Experimental Study on Strengthening Effect Analysis of a Deteriorated Bridge Using External Prestressing Method

Abstract

:1. Introduction

2. Experimental Program

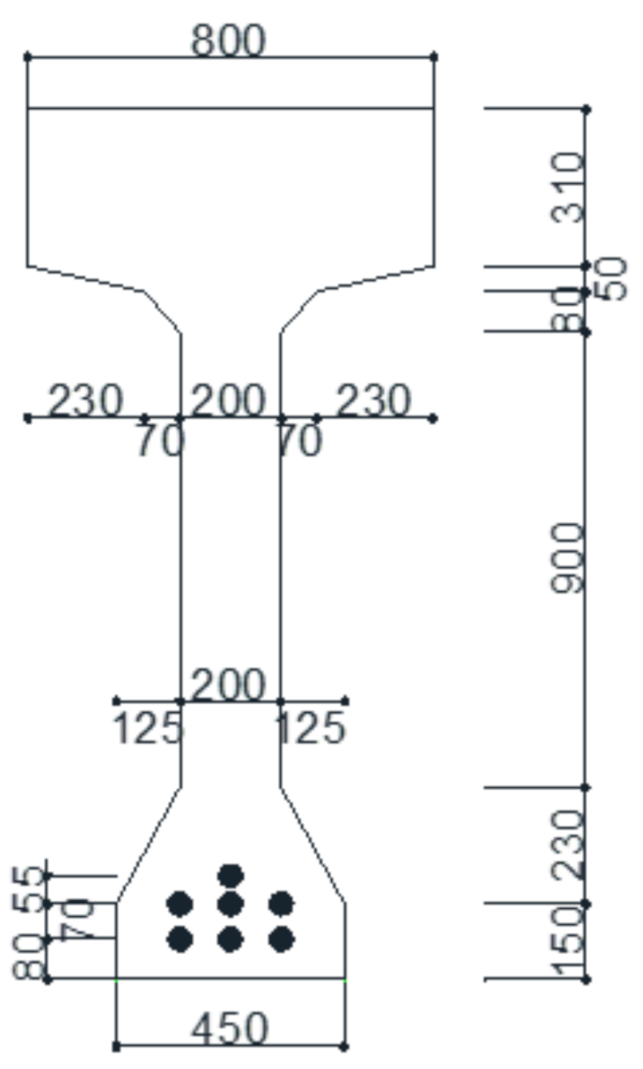

2.1. Deteriorated Bridge

2.2. Material Properties

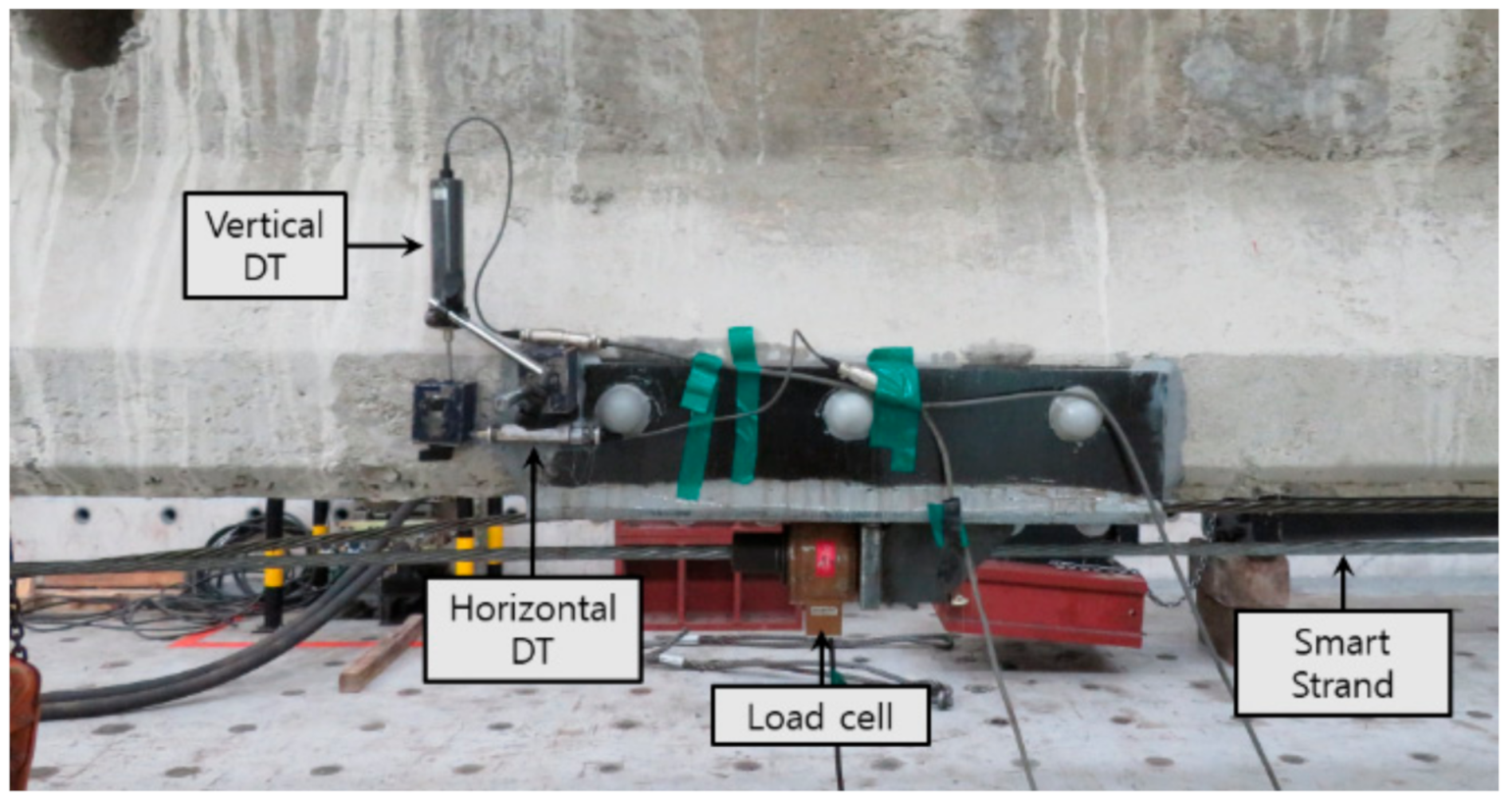

2.3. Measurement and Loading Plan

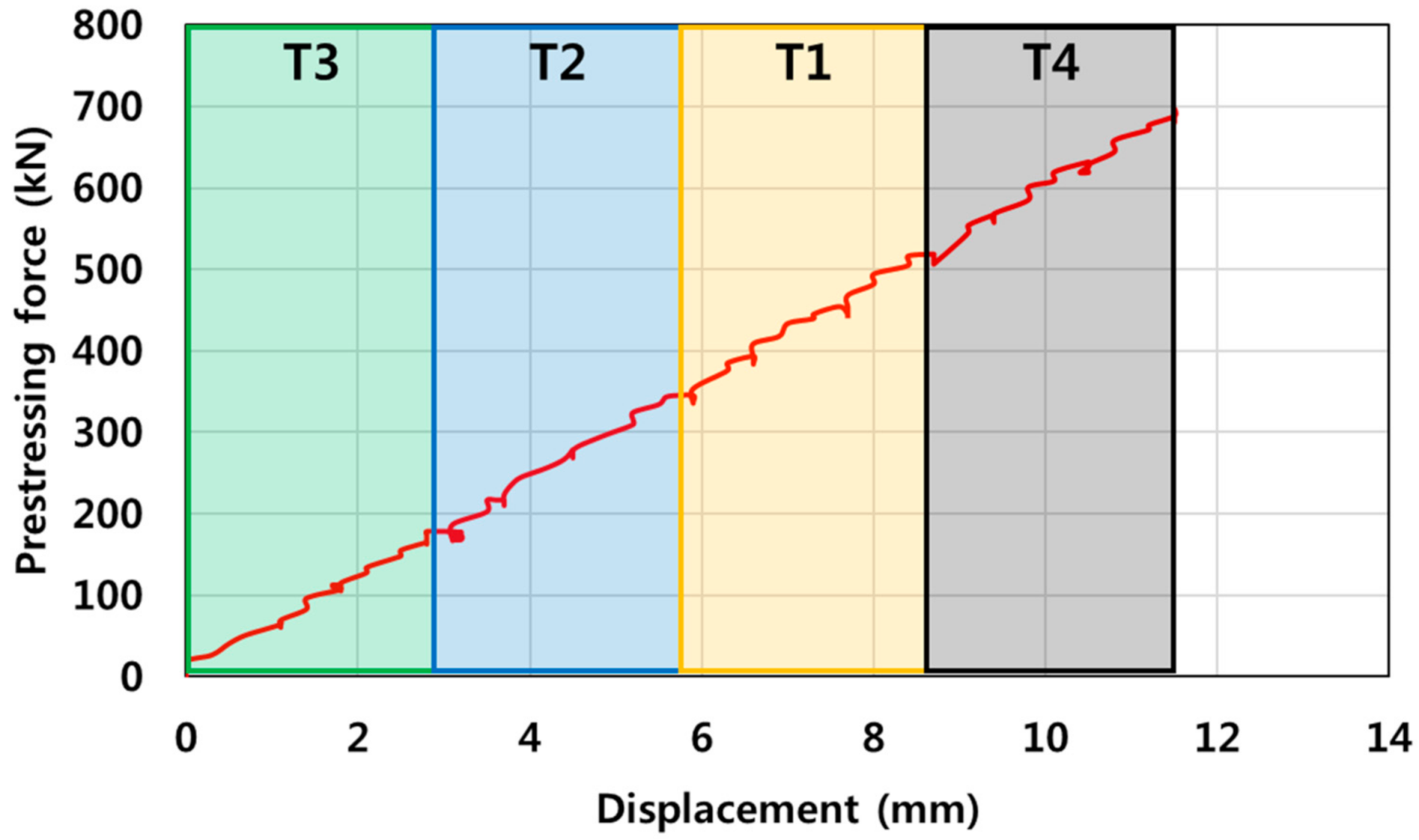

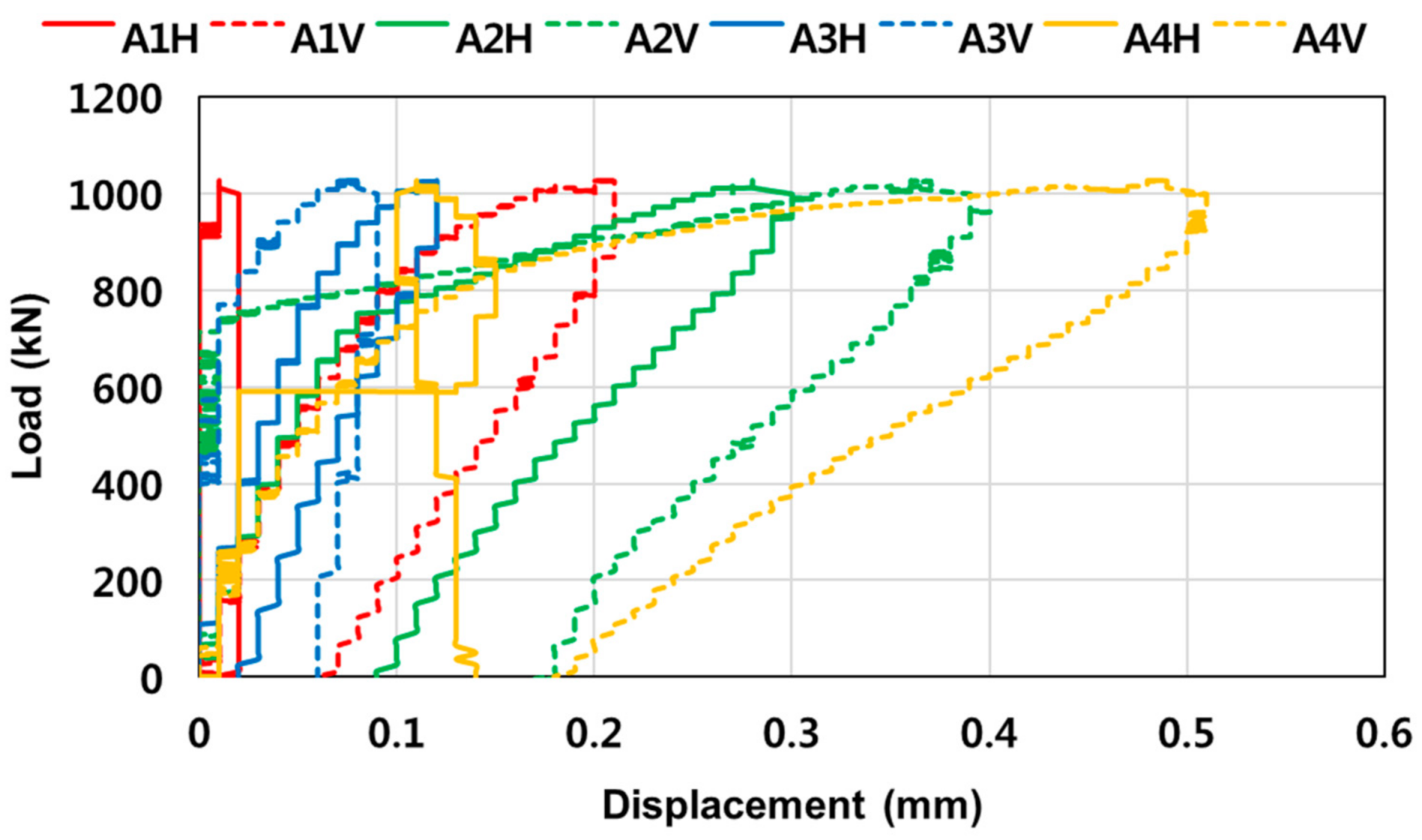

