To solve the above problems, it is necessary to study technologies of collaborative operation, such as environment perception, task allocation, path planning, formation control, and communication-based on multi-robot architecture. Since each technology does not solve the same agricultural problems, this section first classifies the types of development of these technologies, then describes and reviews each of these cooperative technologies in terms of research methods or problem solving, and finally summarizes their research development status and characteristics.

3.1. Architecture of Agricultural Multiple Robot Systems

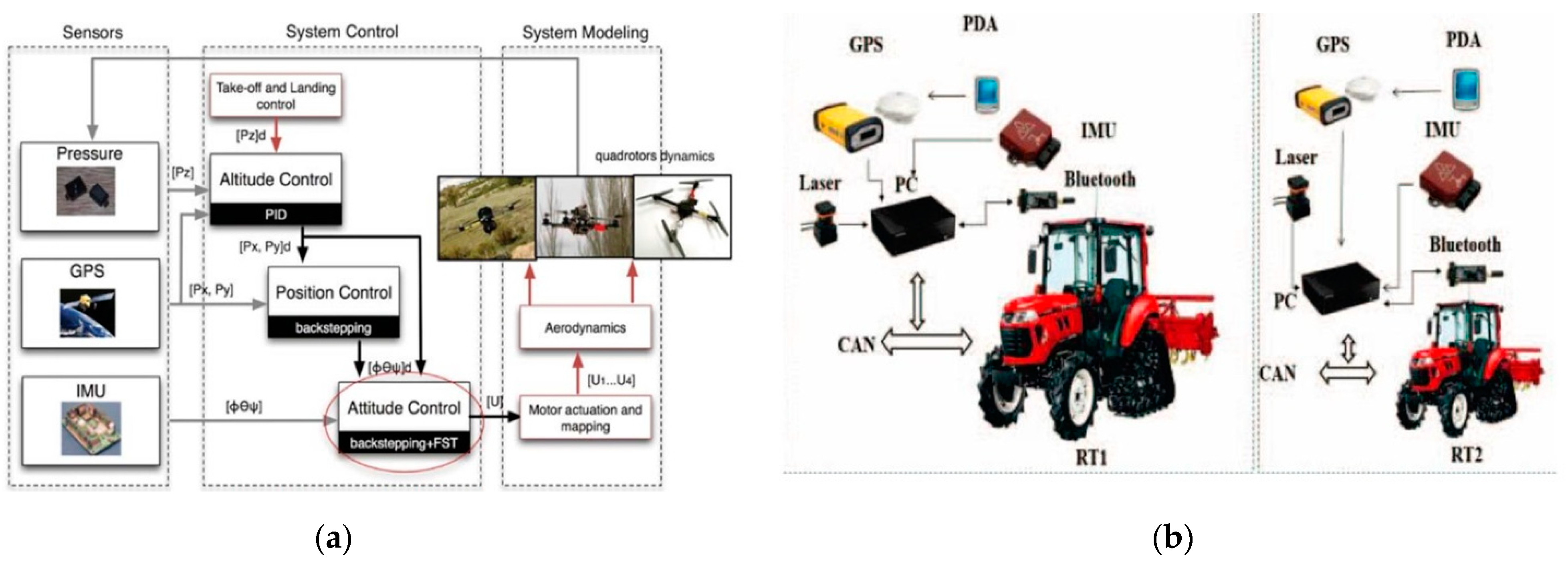

A reasonable architecture can guarantee information flow and control flow in the agricultural multi-robot system and make effective cooperation among multiple robots possible [

22]. At present, the architecture of agricultural multi-robots can be divided into centralized architecture and distributed architecture. It is found that the earliest recorded structure of agricultural multiple robot systems comes from hay harvesting and transportation robots in farmland [

23,

24], for which these multi-robot systems were operated under the principle of centralized architecture. As shown in

Figure 2a, in leader-follower mode, a relatively powerful robot is selected as the “leader” of the swarm robots, performing specific motion planning for the remaining robots after analyzing and processing the sensory information, but these remaining robots are just executors, without the ability to choose their actions or coordinate with each other. Alternatively, as shown in

Figure 2b, in the central controller mode, each robot can perform tasks independently and is commanded by a central controller [

25]. The advantage of this centralized architecture is that the theoretical background is clear, and the implementation is intuitive, but the flexibility, fault tolerance, and adaptability are poor [

26].

