The Research of 30 mm Detecting Distance of Testing Device for Wire Rope Based on Open Magnetizer

Abstract

:1. Introduction

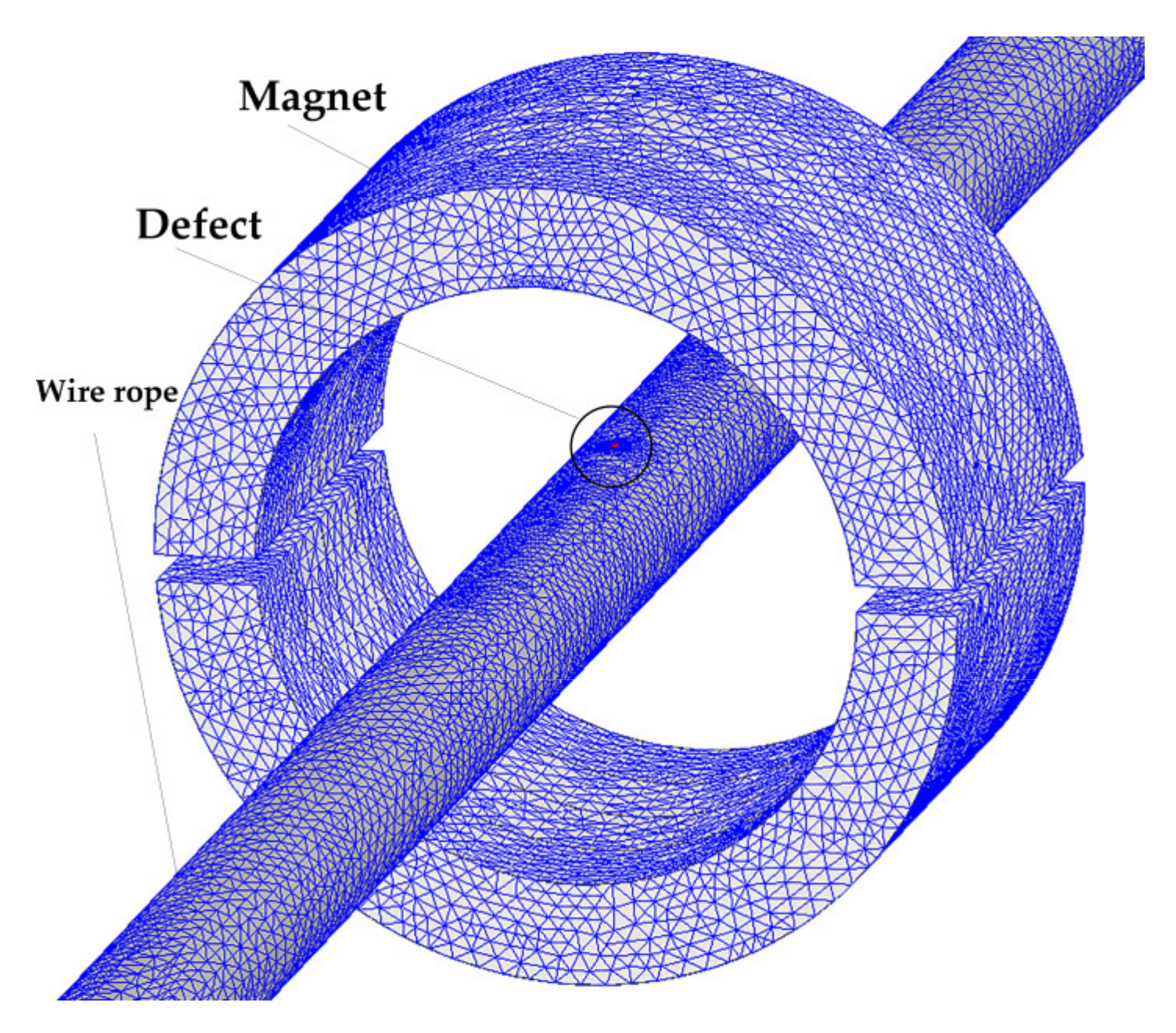

2. Magnetizer Modeling and Simulation Analysis

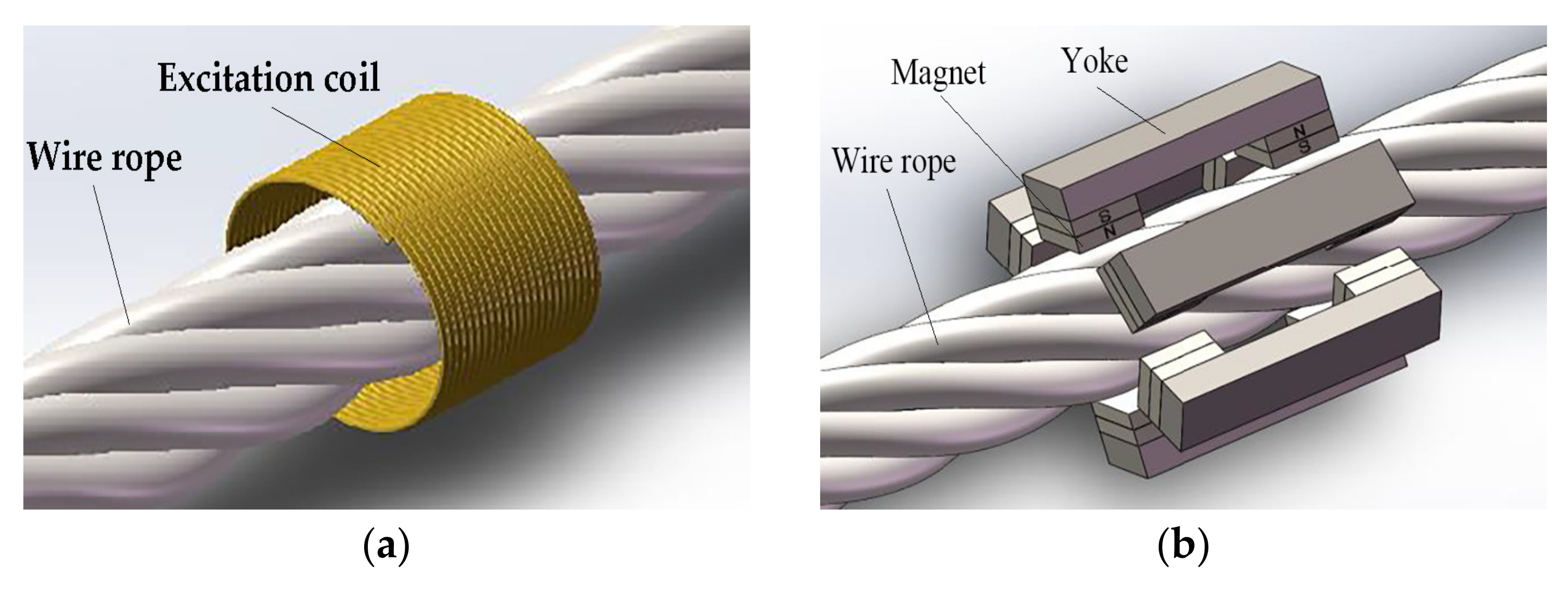

