1. Introduction

The rigid inclusions-reinforced soft soil, known as a piled embankment, were applied for infrastructural and industrial projects such as highway and railway embankments, bridges, retaining walls, wind turbines, oil tanks, and industrial houses. Indeed, traffic vehicles, wave and wind on structures, water levels’ fluctuation inside the ground, earthquake events, storage facilities, and vibrations induce monotonous and cyclic impacts on both the structures and soils. Therefore, the analysis of rigid inclusions-reinforced soils under monotonic and cyclic loading in an important issue in practice.

Several authors experimentally and numerically studied the behavior of rigid inclusions-reinforced soils under load transfer platforms (LTP) subjected to cyclic loadings [

1]. Similarly to the static loading case, the arching effect within the load transfer platform and settlements are interesting to evaluate the cyclic loading response of the rigid inclusions-reinforced soils behavior. The arching effect is a phenomenon that occurs when stresses are transferred from the soil to the adjacent rigid piles. This effect is usually expressed by the pile efficacy and the stress concentration ratio. The pile efficacy (

E) is measured as the ratio of the load transmitted to the pile cap by the total load. The stress concentration ratio (SCR) is equal to the stress transferred to the pile divided by the stress applied to the soft soil. The higher the pile efficacy (or SCR) is, the more the arching effect is. The cumulative settlements of the embankment and soft soil can also be considered for its evaluation.

In the literature, a few experimental works were performed to investigate the cyclic behavior of rigid inclusions-reinforced soft soils [

1]. Some conclusions were figured out. A decrease in the soil arching and cumulative settlements was presented with respect to the load cycles number [

2,

3,

4,

5,

6,

7,

8,

9]. The authors also indicated no existence of the soil arches under a limited number of loading cycles. The higher the frequency, the greater the soil arching reduction. The use of geogrid layers allows us to stabilize the soil arches and reduce the cumulated ground settlements. An increase in the loading amplitude also results in a soil arching decrease. Yu et al. [

5] found an increase in the vertical soft soil stresses with respect to an increase in the load cycles number, and there was nonexistence of the soil arching when the cycles number was superior to 300. Moreover, the soil arches collapsed when the ratio of the embankment height and diameter of the trap door was lower than 3, and vice versa [

4,

10]. Studying the LTP on the rigid inclusion-reinforced compressible soils under 50 load cycles, Houda et al. [

7] found that 50% of the total cumulated settlements took place after the first ten cycles and the pile efficacy increases slightly.

The numerical modeling is an efficient method to simulate rigid inclusion-reinforced soft soils under loading cycles. It also allows extending the parametric studies. Han and Bhandari [

11] figured out the plastic strain cumulation in the embankment. Han et al. [

3] investigated the influence of the dynamic loading amplitude effect and embankment height on the soil arching. Zhuang and Li [

12] showed that the traffic loading type is significantly influent on the soil arching, especially for the embankment settlements. The presence of a geogrid increased the stability of soil arches under dynamic loading [

4]. However, simple constitutive models were often applied for soils, which led to under- or overestimations of the results. The embankments and soft soils were often modelled using linear elasticity or linear elastic with perfectly plastic models combined with damping characteristics [

4,

12,

13,

14,

15]. As a result, the cumulated settlements and stress degradation on piles were not clearly illustrated. When using the CYsoil constitutive model for LTP, Houda et al. [

9] found that the soft soil settlements cumulation and the soil arching slightly decrease under very low frequency cyclic loadings. Nevertheless, underestimations in terms of settlements and pile efficacies were shown.

The Hypoplastic model is an advanced constitutive model. It is normally used for granular soils. Thanks to its

intergranular strain concept, the model can address the microstructure mechanism (rearrangement of particles and deformation of the intergranular interface layers) and the stiffness variation with the strain history [

16]. When considering soils under cyclic loads, the constitutive model can describe the cumulative strain/settlement and stiffness degradation without considering damping parameters. This constitutive model was already used to consider different geotechnical problems subjected to monotonic, cyclic as well as dynamic loads: a building [

17,

18]; shallow foundations [

19,

20]; single vertical piles [

21]; saving-water basins [

22]; unreinforced and reinforced piled embankments [

23].

