Adaptive Cruise Control for Intelligent City Bus Based on Vehicle Mass and Road Slope Estimation

Abstract

:1. Introduction

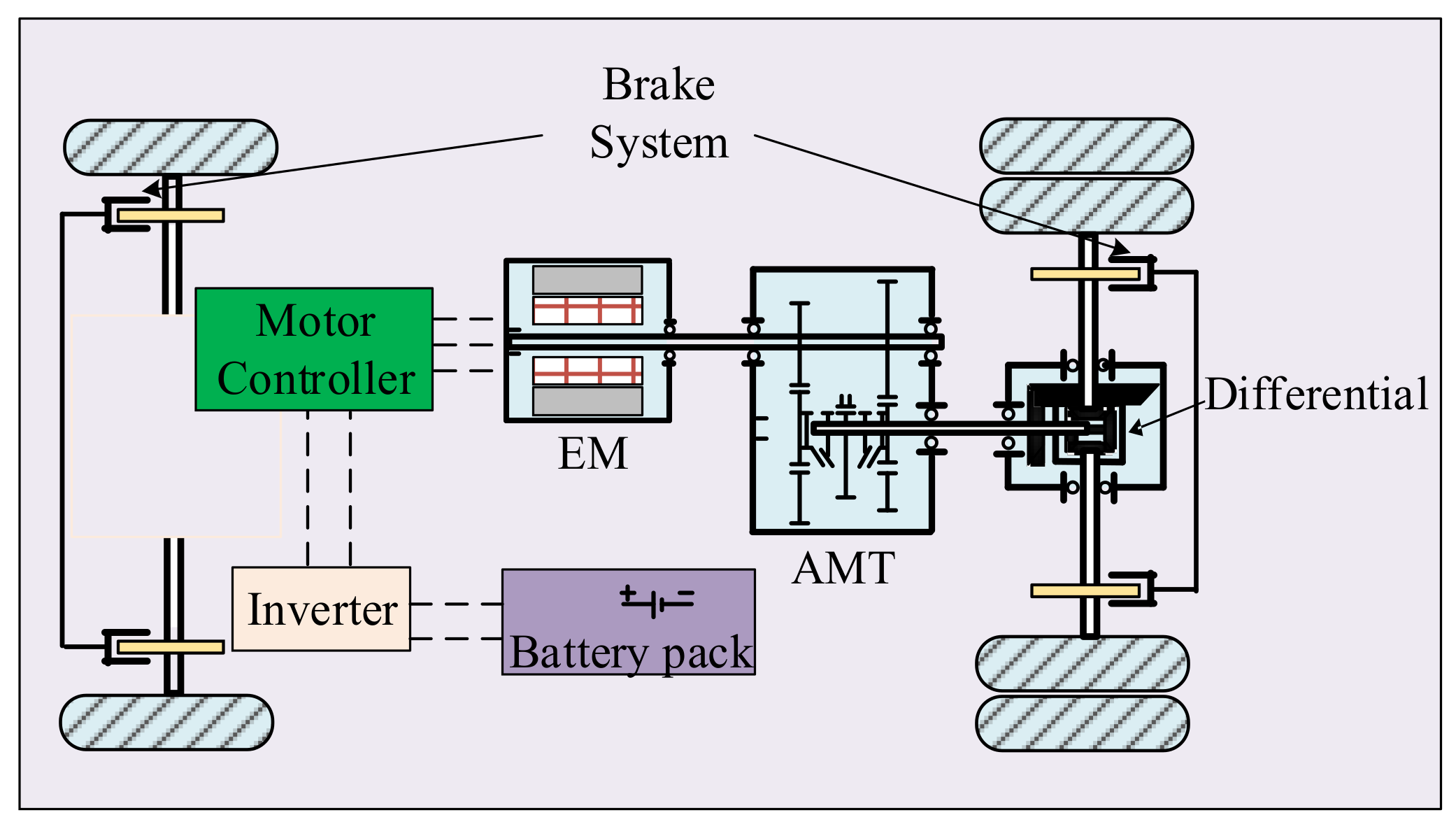

2. Model of Intelligent City Bus

2.1. EM Model

2.2. Battery Model

- (1)

- When SoC ≥ 0.8, for the safty of battery, EM is no longer engaged in braking and the mechanical braking system provides the brake torque. Thus, = 0;

- (2)

- When the brake severity Z is in the range of 0 to 0.1, EM provides the brake torque for the vehicle and = ;

- (3)

- When Z is in the range of 0.1 to 0.7 or EM cannot provide enough brake torque, EM and mechanical braking system provides power for together. Thus, = ;

- (4)

- When Z > 0.7, EM quits from working and the braking power is provided by mechanical braking system. Thus, = 0;

- (5)

- The EM braking effect is not obvious when its output speed below 500 r/min and the braking torque of the rear axle is provided by traditional mechanical braking system.

