Dehumidified-Air-Assisted Spray Drying of Buckwheat Honey with Maltodextrin and Skim Milk Powder as Carriers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Feed Solutions

2.3. Viscosity Determination

2.4. Spray Drying

2.4.1. Powder Recovery

2.4.2. Energy Consumption and Energy Efficiency

2.5. Powder Characterization

Physiochemical Properties

Antioxidant Activity

2.6. Statistical Analysis

3. Results

3.1. Buckwheat Honey Characterization

3.2. Viscosity of Feed Solutions

3.3. Powder Recovery

3.4. Energy Consumption and Energy Efficiency

3.5. Physiochemical Properties of Powders

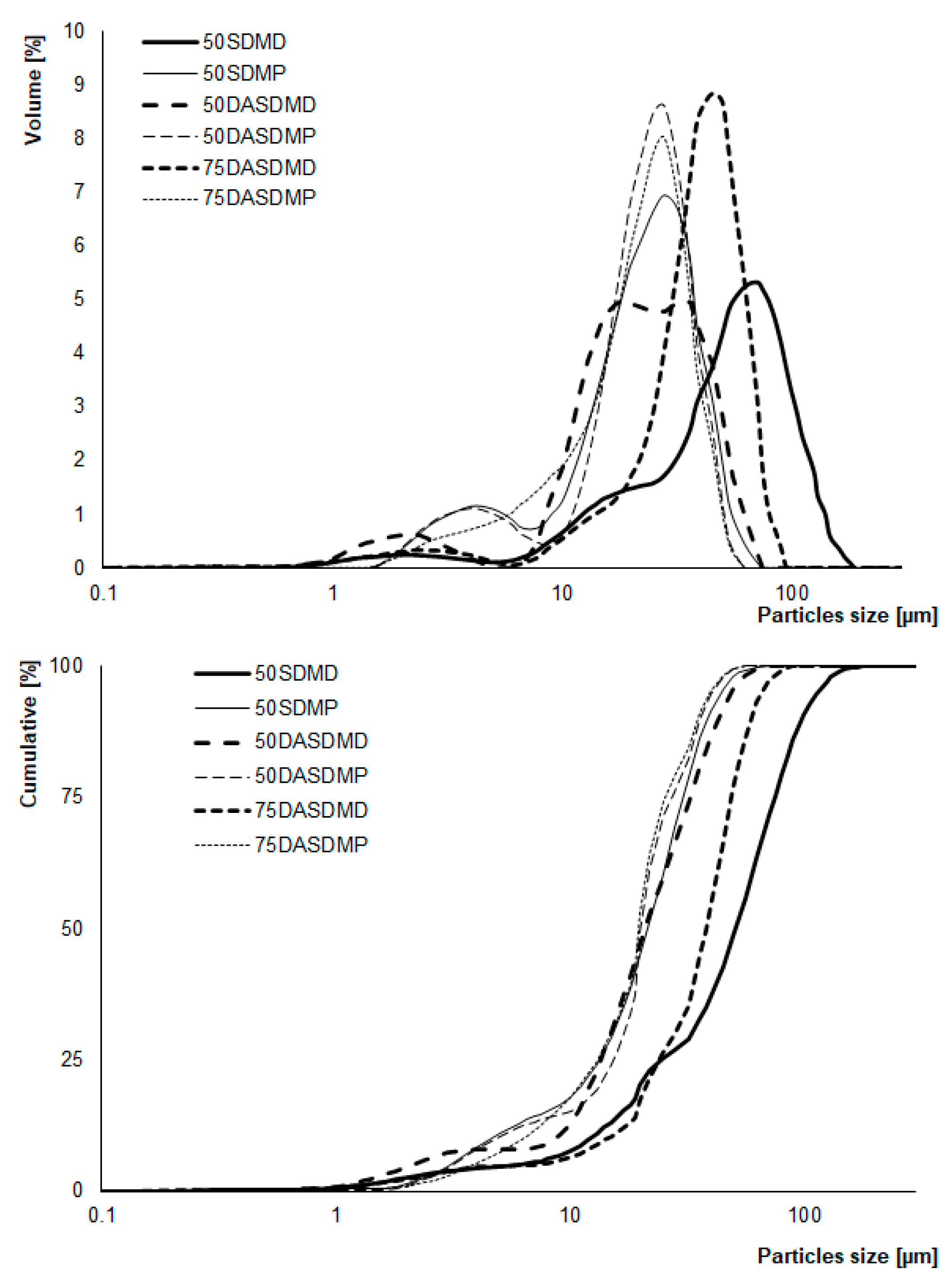

3.5.1. Particle Morphology and Size

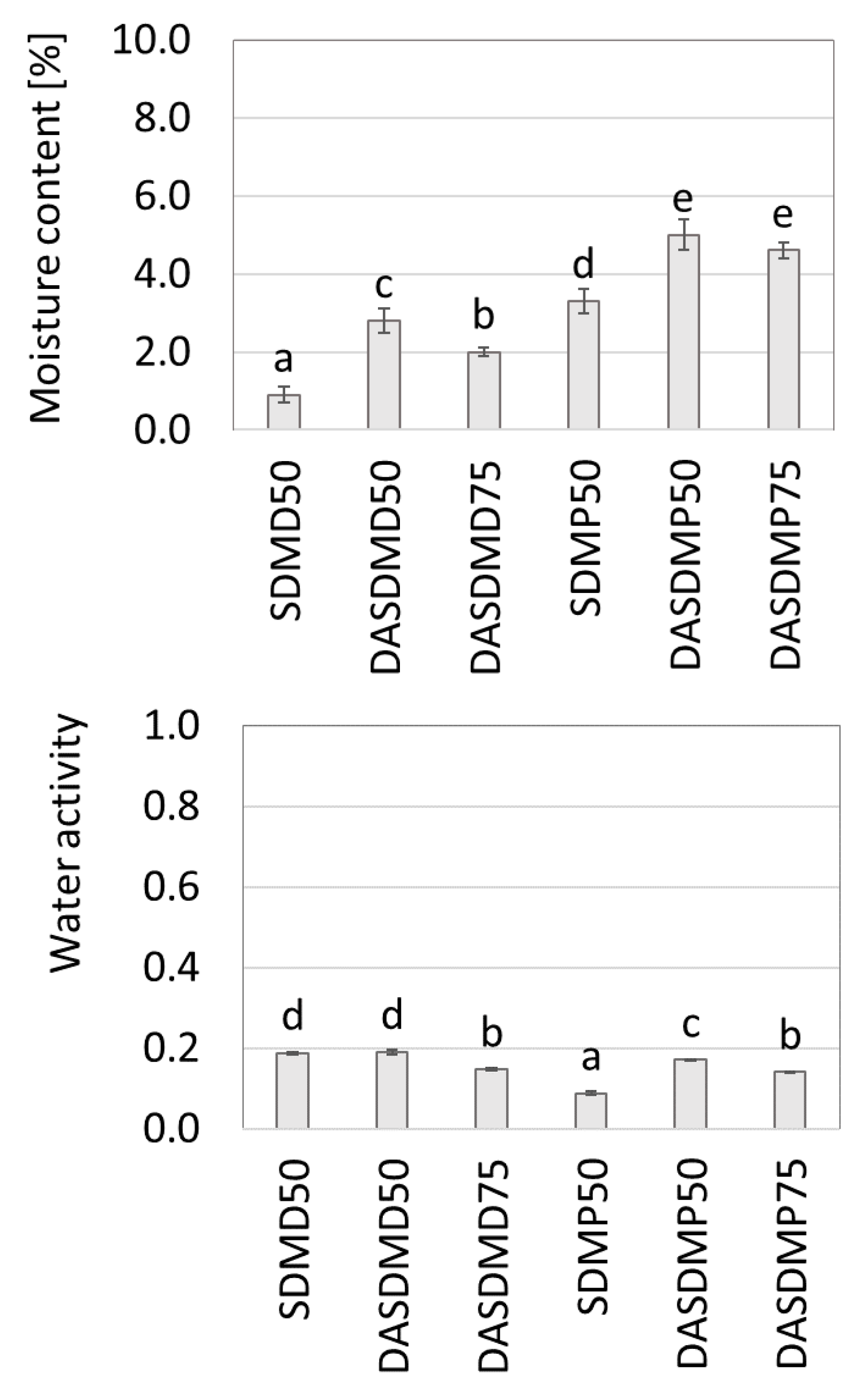

3.5.2. Moisture Content and Water Activity

3.5.3. Hygroscopicity

3.5.4. Bulk Density and Flowability

3.5.5. Apparent Density and Loose Bed Porosity

3.5.6. Color

3.6. Antioxidant Activity

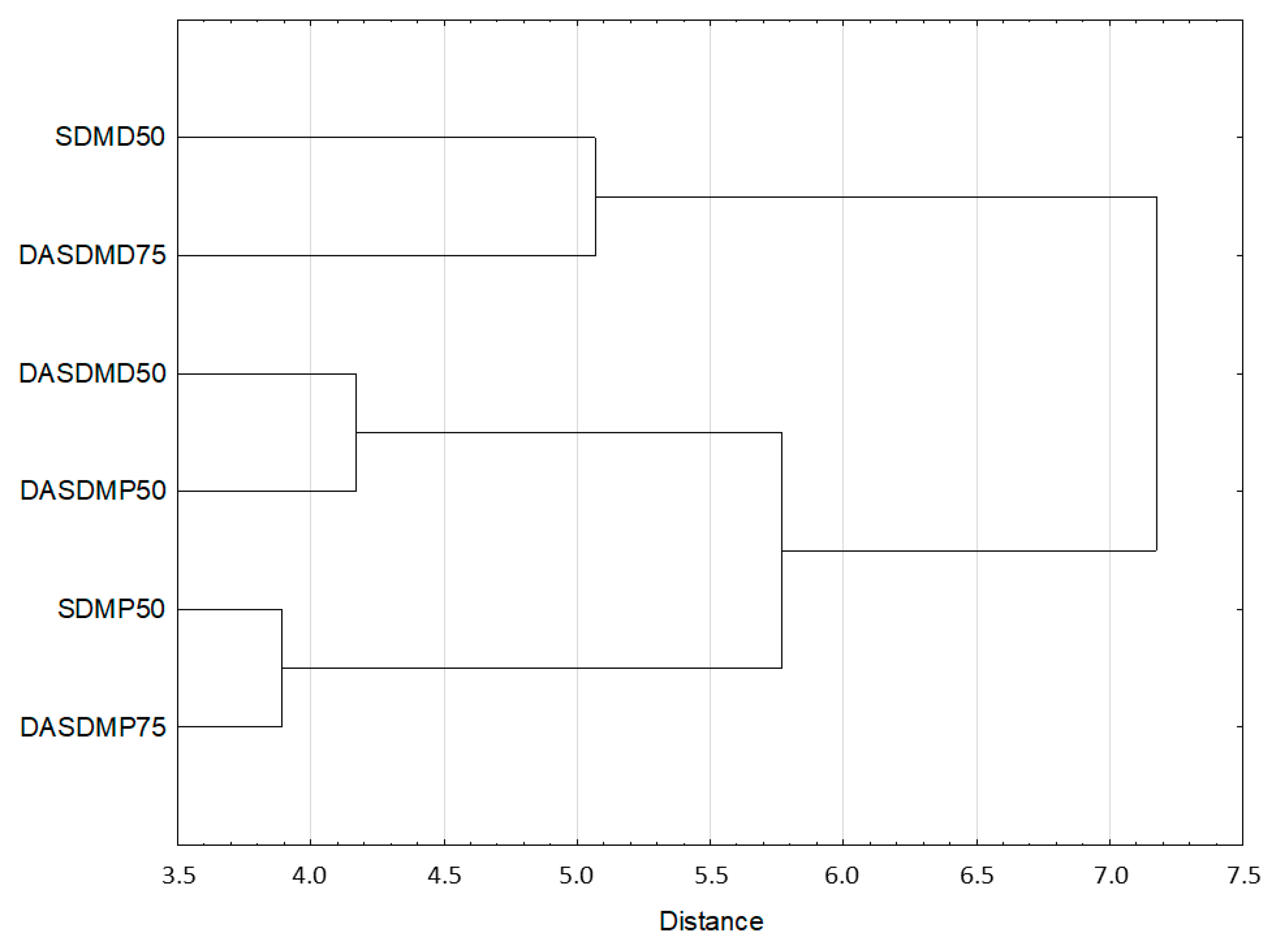

3.7. Hierarchical Cluster Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| MC | aw | H | D50 | DL | DT | HR | Dap | εL | L* | a* | b* | EC50 ABTS | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rp | 0.593 | −0.142 | −0.721 | −0.495 | 0.178 | −0.046 | −0.720 | 0.314 | 0.025 | 0.188 | −0.360 | −0.050 | −0.215 |

| MC | −0.271 | 0.034 | −0.886 * | −0.705 | 0.718 | −0.355 | 0.510 | −0.700 | −0.054 | −0.700 | 0.335 | −0.704 | |

| aw | −0.294 | 0.456 | 0.184 | 0.130 | 0.105 | 0.012 | −0.201 | 0.884 * | −0.406 | −0.929 * | 0.616 | ||