Compared with the operating environment of UGVs, the operating area of UAVs has the advantage of no obstacles, so these systems generally adopt the distributed structure [

28]. As shown in

Figure 3, the three UAVs in the multi-robot system carry out agricultural situation monitoring in the individual workspaces independently; each robot of this system had a high degree of autonomous operation ability and can complete a given task according to its aims; robots can communicate with each other, exchange information, and coordinate their behaviors equally and independently to complete a given task [

28]. This structure has strong scalability and certain advantages in real-time operation, fault tolerance, and reliability, etc. [

29] and is suitable for handling tasks related to spatial states [

30]. However, “it costs a lot in terms of the coordination mechanism, such as task allocation and motion planning” [

29].

The centralized architecture that can be divided into a leader and follower robots is suitable for highly coordinated tasks and is advantageous in a fully known environment. The distributed architecture, in which there is no affiliation among robots, is suitable for weakly coordinated tasks and is advantageous in large-scale, complex, and varying environments.

3.3. Multi-Robot Task Allocation

Multi-robot task allocation (MRTA) provides evaluation indicators of a multi-robot system, a task set, and system performance and finds a suitable robot for each subtask to perform, bringing the benefit of a robot system to perform mostly task collection. Thus, the quality of the MRTA results directly affects the efficiency of the entire system and whether each robot of the system can maximize its capabilities [

78].

Solve the MRTA problem [

79] involves many aspects, such as the capability attributes of the system members, the structural attributes of the tasks, the robot coordination mechanism, and the strategy of task allocation [

80]. This approach divides the assignment of agricultural multi-robots into centralized components based on the decision of the central controller in this part.

The centralized allocation means that the leading robot or control center of the system decomposes the global task and then sends the decomposed subtask to each robot according to the corresponding allocation method.

In 2012, reference [

14] reported the work area division and task assignment of two UGVs by a person through remote monitoring based on a citrus orchard map. However, as the number of robots increased, manual task assignment stops when a robot hits a tree or fails to make a reliable turn. Some scholars [

66] solved the manual assignment of tasks to multiple robots from the perspective of dividing maps, namely, as many sub-regions as there are robots needed. The edges of these sub-regions are generated from discrete fruit tree points and K-mean clustering points on the map boundary using an integer programming approach. However, this view is too ideal and does not consider the case where the number of robots is less or more than the total number of tasks.

A similar study on the number of robots over the number of tasks is multiple robots and a small number of refueling stations [

81]. In this reference, an approximate arbitrary time algorithm based on the branch delimitation method was used to obtain the task sequence of multi-robot collaborative refueling. The limit value of the path length distance was first calculated and used as the upper and lower bounds of the algorithm nodes based on the rules for robots walking infield and the total time cost function of refueling and waiting in the queue. Then the optimal solution was obtained by deleting the sub-nodes whose lower limits were greater than or equal to the optimal upper limits during iteration. Simulation experiments showed that the optimal approximate solution on resource utilization can be found by this method, but it is difficult to apply the method to other aspects of agriculture, such as spraying.

A reinforcement learning-based method (Dyna-Q +) was used to find the optimal search path from the current point to the endpoint, that is, multiple robots randomly selected actions (front, back, left, right) and each action was recorded, and the optimal path was obtained by rewarding and punishing the actions selected by the robots according to the presence or absence of obstacles [

62]. Then a weighted graph was used to represent the Gird model, including parameters such as the current position of the robot, the set of grids, and whether there is a path between the grids. The minimum cost time for the UAVs to fly at different speeds under the optimal path was calculated using Dijkstra’s algorithm, and finally, the search space was obtained based on the optimal path and time and allocated to multiple robots in proportion to the size of the space. A reinforcement learning [

82] is a Markovian decision process where the basic idea is all about modeling or fitting a strategy using a function for more complex decision problems. However, the method requires a large number of samples and a long time when used.

Also, multiple robots working in an agricultural environment are often subject to resource-sharing conflicts. For predictable conflicts, relying only on a central task allocation approach to avoid conflicts, the adaptability of multiple robots is very limited, while adding a decision support system (DDS) to provide options for multi-robot collaboration, i.e., identifying problems and building or modifying decision models to avoid resource conflicts based on explicit goals. For example, as shown in

Figure 9, in reference [

58], the authors adopted a central entity (OptiVisor) to build a multi-robot seeding map based on inputs such as the location of static obstacles in a large field, the seeding method, the seed density, the location of the central controller, and the number of robots. Based on this map, the location and density of each seed are precisely located and the sowing task is assigned to multiple robots. When the robot finished the job, the path from the robot location to the Central Logistic Unit (CLU) was recorded and the robot was allowed to return to the CLU. Especially when one or more robots failed, the task of the failed robot was reassigned to the other robots of the failed robot, and the sowing path was updated for these replacement robots. OptiVisor could also stop a robot’s motion when a multi-robot collision is imminent, and define restricted motion areas for the faulty robot. However, this task assignment method was implemented in a simulation environment and needs to be further tested in real applications.

