Multi-Resolution SPH Simulation of a Laser Powder Bed Fusion Additive Manufacturing Process

Abstract

:1. Introduction

2. Computational Framework

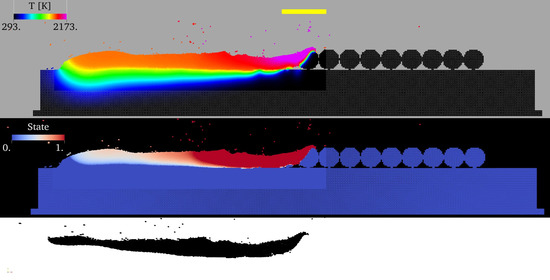

2.1. Thermal Model

2.2. Mechanical Model

2.3. Material Model

2.4. Time Integration

2.5. Dynamic Particle Refinement

3. Validation

3.1. Liquid Droplet: Validation of Surface Tension

3.2. Weld Pool Experiment: Validation of Multiphysics Modeling

4. Application: Laser Powder Bed Fusion

4.1. Parameter Study and Some General Observations

4.2. Computational Performance

- Single resolution w/o dynamics particle refinement w/uniform discretization size

- Multi resolution w/dynamics particle refinement w/o neighbor-list optimization

- Multi resolution w/dynamics particle refinement w/neighbor-list optimization

- Single resolution w/o dynamics particle refinement w/uniform discretization size

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | additive manufacturing |

| CFD | computational fluid dynamics |

| CPU | central processing unit |

| FEM | finite element method |

| FVM | finite volume method |

| GPU | graphics processing unit |

| LBM | Lattice Boltzmann method |

| LPBF | laser powder bed fusion |

| PBF | powder bed fusion |

| SPH | smoothed particle hydrodynamics |

References

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- King, W.E.; Anderson, A.T.; Ferencz, R.M.; Hodge, N.E.; Kamath, C.; Khairallah, S.A.; Rubenchik, A.M. Laser powder bed fusion additive manufacturing of metals; physics, computational, and materials challenges. Appl. Phys. Rev. 2015, 2, 041304. [Google Scholar] [CrossRef]

- Lachmayer, R.; Lippert, R.B.; Fahlbusch, T. 3D-Druck beleuchtet. In Additive Manufacturing auf dem Weg in die Anwendung; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Uriondo, A.; Esperon-Miguez, M.; Perinpanayagam, S. The present and future of additive manufacturing in the aerospace sector: A review of important aspects. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2015, 229, 2132–2147. [Google Scholar] [CrossRef]

- Liu, R.; Wang, Z.; Sparks, T.; Liou, F.; Newkirk, J. Aerospace applications of laser additive manufacturing. In Laser Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2017; pp. 351–371. [Google Scholar]

- Wohlers, T.T. Wohlers Report…: 3D Printing and Additive Manufacturing, State of the Industry, Annual Worldwide Progress Report; Wohlers Associates Incorporated: Auckland, New Zealand, 2014. [Google Scholar]

- Francis, M.P.; Kemper, N.; Maghdouri-White, Y.; Thayer, N. Additive manufacturing for biofabricated medical device applications. In Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2018; pp. 311–344. [Google Scholar]

- Zaeh, M.F.; Branner, G. Investigations on residual stresses and deformations in selective laser melting. Prod. Eng. 2010, 4, 35–45. [Google Scholar] [CrossRef]

- Körner, C.; Attar, E.; Heinl, P. Mesoscopic simulation of selective beam melting processes. J. Mater. Process. Technol. 2011, 6, 978–987. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef] [Green Version]

- Gürtler, F.-J.; Karg, M.; Leitz, K.-H.; Schmidt, M. Simulation of laser beam melting of steel powders using the three-dimensional volume of fluid method. Phys. Procedia 2013, 41, 881–886. [Google Scholar] [CrossRef] [Green Version]

- Khairallah, S.A.; Anderson, A. Mesoscopic simulation model of selective laser melting of stainless steel powder. J. Mater. Process. Technol. 2014, 214, 2627–2636. [Google Scholar] [CrossRef]

- Lee, Y.; Zhang, W. Mesoscopic Simulation of Heat Transfer and Fluid Flow in Laser Powder Bed Additive Manufacturing. In Proceedings of the 26th Solid Freeform Fabrication Symposium, Austin, TX, USA, 10–12 August 2015. [Google Scholar]

