Numerical Simulation and Experiment of a High-Efficiency Tunnel Oxide Passivated Contact (TOPCon) Solar Cell Using a Crystalline Nanostructured Silicon-Based Layer

Abstract

:1. Introduction

2. Experimental Details and Simulation Setup

3. Results and Discussion

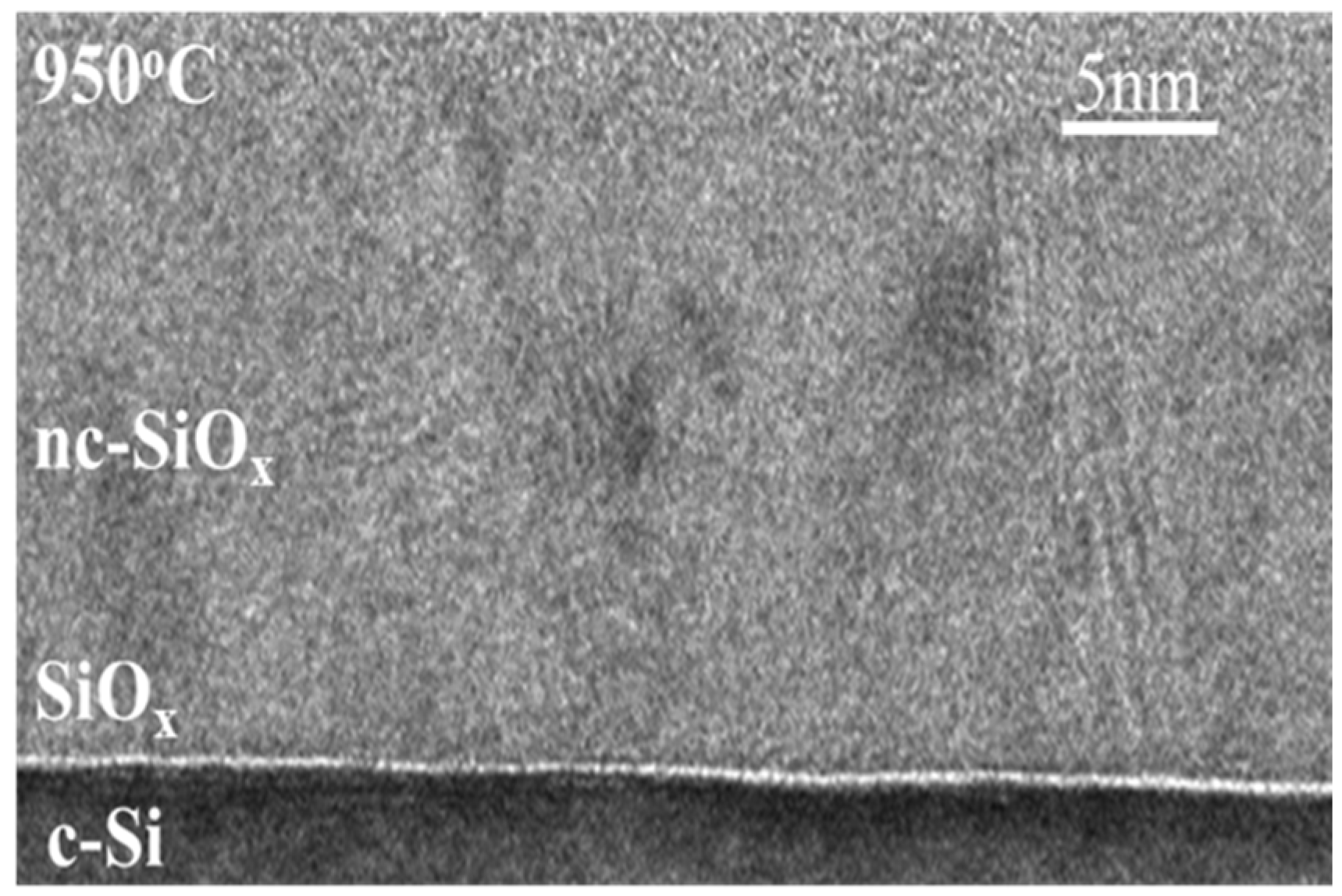

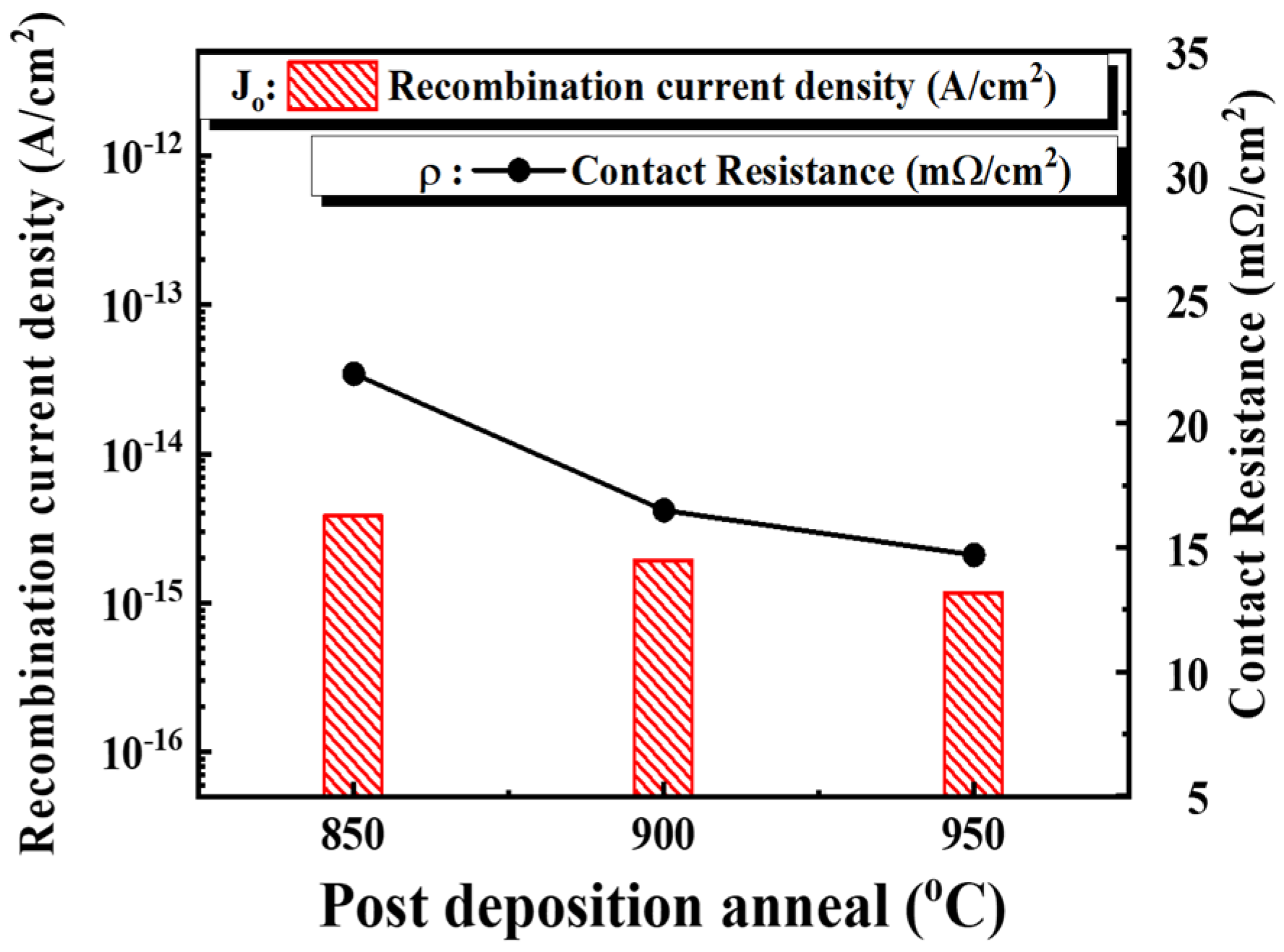

3.1. Electrical Properties of the nc-SiOx Layer

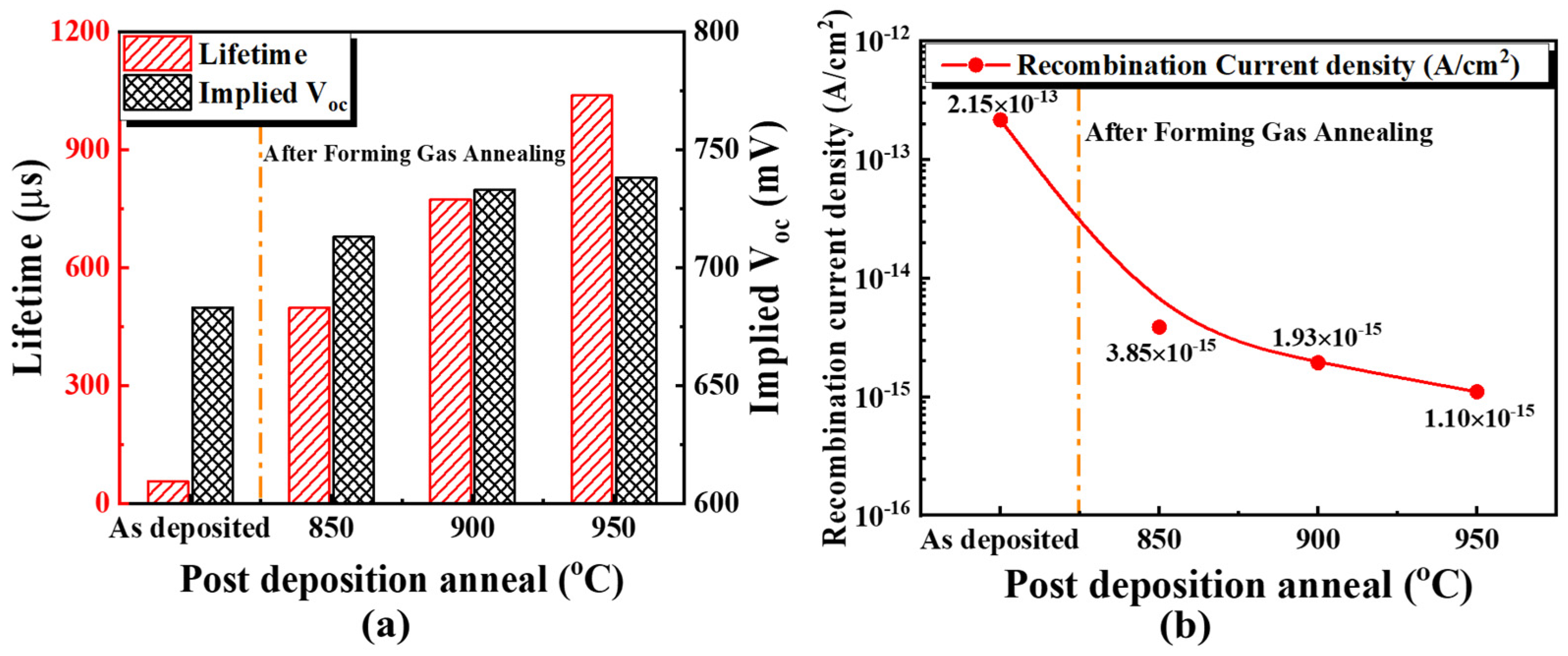

3.2. Analysis of Passivation Properties

