Evaluation of Jatropha curcas and Pistachio Shell Particles as Modifier for Asphalt Binder

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Methods

Materials

2.2. Preparation of Asphalt Binder

2.3. Asphalt Binders Characterization

3. Results and Discussion

3.1. Physical Properties

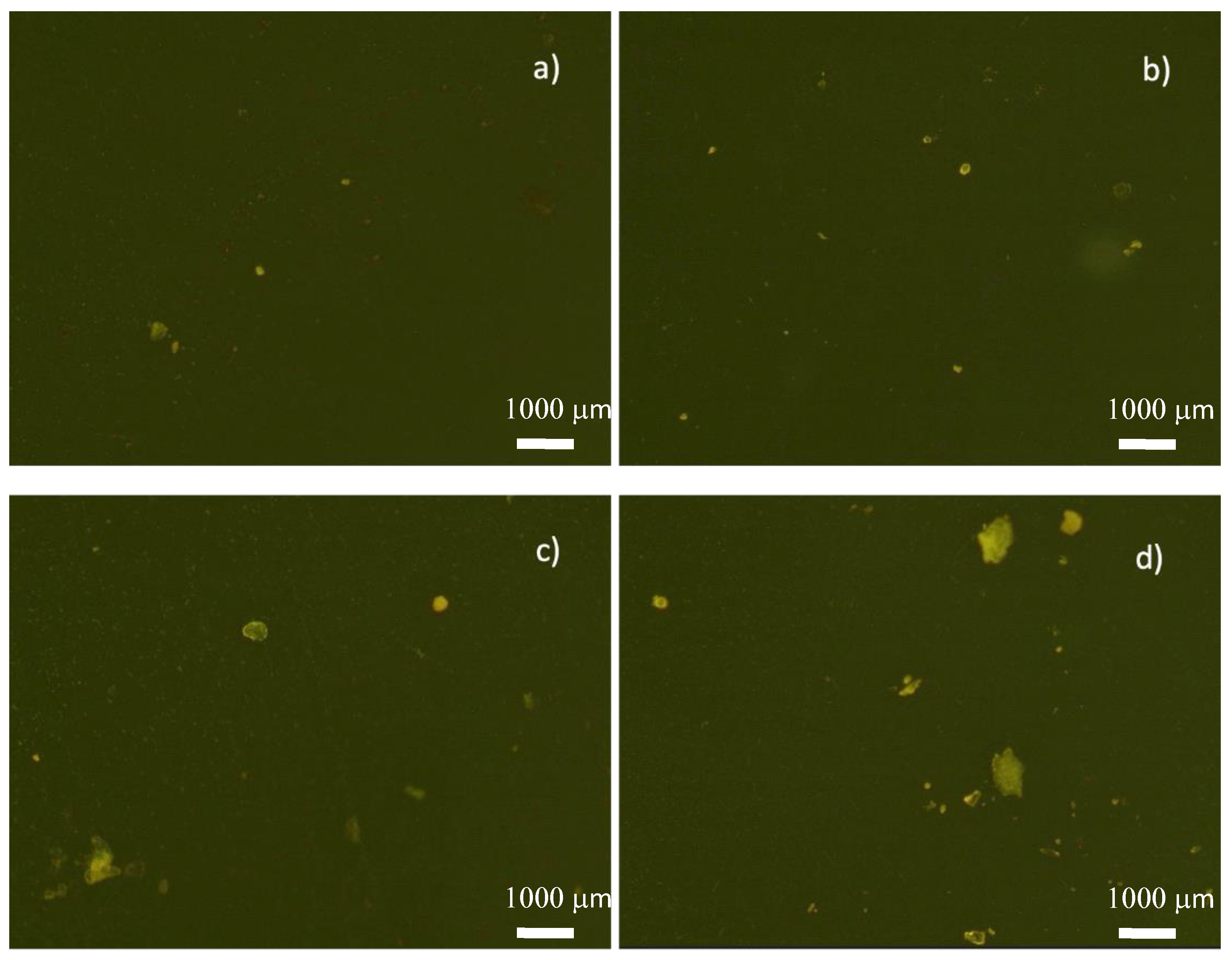

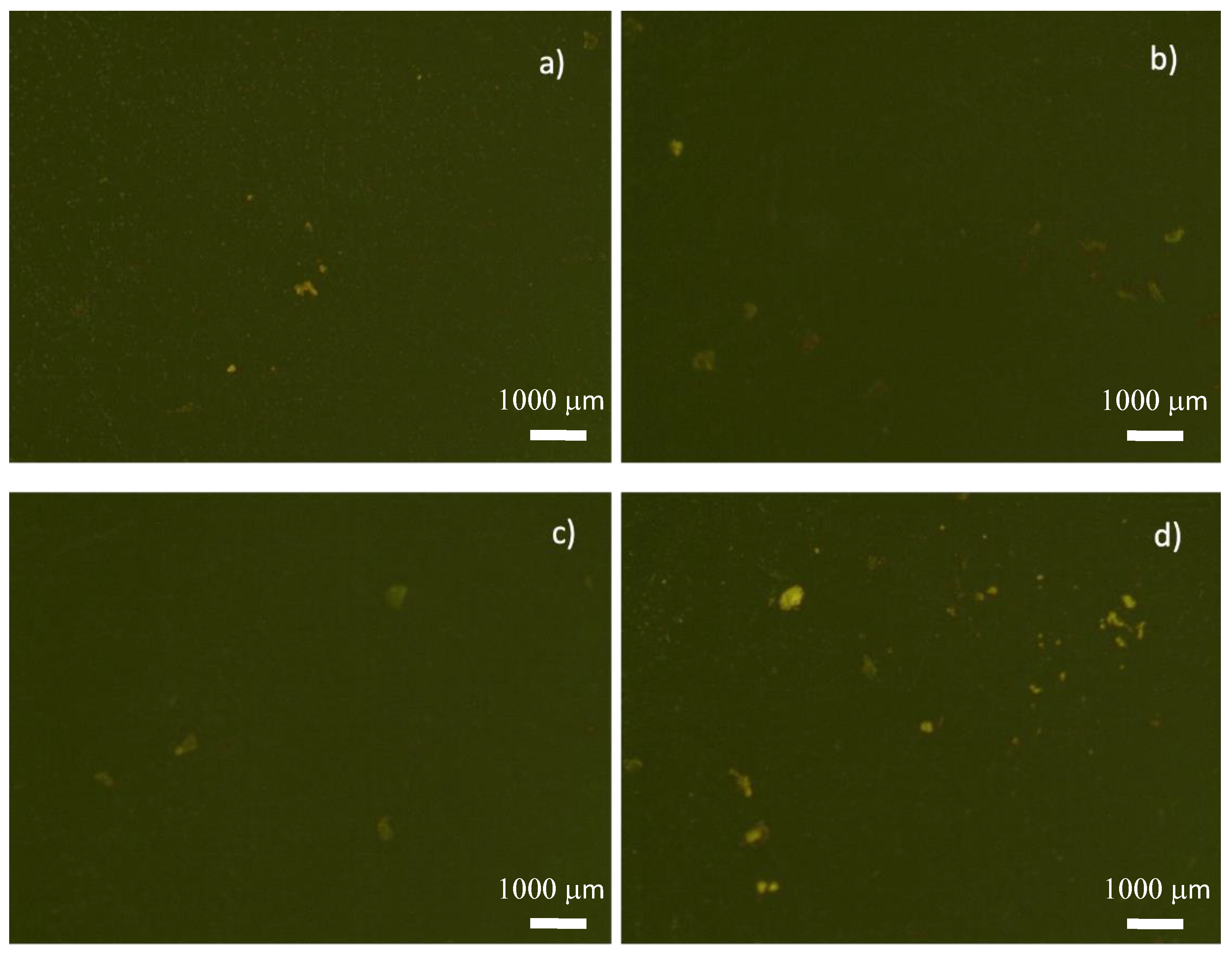

3.2. Fluorescence Microscopy

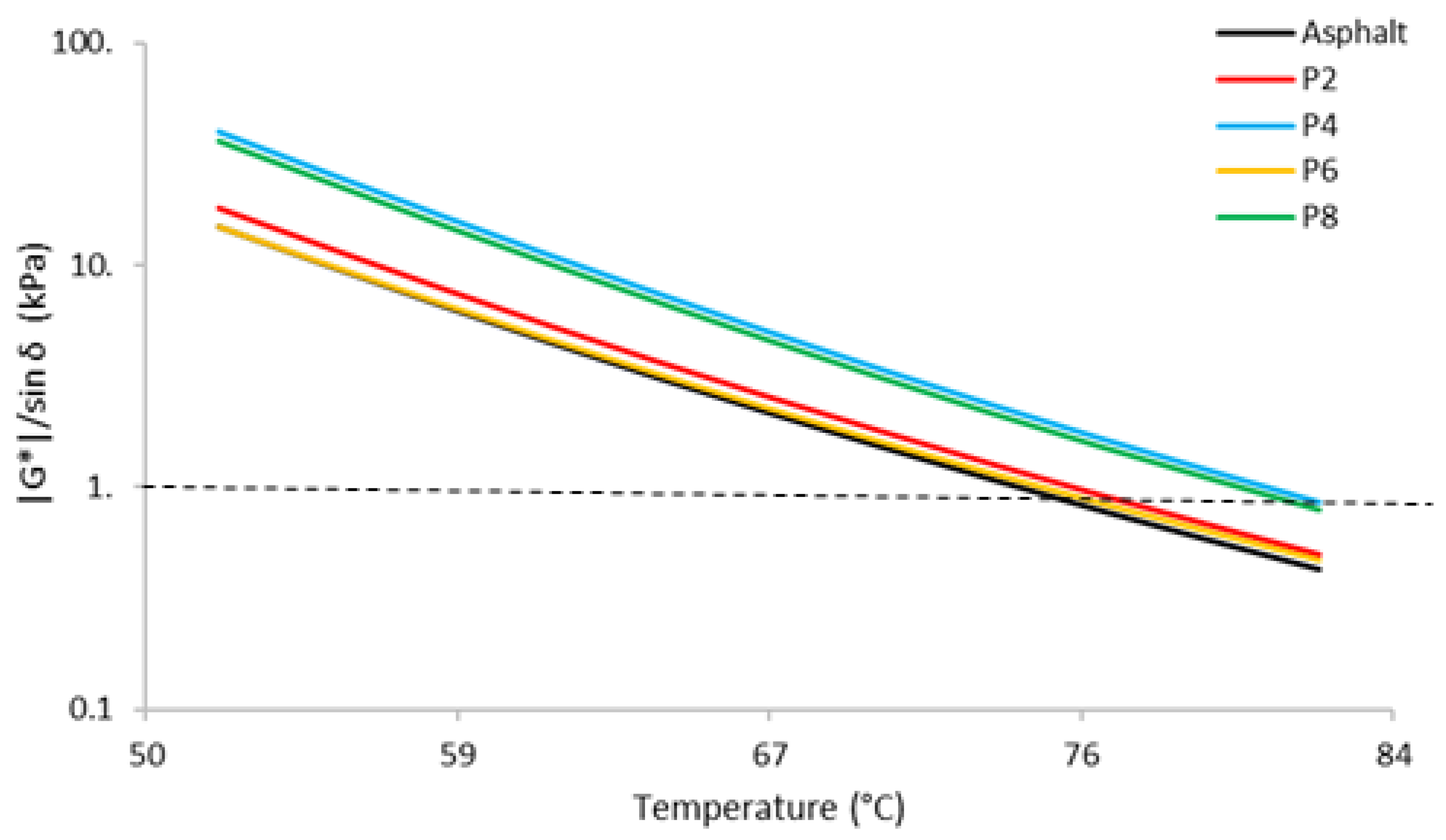

3.3. Rheology

