrochar and aqueous phase products generated by hydrothermal carbonization at different temperatures. J. Anal. Appl. Pyrolysis 2017, 127, 335–342. [Google Scholar] [CrossRef]

- Gascó, G.; Paz-Ferreiro, J.; Álvarez, M.L.; Saa, A.; Méndez, A. Biochars and hydrochars prepared by pyrolysis and hydrothermal carbonisation of pig manure Biochars and hydrochars prepared by pyrolysis and hydrothermal carbonisation of pig manure. Waste Manag. 2018, 79, 395–403. [Google Scholar] [CrossRef]

- Sheng, C.; Azevedo, J.L.T. Estimating the higher heating value of biomass fuels from basic analysis data. Biomass Bioenergy 2005, 28, 499–507. [Google Scholar] [CrossRef]

- Kulikowska, D.; Bernat, K. Waste Willow-Bark from Salicylate Extraction Successfully Reused as an Amendment for Sewage Sludge Composting. Sustainability 2021, 13, 6771. [Google Scholar] [CrossRef]

- Chung, J.W.; Edewi, O.C.; Foppen, J.W.; Gerner, G.; Krebs, R.; Lens, P.N.L. Removal of Escherichia coli by intermittent operation of saturated sand columns supplemented with hydrochar derived from sewage sludge. Appl. Sci. 2017, 7, 839. [Google Scholar] [CrossRef] [Green Version]

- Purnomo, C.W.; Castello, D.; Fiori, L. Granular activated carbon from grape seeds hydrothermal char. Appl. Sci. 2018, 8, 331. [Google Scholar] [CrossRef] [Green Version]

- Diaz, E.; Manzano, F.J.; Villamil, J.; Rodriguez, J.J.; Mohedano, A.F. Low-cost activated grape seed-derived hydrochar through hydrothermal carbonization and chemical activation for sulfamethoxazole adsorption. Appl. Sci. 2019, 9, 5127. [Google Scholar] [CrossRef] [Green Version]

- Toufiq Reza, M.; Freitas, A.; Yang, X.; Hiibel, S.; Lin, H.; Coronella, C.J. Hydrothermal carbonization (HTC) of cow manure: Carbon and nitrogen distributions in HTC products. Environ. Prog. Sustain. Energy 2016, 35, 1002–1011. [Google Scholar] [CrossRef]

- Arauzo, P.J.; Atienza-Martínez, M.; Ábrego, J.; Olszewski, M.P.; Cao, Z.; Kruse, A. Combustion characteristics of hydrochar and pyrochar derived from digested sewage sludge. Energies 2020, 13, 4164. [Google Scholar] [CrossRef]

- Gómez, X.; Meredith, W.; Fernández, C.; Sánchez-García, M.; Díez-Antolínez, R.; Garzón-Santos, J.; Snape, C.E. Evaluating the effect of biochar addition on the anaerobic digestion of swine manure: Application of Py-GC/MS. Environ. Sci. Pollut. Res. 2018, 25, 25600–25611. [Google Scholar] [CrossRef]

- Sánchez, E.; Herrmann, C.; Maja, W.; Borja, R. Effect of organic loading rate on the anaerobic digestion of swine waste with biochar addition. Environ. Sci. Pollut. Res. 2021, 28, 38455–38456. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Guo, Y.; Wang, W.; Chen, L.; Sun, Y.; Xing, T.; Kong, X. Effect of Biochar Addition on the Microbial Community and Methane Production in the Rapid Degradation Process of Corn Straw. Energies 2021, 14, 2223. [Google Scholar] [CrossRef]

- González, J.; Sánchez, M.E.; Gómez, X. Enhancing anaerobic digestion: The effect of carbon conductive materials. C 2018, 4, 59. [Google Scholar] [CrossRef] [Green Version]

- Ren, S.; Usman, M.; Tsang, D.C.; O-Thong, S.; Angelidaki, I.; Zhu, X.; Zhang, S.; Luo, G. Hydrochar-facilitated anaerobic digestion: Evidence for direct interspecies electron transfer mediated through surface oxygen-containing functional groups. Environ. Sci. Technol. 2020, 54, 5755–5766. [Google Scholar] [CrossRef]

- Chiappero, M.; Cillerai, F.; Berruti, F.; Mašek, O.; Fiore, S. Addition of Different Biochars as Catalysts during the Mesophilic Anaerobic Digestion of Mixed Wastewater Sludge. Catalysts 2021, 11, 1094. [Google Scholar] [CrossRef]

