State of the Art and Future Directions of Digital Twins for Production Logistics: A Systematic Literature Review

Abstract

:1. Introduction

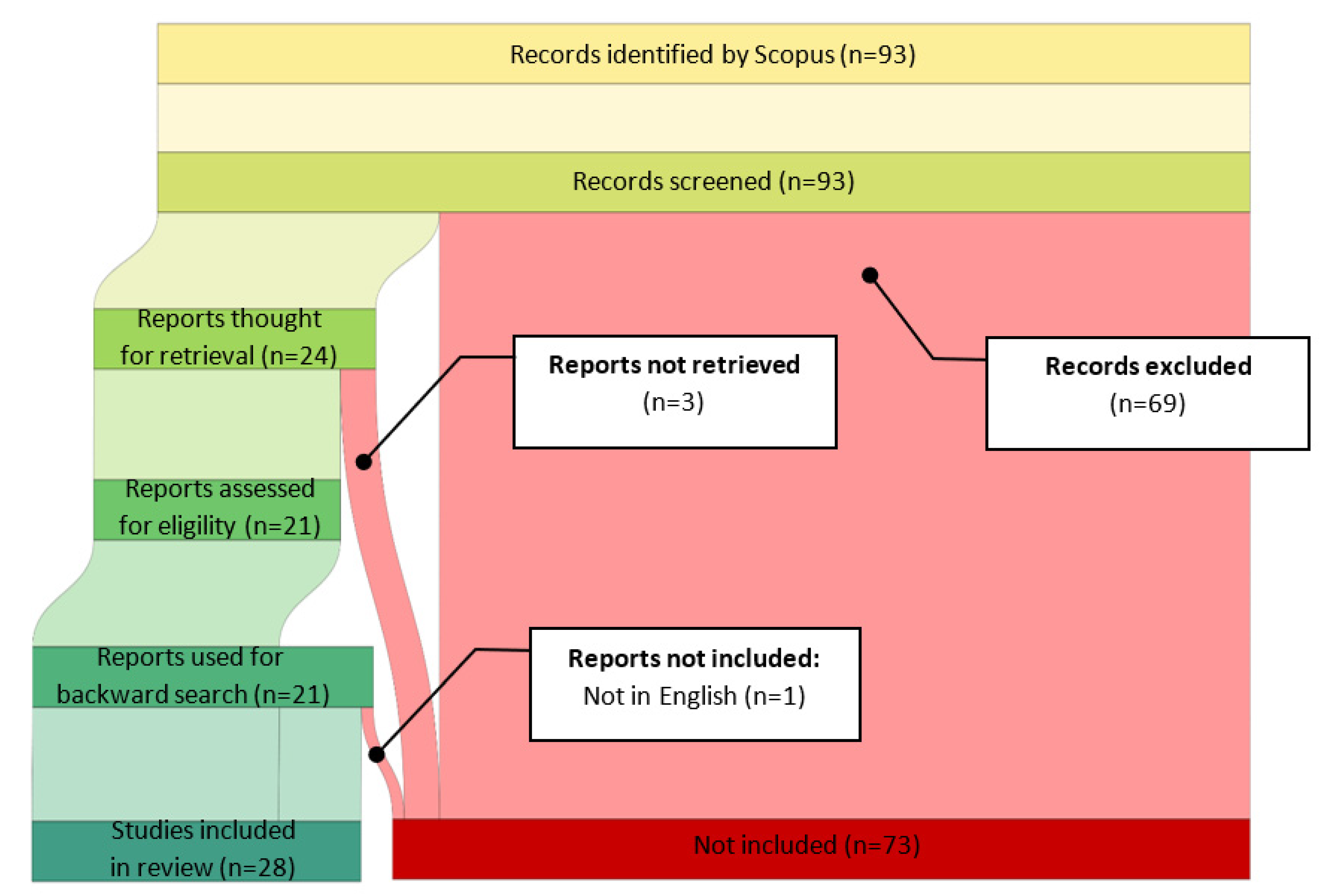

2. Materials and Methods

3. Results

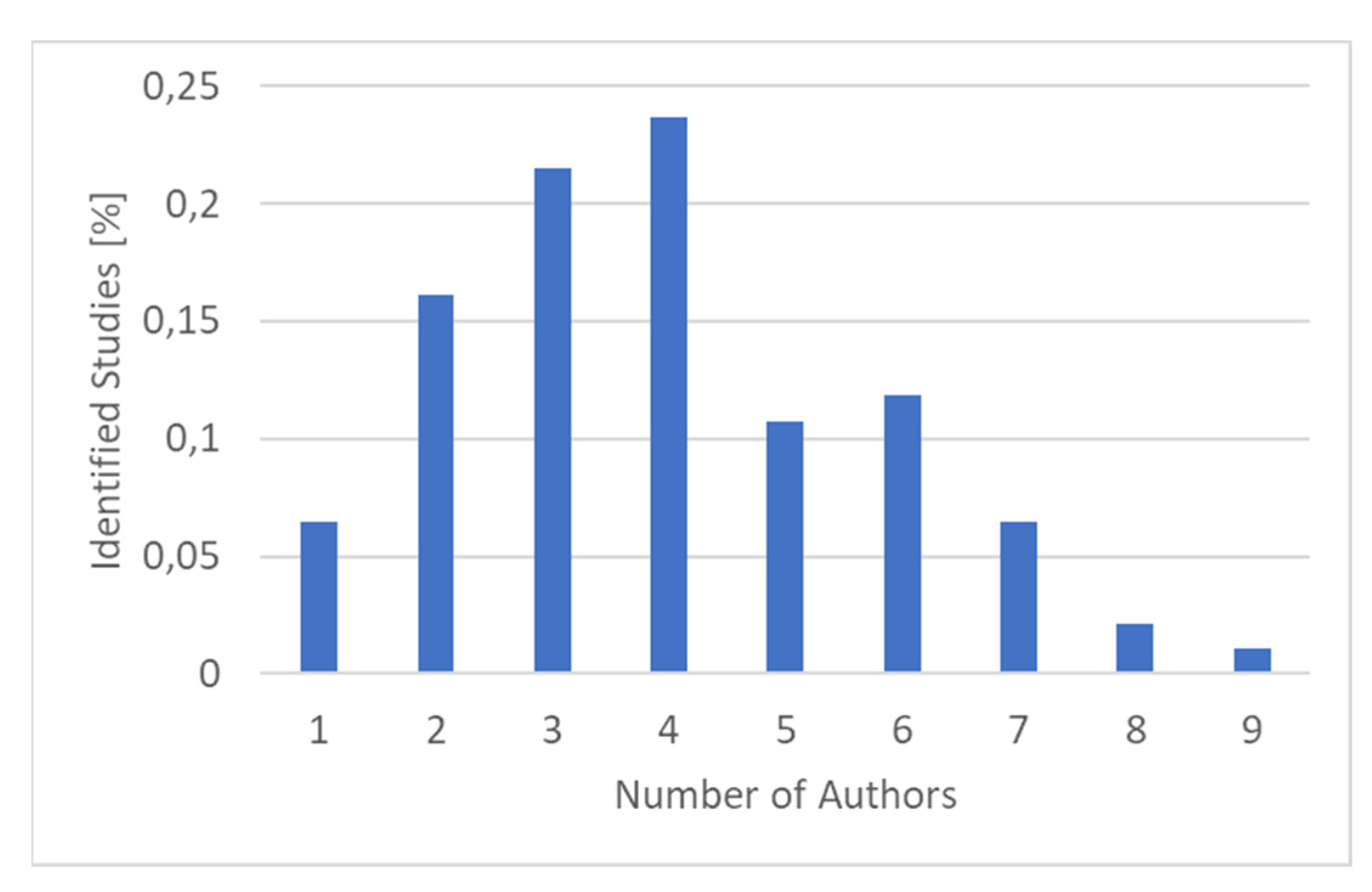

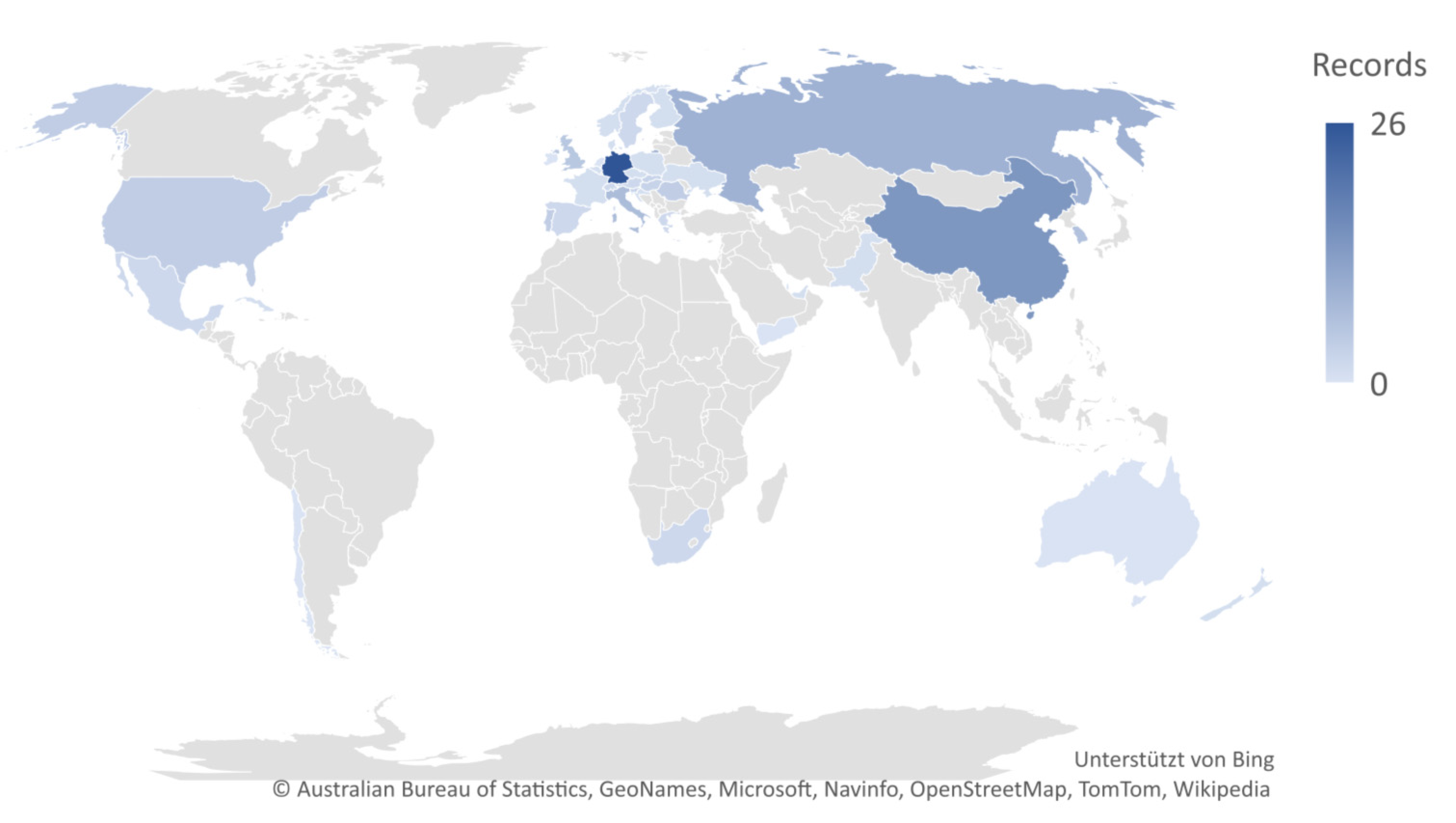

3.1. Descriptive Analyses

Backward Reference Search

3.2. Content Analyses

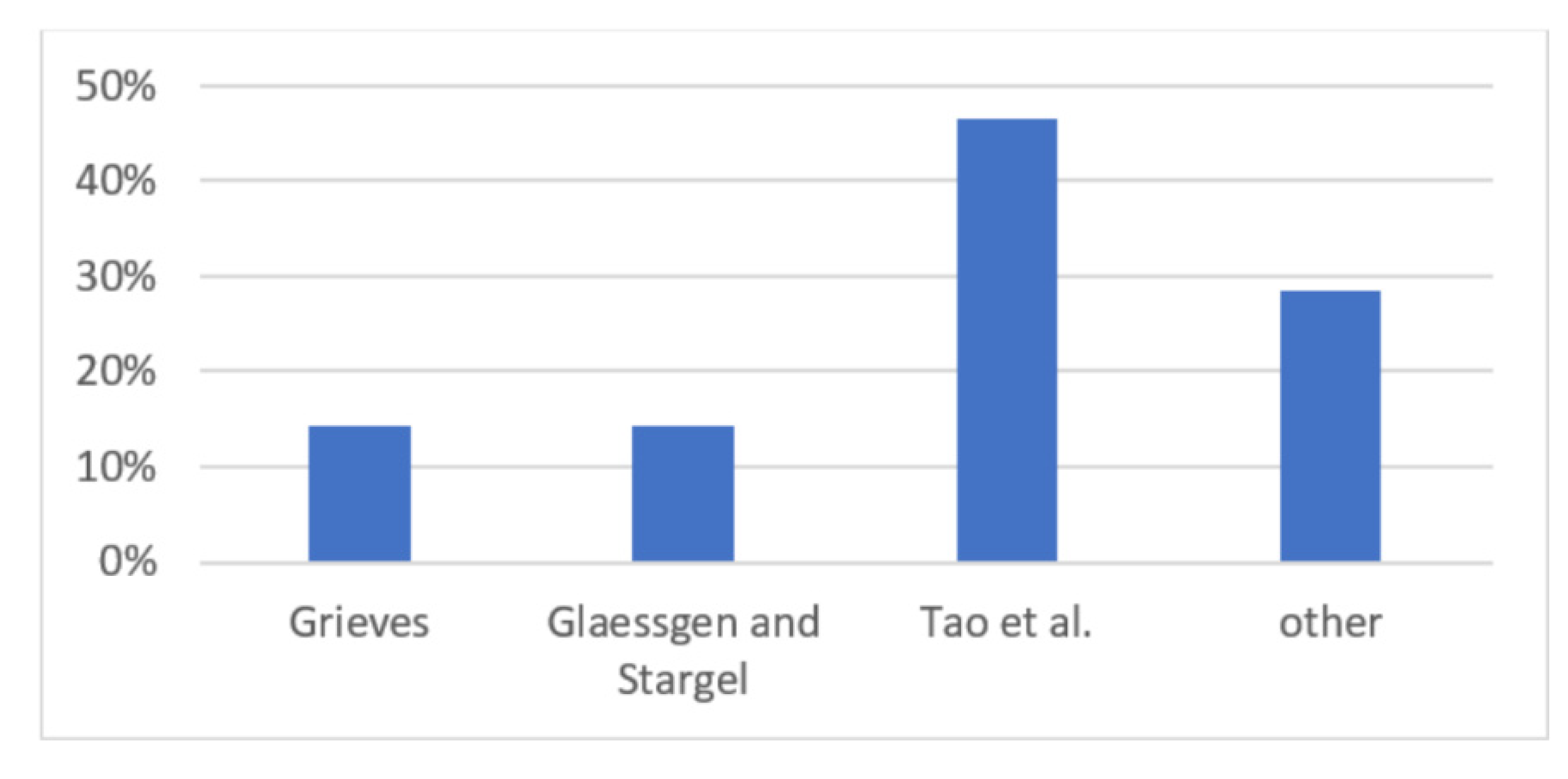

3.3. Definitions of Digital Twins

3.3.1. Three Dimensions by Grieves

3.3.2. Definition by Glaessgen and Stargel

3.3.3. Five Dimensions by Tao et al.

3.3.4. Similarities and Differences of DT Definitions

3.4. Systematic Evaluation of the Identified Literature

3.4.1. Enabling Concepts

3.4.2. Areas of Operation and State of Development

3.4.3. Virtual Model Creation

3.4.4. Enterprise Information Systems

3.4.5. Decentralized Applications

3.4.6. Machinery Prognostics and Maintenance Management

3.5. Case Study Analyses

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thoben, K.-D.; Wiesner, S.; Wuest, T. “Industrie 4.0” and Smart Manufacturing—A Review of Research Issues and Application Examples. Int. J. Automot. Technol. 2017, 11, 4–16. [Google Scholar] [CrossRef] [Green Version]