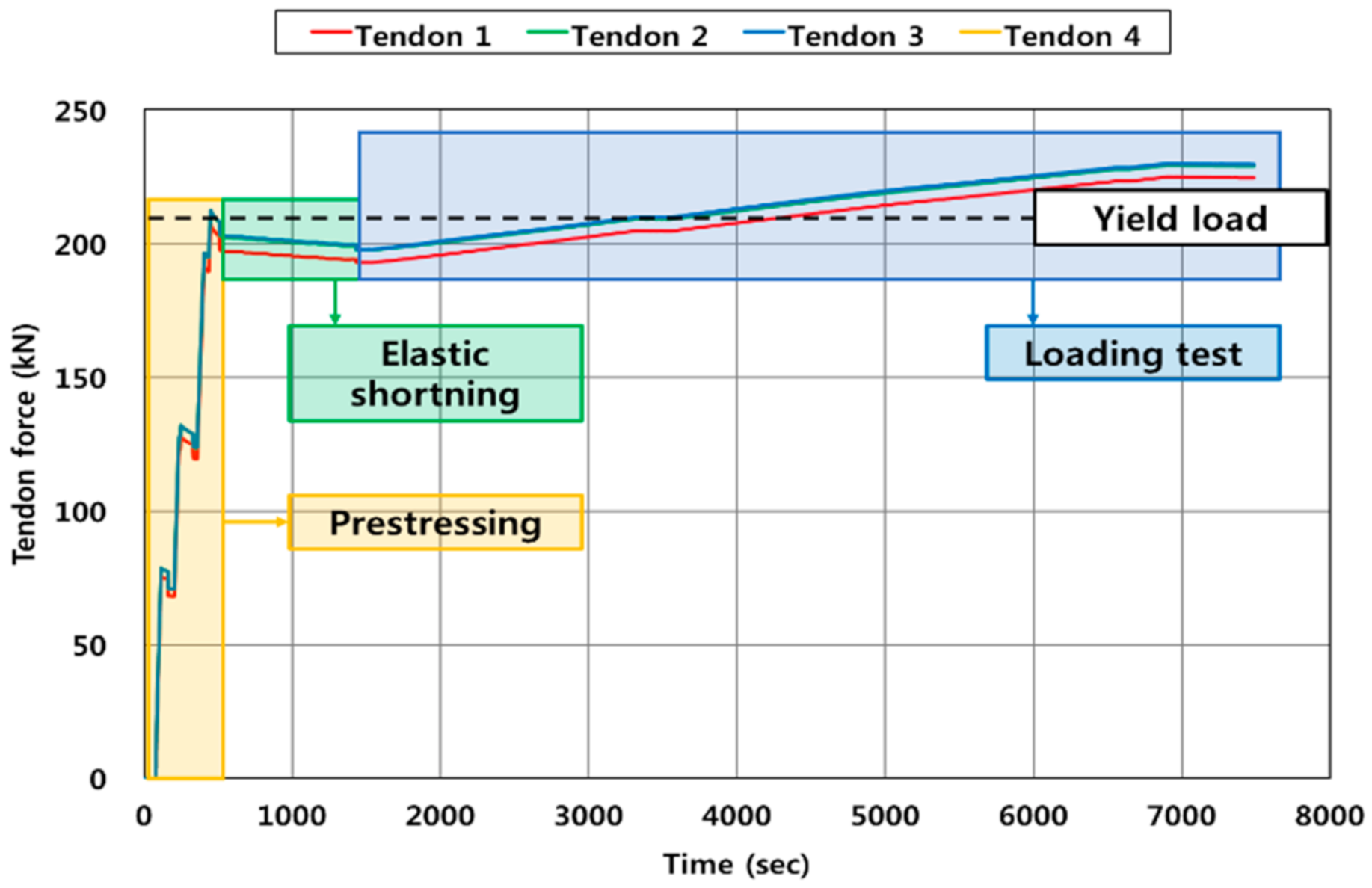

2.4. Strengthening Deteriorated Bridge

3. Experiment Result and Analysis

4. Conclusions

- (1)

- As a result of conducting a concrete material test by collecting approximately 50 cores from the girders of an old bridge, the compressive strength of concrete was found to be 33 MPa, which was 22% higher than that used in the design (27 MPa). However, it was not possible to confirm the change in compressive strength due to the absence of the experimental values during the bridge’s construction. In addition, as a result of performing the tensile strength test by cutting five tendons in the deteriorated bridge, it can be concluded that the decrease in tensile performance was not significant as the tendons used in the bridge exposed for 45 years were also sealed with grout.

- (2)

- After exposing the internal tendon of the deteriorated bridge, the tendon was pulled in the transverse direction to evaluate the effective tension of the existing tendon. The effective tension is 25.1~32.7 kN and assuming the maximum introduced tension, the effective tension of 40~53% is measured; it is conceivable that about 50% of the prestressing force is lost during its service period.

