Microwave Drying for Production of Rehydrated Foods: A Case Study of Stink Bean (Parkia speciosa) Seed

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Dehydration of Stink Bean

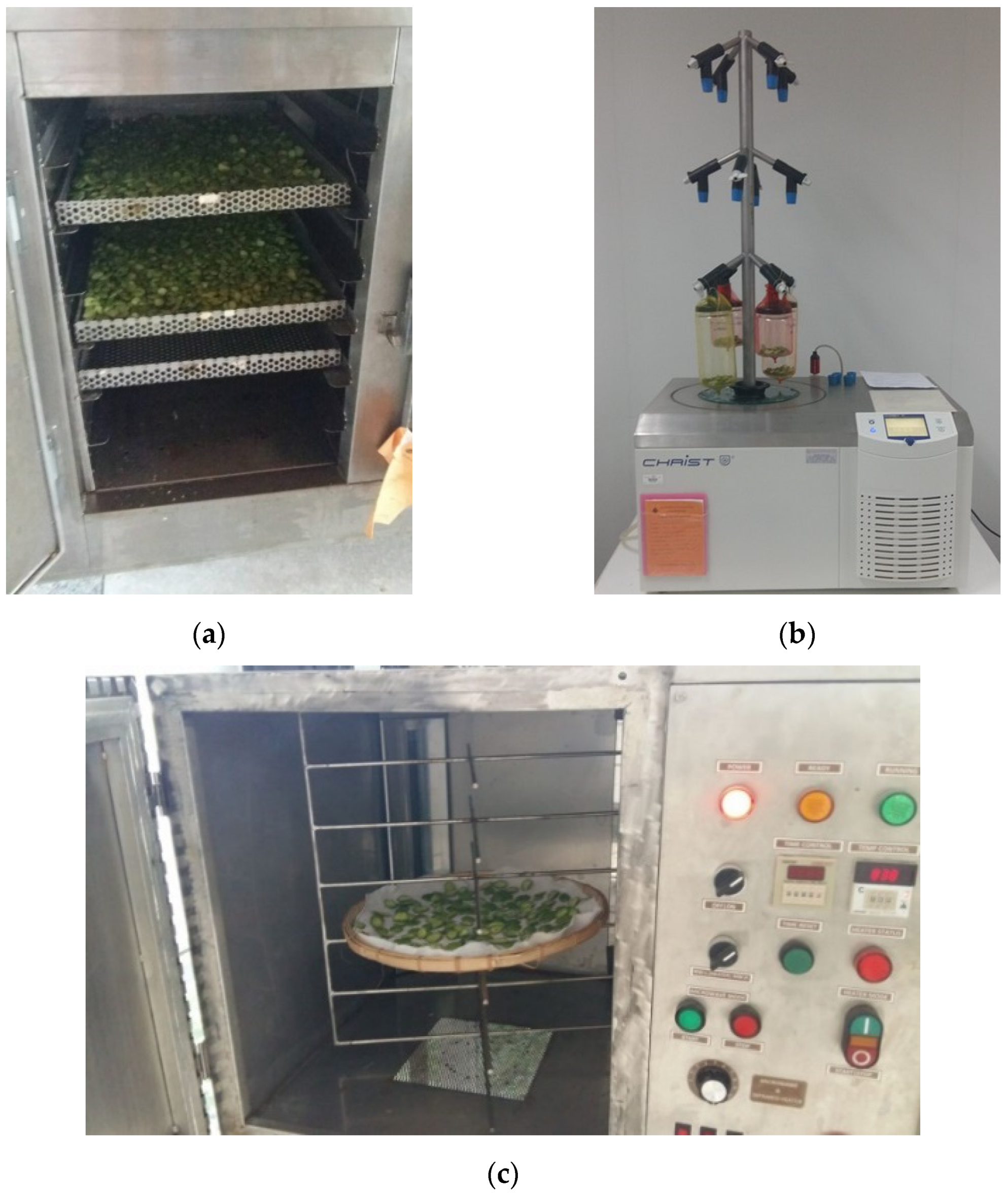

- (1)

- Convective drying: Approximately 1185 g of stink beans was placed on the trays and dried in a convective oven at the Food Technology laboratory of Walailak University, Thailand at 60 °C for 6 h. The drying time was determined based on the characteristics of drying curves in preliminary experiments. To achieve moisture content down to 5%, a drying time shorter than 6 h would require an increase in temperature, which is the critical cause of the degradation of the nutritional value of plants and seeds [17]. The total phenolic compound reduces significantly if the temperature exceeds 60 °C [61]. The temperature of 60 °C was therefore selected to ensure that nutritional quality is retained.

