Energym: A Building Model Library for Controller Benchmarking

Abstract

:1. Introduction

2. Buildings Overview

- Apartments: A residential building with four stories, each being one apartment, and eight thermal zones (two per story). It is located in Spain and has a central geothermal Heat Pump (HP) providing heat to all apartments. The building envelope is fictive, based on typical Spanish construction materials, but the HP was calibrated with a real HP located in the IREC laboratory (see Section 4.2).

- Apartments2: This building shares its envelope with the Apartments building, but differs in the details of the technical equipment: each apartment possesses its own air-to-water HP and its own heating storage tank. In this building, the electrical systems (solar panels, battery) were calibrated with real systems.

- Offices: This building consists of 25 thermal zones, 14 of which are controlled with thermostats, and is located in the Attica region of Greece. Both the envelope and the technical systems were calibrated with the corresponding test site data.

- MixedUse: A building with 13 thermal zones (eight controlled with thermostats) used for residential and office spaces. It is also located in the Attica region of Greece. Both the envelope and the technical systems were calibrated with the corresponding test site data.

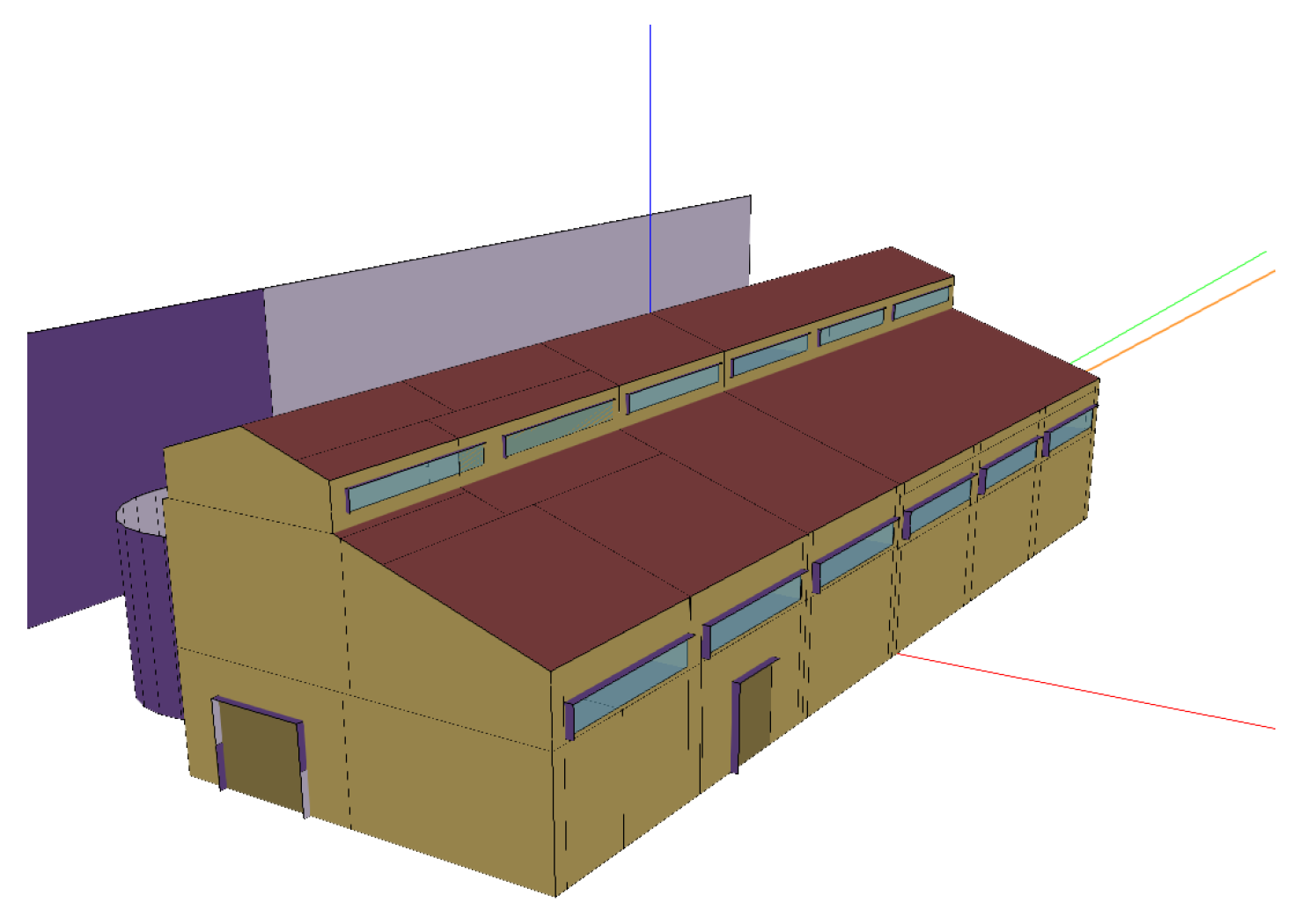

- Seminarcenter: This building encapsulates 27 thermal zones, belonging to 22 rooms of which 18 are controlled with thermostats. It is located in the Region of Southern Denmark. Both the envelope and the technical systems were calibrated with the corresponding test site measurements.

- SimpleHouse: This building is a standard single room house with HP and sun heating effects through glazing. Two versions exist, one with a standard radiator (SimpleHouseRad) and the other one with floor heating (SimpleHouseSlab). The first order envelope model is designed based on thermal peak power and minimal outdoor temperature.

- SwissHouse: This building is a large-scale version of the SimpleHouse building with radiators. It has been designed with parameters (thermal peak power, outdoor temperature) from a real house. The heat pump control differs from the SimpleHouse model, see Table A6.