- (3)

- When designing the anchorage for strengthening using the external prestressing method, in some cases, early failure of the anchorage was confirmed by considering the design strength up to the applied tension and not the tensile strength of the tendon. However, in this study, the anchorage did not fail until the member was destroyed because of the design reflecting the tensile strength of the tendon, the regulation of the anchor bolt spacing, and the strict consideration of the side anchors not considered in the design. Thus, it was confirmed that sufficient attention is required when managing strengthening design.

- (4)

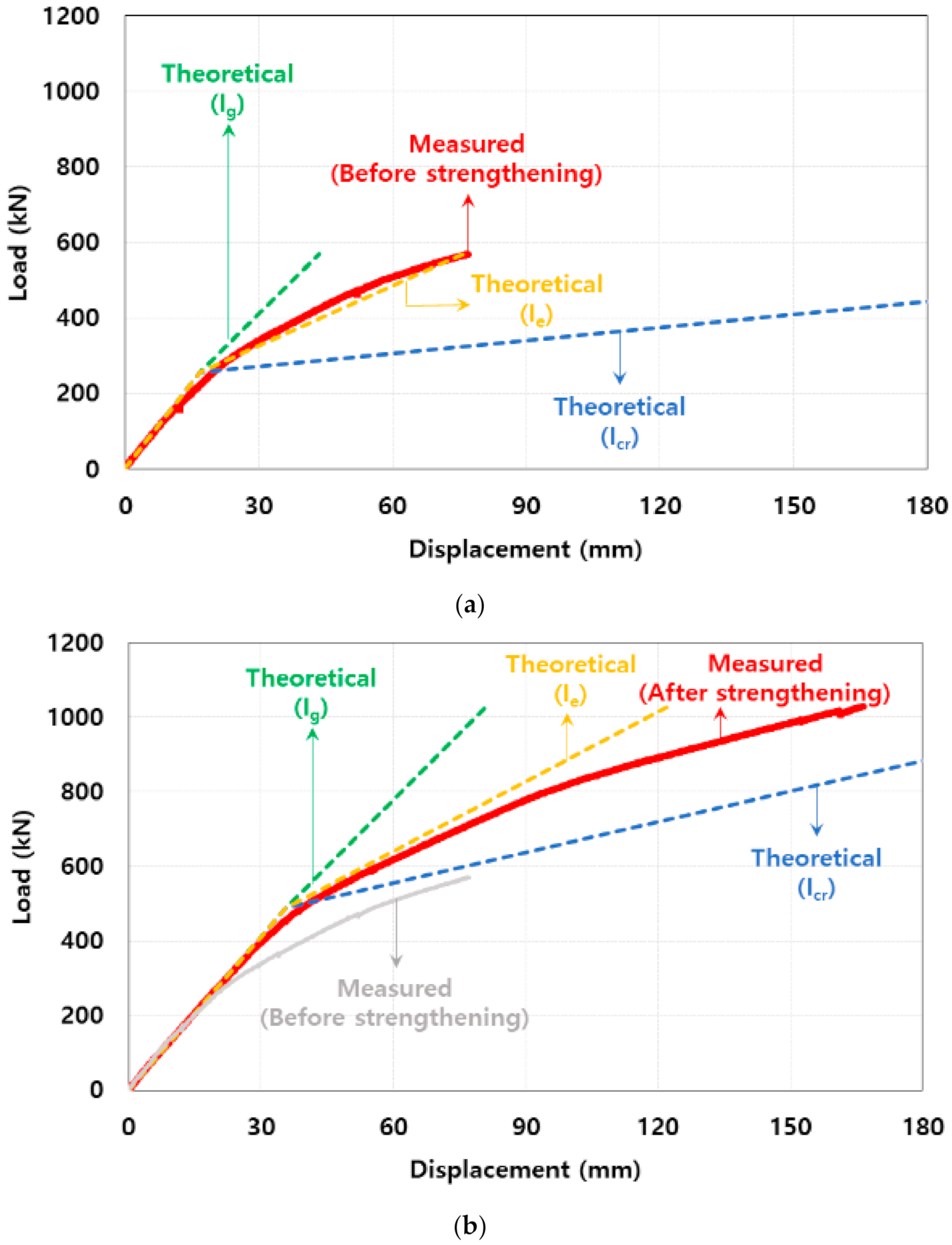

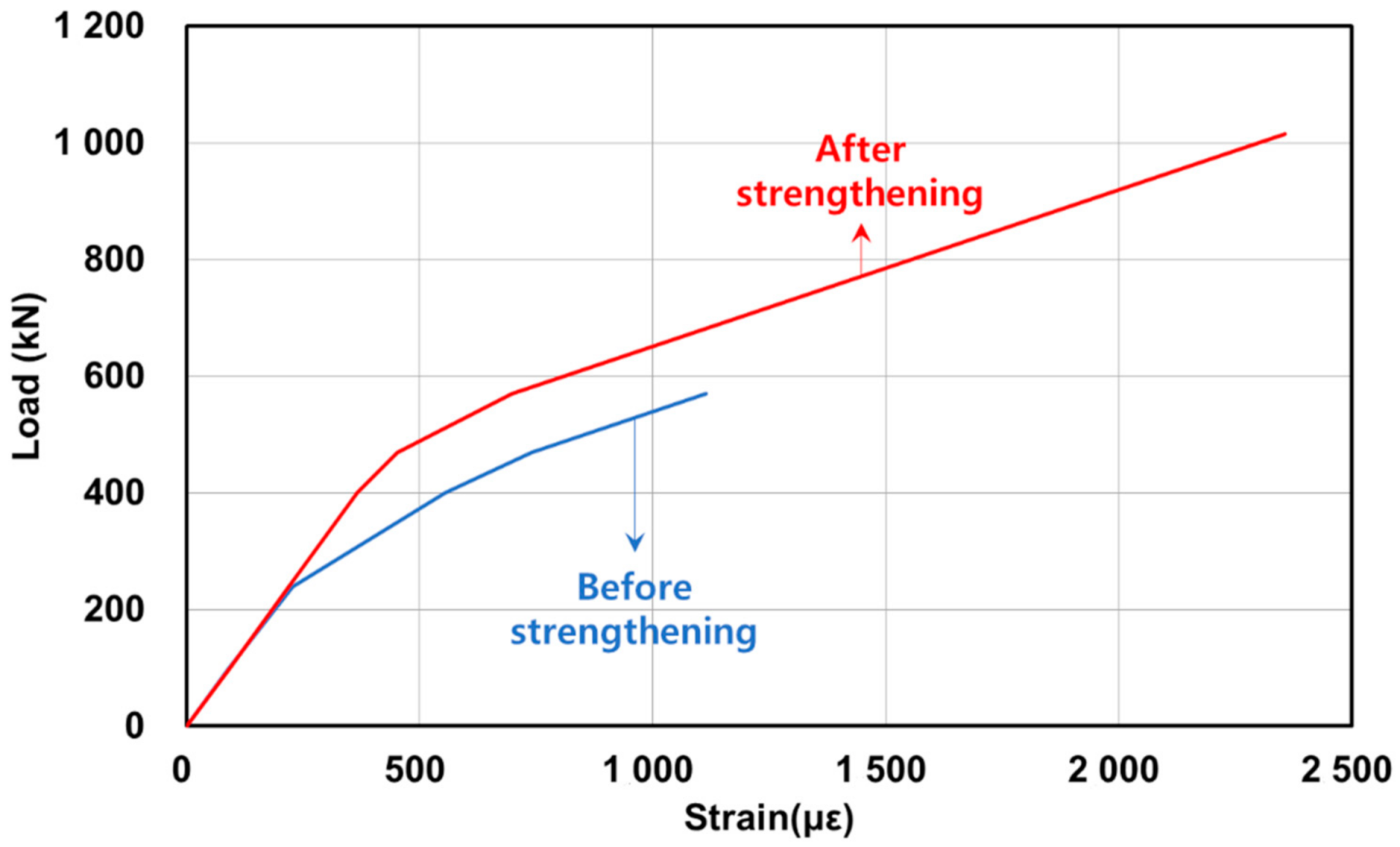

- The four-point loading test before and after strengthening was performed, and the strengthening effect was determined through the increase in the measured crack load. Moreover, the behavior of the bridge was relatively accurately predicted by applying the effective moment of inertia. In addition, it was difficult to determine the strengthening effect before cracking because the external tensioning method had a minimal contributive effect on the stiffness before cracking.