Effect of the Incoherent Encapsulation Layer and Oblique Sunlight Incidence on the Optical and Current-Voltage Characteristics of Surface-Textured Cu(In,Ga)Se2 Solar Cells Based on the Angle-Dependent Equispaced Thickness Averaging Method

Abstract

:1. Introduction

2. Theory of ADETAM

3. Optical Modeling Results

3.1. Planar CIGS Solar Cells

3.2. Surface-Textured CIGS Solar Cells

4. Electrical Modeling Results

4.1. Electrical Modeling Procedure

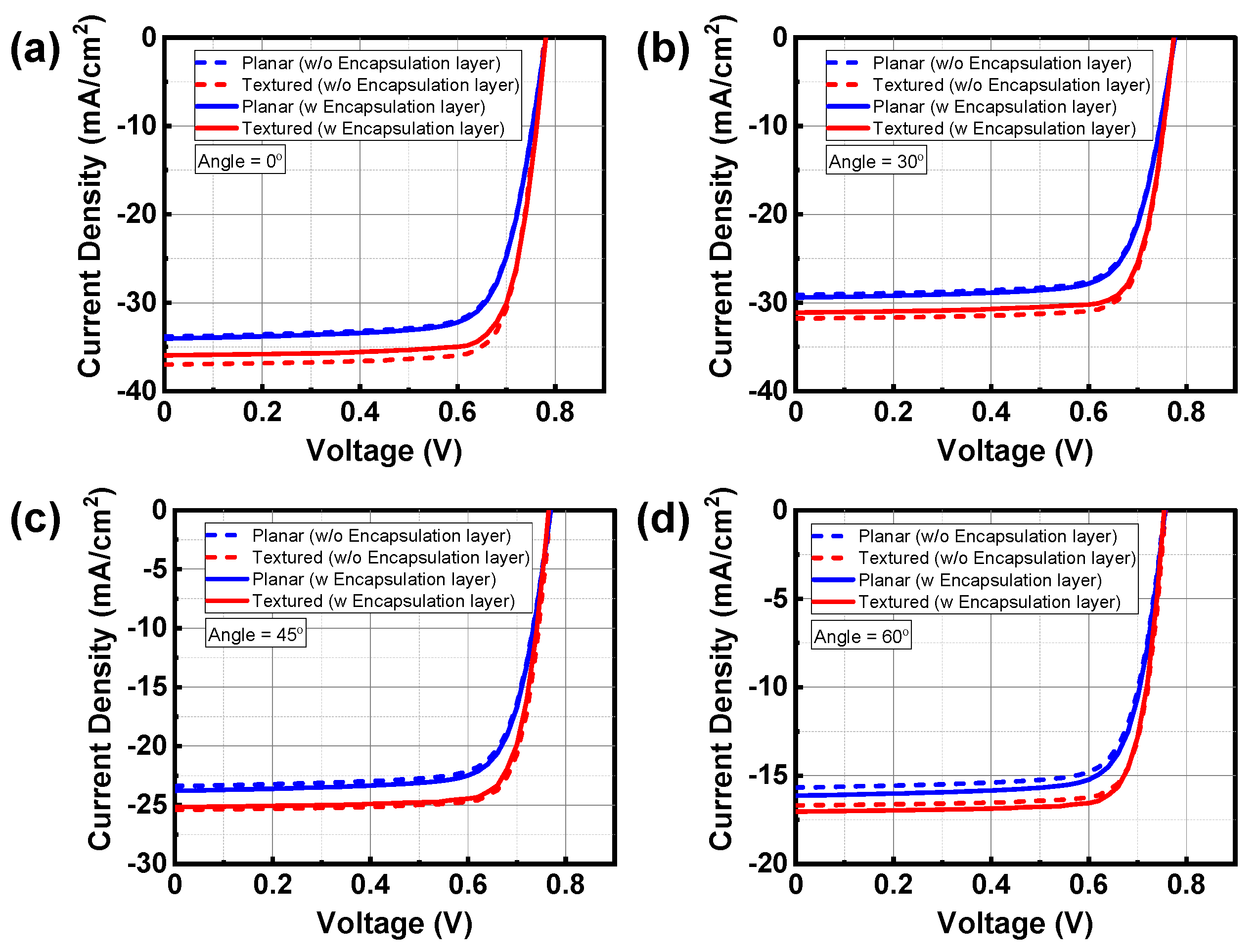

4.2. Comparison of the J–V Characteristics without and with the Inclusion of the Incoherent Front Encapsulation Layers

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Green, M.A.; Emery, K.; Hishikawa, Y.; Warta, W.; Dunlop, D.E. Solar cell efficiency tables (version 39). Prog. Photovolt. Res. 2012, 20, 12–20. [Google Scholar] [CrossRef]