It can be concluded that most of the numerical studies by the fact that they have used a simplified constitutive model are not able to simulate accurately rigid inclusion-reinforced soils. Using these kind of constitutive models does not allow to accurately give an accurate evolution of the arching effect and the cumulation of settlements under cyclic loading.

The hypoplastic model with the intergranular strain concept can express with more accuracy the cyclic loading of a soil. The proposed numerical modeling is carried out to investigate the behavior of rigid inclusion-improved soft soils under monotonic and cyclic loads in which the HYP model is used for the LTP. The development of soil arching and cumulative settlements are presented. In addition, the proposed numerical results are validated against experimental data and previous numerical results. Parametric studies related to the cyclic loading type, the boundary conditions and the LTP thickness allowed us then to provide more insights into the cyclic behavior of rigid inclusion-reinforced soft soil systems.

2. Experimental Test Description

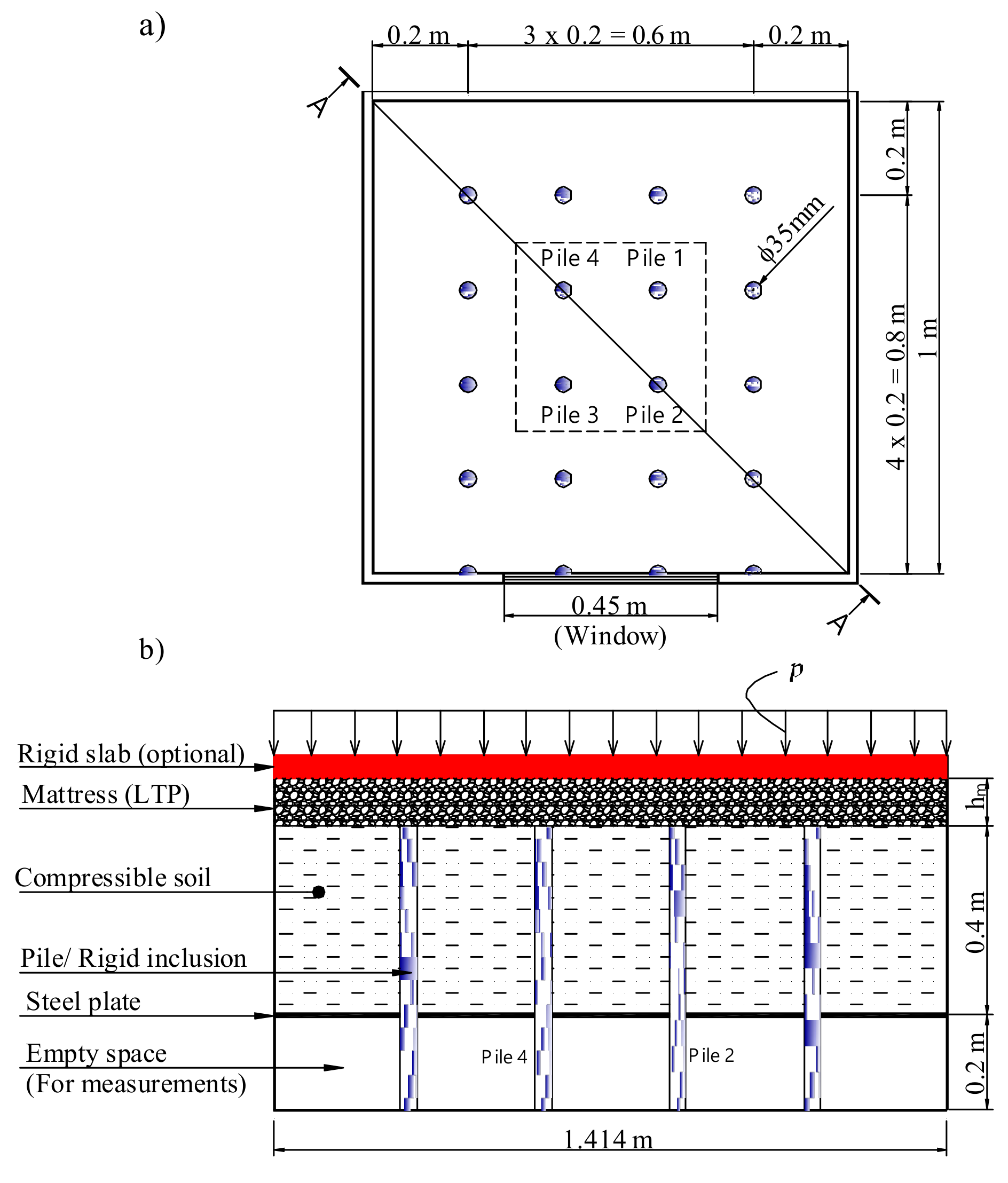

The French national project (ASIRI, 2012 [

24]) studied the soft soil improvement by rigid inclusions technique. However, this research project was mainly concentrated on the system behavior subjected to static loadings. Structures under cyclic loading are commonly encountered in practice. Experiments were done to better understand the soft soil improved by rigid inclusions under monotonic and cyclic loading. A 1:10 scale physical model under normal gravity was set up, in which all the dimensions were reduced 10 times. The detail of the model was presented in Houda (2016) [