2.3. Vehicle Longitudinal Dynamics

3. Problem Formulation

3.1. State Space Equation for ACC

3.2. State Space for Vehicle Mass and Road Slope Estimating

3.3. ACC Optimizing Indexes

3.4. MPC Optimizing Algorithm

4. Simulation and Experiment Results

4.1. Driving Cycles

4.2. Simulation Results

4.3. Experiment Test Bases on HIL

5. Conclusions

- (1)

- The EKF strategy was used to realize the real-time estimation of vehicle mass and road slope. The estimation error of vehicle mass can be reduced to within ±5% in 40 s, and the estimation error of road slope can follow the actual value well. Real-time estimation for mass and slope provides key parameters for ACC implementation;

- (2)

- In this paper, we established the cost functions about speed, acceleration, impact, and SoC. Based on cost functions, we proposed the nonlinear MPC control algorithm. By adjusting the cost coefficients, we realized the multi-objective optimization of ACC;

- (3)

- Through simulation and HIL experiments, the feasibility of the EKF+MPC control strategy was verified. On the basis of ensuring safety and tracking ability, the maximum impact of the current vehicle was reduced to 5 m/s3, the consumption of the SoC was reduced by about 10%, and the vehicle comfort and energy efficiency are well improved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lv, C.; Xing, Y.; Zhang, J.; Na, X.; Li, Y.; Liu, T.; Cao, D.; Wang, F.-Y. Levenberg–Marquardt Backpropagation Training of Multilayer Neural Networks for State Estimation of a Safety-Critical Cyber-Physical System. IEEE Trans. Ind. Inform. 2018, 14, 3436–3446. [Google Scholar] [CrossRef] [Green Version]

- Yang, C.; You, S.; Wang, W.; Li, L.; Xiang, C. A stochastic predictive energy management strategy for plug-in hybrid electric vehicles based on fast rolling optimization. IEEE Trans. Ind. Electron. 2019, 67, 9659–9670. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, X.; Li, L.; Shi, J.; An, Q. Modelling and control for economy-oriented car-following problem of hybrid electric vehicle. IET Intell. Transp. Syst. 2019, 13, 825–833. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, X.; Raksincharoensak, P. Automated Vehicle’s Overtaking Maneuver with Yielding to Oncoming Vehicles in Urban Area Based on Model Predictive Control. Appl. Sci. 2021, 11, 9003. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, Y.; Liang, H. Effects of ACC and CACC vehicles on traffic flow based on an improved variable time headway spacing strategy. IET Intell. Transp. Syst. 2019, 13, 1365–1373. [Google Scholar] [CrossRef]

- Guo, C.; Meguro, J.; Kojima, Y.; Naito, T. A multimodal ADAS system for unmarked urban scenarios based on road context understanding. IEEE Trans. Intell. Transp. Syst. 2015, 16, 1690–1704. [Google Scholar] [CrossRef]

- Schreier, M.; Willert, V.; Adamy, J. Compact representation of dynamic driving environments for ADAS by parametric free space and dynamic object maps. IEEE Trans. Intell. Transp. Syst. 2016, 17, 367–384. [Google Scholar] [CrossRef]

- Cheng, S.; Li, L.; Mei, M.M.; Nie, Y.L.; Zhao, L. Multiple objective adaptive cruise control system integrated with DYC. IEEE Trans. Veh. Technol. 2019, 68, 4550–4559. [Google Scholar] [CrossRef]

- Kim, H.; Kim, D.; Shu, I.; Yi, K. Time-varying parameter adaptive vehicle speed control. IEEE Trans. Veh. Technol. 2015, 65, 581–588. [Google Scholar] [CrossRef]

- Ren, Y.; Zheng, L.; Yang, W.; Li, Y. Potential field–based hierarchical adaptive cruise control for semi-autonomous electric vehicle. Proc. Inst. Mech. Eng. Part. D J. Automob. Eng. 2019, 233, 2479–2491. [Google Scholar] [CrossRef]

