Contrastive Analysis on the Ventilation Performance of a Combined Solar Chimney

Abstract

:1. Introduction

2. Materials and Methods

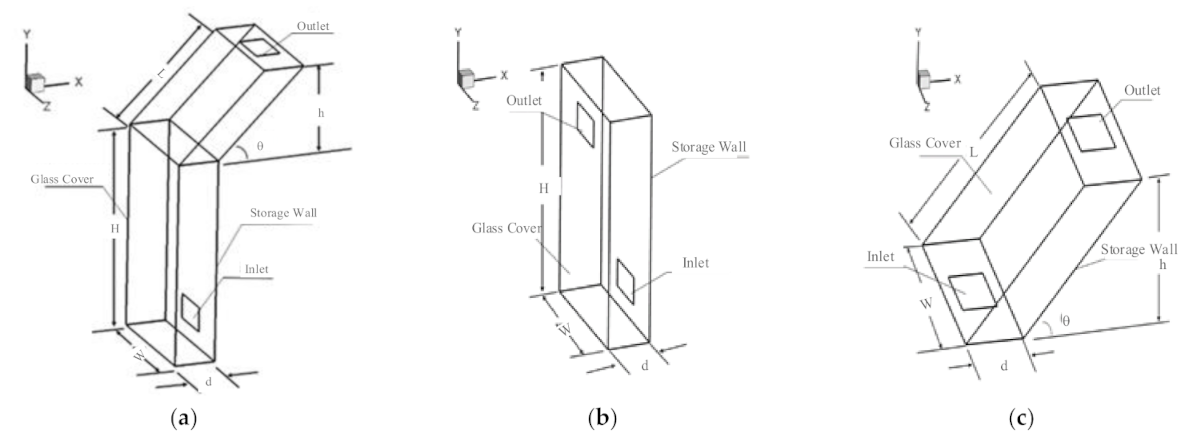

2.1. Physical Models

2.2. Mathematical Description

- The air inside the chimney was an incompressible Newtonian fluid;

- The heat transfer was in a steady-state [16]. Both the solar irradiation and the outdoor ambient temperature were constant;

- All relevant physical properties of the chimney material were independent of the temperature [20];

- Air penetration was ignored. Heat storage on the storage wall was also ignored to simplify the heat transfer process;

- This simulation only considered the ventilation performance of a solar chimney under hot-pressing [18].