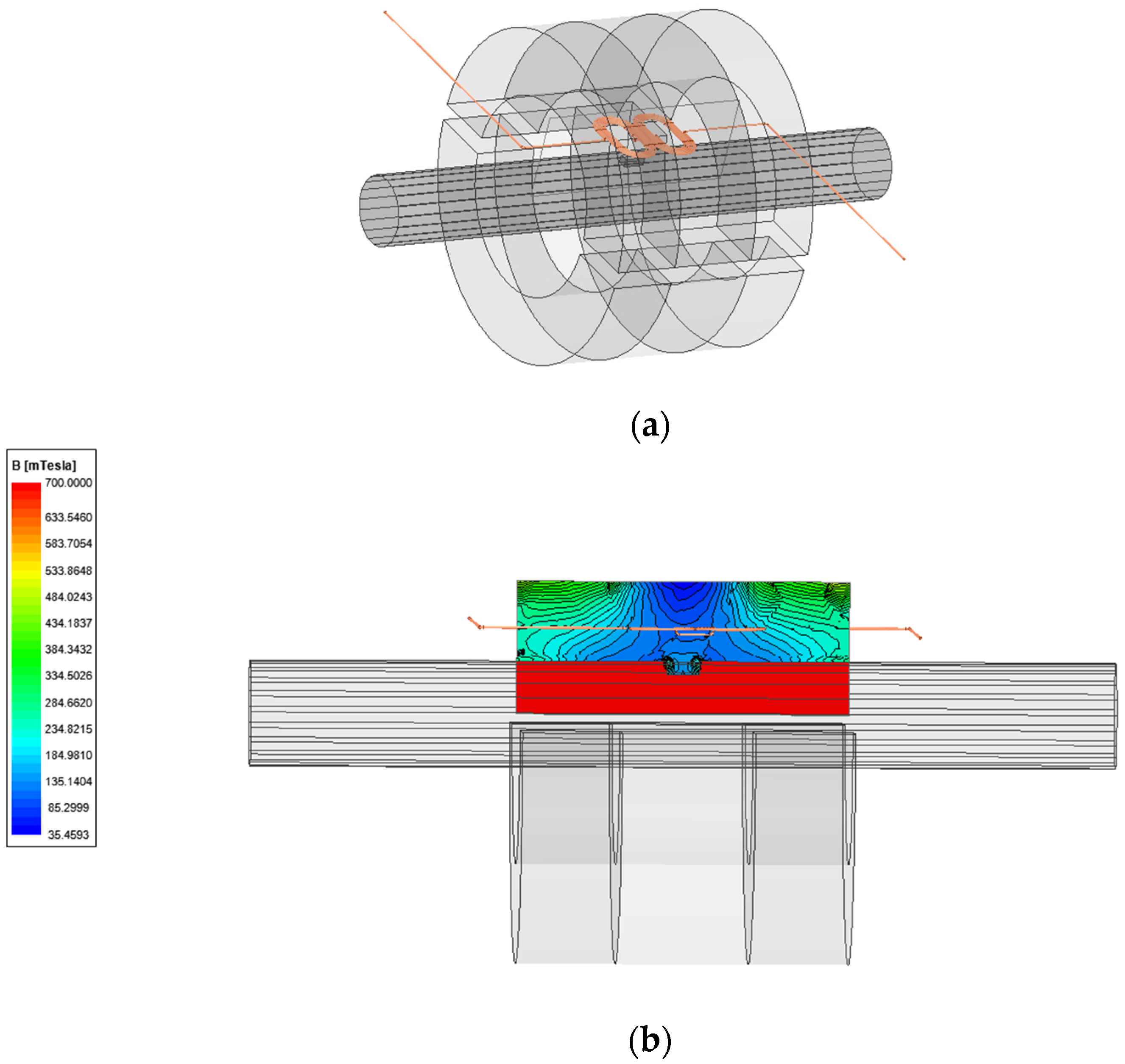

2.1. Open Permanent Magnetizer

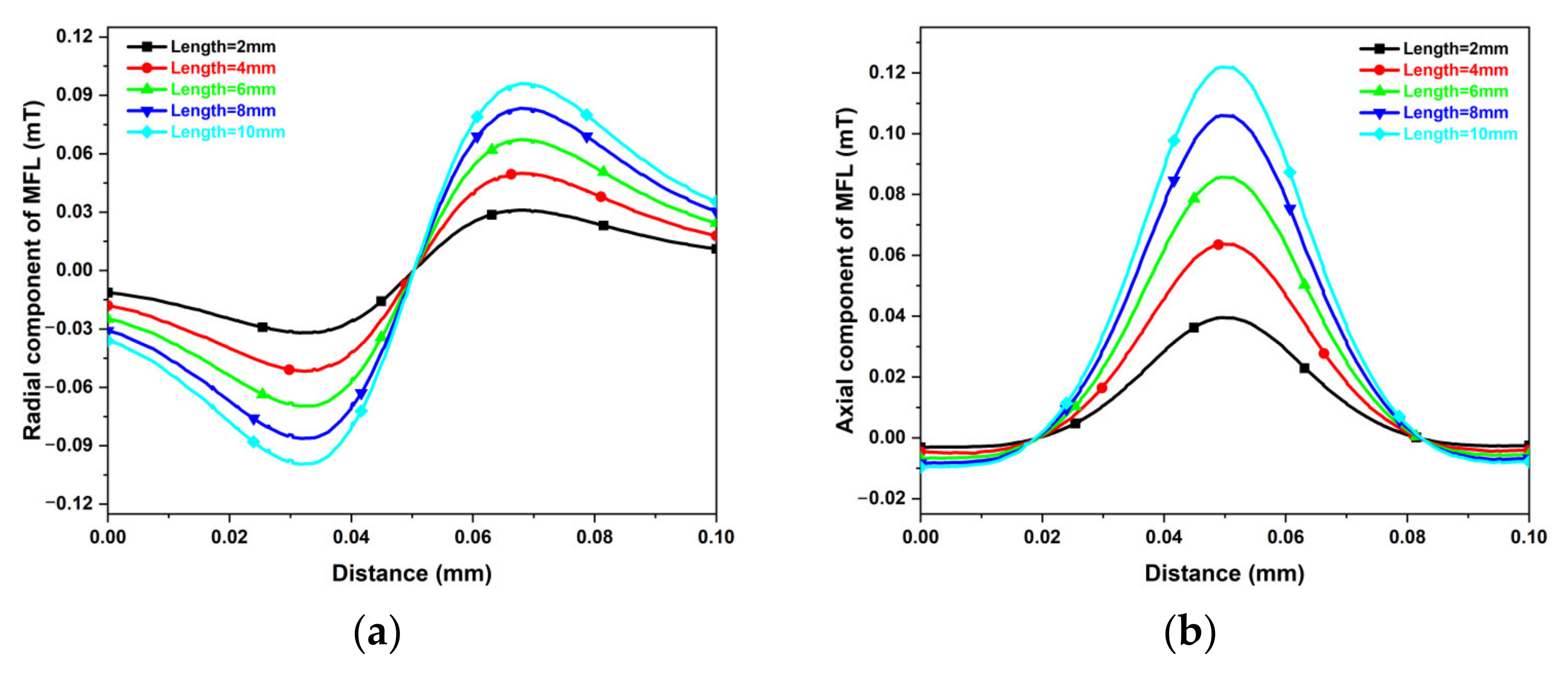

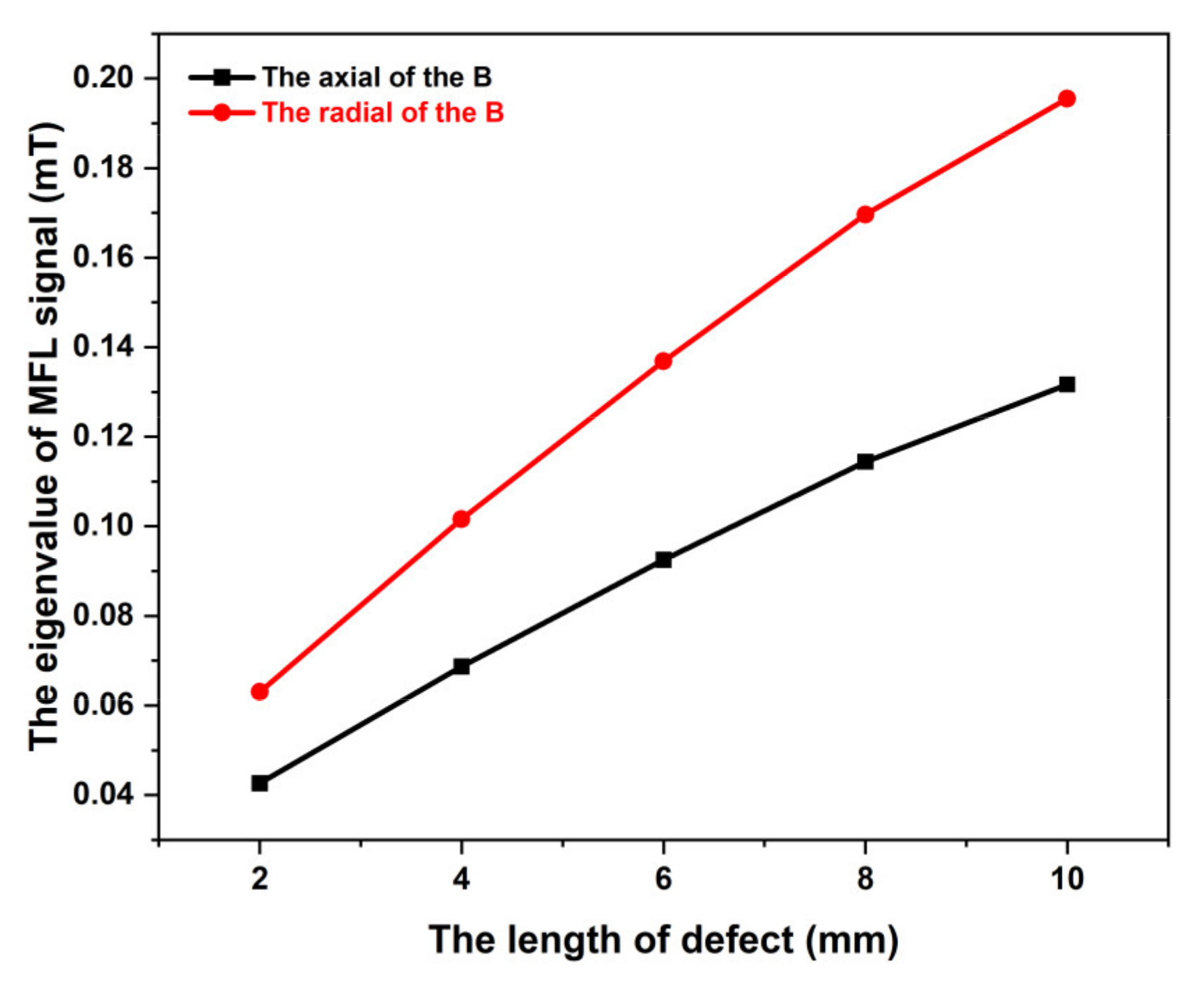

2.2. Analysis of the Feasibility of Large Lift-Off

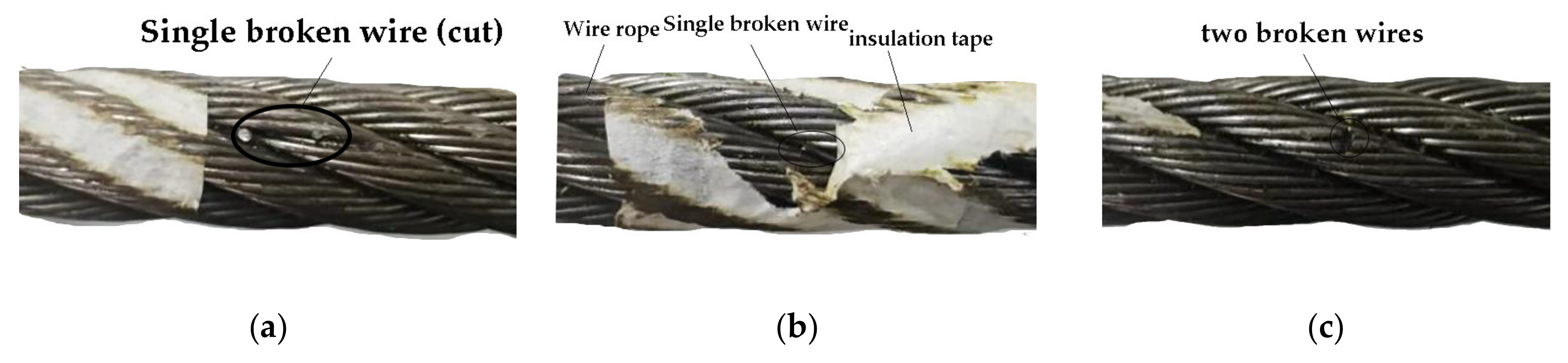

