Long Term Effects of Reduced Track Tamping Works

Abstract

:Featured Application

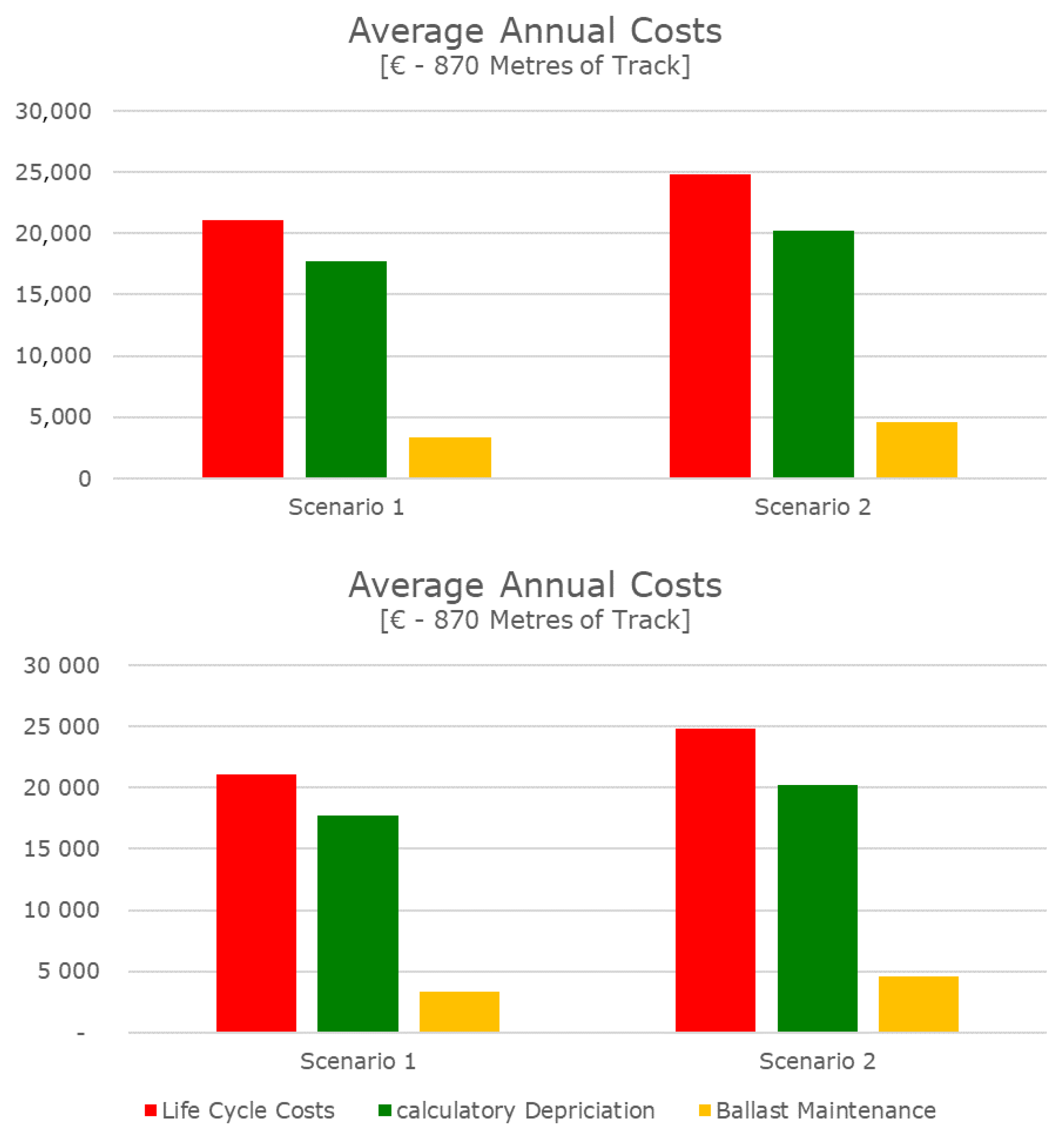

Abstract

1. Introduction

2. Methodology

2.1. Pre-Work and Applied Algorithms

2.1.1. Precision-Positioning of Longitudinal Level Measurement Signal

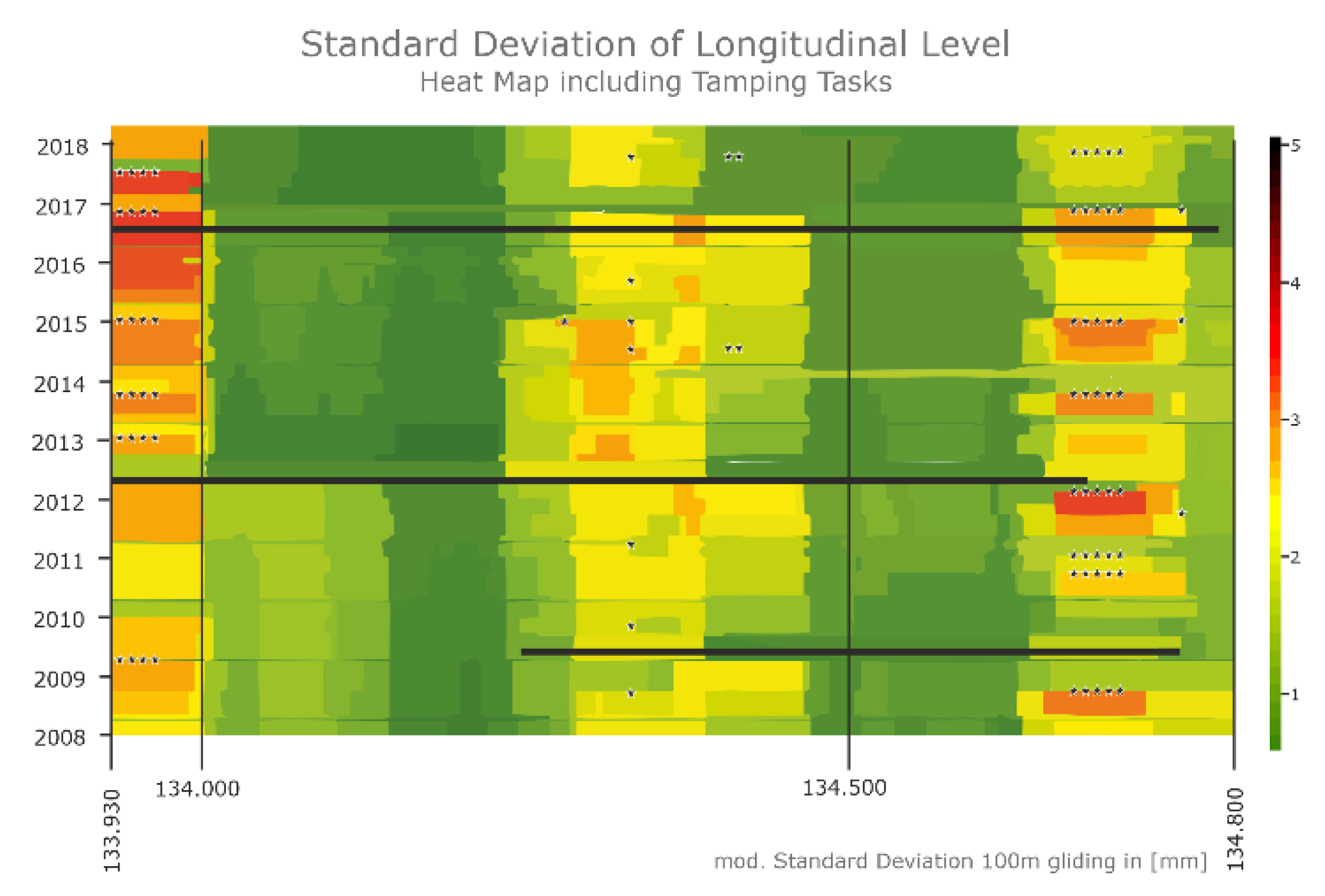

2.1.2. Defining the Interaction between Track Quality and Tamping Measures

