A Preliminary Experimental Study on the Workers’ Workload Assessment to Design Industrial Products and Processes

Abstract

:1. Introduction

- The definition of a novel holistic ergonomic assessment method, which includes both physical and cognitive ergonomic evaluations, and that can easily be adopted during workers’ shifts within industrial environments;

- An improved analysis of human cognitive conditions that represents the most critical aspect in the modern industrial scenario, where interaction is more complex, mentally demanding, and potentially stressful;

- A focus on industrial task analysis, as the majority of the existing literature is aimed towards other domains (e.g., healthcare, aviation).

2. Research Background

2.1. Physical Comfort Evaluation

2.2. Cognitive Evaluation

2.3. Stress Evaluation

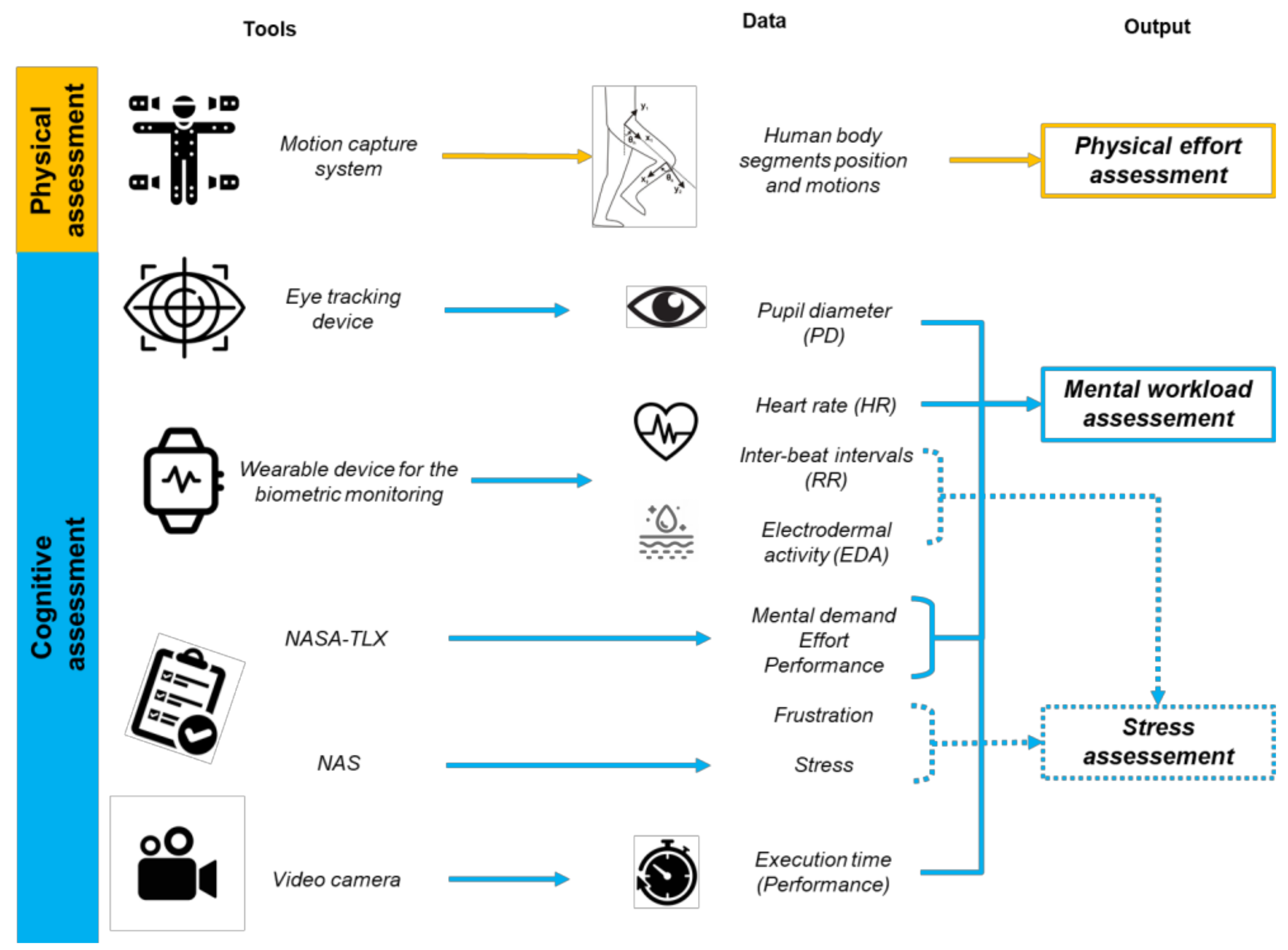

3. The Proposed Method for Operators’ Workload Assessment

- Human body segment position and motions into the three-dimensional space, collected by the motion capture systems;

- Pupil diameter collected by the eye tracking system;

- Physiological parameters referring to the user’s cardiovascular activity (i.e., HR and RR) and skin conductance (i.e., EDA), collected by the biometric wearable device;

