Spectroscopic Ellipsometry and Optical Modelling of Structurally Colored Opaline Thin-Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Ellipsometry

2.3. Modelling and Simulation

3. Results

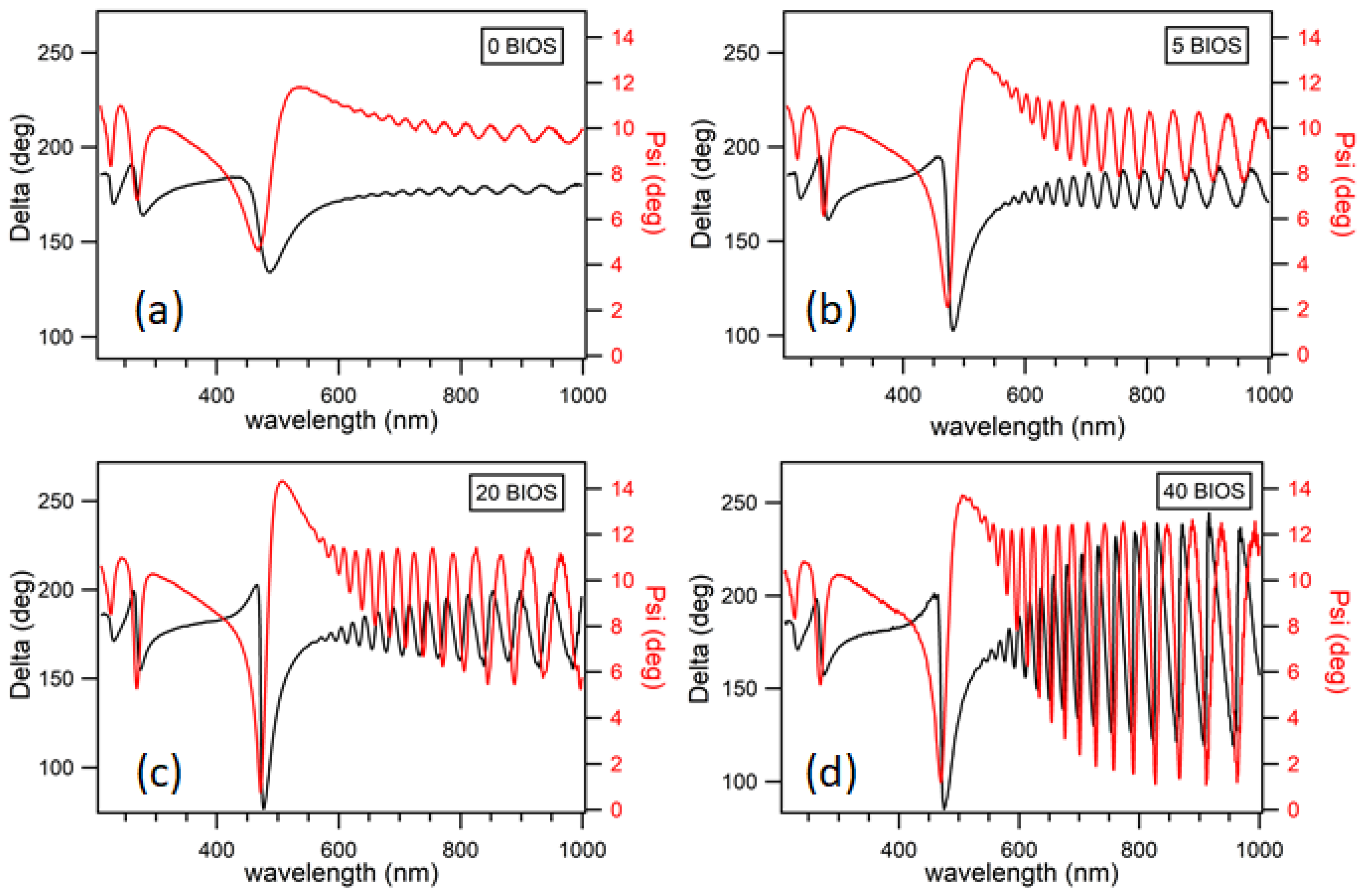

3.1. Experimental Ellipsometry

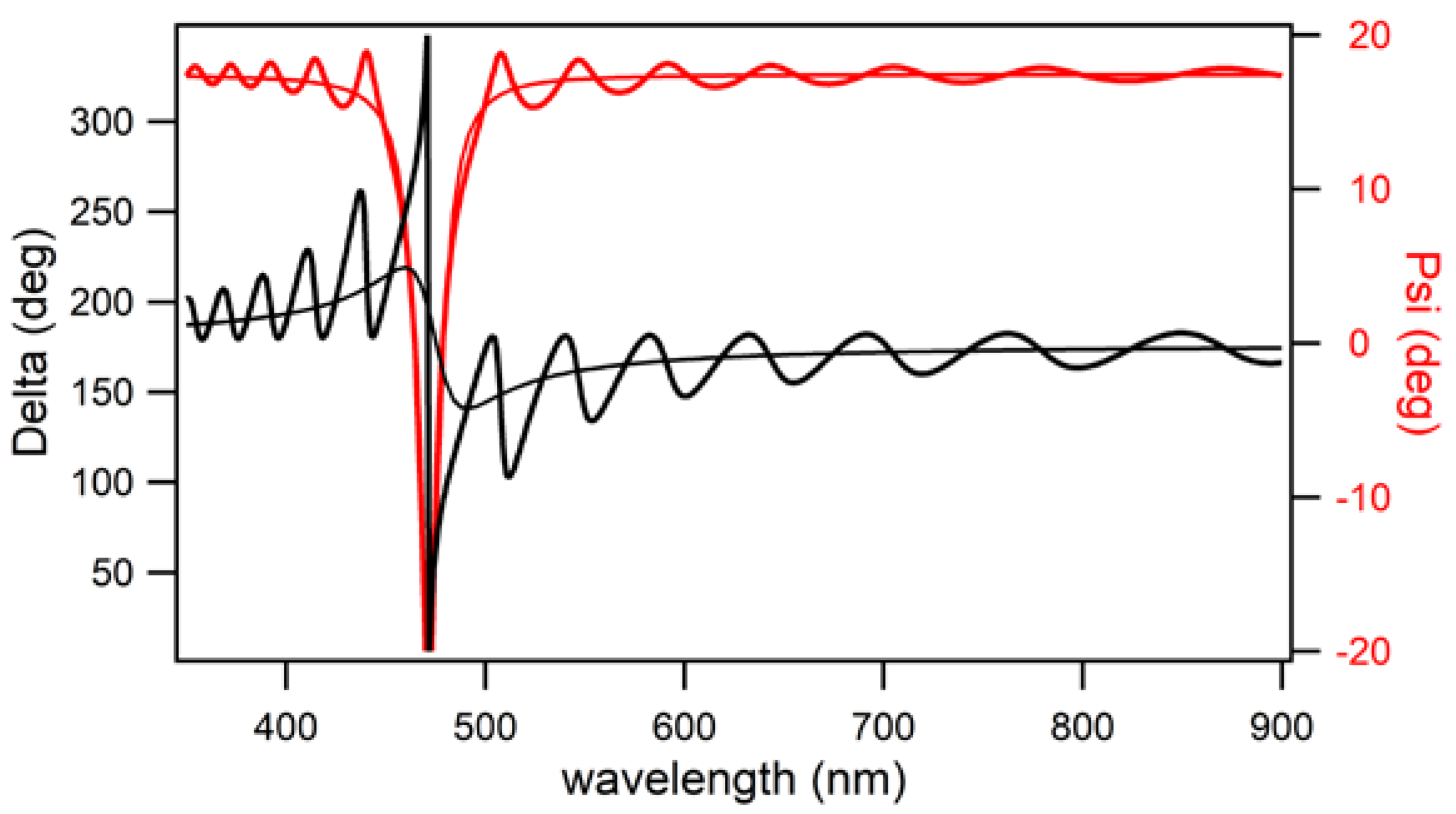

3.2. Simulation

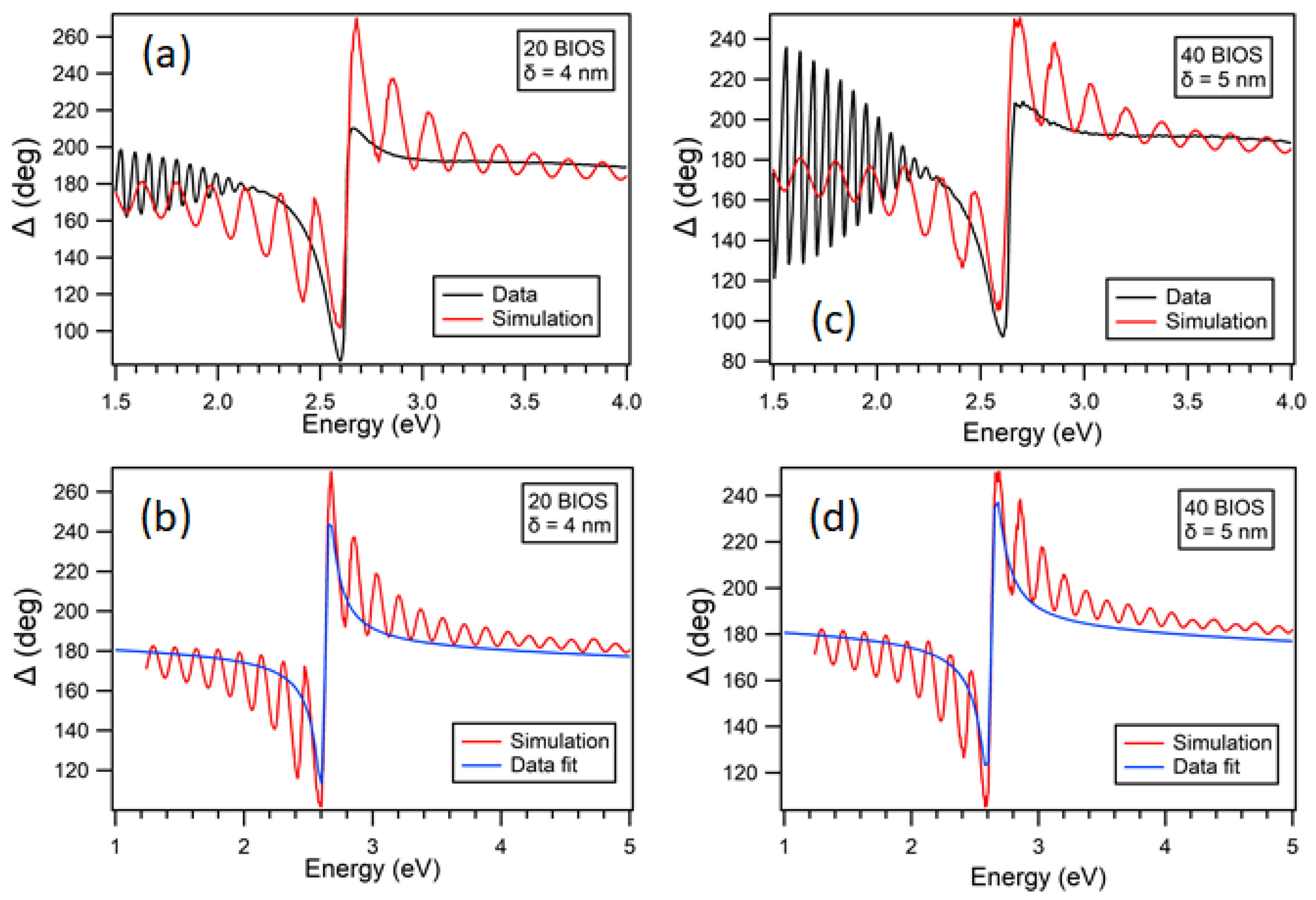

3.3. Matching of Data to Simulation Outputs

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vedam, K. Spectroscopic ellipsometry: A historical overview. Thin Solid Films 1998, 313, 1–9. [Google Scholar] [CrossRef]

- Ramsdale, C.M.; Greenham, N.C. The optical constants of emitter and electrode materials in polymer light-emitting diodes. J. Phys. D Appl. Phys. 2003, 36, L29–L34. [Google Scholar] [CrossRef]

- Tomes, J. Imaging Ellipsometry as a Novel Detection Method for Protein-Protein Interactions. Ph.D. Thesis, Aberystwyth University, Aberystwyth, UK, 2019. [Google Scholar]

- Woollam, J.A.; McGahan, W.A.; Johs, B. Spectroscopic Ellipsometry Studies of Indium Tin Oxide and Other Flat-Panel Display Multilayer Materials. Thin Solid Film. 1994, 241, 44–46. [Google Scholar] [CrossRef]

- Irene, E.A. Applications of Spectroscopic Ellipsometry to Microelectronics. Thin Solid Film. 1993, 233, 96–111. [Google Scholar] [CrossRef]

- Tompkins, H.G.; Hilfiker, J.N. Spectroscopic Ellipsometry: Practical Application to Thin Film Characterization; Momentum Press: New York, NY, USA, 2016. [Google Scholar]