| H | −0.224 | 0.265 | 0.502 | 0.539 | 0.169 | −0.445 | −0.474 | 0.117 | 0.503 | −0.282 | |||

| D50 | −0.705 | −0.616 | 0.459 | −0.616 | 0.619 | 0.161 | 0.504 | −0.427 | 0.539 | ||||

| DL | 0.910 * | −0.256 | 0.431 | −0.966 * | 0.347 | −0.909 * | −0.062 | −0.305 | |||||

| DT | 0.145 | 0.523 | −0.978 * | 0.113 | −0.732 | 0.113 | −0.475 | ||||||

| HR | −0.002 | 0.003 | −0.366 | 0.399 | 0.195 | −0.179 | |||||||

| Dap | −0.452 | 0.064 | −0.241 | 0.021 | −0.163 | ||||||||

| εL | −0.249 | 0.821 * | 0.000 | 0.353 | |||||||||

| L* | −0.596 | −0.949 * | 0.650 | ||||||||||

| a* | 0.329 | 0.163 | |||||||||||

| b* | −0.796 |

References

- Dżugan, M.; Grabek-Lejko, D.; Swacha, S.; Tomczyk, M.; Bednarska, S.; Kapusta, I. Physicochemical quality parameters, antibacterial properties and cellular antioxidant activity of Polish buckwheat honey. Food Biosci. 2020, 34, 100538. [Google Scholar] [CrossRef]

- Pentoś, K.; Łuczycka, D.; Oszmiański, J.; Lachowicz, S.; Pasternak, G. Polish honey as a source of antioxidants—A comparison with Manuka honey. J. Apic. Res. 2020, 59, 939–945. [Google Scholar] [CrossRef]

- Liu, J.R.; Ye, Y.L.; Lin, T.Y.; Wang, Y.W.; Peng, C.C. Effect of floral sources on the antioxidant, anti-microbial, and anti-inflammatory activities of honeys in Taiwan. Food Chem. 2013, 139, 938–943. [Google Scholar] [CrossRef] [PubMed]

- Erejuwa, O.O.; Sulaiman, S.A.; Ab Wahab, M.S. Honey: A novel antioxidant. Molecules 2012, 17, 4400–4423. [Google Scholar] [CrossRef] [PubMed]

- Flanjak, I.; Kenjeric, D.; Bubalo, D.; Primorac, L. Characterisation of selected Croatian honey types based on the combination of antioxidant capacity, quality parameters, and chemometrics. Eur. Food Res. Technol. 2016, 242, 467–475. [Google Scholar] [CrossRef]

- Gheldof, N.; Engeseth, N.J. Antioxidant capacity of honeys from various floral sources based on the determination of oxygen radical absorbance capacity and inhibition of in vitro lipoprotein oxidation in human serum samples. J. Agric. Food Chem. 2002, 50, 3050–3055. [Google Scholar] [CrossRef]

- Jiang, L.; Xie, M.; Chen, G.; Qiao, J.; Zhang, H.; Zeng, X. Phenolics and Carbohydrates in Buckwheat Honey Regulate the Human Intestinal Microbiota. Evid. Based Complement. Altern. Med. 2020, 6432942. [Google Scholar] [CrossRef]

- Hammond, E.N.-A.; Duster, M.; Musuuza, J.S.; Safdar, N. Effect of United States buckwheat honey on antibiotic-resistant hospital acquired pathogens. Pan Afr. Med. J. 2016, 25, 212. [Google Scholar] [CrossRef]

- Baranowska-Wójcik, E.; Szwajgier, D.; Winiarska-Mieczan, A. Honey as the Potential Natural Source of Cholinesterase Inhibitors in Alzheimer’s Disease. Plant Foods Hum. Nutr. 2020, 75, 30–32. [Google Scholar] [CrossRef]

- Samborska, K. Powdered honey—Drying methods and parameters, types of carriers and drying aids, physicochemical properties and storage stability. Trends Food Sci. Technol. 2019, 88, 133–142. [Google Scholar] [CrossRef]

- Samborska, K.; Barańska, A.; Bodel, D. Investigation on the possibility to enhancing honey spray drying process and powders properties by ultrafiltration pre-treatment. Chem. Process Eng. 2019, 40, 305–313. [Google Scholar] [CrossRef]

- Samborska, K.; Langa, E.; Kamińska-Dwórznicka, A.; Witrowa-Rajchert, D. The influence of sodium caseinate on the physical properties of spray-dried honey. Int. J. Food Sci. Technol. 2015, 50, 256–262. [Google Scholar] [CrossRef]

- Bhandari, B.R.; Datta, N.; Howe, T. Problems Associated with Spray Drying of Sugar-Rich Foods. Dry. Technol. 1997, 15, 671–684. [Google Scholar] [CrossRef]