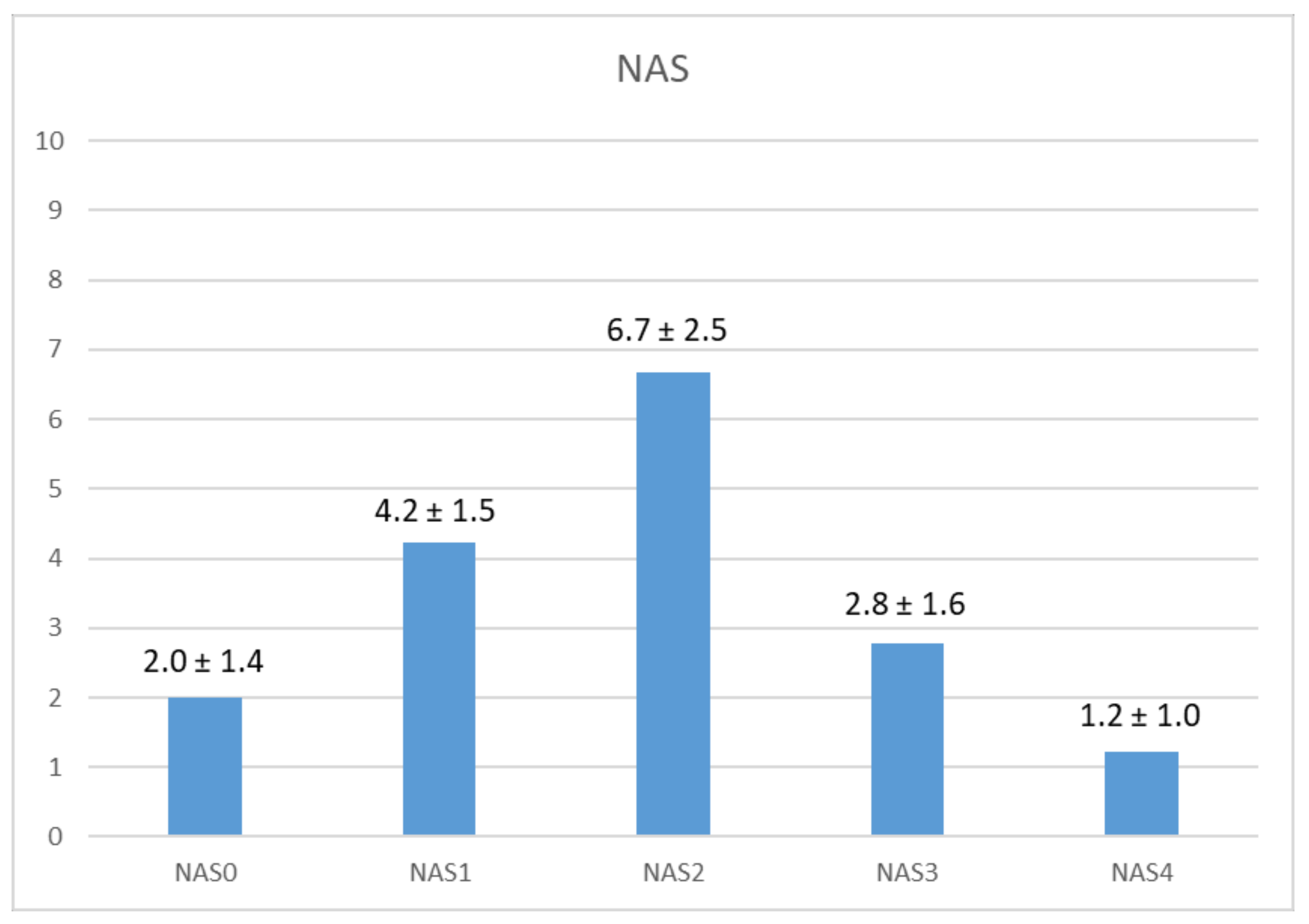

- Subjective assessment based on NAS and NASA-TLX questionnaires;

- Performance data like execution time, collected by video analysis.