3. Library Design and Functionalities

3.1. Design Features

3.1.1. Standardized Evaluation

3.1.2. Wrappers

3.1.3. Forecasting Capabilities

3.2. Usage and Code Example

Basic Structure and Usage

3.3. Performance Evaluation

KPI Definition

4. Calibration Methodology

4.1. Building Calibration

4.1.1. Method

4.1.2. Model Evaluation

4.1.3. Example: The MixedUse Building

4.2. Heat Pump Calibration

- –, –: Fitting coefficients for heating mode

- : Reference temperature, [K]

- : Temperature of water entering the load side, [K]

- : Temperature of water entering the source side, [K]

- : Load side volumetric flow rate, [m/s]

- : Reference load side volumetric flow rate, [m/s]

- : Source side volumetric flow rate, [m/s]

- : Reference source side volumetric flow rate, [m/s]

- : Power consumption [kW]

- : Rated heating power consumption [kW]

- : Condenser heating rate [kW]

- : Rated condenser heating rate [kW]

4.3. Modelica Models

5. Conclusions and Future Directions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Code Examples

Appendix A.1. Basic Usage Example

| import energym |

| env = energym.make(“Apartments2Grid–v0”) |

| out = env.get_output() |

| for i in range(100): |

| forecast = env.get_forecast(forecast_length=10) |

| inp = get_input(out, forecast) |

| out = env.step(inp) |

| kpis = env.get_kpi() |

| env.close() |

Appendix A.2. KPI Example

| kpi_dict = {“kpi1”: {“name”: “Fa_Pw_All”, “type”: “avg”}, |

| “kpi2”: { |

| “name”: “Z01_T”, |

| “type”: “tot_viol”, |

| “target”: [19,24], |

| } |

| } |

Appendix B. Building Descriptions

| Variable Name | Description | Bounds | Units |

|---|---|---|---|

| Ext_T | Current outdoor temperature | [−25,40] | °C |

| Ext_RH | Current outdoor relative humidity | [0,100] | %RH |

| Ext_Irr | Current direct normal irradiance | [0,1000] | W·m |

Appendix B.1. Apartments and Apartments2 Buildings

| Variable Name | Description | Bounds | Units | Model |

|---|---|---|---|---|

| Inputs | ||||

| P1_T_Thermostat_sp ⋯ P4_T_Thermostat_sp | Temperature setpoint per appartment | [16,26] | °C | 1/2/3/4 |