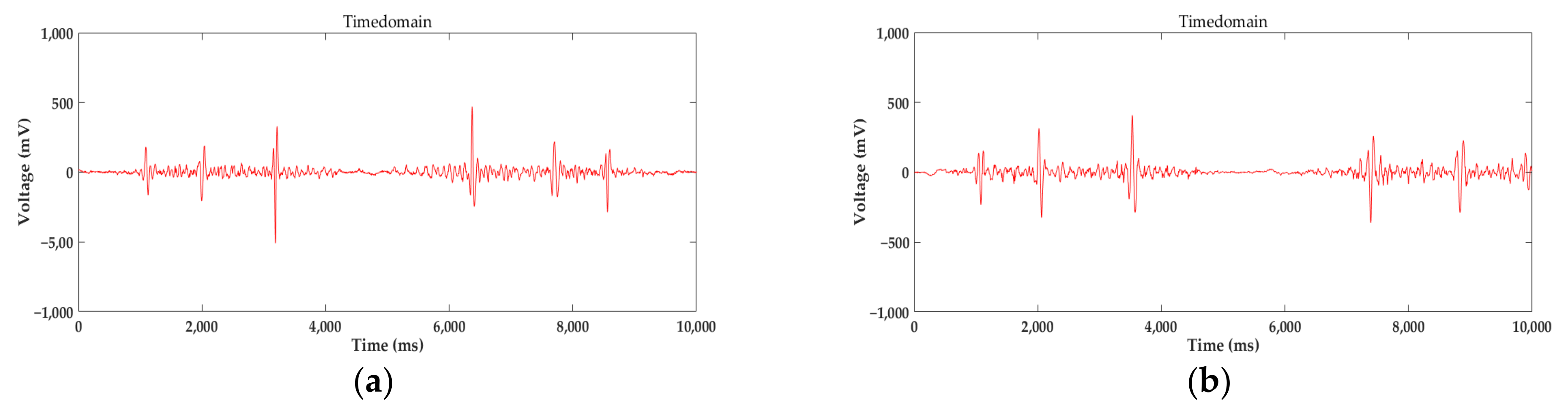

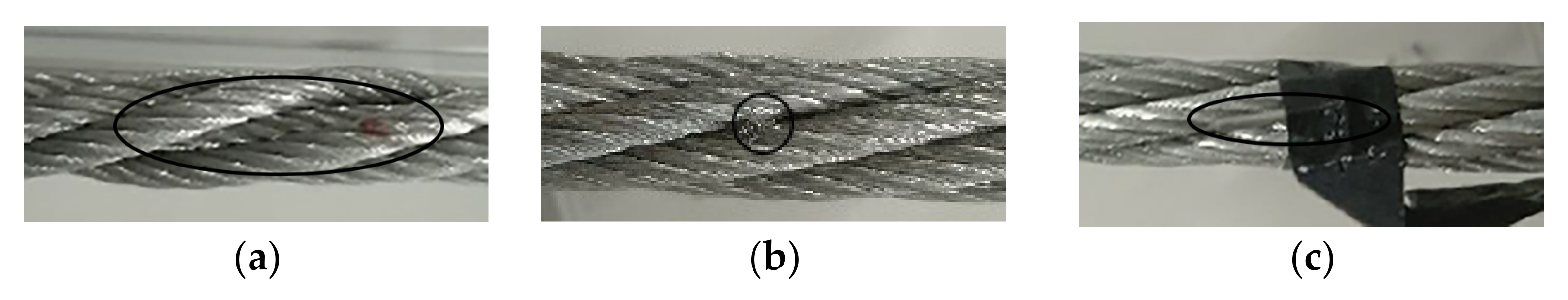

2.3. Preliminary Experiment

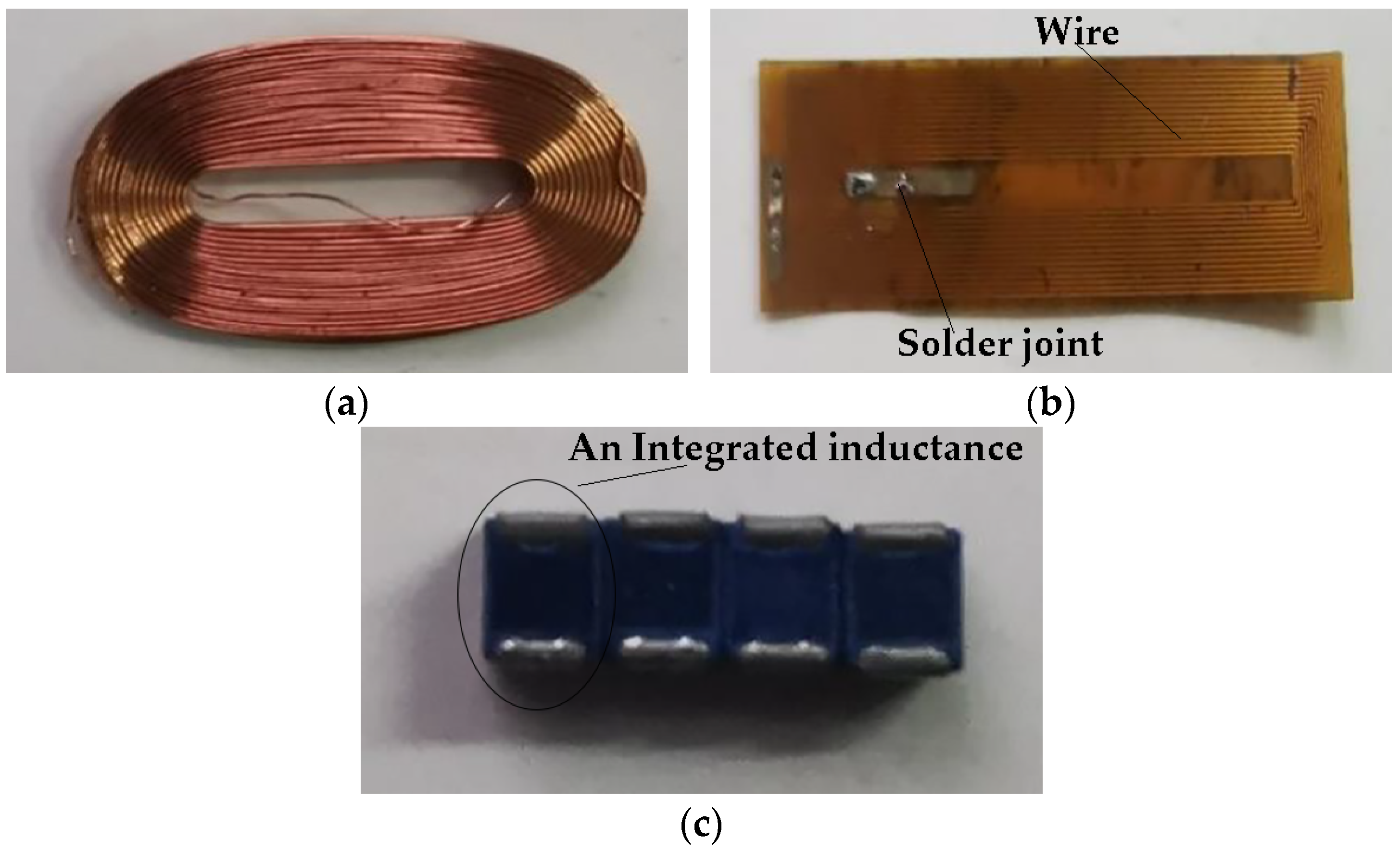

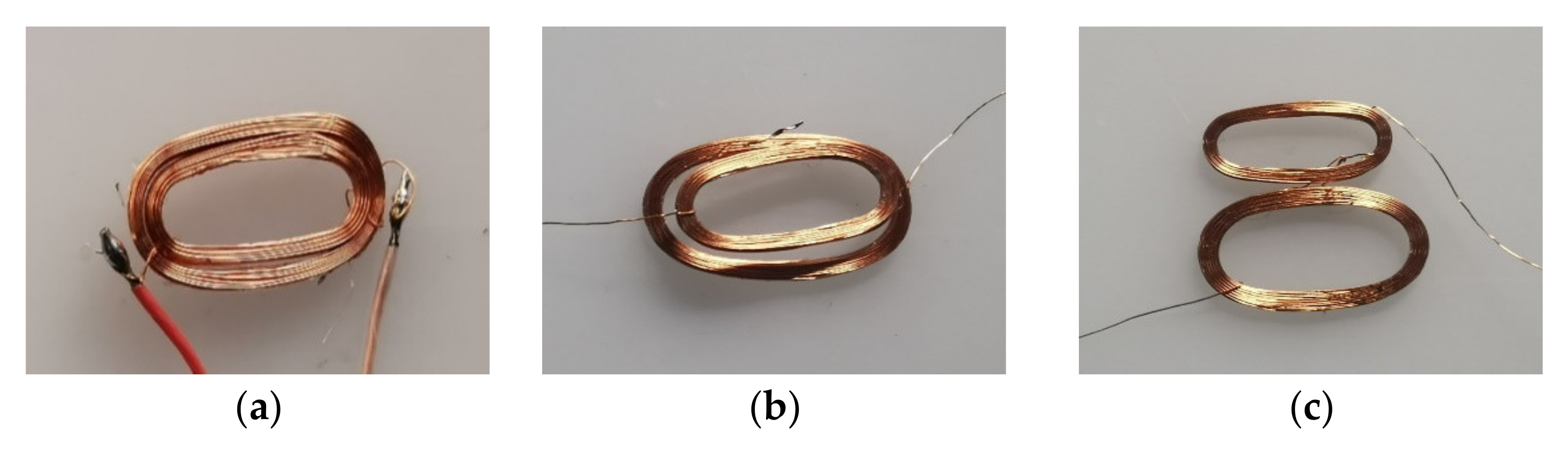

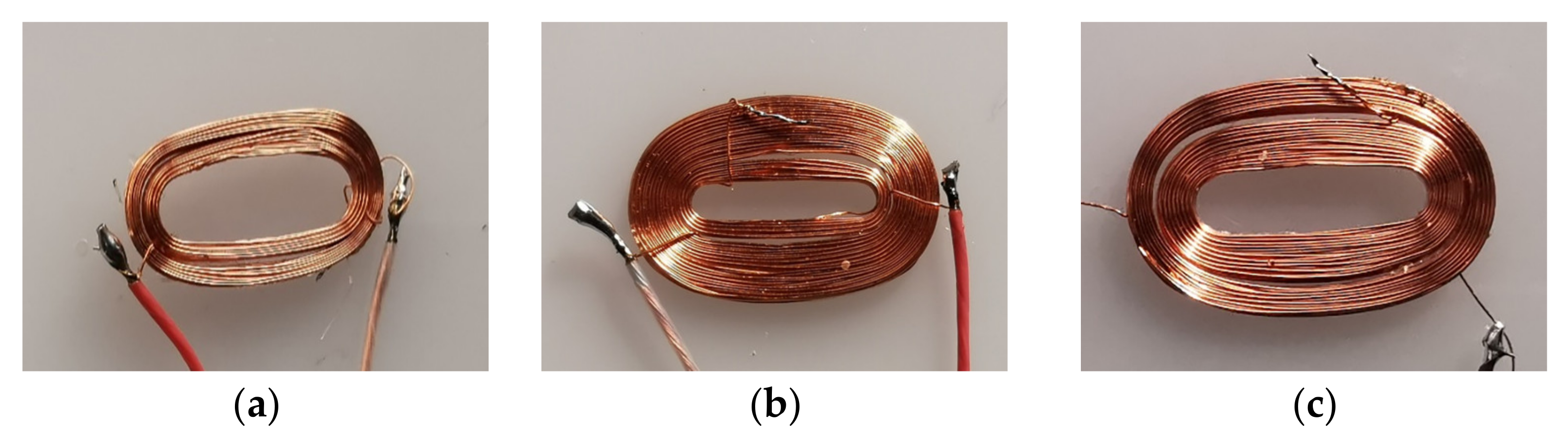

3. Induction Coils