4. Experimental Study

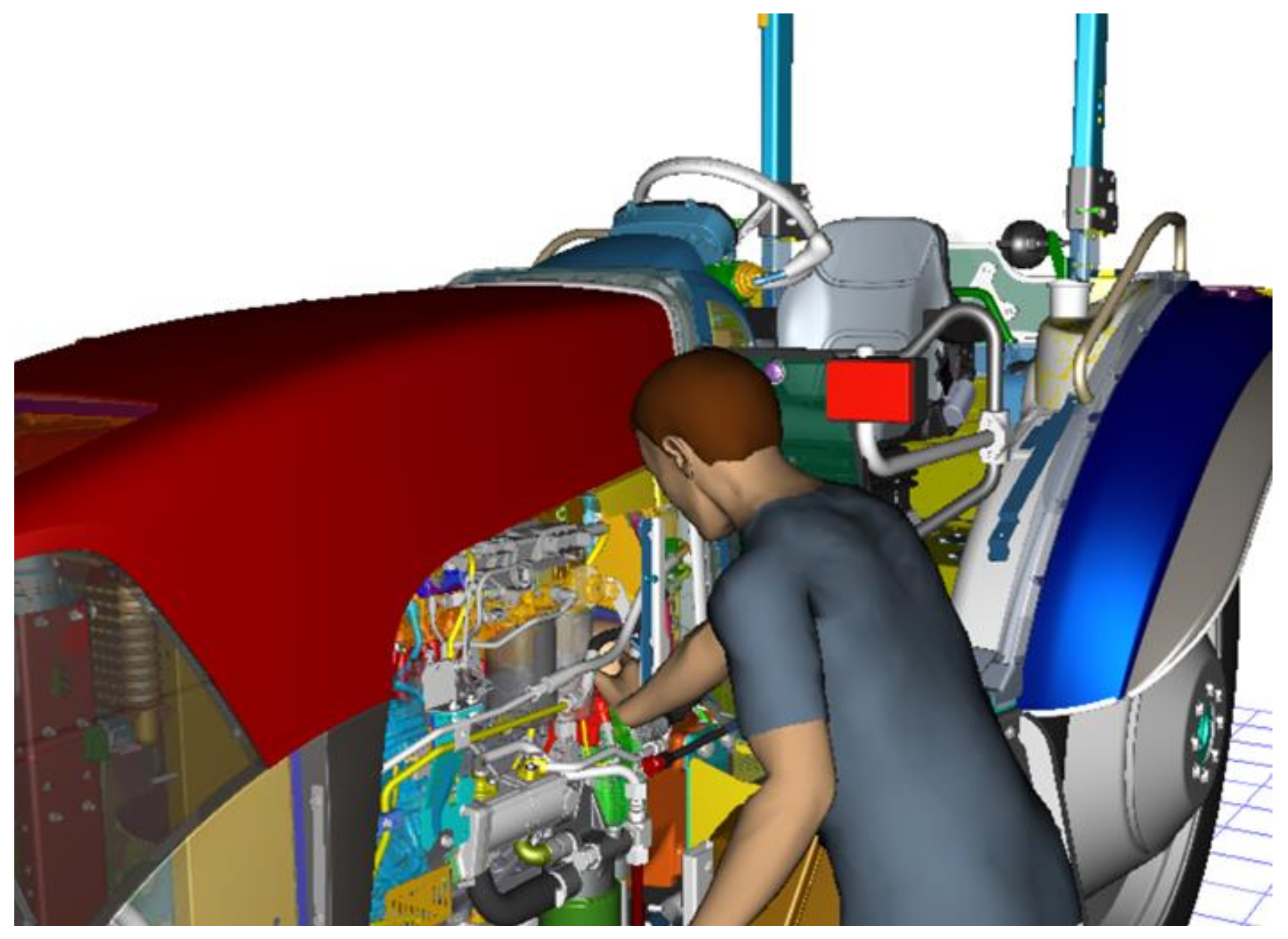

4.1. The Industrial Case Study

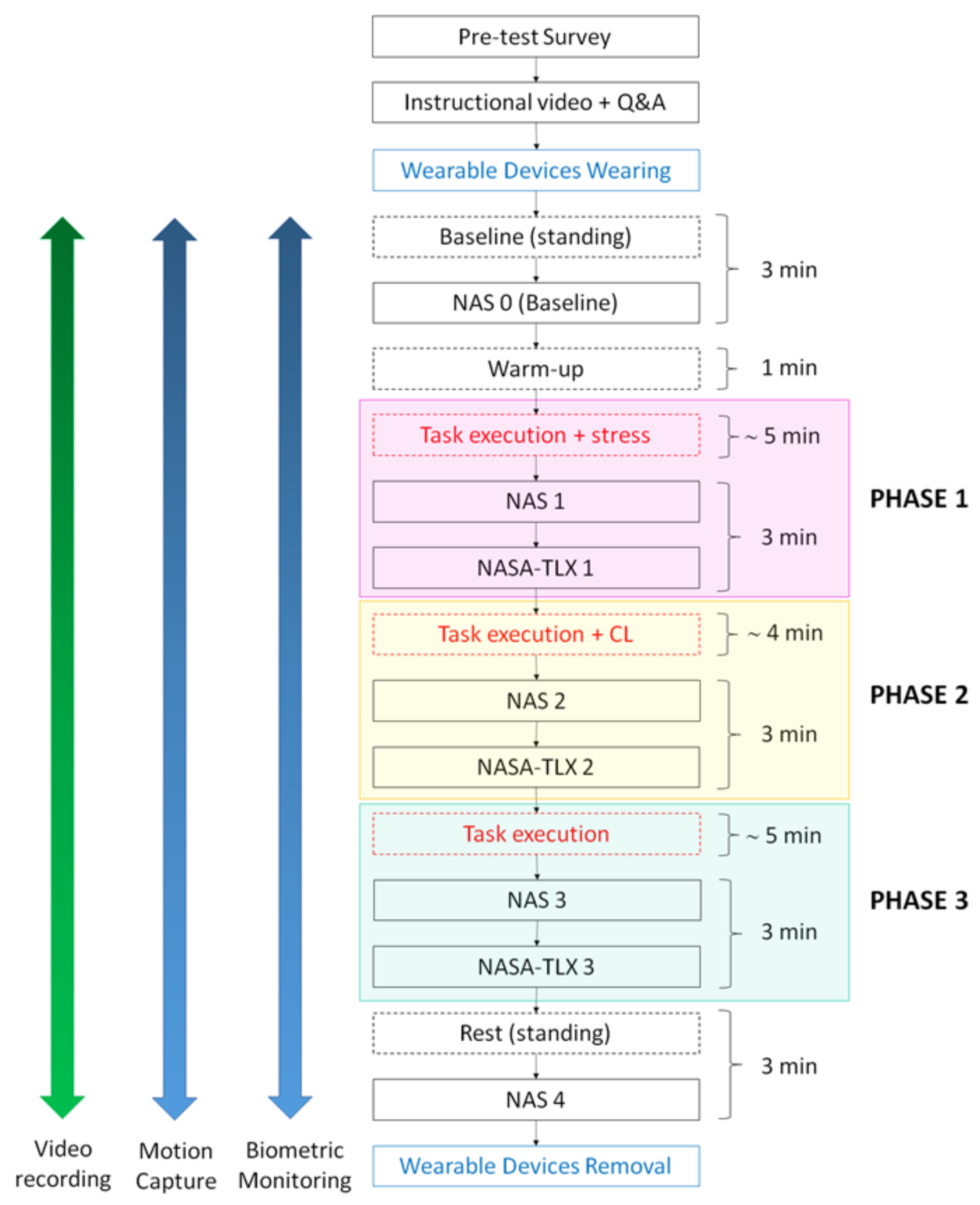

4.2. The Experimental Protocol for User Testing

- Demographic data such as gender, age, weight, height, educational qualification, occupational role;

- Previous experience with manual working tasks like the ones performed during the trial (e.g., use of wrenches, screwing, working with electrical wires, etc.);

- Familiarity with the use of wearable devices (e.g., activity trackers, smartwatches, sensorised t-shirts, etc.).

- Phase 1—task execution with increased stress: in the first phase the participant has to remove the electrical wires bracket, the cover bracket, unplug the electrical switch, unscrew the engine oil filter with tools, unscrew the engine oil filter manually, disconnect the power steering pipes, unplug the gasoline pipe, and unplug the temperature sensor electrical switch. The expected duration is about five minutes. For this reason, to increment the stress, a 4-min countdown is shown to the participant introducing time pressure.

- Phase 2—task execution with increased cognitive load (dual task): in the second phase the participant has to unscrew the pre-fuel filter with tools, finalize to unscrew the pre-fuel filter manually, unscrew the temperature sensor from the pre-fuel filter, screw the new temperature sensor on the pre fuel filter, screw the pre-fuel filter manually, finalize to screw the pre-fuel filter with tools, plug the temperature sensor electrical switch, plug the gasoline pipe, pump the gasoline into the filters, connect the power steering pipes manually, and then with tools. To increase the cognitive load, a secondary task has been inserted. The participant, while performing the main task in the most accurate manner, must count backward from 874, with steps of 7, until the completion of the main task. The backward counting task is often chosen as an interfering task as it involves multiple cognitive resources without requiring visual processing.

- Phase 3—task execution in standard conditions: in the third part the participant has to fill the new filter with oil, screw the engine oil filter manually, and then with tools, plug the electrical switch, mount the cover bracket, and then the electrical wires bracket. In this phase, the steps are executed in normal conditions, without adding any stressful or mentally demanding events.