- Bosch, G.; Bromberg, T.; Haipeter, T.; Schmitz, J. Industrie und Arbeit 4.0: Befunde zu Digitalisierung und Mitbestimmung im Industriesektor auf Grundlage des Projekts „Arbeit 2020“. IAQ Rep. 2017, 2017, 1–24. [Google Scholar] [CrossRef]

- Woschank, M.; Kaiblinger, A.; Miklautsch, P. Digitalization in Industrial Logistics: Contemporary Evidence and Future Directions. In Proceedings of the International Conference on Industrial Engineering and Operations Management, IEOM Society, Singapore, 7–11 March 2021; pp. 1322–1333. [Google Scholar]

- Ivanov, D.; Sethi, S.; Dolgui, A.; Sokolov, B. A survey on control theory applications to operational systems, supply chain management, and Industry 4.0. Annu. Rev. Control 2018, 46, 134–147. [Google Scholar] [CrossRef]

- Scholz-Reiter, B.; Görges, M.; Philipp, T. Autonomously controlled production systems—Influence of autonomous control level on logistic performance. CIRP Ann. 2009, 58, 395–398. [Google Scholar] [CrossRef]

- Resman, M.; Protner, J.; Simic, M.; Herakovic, N. A Five-Step Approach to Planning Data-Driven Digital Twins for Discrete Manufacturing Systems. Appl. Sci. 2021, 11, 3639. [Google Scholar] [CrossRef]

- Haße, H.; Li, B.; Weissenberg, N.; Cirullies, J.; Otto, B. Digital twin for real-time data processing in logistics. In Proceedings of the Hamburg International Conference of Logistics (HICL), Hamburg, Germany, 26–27 September 2019; Epubli GmbH: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Grieves, M. Digital Twin: Manufacturing Excellence through Virtual Factory Replication. White Pap. 2014, 1, 1–7. [Google Scholar]

- Piascik, R.; Vickers, J.; Lowry, D.; Scotti, S.; Stewart, J.; Calomino, A. DRAFT Materials, Structures, Mechanical Systems, and Manufacturing Roadmap: Technology Area 12; National Aeronautics and Space Administration: Washington, DC, USA, 2010; pp. TA12-1–TA12-30. Available online: https://www.nasa.gov/pdf/501625main_TA12-MSMSM-DRAFT-Nov2010-A.pdf (accessed on 21 June 2021).

- Glaessgen, E.; Stargel, D. The Digital Twin Paradigm for Future NASA and U.S. Air Force Vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference—Special Session on the Digital Twin, Honolulu, Hawaii, 23–26 April 2012; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2012; p. 1818. [Google Scholar]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-Pap. 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Stark, R.; Damerau, T. Digital Twin. In CIRP Encyclopedia of Production Engineering; Chatti, S., Laperrière, L., Reinhart, G., Tolio, T., Eds.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1–8. ISBN 978-3-642-35950-7. [Google Scholar]

- ISO. Automation Systems and Integration—Digital Twin Framework for Manufacturing: Overview and General Principles; Draft; Vernier: Geneva, Switzerland, 2020; ISO/DIS 23247-1:2020(E). [Google Scholar]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A. Enabling technologies and tools for digital twin. J. Manuf. Syst. 2019, 58, 3–21. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M. Digital Twin Shop-Floor: A New Shop-Floor Paradigm Towards Smart Manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Parrot, A.; Warshaw, L. Industry 4.0 and the digital twin: Manufacturing meets its match. In A Deloitte Series on Industry 4.0, Digital Manufacturing Enterprises, and Digital Supply Networks; Deloitte University Press: New York, NY, USA, 2017; pp. 1–17. [Google Scholar]

- Kuehn, W. Digital twins for decision making in complex production and logistic enterprises. Int. J. Des. Nat. Ecodynamics 2018, 13, 260–271. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Sommer, M.; Stjepandic, J.; Stobrawa, S.; von Soden, M. Improvement of Factory Planning by Automated Generation of a Digital Twin. In Proceedings of the 27th ISTE International Conference on Transdisciplinary Engineering for Complex Socio-technical Systems, Warsaw, Poland, 2–10 July 2020; IOS Press: Amsterdam, The Netherlands, 2020. ISBN 978-1-64368-110-8. [Google Scholar]

- Zheng, Y.; Yang, S.; Cheng, H. An application framework of digital twin and its case study. J. Ambient Intell. Humaniz. Comput. 2019, 10, 1141–1153. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q. New IT Driven Service-Oriented Smart Manufacturing: Framework and Characteristics. IEEE Trans. Syst. Man Cybern. Syst. 2017, 49, 81–91. [Google Scholar] [CrossRef]

- Durach, C.F.; Kembro, J.; Wieland, A. A New Paradigm for Systematic Literature Reviews in Supply Chain Management. J. Supply Chain Manag. 2017, 53, 67–85. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372. [Google Scholar] [CrossRef]

- Vom Brocke, J.; Simons, A.; Niehaves, B.; Riemer, K.; Plattfaut, R.; Cleven, A. Reconstructing the Giant: On the Importance of Rigour in Documenting the Literature Search Process. In Proceedings of the 27th European Conference on Information Systems (ECIS) AIS, Uppsala, Sweden, 8–14 June 2009. [Google Scholar]