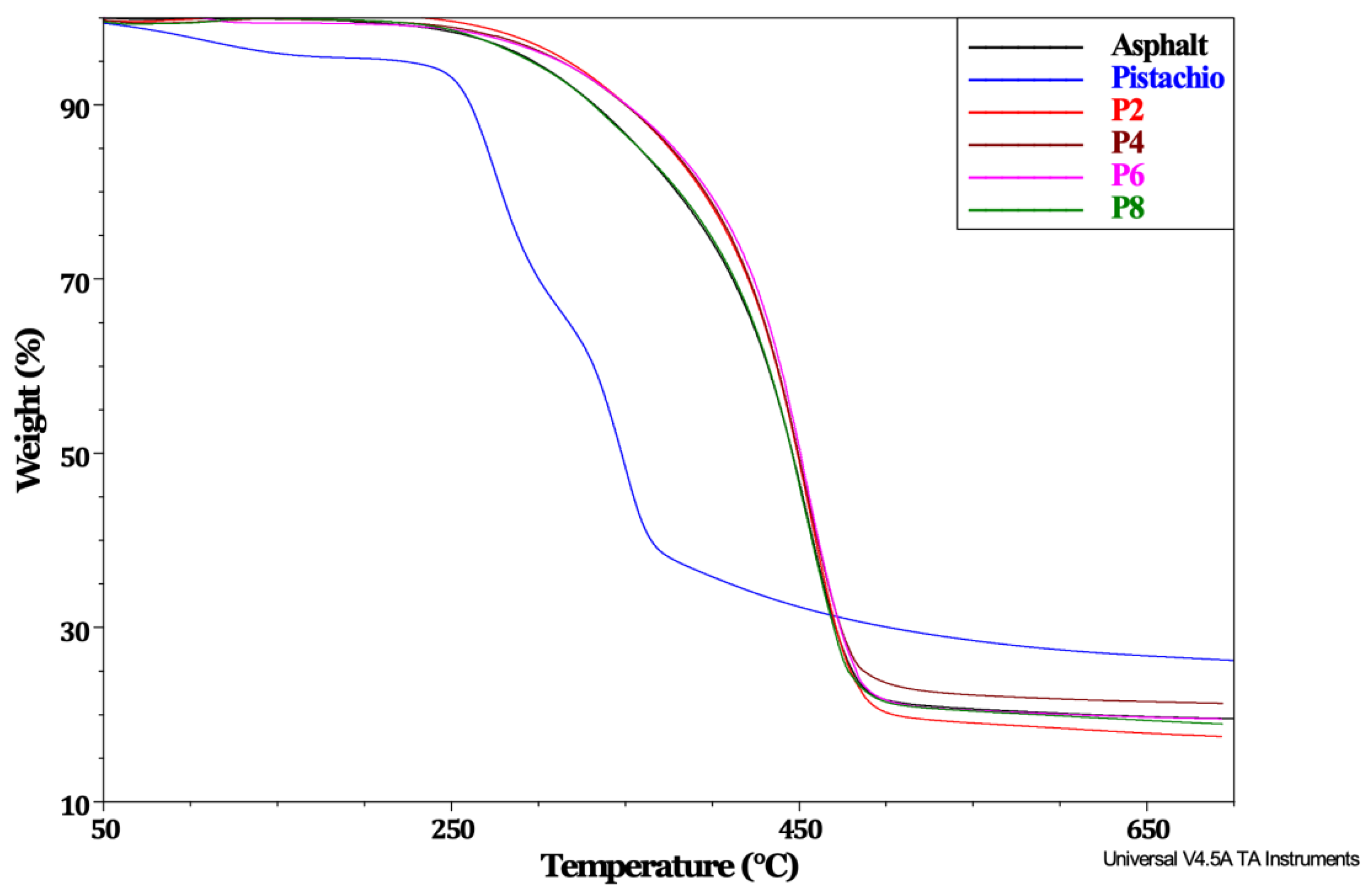

3.4. Thermal Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fareed, A.; Zaidi, S.B.A.; Ahmad, N.; Hafeez, I.; Ali, A.; Ahmad, M.F. Use of agricultural waste ashes in asphalt binder and mixture: A sustainable solution to waste management. Constr. Build. Mater. 2020, 259, 120575. [Google Scholar] [CrossRef]

- Caro, S.; Vega, N.; Husserl, J.; Alvarez, A.E. Studying the impact of biomodifiers produced from agroindustrial wastes on asphalt binders. Constr. Build. Mater. 2016, 126, 369–380. [Google Scholar] [CrossRef]

- Hossain, Z.; Rashid, F.; Mahmud, I.; Rahaman, M.Z. Morphological and nanomechanical characterization of industrial and agricultural waste—Modified asphalt binders. Int. J. Geomech. 2017, 17, 04016084. [Google Scholar] [CrossRef]

- Han, Z.; Sha, A.; Tong, Z.; Liu, Z.; Gao, J.; Zou, X.; Yuan, D. Study on the optimum rice husk ash content added in asphalt binder and its modification with bio-oil. Const. Build. Mater. 2017, 147, 776–789. [Google Scholar] [CrossRef]

- Mistry, R.; Karmakar, S.; Kumar Roy, T. Experimental evaluation of rice husk ash and fly ash as alternative fillers in hot-mix asphalt. Road Mater. Pave. Desig. 2019, 20, 979–990. [Google Scholar] [CrossRef]

- Arabani, M.; Tahami, S.A. Assessment of mechanical properties of rice husk ash modified asphalt mixture. Constr. Build. Mater. 2017, 149, 350–358. [Google Scholar] [CrossRef]

