Biomechanical Effect of 3D-Printed Foot Orthoses in Patients with Knee Osteoarthritis

Abstract

1. Introduction

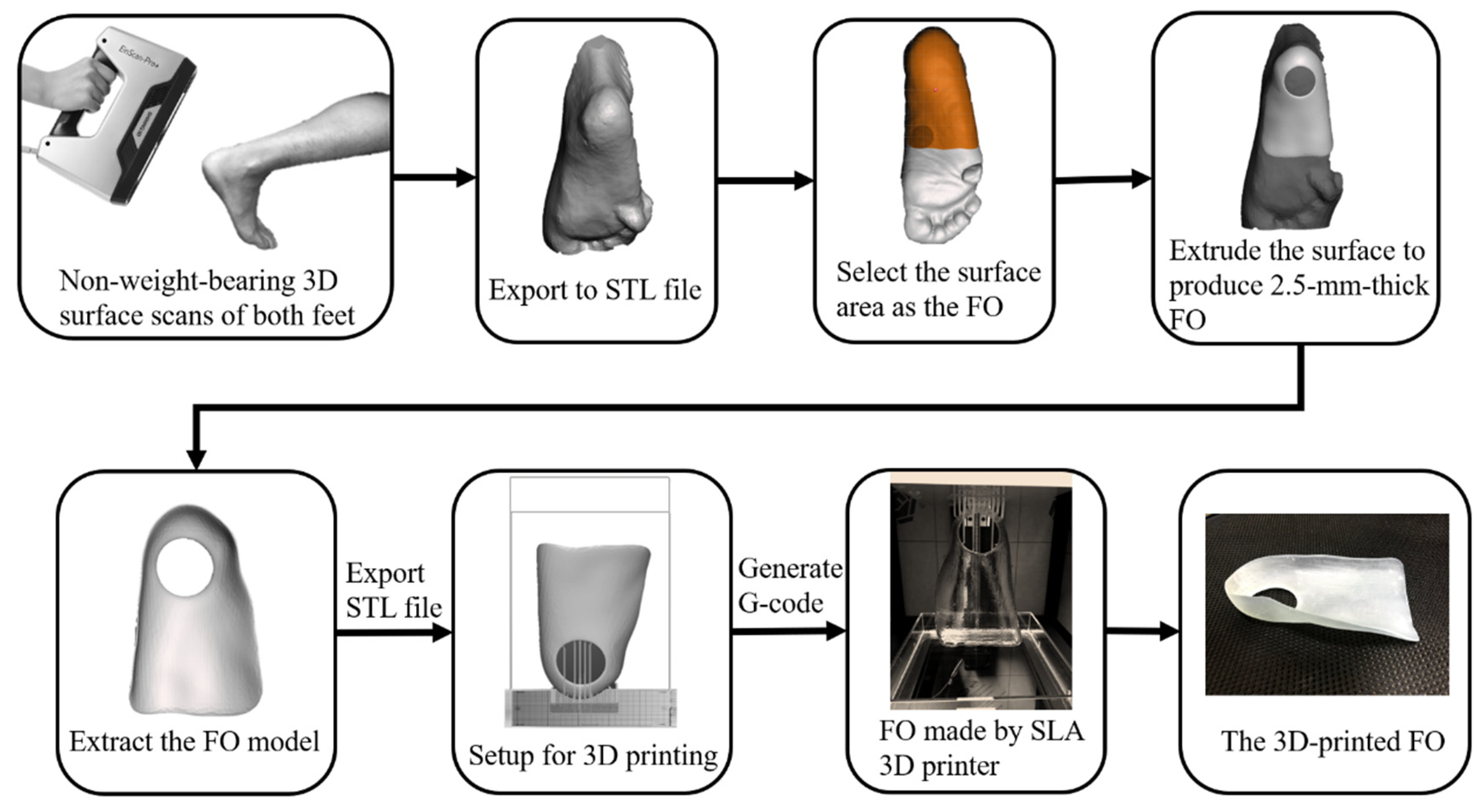

2. Materials and Methods

3. Results

3.1. Walking Speed

3.2. Center of Pressure

3.3. Joint Moments

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cross, M.; Smith, E.; Hoy, D.; Nolte, S.; Ackerman, I.; Fransen, M.; Bridgett, L.; Williams, S.; Guillemin, F.; Hill, C.L. The global burden of hip and knee osteoarthritis: Estimates from the global burden of disease 2010 study. Ann. Rheum. Dis. 2014, 73, 1323–1330. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Wang, S.; Zhan, S.; Niu, J.; Tao, K.; Zhang, Y.; Lin, J. The prevalence of symptomatic knee osteoarthritis in China: Results from the China health and retirement longitudinal study. Arthritis Rheumatol. 2016, 68, 648–653. [Google Scholar] [CrossRef]