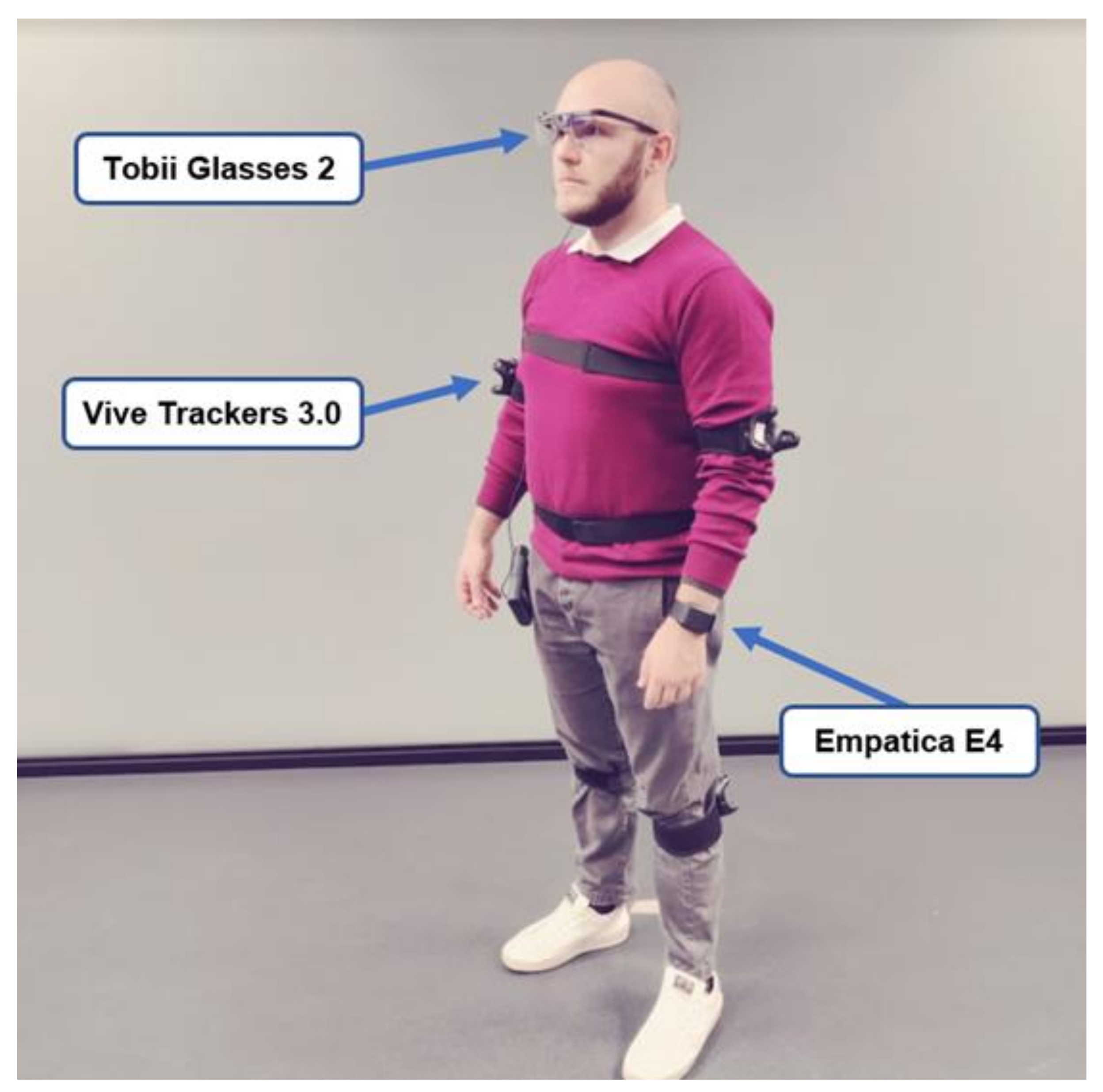

4.3. Experimental Data Monitoring

- HTC Vive Trackers 3.0: they are small, interchangeable motion tracking accessories that can be attached to any part of the body, by proper straps, in order to achieve the motion capture of a joint or a body segment. Each tracker calculates its position based on the infrared signals emitted from a set of base stations that have to be properly positioned in the space. In this specific case, the user wears the trackers, according to a predefined configuration (i.e., two trackers on the arms, one on the belt and two on the legs).

- Empatica E4: it is a wrist-wearable device able to record a set of physiological data of the user, using different types of sensors. In particular, the photoplethysmogram (PPG) sensor measures the Blood Volume Pulse (BVP), from which the heart rate (HR) and inter beat interval (IBI) can be derived. Moreover, the electrodermal activity (EDA) sensor measures the changes in skin conductance resulting from the sympathetic nervous system activity. The device also has a 3-axis accelerometer and an infrared thermopile.

- Tobii Pro Glasses 2: this is a mobile, wearable eye tracking system that looks like a pair of glasses, equipped with four infrared cameras (two cameras for each eye) that records eye movements. The system consists of the head unit (glasses) and the recording unit, in which are stored batteries, and an SD memory card that is usually hung on the belt. A full HD camera in the head unit provides the user point of view. Glasses are also equipped with a microphone, accelerometers, and gyroscopes to track the head movements.

- External camera: this provides the video recording of the user and the workspace environment from a fixed position.

- XRErgo: a standalone application developed in Unity 3D, which allows the evaluation of the users’ postures and working conditions in both real environments and virtual simulations with motion capture. In the case study, it exploits the HTC Vive trackers as the motion capture system to create a digital twin of the operator, animated in real-time, and assesses postural risk by RULA method.

- Steam VR: software that streams the real time position of the Vive Trackers in XRErgo attached to arms, legs and back in XRErgo in order to perform the ergonomic analysis.

- E4 realtime: an application for the real time streaming of data from Empatica to a smartphone or a tablet. This is used to control Empatica E4 calibration and data recording. The application automatically uploads to the cloud the data collected during the tests, to be further analyzed and processed.

- Kubios HRV Standard: this tool provides a detailed HRV analysis to calculate RR data from HR and HRV data collected during the tests.

