Digital Twin for Human–Robot Collaboration in Manufacturing: Review and Outlook

Abstract

:1. Introduction

2. Potential of Digital Twin and Human–Robot Collaboration

3. Review of DT in HRC

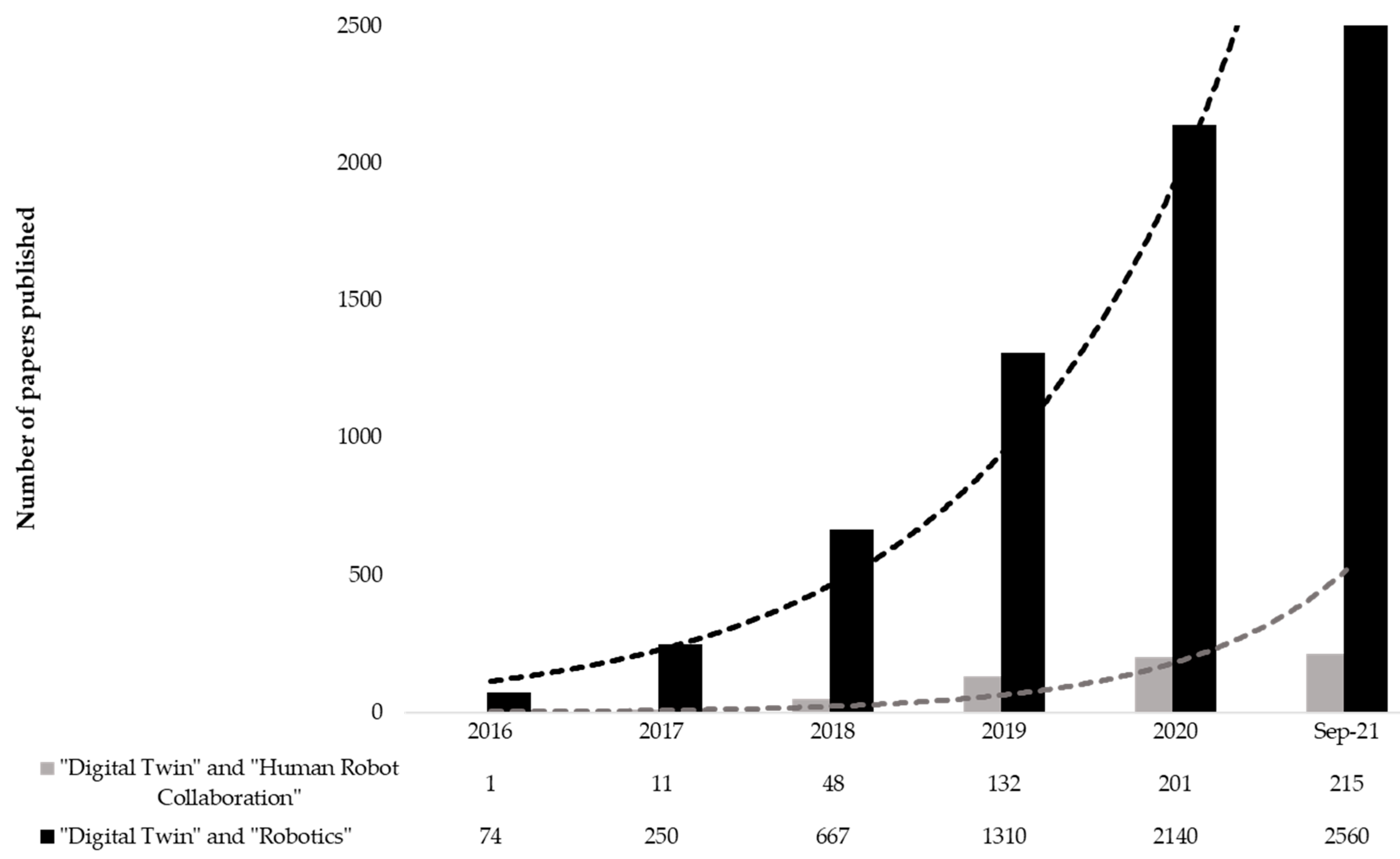

3.1. Summary of Publications

3.2. Definitions

| Scopus Keywords | Total Number of Papers | Publication Year and Number of Papers | Source Type |

|---|---|---|---|

| “Digital Twin” and “Robotics” | 275 | 2016—04 2017—07 2018—19 2019—60 2020—95 2021—90 | Conference Proceeding—155 Journal—92 Book Series—26 Book—02 |

| “Digital Twin” and “Human-Robot Collaboration” | 30 | 2017—01 2018—04 2019—08 2020—05 2021—12 | Conference Proceeding—13 Journal—12 Book Series—04 Book—01 |

3.3. Approaches in DT

3.3.1. Simulation-Based Approach

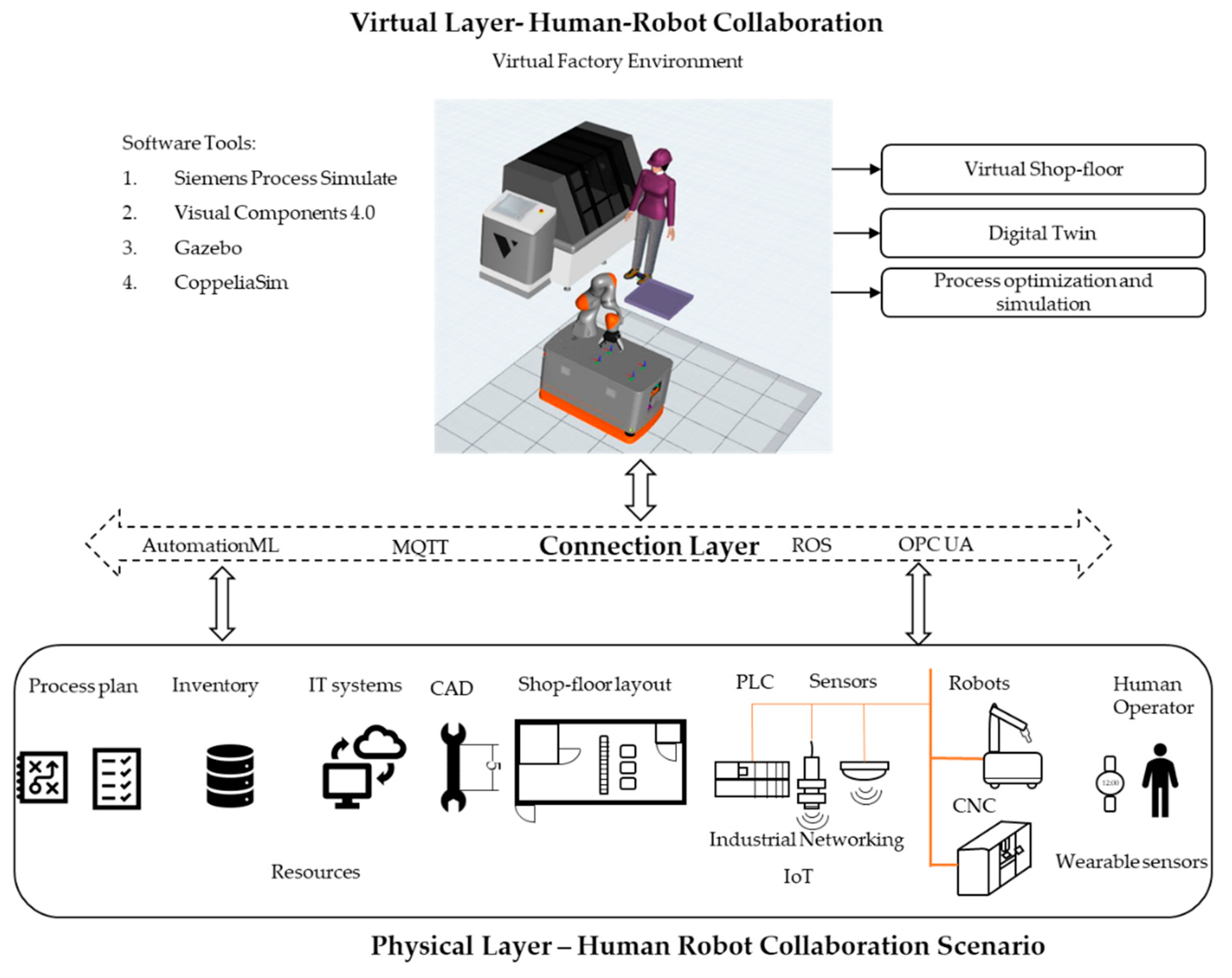

3.3.2. Layer Based Approach

- Physical LayerThe physical layer consists of information about the state, the properties of the system and the properties of the environment, collected through various sources such as smart sensors, product development software, resource management and planning tools, networking tools and communication tools. For example, information obtained in the physical layer includes:

- ○

- Design—CAD/CAM, factory layout, drawings of all the physical parts in the production environment;

- ○

- Resources—inventory data, bill of materials, process plan, physical properties of the product, simulation and modelling results;

- ○

- IoT devices—smart sensors, PLC, SCADA, distributed control system (DCS), actuators;

- ○

- Network—communication protocol, machine-machine interface, feedback and control.

- Virtual LayerThe virtual layer consists of an information model of the physical object and a data processing module [81]. The information model represents the structure of the physical object. The data processing module collects and processes the data about the physical object for real-time reconstruction of the physical object in the virtual world. Hence, the virtual layer represents the digital environment that provides the virtual replica of the object present in the physical layer. The advantage of the virtual layer is that it can create multiple instances of the digital twin model. These multiple models along with the data acquired from the real world can be used to simulate, predict and optimize the process. Additionally, the virtual layer can interact with its physical counterpart to update the system parameters to increase the efficiency of the physical system.

- Connection LayerThe connection layer acts as a bridge to link the physical and the virtual layer, i.e., it provides an exchange of data between the real-world entities and the digital twin model. This layer handles data storage, processing and communication. The connection layers serve to map the data from the physical layer to the virtual layer and vice versa. The changes can be updated automatically in the physical or in the virtual model. Another purpose of this connection layer is optimization by processing the collected data. The raw data obtained via the sensors are processed to extract relevant information from them. Therefore, various data mining and machine learning techniques are used in the connection layer for process planning, optimization and tracking changes [82].