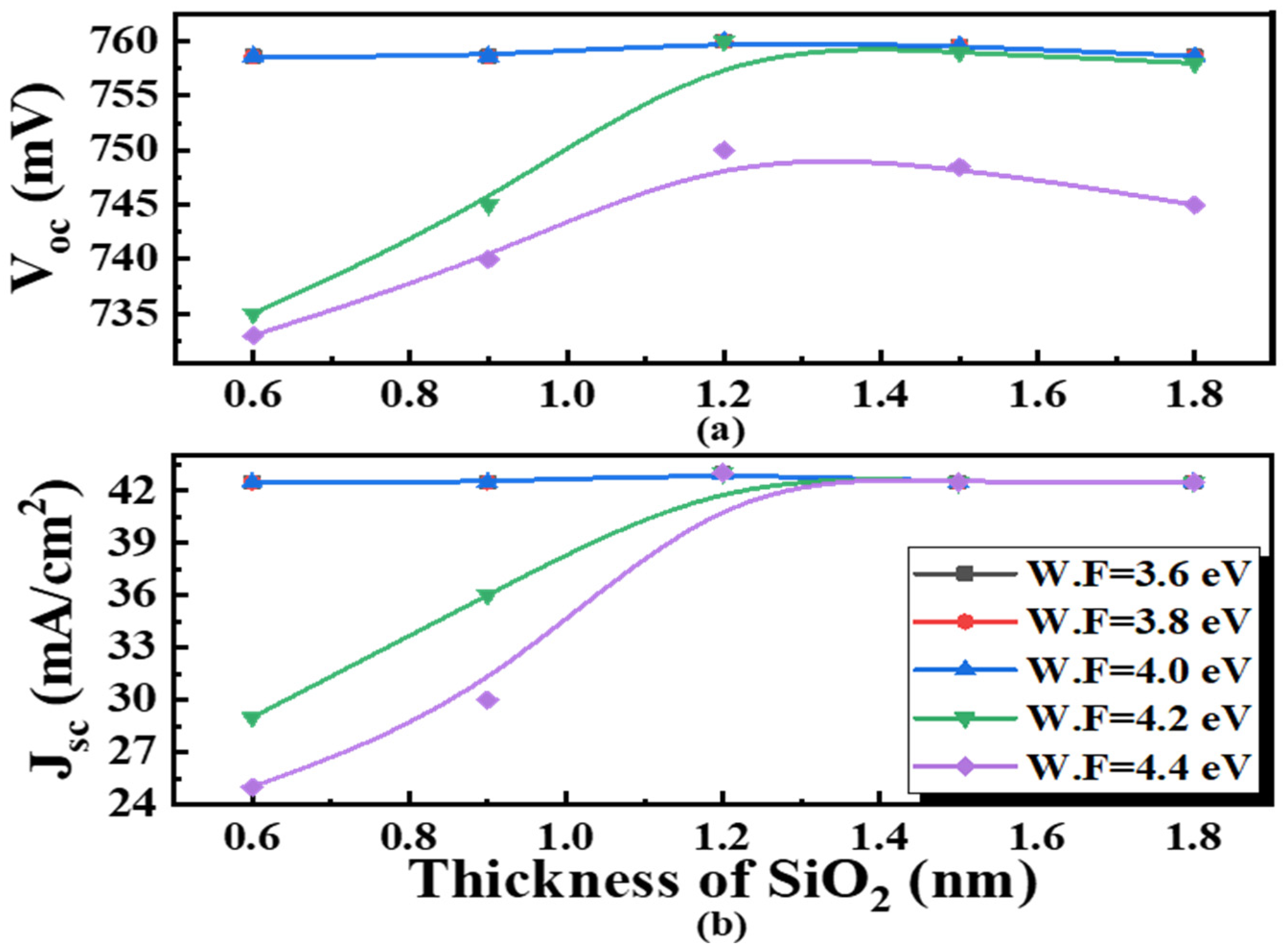

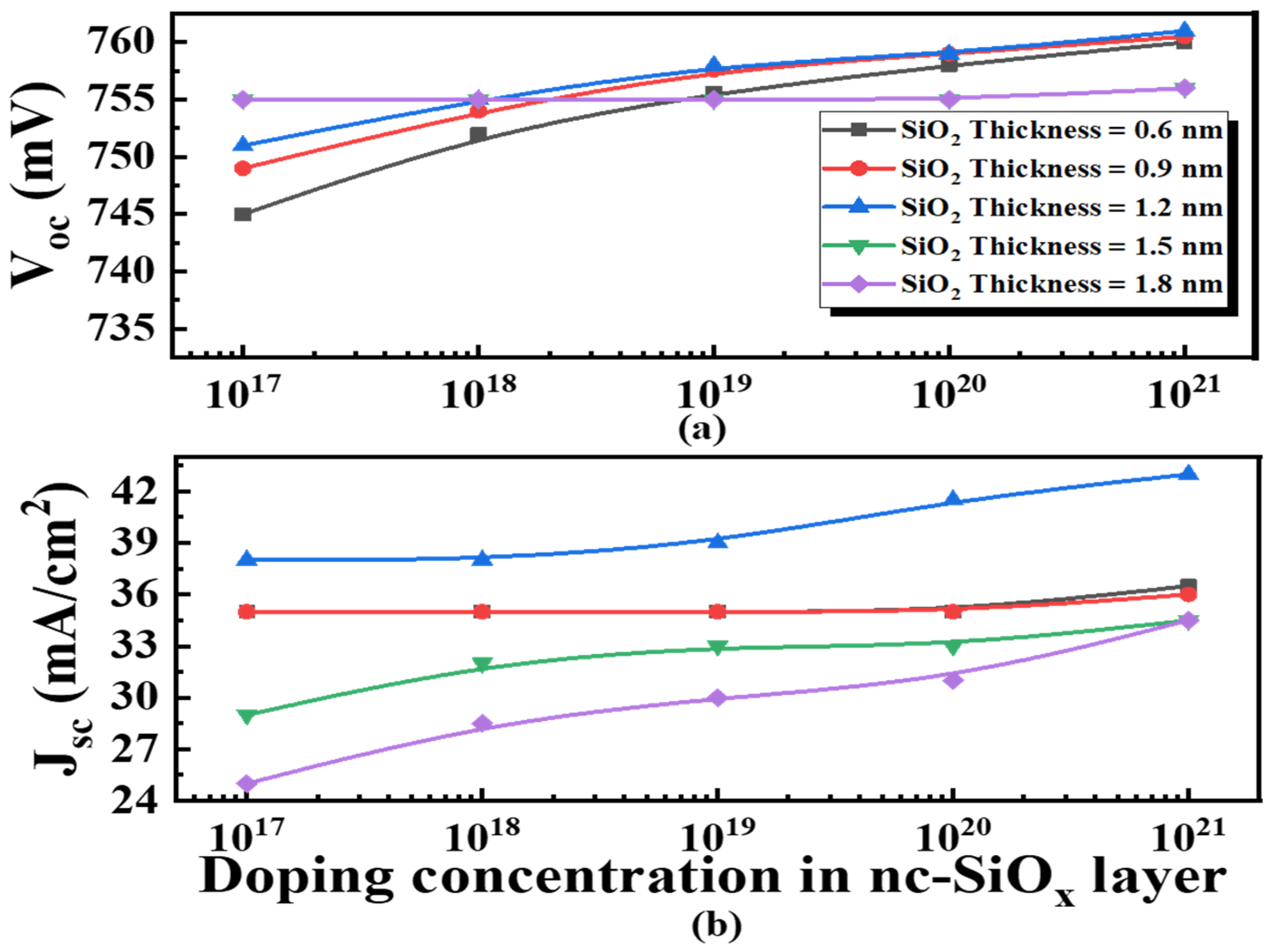

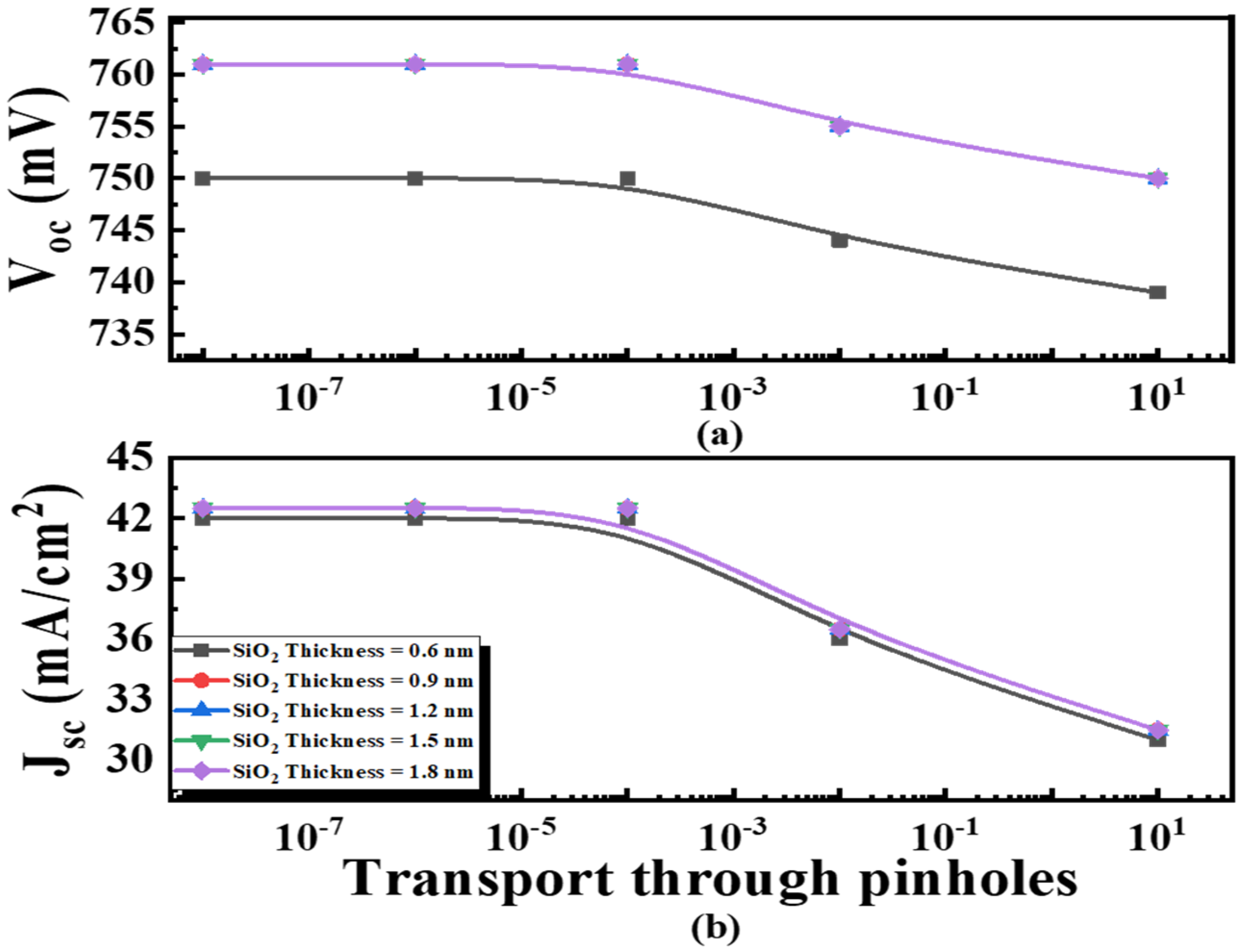

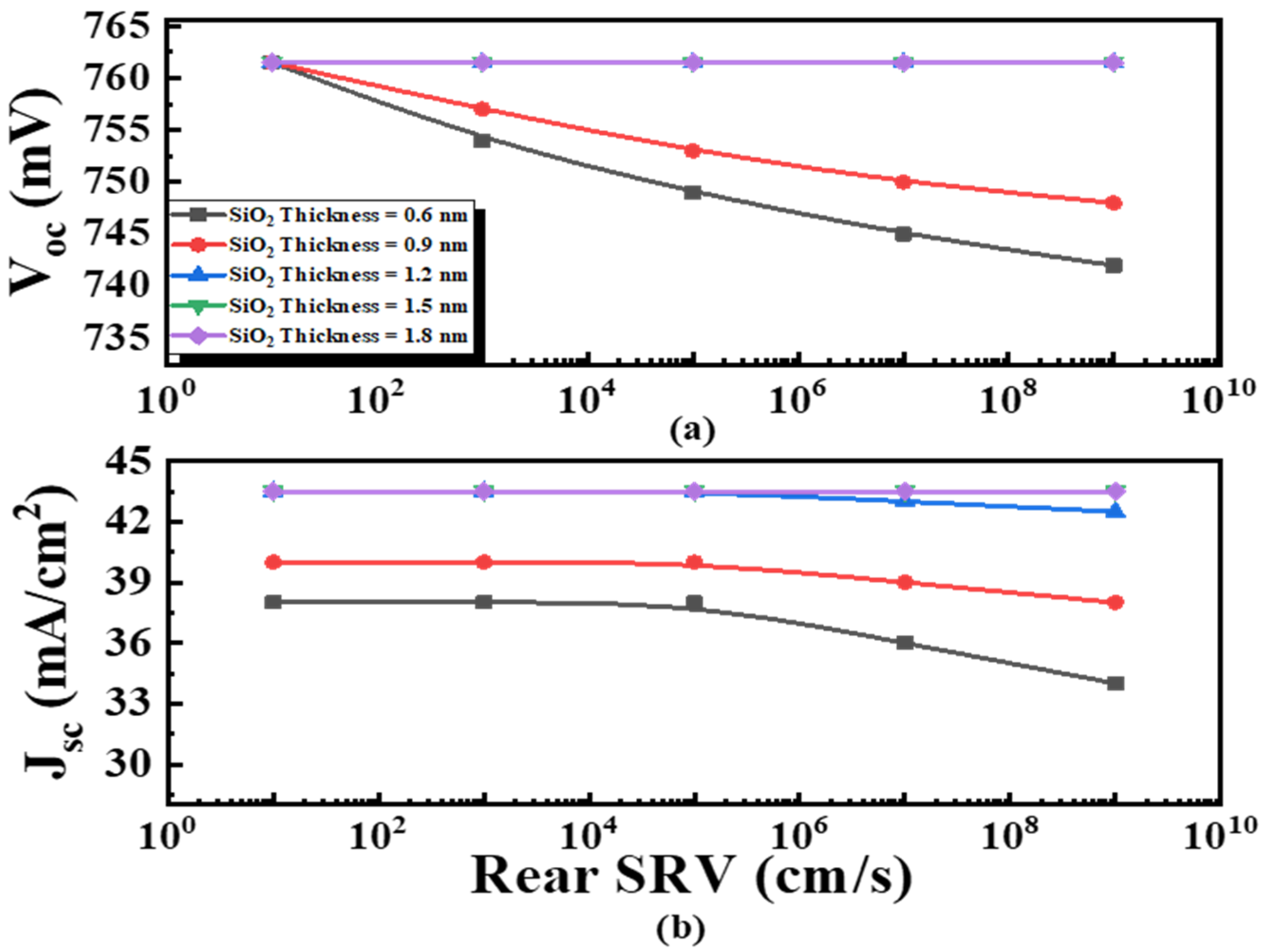

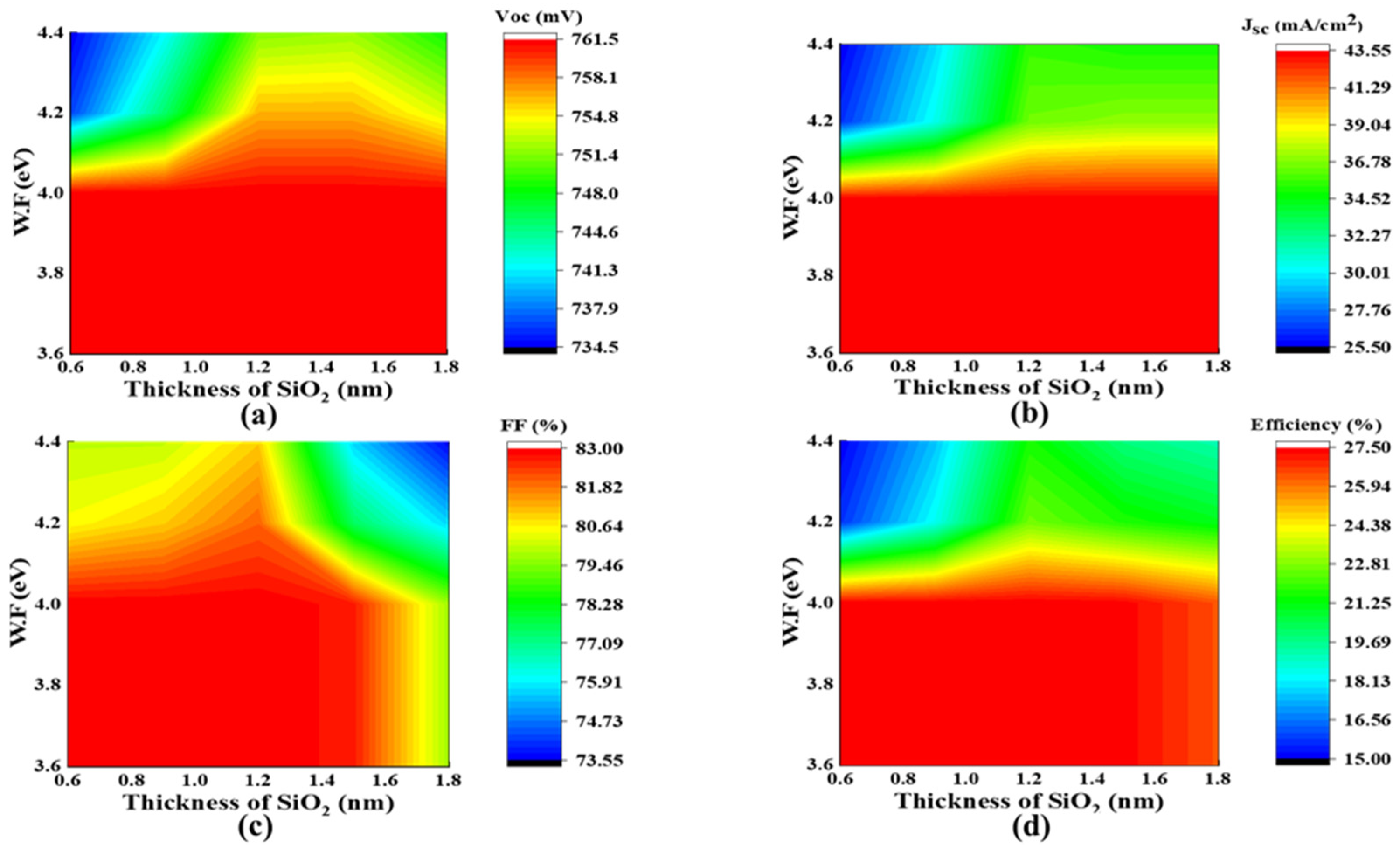

3.3. Path towards Cell Parameters Optimization

3.4. TOPCon Solar Cell Achievement

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Feldmann, F.; Bivour, M.; Reichel, C.; Hermle, M.; Glunz, S.W. A passivated rear contact for high-efficiency n-type