- Tao, F.; Zhang, M.; Liu, Y.; Nee, A. Digital twin driven prognostics and health management for complex equipment. CIRP Ann. 2018, 67, 169–172. [Google Scholar] [CrossRef]

- Tao, F.; Liu, W.; Liu, J.; Liu, X.; Liu, Q.; Qu, T.; Hu, T.; Zhang, Z.; Xiang, F.; Xu, W.; et al. Digital Twin and Its Potential Application Exploration. Comput. Integr. Manuf. Syst. 2018, 24, 1–18. [Google Scholar] [CrossRef]

- Uhlemann, T.H.-J.; Lehmann, C.; Steinhilper, R. The Digital Twin: Realizing the Cyber-Physical Production System for Industry 4.0. Procedia CIRP 2017, 61, 335–340. [Google Scholar] [CrossRef]

- Coelho, F.; Relvas, S.; Barbosa-Póvoa, A.P. Simulation-based decision support tool for in-house logistics: The basis for a digital twin. Comput. Ind. Eng. 2021, 153, 107094. [Google Scholar] [CrossRef]

- Guo, H.; Chen, M.; Mohamed, K.; Qu, T.; Wang, S.; Li, J. A digital twin-based flexible cellular manufacturing for optimization of air conditioner line. J. Manuf. Syst. 2021, 58, 65–78. [Google Scholar] [CrossRef]

- Jiang, H.; Qin, S.; Fu, J.; Zhang, J.; Ding, G. How to model and implement connections between physical and virtual models for digital twin application. J. Manuf. Syst. 2021, 58, 36–51. [Google Scholar] [CrossRef]

- Pan, Y.H.; Qu, T.; Wu, N.Q.; Khalgui, M.; Huang, G.Q. Digital Twin Based Real-time Production Logistics Synchronization System in a Multi-level Computing Architecture. J. Manuf. Syst. 2021, 58, 246–260. [Google Scholar] [CrossRef]

- Vachálek, J.; Šišmišová, D.; Vašek, P.; Fit’ka, I.; Slovák, J.; Šimovec, M. Design and implementation of universal cyber-physical model for testing logistic control algorithms of production line’s digital twin by using color sensor. Sensors 2021, 21, 1842. [Google Scholar] [CrossRef]

- Agalianos, K.; Ponis, S.T.; Aretoulaki, E.; Plakas, G.; Efthymiou, O. Discrete Event Simulation and Digital Twins: Review and Challenges for Logistics. Procedia Manuf. 2020, 51, 1636–1641. [Google Scholar] [CrossRef]

- Agostino, Í.; Broda, E.; Frazzon, E.M.; Freitag, M. Using a Digital Twin for Production Planning and Control in Industry 4.0. Int. Ser. Oper. Res. Manag. Sci. 2020, 289, 39–60. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Dolgov, V.A.; Nikishechkin, P.A.; Dolgov, N.V. Information model of production and logistics systems of machine-building enterprises as the basis for the development and maintenance of their digital twins. In Proceedings of the International Conference on Modern Trends in Manufacturing Technologies and Equipment (ICMTMTE), Sevastopol, Crimeea, 7–11 September 2020; IOP Publishing: Wales, UK, 2020; pp. 1–7. [Google Scholar]

- Hauge, J.B.; Zafarzadeh, M.; Jeong, Y.; Li, Y.; Khilji, W.A.; Wiktorsson, M. Employing digital twins within production logistics. In Proceedings of the 2020 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Cardiff, UK, 15–17 June 2020; IEEE Xplore: New York, NY, USA, 2020; pp. 1–8. [Google Scholar] [CrossRef]

- Hu, C.; Gao, W.; Xu, C.; Ben, K. Study on the application of digital twin technology in complex electronic equipment. Lect. Notes Electr. Eng. 2020, 589, 123–137. [Google Scholar] [CrossRef]

- Makarova, I.; Buyvol, P.; Gubacheva, L. Creation of a Digital Twin of a Truck Assembly Process. In Proceedings of the 2020 International Russian Automation Conference (RusAutoCon), Sochi, Russia, 6–12 September 2020; IEEE Xplore: NewYork, NY, USA, 2020; pp. 1063–1068. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, Z. Digital twin-based production scheduling system for heavy truck frame shop. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 1–12. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, Y.; Zhong, R.Y. A proactive material handling method for CPS enabled shop-floor. Robot. Comput. -Integr. Manuf. 2020, 61, 101848–101849. [Google Scholar] [CrossRef]

- Herakovič, N.; Zupan, H.; Pipan, M.; Protner, J.; Šimic, M. Distributed manufacturing systems with digital agents. Stroj. Vestn. J. Mech. Eng. 2019, 65, 650–657. [Google Scholar] [CrossRef] [Green Version]

- Nikolakis, N.; Alexopoulos, K.; Xanthakis, E.; Chryssolouris, G. The digital twin implementation for linking the virtual representation of human-based production tasks to their physical counterpart in the factory-floor. Int. J. Comput. Integr. Manuf. 2019, 32, 1–12. [Google Scholar] [CrossRef]

- Krajčovič, M.; Grznár, P.; Fusko, M.; Skokan, R. Intelligent Logistics for Intelligent Production Systems. Commun. Sci. Lett. Univ. Zilina 2018, 20, 16–23. [Google Scholar] [CrossRef]

