1. Introduction

Recently, governments worldwide have been pushing for energy transformation to cope with severe climate change. Therefore, fossil-fuel use is decreasing, and eco-friendly energy use is increasing [

1]. According to the 2019 statistics released by the US Energy Information Administration, South Korea ranked fifth among liquefied natural gas, coal, and petroleum fuel importers in the world, and ninth in energy consumption. As such, Korea is highly dependent on fossil fuels [

2]. Changing the fossil-fuel-oriented energy industry in a short time is expensive. Therefore, actively solving the environmental problems of existing coal-fired power plants, while achieving energy conversion, is essential.

Power companies and governments are expanding investment in environmental facilities to respond to environmental problems caused by coal-fired power plants. A typical example is a coal storage shed. In the past, coal was stored outdoors. However, a large volume of coal dust occurs caused by fine dust, generating civil complaints in the surrounding areas [

3]. By storing coal indoors, the scattering of coal dust can be prevented due to airflow. The shapes of indoor coal storage areas are divided into shed, dome, and silo types. The shed-type indoor coal storage is a warehouse-type storage yard, with a triangular iron roof. Compared with other indoor coal storage methods, it has economic advantages and enables the efficient storage and management of coal [

4]. However, there are many problems due to the characteristics of coal in an indoor coal yard built to reduce the scattering of coal dust [

5].

The first problem is the spontaneous combustion of coal. Coal, the primary energy source for thermal power plants, absorbs oxygen from the air and slowly generates heat. Oxidation and exothermic reactions are accelerated, heating the inside of the coal pile, causing spontaneous ignition [

6]. When coal spontaneously ignites in an indoor coal yard, harmful gases accumulate in the indoor silo, due to insufficient ventilation. Moreover, the concentration of carbon monoxide in the poisonous gases generated during spontaneous ignition increases rapidly. Carbon monoxide is 250 times stronger in binding with hemoglobin than oxygen in the blood, causing intermittent headaches, irritability, and mental confusion, and is fatal in high concentrations with a long exposure time [

7]. The appropriate legal standard concentration of carbon monoxide in hazardous gas-generating facilities is managed at 30 ppm [

8]. If this is exceeded, a worker cannot safely work. However, the spontaneous ignition of the indoor coal yard increases the carbon monoxide concentration by more than 30 ppm, making the field workers’ work environment more dangerous.

Second, coal dust is a problem that occurs when coal falls inside a coal storage shed. Coal arrives at the harbor on a coal carrier and is transported to an indoor coal yard using a ship unloader and conveyor belt. Coal is transported by the conveyor belt inside the indoor coal yard, and is stored by dropping it into each cell of the coal yard using a telescopic chute, installed about 11 m above the coal yard. During this time, a large amount of coal dust is scattered and a size of about 50 μm or less is generated. It is difficult for indoor workers to access the site until the dust settles, and it is impossible to take emergency measures when spontaneous ignition occurs. Thus, the indoor coal storage facility, built to prevent dust scattering generated during outdoor coal storage, causes a massive problem in internal fieldwork, due to the characteristics of the internal coal.

Many studies have been conducted to reduce hazardous gases and dust scattering in coal storage sheds. Typically, studies have been conducted to suppress the generation of harmful gases and coal dust in advance. Regarding the prevention of the natural ignition of coal, Kim et al. [

9] analyzed the effect of natural coal ignition on the surface of coal piles. The self-ignition barrier must be applied from the bottom. For larger areas of application, blocking the flow of oxygen is more effective.

Amir Saffari et al. [

10] presented a system that classifies coal by its spontaneous combustion capability, based on the fuzzy Delphi analytic hierarchy process. Based on these figures, the natural ignition propensity of coal was classified, and the initial verification was conducted at the Eastern Alborz coal mines in Iran.

Simion et al. [

11] studied prevention technology based on the theory of the spontaneous combustion of coal and oxidation inhibition. The study results demonstrate the effectiveness of the method of spraying a mixture of inhibitors and water, and the process of inhibiting spontaneous ignition by injecting the mixture.

Regarding coal dust, Kang et al. [

12] studied a method to reduce scattered dust in coal storage using a polyvinyl alcohol surfactant. Their research reveals that polyvinyl alcohol surfactants reduce the scattering amount of carbon dioxide by more than 35% on average, regardless of the low carbonization period.