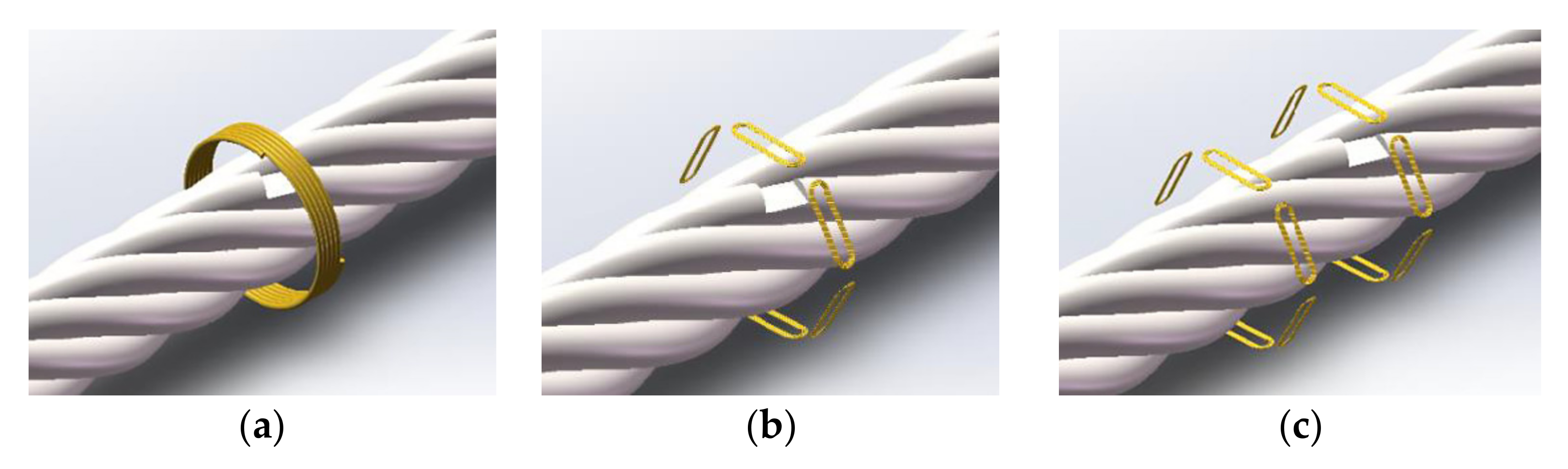

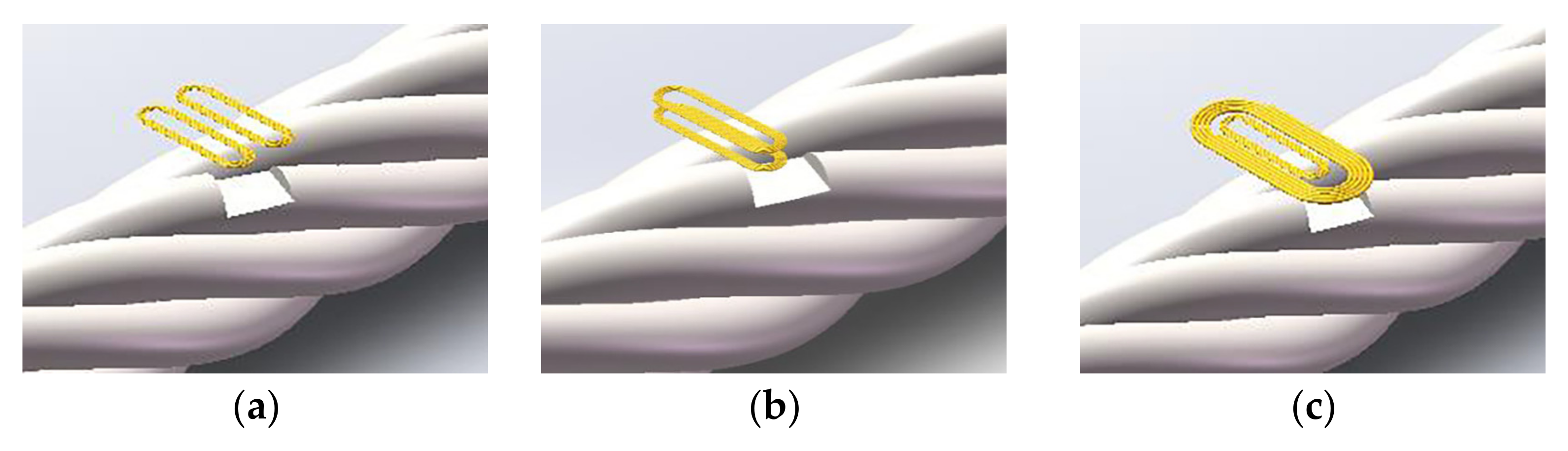

3.1. Coils Type

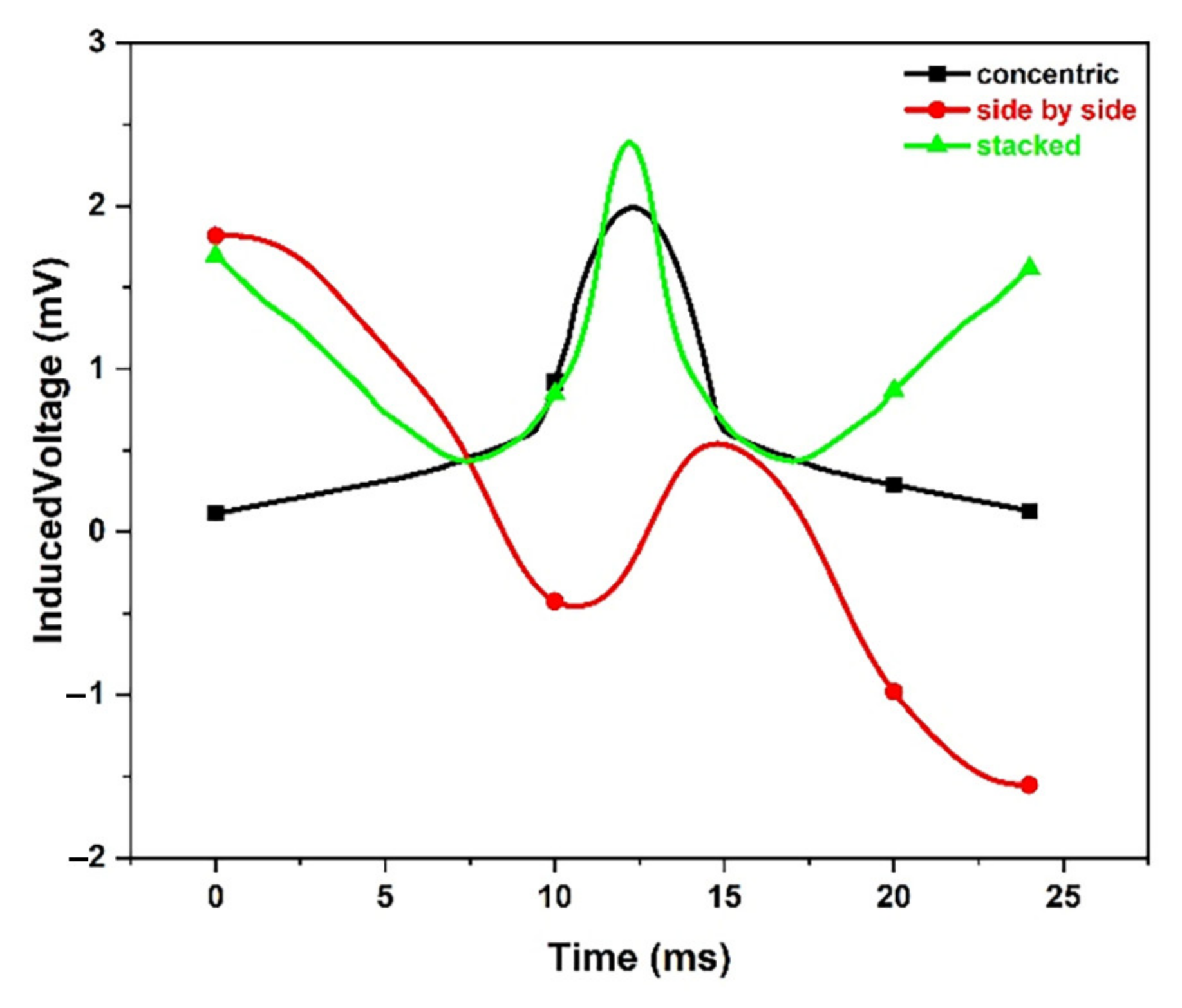

3.2. Magnetic Sensor Array Coupling

3.3. Coil Array

3.4. Coil Structure Parameters