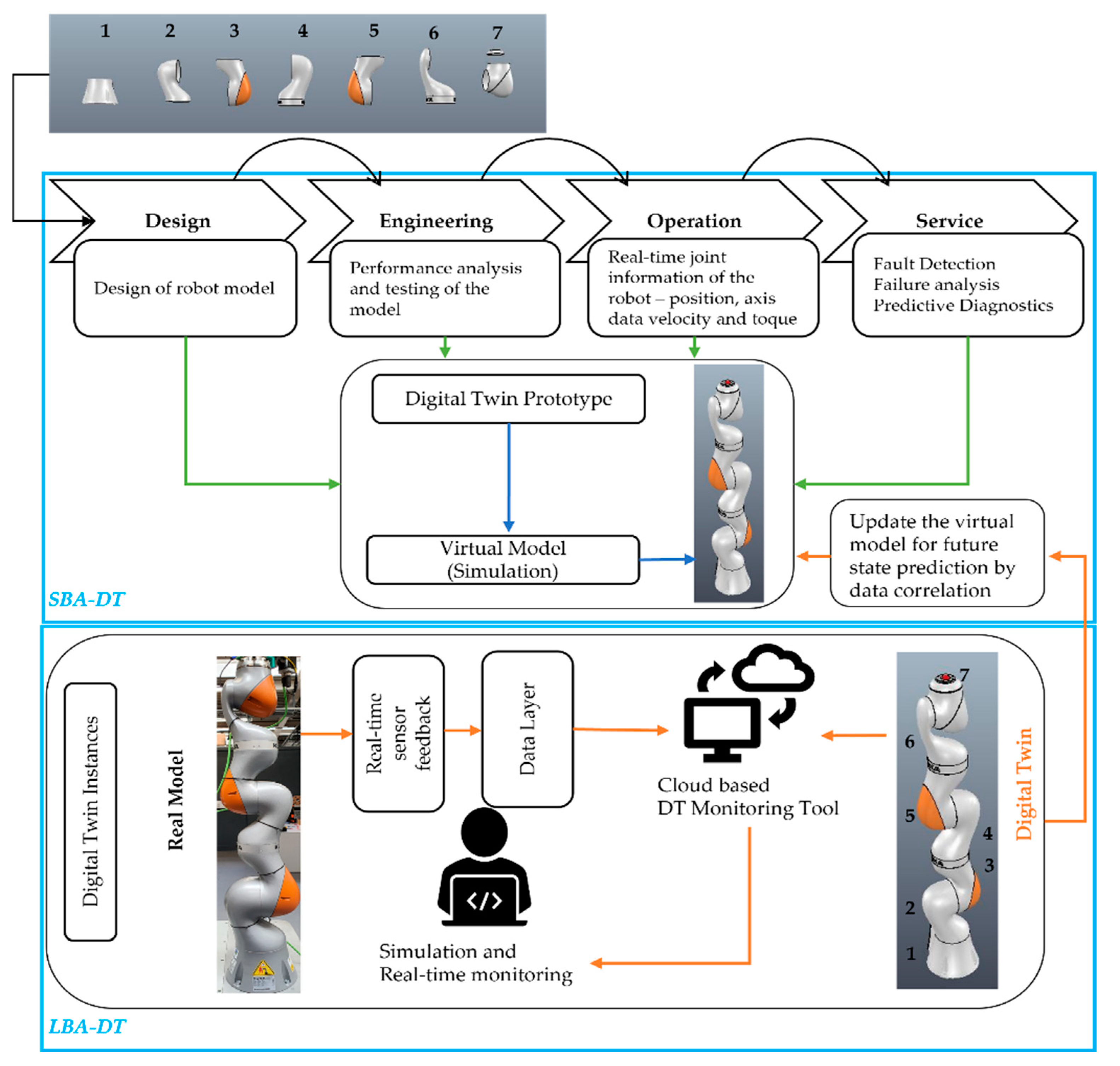

3.4. SBA vs. LBA Development

- For instance, in the development of a collaborative robotic arm, the information pertaining to each of the joints is gathered, including the motor performance data, efficiency, motor velocities, acceleration, torque, data from force/torque sensors, system information and diagnostic data. As the product is developed, the data at each stage of product development are gathered and stored. These parameters can be updated in a virtual model as its initial parameters. In this situation, the SBA can be used during the development phase of the robot arm.

- Likewise, pre-existing sensors along with additional sensors can be utilized so that the robot may send information about its state to the virtual model. These exchanges of data can be linked together by the data layer, as discussed in the LBA.

- A cloud-based software tool containing the DT model with the actual parameters of the robot can be provided by the OEM such that the end-users can connect the real robot to the virtual model and monitor the DT. This could be useful in a series of tasks including tracking, monitoring and parameterising the robot in order to increase the accuracy, repeatability and life of the real robotic arm.

- Furthermore, an application programming interface (API) can be used to extend the scope of the DT of the collaborative arm across different simulation platforms to create a digital factory environment. Developing the DT concurrently with the development of an actual product can enable faster integration of models to build a digital factory environment.

3.4.1. Software for the Development of Digital Twin for HRC

Example of DT-HRC Simulation vs. Visualisation

3.4.2. Deployment and Complexity

3.5. Benefits of DT-HRC

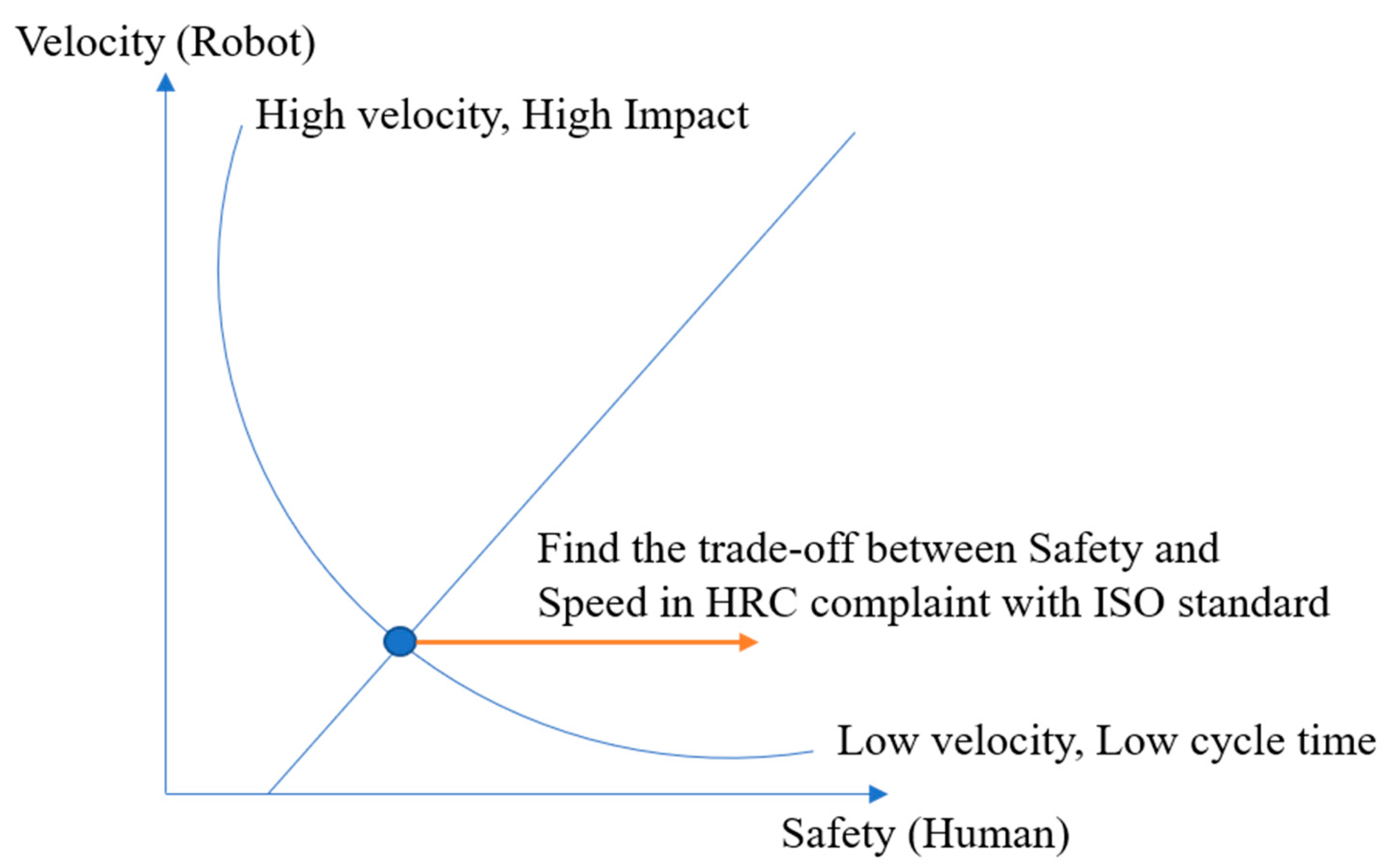

3.5.1. Safety

3.5.2. Maintenance

3.5.3. Task Planning and Optimization

3.5.4. Testing and Training

4. Challenges

5. Outlook and Conclusions

- There are no definite methods to determining the fidelity of the DT platform;

- Various issues and difficulties associated with DT-simulation, as well as with the modelling and visualization, still remain unsolved;

- Lack of standard communication frameworks for handling the multitude of sensor data, avoiding latency and allowing synchronisation to build a real-time DT of a shop-floor.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in Manufacturing: A Categorical Literature Review and Classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, Digitization, and Opportunities for Sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A Glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Mourtzis, D. Simulation in the Design and Operation of Manufacturing Systems: State of the Art and New Trends. Int. J. Prod. Res. 2020, 58, 1927–1949. [Google Scholar] [CrossRef]

- Hozdić, E. Smart Factory for Industry 4.0: A Review. Int. J. Mod. Manuf. Technol. 2015, 7, 28–35. [Google Scholar]

- Lee, J.; Bagheri, B.; Kao, H.-A. A Cyber-Physical Systems Architecture for Industry 4.0-Based Manufacturing Systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing Smart Factory of Industrie 4.0: An Outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Executive Summary World Robotics 2018 Industrial Robots; International Federation of Robotics IFR: Frankfurt, Germany, 2018; pp. 13–22.