Studies to suppress spontaneous coal combustion and dust scattering are continuously being conducted. However, if natural ignition expands and it is impossible to extinguish and block the spread, it is likely to expand into serious fires. Accordingly, research on the aspect of the indoor coal storage system is also continuously conducted.

Regarding predicting the spontaneous ignition temperature of coal, Jun Guo et al. [

13] have established an evaluation method for monitoring spontaneous coal combustion. The study predicted the coal temperature with 97% accuracy, based on the carbon monoxide/dioxide ratio and fire coefficient.

Ning Su et al. [

14] studied the dust suppression effect of porous wind tunnel materials using wind tunnel experiments and computational fluid dynamics (CFD) to reduce coal dust in the coal yard. The primary data for reducing dust in coal storage was presented based on the ventilation and dust suppression rates.

Yaohua Hou et al. [

15] evaluated the ventilation performance according to the shape and opening conditions of the dome-type coal storage shed. According to the study, the rise–span ratio affects the wind pressure difference, and the effective ventilation rate of the opening is increased by 9% to 42%. It also provided helpful information for ventilation control based on the design variables. In addition, various studies have demonstrated the effectiveness of natural ventilation and mechanical ventilation using CFD [

16,

17,

18,

19].

As mentioned, research on the spontaneous combustion characteristics of coal and the indoor coal storage system is continuously being conducted. However, no studies have considered the ventilation system analysis of the shed-type indoor coal storage and the working environment of field workers inside an indoor storage facility. Therefore, this study has analyzed the ventilation characteristics of shed-type coal storage for a coal-fired power plant using CFD. Moreover, the carbon monoxide concentration features in the coal pile were analyzed when spontaneous combustion occurred. Synthesizing the derived results confirmed the areas where the risk of carbon monoxide exposure for field workers was expected in the event of spontaneous coal combustion in indoor coal storage.

2. Introduction of Latest Technologies and Research

This section introduces the latest technologies related to indoor air quality (IAQ) ventilation improvement systems.

Behrouz Pirouz et al. [

20] analyzed the effects of indoor airflow patterns and exits in HVAC systems. CFD was used to improve the HVAC design in the study. It analyzed blind spots where residents were placed and dead zones with poor ventilation. As a result, it was found that the entrance and exit positions of the window and HVAC system had an important influence. Therefore, the analysis of airflow patterns is essential in designing HVAC systems.

Alessandro D’Amico et al. [

21] analyzed the indoor air quality concentration related to the indoor VOC concentration using CFD. It was performed in consideration of a specific environment according to environmental parameters and the sampling of indoor pollutants. CFD simulation was performed under conditions similar to VOC sampling conditions. CFD was useful in emphasizing the role of ventilation in determining the spatial distribution of dispersed pollutants. The study confirmed the possibility, although it characterized by simplification due to the lack of data.

Rafat Al-Waked et al. [

22] analyzed the carbon monoxide emitted from underground parking cars using CFD. It was derived that the ventilation system should be operated at an ACH value of 2 or more. In addition, criteria were presented to meet the allowable concentration of 50 ppm in the parking lot. In addition, it was derived that louver porosity did not significantly affect the CO concentration, when considering the underground parking lot as a single unit.

Lina Seduikyte et al. [

23] numerically simulated the ventilation performance of the sports hall where the mechanical ventilation system works. At Lithuania’s basketball training ground, thermal stratification conditions according to the performance of the HVAC system were analyzed. The same heating output as warm-air heating and floor heating was used. By combining mechanical mixing and displacement ventilation, the possibility of energy saving was shown. As a result, it was found possible to save energy by mixing with the low layer of air.

Ardalan Aflaki et al. [

24] reviewed the simulation for predicting and evaluating the ventilation performance of the building. An experimental model and a CFD coupling building-energy simulation for the evaluation and prediction of natural ventilation (NV) were analyzed. Among the CFD turbulence models, it was concluded that the RANS equation turbulence model was the most appropriate and takes the least computational time. In addition, it was derived that further research is needed on the weaknesses of the k-ω model, compared with other models in buildings.

Nayara Rodrigues Marques Sakiyama et al. [

25] evaluated the natural ventilation of a 3D parameter model using CFD. The authors investigated 3D parameter modeling and natural ventilation, and the natural ventilation effect of the building was explained by analyzing the CFD output. An alternative to 3D design was explored to display and calculate ACH and generate a surface on which wind speed is calculated in parametric modeling.