| Bd_T_HP_sp | Heat pump supplytemperature setpoint | [35,55] | °C | 1/2 |

| P1_T_Tank_sp ⋯ P4_T_Tank_sp | Bottom water tank temperature setpoint | [30,70] | °C | 1/2 |

| Bd_Pw_Bat_sp | Battery charging/discharging setpoint | [−1,1] | - | 1/2/3/4 |

| Bd_Ch_EVBat_sp | EV battery charging setpoint | [0,1] | - | 1/2 |

| Bd_Ch_EV1Bat_sp | EV battery charging setpoint | [0,1] | - | 3/4 |

| Bd_Ch_EV2Bat_sp | EV battery charging setpoint | [0,1] | - | 3/4 |

| HVAC_onoff_HP_sp | Heat pump on/off setpoint | {0,1} | - | 1 |

| P1_onoff_HP_sp ⋯ P4_onoff_HP_sp | Heat pump on/off setpoint | {0,1} | - | 3 |

| Outputs | ||||

| Fa_E_self | Energy exchanged with grid for timestep | [−2000,2000] | Wh | 1/2/3/4 |

| Z01_T ⋯ Z08_T | Current zone temperature | [10,40] | °C | 1/2/3/4 |

Appendix B.2. Offices Building

| Variable Name | Description | Bounds | Units |

|---|---|---|---|

| Inputs | |||

| Z01_T_Thermostat_sp ⋯ Z07_T_Thermostat_sp Z15_T_Thermostat_sp ⋯ Z20_T_Thermostat_sp Z25_T_Thermostat_sp | Zone temperature setpoint | [16,26] | °C |

| Bd_Cooling_onoff_sp | Chiller on/off | {0,1} | - |

| Bd_Heating_onoff_sp | Boiler on/off | {0,1} | - |

| Outputs | |||

| Fa_Pw_All | Current power demand of whole facility | [0,] | W |

| Fa_Pw_PV | Current produced power | [0,2000] | W |

| Z01_T ⋯ Z07_T Z15_T ⋯ Z20_T Z25_T | Current zone temperature | [10,40] | °C |

Appendix B.3. MixedUse Building

| Variable Name | Description | Bounds | Units |

|---|---|---|---|

| Inputs | |||

| Z02_T_Thermostat_sp ⋯ Z05_T_Thermostat_sp Z08_T_Thermostat_sp ⋯ Z11_T_Thermostat_sp | Zone temperature setpoint | [16,26] | °C |

| Bd_T_AHU1_sp Bd_T_AHU2_sp | AHU temperature setpoint | [10,30] | °C |

| Bd_Fl_AHU1_sp Bd_Fl_AHU2_sp | AHU flow rate setpoint | [0,1] | - |

| Outputs | |||

| Fa_Pw_All | Current power demand of whole facility | [0,] | W |

| Z02_T ⋯ Z05_T Z08_T ⋯ Z11_T | Current zone temperature | [10,40] | °C |

Appendix B.4. Seminarcenter Building

| Variable Name | Description | Bounds | Units | Model |

|---|---|---|---|---|

| Inputs | ||||

| Z01_T_Thermostat_sp ⋯ Z06_T_Thermostat_sp Z08_T_Thermostat_sp ⋯ Z11_T_Thermostat_sp Z13_T_Thermostat_sp ⋯ Z15_T_Thermostat_sp Z18_T_Thermostat_sp ⋯ Z22_T_Thermostat_sp | Zone temperature setpoint | [16,26] | °C | 1/2 |

| Bd_onoff_HP1_sp ⋯ Bd_onoff_HP4_sp | Heat pump on/off setpoint | {0,1} | - | 2 |

| Bd_T_HP1_sp ⋯ Bd_T_HP4_sp | Heat pump temperature setpoint | [30,65] | °C | 2 |

| Bd_T_AHU_coil_sp | AHU water coil temperature setpoint | [15,40] | °C | 2 |

| Bd_T_buffer_sp | Buffer tank temperature setpoint | [15,70] | °C | 2 |

| Bd_T_mixer_sp | HPs water loop supply temperature setpoint | [20,60] | °C | 2 |

| Bd_T_HVAC_sp | AHU air supply temperature setpoint | [10,26] | °C | 2 |

| Outputs | ||||

| Bd_CO2 | Timestep equivalent CO emission mass | [0,10] | kg | 1/2 |

| Fa_Pw_All | Current power demand of whole facility | [0,] | W | 1/2 |

| Z01_T ⋯ Z06_T Z08_T ⋯ Z11_T Z13_T ⋯ Z15_T Z18_T ⋯ Z22_T | Current zone temperature | [10,40] | °C | 1/2 |

