Case Study: 3D Modelling and Printing of a Plastic Respirator in Laboratory Conditions

Abstract

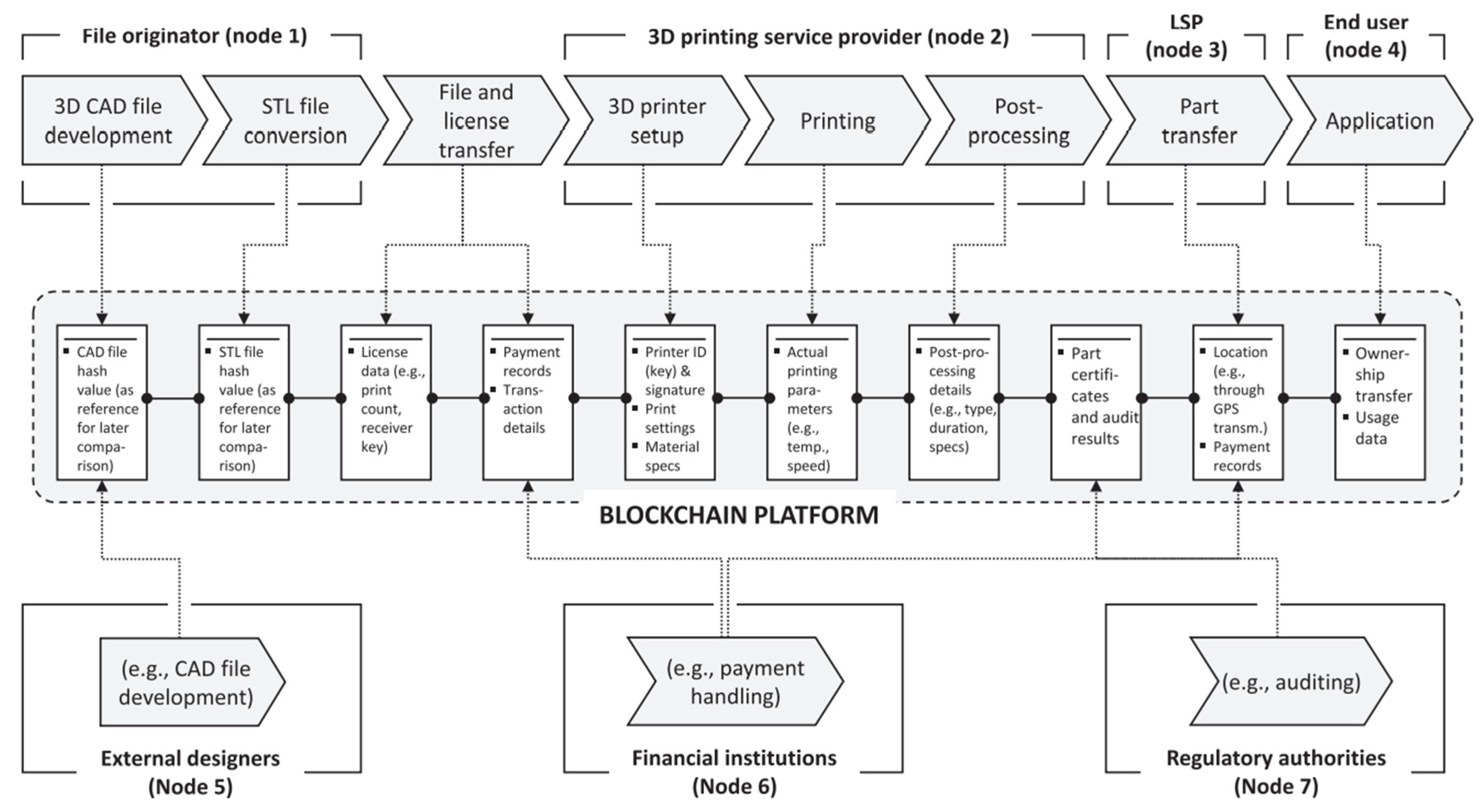

:1. Introduction

- Transparency: Blockchain can require confirmation from all parties;

- Traceability: Blockchain can provide the status of modular housing products with a timestamp;

- Immutability: Blockchain can offer a tamper-proof solution;

- Decentralization: Blockchain can prevent them entirely controlled by one party;

- Privacy-preserve: Blockchain can encrypt them by using hashing algorithms;

- Smartness: smart contracts facilitate the automatic execution process in transparency, traceability, immutability, decentralization, and privacy.

- Delivery times are shortened by creating a production scheme with a global network of 3D printers;

- Back-analysis of parts and reduction of pressure on OEM costs;

- Cost reduction for value-added activities;

- More flexible inventory management through digital assets;

- Elimination of transport costs by using digital transfer via the cloud to the place of use;

- Elimination of storage costs, as parts will be stored in a digital warehouse;

- Elimination of duties and charges as objects move digitally across borders;

- Effective form of payment via Bitcoin;

- Setting standards for digital fibres and digital twins;

- Each object will have a certificate of authenticity, which will prevent fake parts from entering supply chains.

“When an F-15 Eagle fighter needed a metal part, its commanders turned to VeriTX’s virtual marketplace, where they were able to find a nearby supplier who could make it on a 3D printer and deliver it in six hours. Using the old printed catalogue system, it would have taken 265 days, on average, to get the jet flying again.”