In general, the distributed task allocation method has the feature that each robot does not have global knowledge of the task but calculates and plans individually according to the local information obtained by the sensor. The performance of the whole system not only is closely related to the individual but also depends on the combined effects of individuals [

83].

It was reported in the literature [

84] that when the number of tasks is more than the number of farm machines, the ant colony algorithm can be used to find a suitable task sequence for multiple robots. First, the distance between plots was calculated based on the specified coordinate information of each plot, and the relevant parameters of the ant colony algorithm were set. Then randomly generated the starting points of multiple parcels, according to the state transfer probability formula for path selection, and put the generated path parcels into the forbidden table. Finally, the path distance of the plots was calculated, and the pheromones on the path were continuously updated according to the set rules, and iterations were repeated until the optimal task planning for multiple robots was found. The method is mainly used in simulated farmland environments and has not yet seen the practical application.

In reference [

85], researchers adopted Semantic MozartSpaces to describe a task allocation data model based on a resource description framework (RDF) and SPARQL (a query language and data acquisition protocol developed by the RDF) in task storage where the RDF was used to construct nested blank nodes and SPARQL was used for querying, updating and interactions of the entry. As shown in

Figure 10a, a task was mapped to a nested blank node to generate a semantic tuple (entry) in the task-allocation model. The entry was stored in the task storage with an internal ID that concluded the URL (uniform resource locator). Then, the entry could be selected with a URL according to the relationship between the robot’s function and the task requirement. The results of the simulation experiment suggested that the execution time increases correspondingly with an increasing number of tasks, followed by a gradual decrease in production efficiency. It would be necessary to add new robots temporarily to ensure productivity, but the production cost would also increase, so the tasks need to be set in advance.

As shown in

Figure 10b, researchers developed market and auction-based approaches for task subdivision and allocation based on the Rubinstein negotiation protocol [

28]. The advantage of such a protocol was that the auctioneer robot had to split the task into subtasks during the negotiation. In each round of negotiation, each robot initially started proposing the largest possible task allocation for itself and decreased its offers based on a negotiation of cost functions (discount factors) at each round until the other party indicated acceptance. With distributed task assignment under this protocol, each robot comes with a DDS, and each robot can dynamically adjust to the actual situation to get a suitable task. However, the task allocation result was generally an approximate optimal solution because of the discount factors, such as the area of the mission area, the distance of the robot from the goal, the area beyond the target, and the overlapping work area.

Combined with the above task allocation technology, the research progress of agricultural multi-robots in task allocation technology in the past 10 years is summarized in

Table 4.

It can be seen from

Table 5 that the current task allocation methods for agricultural multi-robots are mainly centralized, and most of them are implemented in the simulation experiment.

The centralized task allocation mainly adopts the integer programming method, which describes the nature of the task allocation problem by establishing the objective function and constraints. Integral programming (IP) and mixed-integer programming (MIP) problems are an important branch in the field of operations research, which includes branch and bound method [

89], cutting plane algorithm [

90], graph theory method, etc [

91]. The idea is to determine the transfer method and transfer relationship from one search point to another, and the result is a unique optimal solution, which is suitable for small scale; when the scale is extended, the computation is considerable and the computation time will be greatly increased [

92]. Thus, the computation of the algorithm grows exponentially with increases in the number of tasks and robots. In general, it is often difficult to meet real-time requirements in task allocation issues.

Distributed task allocation mainly uses a method based on behavioral motivation and a market-based approach. The former applies to multi-robot systems with strong autonomy, but the method has low system allocation efficiency; the latter has a wide range of applications based on the resource optimization configuration idea of economics, but the difficulty of this research method is how to design the negotiation mechanism and reasonably determine the cost-income models of the task [

44].

