Design of a Fuzzy Optimization Control Structure for Nonlinear Systems: A Disturbance-Rejection Method

Abstract

:1. Introduction

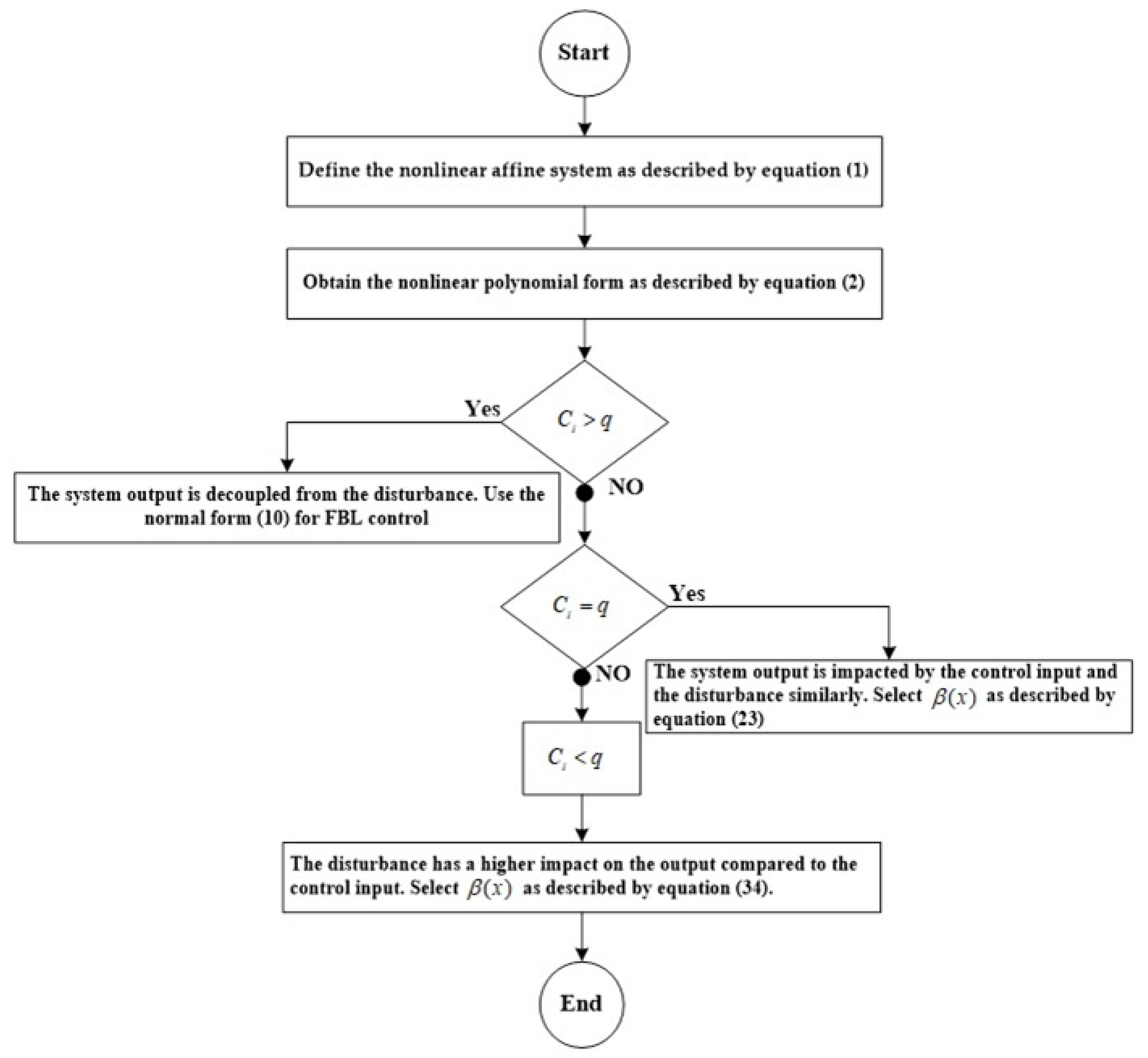

2. Study of a Robust Nonlinear Control Strategy

2.1. Preliminaries

- for all X close toand for all;

- ;

- where

- where:and.

- where .

- where denotes a new reference varying set point that maybe computed to provide a designed-equivalent linear model with specific eigenvalues sets.

2.2. Analytical Design for the SMC and I/O FBL Control Technique

3. Trajectory Tracking Control of a Nonlinear Reactor: A Case Study

3.1. A Preliminary Simulation Analysis of the I/O FBL Control Design

- First stable equilibrium operating zone: ;

- Unstable equilibrium operating zone: ;

- Second Stable equilibrium operating zone: .