Appendix B.5. SimpleHouse and SwissHouse

| Variable Name | Description | Bounds | Units | Model |

|---|---|---|---|---|

| Inputs | ||||

| u | Heat pump normalized power | [0,1] | - | 1 |

| heaSup.f | Heat pump normalized supply flow | [0,1] | - | 2 |

| heaSup.T | Heat pump supply temperature | [293.15,353.15] | K | 2 |

| Outputs | ||||

| TOut.T | Outside Temperature | [253.15,343.15] | K | 1/2 |

| temRoo.T | Room Temperature | [263.15,343.15] | K | 1/2 |

| heaPum.P | Heat pump power | [0,30] | kW | 1/2 |

| temRet.T | Heat pump return temperature | [273.15,353.15] | K | 1/2 |

| temSup.T | Heat pump supply temperature | [273.15,353.15] | K | 1/2 |

Appendix C. Calibration Plots

Appendix C.1. MixedUse HVAC Performance Curves

Appendix C.2. MixedUse HVAC Calibration Results

| Index | ASHRAE | Cooling | Average | Heating | Average |

|---|---|---|---|---|---|

| Thresholds | Energy | Indoor | Energy | Indoor | |

| (Hourly) | Consumption | Temperature | Consumption | Temperature | |

| (Main Building) | (Main Building) | ||||

| DATE | — | May–October | May–October | November 2019– | November 2019– |

| 2019 | 2019 | April 2020 | April 2020 | ||

| NMBE (%) | within | 9.49% | 0.16% | 17.29% | 1.12% |

| CV(RMSE) (%) | 27.57% | 1.04% | 27.57% | 2.75% | |

| R2 (%) | 76.17% | 95.50% | 66.50% | 97.39% |

| Index | ASHRAE | Cooling | TZ-05 | HEATING | TZ-05 |

|---|---|---|---|---|---|

| Thresholds | Energy | Indoor | Energy | Indoor | |

| (Hourly) | Consumption | Temperature | Consumption | Temperature | |

| (Atrium) | (Atrium) | ||||

| DATE | — | July–October | July–October | November 2019– | November 2019– |

| 2019 | 2019 | April 2020 | April 2020 | ||

| NMBE (%) | within | 7.37% | −0.02% | −7.42% | 5.31% |

| CV(RMSE) (%) | ≤ | 27.41% | 1.27% | 27.21% | 8.22% |

| R2 (%) | ≥ | 78.89% | 94.51% | 76.49% | 85.26% |

References

- Global Alliance for Buildings and Construction. 2019 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; Technical Report, International Energy Agency and the United Nations Environment Programme; Global Alliance for Buildings and Construction: Berlin, Germany, 2019. [Google Scholar]

- IEA. Tracking Buildings 2020; Technical Report; IEA: Paris, France, 2020; Available online: https://www.iea.org/reports/tracking-buildings-2020 (accessed on 14 April 2021).

- O’Neill, Z.; Li, Y.; Williams, K. HVAC control loop performance assessment: A critical review (1587-RP). Sci. Technol. Bulit Environ. 2017, 23, 619–636. [Google Scholar] [CrossRef] [Green Version]

- Behrooz, F.; Mariun, N.; Marhaban, M.; Mohd Radzi, M.; Ramli, A. Review of Control Techniques for HVAC Systems—Nonlinearity Approaches Based on Fuzzy Cognitive Maps. Energies 2018, 11, 495. [Google Scholar] [CrossRef] [Green Version]

- Mařík, K.; Rojíček, J.; Stluka, P.; Vass, J. Advanced HVAC Control: Theory vs. Reality. IFAC Proc. Vol. 2011, 44, 3108–3113. [Google Scholar] [CrossRef] [Green Version]