2.3. Boundary Conditions

3. Validation

3.1. Mesh Independence Verification

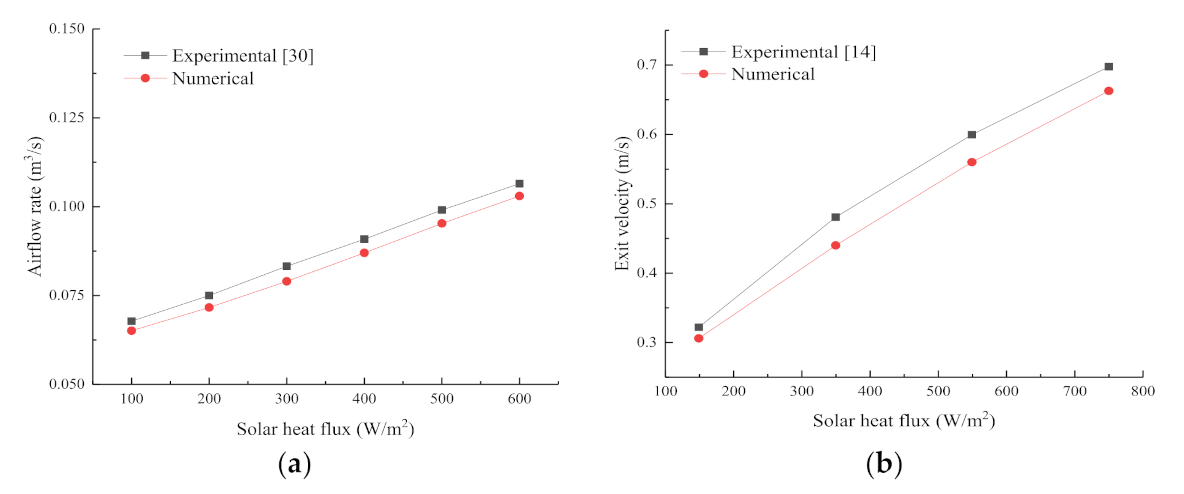

3.2. Validation of the Simulation Method

4. Results and Discussion

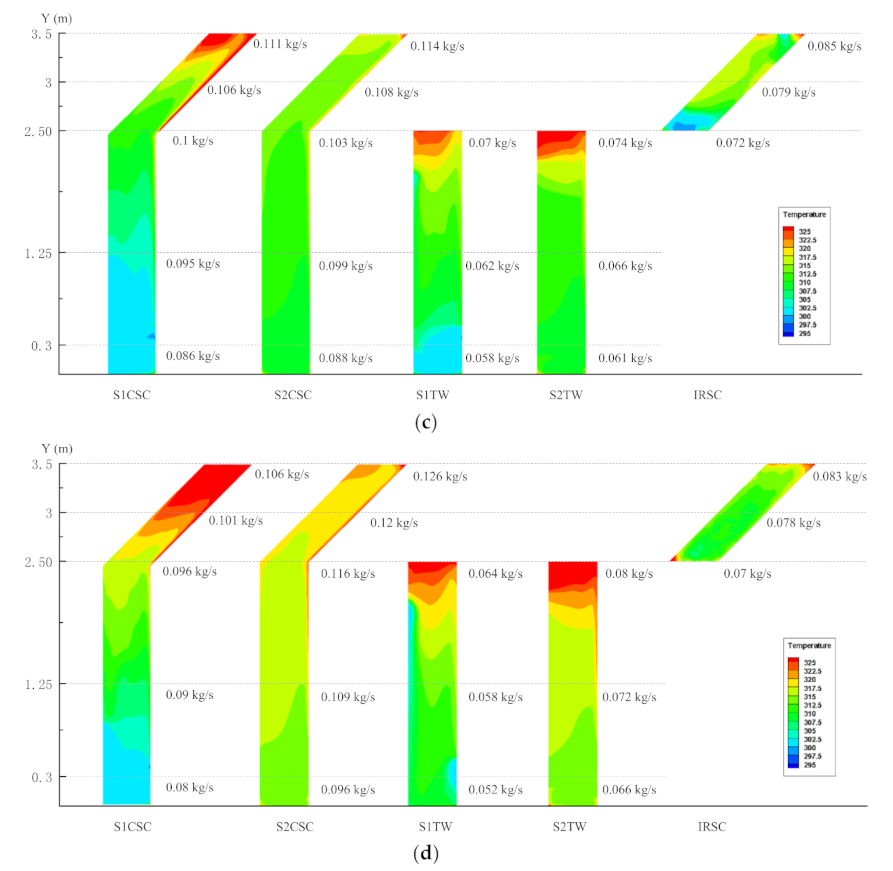

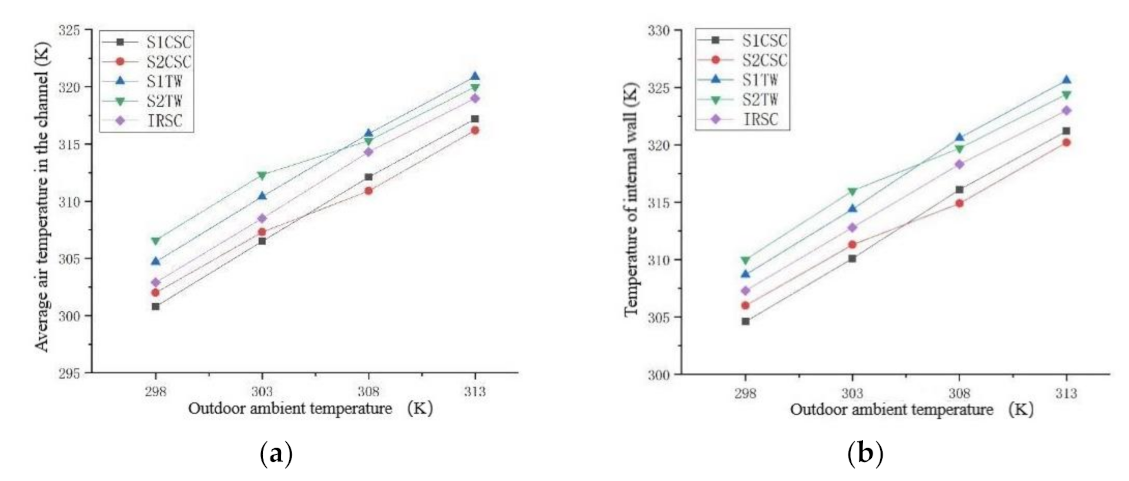

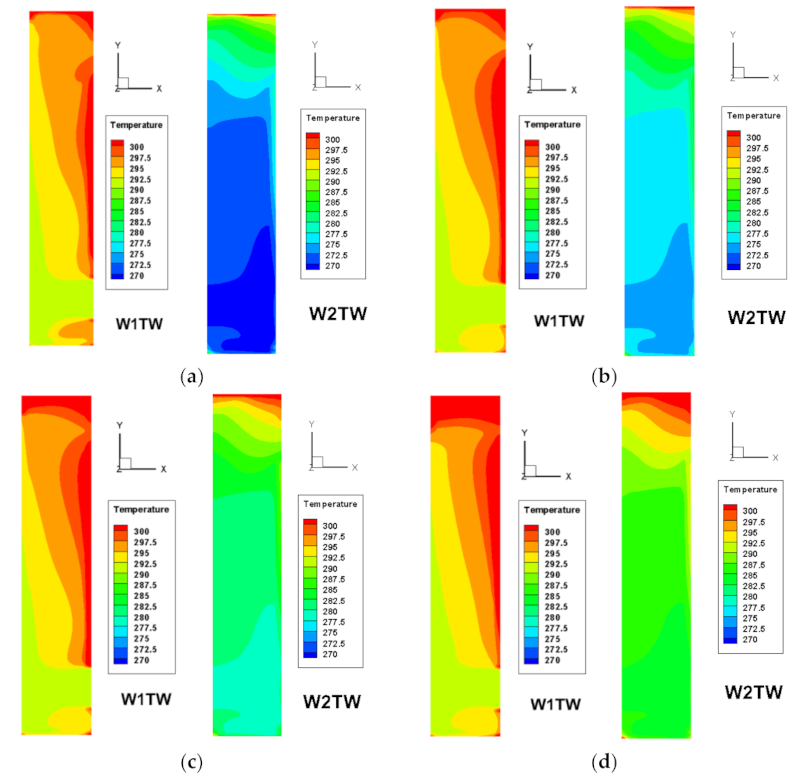

4.1. Temperature Distributions

4.2. Ventilation Performance

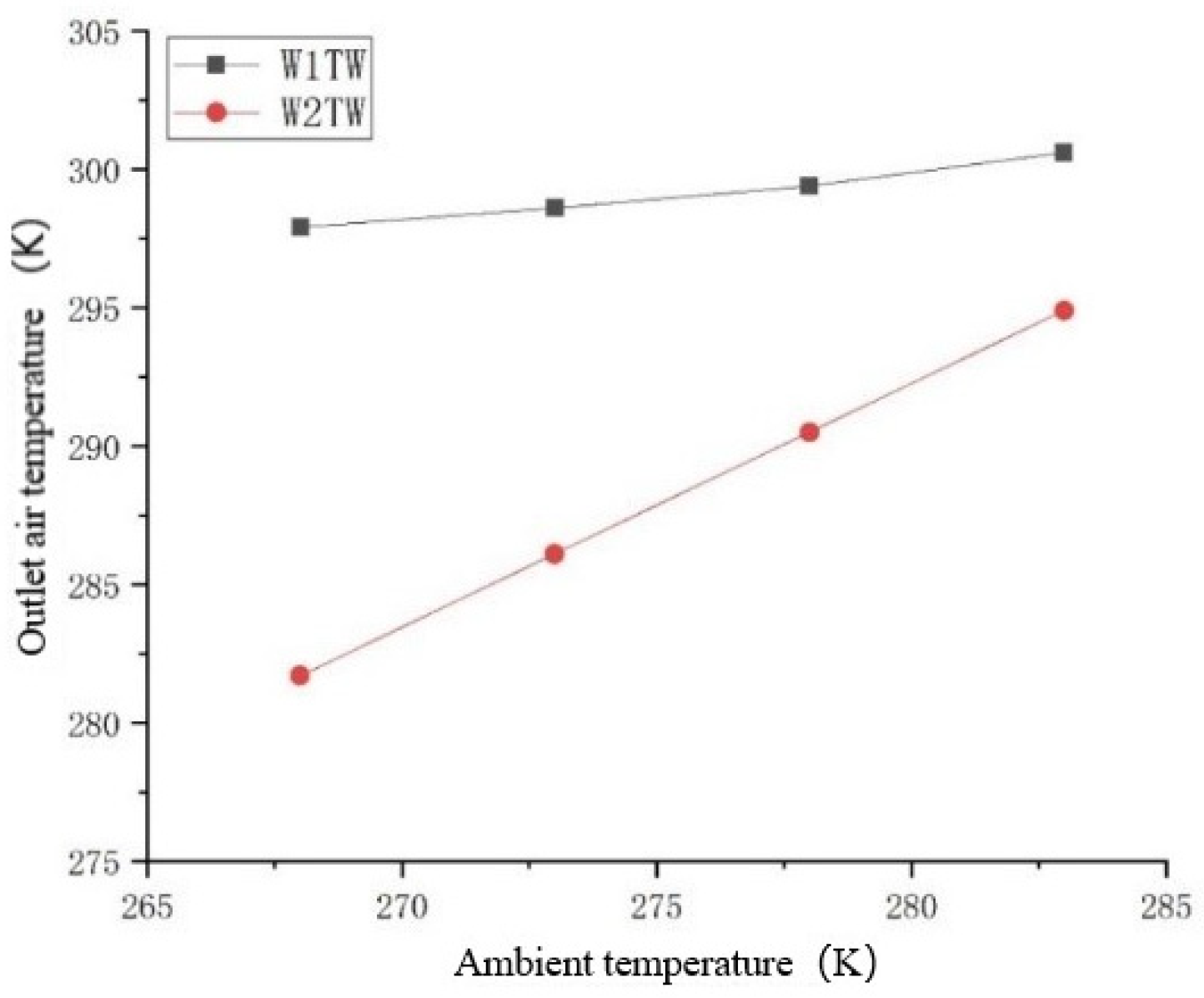

4.3. Thermal Performance in Winter Conditions

5. Conclusions

- The ventilation effect of a combined solar chimney was better than that of a Trombe wall and an inclined-roof solar chimney in the summer. The benefit from the structure and the reasonability of the operation mode suggested that the problem of overheating was negligible for a combined solar chimney.