3.2. Second Simulation Analysis: Implementation of the Analytical SMC and I/O FBL Control Design

4. A Fuzzy PSO-Based Control Design

4.1. Preliminaries on PSO

- The literature specifies that PSO is a highly efficient technique employed to find solutions to non-smooth global optimization problems. The main benefits of the technique are listed below. This technique does not rely on derivatives, unlike similar meta-heuristic optimization techniques.

- The coding and theory corresponding to this method are straightforward, unlike other heuristic optimization techniques;

- It has considerably less sensitive to the aspects of the objective function, unlike traditionally used analytical and heuristic techniques;

- Unlike many heuristic optimization methods, PSO has relatively fewer parameters: inertia weight coefficient and acceleration coefficients. Furthermore, the parameters corresponding to the optimal solutions are relatively less sensitive compared to other heuristic methods;

- PSO is less contingent on the initial set of points compared to numerous evolutionary techniques; also, this algorithm has robust convergence characteristics;

- PSO-based techniques produce high-quality solutions at a lower time-cost but with better stability corresponding to the convergence aspects, as compared to other stochastic methods.

- A set of defined coordinates specifying the position of the particle;

- Speed corresponding to the movement of the particle. There are several iterations when the particles have different positions. The characteristics evolve, considering the best position, neighbor position, and previous position. Such evolution of particles implies that several particles interact directly with a single particle, especially with the one having the optimal criteria.

- represents the present candidate solution comprising the position of the ith particle during the kth iteration, while represents the new position of the particles;

- and represent the old and new velocities of the particles;

- specifies the optimal position, also referred to as the “personnel best”, obtained in the past by the ith particle;

- represents the ideal position corresponding to a particle’s neighbors and is called the global best;

- The and acceleration coefficients are generally equal and have values between 0 and 2. In order to achieve maximum acceleration and are random values generated at each iteration, they respect a uniform distribution;

- The number (k) of iterations is important information for the operation of PSO.

4.2. Computation of Fitness Function

4.3. Algorithm

- Activate the initial population: ;

- For i = 1 up to the maximum number of populations, do:

- For j = 1 until p do:

- Create the objective function for the particle “j” (or the individual “j”) defined by Equation (52);

- Obtain the polynomial system defined by Equation (2);

- Determine the function defined by Equation (34);

- Calculate the control law defined by Equation (40);

- Evaluate the OF that should be minimized;

- End of “j”

- Classify the particles according to the above condition described by Equations (49) and (50).

- End of “i”

- Return:

4.4. Synthesis of the Fuzzy PSO Control

- Step 1: Activate all individuals;

- Step 2: Calculate the control gain defined by Equation (36);

- Step 3: Tune the regulator gains using the rules as demonstrated in the following table.

- Step 4: Calculate parameters of the Gaussian defined by Equations (53) and (54);

- Step 5: Apply the defuzzification formulas;

- Step 6: Calculate the objective function defined by Equation (50);

- Step 7: Update speed and position and iteration defined by Equation (49);

- Step 8: Update of and which are defined by Equation (48);

- Step 9: Go to step 2 to the stop criterion is met;

- Step 10: Determine the control defined by Equation (40);

- Step 11: Determine the fuzzy controller input expressed by:

- Step 12: Calculate the control system defined by Equation (44).

4.5. Third Simulation Analysis: The Fuzzy Sliding Mode Controller Implementation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khalil, H.K. Nonlinear Systems, 3rd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2002. [Google Scholar]

- Kayacan, E.; Khanesar, M.A. Identification of nonlinear dynamic systems using type-2 fuzzy neural networks a novel learning algorithm and a comparative study. IEEE Trans. Ind. Electron. 2015, 62, 1716–1724. [Google Scholar] [CrossRef]

- Gonzalez, J.; Yu, W. Nonlinear system modeling using LSTM neural networks. IFAC Pap. Online 2018, 51, 485–489. [Google Scholar] [CrossRef]

- Yip, P.P.; Hedrick, J.K. Adaptive dynamic surface control: A simplified algorithm for adaptive backstepping control of nonlinear systems. Int. J. Control 1998, 71, 959–979. [Google Scholar] [CrossRef]

- Swaroop, D.; Hedrick, J.K.; Yip, P.P.; Gerdes, J.C. Dynamic surface control for a class of nonlinear systems. IEEE Trans. Autom. Control 2000, 45, 1893–1899. [Google Scholar] [CrossRef] [Green Version]