- Yao, F.; Keller, A.; Ahmad, M.; Ahmad, B.; Harrison, R.; Colombo, A.W. Optimizing the Scheduling of Autonomous Guided Vehicle in a Manufacturing Process. In Proceedings of the 2018 IEEE 16th International Conference on Industrial Informatics (INDIN), Porto, Portugal, 18–20 July 2018; IEEE Xplore: New York, NY, USA, 2018. [Google Scholar] [CrossRef]

- Bottani, E.; Cammardella, A.; Murino, T.; Vespoli, S. From the cyber-physical system to the digital twin: The process development for behaviour modelling of a cyber guided vehicle in M2M logic. In Proceedings of the XXII Summer School “Francesco Turco”–Industrial Systems Engineering, Palermo, Italy, 13–15 September 2017; pp. 96–102. [Google Scholar]

- Brenner, B.; Hummel, V. Digital Twin as Enabler for an Innovative Digital Shopfloor Management System in the ESB Logistics Learning Factory at Reutlingen—University. Procedia Manuf. 2017, 9, 198–205. [Google Scholar] [CrossRef]

- Grieves, M. Product lifecycle management: The new paradigm for enterprises. Int. J. Prod. Dev. 2005, 2, 71–84. [Google Scholar] [CrossRef]

- ISO. Automation Systems and Integration—Digital Twin Framework for Manufacturing: Information Exchange; Draft; Vernier: Geneva, Switzerland, 2020; ISO/DIS 23247-4:2020(E). [Google Scholar]

- Su Min, J.; Gitae, K. A survey of simulation modeling techniques in production planning and control (PPC). Prod. Plan. Control 2016, 27, 360–377. [Google Scholar] [CrossRef]

- De Ferreira, P.W.; Armellini, F.; de Santa-Eulalia, L.A. Simulation in industry 4.0: A state-of-the-art review. Comput. Ind. Eng. 2020, 149, 106868. [Google Scholar] [CrossRef]

- Lechler, T.; Fischer, E.; Metzner, M.; Mayr, A.; Franke, J. Virtual Commissioning: Scientific review and exploratory use cases in advanced production systems. Procedia CIRP 2019, 81, 1125–1130. [Google Scholar] [CrossRef]

| Appropriateness | Records | Records [%] |

|---|---|---|

| Total | 93 | 100.00 |

| High-appropriate papers | 24 | 25.81 |

| Medium-appropriate papers | 23 | 24.73 |

| Low-appropriate papers | 46 | 49.46 |

| Source | Records | Records [%] |

|---|---|---|

| Applied Sciences Switzerland | 5 | 5.38 |

| Journal of Manufacturing Systems | 4 | 4.30 |

| Sensors | 4 | 4.30 |

| Academy of Strategic Management Journal | 3 | 3.23 |

| IEEE Access | 3 | 3.23 |

| IFAC Papersonline | 3 | 3.23 |

| Robotics and Computer Integrated Manufacturing | 3 | 3.23 |

| EAI Endorsed Transactions on Energy Web | 2 | 2.15 |

| International Journal of Computer Integrated Manufacturing | 2 | 2.15 |

| Procedia CIRP | 2 | 2.15 |

| Others | 62 | 66.67 |

| Countries | Records |

|---|---|

| Germany | 26 |

| China | 14 |

| Russian Federation | 9 |

| Hong Kong | 8 |

| Italy | 7 |

| South Korea | 6 |

| United Kingdom | 5 |

| United States | 4 |

| Portugal | 4 |

| Romania | 4 |

| Hungary | 3 |

| Slovakia | 3 |

| Slovenia | 3 |

| Affiliation | Records |

|---|---|

| The University of Hong Kong | 7 |

| Jinan University | 6 |

| Peter the Great St. Petersburg Polytechnic University | 3 |

| Otto von Guericke University of Magdeburg | 3 |

| Technical University of Cluj-Napoca | 3 |

| Univerza v Ljubljani | 3 |

| Macau University of Science and Technology | 3 |

| Southern University of Science and Technology | 3 |

| Index Keywords | Author Keywords | ||

|---|---|---|---|

| Digital Twin | 56.99% | Digital Twin (application) | 70.97% |

| (Smart) Manufacturing (companies) | 24.73% | (Discrete Event/Logistics/Factory) simulation (model) | 18.28% |

| Cyber-Physical Systems | 16.13% | Industry 4.0 | 17.20% |

| Embedded systems | 15.05% | (Production/In-house/Digital/Smart/multi-modal) logistics (4.0) | 13.98% |

| Life cycle | 15.05% | Cyber-Physical (production) Systems | 10.75% |

| Industry 4.0 | 13.98% | (Smart) Supply Chain (management /digitization/control) | 8.60% |

| Decision-making | 11.83% | Internet of Things (IoT) | 7.53% |

| (Production) Logistics (processes) | 11.83% | Big Data | 6.45% |

| Supply Chains | 10.75% | Decision (support/making) | 5.38% |

| (Industrial) Internet of Things (IoT) | 10.75% | Smart manufacturing | 4.30% |

| ID | Ref. No. | Authors and Year | No. of Citations |

|---|---|---|---|

| 1 | [17] | Tao and Zhang, 2017 | 5 |

| 2 | [13] | Tao et al. 2018 | 5 |

| 3 | [11] | Kritzinger et al. 2018 | 4 |

| 4 | [22] | Zheng et al. 2019 | 3 |

| 5 | [27] | Tao et al. 2018 | 3 |

| 6 | [12] | Tao et al. 2019 | 3 |

| 7 | [28] | Tao et al. 2018 | 3 |

| 8 | [29] | Uhlemann et al. 2017 | 3 |

| Ref. No. | Author and Year | DT Definition | Virtual Model | Type | Application Domain |