- Stevenson, E.J.; Watson, A.; Theis, S.; Holz, A.; Harper, L.D.; Russel, M. A comparison of isomaltulose versus maltodextrin ingestion during soccer-specific exercise. Eur. J. Appl. Physiol. 2007, 117, 2321–2333. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Suhag, Y.; Nanda, V. Evaluation of different carrier agents with respect to physico-chemical, functional and morphological characteristics of spray dried nutritionally rich honey powder. J. Food Process. Preserv. 2016, 40, 1429–1437. [Google Scholar] [CrossRef]

- Barańska, A.; Jedlińska, A.; Konachowicz, M.; Samborska, K. The investigation of the application of skim milk as a carrier and diluent during honey solution spray drying. Zesz. Probl. Postępów Nauk Rol. 2019, 597, 3–13. [Google Scholar] [CrossRef]

- Samborska, K.; Barańska, A.; Szulc, K.; Jankowska, E.; Truszkowska, M.; Ostrowska-Ligęza, E.; Wołosiak, R.; Szymańska, E.; Jedlińska, A. Reformulation of spray-dried apple concentrate and honey for the enhancement of drying process performance and the physicochemical properties of powders. J. Sci. Food Agric. 2020, 100, 2224–2235. [Google Scholar] [CrossRef]

- Angel, R.C.M.; Espinosa-Muñoz, L.C.; Aviles-Aviles, C.; González-García, R.; Moscosa-Santillán, M.; Grajales-Lagunes, A.; Abud-Archila, M. Spray-drying of passion fruit juice using lactose-maltodextrin blends as the support material. Brazilian Arch. Biol. Technol. 2009, 52, 1011–1018. [Google Scholar] [CrossRef] [Green Version]

- Barańska, A.; Samborska, K.; Jedlińska, A. Application of Dehumidified Air During Spray Drying for the Production of Food Powders. In Mechatronics 2019: Recent Advances towards Industry 4.0. MECHATRONICS 2019. Advances in Intelligent Systems and Computing; Szewczyk, R., Krejsa, J., Nowicki, M., Ostaszewska-Liżewska, A., Eds.; Springer: Cham, Switzerland, 2020; Volume 1044, pp. 463–468. [Google Scholar] [CrossRef]

- Jedlińska, A.; Samborska, K.; Wieczorek, A.; Wiktor, A.; Ostrowska-Ligęza, E.; Jamróz, W.; Skwarczyńska-Maj, K.; Kiełczewski, D.; Błażowski, Ł.; Tułodziecki, M.; et al. The application of dehumidified air in rapeseed and honeydew honey spray drying—Process performance and powders properties considerations. J. Food Eng. 2019, 245, 80–87. [Google Scholar] [CrossRef]

- Goula, A.M.; Adamopoulos, K.G. Effect of Maltodextrin Addition during Spray Drying of Tomato Pulp in Dehumidified Air: I. Drying Kinetics and Product Recovery. Dry. Technol. 2008, 26, 714–725. [Google Scholar] [CrossRef]

- Chasekioglou, A.N.; Goula, A.M.; Adamopoulos, K.G.; Lazarides, H.N. An approach to turn olive mill wastewater into a valuable food by-product based on spray drying in dehumidified air using drying aids. Powder Technol. 2017, 311, 376–389. [Google Scholar] [CrossRef]

- Al-Mansour, H.E.; Al-Busairi, B.H.; Baker, C.G.J. Energy consumption of a pilot-scale spray dryer. Dry. Technol. 2011, 29, 1901–1910. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Codex Alimentarius Commission Standards. Revised Codex Standards for Honey. Codex Standard 121981, Rev. 2. Available online: http://www.fao.org/fao-who-codexalimentarius/sh-proxy/en/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FStandards%252FCXS%2B12-1981%252FCXS_012e.pdf (accessed on 24 March 2021).

- Council Directive 2001: No. 2001/110/EC of 20 December 2001 Relating to Honey. Official Journal of the European Communites, L 10. pp. 47–52. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32001L0110&from=EN (accessed on 24 March 2021).