- Isidori, A.; Byrnes, C.I. Output regulation of nonlinear systems. IEEE Trans. Autom. Control 1990, 35, 131–140. [Google Scholar] [CrossRef]

- Peroz, H.; Ogunnaike, B.; Devasia, S. Output tracking between operating points for nonlinear processes: Van de Vusse example. IEEE Trans. Contr. Syst. Technol. 2002, 10, 611–617. [Google Scholar] [CrossRef]

- Huang, J.; Rugh, W.J. On a nonlinear multivariable servomechanism problem. Automatica 1990, 26, 963–992. [Google Scholar] [CrossRef]

- Gopalswamy, S.; Hedrick, J.K. Tracking nonlinear non-minimum phase systems using sliding control. Int. J. Control 1993, 57, 1141–1158. [Google Scholar] [CrossRef]

- Kayacan, E.; Ramon, H.; Saeys, W. Robust trajectory tracking error model-based predictive control for unmanned ground vehicles. IEEE/ASME Trans. Mechatron. 2016, 21, 806–814. [Google Scholar] [CrossRef]

- Lau, J.Y.; Liang, W.; Liaw, H.C.; Tan, K.K. Sliding mode disturbance observer-based motion control for a piezoelectric actuator-based surgical device. Asian J. Control 2018, 20, 1194–1203. [Google Scholar] [CrossRef]

- Hamidi, F.; Jerbi, H. On the Estimation of a Maximal Lyapunov Function and Domain of Attraction Determination via a Genetic Algorithm. In Proceedings of the 2009 6th International Multi-Conference on Systems, Signals and Devices, Djerba, Tunisia, 23–26 March 2009; pp. 1–6. [Google Scholar] [CrossRef]

- Sun, T.; Zhang, J.; Pan, Y. Active disturbance rejection control of surface vessels using composite error updated extended state observer. Asian J. Control 2017, 19, 1802–1811. [Google Scholar] [CrossRef]

- Jerbi, H.; Hamidi, F.; Ben Aoun, S.; Olteanu, S.C.; Popescu, D. Lyapunov-based Methods for Maximizing the Domain of Attraction. Int. J. Comput. Commun. Control 2020, 15, 5. [Google Scholar] [CrossRef]

- Cheng, M.X.; Jiao, X.H. Observer-based adaptive l2 disturbance attenuation control of semi-active suspension with MR damper. Asian J. Control 2017, 19, 346–355. [Google Scholar] [CrossRef]

- Gao, F.; Wu, M.; She, J.; Cao, W. Active disturbance rejection in affine nonlinear systems based on equivalent-input disturbance approach. Asian J. Control 2017, 19, 1767–1776. [Google Scholar]

- Kayacan, E.; Peschel, J.M.; Chowdhary, G. A self-learning disturbance observer for nonlinear systems in feedback-error learning scheme. Eng. Appl. Artif. Intell. 2017, 62, 276–285. [Google Scholar] [CrossRef] [Green Version]

- Shtessel, Y.B. Nonlinear non-minimum phase output tracking via dynamic sliding manifolds. J. Frankl. Inst. 1998, 335, 841–850. [Google Scholar] [CrossRef]

- Willems, J.C. Almost invariant subspaces: An approach to high gain feedback design-Part II: Almost conditionally invariant subspaces. IEEE Trans. Autom. Control 1982, 27, 1071–1085. [Google Scholar] [CrossRef]

- Marino, R.; Respondek, W.; Van Der Schaft, A.J. Almost disturbance decoupling for single-input single-output nonlinear. IEEE Trans. Autom. Control 1989, 34, 1013–1017. [Google Scholar] [CrossRef] [Green Version]

- Weiland, S.; Willems, J.C. Almost disturbance decoupling with internal stability. IEEE Trans. Autom. Control 1989, 34, 277–286. [Google Scholar] [CrossRef]

- Marino, R.; Tomei, P. Nonlinear output feedback tracking with almost disturbance decoupling. IEEE Trans. Autom. Control 1999, 44, 18–28. [Google Scholar] [CrossRef]

- Qian, C.; Lin, W. Almost disturbance decoupling for a class of high-order nonlinear systems. IEEE Trans. Autom. Control 2000, 45, 1208–1214. [Google Scholar] [CrossRef]

- Charfeddine, S.; Jerbi, H. Trajectory tracking and disturbance rejection for nonlinear periodic process: A gains Scheduling design. IREMOS 2012, 5, 1075–1083. [Google Scholar]