6]. A total of 16 aluminum cylinder piles were installed in a square box of 1 × 1 m. The piles had a diameter of 35 mm and were arranged in a square grid of 0.2 × 0.2 m, with an improvement area ratio

a = 2.4%. A 0.4-m-thick layer of soft material was setup, followed by a LTP layer by gravel, as shown in

Figure 1. The different testing cases were created by changing the thickness of LTP and with and without a rigid slab: including a mattress of 100 mm with a rigid slab at the surface (test D100); a mattress of 100 mm without rigid slab at the surface (test R100), and a mattress of 50 mm with a rigid slab at the surface (test D50).

The LTP was made from crushed gravel material, in which the content of the particle diameters ranging from 2 to 5 mm accounted for more than 90% of the total material. Corresponding to respectively void ratios in the range from

emin = 0.52 to

emax = 0.78. The measured unit weights were 16.5 and 14 kN/m

3. Monotonic and cyclic triaxial tests on gravel samples allowed determining the geotechnical properties, listed in

Table 1. The compressible soil was a mixture of fine-grained Fontainebleau sand and expanded polystyrene balls with a water content of

w = 10%. Its geotechnical properties were defined by using oedometer tests. The geotechnical parameters of LTP and compressible soil are shown in

Table 1.

Uniform distributed loads were applied onto the surface of the LTP or slab by a pressured control system via a membrane. Both monotonic and cyclic loading was considered in the tests. Two types of cyclic loading were C1 and C2 as shown in

Figure 2. The detail of the applied cyclic loadings is shown in

Figure 3. The examined testing cases are summarized in

Table 2. During the tests, the force applied onto four inclusion heads were measured by 1-kN force censors. Displacement sensors at three different positions recorded the settlements at the LTP base (

Figure 1).