- (2)

- Freeze drying: Stink beans of about 400 g were dried for 72 h at about −70 °C in a freeze dryer (Christ, gamma 2–16 LSCplus, Osterode am Harz, Germany), operated at the maximum fan speed.

- (3)

- Microwave drying: Stink beans of about 200 g were dried in a 600 W microwave drying system, previously designed and constructed for fish and durian drying [24,25], at 35 °C for 10 h and at 40 °C for 6 h. The drying time was determined based on the period needed to reduce the moisture content down to 15%. A microwave vacuum dryer was also developed by reducing the pressure in the microwave cavity with a rotary pump [44]. This low-pressure microwave drying was carried out under the pressure of around 400 Pa at 35 °C until reaching a comparable moisture.

2.2. Characterization of Dehydrated Stink Bean

2.3. Rehydration of Dehydrated Stink Bean

3. Results and Discussion

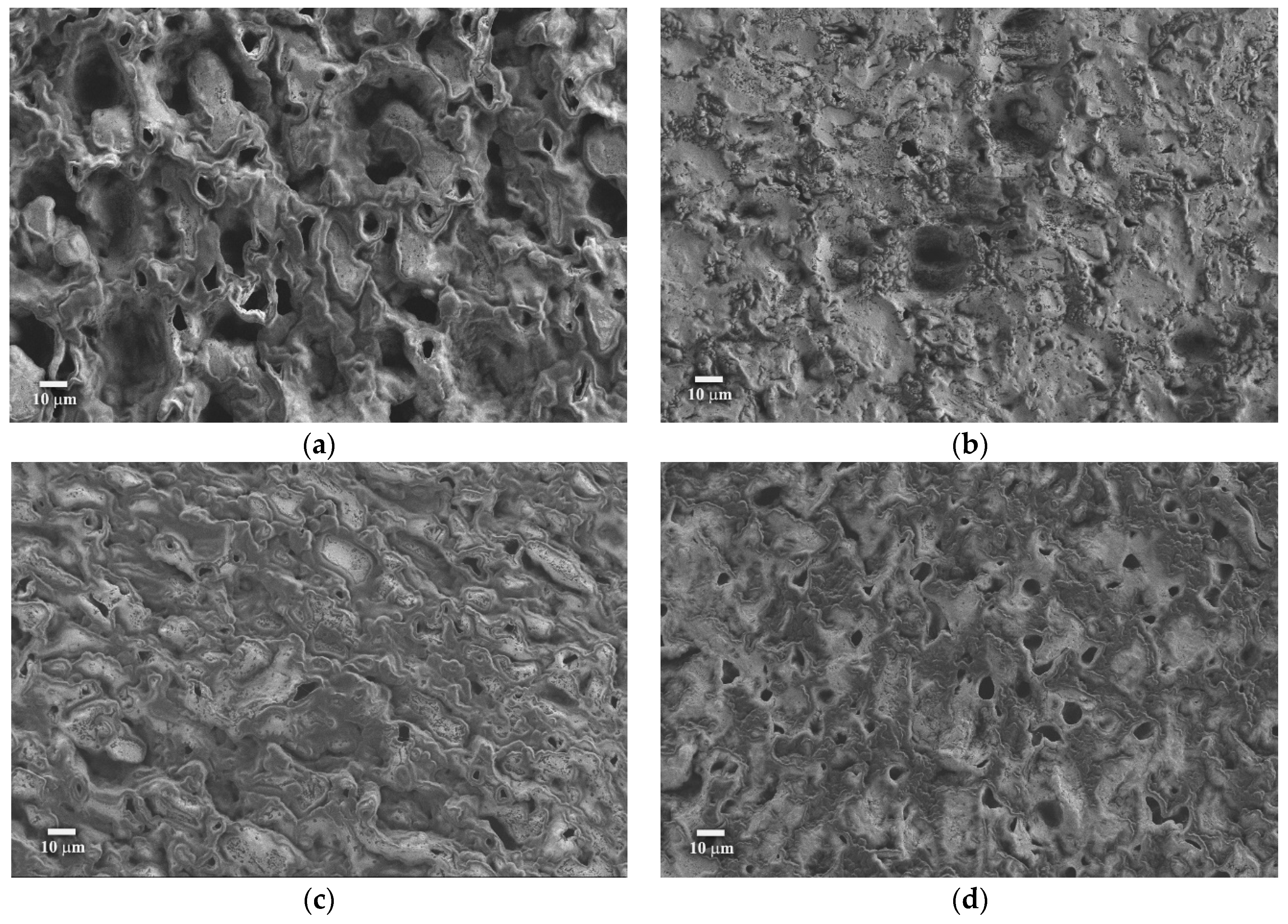

3.1. Characterization and Rehydration of Stink Beans Dehydrated by Different Methods

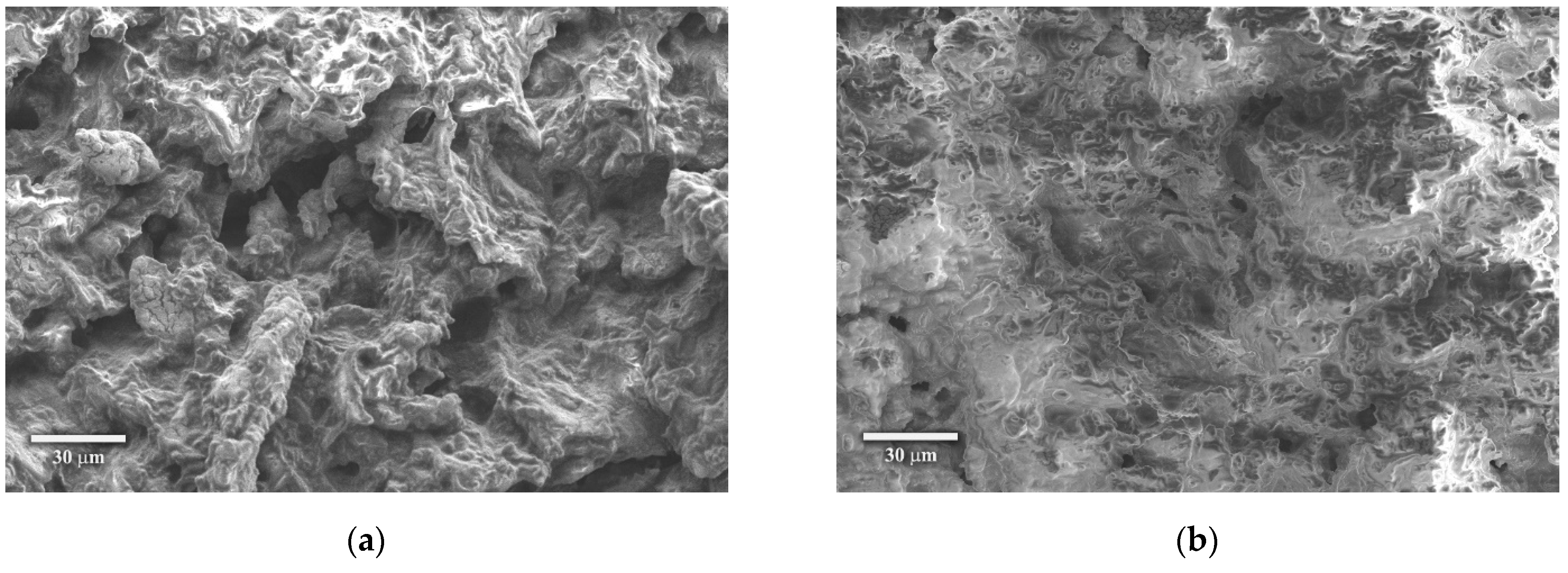

3.2. Reduction in Dehydration and Rehydration Times