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jung, W.T.; Park, J.S.; Kang, J.Y.; Park, H.B. Strengthening effect of prestressed near-surface-mounted CFRP tendon on reinforced concrete beam. Adv. Mater. Sci. Eng. 2018, 9210827. [Google Scholar] [CrossRef] [Green Version]

- Park, H.B.; Park, J.S.; Kang, J.Y.; Jung, W.T. Fatigue Behavior of Concrete Beam with Prestressed Near-Surface Mounted CFRP Reinforcement According to the Strength and Developed Length. Materials 2019, 12, 51. [Google Scholar] [CrossRef] [Green Version]

- Jung, W.T.; Park, J.S.; Kang, J.Y.; Keum, M.S. Flexural behavior of concrete beam strengthened by near-surface mounted CFRP reinforcement using equivalent section model. Adv. Mater. Sci. Eng. 2017, 2017, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.H.; Park, S.Y.; Park, Y.H.; Jeon, S.J. Friction characteristics of post-tensioning tendons in full-scale structures. Eng. Struct. 2019, 183, 389–397. [Google Scholar] [CrossRef]

- Kim, S.H.; Park, S.Y.; Jeon, S.J. Long-term characteristics of prestressing force in post-tensioned structures measured using smart strand. Appl. Sci. 2020, 10, 4084. [Google Scholar] [CrossRef]