- Dragan, A.D.; Bauman, S.; Forlizzi, J.; Srinivasa, S.S. Effects of Robot Motion on Human-Robot Collaboration. In Proceedings of the ACM/IEEE International Conference on Human-Robot Interaction, Portland, OR, USA, 2–5 March 2015; IEEE Computer Society: Washington, DC, USA, 2015; Volume 2015, pp. 51–58. [Google Scholar]

- Sadrfaridpour, B.; Saeidi, H.; Burke, J.; Madathil, K.; Wang, Y. Modeling and Control of Trust in Human-Robot Collaborative Manufacturing. In Robust Intelligence and Trust in Autonomous Systems; Springer: Berlin/Heidelberg, Germany, 2016; pp. 115–142. ISBN 9781489976680. [Google Scholar]

- Bragança, S.; Costa, E.; Castellucci, I.; Arezes, P.M. A Brief Overview of the Use of Collaborative Robots in Industry 4.0: Human Role and Safety. In Occupational and Environmental Safety and Health; Springer: Berlin/Heidelberg, Germany, 2019; pp. 641–650. [Google Scholar] [CrossRef]

- Attanasio, A.; Scaglioni, B.; De Momi, E.; Fiorini, P.; Valdastri, P. Autonomy in Surgical Robotics. Annu. Rev. Control Robot. Auton. Syst. 2021, 4, 651–679. [Google Scholar] [CrossRef]

- Negri, E.; Fumagalli, L.; Macchi, M. A Review of the Roles of Digital Twin in CPS-Based Production Systems. Procedia Manuf. 2017, 11, 939–948. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inf. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Vachalek, J.; Bartalsky, L.; Rovny, O.; Sismisova, D.; Morhac, M.; Loksik, M. The Digital Twin of an Industrial Production Line within the Industry 4.0 Concept. In Proceedings of the 2017 21st International Conference on Process Control, PC, Strbske Pleso, Slovakia, 6–9 June 2017; Kvasnica, M., Fikar, M., Eds.; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2017; pp. 258–262. [Google Scholar]

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Holler, M.; Uebernickel, F.; Brenner, W. Digital Twin Concepts in Manufacturing Industries—A Literature Review and Avenues for Further Research. In Proceedings of the 18th International Conference on Industrial Engineering (IJIE), Seoul, Korea, 10–12 October 2016; pp. 1–9. [Google Scholar]

- Digital Twin Market Size, Share & Trends Analysis Report by End Use. Research and Markets. Available online: https://www.researchandmarkets.com/reports/5415584/digital-twin-market-size-share-and-trends (accessed on 31 March 2022).

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital Twin-Driven Product Design, Manufacturing and Service with Big Data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Savur, C.; Kumar, S.; Arora, S.; Hazbar, T.; Sahin, F. HRC-SoS: Human Robot Collaboration Experimentation Platform as System of Systems. In Proceedings of the 2019 14th Annual Conference System of Systems Engineering (SoSE), Anchorage, AK, USA, 19–22 May 2019; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2019; pp. 206–211. [Google Scholar]

- Tao, F.; Zhang, M. Digital Twin Shop-Floor: A New Shop-Floor Paradigm Towards Smart Manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Malik, A.A.; Bilberg, A. Digital Twins of Human Robot Collaboration in a Production Setting. In Proceedings of the Procedia Manufacturing, Columbus, OH, USA, 11–14 June 2018; Sormaz, D., Chen, F.F., Suer, G., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2018; Volume 17, pp. 278–285. [Google Scholar]

- Boschert, S.; Rosen, R. Digital Twin-the Simulation Aspect. In Mechatron. Futures: Challenges and Solutions for Mechatron. Systems and Their Designers; Springer International Publishing: Cham, Switzerland, 2016; pp. 59–74. ISBN 9783319321561. [Google Scholar]

- Chryssolouris, G.; Mavrikios, D.; Papakostas, N.; Mourtzis, D.; Michalos, G.; Georgoulias, K. Digital Manufacturing: History, Perspectives, and Outlook. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2009, 223, 451–462. [Google Scholar] [CrossRef]

- Minerva, R.; Lee, G.M.; Crespi, N. Digital Twin in the IoT Context: A Survey on Technical Features, Scenarios, and Architectural Models. Proc. IEEE 2020, 108, 1785–1824. [Google Scholar] [CrossRef]

- Shao, G.; Kibira, D. Digital Manufacturing: Requirements and Challenges for Implementing Digital Surrogates. In Proceedings of the 2018 Winter Simulation Conference (WSC), Gothenburg, Sweden, 9–12 December 2018; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2019; Volume 2018, pp. 1226–1237. [Google Scholar]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Rosen, R.; Von Wichert, G.; Lo, G.; Bettenhausen, K.D. About the Importance of Autonomy and Digital Twins for the Future of Manufacturing. IFAC-PapersOnLine 2015, 28, 567–572. [Google Scholar] [CrossRef]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Lu, S.C.-Y.; Nee, A.Y.C. Digital Twin-Driven Product Design Framework. Int. J. Prod. Res. 2019, 57, 3935–3953. [Google Scholar] [CrossRef] [Green Version]

- Matheson, E.; Minto, R.; Zampieri, E.G.G.; Faccio, M.; Rosati, G. Human–Robot Collaboration in Manufacturing Applications: A Review. Robotics 2019, 8, 100. [Google Scholar] [CrossRef] [Green Version]

- Akella, P.; Peshkin, M.; Colgate, E.; Wannasuphoprasit, W.; Nagesh, N.; Wells, J.; Holland, S.; Pearson, T.; Peacock, B. Cobots for the Automobile Assembly Line. Proc. IEEE Int. Conf. Robot. Autom. 1999, 1, 728–733. [Google Scholar]

- Makris, S.; Tsarouchi, P.; Matthaiakis, A.-S.; Athanasatos, A.; Chatzigeorgiou, X.; Stefos, M.; Giavridis, K.; Aivaliotis, S. Dual Arm Robot in Cooperation with Humans for Flexible Assembly. CIRP Ann. Manuf. Technol. 2017, 66, 13–16. [Google Scholar] [CrossRef]

- Kousi, N.; Michalos, G.; Aivaliotis, S.; Makris, S. An Outlook on Future Assembly Systems Introducing Robotic Mobile Dual Arm Workers. In Proceedings of the Procedia CIRP, Stockholm, Sweden, 16–18 May 2018; Kjellberg, T., Wang, L., Ji, W., Wang, X.V., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2018; Volume 72, pp. 33–38. [Google Scholar]

- Maurtua, I.; Ibarguren, A.; Kildal, J.; Susperregi, L.; Sierra, B. Human-Robot Collaboration in Industrial Applications: Safety, Interaction and Trust. Int. J. Adv. Robot. Syst. 2017, 14, 1–10. [Google Scholar] [CrossRef]

- Wang, X.V.; Kemény, Z.; Váncza, J.; Wang, L. Human–Robot Collaborative Assembly in Cyber-Physical Production: Classification Framework and Implementation. CIRP Ann. Manuf. Technol. 2017, 66, 5–8. [Google Scholar] [CrossRef] [Green Version]

- Gervasi, R.; Mastrogiacomo, L.; Franceschini, F. A Conceptual Framework to Evaluate Human-Robot Collaboration. Int. J. Adv. Manuf. Technol. 2020, 108, 841–865. [Google Scholar] [CrossRef]

- Wang, L.; Liu, S.; Liu, H.; Wang, X.V. Overview of Human-Robot Collaboration in Manufacturing. In Proceedings of the 5th International Conference on the Industry 4.0 Model for Advanced Manufacturing, Belgrade, Serbia, 1–4 June 2020; Springer: Berlin/Heidelberg, Germany, 2020; p. 58, ISSN 21954356. ISBN 9783030462116. [Google Scholar]

- Xiao, J.; Wang, P.; Lu, H.; Zhang, H. A Three-Dimensional Mapping and Virtual Reality-Based Human–Robot Interaction for Collaborative Space Exploration. Int. J. Adv. Robot. Syst. 2020, 17. [Google Scholar] [CrossRef]

- Tsarouchi, P.; Makris, S.; Chryssolouris, G. Human–Robot Interaction Review and Challenges on Task Planning and Programming. Int. J. Comput. Integr. Manuf. 2016, 29, 916–931. [Google Scholar] [CrossRef]

- Goodrich, M.A.; Schultz, A.C. Human-Robot Interaction: A Survey. Found. Trends Hum.-Comput. Interact. 2007, 1, 203–275. [Google Scholar] [CrossRef]

- Cherub, A.; Passama, R.; Crosnier, A.; Lasnier, A.; Fraisse, P. Collaborative Manufacturing with Physical Human-Robot Interaction. Robot. Comput. Integr. Manuf. 2016, 40, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Green, S.A.; Billinghurst, M.; Chen, X.; Chase, J.G. Human-Robot Collaboration: A Literature Review and Augmented Reality Approach in Design. Int. J. Adv. Robot. Syst. 2008, 5, 1–18. [Google Scholar] [CrossRef]

- Villani, V.; Pini, F.; Leali, F.; Secchi, C. Survey on Human–Robot Collaboration in Industrial Settings: Safety, Intuitive Interfaces and Applications. Mechatronics 2018, 55, 248–266. [Google Scholar] [CrossRef]

- Wang, L.; Ma, L.; Yang, J.; Wu, J. Human Somatosensory Processing and Artificial Somatosensation. Cyborg Bionic Syst. 2021, 2021, 843259. [Google Scholar] [CrossRef]

- Ramasubramanian, A.K.; Aiman, S.M.; Papakostas, N. On Using Human Activity Recognition Sensors to Improve the Performance of Collaborative Mobile Manipulators: Review and Outlook. Procedia CIRP 2021, 97, 211–216. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, C.; Jin, H.; Sun, L. Classifying Motion Intention of Step Length and Synchronous Walking Speed by Functional Near-Infrared Spectroscopy. Cyborg Bionic Syst. 2021, 2021, 9821787. [Google Scholar] [CrossRef]

- Xu, D.; Wang, Q. Noninvasive Human-Prosthesis Interfaces for Locomotion Intent Recognition: A Review. Cyborg Bionic Syst. 2021, 2021, 9863761. [Google Scholar] [CrossRef]

- Bilberg, A.; Malik, A.A. Digital Twin Driven Human–Robot Collaborative Assembly. CIRP Ann. 2019, 68, 499–502. [Google Scholar] [CrossRef]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the Digital Twin for Design and Production Engineering. CIRP Ann. Manuf. Technol. 2017, 66, 141–144. [Google Scholar] [CrossRef] [Green Version]

- What Is a Digital Twin?|IBM. Available online: https://www.ibm.com/topics/what-is-a-digital-twin (accessed on 31 March 2022).