- Zhang, J.; Ioannou, P.A. Longitudinal control of heavy trucks in mixed traffic: Environmental and fuel economy considerations. IEEE Trans. Intell. Transp. Syst. 2006, 7, 92–104. [Google Scholar] [CrossRef]

- Ganji, B.; Kouzani, A.Z.; Khoo, S.Y.; Shams-Zahraei, M. Adaptive cruise control of a HEV using sliding mode control. Expert Syst. Appl. 2014, 41, 607–615. [Google Scholar] [CrossRef]

- Shakouri, P.; Ordys, A.; Askari, M.R. Adaptive cruise control with stop & go function using the state-dependent nonlinear model predictive control approach. ISA Trans. 2012, 51, 622–631. [Google Scholar]

- Luo, Y.; Chen, T.; Li, K. Multi-objective decoupling algorithm for active distance control of intelligent hybrid electric vehicle. Mech. Syst. Signal. Process. 2015, 64, 29–45. [Google Scholar] [CrossRef]

- Luo, Y.; Chen, T.; Zhang, S.; Li, K. Intelligent hybrid electric vehicle ACC with coordinated control of tracking ability, fuel economy, and ride comfort. IEEE Trans. Intell. Transp. Syst. 2015, 16, 2303–2308. [Google Scholar] [CrossRef]

- Mantovani, G.; Ferrarini, L. Temperature control of a commercial building with model predictive control techniques. IEEE Trans. Ind. Electron. 2014, 62, 2651–2660. [Google Scholar] [CrossRef]

- Choi, D.K.; Lee, K. Dynamic performance improvement of AC/DC converter using model predictive direct power control with finite control set. IEEE Trans. Ind. Electron. 2014, 62, 757–767. [Google Scholar] [CrossRef]

- Sun, J.; Ghaemi, R.; Kolmanovsky, I.; Tao, G. Developments in receding horizon optimization-based controls: Towards real-time implementation for nonlinear systems with fast dynamics. In Advances in Control Theory and Applications; Springer: Berlin, Germany, 2008. [Google Scholar]

- Li, S.E.; Jia, Z.; Li, K.; Cheng, B. Fast online computation of a model predictive controller and its application to fuel economy–oriented adaptive cruise control. IEEE Trans. Intell. Transp. Syst. 2014, 16, 1199–1209. [Google Scholar] [CrossRef]

- Cagienard, R.; Grieder, P.; Kerrigan, E.; Morari, M. Move blocking strategies in receding horizon control. J. Process. Control. 2007, 17, 563–570. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Jia, G.; Chen, J.; Zhu, H.; Cao, D.; Song, J. A novel vehicle dynamics stability control algorithm based on the hierarchical strategy with constrain of nonlinear tyre forces. Veh. Syst. Dyn. 2015, 53, 1093–1116. [Google Scholar] [CrossRef]

- Li, S.E.; Li, K.; Wang, J. Economy-oriented vehicle adaptive cruise control with coordinating multiple objectives function. Veh. Syst. Dyn. 2013, 51, 1–17. [Google Scholar]

- Marzbanrad, J.; Karimian, N. Space control law design in adaptive cruise control vehicles using model predictive control. Proc. Inst. Mech. Eng. Part. D J. Automob. Eng. 2011, 225, 870–884. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, L.; Li, J.; Ouyang, M. Real-Time estimation of vehicle mass and road slope based on multi-sensor data fusion. In Proceedings of the IEEE Vehicle Power and Propulsion Conference (VPPC), Beijing. China, 15–18 October 2013. [Google Scholar]

- Kim, D.; Choi, S.B.; Choi, M. Integrated vehicle mass estimation for vehicle safety control using the recursive least-squares method and adaptation laws. Proc. Inst. Mech. Eng. Part. D J. Automob. Eng. 2015, 229, 14–24. [Google Scholar] [CrossRef]

- Vahidi, A.; Stefanopoulou, A.; Peng, H. Recursive least squares with forgetting for online estimation of vehicle mass and road slope: Theory and experiments. Veh. Syst. Dyn. 2005, 43, 31–55. [Google Scholar] [CrossRef]

- Ding, F.; Wang, Y.; Ding, J. Recursive least squares Parameter identification algorithms for systems with colored noise using the filtering technique and the auxiliary model. Digit. Signal. Process. 2015, 37, 100–108. [Google Scholar] [CrossRef]