- Oldewurtel, F.; Parisio, A.; Jones, C.N.; Morari, M.; Gyalistras, D.; Gwerder, M.; Stauch, V.; Lehmann, B.; Wirth, K. Energy efficient building climate control using Stochastic Model Predictive Control and weather predictions. In Proceedings of the 2010 American Control Conference, Baltimore, MD, USA, 30 June–2 July 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 5100–5105. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Borrelli, F.; Hencey, B.; Coffey, B.; Bengea, S.; Haves, P. Model Predictive Control for the Operation of Building Cooling Systems. IEEE Trans. Control. Syst. 2012, 20, 796–803. [Google Scholar] [CrossRef] [Green Version]

- Moroşan, P.D.; Bourdais, R.; Dumur, D.; Buisson, J. Building temperature regulation using a distributed model predictive control. Energy Build. 2010, 42, 1445–1452. [Google Scholar] [CrossRef]

- Schubnel, B.; Carrillo, R.; Taddeo, P.; Canal Casals, L.; Salom, J.; Stauffer, Y.; Alet, P.J. State-space models for building control: How deep should you go? J. Build. Perform. Simul. 2020, 13, 707–719. [Google Scholar] [CrossRef]

- Tanaskovic, M.; Sturzenegger, D.; Smith, R.; Morari, M. Robust Adaptive Model Predictive Building Climate Control. IFAC-PapersOnLine 2017, 50, 1871–1876. [Google Scholar] [CrossRef]

- Chen, B.; Cai, Z.; Bergés, M. Gnu-RL: A Precocial Reinforcement Learning Solution for Building HVAC Control Using a Differentiable MPC Policy. In Proceedings of the 6th ACM International Conference on Systems for Energy-Efficient Buildings, Cities, and Transportation, BuildSys ’19, New York, NY, USA, 13–14 November 2019; Association for Computing Machinery: New York, NY, USA, 2019; pp. 316–325. [Google Scholar] [CrossRef]

- Wei, T.; Wang, Y.; Zhu, Q. Deep Reinforcement Learning for Building HVAC Control. In Proceedings of the 54th Annual Design Automation Conference 2017, Austin, TX, USA, 18–22 June 2017. [Google Scholar] [CrossRef]

- Schubnel, B.; Carrillo, R.E.; Alet, P.J.; Hutter, A. A Hybrid Learning Method for System Identification and Optimal Control. IEEE Trans. Neural Netw. Learn. 2020, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Drgoňa, J.; Arroyo, J.; Cupeiro Figueroa, I.; Blum, D.; Arendt, K.; Kim, D.; Ollé, E.P.; Oravec, J.; Wetter, M.; Vrabie, D.L.; et al. All you need to know about model predictive control for buildings. Annu. Rev. Control 2020, 50, 190–232. [Google Scholar] [CrossRef]

- Maddalena, E.T.; Lian, Y.; Jones, C.N. Data-driven methods for building control—A review and promising future directions. Control Eng. Pract. 2020, 95, 104211. [Google Scholar] [CrossRef]

- Crawley, D.B.; Pedersen, C.O.; Lawrie, L.K.; Winkelmann, F.C. EnergyPlus: Energy Simulation Program. ASHRAE J. 2000, 42, 49–56. [Google Scholar]

- Mattsson, S.E.; Elmqvist, H. Modelica—An International Effort to Design the Next Generation Modeling Language. IFAC Proc. Vol. 1997, 30, 151–155. [Google Scholar] [CrossRef]

- Lukianykhin, O.; Bogodorova, T. ModelicaGym: Applying Reinforcement Learning to Modelica Models. In Proceedings of the 9th International Workshop on Equation-Based Object-Oriented Modeling Languages and Tools, EOOLT ’19, Berlin, Germany, 5 November 2019; ACM: New York, NY, USA, 2019; pp. 27–36. [Google Scholar] [CrossRef] [Green Version]