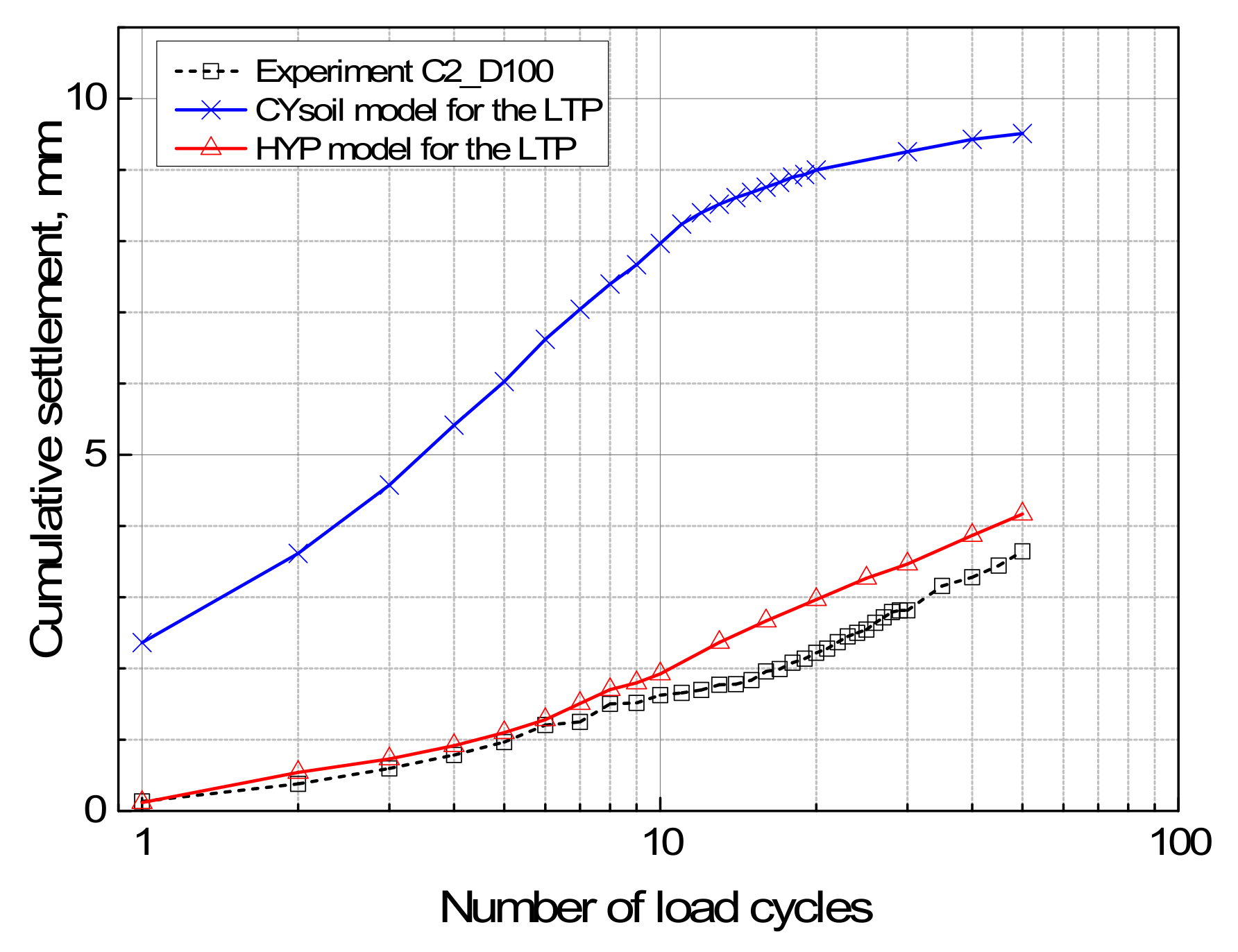

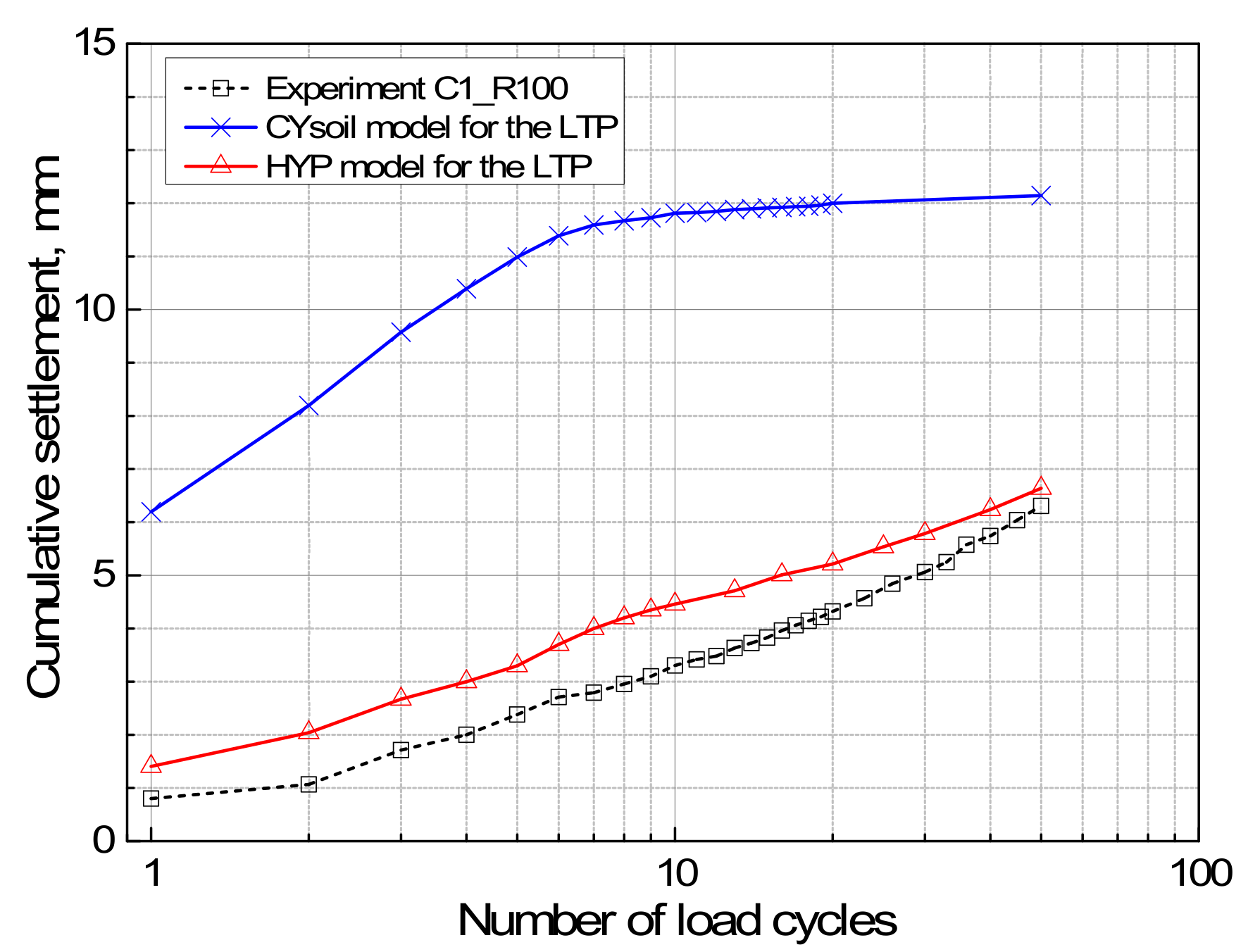

Houda et al. [

9] also carried out numerical simulations to validate the above experimental tests, in which, the LTP and compressible soil were respectively modeled by the CYsoil and MCC models. The finite difference method using the code FLAC3D software was used. Their numerical results were compared with the experimental data. However, as the work considered a simple constitutive model for the LTP, it was not able to rigorously consider the soil behavior under cyclic loading. In this study, a 3D numerical modeling of the rigid inclusion-reinforced compressible soil tests under monotonic and cyclic loading is presented, in which the HYP model is considered to model the effect of cyclic loading.

D Numerical Modeling

In previous researches, a representative elementary volume model, called a quarter of a pile model, was used for investigating the behavior of the piled embankments under cyclic loading since it allowed reducing the calculation time as well as obtaining reliable results [

1,

6,

12,

25,

26,

27,

28,

29,