4. Methodology

4.1. Shed-Type Coal Storage

Building specifications and modeling shapes are listed in

Table 1 and

Figure 2, to analyze the flow characteristics of existing coal storage sheds for coal-fired power plants.

The coal storage shed is a storage room that stores coal indoors to prevent the scattering of coal dust, and consists of three floors of workspace. Coal arriving at the pier through a coal carrier is transported to the indoor coal yard using a conveyor belt. Coal is stored in the telescopic chute above the workspace on the third floor. Sixteen cells, spaces for storing coal, are operated in the indoor coal yard, and a concrete wall separates each cell. The indoor coal storage facility is equipped with ventilation facilities that promote natural ventilation to manage harmful gases, scattering dust, and heat generated from internal coal. Ventilation is ensured by operating the monitor louver on the upper ceiling, the first-floor workspace, and the windows.

Furthermore, on the north and south sides of the coal storage, a conveyor belt transfer port is transferred from the outside, and there is a worker’s entrance door. The indoor coal storage shed measures 447 m in width, 125 m in length, and 66 m in height, and the coal storage shed models a 1:1 3D shape. The shutter is 6 m × 7 m, the louver is 1.5 m × 1.5 m, and the windows are all open. The grid of the modeling shape for the analysis of the internal flow characteristics of the coal storage shed is a tetrahedron, and the total number of grids is about 8 million.

4.2. Field Measurement

The internal flow characteristics of the coal storage shed are closely related to the surrounding meteorological conditions (wind direction, wind speed, and airflow change), considering the location of the coal storage shed and depending on the local environmental characteristics. The wind speed is relatively great, compared with inland areas due to the nature of the coastal zone. In winter, relatively strong winds were recorded with an average wind speed of 1.92 m/s for 36 months, and a maximum wind speed of 12.7 m/s. In summer, the southwest air current is strongly influenced by the northwest air current in winter. In this study, inflow data were measured to identify seasonal wind speeds and temperatures in a coal storage shed to use as boundary conditions for computational analysis. The flow rate and temperature of incoming and outgoing air were measured 10 times a season, using the hot wire anemometer (TSI-9535) presented in

Table 2. The measurement of the inflow rate to the west was high, due to the partial air current caused by the windproof fence installed in the east around the coal storage shed.

The results of the measured flow rate are as follows. The speed was measured every month, and the average speed of each inlet is shown in the table. As a result of measuring the inflow flow rate, the maximum speed was 4.6 m/s and the minimum speed was 0.7 m/s. The rate of inflow from the west was generally high. The reason was that a dustproof wall is installed on the east side of the coal yard. Therefore, the speed in the west was relatively fast. Simulation boundary conditions were entered using the flow velocity measurement result.

The graph reveals the daily average value of the carbon monoxide concentration at four measurement points in the coal storage shed. When spontaneous combustion was actively occurring, a daily average of about 40.25 ppm of carbon monoxide was measured. In this study, 40.25 ppm, the highest daily average concentration value, was used to calculate the generated carbon monoxide. About 27.0 ppm of carbon monoxide was measured in S3 after the initial spontaneous ignition, which rose to 60.0 ppm after four days. At that time, the average concentration of carbon monoxide in the indoor coal storage shed was 40.3 ppm, exceeding the optimum internal concentration of 30.0 ppm. The generated carbon monoxide at the maximum concentration of 100 ppm in the S3 region was derived when spontaneous ignition occurred. Therefore, computational analysis was performed in this study, assuming 16 kg/s of carbon monoxide generation in the natural ignition generation area.

4.3. Numerical Method

The simulation boundary conditions applied in this study are described in

Table 3, as follows. The simulation of the flow analysis in CFD was significant. As described above, the standard

model was used. The louver on the first floor applied the flow rate measurement result, and set it as a velocity inlet. The monitor louver is an outlet through which the introduced air was discharged. Therefore, it was set as a pressure outlet. The most important aspect was the location of spontaneous ignition; in fact, the point where spontaneous ignition occurred in the coal storage shed was measured using thermal images. It was selected by referring to the measured results; therefore, the location where spontaneous ignition occurred most frequently was applied. At the point of the spontaneous ignition of coal, 16.0 kg/s of carbon monoxide was generated. The method of selecting the amount of carbon monoxide generated was as follows.