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Phukasmas, P.; Songsermpong, S. Instant rice process development: Effect of rice cooking methods on the quality of jasmine instant rice dried by industrial microwave oven. J. Microbiol. Biotechnol. Food Sci. 2019, 9, 330–334. [Google Scholar] [CrossRef]

- Bochnak-Niedźwiecka, J.; Świeca, M. Quality of new functional powdered beverages enriched with lyophilized fruits—Potentially bioaccessible antioxidant properties, nutritional value, and consumer analysis. Appl. Sci. 2020, 10, 3668. [Google Scholar] [CrossRef]

- Sagar, V.R.; Suresh Kumar, P. Recent advances in drying and dehydration of fruits and vegetables: A review. J. Food Sci. Technol. 2010, 47, 15–26. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Menon, A.; Stojceska, V.; Tassou, S.A. A systematic review on the recent advances of the energy efficiency improvements in non-conventional food drying technologies. Trends Food Sci. Technol. 2020, 100, 67–76. [Google Scholar] [CrossRef]

- Guimarães, R.M.; Ida, E.I.; Falcão, H.G.; De Rezende, T.A.M.; Silva, J.D.S.; Alves, C.C.F.; Da Silva, M.A.P.; Egea, M.B. Evaluating technological quality of okara flours obtained by different drying processes. LWT Food Sci. Technol. 2020, 123, 109062. [Google Scholar] [CrossRef]