2.2. Track Quality Assessment for Different Scenarios

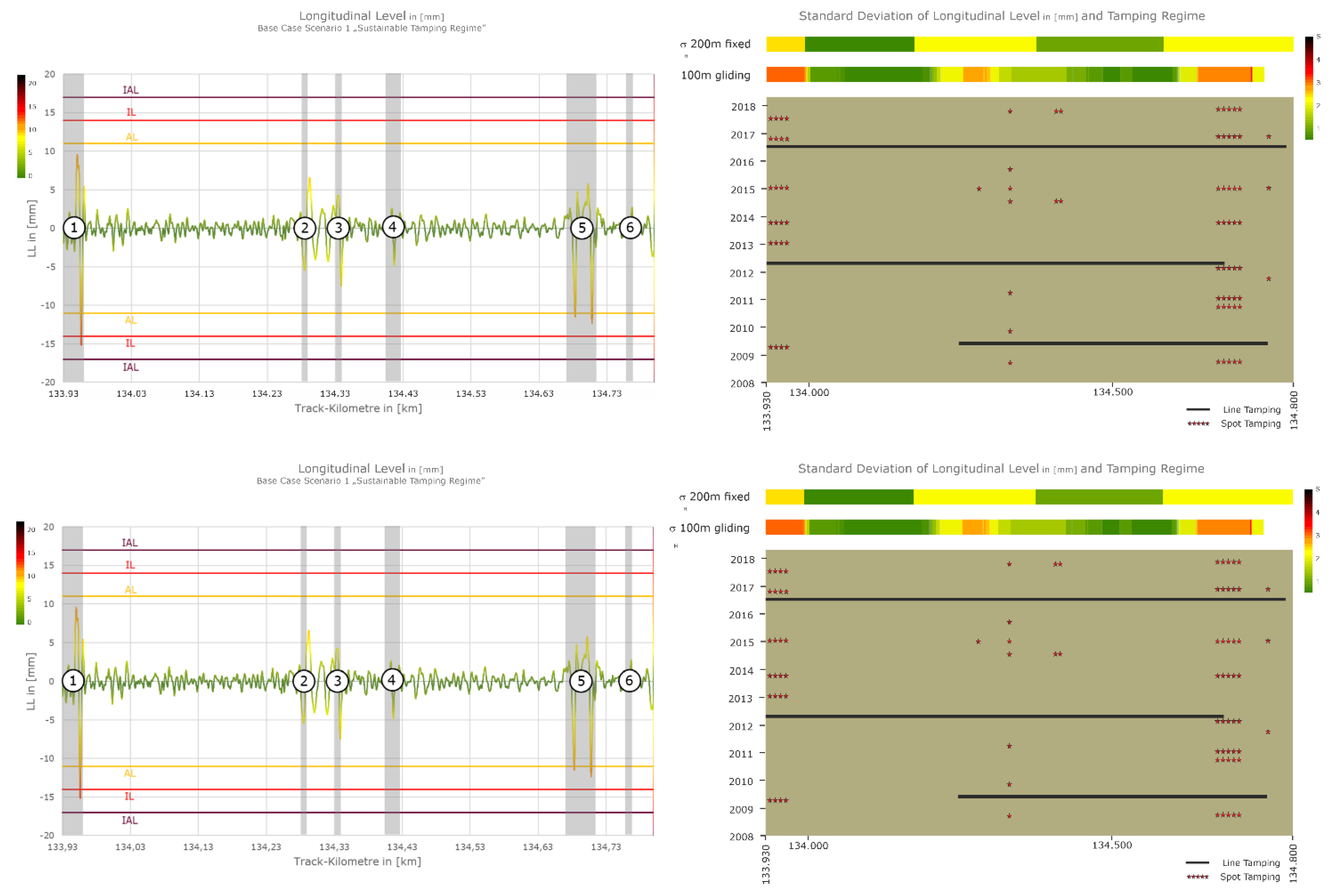

2.2.1. Base Case Scenario (Scenario 1)

2.2.2. Scenario “Spot Tamping Only” (Scenario 2)

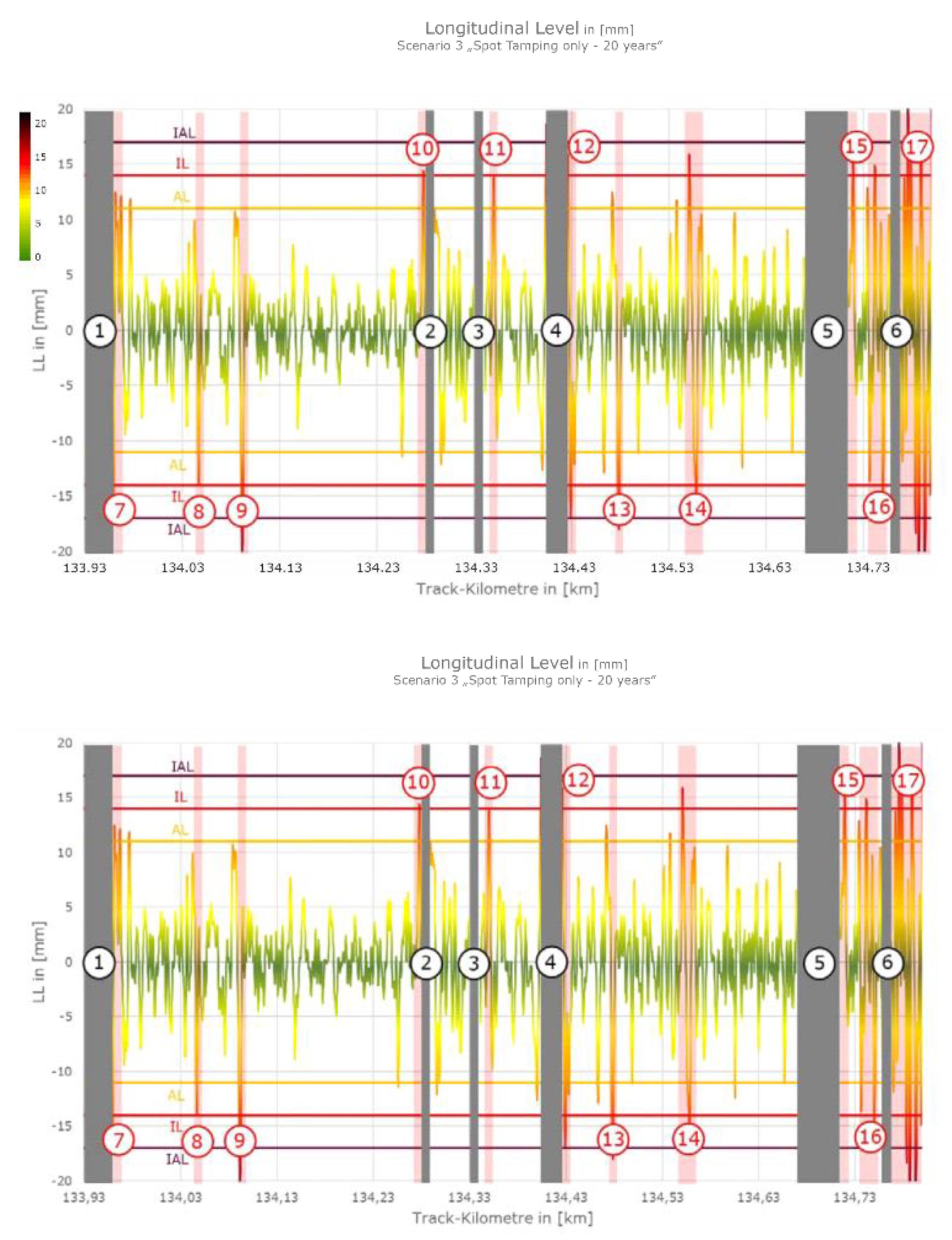

2.2.3. Scenario “Spot Tamping Only–20 Years” (Scenario 2a)

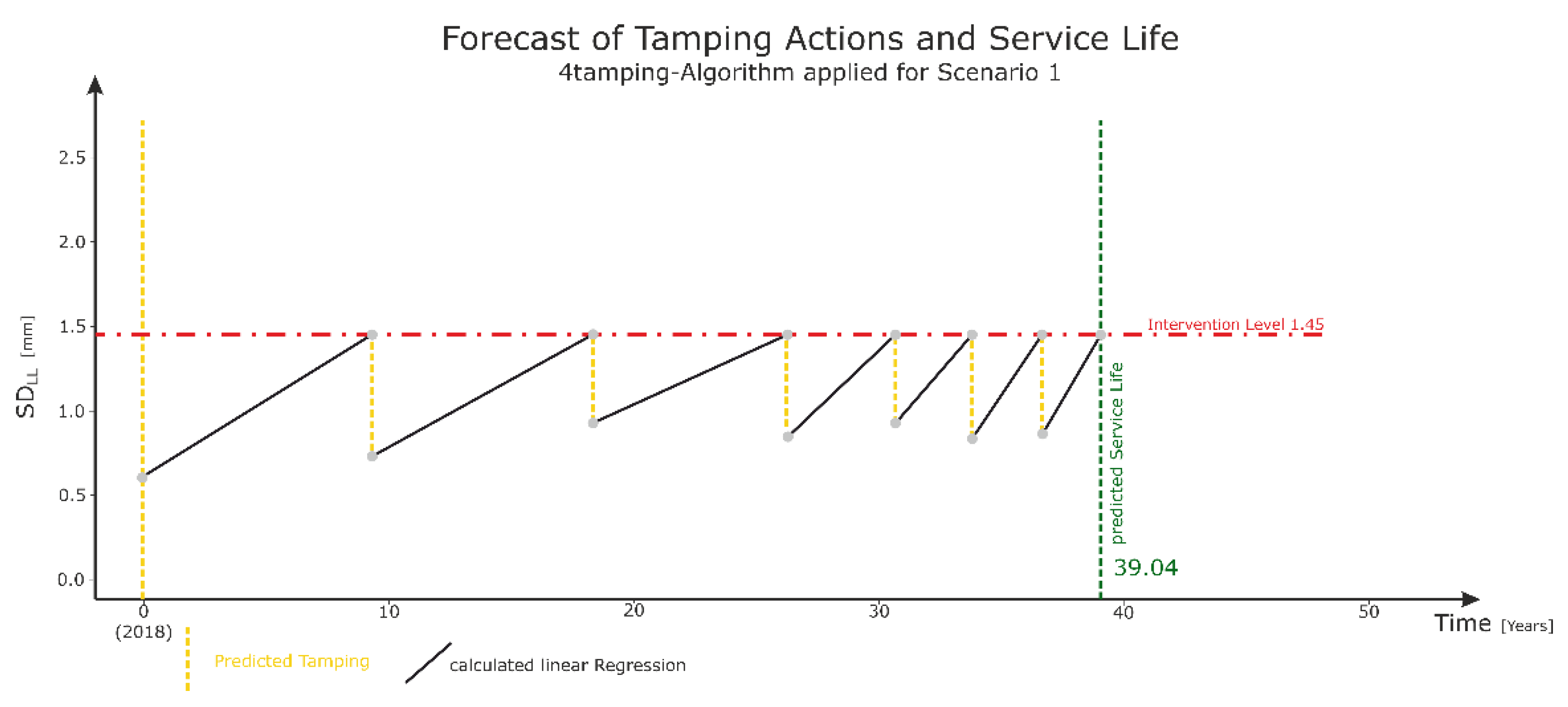

2.3. Prediction of Tamping Demands and Service Lives