Figure 3 below shows the measurement results of carbon monoxide concentration. Carbon monoxide was measured at four points and the simulation was repeated dozens of times, until the results measured at the same four points were obtained using the simulation. The derived CO concentration was applied to the analysis. The coal inside the indoor coal storage shed was modeled at a slope of 40 degrees. Since air flows into the coal pile, the coil was set to a porous zone. This study assumed that the diameter of the coal was 0.01 m, the porosity was 0.2, and the permeability and inertial resistance coefficient were 35,000.

5. Results and Discussion

5.1. Analysis of Internal Flow and Ventilation

Figure 4 shows the velocity contours that appeared from the CFD analysis results of the outdoor air-measurement data, used to analyze the flow characteristics of shed-type coal storage. When the inflow velocity was

, the outside air from the first-floor louver and window rose by the coal pile and the central wall, and flowed out to the monitor louver. Moreover, a recirculation area generated in the upper part of the outside air inflow direction. For

, the velocity of the inflow reduced, and the upper recirculation area gradually reduced. The discharge to the monitor louver also reduced rapidly.

The coal storage shed did not have mechanical ventilation. The discharge of pollutants was not smooth, due to the structural characteristics of generating a large amount of coal dust and harmful gas in the coal pile. Therefore, to improve the indoor working environment of the field workers inside the indoor coal yard, the amount of ventilation must be analyzed for each outdoor air inlet and outlet. The mass flow rate that flows in and out of the natural ventilation system due to changes in wind speed is illustrated in

Figure 5. When the inflow velocity of the outside air was 1.0 m/s, 1634.1 m/s of the outside air was discharged from the first-floor louver. In addition, 1084.4 m/s of the outside air flowed out to the upper monitor louver. The amount of ventilation for each natural ventilation device is described in

Figure 6. When the total outdoor air outflow was 100%, 51.9% of the outdoor air flowed through the monitor louver. Additionally, 33.8% was emitted by the first-floor louver, and 5.0% was by the window. When the inflow velocity was 4.8 m/s, 79.0% of the total outdoor air inflow flowed into the first-floor louver. About 54.3% of the outflow flowed to the upper monitor louver, and 31.9% flowed out of the first-floor louver.

In addition, the air change rate per hour (ACH) in coal storage was analyzed; at the maximum speed, the ventilation volume was 13.1 ACH. At the minimum speed, the ventilation volume was 4.4 ACH. Even at a relatively low wind speed, more than 4.4 ACH were secured. However, it may be difficult to ensure sufficient ventilation because the amount of ventilation decreased sharply if the inflow velocity was further reduced, due to the nature of the indoor coal mine, where substantial harmful gas and dust is generated. Therefore, additional analysis is required on the concentration characteristics of local pollutants when spontaneous ignition occurs.

5.2. Concentration of Carbon Monoxide

The boundary conditions for carbon monoxide concentration analysis appear in

Table 4. Case 2-1 assumes the conditions in which spontaneous ignition occurs in Cell 4: the wind direction being west, and the inflow velocity being 6 m/s. Under the same conditions in Case 2-2, the inflow velocity is 2.0 m/s. These conditions assume that both the inlet and outlet of the coal storage tank are open, and the coal pile is 100% stored.

In the case of spontaneous ignition, the concentration distribution analysis of carbon monoxide, a harmful gas in indoor coal storage sheds, was conducted, and the results are as follows.

Figure 7 illustrates the results of the CFD analysis of carbon monoxide for spontaneous coal combustion in an indoor coal storage shed. For the inflow rate of 6.0 m/s, the ambient air flowed through the louver, and the flow circulated on the left side of the shed and inclined coal surfaces. In addition, carbon monoxide generated from the coal pile surface was only observed at the central wall and the point of spontaneous ignition. About 10.5 ppm of carbon monoxide was found in the upper part of the self-igniting cell. The ventilation volume was secured due to the increase in the inflow rate, and there was no area over 30 ppm (the hazardous standard concentration) in the workspace. As a result of checking the inflow rate of 2.0 m/s, it is possible to check the concentration of carbon monoxide in the upper part of the central shed. As the ventilation rapidly decreased, the accumulated carbon monoxide increased. An area where carbon monoxide exceeded 30 ppm occurs in the workspace was on the second floor, adjacent to the spontaneous ignition cell.

The coal storage shed has three floors of workspace. The characteristics of the carbon monoxide concentration and exposure hazard areas were identified in each workplace.