- Belmiro, R.H.; Tribst, A.A.L.; Cristianini, M. Impact of high pressure processing in hydration and drying curves of common beans (Phaseolus vulgaris L.). Innov. Food Sci. Emerg. Technol. 2018, 47, 279–285. [Google Scholar] [CrossRef]

- Jedlińska, A.; Wiktor, A.; Witrowa-Rajchert, D.; Derewiaka, D.; Wołosiak, R.; Matwijczuk, A.; Niemczynowicz, A.; Samborska, K. Quality assessment of honey powders obtained by high- and low-temperature spray drying. Appl. Sci. 2021, 11, 224. [Google Scholar] [CrossRef]

- Kerr, W.L.; Varner, A. Chemical and physical properties of vacuum-dried red beetroot (Beta vulgaris) powders compared to other drying methods. Dry. Technol. 2020, 38, 1165–1174. [Google Scholar] [CrossRef]

- Cortés-Rojas, D.; Souza, C.; Oliveira, W. Assessment of stability of a spray dried extract from the medicinal plant Bidens pilosa L. J. King Saud Univ. Eng. Sci. 2016, 28, 141–146. [Google Scholar] [CrossRef] [Green Version]

- Maskan, M. Drying, shrinkage and rehydration characteristics of kiwifruits during hot air and microwave drying. J. Food Eng. 2001, 48, 177–182. [Google Scholar] [CrossRef]

- Melgar-Almanza, A.; Horacio Guzmán-Maldonado, S.; Núñez-Colín, C.; Herrera-Hernández, M.G.; Medina-Ramos, G. Effect of drying on antioxidant capacity, physicochemical and functional characteristics of Mexican serviceberry fruit. J. Berry Res. 2015, 5, 97–105. [Google Scholar] [CrossRef] [Green Version]

- Kaveh, M.; Abbaspour-Gilandeh, Y. Impacts of hybrid (convective-infrared-rotary drum) drying on the quality attributes of green pea. J. Food Process. Eng. 2020, 43, 13424. [Google Scholar] [CrossRef]

- Rojas, M.L.; Silveira, I.; Augusto, P.E.D. Ultrasound and ethanol pre-treatments to improve convective drying: Drying, rehydration and carotenoid content of pumpkin. Food Bioprod. Process. 2020, 119, 20–30. [Google Scholar] [CrossRef]

- Abbaspour-Gilandeh, Y.; Kaveh, M.; Aziz, M. Ultrasonic-microwave and infrared assisted convective drying of carrot: Drying kinetic, quality and energy consumption. Appl. Sci. 2020, 10, 6309. [Google Scholar] [CrossRef]

- Ratti, C. Hot air and freeze-drying of high-value foods: A review. J. Food Eng. 2001, 49, 311–319. [Google Scholar] [CrossRef]

- Sánchez, V.; Baeza, R.; Chirife, J. Comparison of monomeric anthocyanins and colour stability of fresh, concentrate and freeze-dried encapsulated cherry juice stored at 38 °C. J. Berry Res. 2015, 5, 243–251. [Google Scholar] [CrossRef] [Green Version]

- How, Y.-K.; Siow, L.-F. Effects of convection-, vacuum-and freeze-drying on antioxidant, physicochemical properties, functional properties and storage stability of stink bean (Parkia speciosa) powder. J. Food Sci. Technol. 2020, 57, 4637–4648. [Google Scholar] [CrossRef] [PubMed]

- Akbar, M.A.; Karyadi, J.N.W.; Imaniar, D.I.; Mar’Fuah, S.; Hati, F.I.P. Changes of Petai during drying using freeze drying method. IOP Conf. Ser. Earth Environ. Sci. 2019, 355, 012053. [Google Scholar] [CrossRef] [Green Version]

- Ahmadi, S.; Sheikh-Zeinoddin, M.; Soleimanian-Zad, S.; Alihosseini, F.; Yadav, H. Effects of different drying methods on the physicochemical properties and antioxidant activities of isolated acorn polysaccharides. LWT Food Sci. Technol. 2019, 100, 1–9. [Google Scholar] [CrossRef]

- Huang, L.-L.; Zhang, M.; Yan, W.-Q.; Mujumdar, A.S.; Sun, D.-F. Effect of coating on post-drying of freeze-dried strawberry pieces. J. Food Eng. 2009, 92, 107–111. [Google Scholar] [CrossRef]