- Green, M.A. Silicon photovoltaic modules: A brief history of the first 50 years. Prog. Photovolts. Res. App. 2005, 13, 447–455. [Google Scholar] [CrossRef]

- Pettersson, L.A.A.; Roman, L.S.; Inganäs, O. Modeling photocurrent action spectra of photovoltaic devices based on organic thin films. J. Appl. Phys. 1999, 86, 487–496. [Google Scholar] [CrossRef]

- Repins, I.; Contreras, M.A.; Egaas, B.; DeHart, C.; Scharf, J.; Perkins, C.L.; To, B.; Noufi, R. 19.9%-efficient ZnO/CdS/CuInGaSe2 solar cell with 81.2% fill factor. Prog. Photovoltaics Res. Appl. 2008, 16, 235–239. [Google Scholar] [CrossRef] [Green Version]

- Jackson, P.; Wuerz, R.; Hariskos, D.; Lotter, E.; Witte, W.; Powalla, M. Effects of heavy alkali elements in Cu(In,Ga)Se2 solar cells with efficiencies up to 22.6%. Phys. Status Solidi Rapid Res. Lett. 2016, 10, 583–586. [Google Scholar] [CrossRef] [Green Version]

- Nakamura, M.; Yamaguchi, K.; Kimoto, Y.; Yasaki, Y.; Kato, T.; Sugimoto, H. Cd-free Cu(In,Ga)(Se,S)2 thin-film solar cell with record efficiency of 23.35%. IEEE J. Photovolt. 2019, 9, 1863–1867. [Google Scholar] [CrossRef]

- Donges, A. The coherence length of black-body radiation. Eur. J. Phys. 1998, 19, 245–249. [Google Scholar] [CrossRef]

- Mitsas, C.L.; Siapkas, D.I. Generalized matrix method for analysis of coherent and incoherent reflectance and transmittance of multilayer structures with rough surfaces, interfaces, and finite substrates. Appl. Opt. 1995, 34, 1678–1683. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.; Lee, S.-Y.; Kim, J.; Kim, S.C.; Lee, B. A numerical analysis of the effect of partially-coherent light in photovoltaic devices considering coherence length. Opt. Express. 2012, 20, A941–A953. [Google Scholar] [CrossRef]

- Katsidis, C.C.; Siapkas, D.I. General transfer-matrix method for optical multilayer systems with coherent, partially coherent, and incoherent interference. Appl. Opt. 2002, 41, 3978–3987. [Google Scholar] [CrossRef]

- Centurioni, E. Generalized matrix method for calculation of internal light energy flux in mixed coherent and incoherent multilayers. Appl. Opt. 2005, 44, 7532–7539. [Google Scholar] [CrossRef]

- Troparevsky, M.C.; Sabau, A.S.; Lupini, A.R.; Zhang, Z. Transfer-matrix formalism for the calculation of optical response in multilayer systems: From coherent to incoherent interference. Opt. Express. 2020, 18, 24715–24721. [Google Scholar] [CrossRef]

- Santbergen, R.; Smets, A.H.M.; Zeman, M. Optical model for multilayer structures with coherent, partly coherent and incoherent layers. Opt. Express. 2013, 21, A262–A267. [Google Scholar] [CrossRef] [Green Version]

- Jung, S.; Kim, K.Y.; Il Lee, Y.; Youn, J.H.; Moon, H.T.; Jang, J.; Kim, J. Optical modeling and analysis of organic solar cells with coherent multilayers and incoherent glass substrate using generalized transfer matrix method. Jpn. J. Appl. Phys. 2011, 50, 122301. [Google Scholar] [CrossRef]