Figure 8 depicts the carbon monoxide concentration contour for each height. The result when the wind direction is a westerly wind of 1.0 m/s, which is the worst condition, must be checked to analyze the risk of carbon monoxide.

It was assumed that the inlets and outlets for outside air were all open, such as the doors and windows. The analysis was conducted assuming that spontaneous ignition occurred in Cell 4. The first floor has many louvers and windows where outdoor air flows in. Therefore, the working space on the first floor did not have a dangerous space of 30 ppm or more carbon monoxide, due to the rise of carbon monoxide at the firing point. In the second-floor workspace, carbon monoxide was relatively high, compared with the surrounding area, because it was adjacent to the point of spontaneous ignition. In particular, up to 48.5 ppm of carbon monoxide concentration was identified on the two-layer central wall adjacent to the ignition point. As this increased, the carbon monoxide concentration gradually diluted. On the third floor, carbon monoxide was discharged into the monitor louver, and elevated carbon monoxide was diluted outside the inflow and outflow air, so no carbon monoxide concentration greater than 20 ppm was identified. However, this is the interpretation of spontaneous ignition conditions in one cell. Therefore, if spontaneous ignition occurred in multiple cells in combination, the risk zone of the second layer would be likely to expand.

5.3. Scattering Coal Dust Emissions

Considerable scattered dust occurs when coal drops in the coal storage shed. The coal storage shed was built to prevent scattering dust, but the indoor field work environment is not safe for workers due to fine dust. An analysis of the behavior and emission characteristics of scattering dust, according to the surrounding weather conditions, is required. Therefore, the amount of natural ventilation of scattered dust, according to the wind direction and speed, for the coal storage was analyzed.

Table 5 and

Table 6 list the boundary conditions for analyzing coal dust emission characteristics, according to wind direction and speed. Cases 3-1 through 3-4 changed the wind direction in the east, west, south and north, under 2.0 m/s wind conditions. Cases 3-5 to 3-8 were analyzed by increasing the wind speed to 1 m/s, 2 m/s, 4 m/s, and 6 m/s under western wind conditions. Coal dust was equally generated in Cell 4, and natural ventilation was assumed to be fully open. In addition, 152 particle tracks were created at the coal storage shed to quantify the natural emission of dust generated when coal fell inside the coal storage shed. By checking the amount discharged to the outside, the dust generated in the indoor low-carbon field was tracked, and the natural emissions were reviewed according to the variables.