- Wise, B.L.; Niu, J.; Yang, M.; Lane, N.E.; Harvey, W.; Felson, D.T.; Hietpas, J.; Nevitt, M.; Sharma, L.; Torner, J. Patterns of compartment involvement in tibiofemoral osteoarthritis in men and women and in whites and African Americans. Arthritis Care Res. 2012, 64, 847–852. [Google Scholar] [CrossRef]

- Hurwitz, D.E.; Sumner, D.R.; Andriacchi, T.P.; Sugar, D.A. Dynamic knee loads during gait predict proximal tibial bone distribution. J. Biomech. 1998, 31, 423–430. [Google Scholar] [CrossRef]

- Zhao, D.; Banks, S.A.; Mitchell, K.H.; D’Lima, D.D.; Colwell Jr, C.W.; Fregly, B.J. Correlation between the knee adduction torque and medial contact force for a variety of gait patterns. J. Orthop. Res. 2007, 25, 789–797. [Google Scholar] [CrossRef] [PubMed]

- Manal, K.; Gardinier, E.; Buchanan, T.S.; Snyder-Mackler, L. A more informed evaluation of medial compartment loading: The combined use of the knee adduction and flexor moments. Osteoarthr. Cartil. 2015, 23, 1107–1111. [Google Scholar] [CrossRef] [PubMed]

- Chan, G.N.; Smith, A.W.; Kirtley, C.; Tsang, W.W. Changes in knee moments with contralateral versus ipsilateral cane usage in females with knee osteoarthritis. Clin. Biomech. 2005, 20, 396–404. [Google Scholar] [CrossRef]

- Brandon, S.C.; Brown, M.J.; Clouthier, A.L.; Campbell, A.; Richards, J.D.; Deluzio, K.J. Contributions of muscles and external forces to medial knee load reduction due to osteoarthritis braces. Knee 2019, 26, 564–577. [Google Scholar] [CrossRef]

- Shull, P.B.; Silder, A.; Shultz, R.; Dragoo, J.L.; Besier, T.F.; Delp, S.L.; Cutkosky, M.R. Six-week gait retraining program reduces knee adduction moment, reduces pain, and improves function for individuals with medial compartment knee osteoarthritis. J. Orthop. Res. 2013, 31, 1020–1025. [Google Scholar] [CrossRef] [PubMed]

- Chapman, G.J.; Parkes, M.J.; Forsythe, L.; Felson, D.; Jones, R. Ankle motion influences the external knee adduction moment and may predict who will respond to lateral wedge insoles?: An ancillary analysis from the SILK trial. Osteoarthr. Cartil. 2015, 23, 1316–1322. [Google Scholar] [CrossRef] [PubMed]

- Duivenvoorden, T.; van Raaij, T.M.; Horemans, H.L.; Brouwer, R.W.; Bos, P.K.; Bierma-Zeinstra, S.M.; Verhaar, J.A.; Reijman, M. Do laterally wedged insoles or valgus braces unload the medial compartment of the knee in patients with osteoarthritis? Clin. Orthop. Relat. Res. 2015, 473, 265–274. [Google Scholar] [CrossRef] [PubMed]

- Jones, R.K.; Chapman, G.J.; Parkes, M.J.; Forsythe, L.; Felson, D.T. The effect of different types of insoles or shoe modifications on medial loading of the knee in persons with medial knee osteoarthritis: A randomised trial. J. Orthop. Res. 2015, 33, 1646–1654. [Google Scholar] [CrossRef]

- Kakihana, W.; Akai, M.; Nakazawa, K.; Takashima, T.; Naito, K.; Torii, S. Effects of laterally wedged insoles on knee and subtalar joint moments. Arch. Phys. Med. Rehabil. 2005, 86, 1465–1471. [Google Scholar] [CrossRef] [PubMed]

- Kakihana, W.; Torii, S.; Akai, M.; Nakazawa, K.; Fukano, M.; Naito, K. Effect of a lateral wedge on joint moments during gait in subjects with recurrent ankle sprain. Am. J. Phys. Med. Rehabil. 2005, 84, 858–864. [Google Scholar] [CrossRef]

- Shimada, S.; Kobayashi, S.; Wada, M.; Uchida, K.; Sasaki, S.; Kawahara, H.; Yayama, T.; Kitade, I.; Kamei, K.; Kubota, M. Effects of disease severity on response to lateral wedged shoe insole for medial compartment knee osteoarthritis. Arch. Phys. Med. Rehabil. 2006, 87, 1436–1441. [Google Scholar] [CrossRef] [PubMed]