- Moriyama, T.; De Magistris, G.; Tatsubori, M.; Pham, T.H.; Munawar, A.; Tachibana, R. Reinforcement Learning Testbed for Power-Consumption Optimization. In Methods and Applications for Modeling and Simulation of Complex Systems; Li, L., Hasegawa, K., Tanaka, S., Eds.; Springer: Singapore, 2018; pp. 45–59. [Google Scholar]

- Blum, D.; Jorissen, F.; Huang, S.; Chen, Y.; Arroyo, J.; Benne, K.; Li, Y.; Gavan, V.; Rivalin, L.; Helsen, L.; et al. Prototyping The BOPTEST Framework for Simulation-Based Testing of Advanced Control Strategies in Buildings. In Proceedings of the 16th International Conference of IBPSA, Rome, Italy, 2–4 September 2019; pp. 2737–2744. [Google Scholar] [CrossRef]

- Vázquez-Canteli, J.R.; Kämpf, J.; Henze, G.; Nagy, Z. CityLearn v1.0: An OpenAI Gym Environment for Demand Response with Deep Reinforcement Learning. In Proceedings of the 6th ACM International Conference on Systems for Energy-Efficient Buildings, Cities, and Transportation, BuildSys ’19, New York, NY, USA, 13–14 November 2019; Association for Computing Machinery: New York, NY, USA, 2019; pp. 356–357. [Google Scholar] [CrossRef]

- Brockman, G.; Cheung, V.; Pettersson, L.; Schneider, J.; Schulman, J.; Tang, J.; Zaremba, W. OpenAI Gym; Technical Report; OpenAI: San Francisco, CA, USA, 2016. [Google Scholar]

- Blochwitz, T.; Otter, M.; Åkesson, J.; Arnold, M.; Clauss, C.; Elmqvist, H.; Friedrich, M.; Junghanns, A.; Mauss, J.; Neumerkel, D.; et al. Functional Mockup Interface 2.0: The Standard for Tool independent Exchange of Simulation Models. In Proceedings of the 9th International Modelica Conference, Munich, Germany, 3–5 September 2012; pp. 173–184. [Google Scholar] [CrossRef] [Green Version]

- Ruiz, G.R.; Bandera, C.F.; Temes, T.G.A.; Gutierrez, A.S.O. Genetic algorithm for building envelope calibration. Appl. Energy 2016, 168, 691–705. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef] [Green Version]

- Ruiz, G.R.; Bandera, C.F. Validation of calibrated energy models: Common errors. Energies 2017, 10, 1587. [Google Scholar] [CrossRef] [Green Version]

- Fuentes, E.; Salom, J. Validation of black-box performance models for a water-to-water heat pump operating under steady state and dynamic loads. E3S Web. Conf. 2019, 111, 01068. [Google Scholar] [CrossRef] [Green Version]

- Tang, C.C. Modeling Packaged Heat Pumps in a Quasi-Steady State Energy Simulation Program. Master’s Thesis, Oklahoma State University, Stillwater, OK, USA, 2005. Available online: https://hvac.okstate.edu/sites/default/files/pubs/theses/MS/27-Tang_Thesis_05.pdf (accessed on 14 April 2021).

- Wetter, M. Modelica Buildings library. J. Build. Perform. Simul. 2014, 7, 253–270. [Google Scholar] [CrossRef]

- Swiss Society of Engineers and Architects. Klimadaten für Bauphysik, Energie- und Gebäudetechnik, SIA 2028:2010. Available online: http://shop.sia.ch/normenwerk/architekt/sia%202028/f/2010/D/Product (accessed on 14 April 2021).