- In the summer, the natural ventilation mode of a combined solar chimney (S1CSC) was appropriate when the ambient temperature ranged from 298 K to 303 K; the anti-overheating mode was feasible when the ambient temperature was higher than 308 K.

- When the ambient temperature was lower than 273 K, the operation mode of space heating in winter (W1TW) was suitable with a better heating effect. A preheating mode could be employed to improve the indoor air quality when the ambient temperature was higher than 278 K.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- bp Statistical Review of World Energy 2020: A Pivotal Moment. Available online: https://www.bp.com/en/global/corporate/news-and-insights/press-releases/bp-statistical-review-of-world-energy-2020-published.html (accessed on 23 November 2021).

- Li, H.; Yu, Y.; Niu, F.; Shafik, M.; Chen, B. Performance of a coupled cooling system with earth-to-air heat exchanger and solar chimney. Renew. Energy 2014, 62, 468–477. [Google Scholar] [CrossRef]

- Perez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Cheng, X.; Shi, L.; Dai, P.; Zhang, G.; Yang, H.; Li, J. Study on optimizing design of solar chimney for natural ventilation and smoke exhaustion. Energy Build. 2018, 170, 145–156. [Google Scholar] [CrossRef]

- Omrany, H.; Ghaffarianhoseini, A.; Ghaffarianhoseini, A.; Raahemifar, K.; Tookey, J. Application of passive wall systems for improving the energy efficiency in buildings: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 62, 1252–1269. [Google Scholar] [CrossRef]

- Kasaeian, A.B.; Molana, S.; Rahmani, K.; Wen, D. A review on solar chimney systems. Renew. Sustain. Energy Rev. 2017, 67, 954–987. [Google Scholar] [CrossRef]