2. Description of the Selected Object for the 3D Printing Process

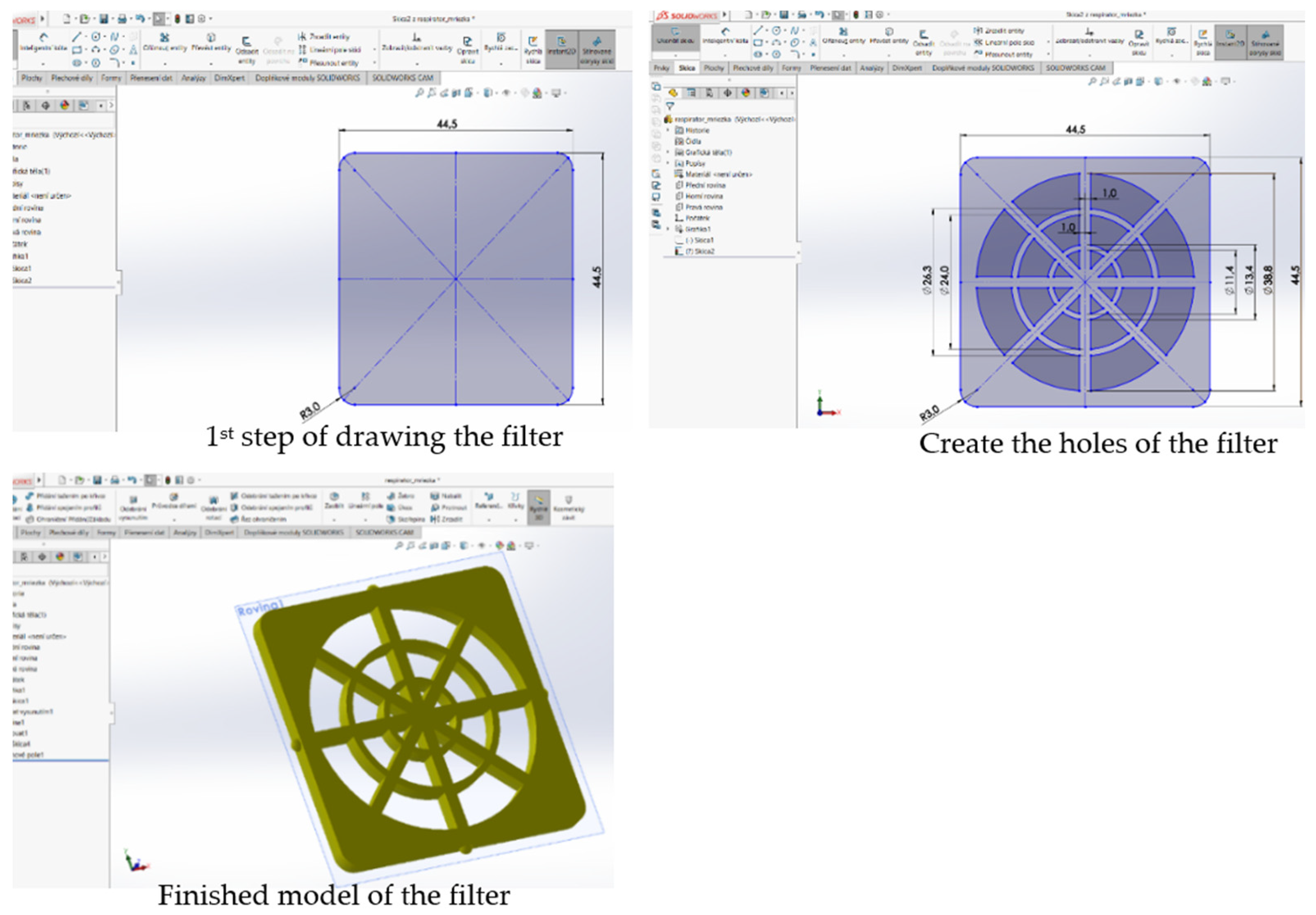

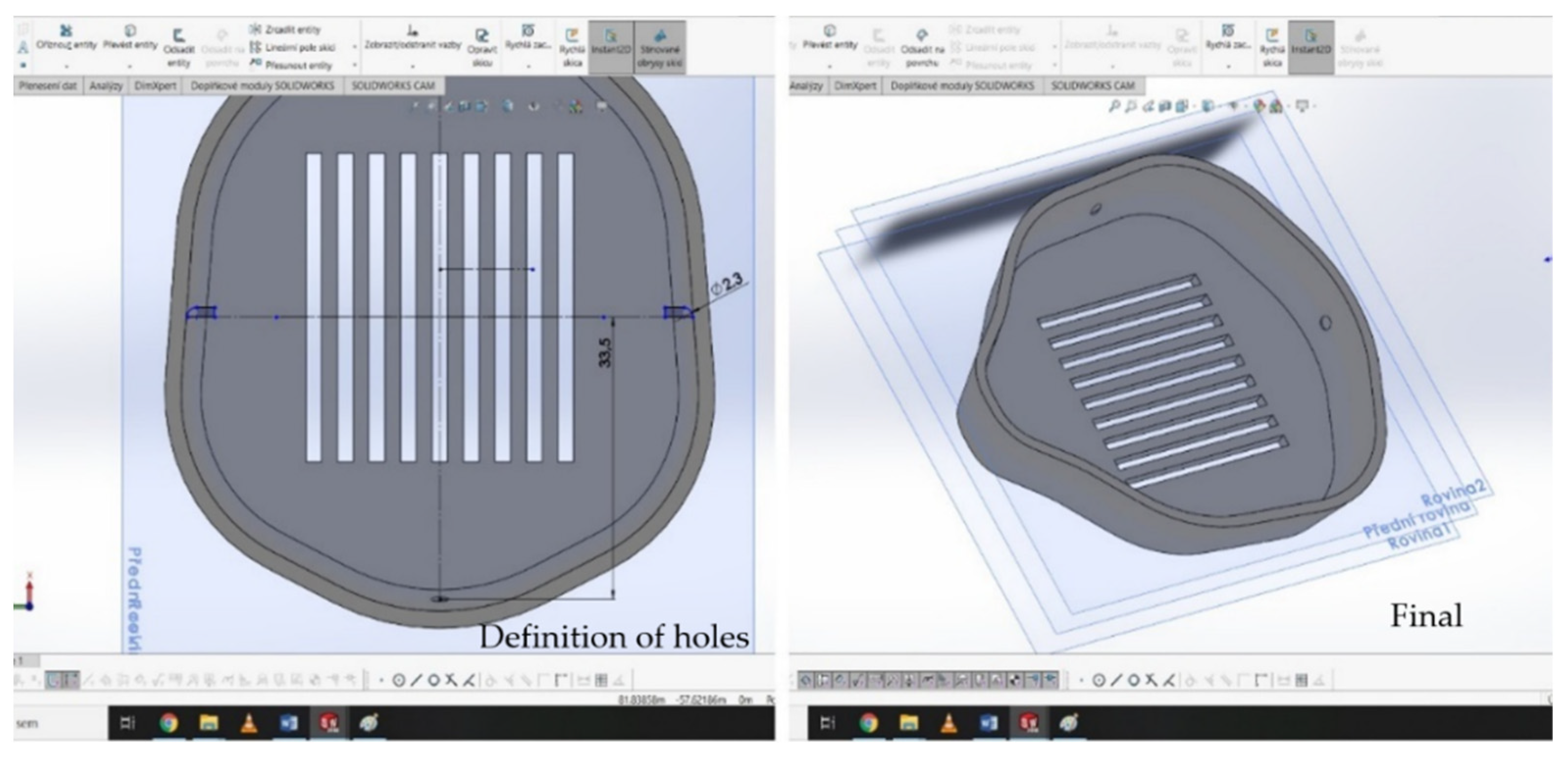

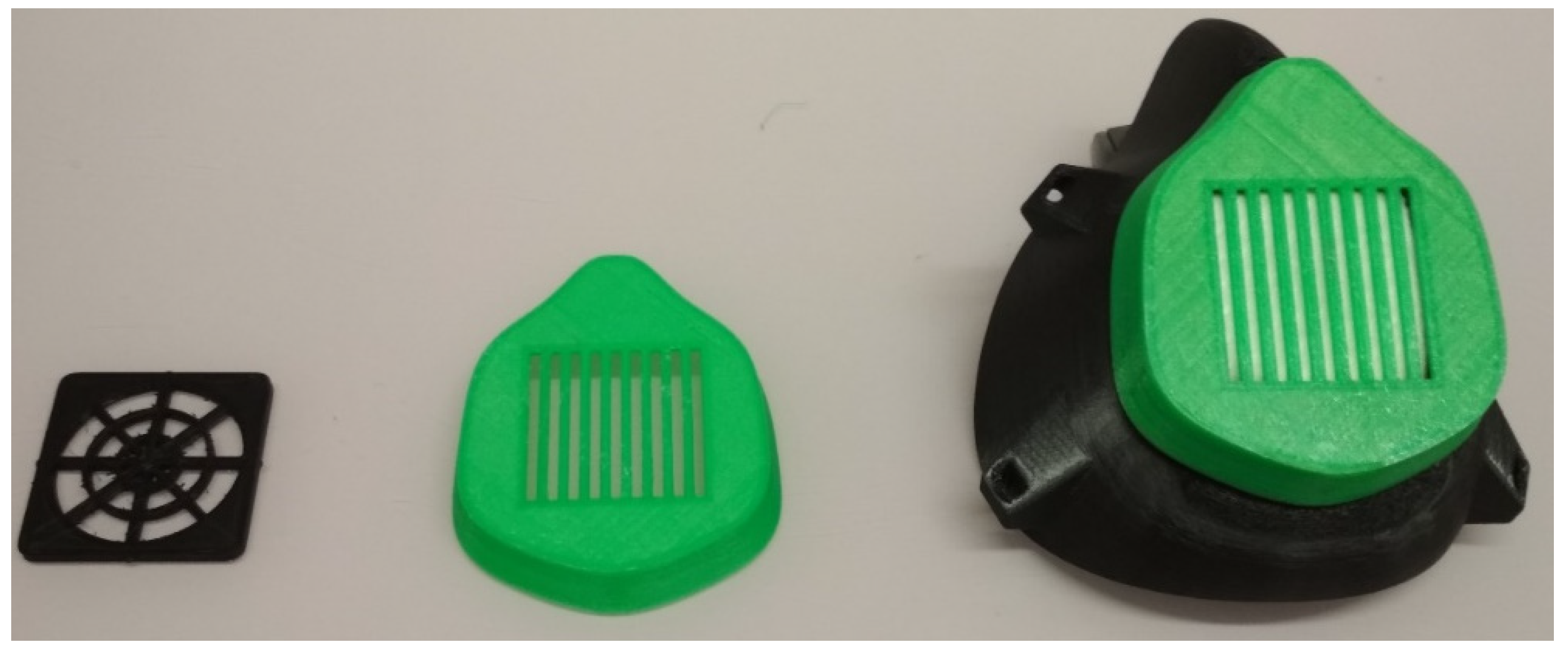