4.4. Participants Involved in the Preliminary User Testing

5. Results and Discussion

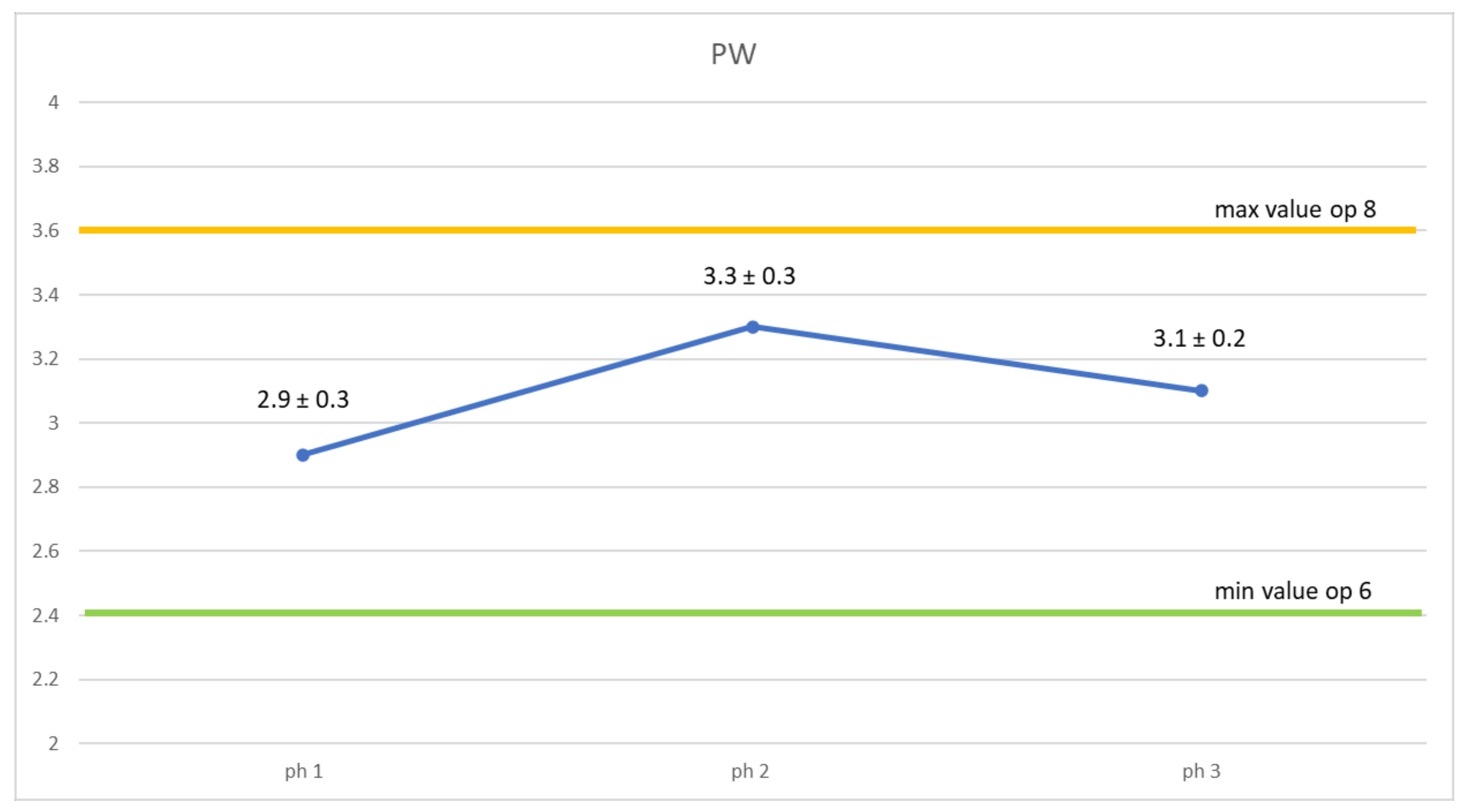

5.1. Physical Assessment

5.2. Cognitive Assessment

- The mental workload slightly changes in the range of 25–33% among the different phases, confirming that the operator keeps the attention and concentration constant during the trial;

- The stress level had minor variation (3–5%) during phase 1 and 3, while it showed a greater variation (54%) during phase 2. This means that the secondary task has a higher impact on the feeling of stress and frustration rather than on the mental effort. This is probably related to the fact that the manual operations needed to replace the engine oil filter do not require a high cognitive load.

- The experimental study also presented several limitations, especially related to:

- The limited number of users involved in the testing that do not allow a statistical relevance;

- Some technical issues related to the devices used for human monitoring, in particular the lack of data during the collection of RR signals from EMPATICA E4 and of PD variations in the data from the Tobii Glasses were observed by some users.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| BR | breathing rate |

| BVP | blood volume pulse |

| EDA | electrodermal activity |

| EEG | electroencephalography |

| GSR | galvanic skin response |

| HR | heart rate |

| HRV | heart rate variability |

| IBI | inter-beat interval |

| MW | mental workload parameter |

| MWL | mental workload |

| NAS | numerical analog scale |

| NASA-TLX | NASA task load index |

| PA | pupil activity parameter |

| PD | pupil diameter |

| PPG | photoplethysmography |

| PW | postural workload parameter |

| REBA | rapid entire body assessment |

| RR | beat-by-beat variations |

| RULA | rapid upper limb assessment |

| STAI | state trait anxiety inventory |

| UT | user time parameter |

References

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards future industrial opportunities and challenges. In Proceedings of the 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; pp. 2147–2152. [Google Scholar] [CrossRef]

- Kong, F. Development of metric method and framework model of integrated complexity evaluations of production process for ergonomics workstations. Int. J. Prod. Res. 2018, 57, 2429–2445. [Google Scholar] [CrossRef]

- Cimini, C.; Pirola, F.; Pinto, R.; Cavalieri, S. A human-in-the-loop manufacturing control architecture for the next generation of production systems. J. Manuf. Syst. 2020, 54, 258–271. [Google Scholar] [CrossRef]

- Pacaux-Lemoine, M.-P.; Trentesaux, D.; Rey, G.Z.; Millot, P. Designing intelligent manufacturing systems through Human-Machine Cooperation principles: A human-centered approach. Comput. Ind. Eng. 2017, 111, 581–595. [Google Scholar] [CrossRef]

- Longo, F.; Nicoletti, L.; Padovano, A. Smart operators in industry 4.0: A human-centered approach to enhance operators’ capabilities and competencies within the new smart factory context. Comput. Ind. Eng. 2017, 113, 144–159. [Google Scholar] [CrossRef]

- Grandi, F.; Zanni, L.; Peruzzini, M.; Pellicciari, M.; Campanella, C.E. A Transdisciplinary digital approach for tractor’s human-centred design. Int. J. Comput. Integr. Manuf. 2019, 33, 377–397. [Google Scholar] [CrossRef]

- European Commission. Industry 5.0. Available online: https://ec.europa.eu/info/research-and-innovation/research-area/industrial-research-and-innovation/industry-50_en (accessed on 5 November 2021).