3.4. Path Planning

Path planning is the fundamental guarantee for multiple robots to accomplish tasks together. This technology refers to using the known static environment information, or the dynamic environment information obtained by the sensor, to autonomously plan a collision-free optimal path for each robot from a known starting point to a target point, which requires not only a single robot to avoid obstacle but also a plan to satisfy collision avoidance among multiple robots [

93]. The path planning methods for single robots to avoid obstacles mainly include traditional methods, intelligent methods, and other methods. The traditional methods include the construction space method, V-Graphic (visibility graph), Voronoi diagram, grid method, A* algorithm, and artificial potential field [

94]. Intelligent methods include the ant colony algorithm, particle swarm algorithm (PSO), reinforcement learning algorithm, immune algorithm, genetic algorithm (GA), neural network, and fuzzy logic algorithm [

95]. Other methods include dynamic programming (DP) and optimal control algorithms. Collision avoidance strategies among multiple robots include the priority method, rate adjustment method, traffic management rule, and consultation method.

The path planning method can be divided into centralized path planning and distributed path planning according to the ability classification of path planning [

96].

The centralized path planning method uses a centralized control unit to plan the optimal path for swarm robots. This method can improve the ability of “close coordination and optimal coordination” among mobile robots [

97]. However, it encounters other problems such as “dimensions”, “computational complexity”, and “non-deterministic polynomial problem (NP) difficulties” with the increase in the number of robots, task difficulty, and space complexity. In particular, the “NP difficulties” problem [

98,

99], in theory, has not yet received a simple or fast solution.

Connecting known path points into a line, which is simulated to a topological model, and letting multiple robots walk along their respective paths is one of the simplest and easiest path planning methods to implement. But, this method requires obtaining accurate known point information in advance, which is a large preliminary job and is not suitable for situations with a large number of robots or a large operating area. A method similar to the point-to-point method is the visible map method, which aims to reduce collisions. That is, the information of the edge projection points of each obstacle is obtained in advance, and the robot free walking path, path points that can be combined or disconnected are represented by edges and nodes, respectively. Then the starting node is connected to the target node, or the starting node is connected to the raised point of each obstacle edge until it reaches the target node, forming a multi-robot walking path. Finally, depending on the size of the robot, the path width is increased or decreased appropriately. Similarly, the workload of measuring points is larger and does not apply when there are more obstacles.

Planning multi-robot paths on mapping is another method of global path planning. For example, in the grid method, the map was divided into multiple grid cells, and the paths were extended in eight directions with each grid cell as the center, and the path segments were formed by connecting the center of the grid vertically and diagonally with the centers of other grid cells. To get the globally optimal path in the grid, the A* algorithm was used to search for the path segment with the lowest travel cost, in which the cost of the free space cell was set to 0, the cost of the cell with obstacles was set to the maximum, and the travel cost was the sum of all grid cells on the travel path segment, and the globally optimal path was set when the sum was the smallest.

Since information about the farmland changes dynamically, multiple robots operating with precision need to re-plan to create multiple paths each time based on different information. This multi-robot path planning problem with time windows has also been solved as a multi-objective optimization problem. As shown in

Figure 11, where a multi-robot system including two aerial robots and three ground robots was jointly developed in Spain and other countries [

49]. This system adopted a centralized control unit to provide global path planning for the multiple robots on a grid map with weed information, which divides the sequence of operations for the multiple robots in advance. The No dominated Sorting Genetic Algorithm II (NSGA-II) algorithm [

100,

101] was then used to coordinate the relationship between the distance of the robot travel path, the number of turns, the number of robots, the amount of weed killer used, and the capacity function to obtain an approximate optimal solution between the time and money spent by the multiple robots and the cost of weed treatment. It is a type of genetic algorithm, which mainly focuses on the simulation of crossover, variation, and hereditary phenomena occurring during natural selection and genetic inheritance, incorporating the natural law of superiority and inferiority, and deriving the candidate solutions for each generation based on the results, and finally deriving the optimal solution from the derived candidate solutions. However, this method is more computationally intensive and the experimental results are not suitable for fields that are unstructured or d fields without a fixed column or row lengths.

The distributed path planning method requires little calculation and is robust but exhibits low efficiency and can provide only a suboptimal solution [

102,

103]. In a fully known environment, it is necessary to consider each robot obstacle avoidance method and collision avoidance strategy among robots [

104], that is, selecting a robot for path planning first, then broadcasting its path to other robots, and finally planning paths of other robots by themselves. However, this method is difficult to achieve [

97] for large numbers of robots. In an unknown environment, the preferred method is to plan a path for each robot to avoid static obstacles based on neglecting the movement of other mobile robots in the environment and then using the multi-robot collision avoidance strategy to solve the conflict problem among mobile robots.