- Shafto, M.; Conroy, M.; Doyle, R.; Glaessgen, E.; Kemp, C.; LeMoigne, J.; Wang, L. Modeling, Simulation, Information Technology & Processing Roadmap; Technology Area 11; National Aeronautics and Space Administration (NASA): Washington, DC, USA, 2021. Available online: https://www.nasa.gov/sites/default/files/501321main_TA11-ID_rev4_NRC-wTASR.pdf (accessed on 31 March 2022).

- Son, Y.H.; Kim, G.-Y.; Kim, H.C.; Jun, C.; Noh, S.D. Past, Present, and Future Research of Digital Twin for Smart Manufacturing. J. Comput. Des. Eng. 2022, 9, 1–23. [Google Scholar] [CrossRef]

- Zheng, Y.; Yang, S.; Cheng, H. An Application Framework of Digital Twin and Its Case Study. J. Ambient Intell. Humaniz. Comput. 2019, 10, 1141–1153. [Google Scholar] [CrossRef]

- Barricelli, B.R.; Casiraghi, E.; Fogli, D. A Survey on Digital Twin: Definitions, Characteristics, Applications, and Design Implications. IEEE Access 2019, 7, 167653–167671. [Google Scholar] [CrossRef]

- Schirrmeister, F. System Emulation and Digital Twins in Aerospace Applications; Cadence Design Systems, Inc.: San Jose, CA, USA, 2019. [Google Scholar]

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems. In Transdisciplinary Perspectives on Complex Systems: New Findings and Approaches; Springer International Publishing: Cham, Switzerland, 2016; pp. 85–113. ISBN 9783319387567. [Google Scholar]

- Gabor, T.; Belzner, L.; Kiermeier, M.; Beck, M.T.; Neitz, A. A Simulation-Based Architecture for Smart Cyber-Physical Systems. In Proceedings of the 2016 IEEE International Conference on Autonomic Computing (ICAC), Wuerzburg, Germany, 17–22 July 2016; Giese, H., Kounev, S., Liu, J., Eds.; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2016; pp. 374–379. [Google Scholar]

- Boschert, S.; Heinrich, C.; Rosen, R. Next Generation Digital Twin. In Proceedings of the TMCE, Las Palmas de Gran Canaria, Spain, 7–11 May 2018; pp. 209–217. [Google Scholar]

- West, T.D.; Pyster, A. Untangling the Digital Thread: The Challenge and Promise of Model-Based Engineering in Defense Acquisition. Insight 2015, 18, 45–55. [Google Scholar] [CrossRef]

- Singh, V.; Willcox, K.E. Engineering Design with Digital Thread. AIAA J. 2018, 56, 4515–4528. [Google Scholar] [CrossRef]

- Lee, C.G.; Park, S.C. Survey on the Virtual Commissioning of Manufacturing Systems. J. Comput. Des. Eng. 2014, 1, 213–222. [Google Scholar] [CrossRef] [Green Version]

- Guerrero, L.V.; López, V.V.; Mejía, J.E. Virtual Commissioning with Process Simulation (Tecnomatix). Comput.-Aided Des. Appl. 2014, 11, S11–S19. [Google Scholar] [CrossRef] [Green Version]

- Lechler, T.; Fischer, E.; Metzner, M.; Mayr, A.; Franke, J. Virtual Commissioning–Scientific Review and Exploratory Use Cases in Advanced Production Systems. In Proceedings of the Procedia CIRP; Butala, P., Govekar, E., Vrabic, R., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2019; Volume 81, pp. 1125–1130. [Google Scholar]

- Thepmanee, T.; Tantaweenulak, A.; Smerpitak, K. Wincc-Based Process Simulation for Virtual Commissioning of Scada System Integration. ICIC Express Lett. Part B Appl. 2020, 11, 667–674. [Google Scholar] [CrossRef]

- Kunath, M.; Winkler, H. Integrating the Digital Twin of the Manufacturing System into a Decision Support System for Improving the Order Management Process. Procedia CIRP 2018, 72, 225–231. [Google Scholar] [CrossRef]

- Vermaak, H.; Niemann, J. Virtual Commissioning: A Tool to Ensure Effective System Integration. In Proceedings of the 2017 IEEE International Workshop of Electronics, Control, Measurement, Signals and their Application to Mechatronics (ECMSM), Donostia, Spain, 24–26 May 2017; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2017; pp. 1–6. [Google Scholar]

- Metzner, M.; Weissert, S.; Karlidag, E.; Albrecht, F.; Blank, A.; Mayr, A.; Franke, J. Virtual Commissioning of 6 DoF Pose Estimation and Robotic Bin Picking Systems for Industrial Parts. In Proceedings of the IFAC-PapersOnLine, Oshawa, ON, Canada, 12–14 August 2019; Barari, A., Ed.; Elsevier B.V.: Amsterdam, The Netherlands, 2019; Volume 52, pp. 160–164. [Google Scholar]

- Schluse, M.; Rossmann, J. From Simulation to Experimentable Digital Twins: Simulation-Based Development and Operation of Complex Technical Systems. In Proceedings of the 2016 IEEE International Symposium on Systems Engineering (ISSE), Edinburgh, UK, 3–5 October 2016; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2016; pp. 1–6. [Google Scholar]

- Pérez, L.; Rodríguez-Jiménez, S.; Rodríguez, N.; Usamentiaga, R.; García, D.F. Digital Twin and Virtual Reality Based Methodology for Multi-Robot Manufacturing Cell Commissioning. Appl. Sci. 2020, 10, 3633. [Google Scholar] [CrossRef]

- Malik, A.A.; Masood, T.; Bilberg, A. Virtual Reality in Manufacturing: Immersive and Collaborative Artificial-Reality in Design of Human-Robot Workspace. Int. J. Comput. Integr. Manuf. 2020, 33, 22–37. [Google Scholar] [CrossRef]

- Papakostas, N.; Alexopoulos, K.; Kopanakis, A. Integrating Digital Manufacturing and Simulation Tools in the Assembly Design Process: A Cooperating Robots Cell Case. CIRP J. Manuf. Sci. Technol. 2011, 4, 96–100. [Google Scholar] [CrossRef]

- Schäffer, E.; Mayr, A.; Fuchs, J.; Sjarov, M.; Vorndran, J.; Franke, J. Microservice-Based Architecture for Engineering Tools Enabling a Collaborative Multi-User Configuration of Robot-Based Automation Solutions. Procedia CIRP 2019, 86, 86–91. [Google Scholar] [CrossRef]

- Latif, H.; Shao, G.; Starly, B. A Case Study of Digital Twin for a Manufacturing Process Involving Human Interactions. In Proceedings of the Proceedings-Winter Simulation Conference, Orlando, FL, USA, 14–18 December 2020; Bae, K.-H., Feng, B., Kim, S., Lazarova-Molnar, S., Zheng, Z., Roeder, T., Eds.; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2020; Volume 2020, pp. 2659–2670. [Google Scholar]

- Gyulai, D.; Bergmann, J.; Lengyel, A.; Kadar, B.; Czirko, D. Simulation-Based Digital Twin of a Complex Shop-Floor Logistics System. In Proceedings of the Proceedings-Winter Simulation Conference, Orlando, FL, USA, 14–18 December 2020; Bae, K.-H., Feng, B., Kim, S., Lazarova-Molnar, S., Zheng, Z., Roeder, T., Eds.; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2020; Volume 2020, pp. 1849–1860. [Google Scholar]

- Rolo, G.R.; Rocha, A.D.; Tripa, J.; Barata, J. Application of a Simulation-Based Digital Twin for Predicting Distributed Manufacturing Control System Performance. Appl. Sci. 2021, 11, 2202. [Google Scholar] [CrossRef]

- Martínez, G.S.; Sierla, S.; Karhela, T.; Vyatkin, V. Automatic Generation of a Simulation-Based Digital Twin of an Industrial Process Plant. In Proceedings of the Proceedings: IECON 2018-44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2018; pp. 3084–3089. [Google Scholar]

- Lektauers, A.; Pecerska, J.; Bolsakovs, V.; Romanovs, A.; Grabis, J.; Teilans, A. A Multi-Model Approach for Simulation-Based Digital Twin in Resilient Services. WSEAS Trans. Syst. Control 2021, 16, 133–145. [Google Scholar] [CrossRef]

- Flumerfelt, S.; Alves, A.; Calvo-Amodio, J.; Hoyle, C.; Kahlen, F.-J. Managing Systems Complexity through Congruence. In Transdisciplinary Perspectives on Complex Systems: New Findings and Approaches; Springer International Publishing: Cham, Switzerland, 2016; pp. 115–144. ISBN 9783319387567. [Google Scholar]

- Aheleroff, S.; Polzer, J.; Huang, H.; Zhu, Z.; Tomzik, D.; Lu, Y.; Lin, Y.; Xu, X. Smart Manufacturing Based on Digital Twin Technologies. In Industry; CRC Press: Boca Raton, FL, USA, 2020; Volume 4, p. 77. [Google Scholar]

- Zheng, X.; Lu, J.; Kiritsis, D. The Emergence of Cognitive Digital Twin: Vision, Challenges and Opportunities. Int. J. Prod. Res. 2021. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Wang, K.I.-K.; Huang, H.; Xu, X. Digital Twin-Driven Smart Manufacturing: Connotation, Reference Model, Applications and Research Issues. Robot. Comput. Integr. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- Jaensch, F.; Csiszar, A.; Scheifele, C.; Verl, A. Digital Twins of Manufacturing Systems as a Base for Machine Learning. In Proceedings of the 2018 25th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Stuttgart, Germany, 20–22 November 2018; Xu, P., Csiszar, A., Verl, A., Eds.; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar]