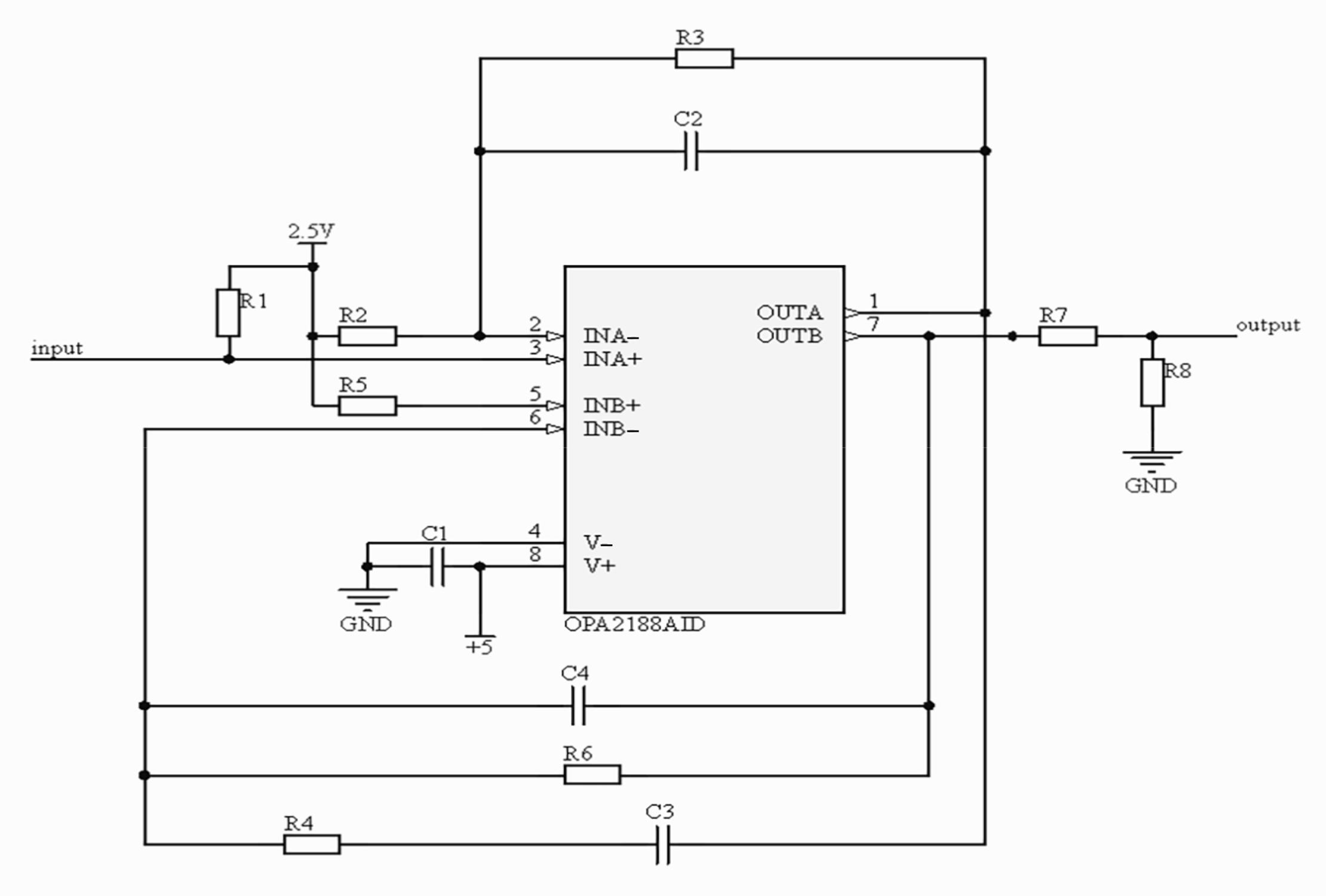

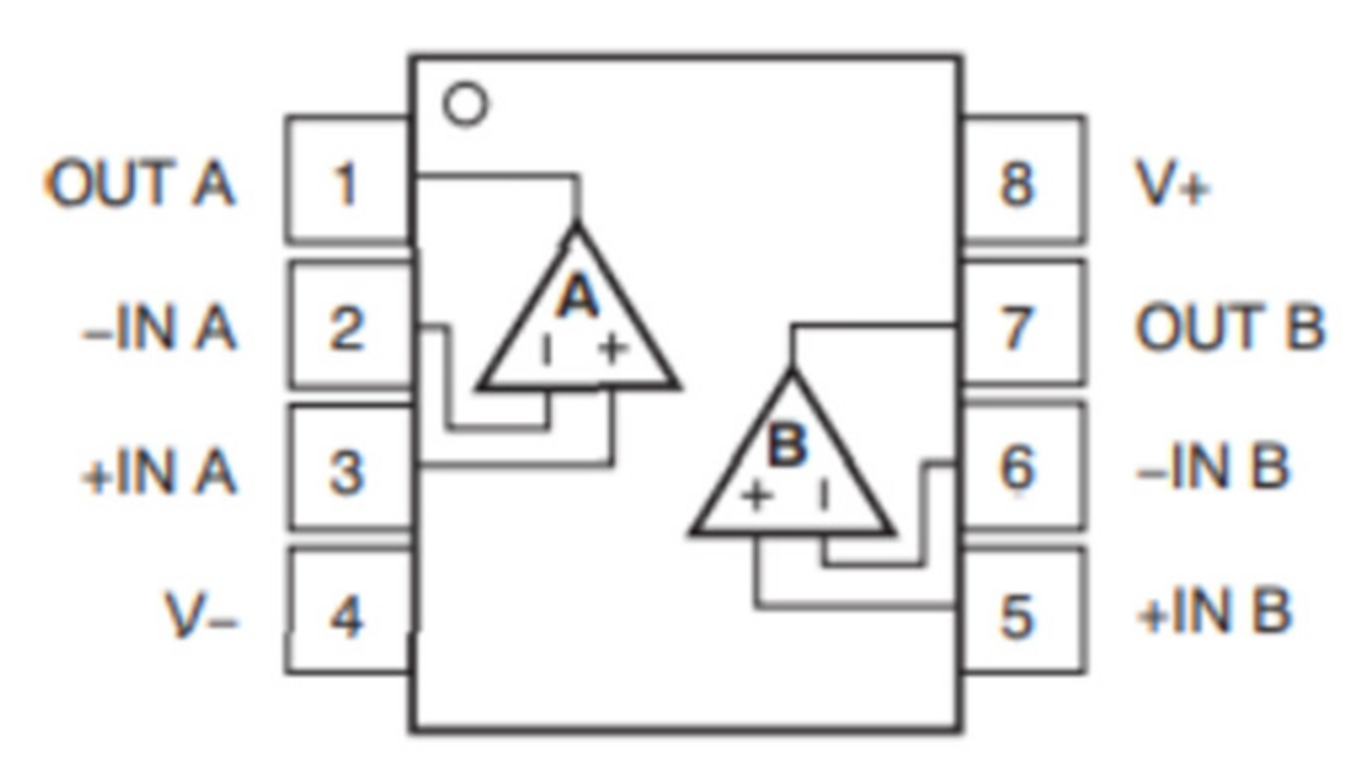

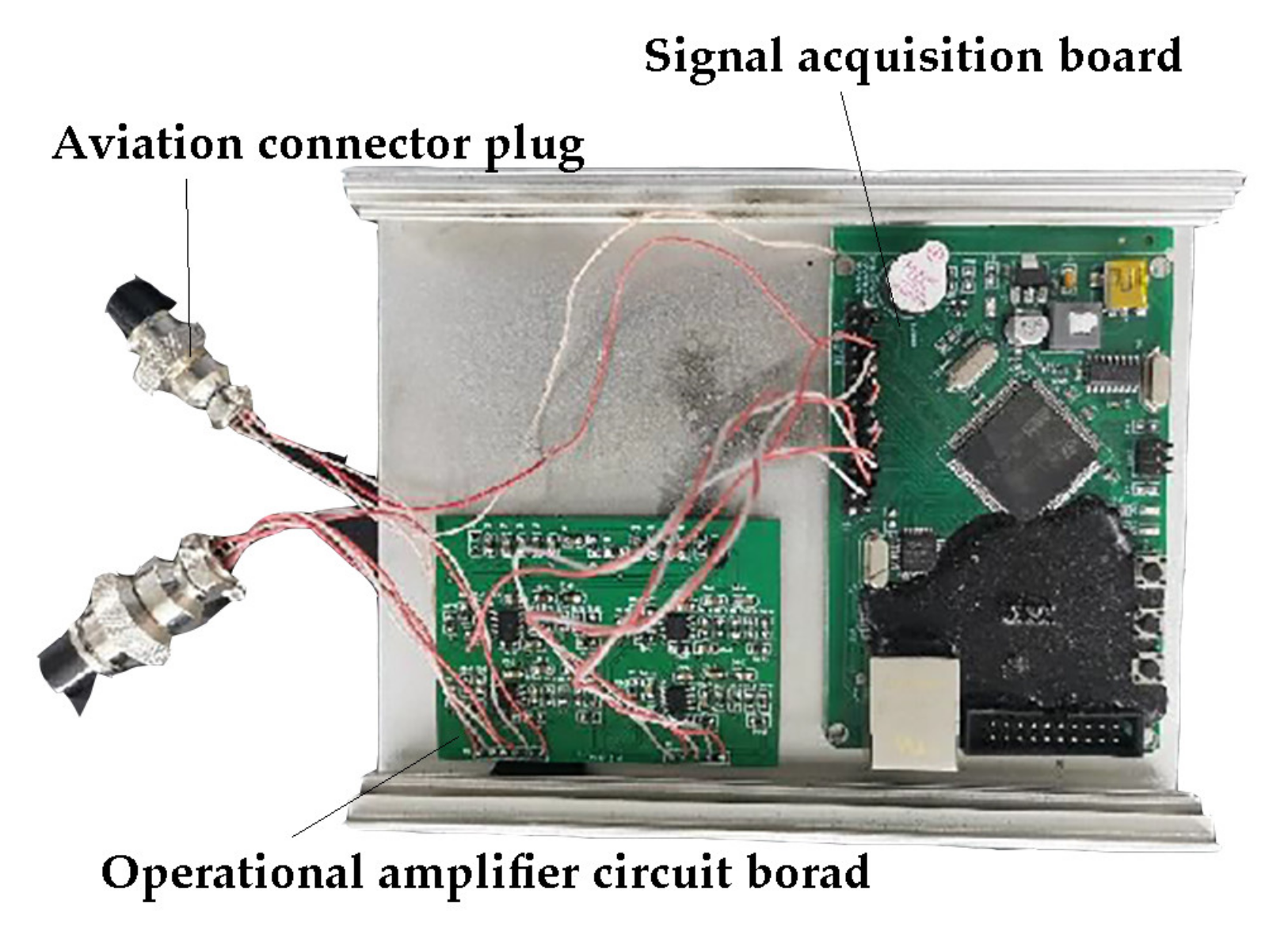

4. Analog Circuit

4.1. Circuit Design

- High input impedance;

- High voltage gain;

- Single power supply;

- Low noise;

- Proper bandwidth;