- Peruzzini, M.; Pellicciari, M. A framework to design a human-centred adaptive manufacturing system for aging workers. Adv. Eng. Inform. 2017, 33, 330–349. [Google Scholar] [CrossRef]

- Papetti, A.; Ciccarelli, M.; Brunzini, A.; Germani, M. Design of ergonomic manufacturing equipment by a human-centered methodology. Int. J. Interact. Des. Manuf. (IJIDeM) 2020, 15, 107–111. [Google Scholar] [CrossRef]

- Gasson, S. Human-centered vs. user-centered approaches to information system design. J. Inf. Technol. Theory Appl. 2003, 5, 29–46. [Google Scholar]

- Benn, S.; Edwards, M.; Williams, T. Organizational Change for Corporate Sustainability; Routledge: London, UK, 2014. [Google Scholar] [CrossRef]

- Waterson, P.; Kolose, S.L. Exploring the social and organisational aspects of human factors integration: A framework and case study. Saf. Sci. 2010, 48, 482–490. [Google Scholar] [CrossRef] [Green Version]

- Zolotová, I.; Papcun, P.; Kajáti, E.; Miškuf, M.; Mocnej, J. Smart and cognitive solutions for Operator 4.0: Laboratory H-CPPS case studies. Comput. Ind. Eng. 2018, 139, 105471. [Google Scholar] [CrossRef]

- Longo, F.; Nicoletti, L.; Padovano, A. Modeling workers’ behavior: A human factors taxonomy and a fuzzy analysis in the case of industrial accidents. Int. J. Ind. Ergon. 2018, 69, 29–47. [Google Scholar] [CrossRef]

- Papetti, A.; Gregori, F.; Pandolfi, M.; Peruzzini, M.; Germani, M. A method to improve workers’ well-being toward human-centered connected factories. J. Comput. Des. Eng. 2020, 7, 630–643. [Google Scholar] [CrossRef]

- ISO 9241-210:2010, Ergonomics of Human-System Interaction—Part 210: Human-Centred Design for Interactive Systems; ISO: Geneva, Switzerland, 2010.

- Dadashi, N.; Lawson, G.; Marshall, M.; Stokes, G. Cognitive and metabolic workload assessment techniques: A review in automotive manufacturing context. Hum. Factors Ergon. Manuf. 2021, 32, 20–34. [Google Scholar] [CrossRef]

- ISO 26800:2011, Ergonomics—General Approach, Principles and Concepts; ISO: Geneva, Switzerland, 2011.

- Pheasant, S. Body Space: Anthropometry, Ergonomics, and the Design of Work; Taylor & Francis: Abingdon, UK, 1999; pp. 121–123. [Google Scholar] [CrossRef]

- Lasota, A.M. A New Approach to Ergonomic Physical Risk Evaluation in Multi-Purpose Workplaces. Teh. Vjesn.-Tech. Gaz. 2020, 27, 467–474. [Google Scholar] [CrossRef]

- Joshi, M.; Deshpande, V. A systematic review of comparative studies on ergonomic assessment techniques. Int. J. Ind. Ergon. 2019, 74, 102865. [Google Scholar] [CrossRef]

- ISO/TR 12295: Ergonomics-Document for the Application of ISO Standards to Manual Handling of Loads (ISO 11228) and Evaluation of Static Work Postures (ISO 11226); ISO: Geneva, Switzerland, 2014.

- ISO 11226:2000: Ergonomics-“Evaluation of Static Work Postures”; ISO: Geneva, Switzerland, 2000.

- Part 1: “Terms and definitions”, Part 2: “Manual handling of machinery and parts of machinery”, Part 3: “Recommended force limits for the use of machinery”, Part 4: “Evaluation of postures and work movements in relation to machinery”, Part 5: “Risk assessment related to high frequency repetitive handling”. In UNI EN 1005:2009: Machine Safety-Human Physical Performance; UNI EN: Milan, Italy, 2009.

- Part 1: “Lifting and Moving”. Part 2: “Pushing and Pulling”. Part 3: “Handling of Small Loads with Great Frequency”. In ISO 11228-1,2,3: Ergonomics-Manual Handling; ISO: Geneva, Switzerland, 2021.

- McAtamney, L.; Corlett, E.N. RULA: A survey method for the investigation of work-related upper limb disorders. Appl. Ergon. 1993, 24, 91–99. [Google Scholar] [CrossRef]

- Hignett, S.; McAtamney, L. Rapid Entire Body Assessment (REBA). Appl. Ergon. 2000, 31, 201–205. [Google Scholar] [CrossRef]

- Karhu, O.; Härkönen, R.; Sorvali, P.; Vepsäläinen, P. Observing working postures in industry: Examples of OWAS application. Appl. Ergon. 1981, 12, 13–17. [Google Scholar] [CrossRef]

- Occhipinti, E. OCRA: A concise index for the assessment of exposure to repetitive movements of the upper limbs. Ergonomics 1998, 41, 1290–1311. [Google Scholar] [CrossRef]

- Dempsey, P.G. Usability of the revised NIOSH lifting equation. Ergonomics 2002, 45, 817–828. [Google Scholar] [CrossRef]

- Peruzzini, M.; Grandi, F.; Cavallaro, S.; Pellicciari, M. Using virtual manufacturing to design human-centric factories: An industrial case. Int. J. Adv. Manuf. Technol. 2020, 115, 873–887. [Google Scholar] [CrossRef]

- Hart, S.G. Nasa-Task Load Index (NASA-TLX); 20 Years Later. Proc. Hum. Factors Ergon. Soc. Annu. Meet. 2006, 50, 904–908. [Google Scholar] [CrossRef] [Green Version]

- Wickens, C.D.; Gordon, S.E.; Liu, Y. An Introduction to Human Factors Engineering; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2004; pp. 64–90. [Google Scholar]

- Cain, B. A Review of the Mental Workload Literature; RTO-TR-HFM-121-Part-II; Defence Research and Development Canada: Toronto, Canada, 2007.

- Part 3: Principles and Requirements Concerning Methods for Measuring and Assessing Mental Workload. In ISO 10075-3:2004, Ergonomic Principles Related to Mental Workload; ISO: Geneva, Switzerland, 2004.

- Karwowski, W. International Encyclopedia of Ergonomics and Human Factors; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar] [CrossRef]

- Hart, S.G.; Staveland, L.E. Development of NASA-TLX (Task Load Index): Results of Empirical and Theoretical Research. In Advances in Psychology; Hancock, P.A., Meshkati, N., Eds.; Human Mental Workload: North-Holland, The Netherlands, 1988; Volume 52, pp. 139–183. [Google Scholar] [CrossRef]

- La Bara, L.; Meloni, L.; Giusino, D.; Pietrantoni, L. Assessment Methods of Usability and Cognitive Workload of Rehabilitative Exoskeletons: A Systematic Review. Appl. Sci. 2021, 11, 7146. [Google Scholar] [CrossRef]

- Pilco, H.; Sanchez-Gordon, S.; Calle-Jimenez, T.; Pérez-Medina, J.L.; Rybarczyk, Y.; Jadán-Guerrero, J.; Maldonado, C.G.; Nunes, I.L. An Agile Approach to Improve the Usability of a Physical Telerehabilitation Platform. Appl. Sci. 2019, 9, 480. [Google Scholar] [CrossRef] [Green Version]