- Ameli, A.; Babagoli, R.; Norouzi, N.; Jalali, F.; Mamaghani, F.P. Laboratory evaluation of the effect of coal waste ash (CWA) and rice husk ash (RHA) on performance of asphalt mastics and Stone matrix asphalt (SMA) mixture. Constr. Build. Mater. 2020, 236, 117557. [Google Scholar] [CrossRef]

- Jeffry, S.N.A.; Jaya, R.P.; Manap, N.; Miron, N.A.; Hassan, N.A. The influence of coconut shell as coarse aggregates in asphalt mixture. In Key Engineering Materials; Trans Tech Publications Ltd.: Zurich, Switzerland, 2016; Volume 700, pp. 227–237. [Google Scholar]

- Al-Mansob, R.A.; Ismail, A.; Algorafi, M.A.; Hafezi, M.H.; Baghini, M.S. Comparison between mixtures of asphalt with Palm Oil Shells and coconut Shells as additives. J. Kejuruter. 2013, 25, 25–31. [Google Scholar] [CrossRef]

- Jeffry, S.N.A.; Jaya, R.P.; Hassan, N.A.; Yaacob, H.; Mirza, J.; Drahman, S.H. Effects of nanocharcoal coconut-shell ash on the physical and rheological properties of bitumen. Constr. Build. Mater. 2018, 158, 1–10. [Google Scholar] [CrossRef]

- Maharaj, R.; Ali, R.; Ramlochan, D.; Mohamed, N. Utilization of coir fibre as an asphalt modifier. Prog. Rubber Plast. Recycl. Tech. 2019, 35, 59–74. [Google Scholar] [CrossRef]

- Yacoob, H.; Jaya, R.P.; Madzaili, A.H.; Hassan, N.A.; Hainin, M.R.; Nazri, F.M. Stability properties of asphalt mixture incorporating coconut shell. J. Fund. Appl. Sci. 2017, 9, 16–24. [Google Scholar] [CrossRef] [Green Version]

- Ting, T.L.; Jaya, R.P.; Hassan, N.A.; Yaacob, H. Resilient modulus of double layer porous asphalt: Application of alkali treated coconut shell and fiber as aggregate replacement. Malays. J. Civ. Eng. 2017, 29, 187–194. [Google Scholar]

- Nejres, A.M.; Mustafa, Y.F.; Aldewachi, H.S. Evaluation of natural asphalt properties treated with egg shell waste and low density polyethylene. Int. J. Pavement Eng. 2020, 2020, 1–7. [Google Scholar] [CrossRef]

- Razzaq, A.K.; Yousif, R.A.; Tay, S.A. Characterization of hot mix asphalt modified by egg shell powder. Int. J. Eng. Res. Tech. 2018, 11, 481–492. [Google Scholar]

- Zofka, A.; Yut, I. Investigation of rheology and aging properties of asphalt binder modified with waste coffee grounds. Transp. Resear. E-Circ. 2012, 2012, 61–72. [Google Scholar]

- Arabani, M.; Esmaaeli, N. Laboratory evaluation on effect of groundnut shell ash on performance parameters of asphalt binder and mixes. Road Mater. Pave. Desig. 2020, 21, 1565–1587. [Google Scholar] [CrossRef]

- Nciri, N.; Shin, T.; Lee, H.; Cho, N. Potential of waste oyster shells as a novel biofiller for hot-mix asphalt. Appl. Sci. 2018, 8, 415. [Google Scholar] [CrossRef] [Green Version]

- Kuo, W.T.; Wang, H.Y.; Shu, C.Y.; Su, D.S. Engineering properties of controlled low-strength materials containing waste oyster shells. Constr. Build. Mater. 2013, 46, 128–133. [Google Scholar] [CrossRef] [Green Version]

- Nwaobakata, C.; Eluozo, S.N. Predicting the performance rate of calm shell ash application in asphalt for flexible pavement. World 2015, 1, 1–8. [Google Scholar]

- Lv, S.; Xia, C.; Yang, Q.; Guo, S.; You, L.; Guo, Y.; Zheng, J. Improvements on the high-temperature stability, rheology, and stiffness performance of asphalt binder modified with waste crayfish shell powder. J. Clean. Prod. 2020, 264, 121745. [Google Scholar] [CrossRef]