- Zhang, Z.; Lu, J.; Xia, L.; Wang, S.; Zhang, H.; Zhao, R. Digital Twin System Design for Dual-Manipulator Cooperation Unit. In Proceedings of the 2020 IEEE 4th Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chongqing, China, 12–14 June 2020; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2020; pp. 1431–1434. [Google Scholar]

- Zhang, C.; Zhou, G.; He, J.; Li, Z.; Cheng, W. A Data-And Knowledge-Driven Framework for Digital Twin Manufacturing Cell. In Proceedings of the Procedia CIRP; Huang, G.Q., Qu, T., Thurer, M., Xu, S., Khalgui, M., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2019; Volume 83, pp. 345–350. [Google Scholar]

- Zhang, C.; Xu, W.; Liu, J.; Liu, Z.; Zhou, Z.; Pham, D.T. A Reconfigurable Modeling Approach for Digital Twin-Based Manufacturing System. In Proceedings of the Procedia CIRP; Huang, G.Q., Qu, T., Thurer, M., Xu, S., Khalgui, M., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2019; Volume 83, pp. 118–125. [Google Scholar]

- Zhang, C.; Xu, W.; Liu, J.; Liu, Z.; Zhou, Z.; Pham, D.T. Digital Twin-Enabled Reconfigurable Modeling for Smart Manufacturing Systems. Int. J. Comput. Integr. Manuf. 2019, 34, 1–25. [Google Scholar] [CrossRef]

- Stark, R.; Fresemann, C.; Lindow, K. Development and Operation of Digital Twins for Technical Systems and Services. CIRP Ann. 2019, 68, 129–132. [Google Scholar] [CrossRef]

- Uhlemann, T.H.-J.; Lehmann, C.; Steinhilper, R. The Digital Twin: Realizing the Cyber-Physical Production System for Industry 4.0. In Proceedings of the Procedia CIRP; Umeda, Y., Kondoh, S., Takata, S., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2017; Volume 61, pp. 335–340. [Google Scholar]

- Uhlemann, T.H.-J.; Schock, C.; Lehmann, C.; Freiberger, S.; Steinhilper, R. The Digital Twin: Demonstrating the Potential of Real Time Data Acquisition in Production Systems. In Proceedings of the Procedia Manufacturing; Elsevier B.V.: Amsterdam, The Netherlands, 2017; Volume 9, pp. 113–120. [Google Scholar]

- Redelinghuys, A.; Basson, A.; Kruger, K. A Six-Layer Digital Twin Architecture for a Manufacturing Cell. In Proceedings of the Studies in Computational Intelligence; Springer: Berlin/Heidelberg, Germany, 2019; Volume 803, pp. 412–423. [Google Scholar]

- Azangoo, M.; Taherkordi, A.; Blech, J.O.; Vyatkin, V. Digital Twin-Assisted Controlling of AGVs in Flexible Manufacturing Environments. In Proceedings of the IEEE International Symposium on Industrial Electronics, Kyoto, Japan, 20–23 June 2021; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2021; Volume 2021. [Google Scholar]

- Latifah, A.; Supangkat, S.H.; Ramelan, A.; Rahman, F.R.; Afandy, M. A Workspace Design Prediction: Concept Overview Using the Digital Twin. In Proceedings of the 8th International Conference on ICT for Smart Society: Digital Twin for Smart Society, ICISS 2021-Proceeding, Bandung, Indonesia, 2–4 August 2021; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2021. [Google Scholar]

- Zhang, H.; Zhang, G.; Yan, Q. Dynamic Resource Allocation Optimization for Digital Twin-Driven Smart Shopfloor. In Proceedings of the ICNSC 2018-15th IEEE International Conference on Networking, Sensing and Control, Zhuhai, China, 27–29 March 2018; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2018; pp. 1–5. [Google Scholar]

- Abburu, S.; Berre, A.J.; Jacoby, M.; Roman, D.; Stojanovic, L.; Stojanovic, N. COGNITWIN-Hybrid and Cognitive Digital Twins for the Process Industry. In Proceedings of the Proceedings-2020 IEEE International Conference on Engineering, Technology and Innovation, ICE/ITMC 2020, Cardiff, UK, 15–17 June 2020; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2020. [Google Scholar]

- Weyer, S.; Meyer, T.; Ohmer, M.; Gorecky, D.; Zühlke, D. Future Modeling and Simulation of CPS-Based Factories: An Example from the Automotive Industry. IFAC-PapersOnLine 2016, 49, 97–102. [Google Scholar] [CrossRef]

- Ayani, M.; Ganebäck, M.; Ng, A.H.C. Digital Twin: Applying Emulation for Machine Reconditioning. In Proceedings of the Procedia CIRP; Kjellberg, T., Wang, L., Ji, W., Wang, X.V., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2018; Volume 72, pp. 243–248. [Google Scholar]

- Erdős, G.; Paniti, I.; Tipary, B. Transformation of Robotic Workcells to Digital Twins. CIRP Ann. 2020, 69, 149–152. [Google Scholar] [CrossRef]

- Kousi, N.; Gkournelos, C.; Aivaliotis, S.; Giannoulis, C.; Michalos, G.; Makris, S. Digital Twin for Adaptation of Robots’ Behavior in Flexible Robotic Assembly Lines. In Proceedings of the Procedia Manuf. da Cunha, C., Bernard, A., Zah, M., ElMaraghy, W., ElMaraghy, H., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2019; Volume 28, pp. 121–126. [Google Scholar]

- Cai, Y.; Starly, B.; Cohen, P.; Lee, Y.-S. Sensor Data and Information Fusion to Construct Digital-Twins Virtual Machine Tools for Cyber-Physical Manufacturing. Procedia Manuf. 2017, 10, 1031–1042. [Google Scholar] [CrossRef]

- Nikolakis, N.; Alexopoulos, K.; Xanthakis, E.; Chryssolouris, G. The Digital Twin Implementation for Linking the Virtual Representation of Human-Based Production Tasks to Their Physical Counterpart in the Factory-Floor. Int. J. Comput. Integr. Manuf. 2019, 32, 1–12. [Google Scholar] [CrossRef]

- Guo, J.; Zhao, N.; Sun, L.; Zhang, S. Modular Based Flexible Digital Twin for Factory Design. J. Ambient Intell. Humaniz. Comput. 2019, 10, 1189–1200. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, X.; Xu, W.; Liu, A.; Zhou, Z.; Pham, D.T. Modeling of Digital Twin Workshop Based on Perception Data; Springer: Berlin/Heidelberg, Germany, 2017; Volume 10464 LNCS, p. 14. ISSN 03029743. ISBN 9783319652979. [Google Scholar]

- Mourtzis, D.; Doukas, M.; Bernidaki, D. Simulation in Manufacturing: Review and Challenges. In Proceedings of the Procedia CIRP; Sauer, O., Maropoulos, P., Constantinescu, C., Bauer, W., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2014; Volume 25, pp. 213–229. [Google Scholar]

- Haag, S.; Anderl, R. Digital Twin–Proof of Concept. Manuf. Lett. 2018, 15, 64–66. [Google Scholar] [CrossRef]

- Burghardt, A.; Szybicki, D.; Gierlak, P.; Kurc, K.; Pietruś, P.; Cygan, R. Programming of Industrial Robots Using Virtual Reality and Digital Twins. Appl. Sci. 2020, 10, 486. [Google Scholar] [CrossRef] [Green Version]

- Segura, Á.; Diez, H.V.; Barandiaran, I.; Arbelaiz, A.; Álvarez, H.; Simões, B.; Posada, J.; García-Alonso, A.; Ugarte, R. Visual Computing Technologies to Support the Operator 4.0. Comput. Ind. Eng. 2020, 139, 105550. [Google Scholar] [CrossRef]

- Kumar, S.; Arora, S.; Sahin, F. Speed and Separation Monitoring Using On-Robot Time-of-Flight Laser-Ranging Sensor Arrays. In Proceedings of the 2019 IEEE 15th International Conference on Automation Science and Engineering (CASE), Vancouver, BC, Canada, 22–26 August 2019; IEEE Computer Society: Washington, DC, USA, 2019; Volume 2019, pp. 1684–1691. [Google Scholar]

- Øvern, A. Industry 4.0-Digital Twins and OPC UA; Master Thesis, Norwegian University of Science and Technology: Trondheim, Norway, 2018. [Google Scholar]

- Kuts, V.; Otto, T.; Tähemaa, T.; Bondarenko, Y. Digital Twin Based Synchronised Control and Simulation of the Industrial Robotic Cell Using Virtual Reality. J. Mach. Eng. 2019, 19, 128–144. [Google Scholar] [CrossRef] [Green Version]

- Eyre, J.M.; Lanyon-Hogg, M.R.; Dodd, T.J.; Lockwood, A.J.; Freeman, C.; Scott, R.W. Demonstration of an Industrial Framework for an Implementation of a Process Digital Twin. In Proceedings of the ASME 2018 International Mechanical Engineering Congress and Exposition, Pittsburgh, PA, USA, 2018; American Society of Mechanical Engineers (ASME): New York, NY, USA, 2018; Volume 2. [Google Scholar]

- Dröder, K.; Bobka, P.; Germann, T.; Gabriel, F.; Dietrich, F. A Machine Learning-Enhanced Digital Twin Approach for Human-Robot-Collaboration. In Proceedings of the Procedia CIRP; Elsevier B.V.: Amsterdam, The Netherlands, 2018; Volume 76, pp. 187–192. [Google Scholar]

- Kuts, V.; Otto, T.; Tähemaa, T.; Bukhari, K.; Pataraia, T. Adaptive Industrial Robots Using Machine Vision. In Proceedings of the ASME 2018 International Mechanical Engineering Congress and Exposition, Pittsburgh, PA, USA, 2018; American Society of Mechanical Engineers (ASME): New York, NY, USA, 2018; Volume 2, pp. 1–8. [Google Scholar]