- Tao, D.; Tan, H.; Wang, H.; Zhang, X.; Qu, X.; Zhang, T. A Systematic Review of Physiological Measures of Mental Workload. Int. J. Environ. Res. Public Health 2019, 16, 2716. [Google Scholar] [CrossRef] [Green Version]

- Debie, E.; Rojas, R.F.; Fidock, J.; Barlow, M.; Kasmarik, K.; Anavatti, S.; Garratt, M.; Abbass, H.A. Multimodal Fusion for Objective Assessment of Cognitive Workload: A Review. IEEE Trans. Cybern. 2019, 51, 1542–1555. [Google Scholar] [CrossRef]

- Charles, R.L.; Nixon, J. Measuring mental workload using physiological measures: A systematic review. Appl. Ergon. 2019, 74, 221–232. [Google Scholar] [CrossRef]

- Lee, B.C.; Chung, K.; Kim, S.-H. Interruption Cost Evaluation by Cognitive Workload and Task Performance in Interruption Coordination Modes for Human–Computer Interaction Tasks. Appl. Sci. 2018, 8, 1780. [Google Scholar] [CrossRef] [Green Version]

- Spielberger, C.D.; Gorsuch, R.L. State-Trait Anxiety Inventory for Adults: Sampler Set, Manual, Test, Scoring Key; Mind Garden: Redwood City, CA, USA, 1983. [Google Scholar]

- Brunzini, A.; Papetti, A.; Germani, M.; Barbadoro, P.; Messi, D.; Adrario, E. Mixed Reality Simulation for Medical Training: How It Affects Learners’ Cognitive State. In Advances in Simulation and Digital Human Modeling; AHFE 2021; Lecture Notes in Networks and Systems; Springer: Berlin/Heidelberg, Germany, 2021; Volume 264. [Google Scholar] [CrossRef]

- Plechawska-Wójcik, M.; Tokovarov, M.; Kaczorowska, M.; Zapała, D. A Three-Class Classification of Cognitive Workload Based on EEG Spectral Data. Appl. Sci. 2019, 9, 5340. [Google Scholar] [CrossRef] [Green Version]

- Arora, S.; Sevdalis, N.; Nestel, D.; Woloshynowych, M.; Darzi, A.; Kneebone, R. The impact of stress on surgical performance: A systematic review of the literature. Surgery 2010, 147, 318–330.e6. [Google Scholar] [CrossRef] [PubMed]

- Part 1: General Issues and Concepts, Terms and Definitions. In ISO 10075-1:2017, Ergonomic Principles Related To Mental Workload; ISO: Geneva, Switzerland, 2017.

- Lazarus, R.S.; Folkman, S. Stress, Appraisal, and Coping; Springer: Berlin/Heidelberg, Germany, 1984. [Google Scholar]

- Boucsein, W. Electrodermal Activity; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar] [CrossRef]

- Waller, L.; Reitz, M.; Poole, E.; Riddell, P.M.; Muir, A. Experiential learning as preparation for leadership: An exploration of the cognitive and physiological processes. Leadersh. Organ. Dev. J. 2017, 38, 513–529. [Google Scholar] [CrossRef]

- Luque-Casado, A.; Perales, J.C.; Cárdenas, D.; Sanabria, D. Heart rate variability and cognitive processing: The autonomic response to task demands. Biol. Psychol. 2016, 113, 83–90. [Google Scholar] [CrossRef] [PubMed]

- Castaldo, R.; Melillo, P.; Bracale, U.; Caserta, M.; Triassi, M.; Pecchia, L. Acute mental stress assessment via short term HRV analysis in healthy adults: A systematic review with meta-analysis. Biomed. Signal Process. Control 2015, 18, 370–377. [Google Scholar] [CrossRef] [Green Version]

- Mingardi, M.; Pluchino, P.; Bacchin, D.; Rossato, C.; Gamberini, L. Assessment of Implicit and Explicit Measures of Mental Workload in Working Situations: Implications for Industry 4.0. Appl. Sci. 2020, 10, 6416. [Google Scholar] [CrossRef]

- Stawarczyk, D.; François, C.; Wertz, J.; D’Argembeau, A. Drowsiness or mind-wandering? Fluctuations in ocular parameters during attentional lapses. Biol. Psychol. 2020, 156, 107950. [Google Scholar] [CrossRef] [PubMed]

- Bommer, S.C.; Fendley, M. A theoretical framework for evaluating mental workload resources in human systems design for manufacturing operations. Int. J. Ind. Ergon. 2018, 63, 7–17. [Google Scholar] [CrossRef] [Green Version]

- Yang, E.; Dorneich, M.C. The Emotional, Cognitive, Physiological, and Performance Effects of Variable Time Delay in Robotic Teleoperation. Int. J. Soc. Robot. 2017, 9, 491–508. [Google Scholar] [CrossRef]

- Leone, A.; Rescio, G.; Siciliano, P.; Papetti, A.; Brunzini, A.; Germani, M. Multi sensors platform for stress monitoring of workers in smart manufacturing context. In Proceedings of the 2020 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Dubrovnik, Croatia, 25–28 May 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Blanco, M.; Biever, W.J.; Gallagher, J.P.; Dingus, T.A. The impact of secondary task cognitive processing demand on driving performance. Accid. Anal. Prev. 2006, 38, 895–906. [Google Scholar] [CrossRef] [PubMed]

- Grandi, F.; Peruzzini, M.; Cavallaro, S.; Prati, E.; Pellicciari, M. Creation of a UX index to design human tasks and workstations. Int. J. Comput. Integr. Manuf. 2021, 1–17. [Google Scholar] [CrossRef]

| No. | Subtask | Adopted Tools |

|---|---|---|

| 1 | Remove electrical wiresbracket | Wrench |

| 2 | Remove cover bracket | Socket wrench |

| 3 | Unplug electrical switch | None |

| 4 | Unscrew engine oil filter with tools | Strap wrench |

| 5 | Unscrew engine oil filter manually | None |

| 6 | Disconnect power steering pipes (n.2) | Wrench |

| 7 | Unplug gasoline pipe | None |

| 8 | Unplug temperature sensor electrical switch | None |

| 9 | Unscrew pre-fuel filter with tools | Strap wrench |

| 10 | Finalize to unscrew pre-fuel filter manually | None |

| 11 | Unscrew temperature sensor from pre-fuel filter | None |

| 12 | Screw the new temperature sensor on the pre-fuel filter | None |

| 13 | Screw the pre-fuel filter manually | None |

| 14 | Finalize to screw the pre-fuel filter with tools | Strap wrench |

| 15 | Plug temperature sensor into electrical switch | None |

| 16 | Plug gasoline pipe | None |

| 17 | Pump the gasoline into the filters | None |

| 18 | Connect power steering pipes (n.2) manually | None |

| 19 | Connect power steering pipes (n.2) with tools | Wrench |

| 20 | Fill new filter with oil | None |

| 21 | Screw engine oil filter manually | None |

| 22 | Screw engine oil filter with tools | Strap wrench |

| 23 | Plug electrical switch | None |

| 24 | Mount cover bracket | Socket wrench |

| 25 | Mount electrical wiresbracket | Wrench |

| Demographic Info | Physical Data | Previous Experience (5-Points Likert Scale) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Operator Code | Gender | Age | Height | ANSUR Height Percentile | Weight | ANSUR Weight Percentile | In Maintenance Tasks | In Using Mechanical Tools | In Using Monitoring Devices |