- Tribuzi, G.; Laurindo, J.B. Dehydration and rehydration of cooked mussels. Int. J. Food Eng. 2016, 12, 173–180. [Google Scholar] [CrossRef]

- Monteiro, R.L.; Carciofi, B.A.M.; Marsaioli, A.; Laurindo, J.B. How to make a microwave vacuum dryer with turntable. J. Food Eng. 2015, 166, 276–284. [Google Scholar] [CrossRef] [Green Version]

- Figiel, A.; Michalska, A. Overall quality of fruits and vegetables products affected by the drying processes with the assistance of vacuum-microwaves. Int. J. Mol. Sci. 2017, 18, 71. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pianroj, Y.; Kerdthongmee, P.; Nisoa, M.; Kerdthongmee, P.; Galakarn, J. Development of a microwave system for highly-efficient drying of fish. Walailak J. Sci. Tech. 2006, 3, 237–250. [Google Scholar]

- Suwanchote, C.; Weerakul, J.; Sirisathitkul, C.; Nisoa, M. Color and hardness of durian chips irradiated by controlled low power microwave. Food Sci. Biotechnol. 2012, 21, 1767–1770. [Google Scholar] [CrossRef]

- Pongpichaiudom, A.; Songsermpong, S. Characterization of frying, microwave-drying, infrared-drying, and hot-air drying on protein-enriched, instant noodle microstructure, and qualities. J. Food Process. Preserv. 2017, 42, e13560. [Google Scholar] [CrossRef]

- Subramaniam, S.; Wen, X.-Y.; Jing, P. One-step microwave curing-dehydration of Gastrodia elata Blume: Relationship between phytochemicals, water states and morphometric characteristics. Ind. Crop. Prod. 2020, 153, 112579. [Google Scholar] [CrossRef]

- Hizaji, A.S.; Maghsoudlou, Y.; Jafari, S.M. Effect of water temperature, variety and shelf life of rehydration kinetics of mi-crowave dried potato cubes. Lat. Am. Appl. Res. 2011, 41, 249–254. [Google Scholar]

- Mujaffar, S.; Loy, A.L. The rehydration behavior of microwave-dried amaranth (Amaranthus dubius) leaves. Food Sci. Nutr. 2017, 5, 399–406. [Google Scholar] [CrossRef]

- Nguyen, T.; Nguyen, Q.; Nguyen, P.; Tran, B.; Huynh, P.T. Effects of drying conditions in low-temperature microwave-assisted drying on bioactive compounds and antioxidant activity of dehydrated bitter melon (Momordica charantia L.). Food Sci. Nutr. 2020, 8, 3826–3834. [Google Scholar] [CrossRef]

- Monteiro, R.L.; De Moraes, J.O.; Domingos, J.D.; Carciofi, B.A.M.; Laurindo, J.B. Evolution of the physicochemical properties of oil-free sweet potato chips during microwave vacuum drying. Innov. Food Sci. Emerg. Technol. 2020, 63, 102317. [Google Scholar] [CrossRef]

- Nijhuis, H.; Torringa, H.; Muresan, S.; Yuksel, D.; Leguijt, C.; Kloek, W. Approaches to improving the quality of dried fruit and vegetables. Trends Food Sci. Technol. 1998, 9, 13–20. [Google Scholar] [CrossRef]

- Reyes, A.; Campos, C.; Vega, R. Drying of turnip seeds with microwaves in fixed and pulsed fluidized beds. Dry. Technol. 2006, 24, 1469–1480. [Google Scholar] [CrossRef]

- Barreto, I.; Tribuzi, G.; Junior, A.M.; Carciofi, B.; Laurindo, J. Oil–free potato chips produced by microwave multiflash drying. J. Food Eng. 2019, 261, 133–139. [Google Scholar] [CrossRef]

- Zielinska, M.; Michalska, A. Microwave-assisted drying of blueberry (Vaccinium corymbosum L.) fruits: Drying kinetics, polyphenols, anthocyanins, antioxidant capacity, colour and texture. Food Chem. 2016, 212, 671–680. [Google Scholar] [CrossRef] [PubMed]

- Nawirska, A.; Figiel, A.; Kucharska, A.Z.; Sokół-Łętowska, A.; Biesiada, A. Drying kinetics and quality parameters of pumpkin slices dehydrated using different methods. J. Food Eng. 2009, 94, 14–20. [Google Scholar] [CrossRef]

- Calín-Sánchez, Á.; Figiel, A.; Lech, K.; Szumny, A.; Martínez-Tomé, J.; Carbonell-Barrachina, Á.A. Dying methods affect the aroma of Origanum majorana L. analyzed by GC–MS and descriptive sensory analysis. Ind. Crop. Prod. 2015, 74, 218–227. [Google Scholar] [CrossRef]