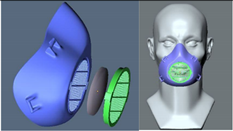

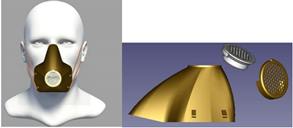

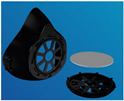

2.1. Modelling of a Respirator Plastic Filter

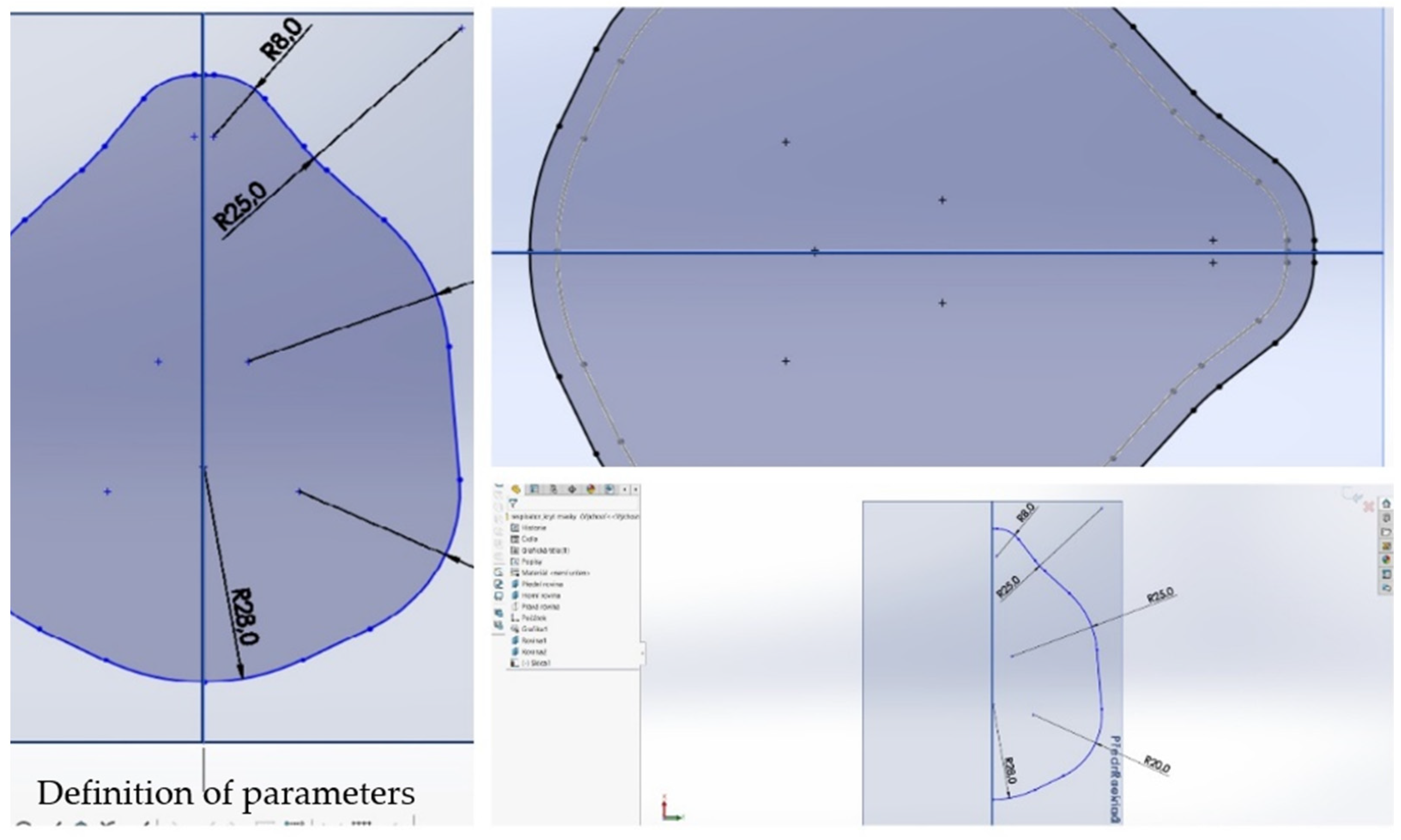

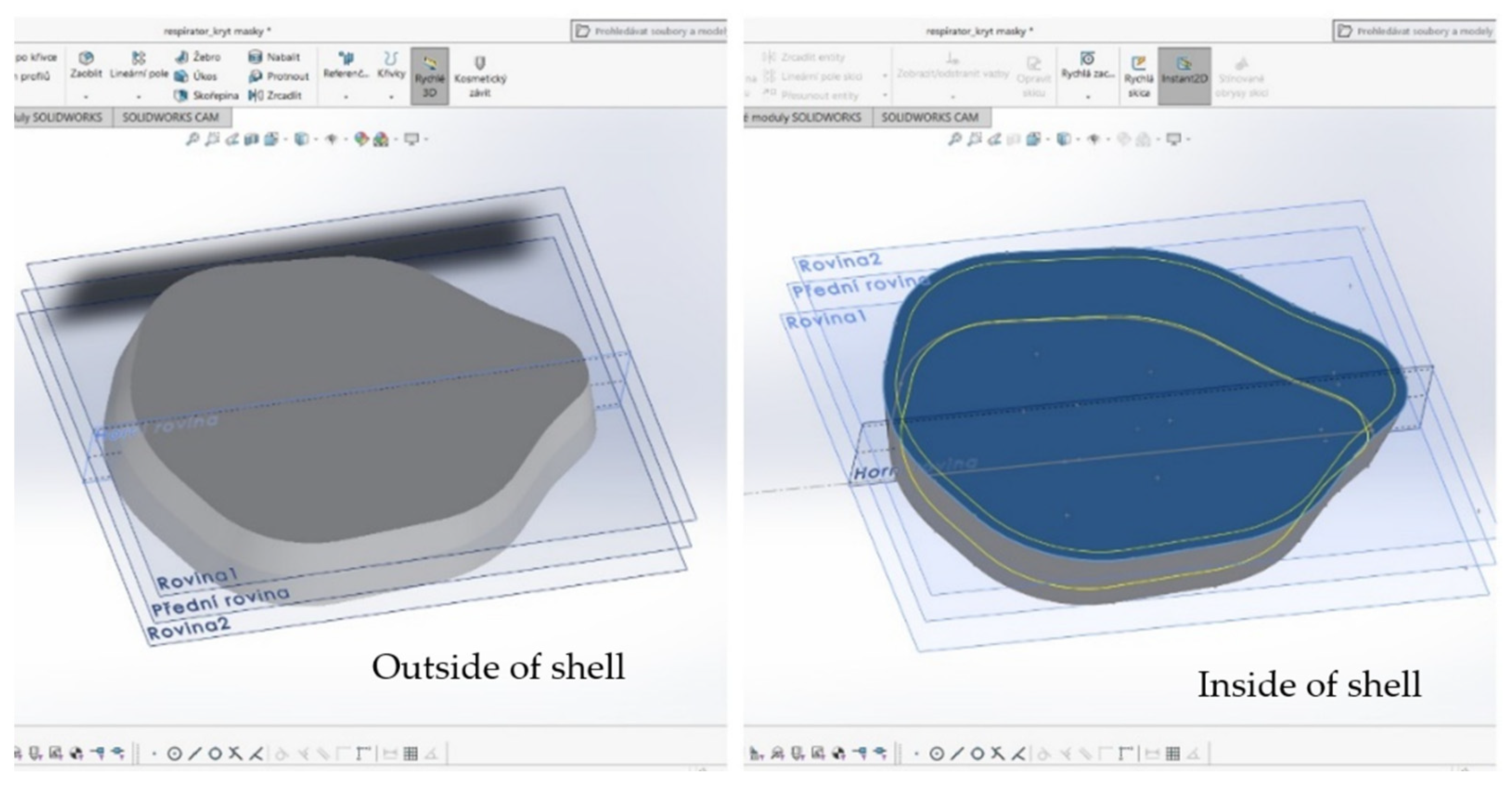

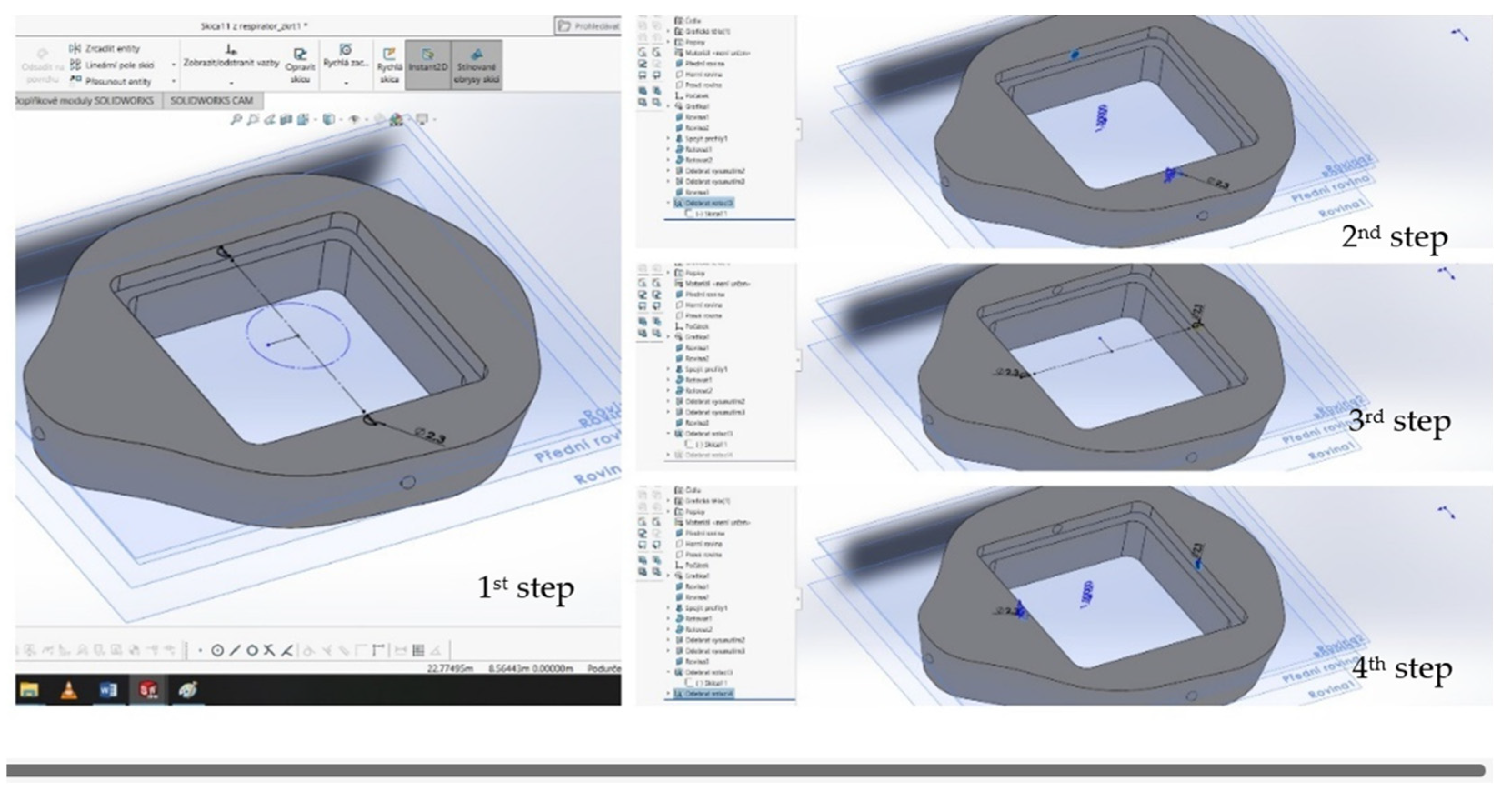

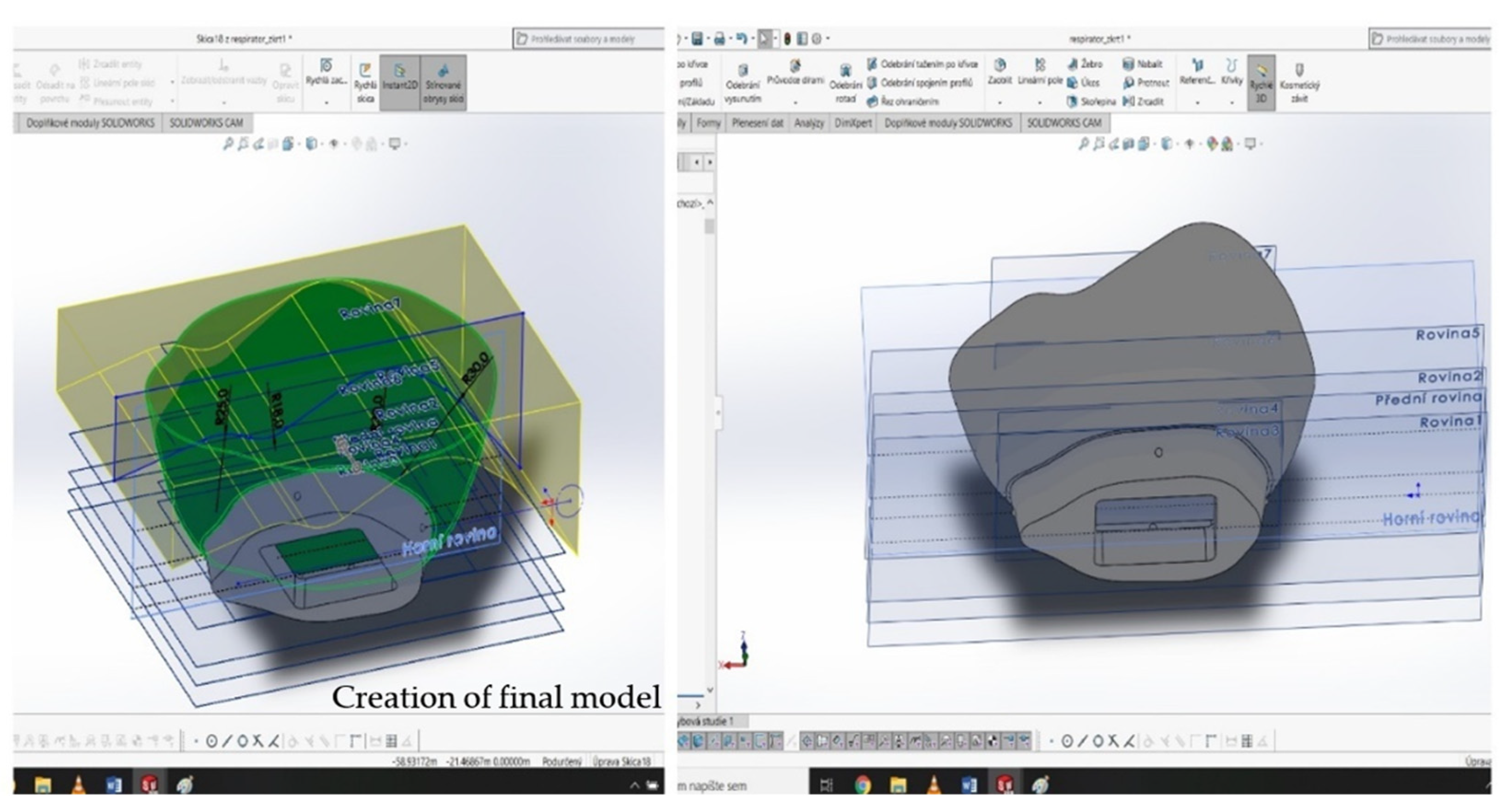

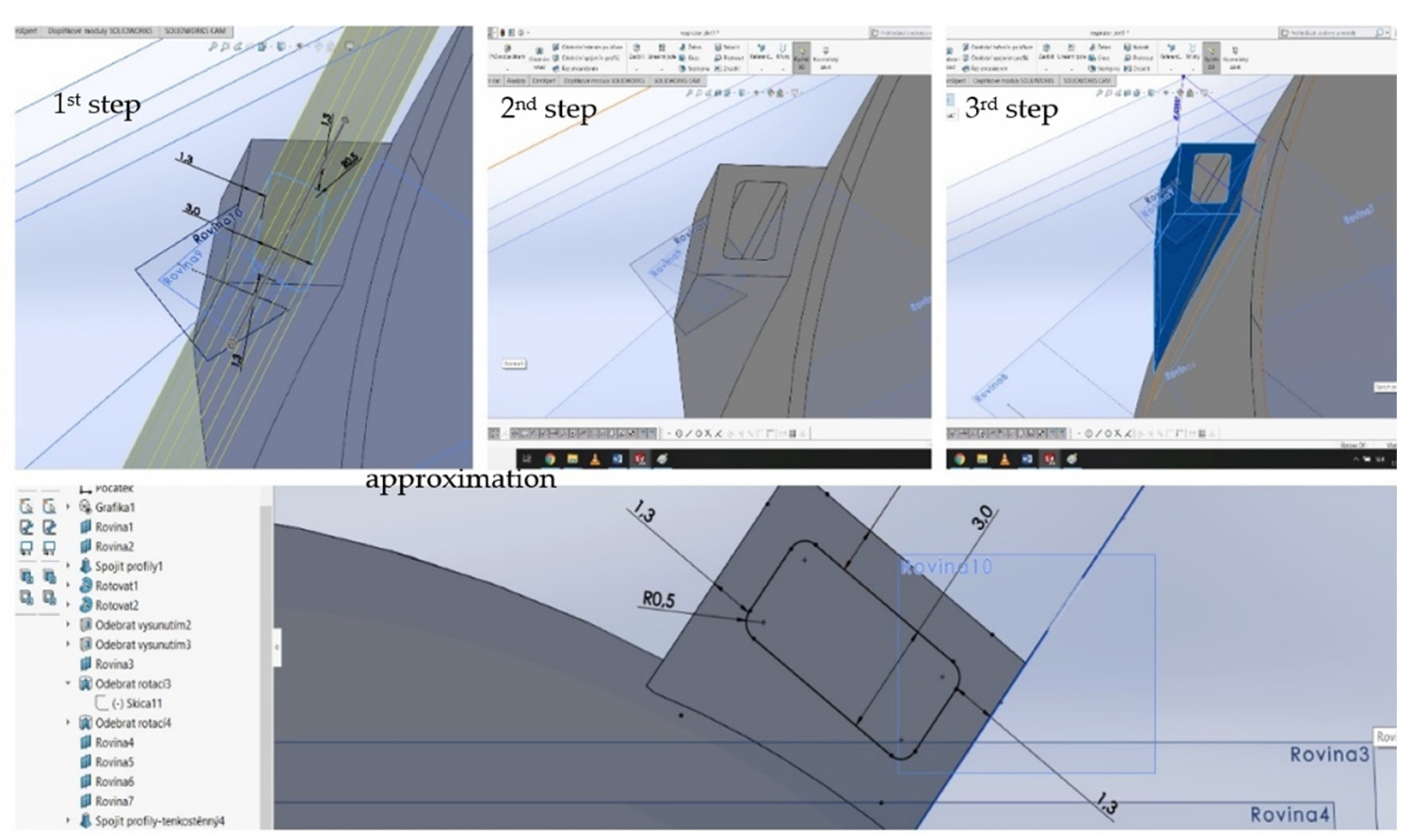

2.2. Modelling the Respirator Cap

3. Description of the 3D Printing Procedure of the Selected Object

- Interchangeable tool heads;

- Can print thick paste as well (ceramics, dough, chocolate);

- CNC machining, engraving, two-color 3D printing;

- Print two materials simultaneously;

- Very high print quality;

- Handles high-level professional models;

- LCD display.