- Cook, P.S.; Murphy, A.B. Simulation of melt pool behaviour during additive manufacturing: Underlying physics and progress. Addit. Manuf. 2020, 31, 100909. [Google Scholar] [CrossRef]

- Lee, Y.; Zhang, W. Modeling of heat transfer, fluid flow and solidification microstructure of nickel-base superalloy fabricated by laser powder bed fusion. Addit. Manuf. 2016, 12, 178–188. [Google Scholar] [CrossRef] [Green Version]

- Dai, D.; Gu, D. Influence of thermodynamics within molten pool on migration and distribution state of reinforcement during selective laser melting of AlN/AlSi10Mg composites. Int. J. Mach. Tools Manuf. 2016, 100, 14–24. [Google Scholar] [CrossRef]

- Yuan, P.; Gu, D. Molten pool behaviour and its physical mechanism during selective laser melting of TiC/AlSi10Mg nanocomposites: Simulation and experiments. J. Phys. D Appl. Phys. 2015, 48, 035303. [Google Scholar] [CrossRef]

- Bidare, P.; Bitharas, I.; Ward, R.; Attallah, M.; Moore, A.J. Fluid and particle dynamics in laser powder bed fusion. Acta Mater. 2018, 142, 107–120. [Google Scholar] [CrossRef]

- Lucy, L.B. A numerical approach to the testing of the fission hypothesis. Astron. J. 1977, 82, 1013–1024. [Google Scholar] [CrossRef]

- Gingold, R.A.; Monaghan, J.J. Smoothed particle hydrodynamics: Theory and application to non-spherical stars. Mon. Not. R. Astron. Soc. 1977, 181, 375–389. [Google Scholar] [CrossRef]

- Röthlin, M.; Klippel, H.; Afrasiabi, M.; Wegener, K. Metal cutting simulations using smoothed particle hydrodynamics on the GPU. Int. J. Adv. Manuf. Technol. 2019, 102, 3445–3457. [Google Scholar] [CrossRef]

- Afrasiabi, M.; Meier, L.; Röthlin, M.; Klippel, H.; Wegener, K. GPU-accelerated meshfree simulations for parameter identification of a friction model in metal machining. Int. J. Mech. Sci. 2020, 176, 105571. [Google Scholar] [CrossRef]

- Roethlin, M.; Klippel, H.; Afrasiabi, M.; Wegener, K. Meshless single grain cutting simulations on the GPU. Int. J. Mechatronics Manuf. Syst. 2019, 12, 272–297. [Google Scholar] [CrossRef]

- Afrasiabi, M.; Klippel, H.; Roethlin, M.; Wegener, K. Smoothed Particle Hydrodynamics Simulation of Orthogonal Cutting with Enhanced Thermal Modeling. Appl. Sci. 2021, 11, 1020. [Google Scholar] [CrossRef]

- Afrasiabi, M.; Klippel, H.; Roethlin, M.; Wegener, K. Parameter Identification of a Friction Model in Metal Cutting Simulations with GPU-Accelerated Meshfree Methods. In Proceedings of the 14th World Congress on Computational Mechanics, Paris, France, 19–24 July 2020; pp. 1–12. [Google Scholar]

- Hu, H.; Eberhard, P. Thermomechanically coupled conduction mode laser welding simulations using smoothed particle hydrodynamics. Comput. Part. Mech. 2017, 4, 473–486. [Google Scholar] [CrossRef]

- Trautmann, M.; Hertel, M.; Füssel, U. Numerical simulation of TIG weld pool dynamics using smoothed particle hydrodynamics. Int. J. Heat Mass Transf. 2017, 115, 842–853. [Google Scholar] [CrossRef]

- Russell, M.; Souto-Iglesias, A.; Zohdi, T. Numerical simulation of Laser Fusion Additive Manufacturing processes using the SPH method. Comput. Methods Appl. Mech. Eng. 2018, 341, 163–187. [Google Scholar] [CrossRef]

- Park, C.Y.; Zohdi, T.I. Numerical modeling of thermo-mechanically induced stress in substrates for droplet-based additive manufacturing processes. J. Manuf. Sci. Eng. 2019, 141, 061001. [Google Scholar] [CrossRef]

- Afrasiabi, M.; Chatzi, E.; Wegener, K. A Particle Strength Exchange Method for Metal Removal in Laser Drilling. Procedia CIRP 2018, 72, 1548–1553. [Google Scholar] [CrossRef]