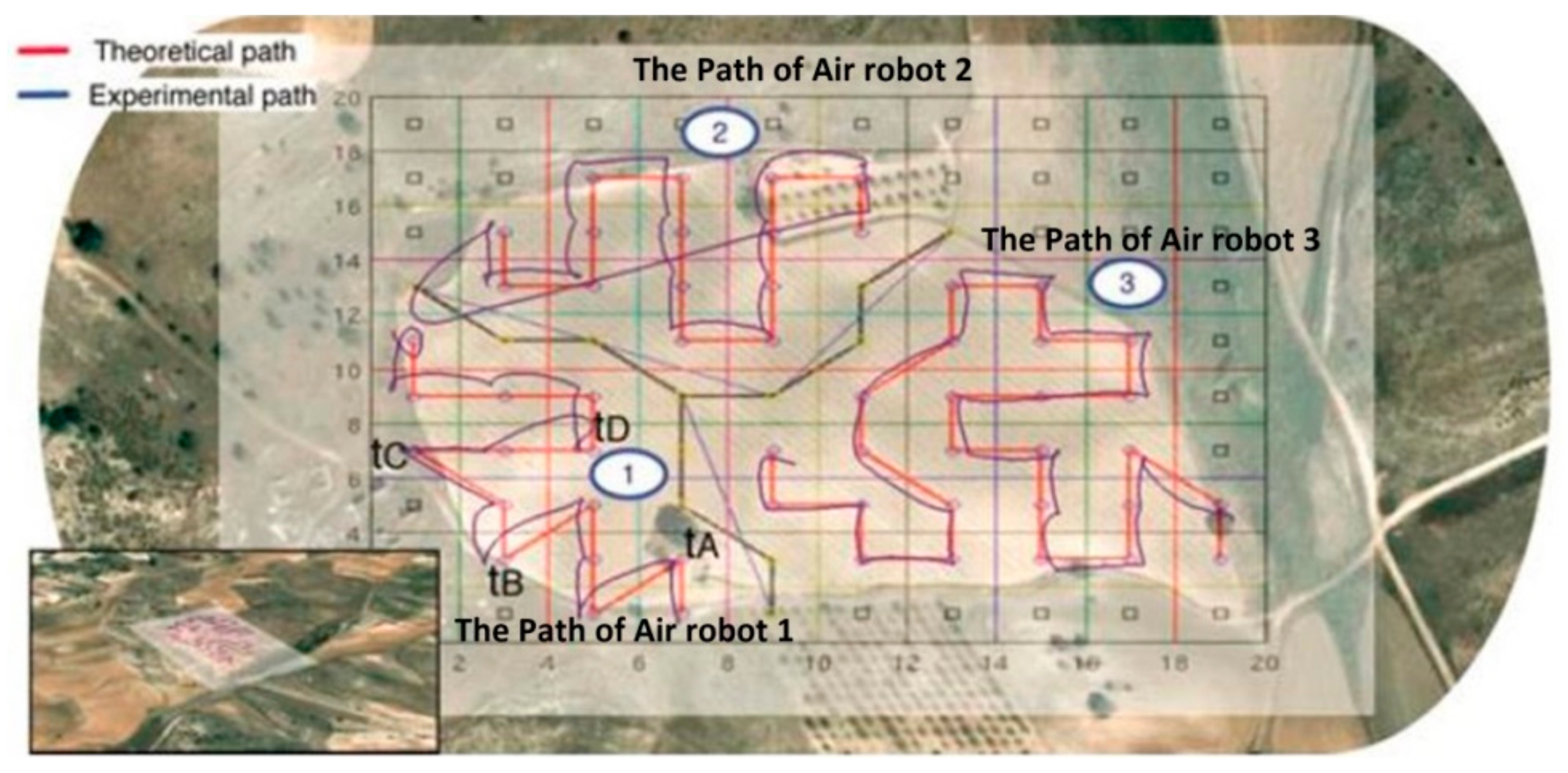

At present, there is little research on the distributed path planning of agricultural multi-robots. As shown in

Figure 12, Bouzouita et al. [

28] developed UAVs to monitor agricultural information in the vineyard. The path planning of the UAVs is based on the grid map and A*. On the map, the UAV path planning function is constructed according to constraint conditions, such as the number of UAV turns, the number of covered grid visits, and the time to complete the single partition. And using a heuristic algorithm like A*, the next best node to be expanded is obtained by partying the generation value of each node. Then, the breadth-first search (BFS) algorithm is used to find the local maximum of the function by the distance between the cells. The result is the path from any starting point in the environment to the target unit. The practice shows that the method can find the approximate optimal solution, reduce the possibility of repeated access to the same cell, and facilitate the avoidance of known obstacles. However, it needs to consider the local environmental conditions to find wide applicability.