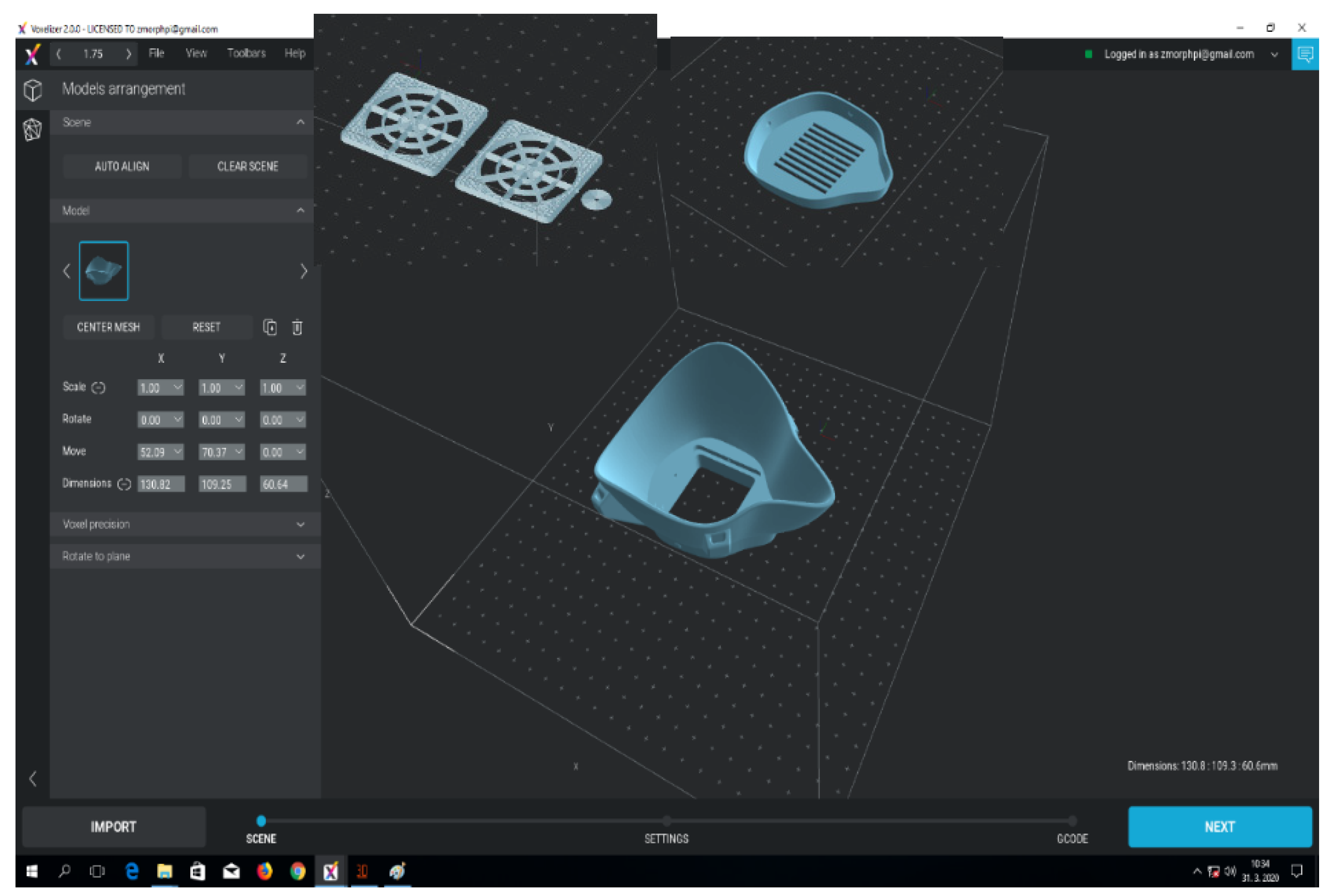

Print a Respirator on a ZMorph Printer

- Washable and disinfectable respirator with replaceable filter;

- Different materials can be used as a filter—the recommendation for achieving high quality is colloidal silver;

- The inner space of the filter can be modified;

- The respirator has an ergonomic shape for most face types—resize by adjusting the STL model;

- The cord is not part of the 3D printing—it must be rubber, resp. another improvised means.

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bousonville, T. Logistik 4.0: Die Digitale Transformation der Wertschöpfungskette; Springer Gabler: Wiesbaden, Germany, 2017. [Google Scholar]

- Barrenechea, M.J.; Jenkins, T. Digital Manufacturing; Open Text Corporation: Waterloo, ON, Canada, 2018. [Google Scholar]

- Fusko, M.; Bučková, M.; Gašo, M.; Krajčovič, M.; Dulina, L. Concept of Long-Term Sustainable Intralogistics in Plastic Recycling Factory. Sustainability 2019, 11, 6750. [Google Scholar] [CrossRef] [Green Version]

- Balogova, F.A.; Trebunova, M.; Rajtukova, V.; Hudak, R. Fresh method: 3D bioprinting as a new approach for tissue and organ regenration. Acta Tecnol. 2021, 7, 79–82. [Google Scholar] [CrossRef]

- DHL. Available online: https://www.dhl.com/global-en/home/insights-and-innovation/thought-leadership/trend-reports/3d-printing-and-the-future-of-supply-chains.html (accessed on 6 April 2021).

- DHL. Available online: https://www.dhl.com/content/dam/downloads/g0/about_us/logistics_insights/dhl_trendreport_3dprinting.pdf (accessed on 6 April 2021).