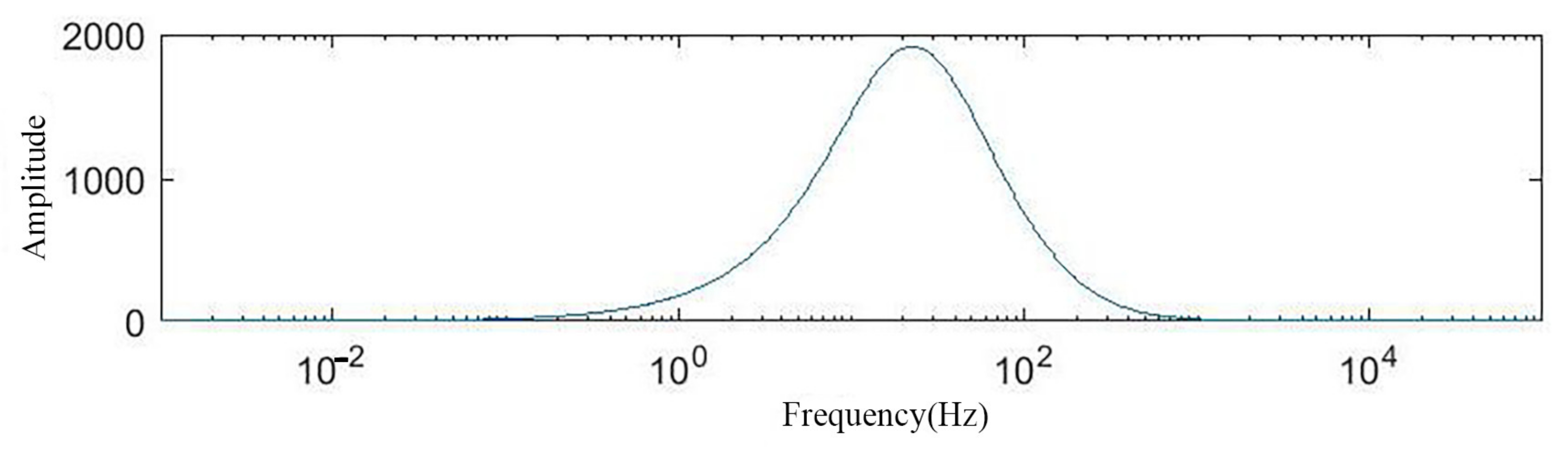

4.2. Circuit Simulation Analysis

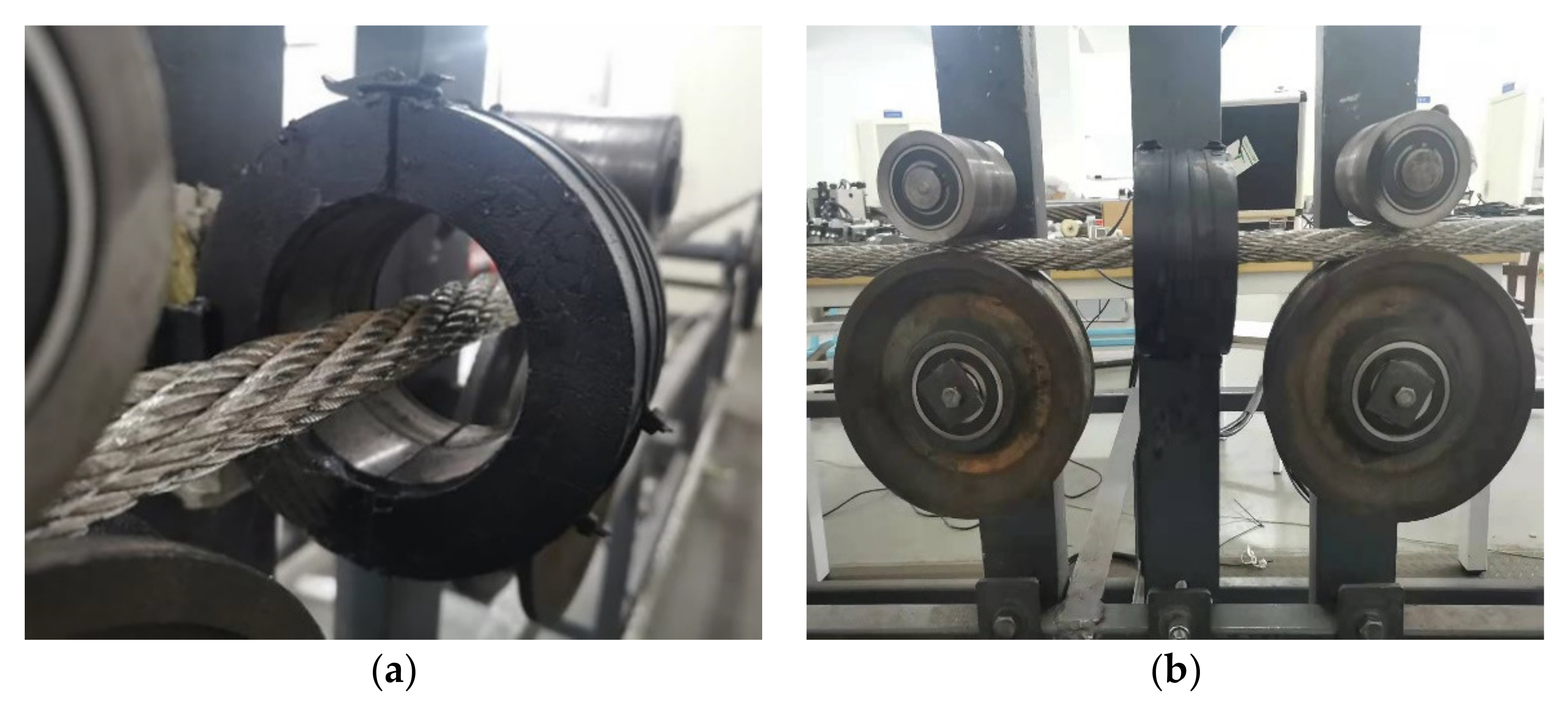

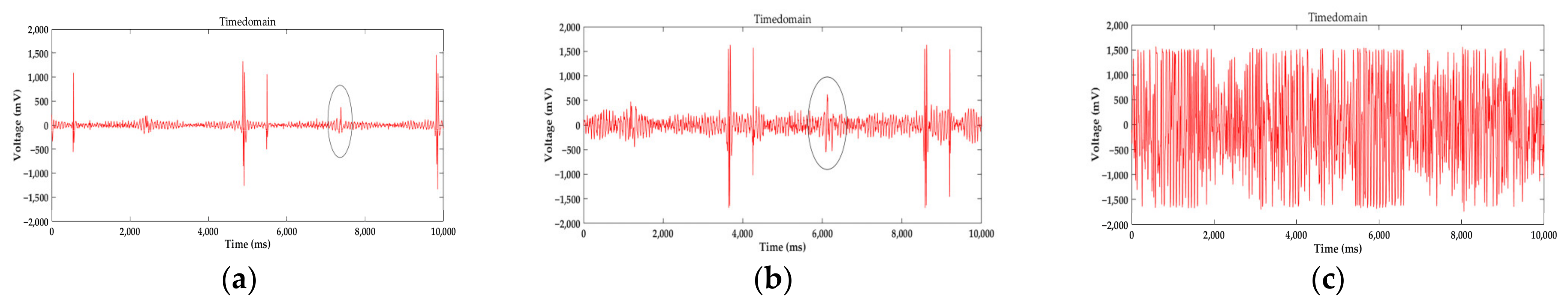

5. Experiments

5.1. Experiment Arrangement

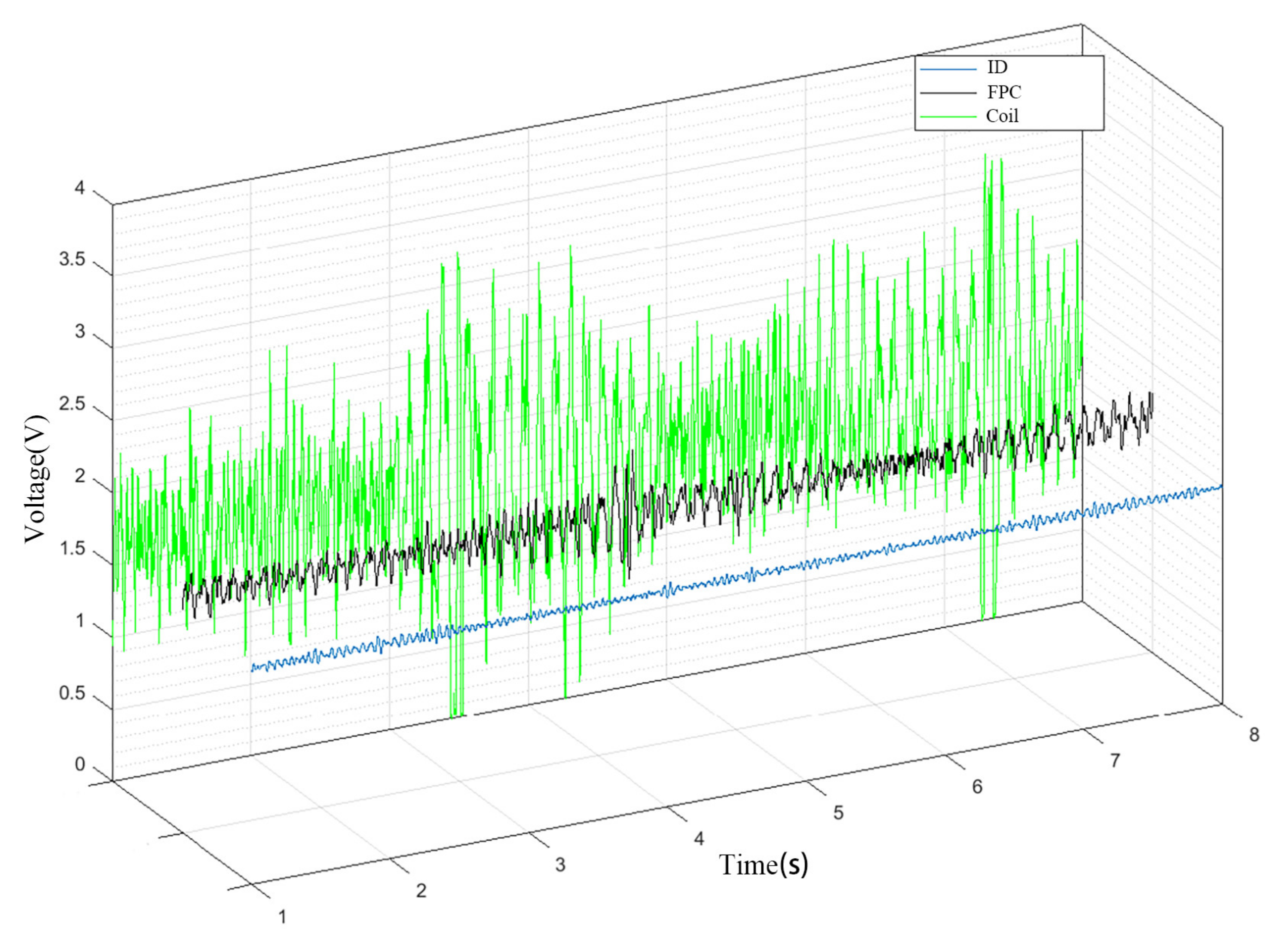

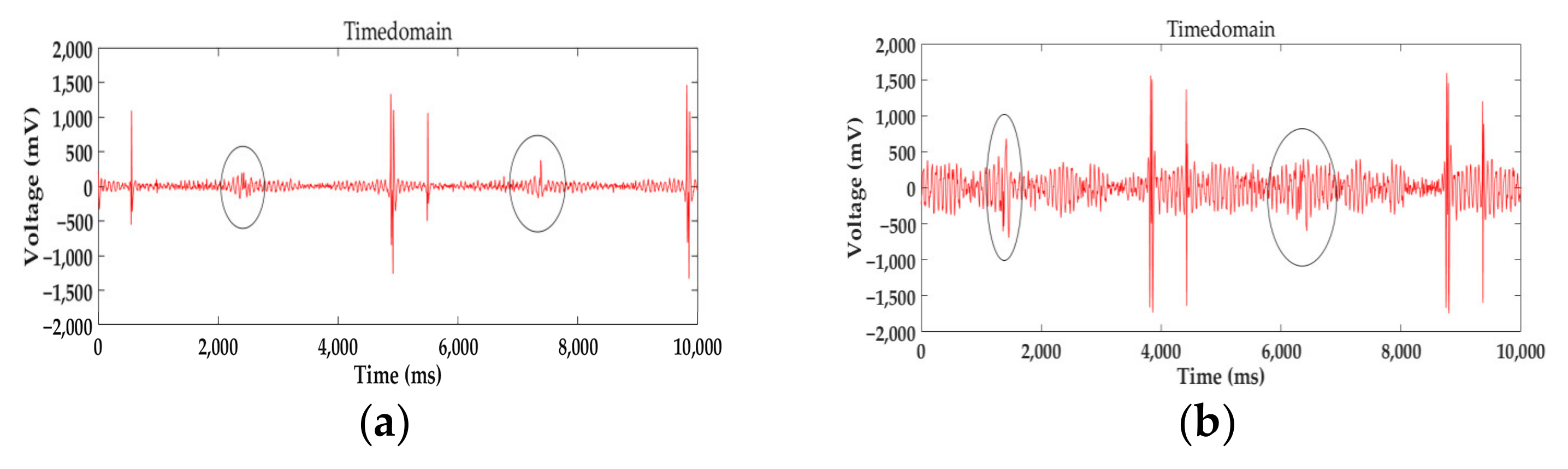

5.2. Effect of Coil Arrays

5.3. Effect of Coil Structure Parameters

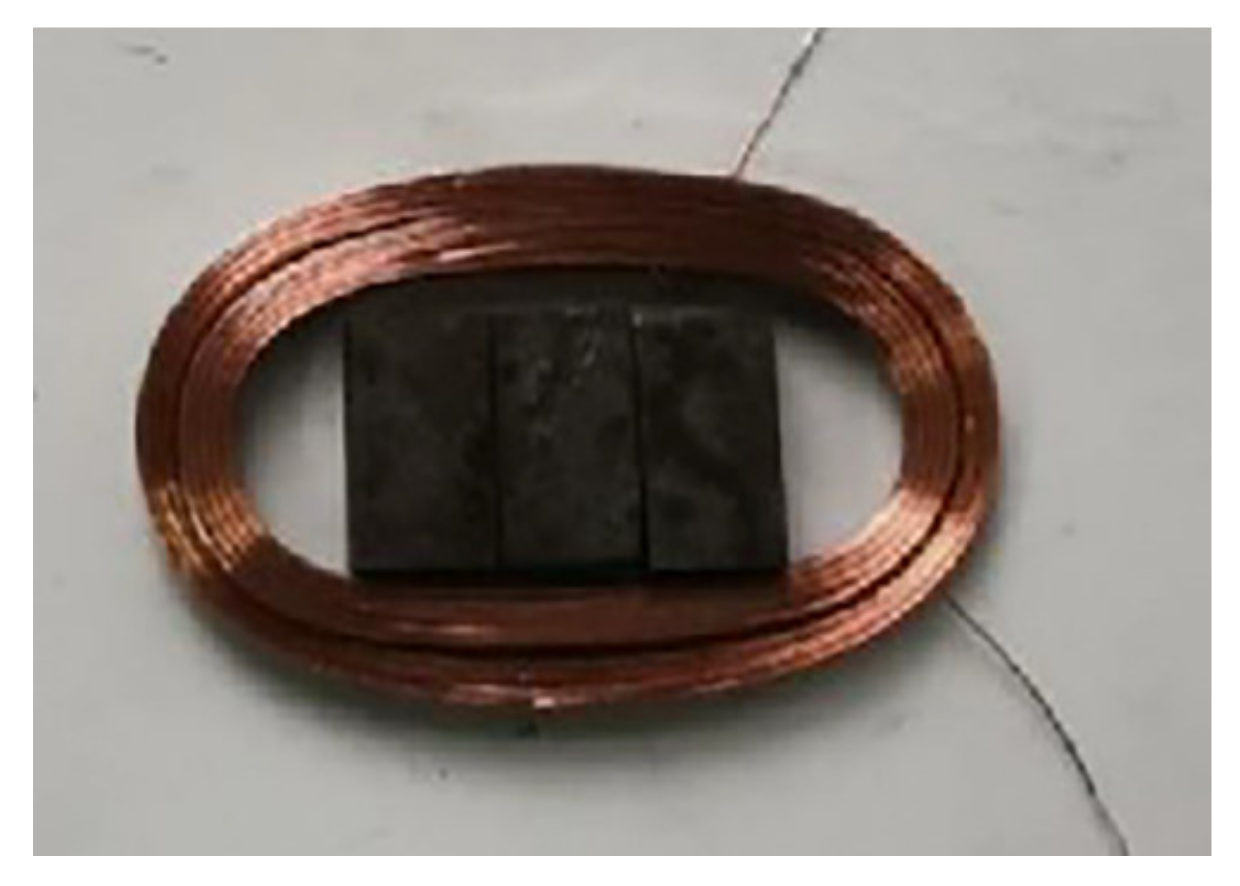

5.4. Effect of Magnetic Material

6. Discussion

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tian, J.; Zhao, C.; Wang, W.; Sun, G. Detection Technology of Mine Wire Rope Based on Radial Magnetic Vector With Flexible Printed Circuit. IEEE Trans. Instrum. Meas. 2021, 70, 1–10. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, E.; Yan, X. Quantitative method for detecting internal and surface defects in wire rope. NDT E Int. 2021, 119, 102405. [Google Scholar] [CrossRef]

- Liu, X.; Xiao, J.; Wu, B.; He, C. A novel sensor to measure the biased pulse magnetic response in steel stay cable for the detection of surface and internal flaws. Sens. Actuators A Phys. 2018, 269, 218–226. [Google Scholar] [CrossRef]

- Hua, G.; Wang, H.-Y.; Chen, F.-J.; Lu, Y.-H.; Xu, Z.; Tian, J.; Zhou, B.B. Improving SNR of MFL Signal in Flaw Detection of Coal Mine Wire Ropes; IEEE: Piscataway, NJ, USA, 2009. [Google Scholar]

- Wei, X.; Liu, H.; Jia, L. Fault Detection of Urban Rail Vehicle Suspension System Based on Acceleration Measurements. In Proceedings of the 2012 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Kaohsiung, Taiwan, 11–14 July 2012. [Google Scholar]

- Sun, Y.; Liu, S.; Li, R.; Ye, Z.; Kang, Y.; Chen, S. A new magnetic flux leakage sensor based on open magnetizing method and its on-line automated structural health monitoring methodology. Struct. Health Monit. 2015, 14, 583–603. [Google Scholar] [CrossRef]

- Rostami, J.; Tse, P.W.; Yuan, M. Detection of broken wires in elevator wire ropes with ultrasonic guided waves and tone-burst wavelet. Struct. Health Monit. 2020, 19, 481–494. [Google Scholar] [CrossRef]

- Zhou, P.; Zhou, G.; Li, Y.; He, Z.; Liu, Y. A Hybrid Data-Driven Method for Wire Rope Surface Defect Detection. IEEE Sens. J. 2020, 20, 8297–8306. [Google Scholar] [CrossRef]

- Jomdecha, C.; Prateepasen, A. Design of modified electromagnetic main-flux for steel wire rope inspection. NDT E Int. 2009, 42, 77–83. [Google Scholar] [CrossRef]