- Afrasiabi, M.; Wegener, K. 3D Thermal Simulation of a Laser Drilling Process with Meshfree Methods. J. Manuf. Mater. Process. 2020, 4, 58. [Google Scholar] [CrossRef]

- Fürstenau, J.P.; Wessels, H.; Weißenfels, C.; Wriggers, P. Generating virtual process maps of SLM using powder-scale SPH simulations. Comput. Part. Mech. 2020, 7, 655–677. [Google Scholar] [CrossRef]

- Afrasiabi, M.; Röthlin, M.; Klippel, H.; Wegener, K. Meshfree simulation of metal cutting: An updated Lagrangian approach with dynamic refinement. Int. J. Mech. Sci. 2019, 160, 451–466. [Google Scholar] [CrossRef]

- Monaghan, J.J. Smoothed particle hydrodynamics. Annu. Rev. Astron. Astrophys. 1992, 30, 543–574. [Google Scholar] [CrossRef]

- Wendland, H. Piecewise polynomial, positive definite and compactly supported radial functions of minimal degree. Adv. Comput. Math. 1995, 4, 389–396. [Google Scholar] [CrossRef]

- Liu, M.; Liu, G. Smoothed particle hydrodynamics (SPH): An overview and recent developments. Arch. Comput. Methods Eng. 2010, 17, 25–76. [Google Scholar] [CrossRef] [Green Version]

- Hu, X.; Adams, N.A. A multi-phase SPH method for macroscopic and mesoscopic flows. J. Comput. Phys. 2006, 213, 844–861. [Google Scholar] [CrossRef]

- Marrone, S.; Colagrossi, A.; Di Mascio, A.; Le Touzé, D. Analysis of free-surface flows through energy considerations: Single-phase versus two-phase modeling. Phys. Rev. E 2016, 93, 053113. [Google Scholar] [CrossRef] [PubMed]

- Cleary, P.W.; Monaghan, J.J. Conduction modelling using smoothed particle hydrodynamics. J. Comput. Phys. 1999, 148, 227–264. [Google Scholar] [CrossRef]

- Afrasiabi, M.; Roethlin, M.; Wegener, K. Contemporary Meshfree Methods for Three Dimensional Heat Conduction Problems. Arch. Comput. Methods Eng. 2020, 27, 1413–1447. [Google Scholar] [CrossRef]

- Gusarov, A.; Yadroitsev, I.; Bertrand, P.; Smurov, I. Model of radiation and heat transfer in laser-powder interaction zone at selective laser melting. J. Heat Transf. 2009, 131, 072101. [Google Scholar] [CrossRef]

- Antuono, M.; Colagrossi, A.; Marrone, S.; Molteni, D. Free-surface flows solved by means of SPH schemes with numerical diffusive terms. Comput. Phys. Commun. 2010, 181, 532–549. [Google Scholar] [CrossRef]

- Colagrossi, A.; Antuono, M.; Le Touzé, D. Theoretical considerations on the free-surface role in the smoothed-particle-hydrodynamics model. Phys. Rev. E 2009, 79, 056701. [Google Scholar] [CrossRef]

- Becker, M.; Teschner, M. Weakly compressible SPH for free surface flows. In Proceedings of the 2007 ACM SIGGRAPH/Eurographics Symposium on Computer Animation, San Diego, CA, USA, 2–4 August 2007; pp. 209–217. [Google Scholar]

- Afrasiabi, M.; Mohammadi, S. Analysis of bubble pulsations of underwater explosions by the smoothed particle hydrodynamics method. In Proceedings of the ECCOMAS International Conference on Particle Based Methods, Spain, Barcelona, 25–27 November 2009. [Google Scholar]

- Afrasiabi, M.; Roethlin, M.; Wegener, K. Thermal simulation in multiphase incompressible flows using coupled meshfree and particle level set methods. Comput. Methods Appl. Mech. Eng. 2018, 336, 667–694. [Google Scholar] [CrossRef]

- Afrasiabi, M.; Roethlin, M.; Chatzi, E.; Wegener, K. A Robust Particle-Based Solver for Modeling Heat Transfer in Multiphase Flows. In Proceedings of the ECCM-ECFD, Glasgow, UK, 11–15 June 2018. [Google Scholar]

- Brackbill, J.U.; Kothe, D.B.; Zemach, C. A continuum method for modeling surface tension. J. Comput. Phys. 1992, 100, 335–354. [Google Scholar] [CrossRef]