- Ouyang, M.; Wang, Y. Optimization and Realization of the Continuous Reactor with Improved Automatic Disturbance Rejection Control. Complexity 2020, 2020, 4519428. [Google Scholar] [CrossRef]

- Charfeddine, S.; Jerbi, H. A Survey of nonlinear gain scheduling design control of continuous and discrete time systems. IJMIC 2013, 19, 203–216. [Google Scholar] [CrossRef]

- Charfeddine, S.; Jerbi, H.; Sbita, L. Nonlinear discrete–time gain scheduling control for affine nonlinear polynomial systems. IREMOS 2013, 6, 1031–1041. [Google Scholar]

- Chaouech, H.; Charfeddine, S.; Ouni, K.; Jerbi, H.; Nabli, L. Intelligent supervision approach based on multilayer neural PCA and nonlinear gain scheduling. Neural Comput. Appl. 2019, 31, 1153–1163. [Google Scholar] [CrossRef]

- Alshammari, O.; Mahyuddin, M.N.; Jerbi, H. A neural network-based adaptive backstepping control law with covariance resetting for asymptotic output tracking of a CSTR plant. IEEE Access 2020, 8, 29755–29766. [Google Scholar] [CrossRef]

- Alshammari, O.; Mahyuddin, M.N.; Jerbi, H. An advanced PID based control technique with adaptive parameter scheduling for a nonlinear CSTR plant. IEEE Access 2019, 7, 158085–158094. [Google Scholar] [CrossRef]

- Kravaris, C.; Arkun, Y. Geometric Nonlinear Control—An Overview. In Proceedings of the 4th International Conference on Chemical Process Control, Padre Island, TX, USA, 17–22 February 1991; pp. 477–515. [Google Scholar]

- Fernhndez, B.; Hedrick, K. Control of Multivariable Nonlinear Systems by the Sliding Mode Method. Int. J. Control 1987, 46, 1019–1040. [Google Scholar] [CrossRef]

- Sira-Ramirez, H. Sliding regimes in general nonlinear systems: A relative degree approach. Int. J. Control 1989, 50, 1487–1506. [Google Scholar] [CrossRef]

- Elmali, H.; Olga, N. Robust output tracking control of nonlinear MIMO systems via sliding mode technique. Automatica 1992, 45, 145–151. [Google Scholar] [CrossRef]

- Chiacchiarini, H.; Desages, A.C.; Romagnoli, J.A.; Palazoglu, A. Variable structure control with a second-order sliding condition: Application to a steam generator. Automatica 1995, 31, 1157–1168. [Google Scholar] [CrossRef]

- Kravaris, C.; Kantor, J.C. Geometric methods for nonlinear process control: 2. Synthesis methods. Ind. Eng. Chem. Res. 1990, 29, 2310–2323. [Google Scholar] [CrossRef]

- Dombi, J.; Hussain, A. A new approach to fuzzy control using the distending function. J. Process Control 2020, 86, 16–29. [Google Scholar] [CrossRef]

- Isidori, A. Nonlinear Control Systems, an Introduction; Springer: New York, NY, USA, 1989. [Google Scholar]

- Jerbi, H. Estimations of the Domains of Attraction for Classes of Nonlinear Continuous Polynomial Systems. Arab. J. Sci. Eng. 2017, 42, 2829–2837. [Google Scholar] [CrossRef]

- Daoutidis, P.; Kravaris, C. Synthesis of Feedforward state feedback controllers for nonlinear processes. AIChE J. 1989, 35, 1602–1616. [Google Scholar] [CrossRef] [Green Version]

- Utkin, V. Variable structure systems with sliding modes. IEEE Trans. Autom. Control 1977, 22, 212–222. [Google Scholar] [CrossRef]

- Ray, W.H. Advanced Process Control; McGraw Hill: New York, NY, USA, 1981. [Google Scholar]

- Calvet, J.P.; Arkun, Y. Feedforward and Feedback Linearization of Nonlinear Systems and Its Implementation Using Internal Model Control (IMC). Ind. Eng. Chem. Res. 1988, 27, 1822–1831. [Google Scholar] [CrossRef]

- Morari, M.; Zafiriou, E. Robust Process Control; Prentice Hall: New York, NY, USA, 1989. [Google Scholar]

- Henson, M.A.; Seborg, D.E. An internal model control strategy for nonlinear systems. AIChE J. 1991, 37, 1065–1081. [Google Scholar] [CrossRef]