- Raffone, E. Road slope and vehicle mass estimation for light commercial vehicle using linear Kalman filter and RLS with forgetting factor integrated approach. In Proceedings of the 16th International Conference on Information Fusion, Istanbul, Turkey, 9–12 July 2013. [Google Scholar]

- Korayem, A.H.; Khajepour, A.; Fidan, B. Trailer mass estimation using system model-based and machine learning approaches. IEEE Trans. Veh. Technol. 2020, 69, 12536–12546. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, H.; Feng, Z. Speed synchronization control for integrated automotive motor-transmission powertrain system with random delays. Mech. Syst. Signal. Process. 2015, 64/65, 46–57. [Google Scholar] [CrossRef]

- Li, L.; You, S.; Yang, C.; Yan, B.; Song, J.; Chen, Z. Driving-behavior-aware stochastic model predictive control for plug-in hybrid electric buses. Appl. Energy 2016, 162, 868–897. [Google Scholar] [CrossRef]

- Liu, B.; Li, L.; Wang, X.; Cheng, S. Hybrid electric vehicle downshifting strategy based on stochastic dynamic programming during regenerative braking process. IEEE Trans. Veh. Technol. 2018, 67, 4716–4727. [Google Scholar] [CrossRef]

- Wang, X.; Li, L.; Yang, C. Hierarchical control of dry clutch for engine-start process in a parallel hybrid electric vehicle. IEEE Trans. Transp. Electrif. 2016, 2, 231–243. [Google Scholar] [CrossRef]

- Li, L.; Wang, X.; Song, J. Fuel consumption optimization for smart hybrid electric vehicle during a car-following process. Mech. Syst. Signal. Process. 2017, 87, 17–29. [Google Scholar] [CrossRef]

- Peng, P.; Wang, H.; Pi, D.; Wang, E.; Yin, G. Two-layer mass-adaptive hill start assist control method for commercial vehicles. Proc. Inst. Mech. Eng. Part. D J. Automob. Eng. 2020, 234, 438–448. [Google Scholar] [CrossRef]

| Parameters | Symbol | Value | Parameters | Symbol | Value |

|---|---|---|---|---|---|

| Bus Mass (kg) | - | time-delay constant of EM (s) | 0.5 | ||

| Curb Mass (kg) | 12,200 | output speed of EM (rpm) | - | ||

| Gross Mass (kg) | 18,000 | output speed of EM (rad/s) | - | ||

| Frontal Area (m2) | 8.98 | Final drive ratio | 4.50 | ||

| Air Resistance Coefficient | 0.65 | Gear ratio | [2.60, 1] | ||

| Road resistance coefficient | 0.125 | Transmission efficiency | 0.85 | ||

| Tire radius (m) | 0.502 | output power of battery (kW) | - | ||

| rated/peak power of EM (kW) | 80/160 | Voltage of Battery (V) | - | ||

| rated/peak torque of EM (Nm) | 500/1100 | internal resistance (Ω) | - | ||

| desired torque of EM (Nm) | - | Capacity of Battery (A·h) | 348 | ||

| regenerative torque of EM(Nm) | - | State of Charge of Battery | - |

| Parameters | Symbol | Value |

|---|---|---|

| Predictive horizon | P | 8 |

| Control horizon | m | 1 |

| Optimal distance efficient | α | 0.4 |

| Distance cost efficient Ⅰ | k1 | 200 |

| Distance cost efficient Ⅱ | k2 | 100 |

| Distance cost efficient Ⅲ | k3 | 1000 |

| Speed cost efficient | k4 | 50 |

| Acceleration cost efficient | k5 | 100 |

| Jerk cost efficient | k6 | 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.-X.; Peng, Q.; Zang, X.-L.; Xue, Q.-F. Adaptive Cruise Control for Intelligent City Bus Based on Vehicle Mass and Road Slope Estimation. Appl. Sci. 2021, 11, 12137. https://doi.org/10.3390/app112412137

Wang F-X, Peng Q, Zang X-L, Xue Q-F. Adaptive Cruise Control for Intelligent City Bus Based on Vehicle Mass and Road Slope Estimation. Applied Sciences. 2021; 11(24):12137. https://doi.org/10.3390/app112412137

Chicago/Turabian StyleWang, Fei-Xue, Qian Peng, Xin-Liang Zang, and Qi-Fan Xue. 2021. "Adaptive Cruise Control for Intelligent City Bus Based on Vehicle Mass and Road Slope Estimation" Applied Sciences 11, no. 24: 12137. https://doi.org/10.3390/app112412137