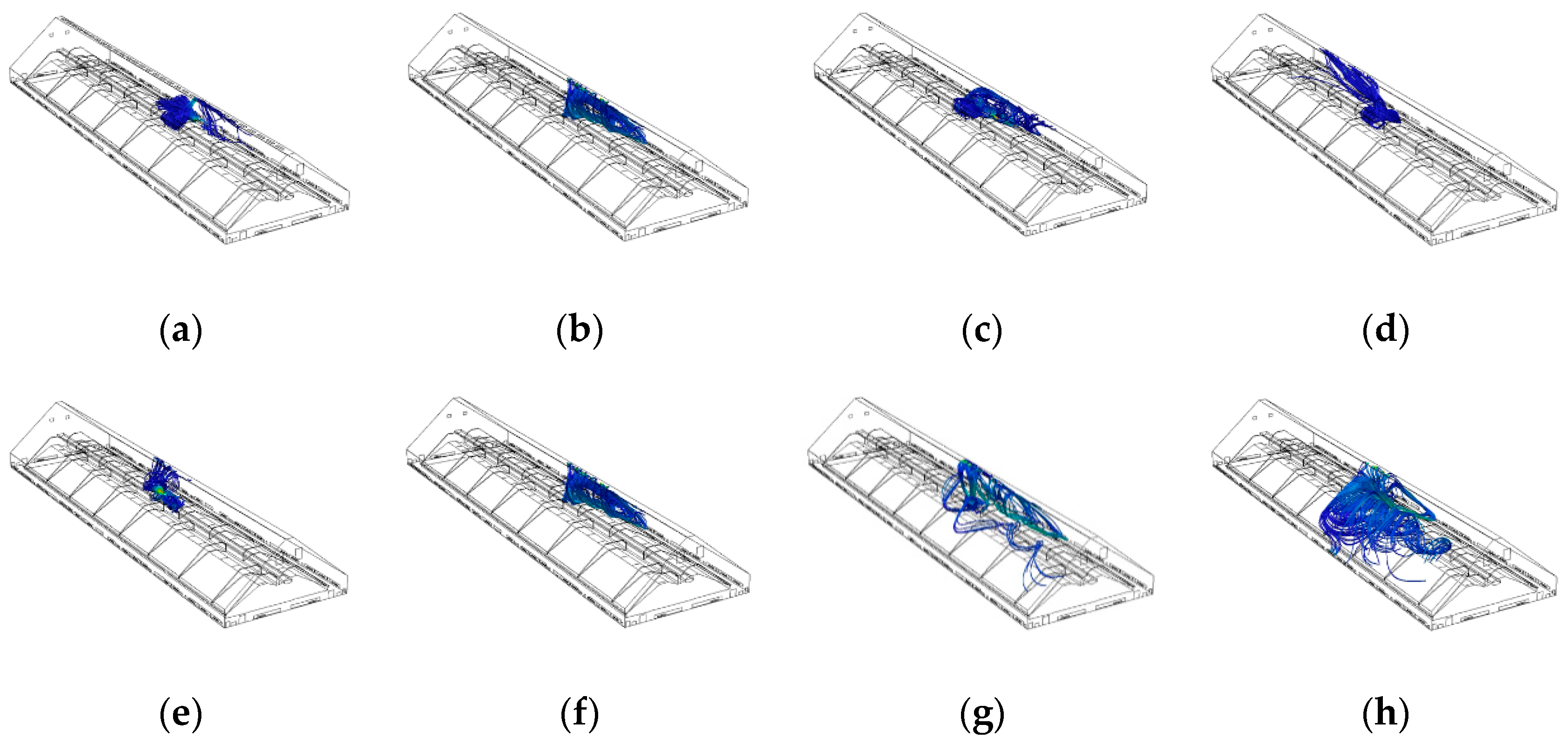

Computational fluid dynamics were used to analyze the dust emission according to the wind direction and speed when coal dust was generated in a coal storage shed.

When the wind speed is 2.0 m/s, the dust behavior according to the wind direction during coal storage in cell No. 4 must be checked. In Cases 4-1 and 4-2, which were the east and west wind conditions, the scattered coal dust was distributed in large quantities on the top of the center retaining wall of the cell, where the drop operation occurs. The scattered dust was discharged to the monitor louver. In Cases 4-3 and 4-4, which were the conditions of southerly and northerly winds, dust was distributed in the upper part of the cell, and the horizontal spread of dust was active due to the north–south winds. Regarding the dust emission ratio, 50.6% of the dust was emitted if outside air flowed in from the direction of the coal fall operation. For east wind inflow conditions, the airflow was blocked by the central wall, and 19.1% was discharged to the outside. Therefore, the emission of dust was reduced.

Results of simulating the scattering dust behavior characteristics are described in

Figure 9. Regarding the analysis results of the behavioral characteristics of scattered dust, according to the inflow flow rate of the coal storage shed, when the wind speed is the lowest at 1.0 m/s, about 14.5% of the dust is discharged outside. As the flow rate increases, the amount of scattered dust also increases. For 2.0 m/s and 6.0 m/s flow velocities, 50.6% and 92.1% of scattered dust are discharged to the outside, respectively. If the flow rate is slow, it stagnates at the top of the dust point. However, if the flow rate is high, the emissions increase over the central retaining wall, and most dust is emitted outside.

6. Verification of Results

In order to verify the results of the CFD analysis of the indoor coal pit, it is necessary to check the flow field visually. The flow visualization experiment was used to obtain flow information by visualizing transmission phenomena such as speed, pressure, and density. Among various flow visualization experiments, the tomographic technique is an experiment that acquires flow information from a cross-section formed by a laser. In this study, flow information was acquired using the tomographic method. Then, using the visualization result, it was compared qualitatively with the CFD simulation result. The experimental visualization device is manufactured to visualize the flow field that occurs according to the change in flow rate.

Figure 10 below explains the experimental setup and photos. Using acrylic, we made a scaled model of the indoor coal yard with a scale of 1/180, implementing natural ventilation (window, coal transfer port, monitor louver). We installed a wind fan in front of the experimental device to realize the external wind, and changed the wind speed by adjusting the fan’s RPM and installing a flow stabilizer in front of the fan. Then, a smoke generator was installed at the louver entrance on the first floor of the indoor coal storage shed. Smoke from a smoke generator passed through a cross-section formed by a laser. At this time, the formed flow field was visualized, and compared with the CFD result.