silicon solar cells enabling high Vocs and FF > 82%. In Proceedings of the 28th European PV Solar Energy Conference and Exhibition, Villepinte, France, 30 September–4 October 2013. [Google Scholar]

- Feldmann, F.; Bivour, M.; Reichel, C.; Hermle, M.; Glunz, S.W. Passivated rear contacts for high-efficiency n-type Si solar cells providing high interface passivation quality and excellent transport characteristics. Sol. Energy Mater. Sol. Cells 2014, 120, 270–274. [Google Scholar] [CrossRef]

- Feldmann, F.; Bivour, M.; Reichel, C.; Steinkemper, H.; Hermle, M.; Glunz, S.W. Tunnel oxide passivated contacts as an alternative to partial rear contacts. Sol. Energy Mater. Sol. Cells 2014, 131, 46–50. [Google Scholar] [CrossRef]

- Feldmann, F.; Simon, M.; Bivour, M.; Reichel, C.; Hermle, M.; Glunz, S.W. Efficient carrier-selective p-and n-contacts for Si solar cells. Sol. Energy Mater. Sol. Cells 2014, 131, 100–104. [Google Scholar] [CrossRef]

- Reichel, C.; Feldmann, F.; Müller, R.; Moldovan, A.; Hermle, M.; Glunz, S.W. Interdigitated back contact silicon solar cells with tunnel oxide passivated contacts formed by ion implantation. In Proceedings of the 29th European PV Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 22–26 September 2014. [Google Scholar]

- Moldovan, A.; Feldmann, F.; Kaufmann, K.; Richter, S.; Werner, M.; Hagendorf, C.; Zimmer, M.; Rentsch, J.; Hermle, M. Tunnel oxide passivated carrier-selective contacts based on ultra-thin SiO2 layers grown by photo-oxidation or wet-chemical oxidation in ozonized water. In Proceedings of the 2015 IEEE 42nd Photovoltaic Specialist Conference (PVSC), New Orleans, LA, USA, 14–19 June 2015; pp. 1–6. [Google Scholar]

- Yan, D.; Cuevas, A.; Bullock, J.; Wan, Y.; Samundsett, C. Phosphorus-diffused polysilicon contacts for solar cells. Sol. Energy Mater. Sol. Cells 2015, 142, 75–82. [Google Scholar] [CrossRef]