|---|---|---|---|---|---|

| [30] | Ceolho et al. 2021 | Tao et al. | DES | case study | Distribution Center, Automotive |

| [31] | Guo et al. 2021 | Tao et al. | DES | case study | Electronics |

| [32] | Jiang et al. 2021 | Tao et al. | DES | case study | Aerospace |

| [33] | Pan et al. 2021 | Tao et al. | MDO | case study | Paint Manufacturer |

| [34] | Vachalek et al. 2021 | Grieves | DES | case study | Laboratory |

| [35] | Aglianos et al. 2020 | Glaessgen and Stargel | - | review | - |

| [36] | Agostino et al. 2020 | Glaessgen and Stargel | DES | case study | Automotive |

| [37] | Grigoriev et al. 2020 | Grieves | - | concept | - |

| [38] | Hauge et al. 2020 | Tao et al. | GE | case study | Laboratory |

| [39] | Hu et al. 2020 | Tao et al. | PS | case study | Electronics |

| [40] | Makarova et al. 2020 | other | DES | case study | Automotive |

| [21] | Sommer et al. 2020 | other | DES | case study | not assignable |

| [41] | Wang and Wu, 2020 | Glaessgen and Stargel | AM | case study | not assignable |

| [42] | Wang et al. 2020 | Tao et al. Glaessgen and Stargel | TWMLR | case study | Metalworking |

| [43] | Herakovic et al. 2019 | Tao et al. | ABS | case study | Laboratory |

| [44] | Nikolakis et al. 2019 | Grieves | CRS | case study | Warehouse |

| [12] | Tao et al. 2019 | Tao et al. | - | review | - |

| [22] | Zheng et al. 2019 | Tao et al. | PS | case study | Metalworking |

| [45] | Krajcovic et al. 2018 | other | - | case study | not assignable |

| [11] | Kritzinger et al. 2018 | other | - | review | - |

| [19] | Kuehn, 2018 | other | - | concept | - |

| [13] | Tao et al. 2018 | Tao et al. | - | concept | - |

| [27] | Tao et al. 2018 | Tao et al. | PS | case study | Energy |

| [46] | Yao et al. 2018 | Grieves | DES/AGV Simulator | case study | Laboratory |

| [47] | Bottani et al. 2017 | other | DES/AGV Simulator | case study | not assignable |

| [48] | Brenner and Hummel, 2017 | other | KD | case study | Laboratory |

| [17] | Tao and Zhang, 2017 | Tao et al. | - | concept | - |

| [29] | Uhlemann et al. 2017 | other | - | concept | - |

| Cluster | Records | Records [%] |

|---|---|---|

| Enablers and Implementation Concepts | 5 | 17.86 |

| Areas of Operation and State of Development | 3 | 10.71 |

| Virtual Model Creation | 4 | 14.29 |

| Enterprise Information Systems | 6 | 21.43 |

| Decentralized Applications | 7 | 25.00 |

| Machinery Prognostics and Maintenance Management | 3 | 10.71 |

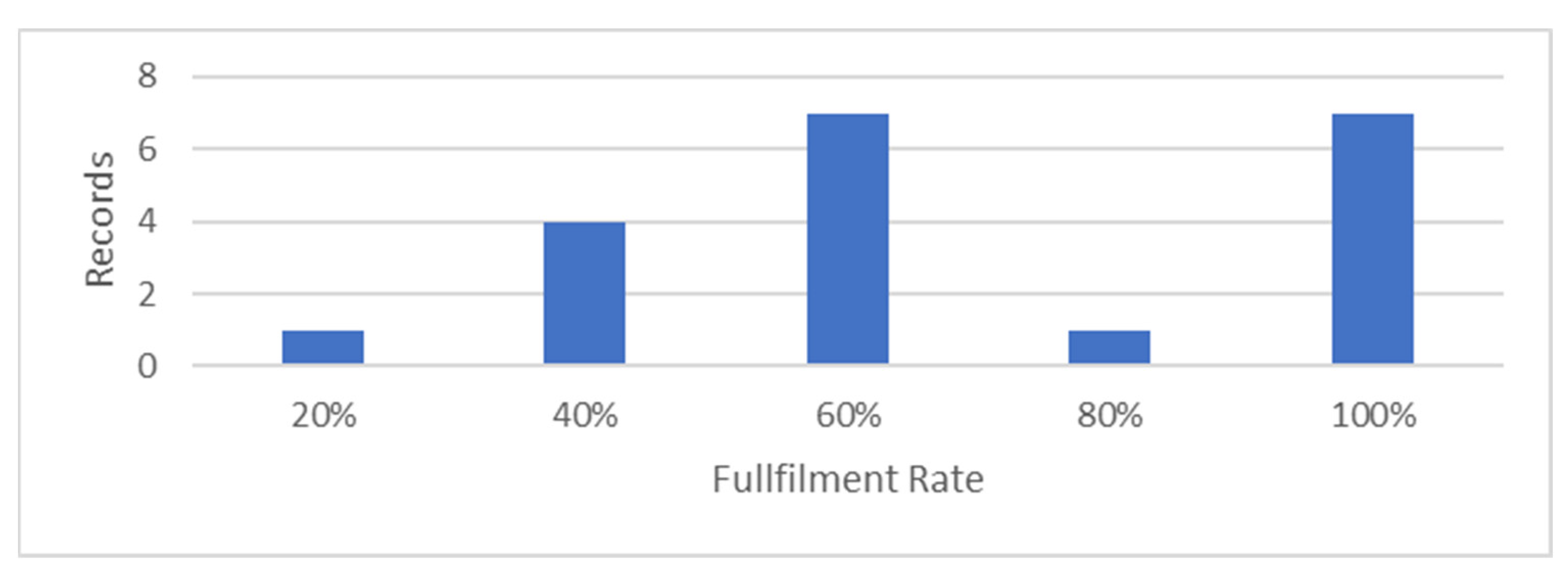

| Ref. No. | Authors and Year | Five Dimensions of Tao et al. | Fulfillment | ||||