- Hatfield, G.L.; Cochrane, C.K.; Takacs, J.; Krowchuk, N.M.; Chang, R.; Hinman, R.S.; Hunt, M.A. Knee and ankle biomechanics with lateral wedges with and without a custom arch support in those with medial knee osteoarthritis and flat feet. J. Orthop. Res. 2016, 34, 1597–1605. [Google Scholar] [CrossRef] [PubMed]

- Hinman, R.S.; Bowles, K.A.; Metcalf, B.B.; Wrigley, T.V.; Bennell, K.L. Lateral wedge insoles for medial knee osteoarthritis: Effects on lower limb frontal plane biomechanics. Clin. Biomech. 2012, 27, 27–33. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.K.; Jin, Y.-A.; Wensman, J.; Shih, A. Additive manufacturing of custom orthoses and prostheses—A review. Addit. Manuf. 2016, 12, 77–89. [Google Scholar] [CrossRef]

- Salles, A.S.; Gyi, D.E. An evaluation of personalised insoles developed using additive manufacturing. J. Sports Sci. 2013, 31, 442–450. [Google Scholar] [CrossRef]

- Lin, K.-W.; Hu, C.-J.; Yang, W.-W.; Chou, L.-W.; Wei, S.-H.; Chen, C.-S.; Sun, P.-C. Biomechanical Evaluation and Strength Test of 3D-Printed Foot Orthoses. Appl. Bionics. Biomech. 2019, 2019, 4989534. [Google Scholar] [CrossRef]

- Altman, R.; Asch, E.; Bloch, D.; Bole, G.; Borenstein, D.; Brandt, K.; Christy, W.; Cooke, T.; Greenwald, R.; Hochberg, M. Development of criteria for the classification and reporting of osteoarthritis: Classification of osteoarthritis of the knee. Arthritis Rheum. 1986, 29, 1039–1049. [Google Scholar] [CrossRef] [PubMed]

- Forghany, S.; Nester, C.J.; Richards, B.; Hatton, A.L.; Liu, A. Rollover footwear affects lower limb biomechanics during walking. Gait Posture 2014, 39, 205–212. [Google Scholar] [CrossRef] [PubMed]

- Hunt, M.A.; Birmingham, T.B.; Giffin, J.R.; Jenkyn, T.R. Associations among knee adduction moment, frontal plane ground reaction force, and lever arm during walking in patients with knee osteoarthritis. J. Biomech. 2006, 39, 2213–2220. [Google Scholar] [CrossRef] [PubMed]

- Andriacchi, T.; Ogle, J.; Galante, J. Walking speed as a basis for normal and abnormal gait measurements. J. Biomech. 1977, 10, 261–268. [Google Scholar] [CrossRef]

- Jones, R.K.; Zhang, M.; Laxton, P.; Findlow, A.H.; Liu, A. The biomechanical effects of a new design of lateral wedge insole on the knee and ankle during walking. Hum. Mov. Sci. 2013, 32, 596–604. [Google Scholar] [CrossRef] [PubMed]

- Nakajima, K.; Kakihana, W.; Nakagawa, T.; Mitomi, H.; Hikita, A.; Suzuki, R.; Akai, M.; Iwaya, T.; Nakamura, K.; Fukui, N. Addition of an arch support improves the biomechanical effect of a laterally wedged insole. Gait Posture 2009, 29, 208–213. [Google Scholar] [CrossRef]

- Nigg, B.M.; Stergiou, P.; Cole, G.; Stefanyshyn, D.; Mündermann, A.; Humble, N. Effect of shoe inserts on kinematics, center of pressure, and leg joint moments during running. Med. Sci. Sports Exerc. 2003, 35, 314–319. [Google Scholar] [CrossRef]

- Trepczynski, A.; Kutzner, I.; Bergmann, G.; Taylor, W.R.; Heller, M.O. Modulation of the relationship between external knee adduction moments and medial joint contact forces across subjects and activities. Arthritis Rheumatol. 2014, 66, 1218–1227. [Google Scholar] [CrossRef]

- Sharma, L.; Hurwitz, D.E.; Thonar, E.J.M.; Sum, J.A.; Lenz, M.E.; Dunlop, D.D.; Schnitzer, T.J.; Kirwan-Mellis, G.; Andriacchi, T.P. Knee adduction moment, serum hyaluronan level, and disease severity in medial tibiofemoral osteoarthritis. Arthritis Rheum. 1998, 41, 1233–1240. [Google Scholar] [CrossRef]