- Yan, D.; Cuevas, A.; Wan, Y.; Bullock, J. Passivating contacts for silicon solar cells based on boron-diffused recrystallized amorphous silicon and thin dielectric interlayers. Sol. Energy Mater. Sol. Cells 2016, 152, 73–79. [Google Scholar] [CrossRef]

- Tao, Y.; Upadhyaya, V.; Chen, C.W.; Payne, A.; Chang, E.L.; Upadhyaya, A.; Rohatgi, A. Large area tunnel oxide passivated rear contact n-type Si solar cells with 21.2% efficiency. Prog. Photovolt. Res. Appl. 2016, 24, 830–835. [Google Scholar] [CrossRef]

- Peibst, R.; Larionova, Y.; Reiter, S.; Turcu, M.; Brendel, R.; Tetzlaff, D.; Krügener, J.; Wietler, T.; Höhne, U.; Kähler, J. Implementation of n+ and p+ poly junctions on front and rear side of double-side contacted industrial silicon solar cells. In Proceedings of the 32nd European Photovoltaic Solar Energy Conference and Exhibition, München, Germany, 21–24 June 2016; pp. 323–327. [Google Scholar]

- Moldovan, A.; Feldmann, F.; Krugel, G.; Zimmer, M.; Rentsch, J.; Hermle, M.; Roth-Fölsch, A.; Kaufmann, K.; Hagendorf, C. Simple cleaning and conditioning of silicon surfaces with UV/ozone sources. Energy Procedia 2014, 55, 834–844. [Google Scholar] [CrossRef]

- Richter, S.; Kaufmann, K.; Naumann, V.; Werner, M.; Graff, A.; Großer, S.; Moldovan, A.; Zimmer, M.; Rentsch, J.; Bagdahn, J. High-resolution structural investigation of passivated interfaces of silicon solar cells. Sol. Energy Mater. Sol. Cells 2015, 142, 128–133. [Google Scholar] [CrossRef]

- Ge, H. Development of High Efficiency SHJ/Poly-Si Passivating Contact Hybrid Solar Cells. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2017. [Google Scholar]

- Glunz, S.; Preu, R.; Biro, D. Crystalline silicon solar cells: State-of-the-art and future developments. Compr. Renew. Energy 2012, 1, 353–387. [Google Scholar]

- Steinkemper, H.; Hermle, M.; Glunz, S.W. Comprehensive simulation study of industrially relevant silicon solar cell architectures for an optimal material parameter choice. Prog. Photovolt. Res. Appl. 2016, 24, 1319–1331. [Google Scholar] [CrossRef]

- Steinkemper, H.; Feldmann, F.; Bivour, M.; Hermle, M. Numerical simulation of carrier-selective electron contacts featuring tunnel oxides. IEEE J. Photovolt. 2015, 5, 1348–1356. [Google Scholar] [CrossRef]

- Steinkemper, H.; Feldmann, F.; Bivour, M.; Hermle, M. Theoretical investigation of carrier-selective contacts featuring tunnel oxides by means of numerical device simulation. Energy Procedia 2015, 77, 195–201. [Google Scholar] [CrossRef]

- Mitra, S.; Ghosh, H.; Saha, H.; Ghosh, K. Recombination Analysis of Tunnel Oxide Passivated Contact Solar Cells. IEEE Trans. Electron Devices 2019, 66, 1368–1376. [Google Scholar] [CrossRef]

- Fell, A.; Schön, J.; Müller, M.; Wöhrle, N.; Schubert, M.C.; Glunz, S.W. Modeling edge recombination in silicon solar cells. IEEE J. Photovolt. 2018, 8, 428–434. [Google Scholar] [CrossRef]

- Stephens, A.; Aberle, A.; Green, M. Surface recombination velocity measurements at the silicon–silicon dioxide interface by microwave-detected photoconductance decay. J. Appl. Phys. 1994, 76, 363–370. [Google Scholar] [CrossRef]

- Luke, K.L.; Cheng, L.J. Analysis of the interaction of a laser pulse with a silicon wafer: Determination of bulk lifetime and surface recombination velocity. J. Appl. Phys. 1987, 61, 2282–2293. [Google Scholar] [CrossRef]

- Sproul, A. Dimensionless solution of the equation describing the effect of surface recombination on carrier decay in semiconductors. J. Appl. Phys. 1994, 76, 2851–2854. [Google Scholar] [CrossRef]

- Brody, J.; Rohatgi, A. Analytical approximation of effective surface recombination velocity of dielectric-passivated p-type silicon. Solid-State Electron. 2001, 45, 1549–1557. [Google Scholar] [CrossRef]

- Kim, S.; Park, J.; Phong, P.D.; Shin, C.; Iftiquar, S.; Yi, J. Improving the efficiency of rear emitter silicon solar cell using an optimized n-type silicon oxide front surface field layer. Sci. Rep. 2018, 8, 10657. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Y.; Tong, H.; Quan, C.; Cai, L.; Yang, Z.; Chen, K.; Yuan, Z.; Wu, C.-H.; Yan, B.; Gao, P. Theoretical exploration towards high-efficiency tunnel oxide passivated carrier-selective contacts (TOPCon) solar cells. Sol. Energy 2017, 155, 654–660. [Google Scholar] [CrossRef]

- Anand, N.; Kale, P. Optimization of TOPCon Structured Solar Cell Using AFORS-HET. Trans. Electr. Electron. Mater. 2021, 22, 160–166. [Google Scholar] [CrossRef]

- Lancaster, K.; Großer, S.; Feldmann, F.; Naumann, V.; Hagendorf, C. Study of pinhole conductivity at passivated carrier-selected contacts of silicon solar cells. Energy Procedia 2016, 92, 116–121. [Google Scholar] [CrossRef]