- Deng, J.; Liu, R.; Lu, Q.; Hao, P.; Xu, A.; Zhang, J.; Tan, J. Biochemical properties, antibacterial and cellular antioxidant activities of buckwheat honey in comparison to manuka honey. Food Chem. 2018, 252, 243–249. [Google Scholar] [CrossRef] [PubMed]

- Kowalski, S.; Łukasiewicz, M.; Berski, W. Applicability of physico-chemical parameters of honey for identification of the botanical origin. Acta Sci. Pol. Technol. Aliment. 2013, 12, 51–59. [Google Scholar] [PubMed]

- Samborska, K.; Gajek, P.; Kamińska-Dwórznicka, A. Spray Drying of Honey: The Effect of Drying Agents on Powder Properties. Polish J. Food Nutr. Sci. 2015, 65, 109–118. [Google Scholar] [CrossRef] [Green Version]

- Suhag, Y.; Nanda, V. Optimisation of process parameters to develop nutritionally rich spray-dried honey powder with vitamin C content and antioxidant properties. Int. J. Food Sci. Technol. 2015, 50, 1771–1777. [Google Scholar] [CrossRef]

- Shi, Q.; Fang, Z.; Bhandari, B. Effect of Addition of Whey Protein Isolate on Spray-Drying Behavior of Honey with Maltodextrin as a Carrier Material. Dry. Technol. 2013, 31, 1681–1692. [Google Scholar] [CrossRef] [Green Version]

- Truong, V.; Bhandari, B.R.; Howes, T. Optimization of co-current spray drying process of sugar-rich foods. Part I—Moisture and glass transition temperature profile during drying. J. Food Eng. 2005, 71, 55–65. [Google Scholar] [CrossRef]

- Poozesh, S.; Bilgili, E. Scale-up of pharmaceutical spray drying using scale-up rules: A review. Int. J. Pharm. 2019, 562, 271–292. [Google Scholar] [CrossRef]

- Gimbun, J.; Choong, T.S.; Fakhruâ, A.; Chuah, T.G. Prediction of the effect of dimension, particle density, temperature, and inlet velocity on cyclone collection efficiency. J. Teknol. 2004, 40, 37–50. [Google Scholar] [CrossRef] [Green Version]

- Jayasundera, M.; Adhikari, B.; Aldred, P.; Ghandi, A. Surface modification of spray dried food and emulsion powders with surface-active proteins: A review. J. Food Eng. 2009, 93, 266–277. [Google Scholar] [CrossRef] [Green Version]

- Bhusari, S.N.; Muzaffar, K.; Kumar, P. Effect of carrier agents on physical and microstructural properties of spray dried tamarind pulp powder. Powder Technol. 2014, 266, 354–364. [Google Scholar] [CrossRef]

- Bhandari, B. Spray drying and powder properties. In Food Drying Science and Technology: Microbiology, Chemistry, Applications; DEStech Publications, Inc.: Lancaster, PA, USA, 2008; pp. 215–248. [Google Scholar]

- Baker, C.G.J.; McKenzie, K.A. Energy consumption of industrial spray dryers. Dry. Technol. 2005, 23, 365–386. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Mobli, H.; Rafiee, S.; Madadlou, A. Energy and exergy analyses of the spray drying process of fish oil microencapsulation. Biosyst. Eng. 2012, 111, 229–241. [Google Scholar] [CrossRef]

- Julklang, W.; Golman, B. Effect of process parameters on energy performance of spray drying with exhaust air heat recovery for production of high value particles. Appl. Energy 2015, 151, 285–295. [Google Scholar] [CrossRef]

- Samborska, K.; Sokołowska, P.; Szulc, K. Diafiltration and agglomeration as methods to improve the properties of honey powder obtained by spray drying. Innov. Food Sci. Emerg. Technol. 2017, 39, 33–41. [Google Scholar] [CrossRef]

- Tonon, R.V.; Brabet, C.; Hubinger, M. D Influence of process conditions on the physicochemical properties of acai (Euterpe oleraceae Mart.) powder produced by spray drying. J. Food Eng. 2008, 88, 411–418. [Google Scholar] [CrossRef]

- Belščak-Cvitanović, A.; Lević, S.; Kalušević, A.; Špoljarić, I.; Đorđević, V.; Komes, D.; Mršić, G.; Nedović, V. Efficiency assessment of natural biopolymers as encapsulants of green tea (Camellia sinensis L.) bioactive compounds by spray drying. Food Bioprocess Technol. 2015, 8, 2444–2460. [Google Scholar] [CrossRef]

- Muzaffar, K.; Kumar, P. Comparative efficiency of maltodextrin and protein in the production of spray-dried tamarind pulp powder. Dry. Technol. 2016, 34, 802–809. [Google Scholar] [CrossRef]

- Nurhadi, B.; Andoyo, R.; Indiarto, R. Study the properties of honey powder produced from spray drying and vacuum drying method. Int. Food Res. J. 2012, 19, 907–912. [Google Scholar]