- Martínez, E.J.; Rosas, J.G.; Sotres, A.; Moran, A.; Cara, J.; Sánchez, M.E.; Gómez, X. Codigestion of sludge and citrus peel wastes: Evaluating the effect of biochar addition on microbial communities. Biochem. Eng. J. 2018, 137, 314–325. [Google Scholar] [CrossRef]

- Sun, C.; Fang, L.; Zhiwei, S.; Jing, W.; Yongfeng, L.; Yu, P.; Tao, S.; Lixin, L. Feasibility of dry anaerobic digestion of beer lees for methane production and biochar enhanced performance at mesophilic and thermophilic temperature. Bioresour. Technol. 2019, 276, 65–73. [Google Scholar] [CrossRef]

- Quintana-Najera, J.; Blacker, A.J.; Fletcher, L.A.; Ross, A.B. The effect of augmentation of biochar and hydrochar in anaerobic digestion of a model substrate. Bioresour. Technol. 2021, 321, 124494. [Google Scholar] [CrossRef]

- Cai, J.; He, P.; Wang, Y.; Shao, L.; Lü, F. Effects and optimization of the use of biochar in anaerobic digestion of food wastes. Waste Manag. Res. 2016, 34, 409–416. [Google Scholar] [CrossRef]

- Mayer, F.; Bhandari, R.; Gäth, S.A. Life cycle assessment on the treatment of organic waste streams by anaerobic digestion, hydrothermal carbonization and incineration. Waste Manag. 2021, 130, 93–106. [Google Scholar] [CrossRef] [PubMed]

- Heidari, M.; Salaudeen, S.; Norouzi, O.; Acharya, B.; Dutta, A. Numerical comparison of a combined hydrothermal carbonization and anaerobic digestion system with direct combustion of biomass for power production. Processes 2020, 8, 43. [Google Scholar] [CrossRef] [Green Version]

- Dieguez-Alonso, A.; Funke, A.; Anca-Couce, A.; Rombolà, A.G.; Ojeda, G.; Bachmann, J.; Behrendt, F. Towards biochar and hydrochar engineering—Influence of process conditions on surface physical and chemical properties, thermal stability, nutrient availability, toxicity and wettability. Energies 2018, 11, 496. [Google Scholar] [CrossRef] [Green Version]

- Jugal Sukhesh, M.; Venkateswara Rao, P. Synergistic effect in anaerobic co-digestion of rice straw and dairy manure-a batch kinetic study. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 2145–2156. [Google Scholar] [CrossRef]

- Al Afif, R.; Amon, T. Mesophilic anaerobic co-digestion of cow manure with three-phase olive mill solid waste. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 1800–1808. [Google Scholar] [CrossRef]

- Baek, G.; Kim, D.; Kim, J.; Kim, H.; Lee, C. Treatment of cattle manure by anaerobic co-digestion with food waste and pig manure: Methane yield and synergistic effect. Int. J. Environ. Res. Public Health 2020, 17, 4737. [Google Scholar] [CrossRef]

- Aboudi, K.; Gómez-Quiroga, X.; Álvarez-Gallego, C.J.; Romero-García, L.I. Insights into anaerobic co-digestion of lignocellulosic biomass (sugar beet by-products) and animal manure in long-term semi-continuous assays. Appl. Sci. 2020, 10, 5126. [Google Scholar] [CrossRef]

- Gonzalez-Piedra, S.; Hernández-García, H.; Perez-Morales, J.M.; Acosta-Domínguez, L.; Bastidas-Oyanedel, J.R.; Hernandez-Martinez, E. A Study on the Feasibility of Anaerobic Co-Digestion of Raw Cheese Whey with Coffee Pulp Residues. Energies 2021, 14, 3611. [Google Scholar] [CrossRef]

- Hallaji, S.M.; Kuroshkarim, M.; Moussavi, S.P. Enhancing methane production using anaerobic co-digestion of waste activated sludge with combined fruit waste and cheese whey. BMC Biotechnol. 2019, 19, 19. [Google Scholar] [CrossRef] [PubMed]

- Monfet, E.; Aubry, G.; Ramirez, A.A. Nutrient removal and recovery from digestate: A review of the technology. Biofuels 2018, 9, 247–262. [Google Scholar] [CrossRef]