Combining the above path planning techniques, we summarize the research progress of agricultural multi-robots in path planning methods over the past 10 years, as shown in

Table 5.

It can be seen from

Table 5 that agricultural mobile robots mainly use ground robots in farmland, and the number of robots is no more than four. The path planning method of multi-robots is mainly conducted in fully known conditions, and the grid method and V-Graphic under centralized planning are the methods most commonly used.

The collision avoidance strategy between agriculture robots usually does not incorporate changes in the path [

110], and the obstacle avoidance strategy of a single robot comprises mainly speed adjustment and the priority principle. The path planning of multi-robot generally does not consider the presence of obstacles in agricultural production.

When the UGVs turn around at the headland, they need to consider the relationship between the minimum turning radius and the headspace. The general head-turning method has a bulb shape (as shown in

Figure 11b), zigzag or U-shape, etc. The U-shape predominates in practice. As shown in

Figure 13, the zigzag (forward-reverse-forward) is used in smaller spaces; in contrast, the U-shape turn (turn-straight- turn) is used in larger spaces. However, the difficulty of robot control is increased with the zigzag turning shape, and the task allocation and path planning of the multi-robot are prepared for U-shape turning in advance.

3.5. Formation Control

Multi-robot formation control technology means that multiple robots maintain a certain formation to the target while still adapting to environmental constraints such as obstacle blocking or spatial physical limitations [

111]. This technology can improve the robustness of the multi-robot system, and the robots can complete the task with higher efficiency and shorter time [

112]. At present, the formation control technology of agricultural multi-robots is divided into forming formation and formation control.

As shown in

Figure 14, the formation of agricultural multi-robots generally has five types: column, I-shape, linear, V-shape, and W-shape, and the circular nodes in the formation structure represent robots. Each robot is represented by RID, such as R1 and R2, and the black arrow indicates the direction of robot movement.

It is necessary to achieve the desired formation by determining the formation position reference point after determining the root formation. There are usually three reference points: center, neighbors, and leading robot; as shown in

Figure 15, the position of each root node is represented by PID, such as P1 and P2, and the arrows indicate the relationship between robot dependence and information transfer.

From the perspective of a multi-robot system control framework, formation control is divided into two types: centralized control and distributed control. The former uses a centralized control unit to make decisions, optimize robot coordination, accommodate individual robot failures, and supervise the entire group of robots. The latter does not have a unified control unit, and a single robot makes decisions based on its local information [

112,

113].

At present, the method of centralized formation control of agricultural multi-robots includes the virtual structure, graph-theoretic approach [

114], and model predictive control [

115,

116]. The method of distributing the formation control of agricultural multi-robots includes leader-follower [

34,

41,

75,

117] and the artificial potential field [

113].

Guillet et al. in France [

44] adopted the bidirectional control strategy based on the virtual structure method. As shown in

Figure 16a, each robot of the whole queue is a fixed point on the virtual structure. In this structure, the queue also increases two virtual leaders’ interaction with the extreme robots and carries the desired global velocity for the whole fleet. The advantage of this method is simpler communication protocols and lower communication costs; however, the reaction of the robots is slower because of different acceleration performances.

Berman et al. in the USA adopted the graph theory approach in bee pollination [

108]. When a beehive was opened, the swarm robot flew radially from a moving beacon at a constant speed. And once it encountered the edge of the graph, it flew eastward at a fixed speed. As the robot flies over the plant, it acquires at least one flower within its range through sensors and hovers over the flower with unit time probability to pollinate it and record the location of the pollinated flower, returning to the hive after pollination and starting the next flight until complete coverage of the whole field is achieved. However, this method takes a long time and the model used in the simulation is too idealized. Whether they can be used for practical production needs to be further explored.