- Bringas-Lantingua, M.; Pino, J.A.; Aragüez-Fortes, Y. Influence of process conditions on the physicochemical properties of honey powder produced by spray drying. Rev. CENIC Cienc. Quim. 2016, 47, 64–69. [Google Scholar]

- Leyva-Moguel, K.; Sosa-Moguel, O.; A Pino, J.; Bolivar-Moreno, D.; Cuevas-Glory, L. Physicochemical parameters of liquid and spray-dried honey of stingless bee Scaptotrigona Pectoralis. J. Apic. Res. 2019, 1–9. [Google Scholar] [CrossRef]

- Ferrari, C.C.; Germer, S.P.M.; Alvim, I.D.; Vissotto, F.Z.; de Aguirre, J.M. Influence of carrier agents on the physicochemical properties of blackberry powder produced by spray drying. Int. J. Food Sci. Technol. 2012, 47, 1237–1245. [Google Scholar] [CrossRef]

- Geldart, D.; Harnby, N.; Wong, A.C.Y. Fluidization of cohesive powders. Powder Technol. 1984, 37, 25–37. [Google Scholar] [CrossRef]

- Shishir, M.R.I.; Taip, F.S.; Aziz, N.A.; Talib, R.A. Physical Properties of Spray-dried Pink Guava (Psidium guajava) Powder. Agric. Agric. Sci. Procedia 2014, 2, 74–81. [Google Scholar] [CrossRef] [Green Version]

- Santhalakshmy, S.; Don Bosco, S.J.; Francis, S.; Sabeena, M. Effect of inlet temperature on physicochemical properties of spray-dried jamun fruit juice powder. Powder Technol. 2015, 274, 37–43. [Google Scholar] [CrossRef]

- Zotarelli, M.F.; da Silva, V.M.; Durigon, A.; Hubinger, M.D.; Laurindo, J.B. Production of mango powder by spray drying and cast-tape drying. Powder Technol. 2017, 305, 447–454. [Google Scholar] [CrossRef]

- Cui, Z.W.; Sun, L.J.; Chen, W.; Sun, D.W. Preparation of dry honey by microwave–vacuum drying. J. Food Eng. 2008, 84, 582–590. [Google Scholar] [CrossRef]

- Biskup, I.; Golonka, I.; Gamian, A.; Sroka, Z. Antioxidant activity of selected phenols estimated by ABTS and FRAP methods. Postepy Hig. Med. Dosw. 2013, 67, 958–963. [Google Scholar] [CrossRef]

- Samborska, K.; Jedlińska, A.; Wiktor, A.; Derewiaka, D.; Wołosiak, R.; Matwijczuk, A.; Jamróz, W.; Skwarczyńska-Maj, K.; Kiełczewski, D.; Błażowski, Ł.; et al. The Effect of Low-Temperature Spray Drying with Dehumidified Air on Phenolic Compounds, Antioxidant Activity, and Aroma Compounds of Rapeseed Honey Powders. Food Bioprocess Technol. 2019, 12, 919–932. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Result |

|---|---|

| Sugar extract [%] | 80.9 |

| Sum of fructose and glucose [g·100 g−1] | 70.6 |

| Sucrose [g·100 g−1] | <0.5 |

| Total sugars [g·100 g−1] | 70.6 |

| Free acidity [mval·kg−1] | 48.5 |

| Electrical conductivity [mS·cm−1] | 4.24 |

| Color | Dark brown |

| Aroma | Strong, resembling buckwheat flowers |

| Flavor | Sweet and pungent |

| Variant | Carrier Type | Ratio of Honey to Carrier Solids (w/w) | Spray Drying Method | Drying Air Temperature (Inlet/Outlet) |

|---|---|---|---|---|

| SDMD50 * | Maltodextrin | 50:50 | SD | 180 °C/80 °C |

| DASDMD50 | Maltodextrin | 50:50 | DASD | 80 °C/45 °C |

| DASDMD75 | Maltodextrin | 75:25 | DASD | 80 °C/45 °C |

| SDMP50 | Milk powder | 50:50 | SD | 180 °C/80 °C |

| DASDMP50 | Milk powder | 50:50 | DASD | 80 °C/45 °C |

| DASDMP75 | Milk powder | 75:25 | DASD | 80 °C/45 °C |

| Variant | SDMD50 | DASDMD50 | DASDMD75 | SDMP50 | DASDMP50 | DASDMP75 |

|---|---|---|---|---|---|---|

| Viscosity [mPa·s] | 37.0 ± 1.2 c | 16.5 ± 0.8 a | 51.7 ± 2.6 d | 24.3 ± 0.2 b | ||