- Herzinger, C.M.; Johs, B.; McGahan, W.A.; Woollam, J.A.; Paulson, W. Ellipsometric determination of optical constants for silicon and thermally grown silicon dioxide via a multi-sample, multi-wavelength, multi-angle investigation. J. Appl. Phys. 1998, 83, 3323–3336. [Google Scholar] [CrossRef]

- Krebs, F. All solution roll-to-roll processed polymer solar cells free from indium-tin-oxide and vacuum coating steps. Org. Electron. 2009, 10, 761–768. [Google Scholar] [CrossRef]

- Dou, B.; Whitaker, J.B.; Bruening, K.; Moore, D.T.; Wheeler, L.M.; Ryter, J.; Breslin, N.J.; Berry, J.J.; Garner, S.M.; Barnes, F.S.; et al. Roll-to-Roll Printing of Perovskite Solar Cells. ACS Energy Lett. 2018, 3, 2558–2565. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Yang, T.Y.; Suhonen, R.; Kemppainen, A.; Hwang, K.; Jeon, N.J.; Seo, J. Roll-to-Roll gravure-printed flexible perovskite solar cells using eco-friendly antisolvent bathing with wide processing window. Nat. Commun. 2020, 11, 11. [Google Scholar] [CrossRef]

- Shen, X.Q.; Wu, P.; Schafer, C.G.; Guo, J.; Wang, C.C. Ultrafast assembly of nanoparticles to form smart polymeric photonic crystal films: A new platform for quick detection of solution compositions. Nanoscale 2019, 11, 1253–1261. [Google Scholar] [CrossRef]

- Schafer, C.G.; Gallei, M.; Zahn, J.T.; Engelhardt, J.; Hellmann, G.P.; Rehahn, M. Reversible Light-, Thermo-, and Mechano-Responsive Elastomeric Polymer Opal Films. Chem. Mater. 2013, 25, 2309–2318. [Google Scholar] [CrossRef]

- Joannopoulos, J.D. Photonic Crystals; Princeton: Princeton, NJ, USA, 2008. [Google Scholar]

- Kinoshita, S.; Yoshioka, S.; Miyazaki, J. Physics of structural colors. Rep. Prog. Phys. 2008, 71, 30. [Google Scholar] [CrossRef] [Green Version]

- Klatt, M.A.; Steinhardt, P.J.; Torquato, S. Gap Sensitivity Reveals Universal Behaviors in Optimized Photonic Crystal and Disordered Networks. Phys. Rev. Lett. 2021, 127, 6. [Google Scholar] [CrossRef] [PubMed]

- Finlayson, C.E.; Spahn, P.; Snoswell, D.R.E.; Yates, G.; Kontogeorgos, A.; Haines, A.I.; Hellmann, G.P.; Baumberg, J.J. 3D Bulk Ordering in Macroscopic Solid Opaline Films by Edge-Induced Rotational Shearing. Adv. Mater. 2011, 23, 1540–1544. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, Q.; Finlayson, C.; Snoswell, D.; Haines, A.; Schafer, C.; Spahn, P.; Hellmann, G.; Petukhov, A.; Herrmann, L.; Burdet, P.; et al. Large-scale ordering of nanoparticles using viscoelastic shear processing. Nat. Commun. 2016, 7, 11661. [Google Scholar] [CrossRef] [Green Version]

- Ruhl, T.; Spahn, P.; Hellmann, G.P. Artificial opals prepared by melt compression. Polymer 2003, 44, 7625–7634. [Google Scholar] [CrossRef]

- Viel, B.; Ruhl, T.; Hellmann, G. Reversible deformation of opal elastomers. Chem. Mater. 2007, 19, 5673–5679. [Google Scholar] [CrossRef]

- Finlayson, C.; Baumberg, J. Generating Bulk-Scale Ordered Optical Materials Using Shear-Assembly in Viscoelastic Media. Materials 2017, 10, 688. [Google Scholar] [CrossRef] [Green Version]

- Finlayson, C.E.; Baumberg, J.J. Polymer opals as novel photonic materials. Polym. Int. 2013, 62, 1403–1407. [Google Scholar] [CrossRef] [Green Version]

- Li, H.T.; Wu, P.; Zhao, G.W.; Guo, J.; Wang, C.C. Fabrication of industrial-level polymer photonic crystal films at ambient temperature Based on uniform core/shell colloidal particles. J. Colloid Interface Sci. 2021, 584, 145–153. [Google Scholar] [CrossRef]