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wen, M.; Li, R.; Salling, K.B. Optimization of preventive condition-based tamping for railway tracks. Eur. J. Oper. Res. 2016, 252, 455–465. [Google Scholar] [CrossRef] [Green Version]

- Audley, M.; Andrews, J.D. The effects of tamping on railway track geometry degradation. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2013, 227, 376–391. [Google Scholar] [CrossRef]

- Neuhold, J.; Vidovic, I.; Marschnig, S. Preparing Track Geometry Data for Automated Maintenance Planning. J. Transp. Eng. Part A Syst. 2020, 146, 04020032. [Google Scholar] [CrossRef]

- Offenbacher, S.; Neuhold, J.; Veit, P.; Landgraf, M. Analyzing Major Track Quality Indices and Introducing a Universally Applicable TQI. Appl. Sci. 2020, 10, 8490. [Google Scholar] [CrossRef]

- Sadeghi, J. Development of railway track geometry indexes based on statistical distribution of geometry data. J. Transp. Eng. 2010, 136, 693–700. [Google Scholar] [CrossRef]

- Liu, R.K.; Xu, P.; Sun, Z.Z.; Zou, C.; Sun, Q.X. Establishment of track quality index standard recommendations for beijing metro. Discret. Dyn. Nat. Soc. 2015, 2015, 473830. [Google Scholar] [CrossRef] [Green Version]