| Environment | Th | HP | Bat | AHU | EV | PV | Soft. | Loc. | Calib. |

|---|---|---|---|---|---|---|---|---|---|

| ApartmentsThermal-v0 | ✓ | ✓ | ✓ | × | ✓ | # | E+ | ESP | Section 4.2 |

| ApartmentsGrid-v0 | ✓ | # | ✓ | × | ✓ | # | E+ | ESP | Section 4.2 |

| Apartments2Thermal-v0 | ✓ | ✓ | ✓ | × | ✓ | # | E+ | ESP | Section 4.2 |

| Apartments2Grid-v0 | ✓ | # | ✓ | × | ✓ | # | E+ | ESP | Section 4.2 |

| OfficesThermostat-v0 | ✓ | × | × | × | × | # | E+ | GRC | Section 4.1 |

| MixedUseFanFCU-v0 | ✓ | × | × | ✓ | × | × | E+ | GRC | Section 4.1 |

| SeminarcenterThermostat-v0 | ✓ | # | × | # | × | # | E+ | DNK | Section 4.1 |

| SeminarcenterFull-v0 | ✓ | ✓ | × | ✓ | × | # | E+ | DNK | Section 4.1 |

| SimpleHouseRad-v0 | × | ✓ | × | × | × | # | Mod | CHE | Section 4.3 |

| SimpleHouseSlab-v0 | × | ✓ | × | × | × | # | Mod | CHE | Section 4.3 |

| SwissHouseRad-v0 | × | ✓ | × | × | × | # | Mod | CHE | Section 4.3 |

| Model | Simulation Period | Temperature Constraints (°C) | Objective KPI |

|---|---|---|---|

| ApartmentsThermal-v0 | January–April | 19–24 | Grid exchange |

| ApartmentsGrid-v0 | Entire year | 19–24 | Grid exchange |

| Apartments2Thermal-v0 | January–April | 19–24 | Grid exchange |

| Apartments2Grid-v0 | Entire year | 19–24 | Grid exchange |

| OfficesThermostat-v0 | Entire year | 19–24 | Power demand |

| MixedUseFanFCU-v0 | Entire year | 19–24 | Power demand |

| SeminarcenterThermostat-v0 | January–May | 21–24 | CO emissions |

| SeminarcenterFull-v0 | January–May | 21–24 | CO emissions |

| SimpleHouseRad-v0 | January–April | 19–24 | Power demand |

| SimpleHouseSlab-v0 | January–April | 19–24 | Power demand |

| SwissHouseRad-v0 | January–April | 19–24 | Power demand |

| Index | ASHRAE | Cooling | Average | Cooling | TZ-05 |

|---|---|---|---|---|---|

| Enrgy | Indoor | Supply | Indoor | ||

| (Hourly) | Consumption | Temperature | Air | Temperature | |

| (VRV) | (Main Building) | (AHU) | (Atrium) | ||

| Date | — | June–August | June–August | May–July | May–July |

| 2020 | 2020 | 2020 | 2020 | ||

| NMBE (%) | 6.40% | 0.33% | 1.43% | 0.42% | |

| CV(RMSE) (%) | ≤30% | 29.26% | 1.16% | 3.62% | 1.69% |

| R2 (%) | ≥75% | 75.23% | 92.73% | 85.57% | 86.98% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scharnhorst, P.; Schubnel, B.; Fernández Bandera, C.; Salom, J.; Taddeo, P.; Boegli, M.; Gorecki, T.; Stauffer, Y.; Peppas, A.; Politi, C. Energym: A Building Model Library for Controller Benchmarking. Appl. Sci. 2021, 11, 3518. https://doi.org/10.3390/app11083518

Scharnhorst P, Schubnel B, Fernández Bandera C, Salom J, Taddeo P, Boegli M, Gorecki T, Stauffer Y, Peppas A, Politi C. Energym: A Building Model Library for Controller Benchmarking. Applied Sciences. 2021; 11(8):3518. https://doi.org/10.3390/app11083518

Chicago/Turabian StyleScharnhorst, Paul, Baptiste Schubnel, Carlos Fernández Bandera, Jaume Salom, Paolo Taddeo, Max Boegli, Tomasz Gorecki, Yves Stauffer, Antonis Peppas, and Chrysa Politi. 2021. "Energym: A Building Model Library for Controller Benchmarking" Applied Sciences 11, no. 8: 3518. https://doi.org/10.3390/app11083518

APA StyleScharnhorst, P., Schubnel, B., Fernández Bandera, C., Salom, J., Taddeo, P., Boegli, M., Gorecki, T., Stauffer, Y., Peppas, A., & Politi, C. (2021). Energym: A Building Model Library for Controller Benchmarking. Applied Sciences, 11(8), 3518. https://doi.org/10.3390/app11083518