- Bondaruk, J.; Markowski, M.; Błaszczak, W. Effect of drying conditions on the quality of vacuum-microwave dried potato cubes. J. Food Eng. 2007, 81, 306–312. [Google Scholar] [CrossRef]

- Nahimana, H.; Zhang, M. Shrinkage and color change during microwave vacuum drying of carrot. Dry. Technol. 2011, 29, 836–847. [Google Scholar] [CrossRef]

- Ando, Y.; Hagiwara, S.; Nabetani, H.; Sotome, I.; Okunishi, T.; Okadome, H.; Orikasa, T.; Tagawa, A. Effects of prefreezing on the drying characteristics, structural formation and mechanical properties of microwave-vacuum dried apple. J. Food Eng. 2019, 244, 170–177. [Google Scholar] [CrossRef]

- Kumar, V.; Devi, M.K.; Panda, B.K.; Shrivastava, S.L. Shrinkage and rehydration characteristics of vacuum assisted microwave dried green bell pepper. J. Food Process. Eng. 2019, 42, 13030. [Google Scholar] [CrossRef]

- Pankyamma, V.; Mokam, S.Y.; Debbarma, J.; Rao, M.B. Effects of microwave vacuum drying and conventional drying methods on the physicochemical and microstructural properties of squid shreds. J. Sci. Food Agric. 2019, 99, 5778–5783. [Google Scholar] [CrossRef] [PubMed]

- Kantrong, H.; Tansakul, A.; Mittal, G.S. Drying characteristics and quality of shiitake mushroom undergoing microwave-vacuum drying and microwave-vacuum combined with infrared drying. J. Food Sci. Technol. 2014, 51, 3594–3608. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nisoa, M.; Kerdtongmee, P. Low-pressure microwave heating system for drying of swiftlet bird’s nest. In Proceedings of the 3rd International Conference on Agricultural and Food Engineering, Kuala Lumpur, Malaysia, 23–25 August 2016. [Google Scholar]

- Monteiro, R.L.; Link, J.V.; Tribuzi, G.; Carciofi, B.A.; Laurindo, J.B. Microwave vacuum drying and multi-flash drying of pumpkin slices. J. Food Eng. 2018, 232, 1–10. [Google Scholar] [CrossRef]

- Pei, F.; Shi, Y.; Mariga, A.M.; Yang, W.-J.; Tang, X.-Z.; Zhao, L.-Y.; An, X.-X.; Hu, Q.-H. Comparison of freeze-drying and freeze-drying combined with microwave vacuum drying methods on drying kinetics and rehydration characteristics of button mushroom (Agaricus bisporus) slices. Food Bioprocess. Technol. 2014, 7, 1629–1639. [Google Scholar] [CrossRef]

- Chhikara, N.; Devi, H.R.; Jaglan, S.; Sharma, P.; Gupta, P.; Panghal, A. Bioactive compounds, food applications and health benefits of Parkia speciosa (stinky beans): A review. Agric. Food Secur. 2018, 7, 46. [Google Scholar] [CrossRef] [Green Version]

- Asikin, Y.; Kusumiyati; Shikanai, T.; Wada, K. Volatile aroma components and MS-based electronic nose profiles of dogfruit (Pithecellobium jiringa) and stink bean (Parkia speciosa). J. Adv. Res. 2018, 9, 79–85. [Google Scholar] [CrossRef]

- Ghasemzadeh, A.; Jaafar, H.Z.E.; Bukhori, M.F.M.; Rahmat, M.H.; Rahmat, A. Assessment and comparison of phytochemical constituents and biological activities of bitter bean (Parkia speciosa Hassk.) collected from different locations in Malaysia. Chem. Cent. J. 2018, 12, 12. [Google Scholar] [CrossRef] [Green Version]

- Wonghirundecha, S.; Benjakul, S.; Sumpavapol, P. Total phenolic content, antioxidant and antimicrobial activities of stink bean (Parkia speciosa Hassk.) pod extracts. Songklanakarin J. Sci. Technol. 2014, 36, 301–308. [Google Scholar]

- Jongjareonrak, A.; Saelim, K.; Benjakul, S. Changes of antioxidant activities of stink beans (Parkia speciosa Haask) during storage. Agric. Sci. J. 2008, 39, 95–98. (In Thai) [Google Scholar]

- Jongjareonrak, A.; Saelim, K.; Benjakul, S. Effect of pH and heating on antioxidant activities of stink beans. Agric. Sci. J. 2010, 41, 87–90. (In Thai) [Google Scholar]