- Ujor, V.C.; Okonkwo, C.C.; Rush, B.B.; McCrea, G.E.; Ezeji, T.C. Harnessing the Residual Nutrients in Anaerobic Digestate for Ethanol Fermentation and Digestate Remediation Using Saccharomyces cerevisiae. Fermentation 2020, 6, 52. [Google Scholar] [CrossRef]

- Pastor-Bueis, R.; Mulas, R.; Gómez, X.; González-Andrés, F. Innovative liquid formulation of digestates for producing a biofertilizer based on Bacillus siamensis: Field testing on sweet pepper. J. Plant Nutr. Soil Sci. 2017, 180, 748–758. [Google Scholar] [CrossRef]

- Giuliano, A.; Catizzone, E.; Freda, C.; Cornacchia, G. Valorization of OFMSW digestate-derived syngas toward methanol, hydrogen, or electricity: Process simulation and carbon footprint calculation. Processes 2020, 8, 526. [Google Scholar] [CrossRef]

- Wang, D.; Xi, J.; Ai, P.; Yu, L.; Zhai, H.; Yan, S.; Zhang, Y. Enhancing ethanol production from thermophilic and mesophilic solid digestate using ozone combined with aqueous ammonia pretreatment. Bioresour. Technol. 2016, 207, 52–58. [Google Scholar] [CrossRef] [PubMed]

- Stoumpou, V.; Novakovic, J.; Kontogianni, N.; Barampouti, E.M.; Mai, S.; Moustakas, K.; Malamis, D.; Loizidou, M. Assessing straw digestate as feedstock for bioethanol production. Renew. Energy 2020, 153, 261–269. [Google Scholar] [CrossRef]

- Wang, W.; Lee, D.J. Valorization of anaerobic digestion digestate: A prospect review. Bioresour. Technol. 2020, 323, 124626. [Google Scholar] [CrossRef] [PubMed]

- Barba, F.J. An Integrated Approach for the Valorization of Cheese Whey. Foods 2021, 10, 564. [Google Scholar] [CrossRef] [PubMed]

- Mehari, B.B.; Chang, S.; Hong, Y.; Chen, H. Temperature-phased biological hydrolysis and thermal hydrolysis pretreatment for anaerobic digestion performance enhancement. Water 2018, 10, 1812. [Google Scholar] [CrossRef] [Green Version]

- Chang, S.; Filer, J. Thermal Hydrolysis to Enhance Anaerobic Digestion Performance of Wastewater Sludge. Curr. Pollut. Rep. 2020, 6, 452–467. [Google Scholar] [CrossRef]

- Antonopoulou, G.; Vayenas, D.; Lyberatos, G. Biogas production from physicochemically pretreated grass lawn waste: Comparison of different process schemes. Molecules 2020, 25, 296. [Google Scholar] [CrossRef] [Green Version]

- Raju, C.S.; Sutaryo, S.; Ward, A.J.; Møller, H.B. Effects of high-temperature isochoric pre-treatment on the methane yields of cattle, pig and chicken manure. Environ. Technol. 2013, 34, 239–244. [Google Scholar] [CrossRef] [Green Version]

- Cano, R.; Nielfa, A.; Fernández-Polanco, M. Thermal hydrolysis integration in the anaerobic digestion process of different solid wastes: Energy and economic feasibility study. Bioresour. Technol. 2014, 168, 14–22. [Google Scholar] [CrossRef]

- McVoitte, W.P.; Clark, O.G. The effects of temperature and duration of thermal pretreatment on the solid-state anaerobic digestion of dairy cow manure. Heliyon 2019, 5, e02140. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, L.C.; Souza, T.S.O.; Fernández-Polanco, F.; Pérez-Elvira, S.I. Thermal steam explosion pretreatment to enhance anaerobic biodegradability of the solid fraction of pig manure. Bioresour. Technol. 2014, 152, 393–398. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Li, H. Rheological behavior of sewage sludge with high solid content. Water Sci. Technol. 2015, 71, 1686–1693. [Google Scholar] [CrossRef] [PubMed]

- Abu-Orf, M.; Goss, T. Comparing Thermal hydrolysis processes (CAMBI™ and EXELYS™) for solids pretreatment prior to anaerobic digestion. Digestion 2012, 16, 8–12. [Google Scholar]