- Potson, R.W.; Frank, K.H.; West, J.S. Enduring strength. Civ. Eng. ASCE 2003, 73, 58–63. [Google Scholar]

- Lee, H.Y.; Jung, W.T.; Chung, W.S. Field test of an old RC bridge before and after NSM strengthening. Comp. Struct. 2018, 202, 793–801. [Google Scholar] [CrossRef]

- Lee, H.Y.; Jung, W.T.; Chung, W.S. Flexural strengthening of reinforced concrete beams with pre-stressed near surface mounted CFRP systems. Comp. Struct. 2017, 163, 1–12. [Google Scholar] [CrossRef]

- Lee, H.Y.; Jung, W.T.; Chung, W.S. Post-tension near-surface-mounted strengthening systems of full-scale PSC girders. Constr. Build. Mater. 2017, 151, 71–82. [Google Scholar] [CrossRef]

- Lee, H.Y.; Jung, W.T.; Chung, W. Post-tension near-surface mounted strengthening system for reinforced concrete beams with changes in concrete condition. Compos. Part B Eng. 2019, 161, 514–529. [Google Scholar] [CrossRef]

- Jung, W.T.; Park, J.S.; Kang, J.Y.; Keum, M.S.; Park, Y.H. Flexural behaviour of RC beams strengthened with prestressed CFRP NSM tendon using new prestressing system. Int. J. Polym. Sci. 2017, 2017, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Herbrand, M.; Classen, M. Shear tests on continuous prestressed concrete beams with external prestressing. Struct. Concr. 2015, 16, 428–437. [Google Scholar] [CrossRef]

- Pisani, M.A. Behaviour under long-term loading of externally prestressed concrete beams. Eng. Struct. 2018, 160, 24–33. [Google Scholar] [CrossRef]

- Senthil, R.; Manisekar, R. Ultimate flexural behaviour of externally prestressed new beams and distressed beams. J. Eng. Sci. Technol. 2015, 10, 461–484. [Google Scholar]

- Kaur, H.; Singh, J. A Review on external prestressing in concrete. Int. Res. J. Eng. Technol. 2017, 4, 1801–1805. [Google Scholar]

- Li, Y.Y.; Guo, B.; Liu, J. Research on reinforced concrete beam enlarged cross section method experiment and finite element simulation. Appl. Mech. Mater. 2014, 638, 208–213. [Google Scholar] [CrossRef]

- Lee, B.J.; Park, J.K.; Kim, M.Y.; Shin, H.M.; Park, C.H. Experimental study on flexural behavior of PSC I girder and the effect of external prestressing. J. Korea Concr. Inst. 2007, 19, 755–762. [Google Scholar]

- Xue, W.; Tan, Y.; Peng, F. Experimental study on damaged prestressed concrete beams using external post-tensioned tendons. ACI Struct. J. 2020, 117, 159–168. [Google Scholar] [CrossRef]

- Carin, L.; Jose, A.; John, E.; Michael, E. Field measurements of prestress losses in external tendons. ACI Struct. J. 1996, 93, 596–601. [Google Scholar]

- Carin, L.; Michael, E.; David, M.; John, E. Stresses in external tendons at ultimate. ACI Struct. J. 2005, 102, 206–213. [Google Scholar]

- Aparicio, A.C.; Ramos, G.; Casas, J.R. Testing of externally prestressed concrete beams. Eng. Struct. 2002, 24, 73–84. [Google Scholar] [CrossRef]

- Russell, B.W.; Burns, N.H. Measured transfer lengths of 0.5 and 0.6 in. strands in pretensioned concrete. PCI J. 1996, 41, 44–65. [Google Scholar] [CrossRef]

- Shenoy, C.V.; Gregory, C.F. Structural tests of 27-year-old prestressed concrete bridge beams. PCI J. 1991, 36, 80–90. [Google Scholar] [CrossRef]

- Pessiki, S.; Kaczinski, M.; Wescott, H.H. Evaluation of effective prestress force in 28-year-old prestressed concrete bridge beams. PCI J. 1996, 41, 78–89. [Google Scholar] [CrossRef]

- Tabatabai, H.; Dickson, T.J. Structural evaluation of a 34-year-old precast post-tensioned concrete girder. PCI J. 1993, 38, 50–63. [Google Scholar] [CrossRef]

- Naaman, A.E.; Burns, N.H.; French, C.; Gamble, W.L.; Mattock, A.H. Stresses in unbonded prestressing tendons at ultimate: Recommendation. ACI Struct. J. 2002, 99, 518–529. [Google Scholar]

- Saiidi, M.S.; Shields, J.; Oconnor, D.; Hutchens, E. Variation of prestress force in a prestressed concrete bridge during the first 30 months. PCI J. 1996, 41, 66–72. [Google Scholar] [CrossRef]