- Hasim; Faridah, D.; Kurniawati, D.A. Antibacterial activity of Parkia speciosa Hassk peel to Escherichia coli and Staphylo-coccus aureus bacteria. J. Chem. Pharm. 2015, 7, 239–243. [Google Scholar]

- Wong, S.P.; Leong, L.P.; Koh, J.H.W. Antioxidant activities of aqueous extracts of selected plants. Food Chem. 2006, 99, 775–783. [Google Scholar] [CrossRef]

- Kamisah, Y.; Othman, F.; Qodriyah, H.M.S.; Jaarin, K. Parkia speciosa Hassk: A potential phytomedicine. Evid. Based Complement. Altern. Med. 2013, 2013, 709028. [Google Scholar] [CrossRef] [Green Version]

- Tocmo, R.; Liang, D.; Wang, C.; Poh, J.; Huang, D. Organosulfide profile and hydrogen sulfide-releasing capacity of stinky bean (Parkia speciosa) oil: Effects of pH and extraction methods. Food Chem. 2016, 190, 1123–1129. [Google Scholar] [CrossRef]

- Gan, C.-Y.; Latiff, A.A. Antioxidant Parkia speciosa pod powder as potential functional flour in food application: Physicochemical properties’ characterization. Food Hydrocoll. 2011, 25, 1174–1180. [Google Scholar] [CrossRef]

- Ravichandran, V.; Vasanthi, S.; Shalini, S.; Shah, S.A.A.; Tripathy, M.; Paliwal, N. Green synthesis, characterization, antibacterial, antioxidant and photocatalytic activity of Parkia speciosa leaves extract mediated silver nanoparticles. Results Phys. 2019, 15, 102565. [Google Scholar] [CrossRef]

- Siow, H.-L.; Gan, C.-Y. Extraction of antioxidative and antihypertensive bioactive peptides from Parkia speciosa seeds. Food Chem. 2013, 141, 3435–3442. [Google Scholar] [CrossRef]

- Anuar, F.I.; Hadibarata, T.; Muryanto, M.; Yuniarto, A.; Priyandoko, D.; Sari, A.A. Innovative chemically modified biosorbent for removal of procion red. Int. J. Technol. 2019, 10, 776. [Google Scholar] [CrossRef] [Green Version]

- Miranda, M.; Vega-Gálvez, A.; López, J.; Parada, G.; Sanders, M.; Aranda, M.; Uribe, E.; Di Scala, K. Impact of air-drying temperature on nutritional properties, total phenolic content and antioxidant capacity of quinoa seeds (Chenopodium quinoa Willd.). Ind. Crop. Prod. 2010, 32, 258–263. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 17th ed.; The Association of Official Analytical Chemists: Washington, DC, USA, 2000. [Google Scholar]

- Sirisathitkul, Y.; Kaewareelap, S. Color analysis of batik fabric by facile smartphone colorimetry. Int. J. Adv. Sci. Eng. Inf. Technol. 2021, 11, 84–91. [Google Scholar] [CrossRef]

- Zurabravo, L.; Ahhen, K.; Vegagalvez, A.; Garciasegovia, P.; LemusMondaca, R. Effect of rehydration temperature on functional properties, antioxidant capacity and structural characteristics of apple (Granny Smith) slices in relation to mass transfer kinetics. J. Food Process. Eng. 2013, 36, 559–571. [Google Scholar] [CrossRef]

- Ferenczi, S.; Czukor, B.; Cserhalmi, Z. Evaluation of microwave vacuum drying combined with hot-air drying and compared with freeze- and hot-air drying by the quality of the dried apple product. Period. Polytech. Chem. Eng. 2014, 58, 111–116. [Google Scholar] [CrossRef] [Green Version]

- Calín-Sánchez, Á.; Lipan, L.; Cano-Lamadrid, M.; Kharaghani, A.; Masztalerz, K.; Carbonell-Barrachina, Á.A.; Figiel, A. Comparison of traditional and novel drying techniques and its effect on quality of fruits, vegetables and aromatic herbs. Foods 2020, 9, 1261. [Google Scholar] [CrossRef] [PubMed]

- Prasert, W.; Suwannaporn, P. Optimization of instant jasmine rice process and its physicochemical properties. J. Food Eng. 2009, 95, 54–61. [Google Scholar] [CrossRef]

