Relationship between Chemical Weathering Indices and Shear Strength of Highly and Completely Weathered Granite in South Korea

Abstract

:1. Introduction

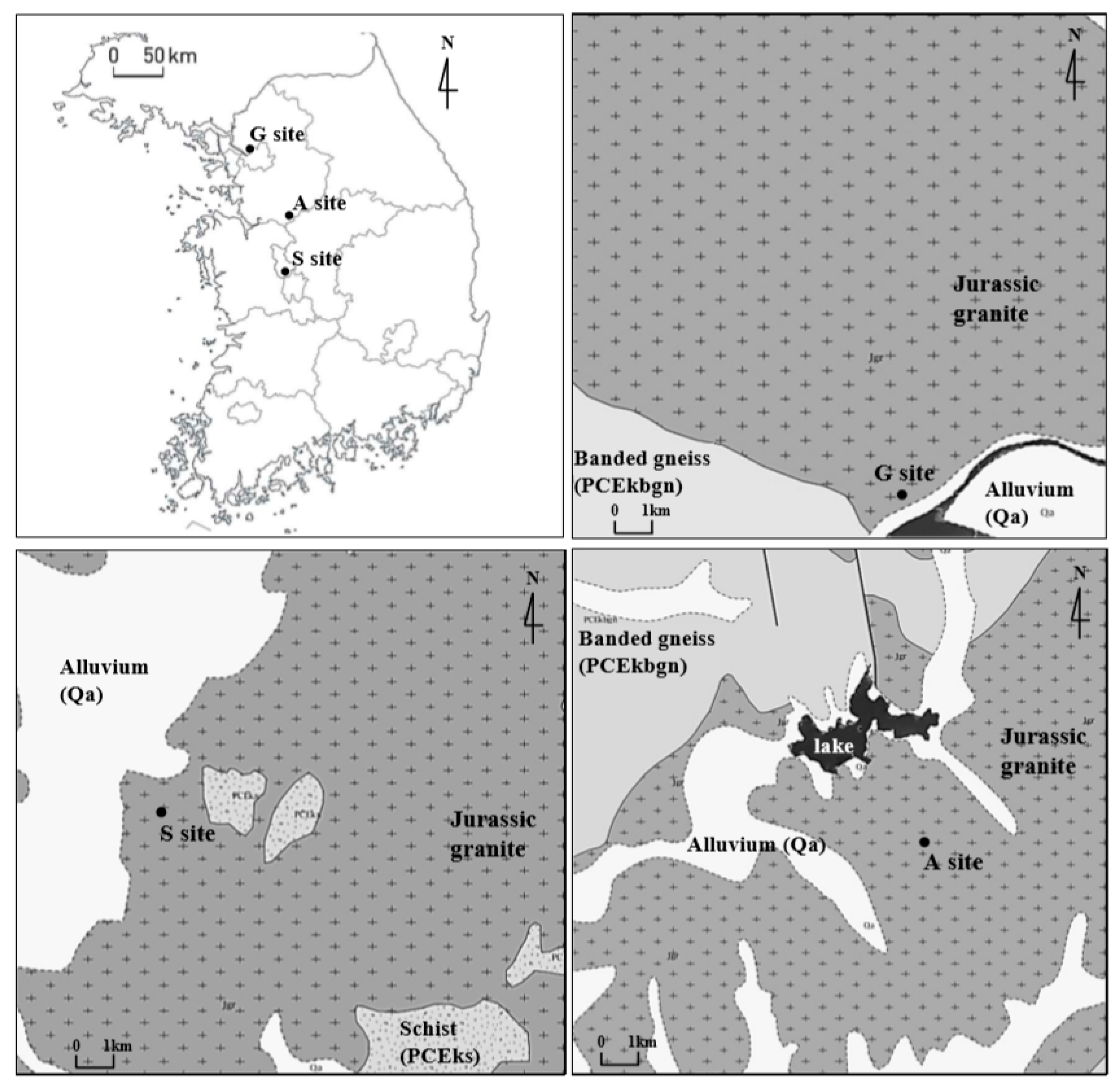

2. Test Sites

3. Test Program and Procedures

3.1. Pressuremeter Tests (PMTs)

3.2. Sampling and Geochemical Analysis

4. Test Results and Discussion

4.1. Shear Strength of Grade IV and V Granite

4.2. Chemical Weathering Indices

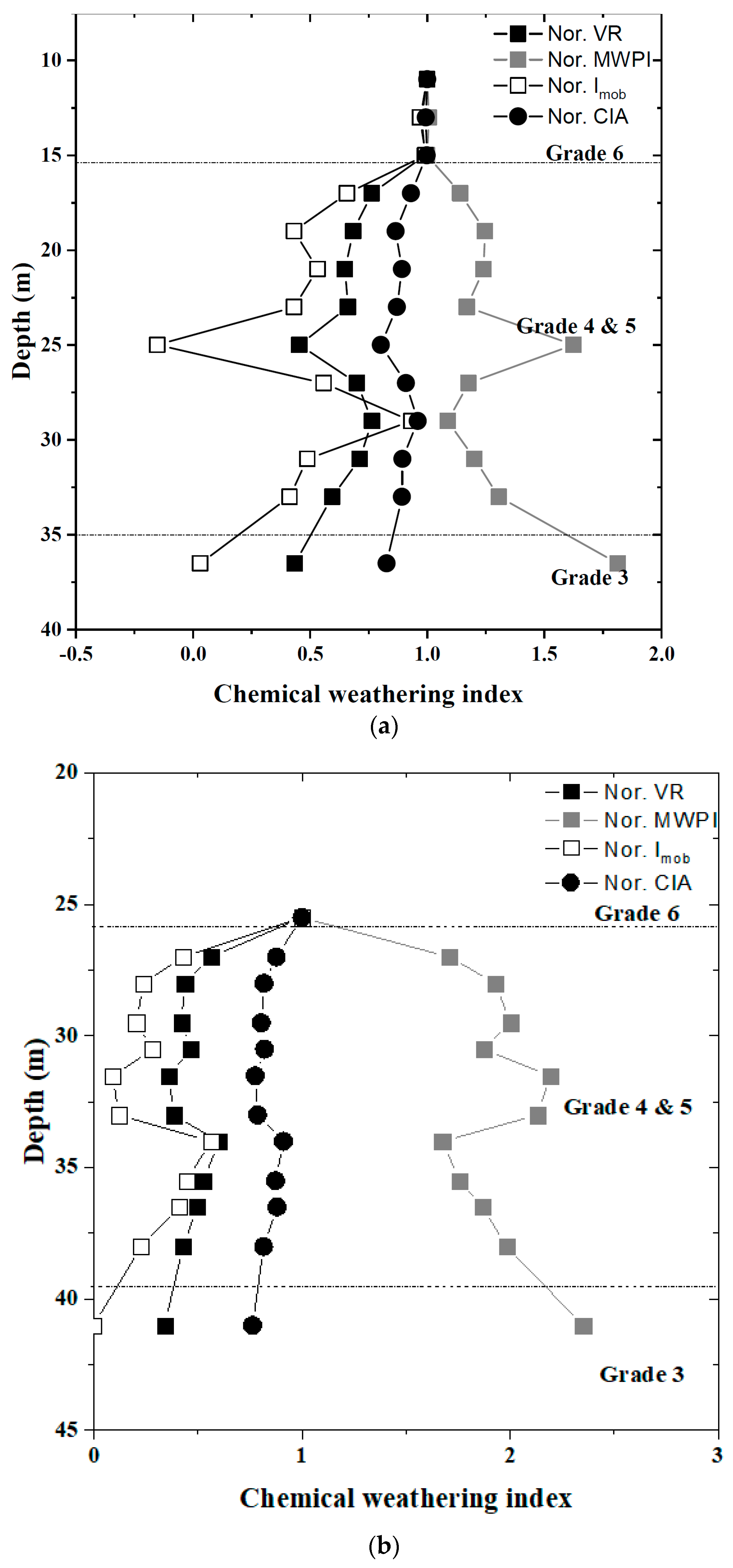

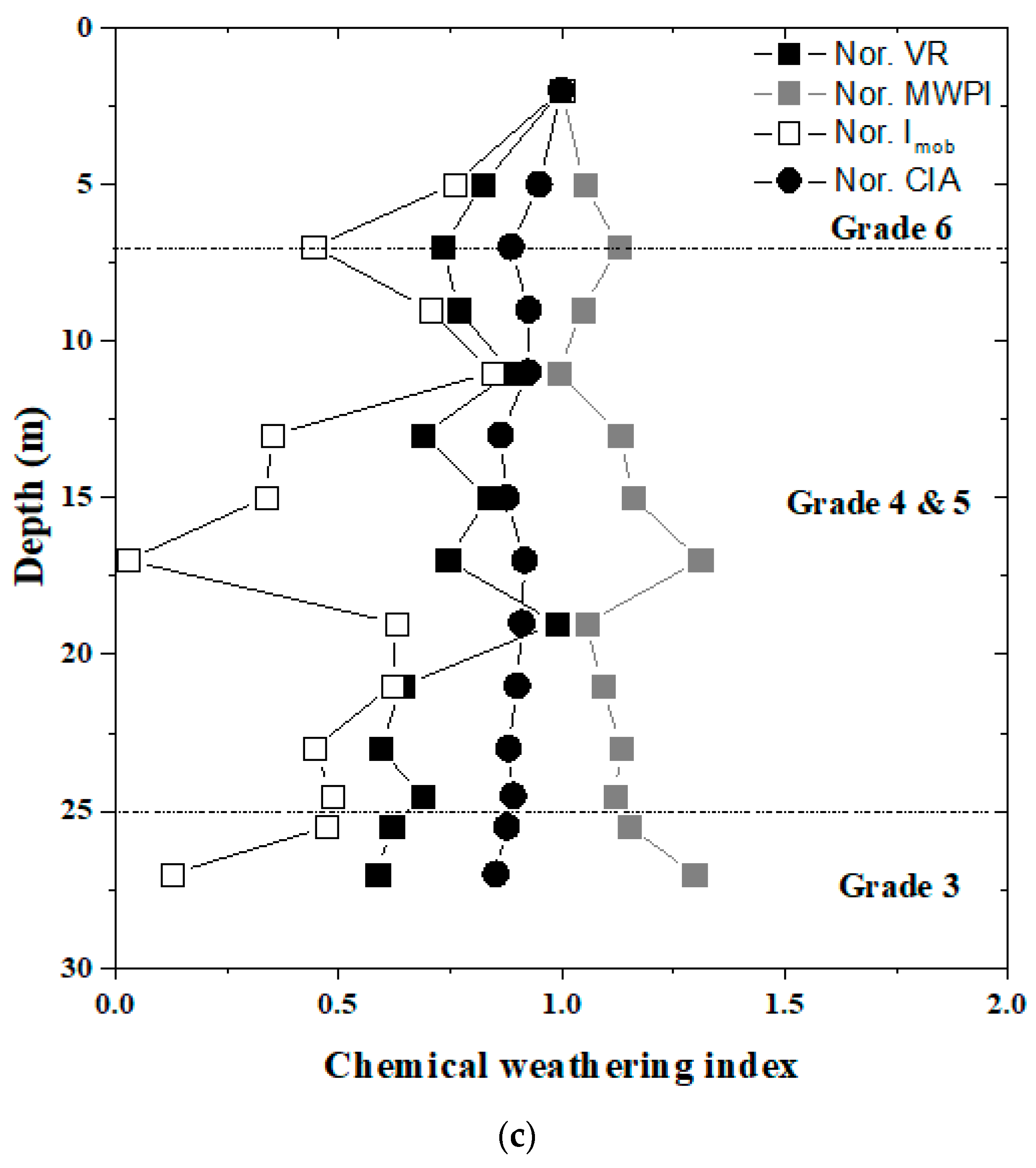

4.3. Correlation Analysis

- (1)

- The friction angles of grade III and IV granite represent site-specific characteristics.

- (2)

- The friction angles of grade III and IV granite affect those of grade IV and V granite.

- (3)

- The friction angles of grade III and IV granite vary with the degree of weathering, which the chemical weathering indices quantitatively represent.

5. Conclusions

- (1)

- By interpreting the results of PMTs, the evaluated friction angles of grade IV and V granite in the test sites are estimated from 33.6° to 52.1°, which is acceptable to the previous studies. However, the friction angles in the particular range decreased with depth, which was different from the general tendency. The weathering profile with depth was studied based on the chemical weathering indices, and the friction angles of grade IV and V granite were evaluated by considering the weathering effect and site-specific characteristics.

- (2)

- The weight percentage of alkaline oxides showed a distinct decrease with weathering intensity; however, the alkali oxides did not show a consistent decreasing tendency with weathering intensity. Especially, the composition of K2O was reduced because of the decomposition of K-feldspar with weathering, but the leached K ions are used to generate illite.

- (3)

- The composition of alkali and alkaline oxides used in the four chemical weathering indices (VR, CIA, Imob, MWPI) was consistently decreased with the change in weathering grade at each test site, so the VR, CIA, Imob, and MWPI has a typical tendency with weathering and can represent the weathering state of grade IV and V granite.