The Reynolds number must be compared to verify the two results. M. Vallikivi et al. [

32] analyzed a very high Reynolds number’s turbulent flow study; statistically similar results were derived at 20,000 or more. As a result of both comparisons, a qualitative comparison was possible, because both were flow fields with Reynolds numbers of 20,000 or more. The experimental conditions and analysis boundary conditions are described in

Table 7 below. The experiment was a reduced model of 1/180 ratio, and the inflow flow rate was 6.2 m/s. The inflow flow rate of the analysis result was 2.0 m/s. The results of analyzing the flow field derived from the experiment are as follows. The air introduced from the louver on the first floor rose through the coal slope, and was discharged to the monitor louver. A recirculation area was generated above the louver on the first floor, and a stagnant area was developed above the central wall. These results were qualitatively consistent with the simulation results. According to the simulation results, the concentration of carbon monoxide was high in the stagnant area above the central wall. Therefore, in order to improve the ventilation system, it was necessary to increase the amount of ventilation or consider the central wall flow dead area.

8. Conclusions

This study analyzed the internal flow and ventilation characteristics of the indoor coal storage shed of a coal-fired power plant using CFD. In addition, the behavior of a large amount of harmful gas generated during spontaneous coal combustion in a coal storage shed was analyzed. The results were combined to identify the hazardous areas of a field workspace.

In conclusion, an analysis was conducted of the internal flow characteristics and ventilation volume considering the location of the coal storage shed. As the flow rate of the outside air increased, the upper recirculation strength increased, and a stagnant area was generated around the central wall. Fluid stagnation occurred near the central wall in the same flow visualization test result to verify the simulation. In the same way as the flow visualization experiment to verify the simulation, flow stagnation occurred in the area near the central wall. Based on these results, when a louver is additionally installed to increase the ventilation amount, it is necessary to consider erasing the flow congestion area of the two-story workspace.

According to the analysis of the ventilation per hour in the low-carbon field, at the maximum speed, the ventilation volume was 13.1 ACH, and at the minimum speed, the ventilation volume was 4.4 ACH. About 51.9% of the natural ventilation emissions of the coal storage shed were discharged to the upper monitor louver. Therefore, the additional installation of the upper monitor louver effectively increased the natural ventilation in the coal storage shed.

Next, the characteristics of the concentration distribution of carbon monoxide generated during spontaneous coal ignition were analyzed. When the inflow velocity was 6 m/s, sufficient ventilation was secured, and carbon monoxide was diluted inside through the inflow of outside air. In this case, no area exceeded the dangerous standard concentration, except the point where spontaneous ignition occurred and the point near the coal pile. However, for an inflow velocity of 2.0 m/s, considering the previously derived ventilation rate of 4.4 ACH, it was possible to identify hazardous areas of 30 ppm or more in the workspace on the second floor, and the area near the central wall.

This study assumed that spontaneous ignition occurred in one specific cell. If spontaneous ignition occurs in multiple cells simultaneously, the risk area of more than 30 ppm of carbon monoxide is highly likely to expand. Therefore, it is essential to prepare for the case in which ventilation is sharply decreased due to decreased outdoor air inflow and spontaneous ignition occurring in many cells. In addition, it is deemed necessary to secure the ventilation volume by installing additional natural ventilation facilities.

The behavioral characteristics of the scattered coal dust in the coal storage shed were analyzed. The discharge characteristics of scattered coal dust in the coal storage shed changed according to the wind direction and speed. If outside air flowed in from the direction in which the coal dust was generated, the coal dust discharged to the monitor louver by the rising airflow, which also increased. However, the emissions of scattered dust were reduced due to the central wall when ambient air was introduced in the opposite direction of the coal drop point. In addition, 19.1% of the coal dust was emitted with an incoming wind speed of 1.0 m/s, and most dust was discharged at 6.0 m/s.

A method for improving the ventilation performance of the coal storage shaded was analyzed. The plan to additionally install louvers had little effect in areas where carbon monoxide was high, and it was confirmed that the plan to use a mobile blower was very effective. Carbon monoxide generated from coal can be diluted, and it is effective to emit carbon monoxide by increasing the amount of natural ventilation. One thing to note is that using a blower at the point of spontaneous ignition is likely to supply oxygen and expand the fire. Therefore, it is necessary to consider operating the blower to avoid spontaneous ignition points.