30]. With respect to the laboratory tests, three geometrical configurations were numerically studied including a mattress of 100 mm over a reinforced soil with/without a slab, and a mattress of 50 mm over a reinforced soil with a rigid slab. The rigid inclusion-reinforced soil is placed on a non-deformable steel plate, the boundary at bottom

z = −0.4 m is therefore restrained in the

z-direction. Due to the symmetry, the vertical boundaries are fixed in their perpendicular directions (

Figure 4). The numerical simulations are performed using the finite element method (FEM) with ABAQUS V6.14 [

31]. The discretized elements size is selected to be lower than one-tenth of the wavelength λ to minimize the distortion effect of the wave [

14]. The quarter pile, soils, and slab were represented by 5742 volumetric 3C8D elements (8-node linear brick) in 3D mesh, as shown in

Figure 5. Concerning the constitutive models, the pile and the slab are represented by the linear elastic model. The compressible soil is modeled by the MCC model. The LTP is characterized by the HYP model. Due to the non-integration of HYP model inside ABAQUS software, the UMAT subroutine of the HYP model developed by Gudehus et al. (2008) was integrated [

17]. The moisture of the compressible soil was kept at 10%, and the loading rate was slowly applied (1 kPa/min). The excess pore water was neglected. The numerical calculations were conducted in drained conditions.