- (4)

- Correlation analysis, including the effect of weathering and site-specific characteristics, was performed to determine the relationship between the chemical weathering indices and friction. The VR, CIA, and Imob have a moderate correlation (R2 > 0.5). Considering the natural variation of the geotechnical properties, the coefficient of determination is acceptable. The highlight of the present study is the simple method to estimate the friction angle of weathered granite for preliminary site investigation, which is more reliable than the SPT.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Geotechnical Control Office (GCO). Geoguide 3 Guide to Rock and Soil Descriptions; The Government of the Hong Kong Special Administrative Region: Hong Kong, 2017. Available online: https://www.cedd.gov.hk/eng/publications/geo/geoguides/geo-g3/index.html (accessed on 13 November 2020).

- Kanji, M.A. Critical issues in soft rocks. J. Rock Mech. Geotech. Eng. 2014, 6, 186–195. [Google Scholar] [CrossRef] [Green Version]

- Benoît, J.; Howie, J.A. A View of Pressuremeter Testing in North America. Soils Rocks 2014, 37, 211–231. [Google Scholar]

- Lee, S.-H.; Baek, S.; Song, Y.-W.; Chung, C.-K. Case Study of Correlation between the SPT- N Value and PMT Results Performed on Weathered Granite Zone in Korea. J. Korean Geotech. Soc. 2019, 35, 15–24. [Google Scholar]

- Schnaid, F.; Ortigao, J.A.R.; Mantaras, F.M.; Cunha, R.P.; MacGregor, I. Analysis of self-boring pressuremeter (SBPM) and Marchetti dilatometer (DMT) tests in granite saprolites. Can. Geotech. J. 2000, 37, 796–810. [Google Scholar] [CrossRef]

- Jacobs, S.A. Insitu Measurement of Florida Limestone Modulus and Strength Properties. Ph.D. Thesis, University of Florida, Gainesville, FL, USA, 2003. [Google Scholar]

- Dafni, J. The Analysis of Weak Rock Using the Pressuremeter. Ph.D. Thesis, University of Washington, Seattle, WA, USA, 2013. [Google Scholar]

- Clarke, B.G.; Smith, A. Self-boring pressuremeter tests in weak rocks. Constr. Build. Mater. 1992, 6, 91–96. [Google Scholar] [CrossRef]

- Bustamante, M.; Gambin, M.; Gianeselli, L. Pile Design at Failure Using the Ménard Pressuremeter: An Up-Date. In Proceedings of the International Foundation Congress & Equipment Expo ‘09, ASCE Geotechnical Special Publication No. 186, Orlando, FL, USA, 15–19 March 2009; pp. 127–134. [Google Scholar]

- Irfan, T.Y. Mineralogy, fabric properties and classification of weathered granites in Hong Kong. Q. J. Eng. Geol. Hydrogeol. 1996, 29, 5–35. [Google Scholar] [CrossRef]

- Arel, E.; Tugrul, A. Weathering and its relation to geomechanical properties of Cavusbasi granitic rocks in Northwestern Turkey. Bull. Eng. Geol. Environ. 2001, 60, 123–133. [Google Scholar] [CrossRef]

- Chiu, C.F.; Ng, C.W.W. Relationships between chemical weathering indices and physical and mechanical properties of decomposed granite. Eng. Geol. 2014, 179, 76–89. [Google Scholar] [CrossRef]

- Kim, S.; Park, H.-D. The relationship between physical and chemical weathering indices of granites around Seoul, Korea. Bull. Eng. Geol. Environ. 2003, 62, 207–212. [Google Scholar] [CrossRef]

- Udagedara, D.T.; Oguchi, C.T.; Gunatilake, A.A.J.K. Combination of chemical indices and physical properties in the assessment of weathering grades of sillimanite-garnet gneiss in tropical environment. Bull. Eng. Geol. Environ. 2017, 76, 145–157. [Google Scholar] [CrossRef]

- Rigopoulos, I.; Tsikouras, B.; Pomonis, P.; Hatzipanagiotou, K. Assessment of the engineering behavior of ultramafic and mafic rocks using chemical indices. Eng. Geol. 2015. [Google Scholar] [CrossRef]

- Lee, S.-H.; Baek, S.-H.; Woo, S.I.; Chung, C.-K. Estimation of in situ geotechnical properties on highly weathered granite using chemical weathering indices. Bull. Eng. Geol. Environ. 2020. [Google Scholar] [CrossRef]

- ASTM D1586. Standard Test Method for Standard Penetration Test (SPT) and Split-Barrel Sampling of Soils; American Society for Testing and Materials: West Conshohocken, PA, USA, 2011. [Google Scholar] [CrossRef]