- Liu, Q.; Liu, Z.; Xu, W.; Tang, Q.; Zhou, Z.; Pham, D.T. Human-Robot Collaboration in Disassembly for Sustainable Manufacturing. Int. J. Prod. Res. 2019, 57, 4027–4044. [Google Scholar] [CrossRef]

- Tsarouchi, P.; Matthaiakis, A.-S.; Makris, S.; Chryssolouris, G. On a Human-Robot Collaboration in an Assembly Cell. Int. J. Comput. Integr. Manuf. 2017, 30, 580–589. [Google Scholar] [CrossRef] [Green Version]

- Sonkoly, B.; Nagy, B.G.; Doka, J.; Pelle, I.; Szabo, G.; Racz, S.; Czentye, J.; Toka, L. Cloud-Powered Digital Twins: Is It Reality? In Proceedings of the 2019 IEEE 8th International Conference on Cloud Networking (CloudNet), Coimbra, Portugal, 4–6 November 2019; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar]

- Liu, C.; Jiang, P.; Jiang, W. Web-Based Digital Twin Modeling and Remote Control of Cyber-Physical Production Systems. Robot. Comput. Integr. Manuf. 2020, 64, 101956. [Google Scholar] [CrossRef]

- Tsarouchi, P.; Makris, S.; Michalos, G.; Matthaiakis, A.-S.; Chatzigeorgiou, X.; Athanasatos, A.; Stefos, M.; Aivaliotis, P.; Chryssolouris, G. ROS Based Coordination of Human Robot Cooperative Assembly Tasks-An Industrial Case Study. In Proceedings of the Procedia CIRP; Erkoyuncu, J., Ed.; Elsevier B.V.: Amsterdam, The Netherlands, 2015; Volume 37, pp. 254–259. [Google Scholar]

- Kousi, N.; Gkournelos, C.; Aivaliotis, S.; Lotsaris, K.; Bavelos, A.C.; Baris, P.; Michalos, G.; Makris, S. Digital Twin for Designing and Reconfiguring Human–Robot Collaborative Assembly Lines. Appl. Sci. 2021, 11, 4620. [Google Scholar] [CrossRef]

- Guerra-Zubiaga, D.; Kuts, V.; Mahmood, K.; Bondar, A.; Nasajpour-Esfahani, N.; Otto, T. An Approach to Develop a Digital Twin for Industry 4.0 Systems: Manufacturing Automation Case Studies. Int. J. Comput. Integr. Manuf. 2021, 34, 933–949. [Google Scholar] [CrossRef]

- Sloretz, Floating Joints Fail #188, Issue #188/Robot_model/Ros. Available online: https://github.com/ros/robot_model/issues/188 (accessed on 16 October 2021).

- He, L.; Glogowski, P.; Lemmerz, K.; Kuhlenkötter, B.; Zhang, W. Method to Integrate Human Simulation into Gazebo for Human-Robot Collaboration. In Proceedings of IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing: Bristol, UK, 2020; Volume 825, pp. 1–8. [Google Scholar]

- Oyekan, J.O.; Hutabarat, W.; Tiwari, A.; Grech, R.; Aung, M.H.; Mariani, M.P.; López-Dávalos, L.; Ricaud, T.; Singh, S.; Dupuis, C. The Effectiveness of Virtual Environments in Developing Collaborative Strategies between Industrial Robots and Humans. Robot. Comput. Integr. Manuf. 2019, 55, 41–54. [Google Scholar] [CrossRef]

- Lee, H.; Liau, Y.Y.; Kim, S.; Ryu, K. Model-Based Human Robot Collaboration System for Small Batch Assembly with a Virtual Fence. Int. J. Precis. Eng. Manuf. 2020, 7, 609–623. [Google Scholar] [CrossRef]

- Darmoul, S.; Abidi, M.H.; Ahmad, A.; Al-Ahmari, A.M.; Darwish, S.M.; Hussein, H.M.A. Virtual Reality for Manufacturing: A Robotic Cell Case Study. In Proceedings of the 2015 International Conference on Industrial Engineering and Operations Management (IEOM), Dubai, United Arab Emirates, 3–5 March 2015; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2015; pp. 1–7. [Google Scholar]

- Blaga, A.; Tamas, L. Augmented Reality for Digital Manufacturing. In Proceedings of the MED-Mediterranean Conference on Control and Automation; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2018; pp. 173–178. [Google Scholar]

- Kuts, V.; Modoni, G.E.; Terkaj, W.; Tähemaa, T.; Sacco, M.; Otto, T. Exploiting Factory Telemetry to Support Virtual Reality Simulation in Robotics Cell; Springer: Berlin/Heidelberg, Germany, 2017; Volume 10324 LNCS, p. 221. ISSN 03029743. ISBN 9783319609218. [Google Scholar]

- Michalos, G.; Makris, S.; Spiliotopoulos, J.; Misios, I.; Tsarouchi, P.; Chryssolouris, G. ROBO-PARTNER: Seamless Human-Robot Cooperation for Intelligent, Flexible and Safe Operations in the Assembly Factories of the Future. In Proceedings of the Procedia CIRP; Putz, M., Ed.; Elsevier B.V.: Amsterdam, The Netherlands, 2014; Volume 23, pp. 71–76. [Google Scholar]

- Makris, S.; Karagiannis, P.; Koukas, S.; Matthaiakis, A.-S. Augmented Reality System for Operator Support in Human–Robot Collaborative Assembly. CIRP Ann. Manuf. Technol. 2016, 65, 61–64. [Google Scholar] [CrossRef]

- Caputo, F.; Greco, A.; D’Amato, E.; Notaro, I.; Spada, S. On the Use of Virtual Reality for a Human-Centered Workplace Design. In Proceedings of the Procedia Structural Integrity; Amodio, D., Bruno, L., Iacoviello, F., Mirone, G., Arcidiacono, G., Bonora, N., Frendo, F., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2018; Volume 8, pp. 297–308. [Google Scholar]

- Liu, H.; Wang, L. Remote Human–Robot Collaboration: A Cyber–Physical System Application for Hazard Manufacturing Environment. J. Manuf. Syst. 2020, 54, 24–34. [Google Scholar] [CrossRef]

- Schluse, M.; Atorf, L.; Rossmann, J. Experimentable Digital Twins for Model-Based Systems Engineering and Simulation-Based Development. In Proceedings of the 2017 Annual IEEE International Systems Conference (SysCon), Montreal, QC, Canada, 24–27 April 2017; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2017. [Google Scholar]

- Cheng, Y.; Zhang, Y.; Ji, P.; Xu, W.; Zhou, Z.; Tao, F. Cyber-Physical Integration for Moving Digital Factories Forward towards Smart Manufacturing: A Survey. Int. J. Adv. Manuf. Technol. 2018, 97, 1209–1221. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The Future of Manufacturing Industry: A Strategic Roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef] [Green Version]

- Ponomarev, K.; Kudryashov, N.; Popelnukha, N.; Potekhin, V. Main Principals and Issues of Digital Twin Development for Complex Technological Processes. In Proceedings of the 28th International DAAAM Symposium Zadar, Croatia, 8–11 November 2017; Katalinic, B., Ed.; Danube Adria Association for Automation and Manufacturing, DAAAM International: Vienna, Austria; pp. 523–528. [Google Scholar]

- Erkoyuncu, J.A.; del Amo, I.F.; Ariansyah, D.; Bulka, D.; Vrabič, R.; Roy, R. A Design Framework for Adaptive Digital Twins. CIRP Ann. 2020, 69, 145–148. [Google Scholar] [CrossRef]

- Freedy, A.; DeVisser, E.; Weltman, G.; Coeyman, N. Measurement of Trust in Human-Robot Collaboration. In Proceedings of the 2007 International Symposium on Collaborative Technologies and Systems, Orlando, FL, USA, 21–25 May 2007; IEEE: Piscatway, NJ, USA, 2007; pp. 106–114. [Google Scholar]

- Chen, M.; Nikolaidis, S.; Soh, H.; Hsu, D.; Srinivasa, S. Planning with Trust for Human-Robot Collaboration. In Proceedings of the 2018 ACM/IEEE International Conference on Human-Robot Interaction, Chicago, IL, USA, 5–8 March 2018; IEEE Computer Society: Washington, DC, USA, 2018; pp. 307–315. [Google Scholar]

- Michalos, G.; Kousi, N.; Karagiannis, P.; Gkournelos, C.; Dimoulas, K.; Koukas, S.; Mparis, K.; Papavasileiou, A.; Makris, S. Seamless Human Robot Collaborative Assembly—An Automotive Case Study. Mechatronics 2018, 55, 194–211. [Google Scholar] [CrossRef]

- Nikolakis, N.; Maratos, V.; Makris, S. A Cyber Physical System (CPS) Approach for Safe Human-Robot Collaboration in a Shared Workplace. Robot. Comput. Integr. Manuf. 2019, 56, 233–243. [Google Scholar] [CrossRef]

- Wang, P.; Liu, H.; Wang, L.; Gao, R.X. Deep Learning-Based Human Motion Recognition for Predictive Context-Aware Human-Robot Collaboration. CIRP Ann. 2018, 67, 17–20. [Google Scholar] [CrossRef]

- Petković, T.; Puljiz, D.; Marković, I.; Hein, B. Human Intention Estimation Based on Hidden Markov Model Motion Validation for Safe Flexible Robotized Warehouses. Robot. Comput. Integr. Manuf. 2019, 57, 182–196. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Wang, L. Human Motion Prediction for Human-Robot Collaboration. J. Manuf. Syst. 2017, 44, 287–294. [Google Scholar] [CrossRef]

- Wang, L.; Gao, R.; Váncza, J.; Krüger, J.; Wang, X.V.; Makris, S.; Chryssolouris, G. Symbiotic Human-Robot Collaborative Assembly. CIRP Ann. 2019, 68, 701–726. [Google Scholar] [CrossRef] [Green Version]

- Dombrowski, U.; Stefanak, T.; Perret, J. Interactive Simulation of Human-Robot Collaboration Using a Force Feedback Device. Procedia Manuf. 2017, 11, 124–131. [Google Scholar] [CrossRef]