The LTP is made of granular soil, so the HYP model is suggested to use due to its cyclic modeling abilities. The HYP model requires thirteen parameters, as presented in

Table 3. The eight parameters from 1 to 8 are representative of the nonlinear elasto-plastic response. They are determined based on a fitting with experimental triaxial test curves (

Figure 6). The five remaining parameters from 9 to 13 are representative of the

intergranular strain concept which enable modelling the soil cyclic behavior. A set of parameters proposed by Niemunis and Herle [

16] was successfully applied to study the cyclic response of sands [

18,

19,

20,

21,

22]. Due to the insufficient data to calibrate the parameters of the intergranular strain state, the set of parameters given in [

16] was used in the numerical analyses. The initial void ratio of the granular layer is set equal to 0.7. All the HYP model parameters for the LTP are listed in

Table 3. In addition, the MCC model is chosen for the compressible soil. The fitting between experimental and numerical results of the

e-log(

p’) curve of the oedometer test allows determining the model’s parameters (

Figure 7). The parameters of the MCC model are illustrated in

Table 4. The vertical pile’s behavior is assumed to be linearly elastic with the Young’s modulus of

E = 72.5 GPa, the Poisson’s ratio of ν = 0.20 and the unit weight of γ = 27 kN/m

3.

Interfaces between the inclusions and the compressible soil, and between the slab and the LTP were considered in the numerical analyses. Interface elements are characterized by the Coulomb friction model. The coefficient of friction is assumed to be equal to 0.67.

The cases of slab-mattress-reinforced soil (D100 and D50) and mattress-reinforced soil (R100) are analyzed. In each simulation, the loading procedure is conducted by the following steps. Firstly, the initial analysis step is performed, in which the geometry, the material properties, the interfaces, and the boundary conditions are assigned. Then, the geostatic phase is established in which the initial stresses, the initial void ratio, and the self-weight of materials are input. The monotonic loading is subsequently applied to the top of the model. After that, the number of cyclic loading is subjected in two stages: six cycles (50 min/cycle) and then 44 cycles (20 min/cycle). Finally, the process is closed by unloading progress (

Figure 2).

4. Conclusions

A 3D numerical modeling is performed to study the behavior of rigid inclusion-improved soft soils under monotonic and cyclic loads. The HYP constitutive model is used for the LTP. A comparison between numerical results and experimental data is presented in terms of the pile efficacy and cumulative settlements.

For the monotonic loading, an increase in the surcharge results in a settlements increase. There is a rather good agreement between the numerical results and experimental data. The settlements in the numerical modeling using the HYP model are closer to experimental data than the ones using the CYsoil constitutive model.

Studying the system behavior under cyclic loading allows to draw the following conclusions: (1) there is an insignificant decrease in the rigid inclusion head stress and a slight increase in the soft soil stress, which results in the pile efficacy decrease (arching effect) with the number of load cycles; (2) the cyclic loading type does not significantly affect the soil arching; (3) the cumulative settlements at the LTP base under cyclic loading were figured out, but the cumulation per cycle reduces gradually with the load cycles number. It then leads to a rate decrease in the cumulative settlements; (4) over-consolidated soft soils cumulated less settlements than normally consolidated ones under cyclic loading; (5) the cumulative settlements in the slab case are 50% larger than those in the case without slab; (6) a reduction of the mattress thickness results in a slight pile efficacy increase and a small decrease in the cumulative settlements.

The application of the HYP constitutive model for granular soils well address the behavior of rigid inclusion-improved soils under cyclic loads. The cumulative settlements and pile efficacy decrease. The numerical results obtained by using the HYP model are more accurate than those obtained by the CYsoil model.

The hypoplastic model is a sophisticated model that requires many parameters, some of them are not physical ones and some others are connected. In addition, the adjusting procedure for the parameter’s determination requires a lot of procedures and interrelationships. In this study, due to the lack of laboratory tests, some of the required parameters for the intergranular strain concept are assumed. To obtain more accurate results in the numerical analysis, a more accurate calibration of all the input parameters should be done by back analysis of complementary laboratory tests.