Smith et al. in Korea adopted model predictive control (MPC) and nonlinear feedback control respectively in fish tracking (simulation) [

117]. MPC is a finite-domain rolling optimal control strategy with three parts: model, prediction, and decision, sacrificing optimality to some extent [

118]. The fish population location was first divided into discrete points, and the discrete points were clustered to get the vertices of fish population density, and the transition model was constructed by transforming the movement of the fish population into the movement between the vertices. The transition model and nonlinear feedback were used to obtain the transition matrix, and the underwater robot was guided to the vertices with high fish population density according to the transition matrix. The simulation results showed that the model-based control of the underwater robot could approach the nearest point, while the feedback control made the underwater robot approach the target point. However, in practice, the underwater robot movement speed is smaller than the fish population movement speed, and the method needs further improvement when applied in practice. The leader-follower method [

48,

105,

117,

119,

120] is also another classic model and widely used in the formation control of agricultural multi-robots. Japan’s Zhang et al. [

106] used the leader-follower method to control UGV formation. As shown in

Figure 16b, the relative positional relationship between the leader and the follower is determined according to the lateral and longitudinal safety distances (l−l) between the robots first, and then the distances are dynamically adjusted with feedback linearization technology to assemble different formations. Based on the leader-follower model, Bai et al. in China also combined slide mode control with the harvester swarm [

48]. The kinematic model of the farmland leader-follower harvester swarm was established first, and based on this model; the asymptotically stable path-following control law and the formation-keeping control law were designed by combining feedback linearization and sliding-mode control theory. The advantage of this leader-follower model is that the behavior of the fleets can be controlled through the determined trajectory of the leading robot. The method decouples the cooperative navigation control problem into lateral distance keeping control and longitudinal distance keeping control. The formation control is mainly accomplished by establishing the location and gesture of the following robot relative to the leading robot, such as (l−φ), (l−l) first, then obtaining the formation information through feedback linearization, and finally adjusting the formation according to the threshold value. The leader-follower test results show that the real paths of robots can achieve centimeter-level average error with the planned path based on the safe distance of the vehicle. But this method is only applicable for environments involving a single-tasking of agricultural production and a fixed site. The adaptability to the headland turns is not strong. The question of how to maintain robot formation in encountering static or dynamic obstacles is not considered. If the leading robot malfunctions, the formation of the fleets cannot be maintained. Once the leading robot fails, the multi-robot system is susceptible to deadlock, and the formation cannot be maintained. The “leader” replacement method was proposed [

121] to overcome this shortcoming, but the method has not been applied to agricultural multi-robots.

Ju and Son in Korea adopted Ramadge-Wonham theory in supervisory control to solve the above deadlock problem [

122]. Supervisory control is a feedback control theory for discrete-event systems, where the control goal is achieved by observing the occurrence of events or states and using allowable or prohibited controllable events. Finally, a time-driven system is combined with a low-level controller and an event-driven system with a high-level controller with the criterion of satisfying the behavior specification and maximizing the allowable events. Time-driven is used when there is no fault, and once the queue encounters a fault, the control outcome is selected based on event-driven. Simulation results demonstrate that the method can be used to control complex dynamic systems, but it has not been tested in practical applications.

The characteristics and formation process of the formation control methods are shown in

Table 6.

From

Table 6, it can be found that more complex or hybrid control methods are mostly used in simple or simulation environments, and the application in actual agricultural production is still dominated by the leader-follower method, and the research is also mainly focused on multiple machines traveling in a straight line in a fixed column. Further research should be conducted on how to continue driving, maintain the formation, or adjust the formation after multiple robots encounter obstacles.

3.6. Communication

Communication is the basis of information interaction and collaboration among multiple robots. In agricultural production, many factors affect the fine operation of agricultural robots, and to maintain coordination and cooperation among multiple robots and to gain a more comprehensive understanding of the environment in which multiple robots perform tasks, robots need to interact with each other through information to better perform a given task [

29]. Balch and Arkin concluded that even a small amount of communication can improve the performance of multi-robot systems tremendously through experiments [

125].

At present, the communication technology of agricultural multi-robots mainly involves three parts: multi-robot communication mode, communication network, and communication protocol.

The multi-robot communication mode is divided into three categories from a macro perspective: explicit communication, implicit communication, and explicit and implicit communication, as shown in

Figure 17. Explicit communication is an interactive mode through communication as a medium, requiring a clear communication protocol between interacting parties. This method is often used for concordant communication among robots, but it incurs fairly large costs. Implicit communication is the acquisition of the required information through the external environment and internal sensors without an explicit exchange of data, so some advanced coordination strategies cannot be used, which affects the capacity to perform certain complex tasks.