- Matsuura, Y.; Takehira, M.; Joti, Y.; Ogasahara, K.; Tanaka, T.; Ono, N.; Kunishima, N.; Yutani, K. Thermodynamics of protein denaturation at temperatures over 100 °C: CutA1 mutant proteins substituted with hydrophobic and charged residues. Sci. Rep. 2015, 5, 15545. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kishore, D.; Kundu, S.; Kayastha, A.M. Thermal, chemical and ph induced denaturation of a multimeric β-galactosidase reveals multiple unfolding pathways. PLoS ONE 2012, 7, e50380. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Drying Methods | Dehydration Time (h) | Starting Weight (g) | Specific Energy Consumption (MJ/kg) | Moisture Content w.b. (%) |

|---|---|---|---|---|

| Convective Dryingat 60 °C | 6 | 1185 | 75 ± 6 | 4.23 ± 0.21 |

| Freeze Drying at −70 °C | 72 | 400 | N/A | 0 |

| Microwave Dryingat 35 °C | 10 | 200 | 146 ± 9 | 13.6 ± 0.7 |

| Microwave Dryingat 40 °C | 6 | 200 | 102 ± 8 | 11.6 ± 0.6 |

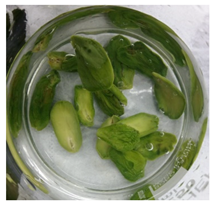

| Drying Methods | Dehydration Time (h) | Appearance | Rehydration Time in 38 °C Water (min) | |

|---|---|---|---|---|

| Dehydrated Product | After Rehydration | |||

| Convective Dryingat 60 °C | 6 |  |  | 90 |

| Freeze Dryingat −70 °C | 72 |  |  | 120 |

| Microwave Dryingat 35 °C | 10 |  |  | 65 |

| Microwave Dryingat 40 °C | 6 |  |  | 65 |

| Pressure during Microwave Drying | Dehydration Time (h) | Appearance and CIE L*a*b* Color Space | Rehydration Time (min) | |

|---|---|---|---|---|

| Dehydrated Product | After Rehydration | |||

| Ambient pressure (101 kPa) | 10 |  L* = 21 ± 4, a* = −3.7 ± 5, b* = 16 ± 1 |  L* = 45 ± 2, a* = −8.3 ± 4, b* = 40 ± 8 | 65 |

| Low pressure (400 Pa) | 6 |  L* = 24 ± 2, a* = −13 ± 1, b* = 24 ± 4 |  L* = 45 ± 2, a* = −22 ± 1, b* = 48 ± 1 | 65 |

| Stink Bean | Moisture Content w.b. (%) | Crude Protein (%) |

|---|---|---|

| Fresh | 73.1 ± 3.7 | 31.02 |

| Microwave drying at 101 kPa | 15.7 ± 0.8 | 31.23 |

| Microwave drying at 400 Pa | 11.3 ± 0.6 | 30.41 |

| Temperature of Water in Rehydration (°C) | Appearance and CIE L*a*b* Color Space | Rehydration Time | |

|---|---|---|---|

| Dehydrated Product | After Rehydration | (min) | |

| 38 |  L* = 34 ± 1, a*= −19 ± 2, b*= 36 ± 3 |  L* = 46 ± 2, a*= −16 ± 1, b*= 48 ± 3 | 65 |

| 50 |  L* = 33 ± 3, a*= −29 ± 3, b*= 37 ± 1 |  L* = 48 ± 7, a*= −33 ± 2, b*= 51 ± 4 | 40 |

| 70 |  L* = 31 ± 3, a*= −21 ± 5, b*= 35 ± 5 |  L* = 59 ± 7, a*= −20 ± 4, b*= 50 ± 2 | 30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nisoa, M.; Wattanasit, K.; Tamman, A.; Sirisathitkul, Y.; Sirisathitkul, C. Microwave Drying for Production of Rehydrated Foods: A Case Study of Stink Bean (Parkia speciosa) Seed. Appl. Sci. 2021, 11, 2918. https://doi.org/10.3390/app11072918

Nisoa M, Wattanasit K, Tamman A, Sirisathitkul Y, Sirisathitkul C. Microwave Drying for Production of Rehydrated Foods: A Case Study of Stink Bean (Parkia speciosa) Seed. Applied Sciences. 2021; 11(7):2918. https://doi.org/10.3390/app11072918

Chicago/Turabian StyleNisoa, Mudtorlep, Karaket Wattanasit, Arlee Tamman, Yaowarat Sirisathitkul, and Chitnarong Sirisathitkul. 2021. "Microwave Drying for Production of Rehydrated Foods: A Case Study of Stink Bean (Parkia speciosa) Seed" Applied Sciences 11, no. 7: 2918. https://doi.org/10.3390/app11072918