- Halme, R.-J.; Lanz, M.; Kämäräinen, J.; Pieters, R.; Latokartano, J.; Hietanen, A. Review of Vision-Based Safety Systems for Human-Robot Collaboration. In Proceedings of the Procedia CIRP; Kjellberg, T., Wang, L., Ji, W., Wang, X.V., Eds.; Elsevier B.V.: Stockholm, Sweden, 2018; Volume 72, pp. 111–116. [Google Scholar]

- Wang, Y.; Ye, X.; Yang, Y.; Zhang, W. Collision-Free Trajectory Planning in Human-Robot Interaction through Hand Movement Prediction from Vision. In Proceedings of the 2017 IEEE-RAS 17th International Conference on Humanoid Robotics (Humanoids), Birmingham, UK, 15–17 November 2017; IEEE Computer Society: Washington, DC, USA, 2017; pp. 305–310. [Google Scholar]

- Mohammed, A.; Schmidt, B.; Wang, L. Active Collision Avoidance for Human–Robot Collaboration Driven by Vision Sensors. Int. J. Comput. Integr. Manuf. 2017, 30, 970–980. [Google Scholar] [CrossRef]

- Horváth, G.; Erdos, G. Gesture Control of Cyber Physical Systems. In Proceedings of the Procedia CIRP; Wang, Y., Tseng, M.M., Tsai, H.-Y., Eds.; Elsevier B.V.: Taichung, Taiwan, 2017; Volume 63, pp. 184–188. [Google Scholar]

- Li, G.; Liu, Z.; Cai, L.; Yan, J. Standing-Posture Recognition in Human–Robot Collaboration Based on Deep Learning and the Dempster–Shafer Evidence Theory. Sensors 2020, 20, 1158. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, X.; Pan, J. Considering Human Behavior in Motion Planning for Smooth Human-Robot Collaboration in Close Proximity. In Proceedings of the 2017 IEEE-RAS 17th International Conference on Humanoid Robotics (Humanoids), Birmingham, UK, 15–17 November 2017; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2018; pp. 985–990. [Google Scholar]

- Zanchettin, A.M.; Ceriani, N.M.; Rocco, P.; Ding, H.; Matthias, B. Safety in Human-Robot Collaborative Manufacturing Environments: Metrics and Control. IEEE Trans. Autom. Sci. Eng. 2016, 13, 882–893. [Google Scholar] [CrossRef] [Green Version]

- Salem, M.; Lakatos, G.; Amirabdollahian, F.; Dautenhahn, K. Towards Safe and Trustworthy Social Robots: Ethical Challenges and Practical Issues; Springer: Berlin/Heidelberg, Germany, 2015; Volume 9388 LNCS, p. 593. ISSN 03029743. [Google Scholar]

- Koppenborg, M.; Nickel, P.; Naber, B.; Lungfiel, A.; Huelke, M. Effects of Movement Speed and Predictability in Human–Robot Collaboration. Hum. Factors Ergon. Manuf. 2017, 27, 197–209. [Google Scholar] [CrossRef]

- Gavriushenko, M.; Kaikova, O.; Terziyan, V. Bridging Human and Machine Learning for the Needs of Collective Intelligence Development. In Proceedings of the Procedia Manufacturing; Longo, F., Qiao, F., Padovano, A., Eds.; Elsevier B.V.: Amsterdam, The Netherlands, 2020; Volume 42, pp. 302–306. [Google Scholar]

- Li, Z.; Wang, K.; He, Y. Industry 4.0-Potentials for Predictive Maintenance. In Proceedings of the Advances in Economics, Business and Management Research; Atlantis Press: Paris, France, 2016; pp. 42–46. [Google Scholar]

- Luo, W.; Hu, T.; Ye, Y.; Zhang, C.; Wei, Y. A Hybrid Predictive Maintenance Approach for CNC Machine Tool Driven by Digital Twin. Robot. Comput. Integr. Manuf. 2020, 65, 1–19. [Google Scholar] [CrossRef]

- Aivaliotis, P.; Georgoulias, K.; Alexopoulos, K. Using Digital Twin for Maintenance Applications in Manufacturing: State of the Art and Gap Analysis. In Proceedings of the 2019 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Valbonne Sophia-Antipolis, France, 17–19 June 2019; Institute of Electrical and Electronics Engineers Inc.: Valbonne Sophia-Antipolis, France, 2019; pp. 1–5. [Google Scholar]

- Vathoopan, M.; Johny, M.; Zoitl, A.; Knoll, A. Modular Fault Ascription and Corrective Maintenance Using a Digital Twin. IFAC-PapersOnLine 2018, 51, 1041–1046. [Google Scholar] [CrossRef]

- Liu, Z.; Meyendorf, N.; Mrad, N. The Role of Data Fusion in Predictive Maintenance Using Digital Twin. In Proceedings of the AIP Conference, San Sebastian, Spain, 17–20 October 2018; Chimenti, D.E., Bond, L.J., Eds.; American Institute of Physics Inc.: Provo, UT, USA, 2018; Volume 1949. [Google Scholar]

- Detzner, A.; Eigner, M. A Digital Twin for Root Cause Analysis and Product Quality Monitoring. In Proceedings of the 15th International Design Conference, Dubrovnik, Croatia, 21–24 May 2018; Volume 4, pp. 1547–1558. [Google Scholar]

- Milton, M.; De La, C.O.; Ginn, H.L.; Benigni, A. Controller-Embeddable Probabilistic Real-Time Digital Twins for Power Electronic Converter Diagnostics. IEEE Trans. Power Electron. 2020, 35, 9852–9866. [Google Scholar] [CrossRef]

- Bohlin, R.; Hagmar, J.; Bengtsson, K.; Lindkvist, L.; Carlson, J.S.; Söderberg, R. Data Flow and Communication Framework Supporting Digital Twin for Geometry Assurance. In Proceedings of the ASME 2017 International Mechanical Engineering Congress and Exposition, Tampa, FL, USA, 3–9 November 2017; American Society of Mechanical Engineers (ASME): New York, NY, USA, 2018; Volume 2, pp. 1–7. [Google Scholar]

- Lee, H.; Kim, T. Smart Factory Use Case Model Based on Digital Twin. ICIC Express Lett. Part B Appl. 2018, 9, 931–936. [Google Scholar] [CrossRef]

- Gašpar, T.; Deniša, M.; Radanovič, P.; Ridge, B.; Savarimuthu, T.R.; Kramberger, A.; Priggemeyer, M.; Roßmann, J.; Wörgötter, F.; Ivanovska, T.; et al. Smart Hardware Integration with Advanced Robot Programming Technologies for Efficient Reconfiguration of Robot Workcells. Robot. Comput. Integr. Manuf. 2020, 66, 101979. [Google Scholar] [CrossRef]

- Sierla, S.; Kyrki, V.; Aarnio, P.; Vyatkin, V. Automatic Assembly Planning Based on Digital Product Descriptions. Comput. Ind. 2018, 97, 34–46. [Google Scholar] [CrossRef]

- Ellgass, W.; Richmond, J.; Holt, N.; Barenji, A.V.; Saldana-Lemus, H.; Gonzalez-Badillo, G. A Digital Twin Concept for Manufacturing Systems. In Proceedings of the ASME 2018 International Mechanical Engineering Congress and Exposition, Pittsburgh, PA, USA, 9–15 November 2018; American Society of Mechanical Engineers (ASME): Pittsburgh, PA, USA, 2018; Volume 2. [Google Scholar]

- Biesinger, F.; Meike, D.; Kraß, B.; Weyrich, M. A Digital Twin for Production Planning Based on Cyber-Physical Systems: A Case Study for a Cyber-Physical System-Based Creation of a Digital Twin. In Proceedings of the Procedia CIRP; Teti, R., Ed.; Elsevier B.V.: Amsterdam, The Netherlands, 2019; Volume 79, pp. 355–360. [Google Scholar]

- Hazbar, T.; Kumar, S.; Sahin, F. Cyber-Physical Testbed for Human-Robot Collaborative Task Planning and Execution. arXiv 2019, arXiv:1905.00199. [Google Scholar]

- Havard, V.; Jeanne, B.; Lacomblez, M.; Baudry, D. Digital Twin and Virtual Reality: A Co-Simulation Environment for Design and Assessment of Industrial Workstations. Prod. Manuf. Res. 2019, 7, 472–489. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Zheng, P.; Li, S.; Pang, Y.; Lee, C.K.M. AR-Assisted Digital Twin-Enabled Robot Collaborative Manufacturing System with Human-in-the-Loop. Robot. Comput. Integr. Manuf. 2022, 76, 102321. [Google Scholar] [CrossRef]

- Berg, L.P.; Vance, J.M. Industry Use of Virtual Reality in Product Design and Manufacturing: A Survey. Virtual Real. 2017, 21, 1–17. [Google Scholar] [CrossRef]

- Turner, C.J.; Hutabarat, W.; Oyekan, J.; Tiwari, A. Discrete Event Simulation and Virtual Reality Use in Industry: New Opportunities and Future Trends. IEEE Trans. Hum. Mach. Syst. 2016, 46, 882–894. [Google Scholar] [CrossRef] [Green Version]

- Durão, L.F.C.S.; Haag, S.; Anderl, R.; Schützer, K.; Zancul, E. Digital Twin Requirements in the Context of Industry 4.0. In Proceedings of the IFIP Advances in Information and Communication Technology; Springer: New York, NY, USA, 2018; Volume 540, pp. 204–214. [Google Scholar]

- Um, J.; Weyer, S.; Quint, F. Plug-and-Simulate within Modular Assembly Line Enabled by Digital Twins and the Use of AutomationML; Elsevier B.V.: Amsterdam, The Netherlands, 2017; Volume 50, pp. 15904–15909. [Google Scholar]

- West, T.D.; Blackburn, M. Is Digital Thread/Digital Twin Affordable? A Systemic Assessment of the Cost of DoD’s Latest Manhattan Project. Procedia Comput. Sci. 2017, 114, 47–56. [Google Scholar] [CrossRef]

- Nurturing Digital Twins: How to Build Virtual Instances of Physical Assets to Boost Performance; Cognizant: Teaneck, NJ, USA, 2019; Available online: https://www.cognizant.com/us/en/whitepapers/documents/nurturing-digital-twins-codex4653.pdf (accessed on 31 March 2022).