- Seoul Metropolitan Corporation. Site Investigation Manual; Seoul Metropolitan Government: Seoul, Korea, 2006. [Google Scholar]

- ASTM D4719. Standard Test Methods for Prebored Pressuremeter Testing in Soils; American Society for Testing and Materials: West Conshohocken, PA, USA, 2007. [Google Scholar]

- Gupta, A.S.; Rao, K.S. Weathering indices and their applicability for crystalline rocks. Bull. Eng. Geol. Environ. 2001, 60, 201–221. [Google Scholar] [CrossRef]

- Duzgoren-Aydin, N.; Aydin, A.; Malpas, J. Re-assessment of chemical weathering indices: Case study on pyroclastic rocks of Hong Kong. Eng. Geol. 2002, 63, 99–119. [Google Scholar] [CrossRef]

- Price, J.R.; Velbel, M.A. Chemical weathering indices applied to weathering profiles developed on heterogeneous felsic metamorphic parent rocks. Chem. Geol. 2003, 202, 397–416. [Google Scholar] [CrossRef]

- Vogt, T. Sulitjelmafeltets geologi og petrografi. Nor. Geo-logiske Undersokelse 1927, 121, 1–560. [Google Scholar]

- Vogel, D.E. Precambrian Weathering in Acid Metavolcanic Rocks from the Superior Province, Villebon Township, South-Central Québec. Can. J. Earth Sci. 1975, 12, 2080–2085. [Google Scholar] [CrossRef]

- Nesbitt, H.W.; Young, G.M. Early Proterozoic climates and plate motions inferred from major element chemistry of lutites. Nature 1982, 299, 715–717. [Google Scholar] [CrossRef]

- Baynes, F.J.; Dearman, W.R. The relationship between the microfabric and the engineering properties of weathered granite. Bull. Int. Assoc. Eng. Geol. 1978, 18, 191–197. [Google Scholar] [CrossRef]

- Seo, Y.-S.; Yun, H.-S.; Kim, D.-G.; Kwon, O.-I. Analysis on Physical and Mechanical Properties of Rock Mass in Korea. J. Eng. Geol. 2016, 26, 593–600. [Google Scholar] [CrossRef] [Green Version]

- Menard, L. The Menard Pressuremeter: Interpretation and Application of Pressuremeter Test Results to Foundation Design. Sols Soils 1975, 26, 5–43. [Google Scholar]

- Lee, C.; Cho, T. Effects of Rock Weathering on the Degradation of Engineering Properties. J. Korean Soc. Rock Mech. 2005, 15, 411–424. [Google Scholar]

- Lee, S.-H. Estimation of Geotechnical Properties on Highly and Completely Weathered Granite using Chemical Weathering Index. Ph.D. Thesis, Seoul National University, Seoul, Korea, 2020. [Google Scholar]

- Paikowsky, S.G.; Canniff, M.C.; Lesny, K.; Kisse, A.; Amatya, S.; Muganga, R. LRFD Design and Construction of Shallow Foundations for Highway Bridge Structures; Transportation Research Board: Washington, DC, USA, 2010. [Google Scholar]

| Chemical Weathering Index | Equation | Ideal Tendency with Degree of Weathering |

|---|---|---|

| Vogt’s Ratio, VR [23] | (Al2O3 + K2O)/(MgO + CaO + Na2O) | ↑ |

| Modified Weathering Potential Index, MWPI [24] | 100(K2O + Na2O + CaO + MgO)/(SiO2 + Al2O3 + Fe2O3 + FeO + TiO2 + CaO + Na2O + MgO+ K2O) | ↓ |

| Chemical Index of Alteration, CIA [25] | 100Al2O3/(Al2O3 + CaO + Na2O + K2O) | ↑ |

| Mobiles Index, Imob [10] | (Ifresh − Iweathered)/Ifresh, I = (K2O + Na2O + CaO) | ↑ |

| Property | Weathering Grade | A Site | G Site | S Site | Seo et al. [27] | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | Mean | Max. | Min. | Mean | Max. | Min. | Mean | Max. | Min. | Mean | Max. | ||