- Adami, S.; Hu, X.; Adams, N. A new surface-tension formulation for multi-phase SPH using a reproducing divergence approximation. J. Comput. Phys. 2010, 229, 5011–5021. [Google Scholar] [CrossRef]

- Hashemi, H.; Sliepcevich, C. A numerical method for solving two-dimensional problems of heat conduction with change of phase. Chem. Eng. Prog. Symp. Ser. 1967, 63, 34–41. [Google Scholar]

- Monaghan, J.J. Smoothed particle hydrodynamics. Rep. Prog. Phys. 2005, 68, 1703. [Google Scholar] [CrossRef]

- Feldman, J.; Bonet, J. Dynamic refinement and boundary contact forces in SPH with applications in fluid flow problems. Int. J. Numer. Methods Eng. 2007, 72, 295–324. [Google Scholar] [CrossRef]

- Vacondio, R.; Rogers, B.; Stansby, P.; Mignosa, P. Variable resolution for SPH in three dimensions: Towards optimal splitting and coalescing for dynamic adaptivity. Comput. Methods Appl. Mech. Eng. 2016, 300, 442–460. [Google Scholar] [CrossRef]

- Afrasiabi, M. Thermomechanical Simulation of Manufacturing Processes Using GPU-Accelerated Particle Methods. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2020. [Google Scholar]

- He, X.; Fuerschbach, P.; DebRoy, T. Heat transfer and fluid flow during laser spot welding of 304 stainless steel. J. Phys. D Appl. Phys. 2003, 36, 1388. [Google Scholar] [CrossRef]

- Sahoo, P.; Debroy, T.; McNallan, M. Surface tension of binary metal—Surface active solute systems under conditions relevant to welding metallurgy. Metall. Trans. B 1988, 19, 483–491. [Google Scholar] [CrossRef]

- Dao, M.H.; Lou, J. Simulations of Laser Assisted Additive Manufacturing by Smoothed Particle Hydrodynamics. Comput. Methods Appl. Mech. Eng. 2021, 373, 113491. [Google Scholar] [CrossRef]

- Weirather, J.; Rozov, V.; Wille, M.; Schuler, P.; Seidel, C.; Adams, N.A.; Zaeh, M.F. A smoothed particle hydrodynamics model for laser beam melting of Ni-based alloy 718. Comput. Math. Appl. 2019, 78, 2377–2394. [Google Scholar] [CrossRef]

- Edelsbrunner, H.; Kirkpatrick, D.; Seidel, R. On the shape of a set of points in the plane. IEEE Trans. Inf. Theory 1983, 29, 551–559. [Google Scholar] [CrossRef] [Green Version]

| Density | Dynamic Viscosity | Surface Tension Coefficient | |

|---|---|---|---|

| Symbol | |||

| Unit | kg/m | Pa·s | N/m |

| Value | 1000 | 0.001 | 1 |

| Property | Symbol | Unit | Solid | Liquid |

|---|---|---|---|---|

| Dynamic viscosity | Pas | 1.0 | 0.01 | |

| Heat conductivity | k | W/(mK) | 20.93 | 209.3 |

| Specific heat capacity | J/(kgK) | 711.2 | 937.4 | |

| Melting temperature | K | 1732 | ||

| Evaporation temperature | K | 3100 | ||

| Melting bandwidth | K | 100 | ||

| Absorption coefficient | – | 0.27 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Afrasiabi, M.; Lüthi, C.; Bambach, M.; Wegener, K. Multi-Resolution SPH Simulation of a Laser Powder Bed Fusion Additive Manufacturing Process. Appl. Sci. 2021, 11, 2962. https://doi.org/10.3390/app11072962

Afrasiabi M, Lüthi C, Bambach M, Wegener K. Multi-Resolution SPH Simulation of a Laser Powder Bed Fusion Additive Manufacturing Process. Applied Sciences. 2021; 11(7):2962. https://doi.org/10.3390/app11072962

Chicago/Turabian StyleAfrasiabi, Mohamadreza, Christof Lüthi, Markus Bambach, and Konrad Wegener. 2021. "Multi-Resolution SPH Simulation of a Laser Powder Bed Fusion Additive Manufacturing Process" Applied Sciences 11, no. 7: 2962. https://doi.org/10.3390/app11072962

APA StyleAfrasiabi, M., Lüthi, C., Bambach, M., & Wegener, K. (2021). Multi-Resolution SPH Simulation of a Laser Powder Bed Fusion Additive Manufacturing Process. Applied Sciences, 11(7), 2962. https://doi.org/10.3390/app11072962