- Zhai, X.Q.; Song, Z.P.; Wang, R.Z. A review for the applications of solar chimneys in buildings. Renew. Sustain. Energy Rev. 2011, 15, 3757–3767. [Google Scholar] [CrossRef]

- Su, Y.; Liu, Z. Research Status on Solar Chimney for Natural Ventilation Enhancement. Sci. Technol. Rev. 2011, 29, 67–72. [Google Scholar]

- Monghasemi, N.; Vadiee, A. A review of solar chimney integrated systems for space heating and cooling application. Renew. Sustain. Energy Rev. 2018, 81, 2714–2730. [Google Scholar] [CrossRef]

- Wan, W.Q.; Xuan, Y.M. Research Status and Theoretical Analysis on Tilt Solar Chimney. Contam. Control. Air Cond. Technol. 2014, 4, 31–33. [Google Scholar]

- Gupta, N.; Tiwari, G.N. Review of passive heating/cooling systems of buildings. Energy Sci. Eng. 2016, 4, 305–333. [Google Scholar] [CrossRef] [Green Version]

- Hu, Z.; He, W.; Ji, J.; Zhang, S. A review on the application of Trombe wall system in buildings. Renew. Sustain. Energy Rev. 2017, 70, 976–987. [Google Scholar] [CrossRef]

- Chan, H.-Y.; Riffat, S.B.; Zhu, J. Review of passive solar heating and cooling technologies. Renew. Sustain. Energy Rev. 2010, 14, 781–789. [Google Scholar] [CrossRef]

- Imran, A.A.; Jalil, J.M.; Ahmed, S.T. Induced flow for ventilation and cooling by a solar chimney. Renew. Energy 2015, 78, 236–244. [Google Scholar] [CrossRef]

- Khedari, J.; Rachapradit, N.; Hirunlabh, J. Field study of performance of solar chimney with air-conditioned building. Energy 2003, 28, 1099–1114. [Google Scholar] [CrossRef]

- Hosien, M.A.; Selim, S.M. Effects of the geometrical and operational parameters and alternative outer cover materials on the performance of solar chimney used for natural ventilation. Energy Build. 2017, 138, 355–367. [Google Scholar] [CrossRef]

- Bassiouny, R.; Koura, N.S.A. An analytical and numerical study of solar chimney use for room natural ventilation. Energy Build. 2008, 40, 865–873. [Google Scholar] [CrossRef]

- Harris, D.J.; Helwig, N. Solar chimney and building ventilation. Appl. Energy 2007, 84, 135–146. [Google Scholar] [CrossRef]

- Jing, H.; Chen, Z.; Li, A. Experimental study of the prediction of the ventilation flow rate through solar chimney with large gap-to-height ratios. Build. Environ. 2015, 89, 150–159. [Google Scholar] [CrossRef]

- Du, W.; Yang, Q.; Zhang, F. A study of the ventilation performance of a series of connected solar chimneys integrated with building. Renew. Energy 2011, 36, 265–271. [Google Scholar] [CrossRef]

- AboulNaga, M.M.; Abdrabboh, S.N. Improving night ventilation into low-rise buildings in hot-arid climates exploring a combined wall-roof solar chimney. Renew. Energy 2000, 19, 47–54. [Google Scholar] [CrossRef]

- Zhang, S.S.; Yang, W.B.; Liu, Y. Research on the Performance of a Composite Structure of Solar Chimney and Trombe Wall. Refrig. Air-Cond. 2012, 26, 112–116. [Google Scholar]

- Zhang, H.H.; Yang, D.; Tam, V.W.Y.; Tao, Y.; Zhang, G.M.; Setunge, S.; Shi, L. A critical review of combined natural ventilation techniques in sustainable buildings. Renew. Sustain. Energy Rev. 2021, 141. [Google Scholar] [CrossRef]

- Hosseini, S.S.; Ramiar, A.; Ranjbar, A.A. Numerical investigation of rectangular fin geometry effect on solar chimney. Energy Build. 2017, 155, 296–307. [Google Scholar] [CrossRef]

- Gu, Y.; Lei, Y.; Wang, F. Numerical Investigation on Ventilation Performance of a New Roof Solar Chimney. J. Eng. Therm. Energy Power 2016, 31, 98–104. [Google Scholar]