|---|---|---|---|---|---|---|---|

| Physical Entity | Virtual Model | DT Data | Service System | Connection | |||

| [30] | Ceolho et al. 2021 | x | x | 40% | |||

| [31] | Guo et al. 2021 | x | x | x | x | 80% | |

| [32] | Jiang et al. 2021 | x | x | x | 60% | ||

| [33] | Pan et al. 2021 | x | x | 40% | |||

| [34] | Vachalek et al. 2021 | x (lab) | x | x | 60% | ||

| [36] | Agostino et al. 2020 | x | x | x | 60% | ||

| [38] | Hauge et al. 2020 | x (lab) | x | x | 60% | ||

| [39] | Hu et al. 2020 | x | x | x | x | x | 100% |

| [40] | Makarova et al. 2020 | x | x | x | 60% | ||

| [21] | Sommer et al. 2020 | x | x | 40% | |||

| [41] | Wang and Wu, 2020 | x | x | x | x | x | 100% |

| [42] | Wang et al. 2020 | x | x | x | x | x | 100% |

| [43] | Herakovic et al. 2019 | x (lab) | x | x | x | x | 100% |

| [44] | Nikolakis et al. 2019 | x | x | x | 60% | ||

| [22] | Zheng et al. 2019 | x | x | x | x | x | 100% |

| [45] | Krajcovic et al. 2018 | x | 20% | ||||

| [27] | Tao et al. 2018 | x | x | x | x | x | 100% |

| [46] | Yao et al. 2018 | x (lab) | x | x | x | x | 100% |

| [47] | Bottani et al. 2017 | x | x | 40% | |||

| [48] | Brenner and Hummel, 2017 | x (lab) | x | x | 60% | ||

| Allocation | 90% | 90% | 70% | 60% | 35% | ||

| Abbr. | Name | Records | Records [%] |

|---|---|---|---|

| DES | Discrete Event Simulation | 9 | 45.00 |

| PS | Physical Simulation | 3 | 15.00 |

| AGV Simulator | Automated Guided Vehicle Simulation | 2 | 10.00 |

| ABS | Agent-based Simulation | 1 | 5.00 |

| AM | Analytical Model | 1 | 5.00 |

| CRS | Catmull-Rom Spline | 1 | 5.00 |

| GE | Game Engine | 1 | 5.00 |

| KD | Knowledge Database | 1 | 5.00 |

| MDO | Multidisciplinary Design Optimization | 1 | 5.00 |

| TWMLR | Time-Weighted Multiple Linear Regression | 1 | 5.00 |

| Objective | Records | Records [%] |

|---|---|---|

| monitoring | 5 | 25.00 |

| production scheduling | 3 | 15.00 |

| AGV control | 3 | 15.00 |

| overall equipment effectiveness (OEE) | 3 | 15.00 |

| line balance rate | 2 | 10.00 |

| reaction time | 2 | 10.00 |

| workstation design | 2 | 10.00 |

| lead time | 2 | 10.00 |

| per capita productivity | 1 | 5.00 |

| number of operators | 1 | 5.00 |

| warehouse costs | 1 | 5.00 |

| energy consumption | 1 | 5.00 |

| travel distance | 1 | 5.00 |

| travel time | 1 | 5.00 |

| shop-floor management | 1 | 5.00 |

| Domain | Records | Records [%] |

|---|---|---|

| laboratory production | 5 | 25.00 |

| not assignable | 4 | 20.00 |

| automotive | 3 | 15.00 |

| electronics | 2 | 10.00 |

| metalworking | 2 | 10.00 |

| distribution center | 1 | 5.00 |

| aerospace | 1 | 5.00 |

| warehouse | 1 | 5.00 |

| energy | 1 | 5.00 |

| others | 1 | 5.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaiblinger, A.; Woschank, M. State of the Art and Future Directions of Digital Twins for Production Logistics: A Systematic Literature Review. Appl. Sci. 2022, 12, 669. https://doi.org/10.3390/app12020669

Kaiblinger A, Woschank M. State of the Art and Future Directions of Digital Twins for Production Logistics: A Systematic Literature Review. Applied Sciences. 2022; 12(2):669. https://doi.org/10.3390/app12020669

Chicago/Turabian StyleKaiblinger, Alexander, and Manuel Woschank. 2022. "State of the Art and Future Directions of Digital Twins for Production Logistics: A Systematic Literature Review" Applied Sciences 12, no. 2: 669. https://doi.org/10.3390/app12020669

APA StyleKaiblinger, A., & Woschank, M. (2022). State of the Art and Future Directions of Digital Twins for Production Logistics: A Systematic Literature Review. Applied Sciences, 12(2), 669. https://doi.org/10.3390/app12020669