- Lee, S.; Jeong, I.; Kim, H.P.; Hwang, S.Y.; Kim, T.J.; Kim, Y.D.; Jang, J.; Kim, J. Effect of incidence angle and polarization on the optimized layer structure of organic solar cells. Sol. Energy Mater. Sol. Cells 2013, 118, 9–17. [Google Scholar] [CrossRef]

- Kim, S.C. Simulation of rough surface of CIGS (CuInGaSe) solar cell by RCWA (rigorous coupled wave analysis) considering the incoherency of light. J. Opt. Soc. Korea 2014, 18, 180–183. [Google Scholar] [CrossRef] [Green Version]

- Ganapati, V.; Miller, O.D.; Yablonovitch, E. Light trapping textures designed by electromagnetic optimization for subwavelength thick solar cells. IEEE J. Photovolt. 2014, 4, 175–182. [Google Scholar] [CrossRef] [Green Version]

- Parsons, R.; Tamang, A.; Jovanov, V.; Wagner, V.; Knipp, D. Comparison of light trapping in silicon nanowire and surface textured thin-film solar cells. Appl. Sci. 2017, 7, 427. [Google Scholar] [CrossRef] [Green Version]

- Bednar, N.; Severino, N.; Adamovic, N. Optical simulation of light management in CIGS thin-film solar cells using finite element method. Appl. Sci. 2015, 5, 1735–1744. [Google Scholar] [CrossRef]

- Kang, K.; Lee, S.; Kim, J.; Kim, S.; Han, Y.; Baek, S. A simple numerical modeling of the effect of the incoherent thick substrate in thin-film solar cells based on the equispaced thickness method. IEEE Photonics J. 2016, 8, 8400312. [Google Scholar] [CrossRef]

- Kang, K.; Kim, S.; Kim, J. Numerical modeling of the effect of multiple incoherent layers in Cu(In,Ga)Se2 solar cells based on the equispaced thickness averaging method. Appl. Opt. 2018, 57, 2758–2765. [Google Scholar] [CrossRef]

- Sarrazin, M.; Herman, A.; Deparis, O. First-principle calculation of solar cell efficiency under incoherent illumination. Opt. Express. 2014, 21, A616–A630. [Google Scholar] [CrossRef] [Green Version]

- Abass, A.; Trompoukis, C.; Leyre, S.; Burgelman, M.; Maes, B. Modeling combined coherent and incoherent scattering structures for light trapping in solar cells. J. Appl. Phys. 2013, 114, 033101. [Google Scholar] [CrossRef] [Green Version]

- Baik, J.; Park, J.; Lee, G.; Kim, S.; Kim, J. Effects of incoherent front cover glass on current-voltage characteristics of Cu(In,Ga)Se2 solar cells: Investigation into calculation accuracy for cover glass modeled as optically coherent or incoherent. Appl. Sci. 2020, 10, 3312. [Google Scholar] [CrossRef]

- Paulson, P.D.; Birkmire, R.W.; Shafarman, W.N. Optical characterization of CuIn1−xGaxSe2 alloy thin films by spectroscopic ellipsometry. J. Appl. Phys. 2003, 94, 879–888. [Google Scholar] [CrossRef]

- Seiler, D.G.; Zollner, S.; Diebold, A.C.; Amirtharaj, P.M. Optical properties of semiconductors. In Handbook of Optics, 3rd ed.; Bass, M., Li, G., Stryland, E.V., Eds.; McGraw-Hill: New York, NY, USA, 2009; Volume 4. [Google Scholar]

- Richter, M.; Schubbert, C.; Eraerds, P.; Riedel, I.; Keller, J.; Parisi, J.; Dalibor, T.; Avellán-Hampe, A. Optical characterization and modeling of Cu(In,Ga)(Se,S)2 solar cells with spectroscopic ellipsometry and coherent numerical simulation. Thin Solid Films. 2013, 535, 331–335. [Google Scholar] [CrossRef]

- Li, Q.H.; Zhu, D.; Liu, W.; Liu, Y.; Ma, X.C. Optical properties of Al-doped ZnO thin films by ellipsometry. Appl. Surf. Sci. 2008, 254, 2922–2926. [Google Scholar] [CrossRef]