- Zhang, Y.; Jing, L.; Chen, C.; Bai, X.; Tan, J. A comprehensive study of the magnetic concentrating sensor for the damage detection of steel wire ropes. Mater. Res. Express 2020, 7, 96102. [Google Scholar] [CrossRef]

- Ni, Y.; Zhang, Q.; Xin, R. Magnetic flux detection and identification of bridge cable metal area loss damage. Measurement 2021, 167, 108443. [Google Scholar] [CrossRef]

- Feng, B.; Ribeiro, A.L.; Rocha, T.J.; Ramos, H.G. Comparison of Inspecting Non-Ferromagnetic and Ferromagnetic Metals Using Velocity Induced Eddy Current Probe. Sensors 2018, 18, 3199. [Google Scholar] [CrossRef] [Green Version]

- Rosado, L.S.; Santos, T.G.; Ramos, P.; Vilaça, P.; Piedade, M. A differential planar eddy currents probe: Fundamentals, modeling and experimental evaluation. NDT E Int. 2012, 51, 85–93. [Google Scholar] [CrossRef]

- Wilson, J.W.; Tian, G.Y. Pulsed electromagnetic methods for defect detection and characterisation. NDT E Int. 2007, 40, 275–283. [Google Scholar] [CrossRef]

- Liu, S.; Sun, Y.; Gu, M.; Liu, C.; He, L.; Kang, Y.; Shiwei, L.; Yanhua, S.; Min, G.; Changde, L.; et al. Review and analysis of three representative electromagnetic NDT methods. Insight-Non-Destr. Test. Cond. Monit. 2017, 59, 176–183. [Google Scholar] [CrossRef]

- Wang, H.; Xu, Z.; Hua, G.; Tian, J.; Zhou, B.-B.; Lu, Y.-H.; Chen, F.-J. Key technique of a detection sensor for coal mine wire ropes. Min. Sci. Technol. (China) 2009, 19, 170–175. [Google Scholar] [CrossRef]

- Lee, J.; Hwang, J. The Detection Probability Improvement of The Far-side Crack on the High Lift-off Using the Magnetic Camera. Int. J. Mod. Phys. B 2006, 20, 4631–4636. [Google Scholar] [CrossRef]

- Dutta, S.M.; Ghorbel, F.H.; Stanley, R.K. Simulation and Analysis of 3-D Magnetic Flux Leakage. IEEE Trans. Magn. 2009, 45, 1966–1972. [Google Scholar] [CrossRef]

- Wu, D.H.; Zhang, Z.Y.; Liu, Z.L.; Xia, X.H. Simulation and Analysis on the Best Range of Lift-Off Values in MFL Testing. Appl. Mech. Mater. 2013, 321–324, 811–814. [Google Scholar] [CrossRef]

- Wu, J.; Fang, H.; Li, L.; Wang, J.; Huang, X.; Kang, Y.; Sun, Y.; Tang, C. A Lift-Off-Tolerant Magnetic Flux Leakage Testing Method for Drill Pipes at Wellhead. Sensors 2017, 17, 201. [Google Scholar] [CrossRef] [Green Version]

- Azad, A.; Kim, N. Design and Optimization of an MFL Coil Sensor Apparatus Based on Numerical Survey. Sensors 2019, 19, 4869. [Google Scholar] [CrossRef] [Green Version]