| Op1 | M | 28 | 178 | 65p | 65 | 5p | 1 | 3 | 1 |

| Op2 | M | 26 | 180 | 75p | 74 | 20p | 2 | 4 | 5 |

| Op3 | F | 27 | 167 | 75p | 54 | 10p | 3 | 5 | 5 |

| Op4 | M | 31 | 168 | 15p | 80 | 40p | 3 | 5 | 5 |

| Op5 | M | 23 | 182 | 85p | 67 | 10p | 1 | 3 | 2 |

| Op6 | M | 27 | 173 | 40p | 71 | 15p | 4 | 5 | 4 |

| Op7 | M | 25 | 172 | 30p | 62 | 5p | 1 | 3 | 4 |

| Op8 | M | 25 | 193 | 99p | 85 | 55p | 1 | 2 | 3 |

| Number | Task | op1 (65p) | op2 (75p) | op3 (75p) | op4 (15p) | op5 (85p) | op6 (40p) | op7 (30p) | op8 (99p) | PW Sub-Task | PW Phase | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Phase 1 | 1 | Remove electrical wires bracket | 1 | 3 | 3 | 3 | 3 | 1 | 3 | 3 | 2.5 | 2.9 |

| 2 | Remove cover bracket | 3 | 3 | 3 | 3 | 4 | 1 | 3 | 5 | 3.1 | ||

| 3 | Unplug electrical switch | 3 | 3 | 3 | 3 | 5 | 1 | 3 | 5 | 3.3 | ||

| 4 | Unscrew engine oil filter with tools | 3 | 3 | 3 | 3 | 3 | 1 | 3 | 3 | 2.8 | ||

| 5 | Unscrew engine oil filter manually | 4 | 3 | 3 | 3 | 3 | 1 | 3 | 3 | 2.9 | ||

| 6 | Disconnect power steering pipes (n.2) | 4 | 3 | 3 | 3 | 3 | 1 | 5 | 4 | 3.3 | ||

| 7 | Unplug gasoline pipe | 3 | 2 | 3 | 3 | 3 | 1 | 3 | 5 | 2.9 | ||

| 8 | Unplug temperature sensor electical switch | 3 | 3 | 4 | 3 | 3 | 1 | 3 | 3 | 2.9 | ||

| Phase 2 | 9 | Unscrew pre-fuel filter with tools | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3.0 | 3.3 |

| 10 | Finalize to unscrew pre-fuel filter manually | 2 | 3 | 3 | 3 | 3 | 3 | 4 | 3 | 3.0 | ||

| 11 | Unscrew temperature sensor from pre-fuel filter | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 3 | 3.1 | ||

| 12 | Screw the new temperature sensor on the pre fuel filter | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 2 | 3.0 | ||

| 13 | Screw the pre-fuel filter manually | 3 | 3 | 4 | 3 | 4 | 3 | 3 | 4 | 3.4 | ||

| 14 | Finalize to screw the pre-fuel filter with tools | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3.0 | ||

| 15 | Plug temperature sensor electical switch | 4 | 3 | 4 | 3 | 4 | 3 | 3 | 4 | 3.5 | ||

| 16 | Plug gasoline pipe | 3 | 3 | 3 | 4 | 4 | 3 | 3 | 4 | 3.4 | ||

| 17 | Pump the gasoline into the filters | 3 | 3 | 3 | 3 | 4 | 3 | 3 | 5 | 3.4 | ||

| 18 | Connect power steering pipes (n.2) manually | 4 | 3 | 4 | 3 | 4 | 3 | 5 | 5 | 3.9 | ||

| 19 | Connect power steering pipes (n.2) with tools | 3 | 3 | 3 | 3 | 4 | 3 | 3 | 4 | 3.3 | ||

| Phase 3 | 20 | Fill new filter with oil | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3.0 | 3.1 |

| 21 | Screw engine oil filter manually | 3 | 3 | 3 | 3 | 4 | 3 | 3 | 3 | 3.1 | ||

| 22 | Screw engine oil filter with tools | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 2 | 2.9 | ||

| 23 | Plug electrical switch | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3.0 | ||

| 24 | Mount cover bracket | 3 | 3 | 3 | 3 | 3 | 3 | 5 | 3 | 3.3 | ||

| 25 | Mount electrical wires bracket | 3 | 4 | 3 | 3 | 3 | 3 | 3 | 4 | 3.3 | ||

| PW operator | 3 | 3 | 3.2 | 3 | 3.4 | 2.4 | 3.4 | 3.6 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brunzini, A.; Peruzzini, M.; Grandi, F.; Khamaisi, R.K.; Pellicciari, M. A Preliminary Experimental Study on the Workers’ Workload Assessment to Design Industrial Products and Processes. Appl. Sci. 2021, 11, 12066. https://doi.org/10.3390/app112412066

Brunzini A, Peruzzini M, Grandi F, Khamaisi RK, Pellicciari M. A Preliminary Experimental Study on the Workers’ Workload Assessment to Design Industrial Products and Processes. Applied Sciences. 2021; 11(24):12066. https://doi.org/10.3390/app112412066

Chicago/Turabian StyleBrunzini, Agnese, Margherita Peruzzini, Fabio Grandi, Riccardo Karim Khamaisi, and Marcello Pellicciari. 2021. "A Preliminary Experimental Study on the Workers’ Workload Assessment to Design Industrial Products and Processes" Applied Sciences 11, no. 24: 12066. https://doi.org/10.3390/app112412066

APA StyleBrunzini, A., Peruzzini, M., Grandi, F., Khamaisi, R. K., & Pellicciari, M. (2021). A Preliminary Experimental Study on the Workers’ Workload Assessment to Design Industrial Products and Processes. Applied Sciences, 11(24), 12066. https://doi.org/10.3390/app112412066