- Açıkalın, K.; Karaca, F.; Bolat, E. Pyrolysis of pistachio shell: Effects of pyrolysis conditions and analysis of products. Fuel 2012, 95, 169–177. [Google Scholar] [CrossRef]

- Tekin, İ.L.K.E.R.; Dirikolu, İ.; Gökçe, H.S. A regional supplementary cementitious material for the cement industry: Pistachio shell ash. J. Clean. Prod. 2020, 2020, 124810. [Google Scholar] [CrossRef]

- Ewunie, G.A.; Morken, J.; Lekang, O.I.; Yigezu, Z.D. Factors affecting the potential of Jatropha curcas for sustainable biodiesel production: A critical review. Renew. Sust. Energy Rev. 2020, 137, 110500. [Google Scholar] [CrossRef]

- Zhang, R.; You, Z.; Wang, H.; Ye, M.; Yap, Y.K.; Si, C. The impact of bio-oil as rejuvenator for aged asphalt binder. Constr. Build. Mater. 2019, 196, 134–143. [Google Scholar] [CrossRef]

- Fu, H.; Xie, L.; Dou, D.; Li, L. Storage stability and compatibility of asphalt binder modified by SBS graft copolymer. Constr. Build. Mater. 2007, 21, 1528–1533. [Google Scholar] [CrossRef]

- Newman, J.K. Dynamic shear rheological properties of polymer-modified asphalt binders. J. Elastomers Plast. 1998, 30, 245–263. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C.; Zhang, Y. The research for SIS compound modified asphalt. Mater. Chem. Phys. 2018, 205, 44–54. [Google Scholar] [CrossRef]

- Alsaadi, M.; Erklig, A.; Albu-khaleefah, K. Effect of Pistachio Shell Particle Content on the Mechanical Properties of Polymer Composite. Arabic J. Sci. Eng. 2018, 43, 4689–4696. [Google Scholar] [CrossRef]

- Wever, D.Z.; Heeres, H.J.; Broekhuis, A. Characterization of Physic nut (Jatropha curcas L.) shells. Biomass Bioenergy 2012, 37, 177–187. [Google Scholar] [CrossRef]

- Sengoz, B.; Isikyakar, G. Analysis of styrene–butadiene–styrene polymer modified bitumen using fluorescent microscopy and conventional test methods. J. Hazard. Mater. 2008, 150, 424–432. [Google Scholar] [CrossRef]

- Scicharoenchaikul, V.; Atong, D. Thermal decomposition study on Jatropha curcas L. waste using TGA and fixed bed reactor. J. Anal. Appl. Pyrolysis 2009, 85, 155–162. [Google Scholar] [CrossRef]

- Nciri, N.; Shin, T.; Kim, N.; Caron, A.; Ben Ismail, H.; Cho, N. Towards the Use of Waste Pig Fat as a Novel Potential Bio-Based Rejuvenator for Recycled Asphalt Pavement. Materials 2020, 13, 1002. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Açıkalın, K. Pyrolytic characteristics and kinetics of pistachio shell by thermogravimetric analysis. J. Therm. Anal. Calorim. 2012, 109, 227–235. [Google Scholar] [CrossRef]

| Waste Material | Function | Phase | Findings | Reference |

|---|---|---|---|---|

| Sugarcane bagasse, rice husk, and corncobs | Additive | Mixture | Improves the chemical properties and the adhesive bond between the binder and the aggregates | Caro et al. [2] |

| Rice husk ash | Additive | Mixture | Causes significant changes in morphology, and found that the dissipation energy of the binder is related to its adhesive properties | Hossain et al. 2017 [3] |

| Rice husk and bio-oil | Additive | Mixture | Improves thermal sensitivity and the adhesive force between binder and the aggregates with 4% by wt. | Han et al. 2017 [4] |

| Rice husk ash | Substitute of filler | Mixture | Good compatibility between asphalt and rice husk particles, improving the Marshall quotient | Mistry et al. 2019 [5] |

| Rice husk | Additive | Mixture | Improves the Marshall stability, stiffness modulus, rutting resistance, and fatigue behavior | Arabani and Tahami, 2017 [6] |

| Rice husk and coal waste | Substitute of filler | Mixture | Rheological data indicate that the asphalt deformation was reduced. | Ameli et al. 2020 [7] |

| Coconut shell | Aggregate | Mixture | Marshall stability improved with 5% by wt. and increased of resilient modulus, stiffness, and tensile strength | Jeffry et al. 2016 [8] |