- Ramos, G. Flexural strength of externally prestressed concrete bridge. ACI Struct. J. 1996, 93, 512–523. [Google Scholar]

- Harajli, M.H.; Mabsout, M.E.; Al-Hajj, J.A. Response of externally post-tensioned continuous members. ACI Struct. J. 2002, 99, 671–680. [Google Scholar]

- Chun, S.C.; Mohsen, S. Understanding capacity rating of bridge from load tests. Pract. Period. Struct. Constr. 2003, 8, 209–216. [Google Scholar]

- Naaman, A.E.; Aldhairi, F.M. Stress at ultimate in unbonded post-tensioning tendon: Part 1-Evaluation of the state of the art. ACI Struct. J. 1991, 85, 641–650. [Google Scholar]

- Naaman, A.E.; Aldhairi, F.M. Stress at ultimate in unbonded post-tensioning tendon: Part 2-Proposed methodology. ACI Struct. J. 1991, 88, 683–690. [Google Scholar]

- Ozkul, O.; Nassif, H.; Tanchan, P.; Harajli, M.H. Rational approach for prediction stress in beams with unbonded tendons. ACI Struct. J. 2008, 105, 338–347. [Google Scholar]

- ACI Committee 318. Building Code Requirements for Structural Concrete; ACI 318-19; American Concrete Institute (ACI): Farmington Hills, MI, USA, 2019. [Google Scholar]

- Branson, D.E. Deformation of Concrete Structures, 1st ed.; McGraw Hill: New York, NY, USA, 1997; pp. 242–263. [Google Scholar]

| Duct No. | Distance 1 (m) | Tendon No. | Measured | |

|---|---|---|---|---|

| Force (kN) | Stress (MPa) | |||

| 1 | 5 | 1 | 30.8 | 613 |

| 2 | 32.7 | 650 | ||

| 2 | 9 | 1 | Tension released | |

| 2 | 33.4 | 664 | ||

| 3 | 25.1 | 499 | ||

| 3 | 23 | 1 | Tension released | |

| 2 | Tension released | |||

| Jacking Order | Tendon Force (kN) | Anchorage Displ. (mm) | ||||

|---|---|---|---|---|---|---|

| Jacking Force | Setting Loss | Elastic Loss | Horizontal | Vertical | ||

| T1 | 3 | 184.8 | 172.8 | 172.0 | 0.06 | 0.05 |

| T2 | 2 | 180.0 | 171.0 | 168.3 | 0.03 | 0.01 |

| T3 | 1 | 179.5 | 169.3 | 164.5 | 0.02 | 0 |

| T4 | 4 | 181.5 | 175.5 | 175.5 | 0.02 | 0.02 |

| Slope (kN/mm) | |||

|---|---|---|---|

| Before strengthening | 11.7 | 5.3 | 1.1 |

| After strengthening | 11.9 | 6.2 | 2.7 |

| Load (kN) | Displacement (mm) | Strengthening Effect 3 (%) | Remark | |

|---|---|---|---|---|

| Before 1 | After 2 | |||

| 100 | 6.6 | 7.2 | - | |

| 240 | 18.3 | 17.4 | - | Before 1 crack |

| 400 | 39.7 | 30.3 | 23.7 | |

| 470 | 51.7 | 37.2 | 28.0 | After 2 crack |

| 570 | 77.1 | 51.3 | 33.0 | |

| 1060 | - | 161.2 | - | |

| Load (kN) | Strain (με) | Strengthening Effect 3 (%) | remark | |

|---|---|---|---|---|

| Before 1 | After 2 | |||

| 100 | 90 | 94 | - | |

| 240 | 227 | 220 | - | Before 1 crack |

| 400 | 555 | 366 | 34.1 | |

| 470 | 741 | 452 | 39.0 | After 2 crack |

| 570 | 1115 | 698 | 37.4 | |

| 1060 | - | 2357 | - | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.-H.; Park, J.-S.; Jung, W.-T.; Kim, T.-K.; Park, H.-B. Experimental Study on Strengthening Effect Analysis of a Deteriorated Bridge Using External Prestressing Method. Appl. Sci. 2021, 11, 2478. https://doi.org/10.3390/app11062478

Kim S-H, Park J-S, Jung W-T, Kim T-K, Park H-B. Experimental Study on Strengthening Effect Analysis of a Deteriorated Bridge Using External Prestressing Method. Applied Sciences. 2021; 11(6):2478. https://doi.org/10.3390/app11062478

Chicago/Turabian StyleKim, Sang-Hyun, Jong-Sup Park, Woo-Tai Jung, Tae-Kyun Kim, and Hee-Beom Park. 2021. "Experimental Study on Strengthening Effect Analysis of a Deteriorated Bridge Using External Prestressing Method" Applied Sciences 11, no. 6: 2478. https://doi.org/10.3390/app11062478