- Grznar, P.; Gregor, M.; Krajcovic, M.; Mozol, S.; Schickerle, M.; Vavrík, V.; Ďurica, L.; Marschall, M.; Bielik, T. Modeling and Simulation of Processes in a Factory of the Future. Appl. Sci. 2020, 10, 4503. [Google Scholar] [CrossRef]

- Vegsoova, O.; Straka, M.; Rosova, A. Protecting and Securing an Environment Affected by Industrial Activity for Future Utilization. Rocz. Ochr. Srdowiska 2019, 21, 98–111. [Google Scholar]

- Straka, M.; Rosova, A.; Malindzakova, M.; Khouri, S.; Culkova, K. Evaluating the Waste Incineration Process for Sustainable Development through Modelling, Logistics, and Simulation. Pol. J. Environ. Stud. 2018, 27, 2739–2748. [Google Scholar] [CrossRef]

- Marasova, D.; Saderova, J.; Ambrisko, L. Simulation of the Use of the Material Handling Equipment in the Operation Process. Open Eng. 2020, 10, 216–223. [Google Scholar] [CrossRef]

- Chang, K. Product Design Modeling Using CAD/CAE; Elsevier Inc.: San Diego, CA, USA, 2014. [Google Scholar]

- Creative Industry. Available online: https://www.cike.sk/blockchain-a-3d-tlac-ako-technologie-pre-udrzatelnu-buducnost/?fbclid=IwAR1RdGkqbFObKW2uepQG280BoPLmUU_6NyRqLzq91WJCAJmFB2YboeoA9HU (accessed on 6 April 2021).

- Modern Consensus. Available online: https://modernconsensus.com/technology/aerospace-marketplace-veritx-turns-to-algorand-to-turbocharge-its-supply-chain/ (accessed on 6 April 2021).

- Klöckner, M.; Kurpjuweit, S.; Velu, C.H.; Wagner, S.W. Does Blockchain for 3D Printing Offer Opportunities for Business Model Innovation? Res. Technol. Manag. 2020, 63, 18–27. [Google Scholar] [CrossRef]

- VeriTX. Available online: https://www.veritx.co/aerospace/#valueprop (accessed on 6 April 2021).

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies, 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing; Springer: New York, NY, USA, 2010. [Google Scholar]

- ZMORPH3D. Available online: https://zmorph3d.com/ (accessed on 6 April 2021).

- 3D-Print-Models/Respirator. Available online: https://www.cgtrader.com/3d-print-models/respirator (accessed on 12 December 2021).

- New Feature. 3D Printing Gets Bigger, Faster and Stronger. Available online: https://www.nature.com/articles/d41586-020-00271-6 (accessed on 6 April 2021).

- Gombar, M.; Kmec, J.; Badida, M.; Sobotova, L.; Vagaska, A.; Michal, P. The simulation of the temperature effects on the microhardness of anodic alumina oxide layers. Metal. Metall. 2014, 53, 59–62. [Google Scholar]

- Mitchell, A.; Holyńska, U.L.M.; Semprimoschnig, C. Additive manufacturing—A review of 4D printing and future applications. Addit. Manuf. 2018, 24, 606–626. [Google Scholar] [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. 2—Review of additive manufacturing technologies and applications in the aerospace industry. In Additive Manufacturing for the Aerospace Industry; Elsevier Inc.: Amsterdam, The Netherlands, 2019; ISBN 978-0-12-814062-8. [Google Scholar]

- SCULPTEO. Available online: https://www.sculpteo.com/en/3d-learning-hub/best-3d-printing-articles/4d-printing-technology/ (accessed on 8 March 2021).

- Cmorej, T.; Panda, A.; Baron, P.; Poor, P.; Pollak, M. Surface finishing of 3D printed samle manufactured by deposition modelling. MM Sci. J. 2017, 5. [Google Scholar] [CrossRef]

- OpenSCAD. The Programmers Solid 3D CAD Modeller. Available online: https://openscad.org/ (accessed on 6 April 2021).

- Bagheri, A.; Jin, J. Photopolymerization in 3D Printing. ACS Appl. Polym. Mater. 2019, 1, 593–611. [Google Scholar] [CrossRef] [Green Version]

- Four New High-Performance Milling Techniques for 3D Machining. Available online: https://www.mmsonline.com/articles/four-new-high-performance-milling-techniques-for-3d-machining (accessed on 8 March 2021).

- Algorand Blockchain Network. Available online: https://www.purestake.com/networks/algorand/ (accessed on 6 April 2021).

- Solidworks. Available online: https://www.solidworks.com/ (accessed on 7 February 2021).

- Husar, J.; Knapcikova, L. Online and offline control of collaborative robot sused mixed reality. Acta Technol. 2021, 7, 61–66. [Google Scholar]

| Business Model Opportunities | Value Proposition | Value Creation | Value Capture | Value Network |

|---|---|---|---|---|

| Local manufacturing |

|

|

|

|

| Shared factories |

|

|

|

|

| Secure design marketplaces |

|

|

|

|

| ZMorph VX | |

|---|---|

| dimensions | 530 × 555 × 480 mm |

| weight | 14 kg |

| software | Voxelizer 2.0.0 |

| print area size | 235 × 250 × 165 mm |

| possibility of connection | USB, SD, Ethernet |

| printing on material | ABS, PLA, PET, ASA, HIPS, TPU |

| print about layer strength | 1.75–3 mm |

| price | 5374.82€ |

| Respirator | Selected Parameters | |

|---|---|---|

| Filter | Ergonomic Shape | |

| replaceable colloidal silver | most face types |

| replaceable filters of different materials | most face types |

| replaceable cotton or gauze | most face types |

| replaceable filters of different materials | two models: suitable for a round face and oval face |

| replaceable homemade filters of different materials | most face types |

| Cotton | most face types |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pekarcikova, M.; Trebuna, P.; Kliment, M.; Kral, S. Case Study: 3D Modelling and Printing of a Plastic Respirator in Laboratory Conditions. Appl. Sci. 2022, 12, 96. https://doi.org/10.3390/app12010096

Pekarcikova M, Trebuna P, Kliment M, Kral S. Case Study: 3D Modelling and Printing of a Plastic Respirator in Laboratory Conditions. Applied Sciences. 2022; 12(1):96. https://doi.org/10.3390/app12010096

Chicago/Turabian StylePekarcikova, Miriam, Peter Trebuna, Marek Kliment, and Stefan Kral. 2022. "Case Study: 3D Modelling and Printing of a Plastic Respirator in Laboratory Conditions" Applied Sciences 12, no. 1: 96. https://doi.org/10.3390/app12010096

APA StylePekarcikova, M., Trebuna, P., Kliment, M., & Kral, S. (2022). Case Study: 3D Modelling and Printing of a Plastic Respirator in Laboratory Conditions. Applied Sciences, 12(1), 96. https://doi.org/10.3390/app12010096