- Fellinger, M.; Neuhold, J.; Marschnig, S. Ballast Condition Monitoring for Turnouts Using Power Spectral Density. J. Transp. Eng. A 2020, 146, 04020099. [Google Scholar] [CrossRef]

- Dahlberg, T. Some railroad settlement models—A critical review. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2001, 215, 289–300. [Google Scholar] [CrossRef]

- Elkhoury, N.; Hitihamillage, L.; Moridpour, S.; Robert, D. Degradation Prediction of Rail Tracks: A Review of the Existing Literature. Open Transp. J. 2018, 12, 88–104. [Google Scholar] [CrossRef] [Green Version]

- Neuhold, J. Tamping within Sustainable Track Asset Management; Monographic Series TU Graz/Railway Research, vol. 6; Verlag der TU Graz: Graz, Austria, 2020; p. 228. ISBN 978-3-85125-782-3. [Google Scholar]

- Andrews, J. A modelling approach to railway track asset management. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2013, 227, 56–73. [Google Scholar] [CrossRef]

- Droździel, J.; Sowiński, B. Simulation of railway track deterioration influenced by ballast stiffness and dry friction. WIT Trans. Built Environ. 2008, 103, 693–702. [Google Scholar]

- Famurewa, S.; Xin, T.; Rantatalo, M.; Kumar, U. Optimisation of maintenance track possession time: A tamping case study. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2013, 229, 12–22. [Google Scholar] [CrossRef]

- Caetano, L.F.; Teixeira, P.F. Predictive maintenance model for ballast tamping. J. Transp. Eng. 2016, 142, 04016006. [Google Scholar] [CrossRef]

- Vale, C.; Ribeiro, I.M.; Calçada, R. Integer Programming to Optimize Tamping in Railway Tracks as Preventive Maintenance. J. Transp. Eng. 2012, 138, 123–131. [Google Scholar] [CrossRef]

- Soleimanmeigouni, I.; Ahmadi, A.; Kumar, U. Track geometry degradation and maintenance modelling: A review. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2018, 232, 73–102. [Google Scholar] [CrossRef]

- Nguyen, K.; José, M.G.; Gabaldon, F. Dynamic effect of high speed railway traffic loads on the ballast track settlement. In Proceedings of the Congresso de Métodos Numéricos em Engenharia, Coimbra, Portugal, 14 June 2011. [Google Scholar]

- Zhang, X. Zhao, C.; Zhai, W.; Shi, C.; Feng, Y. Investigation of track settlement and ballast degradation in the high-speed railway using a full-scale laboratory test. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2019, 233, 869–881. [Google Scholar] [CrossRef]

- UIC Asset Management Working Group. Key Cost Drivers in Railway Asset Management; UIC: Paris, France, 2016. [Google Scholar]

- Marschnig, S.; Vidovic, I. Estimating future tamping demands using the Swiss Wear Factor. In Proceedings of the 12th World Congress on Railway Research, Tokyo, Japan, 28 October–1 November 2019. [Google Scholar]

- Antony, M. Modelling of the ballast maintenance expenses. In Proceedings of the 9th World Congress on Railway Research, Lille, France, 22–26 May 2011. [Google Scholar]

- Vale, C.; Ribeiro, I.; Calçada, R. Scheduling tamping through global optimization of maintenance costs. In Proceedings of the 9th World Congress on Railway Research, Lille, France, 22–26 May 2011. [Google Scholar]

- Hommes, T.O. Optimisation Model for Scheduling Preventive Tamping Maintenance. Master’s Thesis, TU Delft, Delft, The Netherlands, 2016. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marschnig, S.; Neuper, G.; Hansmann, F.; Fellinger, M.; Neuhold, J. Long Term Effects of Reduced Track Tamping Works. Appl. Sci. 2022, 12, 368. https://doi.org/10.3390/app12010368

Marschnig S, Neuper G, Hansmann F, Fellinger M, Neuhold J. Long Term Effects of Reduced Track Tamping Works. Applied Sciences. 2022; 12(1):368. https://doi.org/10.3390/app12010368

Chicago/Turabian StyleMarschnig, Stefan, Georg Neuper, Fabian Hansmann, Michael Fellinger, and Johannes Neuhold. 2022. "Long Term Effects of Reduced Track Tamping Works" Applied Sciences 12, no. 1: 368. https://doi.org/10.3390/app12010368