- Khanal, R.; Lei, C. A numerical investigation of buoyancy induced turbulent air flow in an inclined passive wall solar chimney for natural ventilation. Energy Build. 2015, 93, 217–226. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, D.; Ma, C.; Liu, J. A numerical and experimental analysis of the air vent management and heat storage characteristics of a trombe wall. Sol. Energy 2013, 91, 1–10. [Google Scholar] [CrossRef]

- Wu, S.-Y.; Xu, L.; Xiao, L. Air purification and thermal performance of photocatalytic-Trombe wall based on multiple physical fields coupling. Renew. Energy 2020, 148, 338–348. [Google Scholar] [CrossRef]

- Concepts, R. Fluent User’s Guide, Version 5.0; ANSYS, Inc.: Canonsburg, PA, USA, 2014. [Google Scholar]

- Hou, Y.; Li, H.; Li, A. Experimental and theoretical study of solar chimneys in buildings with uniform wall heat flux. Sol. Energy 2019, 193, 244–252. [Google Scholar] [CrossRef]

| Model | H (m) | h (m) | W (m) | d (m) | θ (°) | Size of Air Vent (m2) |

|---|---|---|---|---|---|---|

| CSC | 2.5 | 1 | 1.5 | 0.5 | 45° | 0.5 × 0.3 |

| TW | 2.5 | -- | 1.5 | 0.5 | -- | 0.5 × 0.3 |

| IRSC | -- | 1 | 1.5 | 0.5 | 45° | 0.5 × 0.3 |

| Material | Density kg/m3 | Specific Heat Capacity J/(kg ∙ K) | Heat Conductivity Coefficient W/(m ∙ K) | Absorptivity α | Transmissivity τ |

|---|---|---|---|---|---|

| Glass cover | 2500 | 837.4 | 0.75 | 0.08 | 0.82 |

| Storage wall | 2500 | 920 | 1.74 | 0.95 | -- |

| Insulation | 100 | 1380 | 0.047 | 0.6 | -- |

| Density kg/m3 | Specific Heat Capacity J/(kg ∙ K) | Heat Conductivity Coefficient W/(m ∙ K) | Viscous Coefficient kg/(m ∙ s) | Thermal Expansion Coefficient K−1 |

|---|---|---|---|---|

| 1.205 | 1005.43 | 0.0259 | 1.81 × 10−5 | 0.0034 |

| Operation Mode | Ta = 298 K | Ta = 303 K | Ta = 308 K | Ta = 311 K |

|---|---|---|---|---|

| S1CSC | 300 | 300 | 300 | 300 |

| 2CSC | 298 | 303 | 308 | 311 |

| S1TW | 300 | 300 | 300 | 300 |

| S2TW | 298 | 303 | 308 | 311 |

| IRSC | 300 | 300 | 300 | 300 |

| Operation Mode | Ta = 268 K | Ta = 273 K | Ta = 278 K | Ta = 283 K |

|---|---|---|---|---|

| W1TW | 291 | 291 | 291 | 291 |

| W2TW | 268 | 273 | 278 | 283 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Li, P.; Yu, B.; Zhang, M.; Tan, Q.; Wang, Y.; Zhang, Y. Contrastive Analysis on the Ventilation Performance of a Combined Solar Chimney. Appl. Sci. 2022, 12, 156. https://doi.org/10.3390/app12010156

Liu H, Li P, Yu B, Zhang M, Tan Q, Wang Y, Zhang Y. Contrastive Analysis on the Ventilation Performance of a Combined Solar Chimney. Applied Sciences. 2022; 12(1):156. https://doi.org/10.3390/app12010156

Chicago/Turabian StyleLiu, Huifang, Peijia Li, Bendong Yu, Mingyi Zhang, Qianli Tan, Yu Wang, and Yi Zhang. 2022. "Contrastive Analysis on the Ventilation Performance of a Combined Solar Chimney" Applied Sciences 12, no. 1: 156. https://doi.org/10.3390/app12010156

APA StyleLiu, H., Li, P., Yu, B., Zhang, M., Tan, Q., Wang, Y., & Zhang, Y. (2022). Contrastive Analysis on the Ventilation Performance of a Combined Solar Chimney. Applied Sciences, 12(1), 156. https://doi.org/10.3390/app12010156