- Mkawi, E.M.; Ibrahim, K.; Ali, M.K.M.; Farrukh, M.A.; Mohamed, A.S. The effect of dopant concentration on properties of transparent conducting Al-doped ZnO films for efficient Cu2ZnSnS4 thin-film solar cells prepared by electrodeposition method. Appl. Nanosci. 2015, 5, 993–1001. [Google Scholar] [CrossRef] [Green Version]

- Allsopp, B.L.; Orman, R.; Johnson, S.R.; Baistow, I.; Sanderson, G.; Sundberg, P.; Stålhandske, C.; Grund, L.; Andersson, A.; Booth, J.; et al. Towards improved cover glasses for photovoltaic devices. Prog. Photovoltaics. 2020, 28, 1187–1206. [Google Scholar] [CrossRef]

- Vogt, M.R.; Holst, H.; Schulte-Huxel, H.; Blankemeyer, S.; Witteck, R.; Hinken, D.; Winter, M.; Min, B.; Schinke, C.; Ahrens, I.; et al. Optical constants of UV transparent EVA and the impact on the PV module output power under realistic irradiation. Energy Procedia. 2016, 92, 523–530. [Google Scholar] [CrossRef] [Green Version]

- Comsol Inc. COMSOL Multiphysics; Version 5.2; Comsol Inc.: Burlington, MA, USA, 2016; Available online: http://www.comsol.com (accessed on 22 December 2020).

- Jehl, Z.; Bouttemy, M.; Lincot, D.; Guillemoles, J.F.; Gerard, I.; Etcheberry, A.; Voorwinden, G.; Powalla, M.; Naghavi, N. Insights on the influence of surface roughness on photovoltaic properties of state of the art copper indium gallium diselenide thin films solar cells. J. Appl. Phys. 2012, 111, 114509. [Google Scholar] [CrossRef]

- Kang, K.; Lee, S.; Kim, J. Effects of an incoherent glass substrate on the absorption efficiency of organic solar cells at oblique incidence analyzed by the transfer matrix method with a glass factor. Jpn. J. Appl. Phys. 2013, 52, 052301. [Google Scholar] [CrossRef]

- Saleh, B.E.A.; Teich, M.C. Fundamentals of Photonics, 2nd ed.; Wiley: Hoboken, NJ, USA, 2007; pp. 209–214. [Google Scholar]

| Incidence Angle | Planar CIGS Solar Cell without the Front Encapsulation Layer | Surface-Textured CIGS Solar Cell without the Front Encapsulation Layer | Planar CIGS Solar Cell with the Front Encapsulation Layer | Surface-Textured CIGS Solar Cell with the Front Encapsulation Layer |

|---|---|---|---|---|

| 0° | −33.83 | −36.98 (9.31%) | −34.05 | −35.95 (5.58%) |

| 30° | −29.11 | −31.78 (9.17%) | −29.42 | −31.11 (5.74%) |

| 45° | −23.40 | −25.40 (8.55%) | −23.79 | −25.16 (5.76%) |

| 60° | −15.68 | −16.68 (6.38%) | −16.14 | −17.03 (5.51%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, G.; Kim, J.; Kim, S.; Kim, J. Effect of the Incoherent Encapsulation Layer and Oblique Sunlight Incidence on the Optical and Current-Voltage Characteristics of Surface-Textured Cu(In,Ga)Se2 Solar Cells Based on the Angle-Dependent Equispaced Thickness Averaging Method. Appl. Sci. 2021, 11, 2121. https://doi.org/10.3390/app11052121

Lee G, Kim J, Kim S, Kim J. Effect of the Incoherent Encapsulation Layer and Oblique Sunlight Incidence on the Optical and Current-Voltage Characteristics of Surface-Textured Cu(In,Ga)Se2 Solar Cells Based on the Angle-Dependent Equispaced Thickness Averaging Method. Applied Sciences. 2021; 11(5):2121. https://doi.org/10.3390/app11052121

Chicago/Turabian StyleLee, Gyeongjun, Jiyong Kim, Sungchul Kim, and Jungho Kim. 2021. "Effect of the Incoherent Encapsulation Layer and Oblique Sunlight Incidence on the Optical and Current-Voltage Characteristics of Surface-Textured Cu(In,Ga)Se2 Solar Cells Based on the Angle-Dependent Equispaced Thickness Averaging Method" Applied Sciences 11, no. 5: 2121. https://doi.org/10.3390/app11052121