- Thorp, L.E.; Sumner, D.R.; Wimmer, M.A.; Block, J.A. Relationship between pain and medial knee joint loading in mild radiographic knee osteoarthritis. Arthritis Care Res. 2007, 57, 1254–1260. [Google Scholar] [CrossRef] [PubMed]

- Miyazaki, T.; Wada, M.; Kawahara, H.; Sato, M.; Baba, H.; Shimada, S. Dynamic load at baseline can predict radiographic disease progression in medial compartment knee osteoarthritis. Ann. Rheum. Dis. 2002, 61, 617–622. [Google Scholar] [CrossRef]

- Maly, M.R.; Acker, S.M.; Totterman, S.; Tamez-Peña, J.; Stratford, P.W.; Callaghan, J.P.; Adachi, J.D.; Beattie, K.A. Knee adduction moment relates to medial femoral and tibial cartilage morphology in clinical knee osteoarthritis. J. Biomech. 2015, 48, 3495–3501. [Google Scholar] [CrossRef]

- Sinclair, J.; Hebron, J.; Taylor, P.J. The test-retest reliability of knee joint center location techniques. J. Appl. Biomech. 2015, 31, 117–121. [Google Scholar] [CrossRef]

- Chuter, V.; Payne, C.; Miller, K. Variability of neutral-position casting of the foot. J. Am. Podiatr. Med. Assoc. 2003, 93, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Schrank, E.S.; Stanhope, S.J. Dimensional accuracy of ankle-foot orthoses constructed by rapid customization and manufacturing framework. J. Rehabil. Res. Dev. 2011, 48, 31. [Google Scholar] [CrossRef] [PubMed]

- Payne, C. Cost benefit comparison of plaster casts and optical scans of the foot for the manufacture of foot orthoses. Aust J. Podiatr. Med. 2007, 41, 29–31. [Google Scholar]

- Dombroski, C.E.; Balsdon, M.E.; Froats, A. The use of a low cost 3D scanning and printing tool in the manufacture of custom-made foot orthoses: A preliminary study. BMC Res. Notes 2014, 7, 443. [Google Scholar] [CrossRef] [PubMed]

| Variable | Shoe (Mean ± SD) | Shoe + FO (Mean ± SD) | p Value | Effect Size |

|---|---|---|---|---|

| Walking speed (m/s) | 0.977 ± 0.163 | 0.925 ± 0.146 | 0.060 | 0.34 |

| COP at peak KAM (mm) | 7.289 ± 3.641 | 9.998 ± 4.054 | 0.001 * | 0.70 |

| 1st peak KAM (N·m·BW−1·LL−1) | 0.049 ± 0.018 | 0.047 ± 0.019 | 0.042 * | 0.11 |

| 2nd peak KAM (N·m·BW−1·LL−1) | 0.044 ± 0.017 | 0.040 ± 0.018 | 0.004 * | 0.23 |

| Peak KFM (N·m·BW−1·LL−1) | 0.036 ± 0.022 | 0.034 ± 0.019 | 0.464 | 0.10 |

| Peak AEM (N·m·BW−1·LL−1) | −0.009 ± 0.005 | −0.010 ± 0.006 | 0.411 | 0.18 |

| Peak AIM (N·m·BW−1·LL−1) | 0.009 ± 0.008 | 0.007 ± 0.008 | 0.033 * | 0.25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, K.-W.; Chou, L.-W.; Su, Y.-T.; Wei, S.-H.; Chen, C.-S. Biomechanical Effect of 3D-Printed Foot Orthoses in Patients with Knee Osteoarthritis. Appl. Sci. 2021, 11, 4200. https://doi.org/10.3390/app11094200

Lin K-W, Chou L-W, Su Y-T, Wei S-H, Chen C-S. Biomechanical Effect of 3D-Printed Foot Orthoses in Patients with Knee Osteoarthritis. Applied Sciences. 2021; 11(9):4200. https://doi.org/10.3390/app11094200

Chicago/Turabian StyleLin, Kuang-Wei, Li-Wei Chou, Yi-Tien Su, Shun-Hwa Wei, and Chen-Shen Chen. 2021. "Biomechanical Effect of 3D-Printed Foot Orthoses in Patients with Knee Osteoarthritis" Applied Sciences 11, no. 9: 4200. https://doi.org/10.3390/app11094200

APA StyleLin, K.-W., Chou, L.-W., Su, Y.-T., Wei, S.-H., & Chen, C.-S. (2021). Biomechanical Effect of 3D-Printed Foot Orthoses in Patients with Knee Osteoarthritis. Applied Sciences, 11(9), 4200. https://doi.org/10.3390/app11094200