- Müller, V.C.; Bostrom, N. Future Progress in Artificial Intelligence: A Survey of Expert Opinion. In Fundamental Issues of Artificial Intelligence; Müller, V.C., Ed.; Springer International Publishing: Cham, Switzerland, 2016; pp. 555–572. ISBN 978-3-319-26483-7. [Google Scholar]

- Uhlenkamp, J.-F.; Hribernik, K.; Wellsandt, S.; Thoben, K.-D. Digital Twin Applications: A First Systemization of Their Dimensions. In Proceedings of the 2019 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), albonne Sophia-Antipolis, France, 17–19 June 2019; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2019; pp. 1–8. [Google Scholar]

- Zheng, P.; Sivabalan, A.S. A Generic Tri-Model-Based Approach for Product-Level Digital Twin Development in a Smart Manufacturing Environment. Robot. Comput. Integr. Manuf. 2020, 64, 1–12. [Google Scholar] [CrossRef]

- Cerrone, A.; Hochhalter, J.; Heber, G.; Ingraffea, A. On the Effects of Modeling As-Manufactured Geometry: Toward Digital Twin. Int. J. Aerosp. Eng. 2014, 2014, 1–10. [Google Scholar] [CrossRef]

- Tao, F.; Liu, W.; Liu, J.; Liu, X.; Liu, Q.; Qu, T.; Hu, T.; Zhang, Z.; Xiang, F.; Xu, W.; et al. Digital twin and its potential application exploration. Comput. Integr. Manuf. Syst. 2018, 24, 1–18. [Google Scholar] [CrossRef]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the Art and Future Trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef] [Green Version]

- Tsuchiya, A.; Fraile, F.; Koshijima, I.; Órtiz, A.; Poler, R. Software Defined Networking Firewall for Industry 4.0 Manufacturing Systems. J. Ind. Eng. Manag. 2018, 11, 318–333. [Google Scholar] [CrossRef] [Green Version]

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards Future Industrial Opportunities and Challenges. In Proceedings of the 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; Tang, Z., Du, J., Yin, S., Li, R., He, L., Eds.; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2016; pp. 2147–2152. [Google Scholar]

- Wärmefjord, K.; Söderberg, R.; Lindkvist, L.; Lindau, B.; Carlson, J.S. Inspection Data to Support a Digital Twin for Geometry Assurance. In Proceedings of the ASME 2017 International Mechanical Engineering Congress and Exposition, Tampa, FL, USA, 3–9 November 2017; American Society of Mechanical Engineers (ASME): Tampa, FL, USA, 2018; Volume 2. [Google Scholar]

- Eaton, M. Bridging the Reality Gap—A Dual Simulator Approach to the Evolution of Whole-Body Motion for the Nao Humanoid Robot. In Proceedings of the 8th International Joint Conference on Computational Intelligence; SCITEPRESS-Science and Technology Publications: Porto, Portugal, 2016; pp. 186–192. [Google Scholar]

- Hanna, J.P.; Desai, S.; Karnan, H.; Warnell, G.; Stone, P. Grounded Action Transformation for Sim-to-Real Reinforcement Learning. Mach. Learn. 2021, 110, 2469–2499. [Google Scholar] [CrossRef]

- Desai, S.; Karnan, H.; Hanna, J.P.; Warnell, G.; Stone, A.P. Stochastic Grounded Action Transformation for Robot Learning in Simulation. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Las Vegas, NV, USA, 24 October–24 January 2021; Institute of Electrical and Electronics Engineers Inc.: Las Vegas, NV, USA, 2020; pp. 6106–6111. [Google Scholar]

- Karnan, H.; Desai, S.; Hanna, J.P.; Warnell, G.; Stone, P. Reinforced Grounded Action Transformation for Sim-to-Real Transfer. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Las Vegas, NV, USA, 24 October–24 January 2021; Institute of Electrical and Electronics Engineers Inc.: Las Vegas, NV, USA, 2020; pp. 4397–4402. [Google Scholar]

- Collins, J.; Howard, D.; Leitner, J. Quantifying the Reality Gap in Robotic Manipulation Tasks. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 24 October–24 January 2021; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2019; Volume 2019, pp. 6706–6712. [Google Scholar]

- Chung, S.-J.; Pollard, N. Predictable Behavior during Contact Simulation: A Comparison of Selected Physics Engines. Comput. Animat. Virtual Worlds 2016, 27, 262–270. [Google Scholar] [CrossRef]

- Horak, P.C.; Trinkle, J.C. On the Similarities and Differences Among Contact Models in Robot Simulation. IEEE Robot. Autom. Lett. 2019, 4, 493–499. [Google Scholar] [CrossRef]

- Collins, J.; Chand, S.; Vanderkop, A.; Howard, D. A Review of Physics Simulators for Robotic Applications. IEEE Access 2021, 9, 51416–51431. [Google Scholar] [CrossRef]

- Mouret, J.-B.; Chatzilygeroudis, K. 20 Years of Reality Gap: A Few Thoughts about Simulators in Evolutionary Robotics. In Proceedings of the Genetic and Evolutionary Computation Conference Companion; Association for Computing Machinery: New York, NY, USA, 2017; pp. 1121–1124. [Google Scholar]

- Ding, K.; Chan, F.T.S.; Zhang, X.; Zhou, G.; Zhang, F. Defining a Digital Twin-Based Cyber-Physical Production System for Autonomous Manufacturing in Smart Shop Floors. Int. J. Prod. Res. 2019, 57, 6315–6334. [Google Scholar] [CrossRef] [Green Version]

- Pires, F.; Cachada, A.; Barbosa, J.; Moreira, A.P.; Leitao, P. Digital Twin in Industry 4.0: Technologies, Applications and Challenges. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN), Helsinki, Finland, 22–25 July 2019; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2019; Volume 2019, pp. 721–726. [Google Scholar]

- Rodič, B. Industry 4.0 and the New Simulation Modelling Paradigm. Organizacija 2017, 50, 193–207. [Google Scholar] [CrossRef] [Green Version]

- Rojko, A. Industry 4.0 Concept: Background and Overview. Int. J. Interact. Mob. Technol. 2017, 11, 77–90. [Google Scholar] [CrossRef] [Green Version]

- Heydaryan, S.; Bedolla, J.S.; Belingardi, G. Safety Design and Development of a Human-Robot Collaboration Assembly Process in the Automotive Industry. Appl. Sci. 2018, 8, 1–22. [Google Scholar] [CrossRef] [Green Version]

- Immerman, D. What Is the Business Value of Digital Twin?|PTC. Available online: https://www.ptc.com/en/blogs/corporate/what-is-business-value-digital-twin (accessed on 16 October 2021).

- Marr, B. What Is Digital Twin Technology—And Why Is It So Important? Available online: https://www.forbes.com/sites/bernardmarr/2017/03/06/what-is-digital-twin-technology-and-why-is-it-so-important/ (accessed on 16 October 2021).

- Connolly, M.; Ramasubramanian, A.K.; Kelly, M.; McEvoy, J.; Papakostas, N. Realistic Simulation of Robotic Grasping Tasks: Review and Application. Procedia CIRP 2021, 104, 1704–1709. [Google Scholar] [CrossRef]

- Li, S.; Xu, L.D.; Zhao, S. 5G Internet of Things: A Survey. J. Ind. Infor. Integr. 2018, 10, 1–9. [Google Scholar] [CrossRef]

- Szabo, G.; Racz, S.; Reider, N.; Munz, H.A.; Peto, J. Digital Twin: Network Provisioning of Mission Critical Communication in Cyber Physical Production Systems. In Proceedings of the 2019 IEEE International Conference on Industry 4.0, Artificial Intelligence, and Communications Technology (IAICT), Bali, Indonesia, 1–3 July 2019; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2019; pp. 37–43. [Google Scholar]

- Munz, H.; Reider, N.; Rácz, S.; Szabó, G. What Will 5G Bring to Industrial Robotics? Available online: https://www.ericsson.com/en/blog/2018/12/what-will-5g-bring-to-industrial-robotics (accessed on 16 October 2021).

- Wong, K. Connecting the Thread: 5G. Available online: https://www.digitalengineering247.com/article/connecting-the-thread-5g (accessed on 16 October 2021).

| Strategies and Technologies | Conceptual Frame Work | Use Case | Implementation/Demonstration |

|---|---|---|---|

| Digital thread based approach | [23,59] | [60] | |

| Hardware in the loop simulation | [63] | [68,73] | [61,62] |

| Software in the loop simulation | [68] | [74] | [66,67,69,75,76] |

| AR and VR | [69,70] | ||

| Data-oriented approach | [65,77] | ||

| DT of manufacturing process | [58,68,73] | [62,69] | |

| Digital factory | [66,73] | [76] | |

| HRC | [63] | [69,70] | |

| Sensor technology | [58] | [69] | |

| Task planning | [73,74] | [70] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramasubramanian, A.K.; Mathew, R.; Kelly, M.; Hargaden, V.; Papakostas, N. Digital Twin for Human–Robot Collaboration in Manufacturing: Review and Outlook. Appl. Sci. 2022, 12, 4811. https://doi.org/10.3390/app12104811

Ramasubramanian AK, Mathew R, Kelly M, Hargaden V, Papakostas N. Digital Twin for Human–Robot Collaboration in Manufacturing: Review and Outlook. Applied Sciences. 2022; 12(10):4811. https://doi.org/10.3390/app12104811

Chicago/Turabian StyleRamasubramanian, Aswin K., Robins Mathew, Matthew Kelly, Vincent Hargaden, and Nikolaos Papakostas. 2022. "Digital Twin for Human–Robot Collaboration in Manufacturing: Review and Outlook" Applied Sciences 12, no. 10: 4811. https://doi.org/10.3390/app12104811

APA StyleRamasubramanian, A. K., Mathew, R., Kelly, M., Hargaden, V., & Papakostas, N. (2022). Digital Twin for Human–Robot Collaboration in Manufacturing: Review and Outlook. Applied Sciences, 12(10), 4811. https://doi.org/10.3390/app12104811