| Coconut shell and palm oilshell | Additive | Mixture | Coconut shell is better additive than palm oil shell, showing an improving resilient modulus | Al-Mansob et al. 2013 [9] |

| Nanocharcoal coconut shell | Additive | Binder | Improvement in penetration, softening point, viscosity, and rheology. | Jeffry et al. 2018 [10] |

| Coconut fiber | Additive | Mixture | Enhancement of the rheological behavior of asphalt mixtures in terms of phase angle (δ) and complex modulus (G*) | Maharaj et al. 2019 [11] |

| Coconut shell | Filler | Binder | Improvement in physical properties: rigidity, stability, and flow behavior. | Yacoob et al. 2017 [12] |

| Coconut shell and coconut fibers | Aggregate | Mixture | Improvement in resilient modulus with 10% of fiber and 15% shell | Ting et al. 2017 [13] |

| Eggshell waste | Additive | Mixture | With eggshell powder, improvement in rheological properties and its softening point, penetration, ductility, and viscosity | Nejres et al. 2020 [14] |

| Eggshell | Additive | Binder | Improvement in stability-flow performance, as well as in penetration, rotation viscosity, and ductility | Razzaq et al. 2018 [15] |

| Coffee grounds | Additive | Binder | There is not a change in temperature susceptibility of base binder, and that served as a solvent rather than as an antioxidant | Zofka and Yut 2012 [16] |

| Peanut shell | Additive | Binder | 10% by wt. of peanut shell enhances the softening point, viscosity, penetration, ductility, fatigue, and low-temperature cracking resistance | Arabani and Esmaaeli 2020 [17] |

| Oyster shell | Filler | Binder | Improvement in rheological properties | Nciri et al. 2018 [18] |

| Oyster shell | Aggregate | Binder | This material can be used as proper replacement of sand in formulations of cementitious materials | Kuo et al. 2013 [19] |

| Clam shell | Filler | Mixture | Reduces the tensile strain, which implies a favorable fatigue life and enhanced stiffness | Nwaobakata et al. 2015 [20] |

| Crayfish shell waste | Filler | Binder | Improvement in the softening point and penetration index, and asphalt rutting resistance | Lv et al. 2020 [21] |

| Sample | Softening Point R and B (°C) | Phase Separation R and B (°C) | Rotational Viscosity @135 °C, (cP) | Rotational Viscosity @160 °C, (cP) | Rotational Viscosity @190 °C, (cP) |

|---|---|---|---|---|---|

| Asphalt | 48.25 | 0 | 383.2 | 126.7 | 47.2 |

| J2 | 52.75 | 1.8 | 431.0 | 140.1 | 50.0 |

| J4 | 50.75 | 1.5 | 447.6 | 146.8 | 54.6 |

| J6 | 51.0 | 2.0 | 481.8 | 152.6 | 55.7 |

| J8 | 53.5 | 2.5 | 434.5 | 140.6 | 52.2 |

| P2 | 52.25 | 0 | 449.1 | 144.7 | 51.3 |

| P4 | 50.5 | 0.5 | 456.5 | 143.9 | 52.3 |

| P6 | 53.5 | 1.0 | 448.4 | 141.7 | 52.9 |

| P8 | 51.0 | 1.7 | 433.8 | 138.6 | 51.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Venegas-Martínez, A.; Salazar-Cruz, B.A.; Rivera-Armenta, J.L.; Ramos-Galván, C.E.; Chávez-Cinco, M.Y. Evaluation of Jatropha curcas and Pistachio Shell Particles as Modifier for Asphalt Binder. Appl. Sci. 2021, 11, 1151. https://doi.org/10.3390/app11031151

Venegas-Martínez A, Salazar-Cruz BA, Rivera-Armenta JL, Ramos-Galván CE, Chávez-Cinco MY. Evaluation of Jatropha curcas and Pistachio Shell Particles as Modifier for Asphalt Binder. Applied Sciences. 2021; 11(3):1151. https://doi.org/10.3390/app11031151

Chicago/Turabian StyleVenegas-Martínez, Abraham, Beatriz Adriana Salazar-Cruz, José Luis Rivera-Armenta, Claudia Esmeralda Ramos-Galván, and María Yolanda Chávez-Cinco. 2021. "Evaluation of Jatropha curcas and Pistachio Shell Particles as Modifier for Asphalt Binder" Applied Sciences 11, no. 3: 1151. https://doi.org/10.3390/app11031151