- Stuckelberger, J.; Nogay, G.; Wyss, P.; Jeangros, Q.; Allebé, C.; Debrot, F.; Niquille, X.; Ledinsky, M.; Fejfar, A.; Despeisse, M. Passivating electron contact based on highly crystalline nanostructured silicon oxide layers for silicon solar cells. Sol. Energy Mater. Sol. Cells 2016, 158, 2–10. [Google Scholar] [CrossRef] [Green Version]

- Quan, C.; Zeng, Y.; Wang, D.; Liao, M.; Tong, H.; Yang, Z.; Yuan, Z.; Gao, P.; Yan, B.; Chen, K. Computational analysis of a high-efficiency tunnel oxide passivated contact (TOPCon) solar cell with a low-work-function electron-selective-collection layer. Sol. Energy 2018, 170, 780–787. [Google Scholar] [CrossRef]

- Park, C.; Balaji, N.; Ahn, S.; Park, J.; Cho, E.-c.; Yi, J. Effects of tunneling oxide defect density and inter-diffused carrier concentration on carrier selective contact solar cell performance: Illumination and temperature effects. Sol. Energy 2020, 211, 62–73. [Google Scholar] [CrossRef]

- Stegemann, B.; Balamou, P.; Lussky, T.; Gad, K.M.; Vössing, D.; Kasemann, M.; Angermann, H. Passivation of Crystalline Silicon Wafers by Ultrathin Oxide Layers: Comparison of Wet-chemical, Plasma and Thermal Oxidation Techniques. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC)(A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa, HI, USA, 10–15 June 2018; pp. 2779–2782. [Google Scholar]

- Zhang, Z.; Zeng, Y.; Jiang, C.-S.; Huang, Y.; Liao, M.; Tong, H.; Al-Jassim, M.; Gao, P.; Shou, C.; Zhou, X. Carrier transport through the ultrathin silicon-oxide layer in tunnel oxide passivated contact (TOPCon) c-Si solar cells. Sol. Energy Mater. Sol. Cells 2018, 187, 113–122. [Google Scholar] [CrossRef]

- Kale, A.S.; Nemeth, W.; Harvey, S.P.; Page, M.; Young, D.L.; Agarwal, S.; Stradins, P. Effect of silicon oxide thickness on polysilicon based passivated contacts for high-efficiency crystalline silicon solar cells. Sol. Energy Mater. Sol. Cells 2018, 185, 270–276. [Google Scholar] [CrossRef]

- Grübel, B.; Cimiotti, G.; Arya, V.; Feldmann, F.; Steinhauser, B.; Kluska, S.; Glatthaar, M. Plated Ni/Cu/Ag for TOPCon solar cell metallization. In Proceedings of the 36th European Photovoltaic Solar Energy Conference, Marseille, France, 9–13 September 2019; pp. 1–5. [Google Scholar]

| Layers | Default Parameter |

|---|---|

| SiNx dielectric | t = 70 nm |

| Front contact boundary | Standard texture surface (54.74°), w/o absorption loss, flat band |

| Front contact | MS Schottky contact model, SRV = 10 cm/s (assuming good passivation) |

| P+-type Si layer | t = 0.3 µm, Na = 2 × 102° cm−3, lifetime setting: 1 μs |

| n-type c-Si layer | t = 150 µm, Nd = 5.0 × 1016 cm−3, lifetime setting: 1 × 105 μs (without bulk defect) |

| Interface: SiOx | Chi = 1.0 eV, Eg = 8.9 eV, dk = 3.9, me = 0.98, mh = 0.49, Dph = 0 |

| nc-SiOx Si layer | t = 30 µm, Nd = 1 × 1017 cm−3, lifetime setting: 50 μs |

| Rear contact | MS Schottky contact model, SRV = 10 cm/s |

| Rear contact boundary | A plane surface, w/o absorption loss, flat band |

| Ag electrode | t = 1 µm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khokhar, M.Q.; Hussain, S.Q.; Zahid, M.A.; Pham, D.P.; Cho, E.-C.; Yi, J. Numerical Simulation and Experiment of a High-Efficiency Tunnel Oxide Passivated Contact (TOPCon) Solar Cell Using a Crystalline Nanostructured Silicon-Based Layer. Appl. Sci. 2022, 12, 392. https://doi.org/10.3390/app12010392

Khokhar MQ, Hussain SQ, Zahid MA, Pham DP, Cho E-C, Yi J. Numerical Simulation and Experiment of a High-Efficiency Tunnel Oxide Passivated Contact (TOPCon) Solar Cell Using a Crystalline Nanostructured Silicon-Based Layer. Applied Sciences. 2022; 12(1):392. https://doi.org/10.3390/app12010392

Chicago/Turabian StyleKhokhar, Muhammad Quddamah, Shahzada Qamar Hussain, Muhammad Aleem Zahid, Duy Phong Pham, Eun-Chel Cho, and Junsin Yi. 2022. "Numerical Simulation and Experiment of a High-Efficiency Tunnel Oxide Passivated Contact (TOPCon) Solar Cell Using a Crystalline Nanostructured Silicon-Based Layer" Applied Sciences 12, no. 1: 392. https://doi.org/10.3390/app12010392

APA StyleKhokhar, M. Q., Hussain, S. Q., Zahid, M. A., Pham, D. P., Cho, E.-C., & Yi, J. (2022). Numerical Simulation and Experiment of a High-Efficiency Tunnel Oxide Passivated Contact (TOPCon) Solar Cell Using a Crystalline Nanostructured Silicon-Based Layer. Applied Sciences, 12(1), 392. https://doi.org/10.3390/app12010392