- Peška, L.; Tashu, T.M.; Horváth, T. Swarm intelligence techniques in recommender systems—A review of recent research. Swarm Evol. Comput. 2019, 48, 201–219. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, S.; Ji, G. A Comprehensive survey on particle swarm optimization algorithm and its applications. Math. Probl. Eng. 2015, 2015, 1–38. [Google Scholar] [CrossRef] [Green Version]

- Del Ser, J.; Osaba, E.; Molina, D.; Yang, X.S.; Salcedo-Sanz, S.; Camacho, D.; Herrera, F. Bio-inspired computation: Where we stand and what’s next. Swarm Evol. Comput. 2019, 48, 220–250. [Google Scholar] [CrossRef]

- Boubaker, S.; Djemai, M.; Manamanni, N.; M’Sahli, F. Active modes and switching instants identification for linear switched systems based on discrete particle swarm optimization. Appl. Soft Comput. 2014, 14, 482–488. [Google Scholar] [CrossRef]

- Park, S.; Song, N.; Yu, W.; Kim, D. PSR: PSO-based signomial regression model. Int. J. Fuzzy Log. Intell. Syst. 2019, 19, 307–314. [Google Scholar] [CrossRef] [Green Version]

- Poli, R.; Kennedy, J.; Blackwell, T. Particle swarm optimization. Swarm Intell. 2007, 1, 33–57. [Google Scholar] [CrossRef]

- Bergh, F.V.D.; Engelbrecht, A.P. A study of particle swarm optimization particle trajectories. Inf. Sci. 2006, 176, 937–971. [Google Scholar]

- Clerc, M.; Kennedy, J. The particle swarm—Explosion, stability, and convergence in a multidimensional complex space. IEEE Trans. Evol. Comput. 2002, 6, 58–73. [Google Scholar] [CrossRef] [Green Version]

- Hamidi, F.; Aloui, M.; Jerbi, H.; Kchaou, M.; Abbassi, R.; Popescu, D.; Ben Aoun, S.; Dimon, C. Chaotic particle swarm optimisation for enlarging the domain of attraction of polynomial nonlinear systems. Electronics 2020, 9, 1704. [Google Scholar] [CrossRef]

| Description | Parameters |

|---|---|

| Activation energy | |

| Adiabatic temperature rise | |

| Damkohler number | |

| Heat transfer coefficient | |

| Dimensionless time | |

| Dimensionless conception | |

| Dimensionless temperature | |

| Dimensionless control input | |

| Feed temperature disturbance | |

| Feed composition disturbance |

| NB | NM | NS | Z | PS | PM | PB | ||

| NB | PB | PB | PB | PB | PM | PM | PM | |

| NM | PB | PB | PB | PM | PS | PS | PS | |

| NS | PM | PM | PM | PS | Z | Z | Z | |

| Z | PS | PS | PS | Z | NS | NS | NS | |

| PS | Z | Z | Z | NS | NM | NM | NM | |

| PM | NS | NS | NS | NM | NB | NB | NB | |

| PB | NM | NM | NM | NB | NB | NB | NB | |

| Parameters | Values |

|---|---|

| Particle number | 10 |

| 2 | |

| 2 | |

| and | Random |

| Iteration | 20 |

| 0.3 | |

| 1.1 |

| Control Strategy | IAE | Control Effort | ISE | Maximum Overshoot |

|---|---|---|---|---|

| Fuzzy PSO | 0.01 | 1152 | 0.000 | 0.11 |

| SMC-based I/O FBL | 0.15 | 1609 | 0.016 | 0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Charfeddine, S.; Boudjemline, A.; Ben Aoun, S.; Jerbi, H.; Kchaou, M.; Alshammari, O.; Elleuch, Z.; Abbassi, R. Design of a Fuzzy Optimization Control Structure for Nonlinear Systems: A Disturbance-Rejection Method. Appl. Sci. 2021, 11, 2612. https://doi.org/10.3390/app11062612

Charfeddine S, Boudjemline A, Ben Aoun S, Jerbi H, Kchaou M, Alshammari O, Elleuch Z, Abbassi R. Design of a Fuzzy Optimization Control Structure for Nonlinear Systems: A Disturbance-Rejection Method. Applied Sciences. 2021; 11(6):2612. https://doi.org/10.3390/app11062612

Chicago/Turabian StyleCharfeddine, Samia, Attia Boudjemline, Sondess Ben Aoun, Houssem Jerbi, Mourad Kchaou, Obaid Alshammari, Zied Elleuch, and Rabeh Abbassi. 2021. "Design of a Fuzzy Optimization Control Structure for Nonlinear Systems: A Disturbance-Rejection Method" Applied Sciences 11, no. 6: 2612. https://doi.org/10.3390/app11062612