| ϕ (deg.) | VI | 34.6 | 35.1 | 35.5 | - * | 31.6 | - | 21.4 | 23.5 | 25.7 | |||

| IV & V | 33.6 | 37.4 | 39.4 | 35.4 | 43.3 | 52.1 | 34.3 | 37.9 | 40.1 | 30 | 33.7 | 55 | |

| III | - | 40.2 | - | - | 55.8 | - | 47.4 | 49.8 | 52.3 | ||||

| Test Site | Weathering Grade | Weight Percentage of Major Oxide | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | TiO2 | Fe2O3 | MgO | CaO | Na2O | K2O | MnO | P2O5 | Loss on Ignition | ||

| A site | VI | 67.24 | 16.81 | 0.62 | 3.84 | 0.51 | 0.65 | 2.08 | 3.71 | 0.05 | 0.24 | 4.22 |

| IV and V | 68.51 | 15.75 | 0.57 | 3.48 | 0.64 | 0.83 | 3.28 | 3.76 | 0.05 | 0.20 | 2.91 | |

| III | 62.58 | 15.81 | 0.54 | 3.98 | 1.89 | 2.63 | 2.2 | 4.29 | 0.05 | 0.16 | 5.85 | |

| G site | VI | 72.82 | 11.58 | 0.33 | 6.58 | 0.80 | 0.46 | 0.74 | 3.59 | 0.36 | 0.08 | 2.65 |

| IV and V | 68.09 | 15.66 | 0.43 | 3.78 | 1.06 | 1.70 | 3.40 | 3.75 | 0.06 | 0.18 | 1.83 | |

| III | 66.89 | 15.94 | 0.45 | 3.69 | 1.40 | 3.32 | 3.52 | 3.55 | 0.06 | 0.17 | 0.82 | |

| S site | VI | 66.45 | 16.17 | 0.56 | 3.69 | 0.88 | 1.58 | 3.16 | 3.82 | 0.06 | 0.19 | 3.46 |

| IV and V | 67.89 | 15.40 | 0.50 | 3.22 | 0.82 | 1.74 | 4.08 | 3.74 | 0.04 | 0.17 | 2.38 | |

| III | 67.54 | 15.10 | 0.52 | 3.51 | 1.15 | 2.84 | 3.72 | 3.23 | 0.05 | 0.15 | 2.22 | |

| Test Site | Weathering Grade | Chemical Weathering Index | |||

|---|---|---|---|---|---|

| VR | MWPI | CIA | Imob | ||

| A site | VI | 3.53 | 6.93 | 66.09 | 0.35 |

| IV and V | 2.37 | 8.59 | 59.01 | 0.17 | |

| III | 1.55 | 12.53 | 54.78 | 0.01 | |

| G site | VI | 3.79 | 5.41 | 66.09 | 0.62 |

| IV and V | 1.77 | 10.35 | 55.27 | 0.19 | |

| III | 1.29 | 12.73 | 50.43 | 0.00 | |

| S site | VI | 1.99 | 9.88 | 57.03 | 0.24 |

| IV and V | 1.65 | 10.76 | 52.53 | 0.13 | |

| III | 1.32 | 11.80 | 50.60 | 0.08 | |

| Weathering Grade | Chemical Weathering Index | |||

|---|---|---|---|---|

| VR | MWPI | CIA | Imob | |

| k | 0.722 | 0.941 | 0.619 | 0.675 |

| R2 | 0.58 | 0.45 | 0.66 | 0.57 |

| Reference | Correlation Equation |

|---|---|

| Peck, Hanson, and Thornburn (PHT) (1974) as mentioned in Kulhawy and Mayne (1990) | |

| Hatanaka and Uchida (1996) | |

| PHT (1974) as mentioned by Wolff (1989) | |

| Mayne et al. (2001) based on data from Hatanaka and Uchida (1996) | |

| Specifications for Highway Bridges (SHB) Japan, JRA (1996) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-H.; Chung, C.-K.; Song, Y.-W.; Woo, S.-I. Relationship between Chemical Weathering Indices and Shear Strength of Highly and Completely Weathered Granite in South Korea. Appl. Sci. 2021, 11, 911. https://doi.org/10.3390/app11030911

Lee S-H, Chung C-K, Song Y-W, Woo S-I. Relationship between Chemical Weathering Indices and Shear Strength of Highly and Completely Weathered Granite in South Korea. Applied Sciences. 2021; 11(3):911. https://doi.org/10.3390/app11030911

Chicago/Turabian StyleLee, Seung-Hwan, Choong-Ki Chung, Young-Woo Song, and Sang-Inn Woo. 2021. "Relationship between Chemical Weathering Indices and Shear Strength of Highly and Completely Weathered Granite in South Korea" Applied Sciences 11, no. 3: 911. https://doi.org/10.3390/app11030911