Since explicit communication and implicit communication have their advantages [

120], explicit communication is used for the integrated control of robots in the upper layer, and implicit communication is used for integrated control of robots in the bottom level. Explicit communication means that the robot communicates directly or indirectly with other robots via wireless networks. For example, robot 1 sends a message to all robots in the communication range in broadcast communication, that is, without specifying a particular robot, robot 2, which does not need the message, receives the message. In implicit communication, the intermediary for inter-robot communication is often the surrounding environment. For example, the UAV can be informed about the farmland in advance and build a model of the farmland environment, and the ground robots operate on the ground based on this farmland model [

122]. The combination of both communication modes can be used to develop their advantages, improve the flexibility to confront the various dynamic and unknown environments, and complete many complex tasks in agricultural production.

For the implicit communication of multiple robots, you can refer to

Section 3.2 environment perceptions, here we focus on robot explicit communication techniques.

In literature [

25], two aerial drones were equipped with GPS, visible and near-infrared spectral cameras, which took pictures of the farmland at a set series of ordered waypoints and uploaded them to the backend, which sends the processed information of weeds in the farmland to the ground robot. The ground robots were equipped with RTK-GPS, RGB camera, and LIDAR. RTK-GPS provided accurate heading for the ground robot, RGB camera detects weeds and crop rows, and LIDAR detects obstacles on the vehicle trajectory. While the ground robots were safely walking along their respective set paths, weeding operations start if the weeds detected by the cameras were the same as the weed information in the farmland. In this multi-robot system, the aerial drones and ground robots did not communicate directly but completed the cooperative operation through the interaction of environmental information.

As shown in

Figure 18, the agricultural multi-robots need to adjust their pose in real-time. Therefore, the data exchange of communication among multiple robots is mainly based on wireless communication technology in agricultural production. This technology mainly involves a wireless local area network (WLAN) and a wireless personal area network (WPAN), such as WI-FI, Bluetooth, ZigBee, and IRDA (infrared data association). Among them, WI-FI technology has been developed most rapidly in agricultural multi-robots.

The wireless communication protocols are primarily used based on wireless communication standards and the unlicensed band. Taking the WLAN as an example, the IEEE 802.11 series standards and the 2.4 GHz or 5 GHz bands are used in this communication. The IEEE 802.15 series of transmission technology protocols are selected in WPAN.

Combined with the above communication technology, the research progress of agricultural multi-robots in communication in the past 10 years is summarized, as shown in

Table 7.

In addition to the above wireless communication technologies, Albani et al. adopted a mobile ad hoc (peer-to-peer) network [

128,

129], which regarded the UAV as a communication node in the network and used three communication strategies (simple, flooding, geo-aware) to solve the communication problem of UAVs flying in the field. The simplest communication strategy is a single broadcast mode, that is, the source node sends information to the nearest node. Flooding constitutes a multi broadcast mode, that is, the source node sends information to multiple agents. Geo-aware employs a source node with the highest utilization rate, and this node sends the messages. All three communication strategies ignore communication errors and focus on the impact of the communication range and protocol on work efficiency. The simulation results show that the effective information of weed monitoring can be transmitted with a minimum number of UAVs under the geo-aware approach. However, the communication strategy discards new information obtained by UAVs of the distributed architecture, and messages cannot be effectively transmitted with a wide range of communication (such as over wide areas of farmland). Agricultural multi-robots working in the farmland often encounter signal occlusion, atypical weather, etc.

Large agricultural multi-robots working in agricultural fields rarely encounter problems such as signal occlusion and atypical weather. However, in other agricultural products, such as greenhouse and orchard, when the size of the multi-robot is smaller than the height of the crop, its communication signal strength is extremely attenuated by factors such as crop planting, growth characteristics, planting scale, and weather (natural wind and rain). Previous references [

126,

127,

130] showed that the test results of the WI-FI communication system of agricultural multi-robots suffered from WI-FI signal intensity attenuation largely because of the reflection and scattering effects of crops, and the effective communication distance was less than 50 m (far less than the theoretical communication distance of 300 m) in mature wheat fields, cornfields, and peach gardens. Therefore, it is a future research direction to select suitable multi-robot communication technology according to the characteristics of crops and to carry out research on multi-robot communication patterns based on crop shape characteristics.