- Hongyao, W.; Jie, T.; Guoying, M. A sensor model for defect detection in mine hoisting wire ropes based on magnetic focusing. Insight-Non-Destr. Test. Cond. Monit. 2017, 59, 143–148. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, S.; Ye, Z.; Chen, S.; Zhou, Q. A Defect Evaluation Methodology Based on Multiple Magnetic Flux Leakage (MFL) Testing Signal Eigenvalues. Res. Nondestruct. Eval. 2016, 27, 1–25. [Google Scholar] [CrossRef]

- Zhang, Y.; Jing, L.; Xu, W.; Zhan, W.; Tan, J. A Sensor for Broken Wire Detection of Steel Wire Ropes Based on the Magnetic Concentrating Principle. Sensors 2019, 19, 3763. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pan, S.; Zhang, D.; Zhang, E. Analysis of the eccentric problem of wire rope magnetic flux leakage testing. In Proceedings of the 2019 IEEE 3rd Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chengdu, China, 15–17 March 2019. [Google Scholar]

- Bjørk, R.; Bahl, C.; Smith, A.; Christensen, D.V.; Pryds, N. An optimized magnet for magnetic refrigeration. J. Magn. Magn. Mater. 2010, 322, 3324–3328. [Google Scholar] [CrossRef] [Green Version]

- Meliani, M.H.; Azari, Z.; Matvienko, Y.G.; Pluvinage, G. The effect of hydrogen on the master failure curve of APL 5L gas pipe steels. Procedia Eng. 2011, 10, 942–947. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Wu, B.; Liu, X.; He, C. Study on Electrical Characteristics of Electromagnetic Induction Coil. Proc. CSEE 2019, 39, 3963–3971. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Zhang, C.; Jiang, X.; Sun, Y.; Jiang, X.; Li, R.; He, L. The Research of 30 mm Detecting Distance of Testing Device for Wire Rope Based on Open Magnetizer. Appl. Sci. 2022, 12, 4829. https://doi.org/10.3390/app12104829

Liu M, Zhang C, Jiang X, Sun Y, Jiang X, Li R, He L. The Research of 30 mm Detecting Distance of Testing Device for Wire Rope Based on Open Magnetizer. Applied Sciences. 2022; 12(10):4829. https://doi.org/10.3390/app12104829

Chicago/Turabian StyleLiu, Mengqi, Chi Zhang, Xiaoyuan Jiang, Yanhua Sun, Xiaotian Jiang, Ran Li, and Lingsong He. 2022. "The Research of 30 mm Detecting Distance of Testing Device for Wire Rope Based on Open Magnetizer" Applied Sciences 12, no. 10: 4829. https://doi.org/10.3390/app12104829

APA StyleLiu, M., Zhang, C., Jiang, X., Sun, Y., Jiang, X., Li, R., & He, L. (2022). The Research of 30 mm Detecting Distance of Testing Device for Wire Rope Based on Open Magnetizer. Applied Sciences, 12(10), 4829. https://doi.org/10.3390/app12104829