| H [%] | 16.2 ± 0.5 c | 15.5 ± 0.3 c | 10.1 ± 0.6 a | 20.5 ± 0.4 d | 16.0 ± 0.7 c | 11.9 ± 0.3 b |

| D50 [µm] | 50.0 ± 2.4 d | 25.4 ± 0.1 b | 38.1 ± 1.6 c | 20.9 ± 0.8 a | 21.8 ± 0.4 a | 21.2 ± 0.8 a |

| DL [g⋅cm−3] | 0.51 ± 0.01 a | 0.65 ± 0.01 c | 0.51 ± 0.02 a | 0.58 ± 0.02 b | 0.73 ± 0.01 d | 0.59 ± 0.02 b |

| DT [g⋅cm−3] | 0.69 ± 0.01 b | 0.76 ± 0.01 c | 0.58 ± 0.02 a | 0.74 ± 0.02 c | 0.87 ± 0.01 d | 0.74 ± 0.02 c |

| HR | 1.34 ± 0.02 d | 1.20 ± 0.02 ab | 1.17 ± 0.02 a | 1.26 ± 0.01 c | 1.23 ± 0.02 bc | 1.23 ± 0.02 bc |

| Dap [g⋅cm−3] | 1.45 ± 0.02 b | 1.50 ± 0.00 c | 1.42 ± 0.02 a | 1.47 ± 0.00 b | 1.46 ± 0.00 b | 1.51 ± 0.00 c |

| εL [%] | 63.3 ± 0.8 d | 56.6 ± 0.6 b | 67.8 ± 0.8 e | 59.9 ± 0.8 c | 50.5 ± 0.6 a | 60.6 ± 1.0 c |

| EC50 ABTS [mg solids/mL] | 5.14 ± 0.11 c | 8.24 ± 0.36 e | 5.72 ± 0.04 d | 0.27 ± 0.01 a | 0.18 ± 0.00 a | 0.39 ± 0.02 a |

| SDMD50 | DASDMD50 | DASDMD75 | SDMP50 | DASDMP50 | DASDMP75 | |

|---|---|---|---|---|---|---|

| Q [kW] | 3.4 ± 0.0 a | 7.3 ± 0.0 c | 7.2 ± 0.8 c | 3.9 ± 0.4 ab | 6.6 ± 0.0 bc | 6.9 ± 0.5 c |

| Es [MJ/kg H2O] | 24.8 ± 0.1 ab | 41.8 ± 0.9 c | 40.6 ± 2.9 c | 22.9 ± 2.6 a | 37.6 ± 1.0 bc | 39.5 ± 2.6 c |

| η [%] | 9.6 ± 0.0 bc | 5.7 ± 0.0 a | 5.9 ± 0.4 a | 10.5 ± 1.2 c | 6.4 ± 0.0 ab | 6.1 ± 0.0 a |

| Variant | L* | a* | b* |

|---|---|---|---|

| SDMD50 | 83.7 ± 0.3 c | +0.6 ± 0.1 e | 13.7 ± 0.3 b |

| DASDMD50 | 86.7 ± 0.5 f | 0.0 ± 0.0 b | 10.4 ± 0.4 a |

| DASDMD75 | 84.3 ± 0.4 d | +0.4 ± 0.0 d | 14.3 ± 0.2 c |

| SDMP50 | 79.8 ± 0.1 a | +0.6 ± 0.1 e | 23.8 ± 0.9 f |

| DASDMP50 | 84.9 ± 0.3 e | −0.5 ± 0.1 a | 15.8 ± 0.4 d |

| DASDMP75 | 83.1 ± 0.3 b | +0.2 ± 0.1 c | 17.3 ± 0.3 e |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barańska, A.; Jedlińska, A.; Samborska, K. Dehumidified-Air-Assisted Spray Drying of Buckwheat Honey with Maltodextrin and Skim Milk Powder as Carriers. Appl. Sci. 2021, 11, 3150. https://doi.org/10.3390/app11073150

Barańska A, Jedlińska A, Samborska K. Dehumidified-Air-Assisted Spray Drying of Buckwheat Honey with Maltodextrin and Skim Milk Powder as Carriers. Applied Sciences. 2021; 11(7):3150. https://doi.org/10.3390/app11073150

Chicago/Turabian StyleBarańska, Alicja, Aleksandra Jedlińska, and Katarzyna Samborska. 2021. "Dehumidified-Air-Assisted Spray Drying of Buckwheat Honey with Maltodextrin and Skim Milk Powder as Carriers" Applied Sciences 11, no. 7: 3150. https://doi.org/10.3390/app11073150