- Ahles, M.; Ruhl, T.; Hellmann, G.P.; Winkler, H.; Schmechel, R.; von Seggern, H. Spectroscopic ellipsometry on opaline photonic crystals. Opt. Commun. 2005, 246, 1–7. [Google Scholar] [CrossRef]

- Allender, E.J.; Stabbins, R.B.; Gunn, M.D.; Cousins, C.R.; Coates, A.J. The ExoMars Spectral Tool (ExoSpec): An image analysis tool for ExoMars 2020 PanCam imagery. In Proceedings of the Conference on Image and Signal Processing for Remote Sensing XXIV, Berlin, Germany, 10–12 September 2018. [Google Scholar]

- Thrane, L.; Jorgensen, T.M.; Jorgensen, M.; Krebs, F.C. Application of optical coherence tomography (OCT) as a 3-dimensional imaging technique for roll-to-roll coated polymer solar cells. Sol. Energy Mater. Sol. Cells 2012, 97, 181–185. [Google Scholar] [CrossRef]

- Alarousu, E.; AlSaggaf, A.; Jabbour, G.E. Online monitoring of printed electronics by Spectral-Domain Optical Coherence Tomography. Sci. Rep. 2013, 3, 4. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Spahn, P.; Finlayson, C.E.; Etah, W.M.; Snoswell, D.R.E.; Baumberg, J.J.; Hellmann, G.P. Modification of the refractive-index contrast in polymer opal films. J. Mater. Chem. 2011, 21, 8893–8897. [Google Scholar] [CrossRef]

- Rosetta, G.; An, T.; Zhao, Q.B.; Baumberg, J.J.; Tomes, J.J.; Gunn, M.D.; Finlayson, C.E. Chromaticity of structural color in polymer thin film photonic crystals. Opt. Express 2020, 28, 36219–36228. [Google Scholar] [CrossRef]

- Zhao, Q.; Finlayson, C.; Schaefer, C.; Spahn, P.; Gallei, M.; Herrmann, L.; Petukhov, A.; Baumberg, J. Nanoassembly of Polydisperse Photonic Crystals Based on Binary and Ternary Polymer Opal Alloys. Adv. Opt. Mater. 2016, 4, 1494–1500. [Google Scholar] [CrossRef] [Green Version]

- Finlayson, C.E.; Rosetta, G.; Baumberg, J.J. An Experimental and Theoretical Determination of Oscillatory Shear-Induced Crystallization Processes in Viscoelastic Photonic Crystal Media. Materials 2021, 14, 5298. [Google Scholar] [CrossRef]

- Hecht, E. Optics, 4th ed.; Pearson Education: San Francisco, CA, USA, 2002. [Google Scholar]

- Tompkins, H.; Haber, E.A. Handbook of Ellipsometry; William Andrew Publishing: New York, NY, USA, 2005. [Google Scholar]

- Snoswell, D.; Kontogeorgos, A.; Baumberg, J.; Lord, T.; Mackley, M.; Spahn, P.; Hellmann, G. Shear ordering in polymer photonic crystals. Phys. Rev. E 2010, 81, 020401. [Google Scholar] [CrossRef]

- Born, M.; Wolf, E. Principles of Optics: Electromagnetic Theory of Propagation, Interference and Diffraction of Light; Pergamon: Oxford, UK, 1964. [Google Scholar]

- Azzam, R.M.A.; Bashara, N.M. Ellipsometry and Polarized Light; Elsevier: Amsterdam, The Netherlands, 1987. [Google Scholar]

- Jin, G.; Jansson, R.; Arwin, H. Imaging ellipsometry revisited: Developments for visualization of thin transparent layers on silicon substrates. Rev. Sci. Instrum. 1996, 67, 2930–2936. [Google Scholar] [CrossRef]

- Bammer, F.; Huemer, F. Inline thickness measurement with imaging-ellipsometry. In Proceedings of the Joint TC1-TC2 International Symposium on Photonics and Education in Measurement Science, Jena, Germany, 17–19 September 2019. [Google Scholar]

| Ψ | ∆ | ||||

|---|---|---|---|---|---|

| Sample | Experimental FWHM (nm) | Simulation FWHM (nm) | Experimental FWHM (eV) | Simulation FWHM (eV) | Disorder (δ) Factor for Best Fit (±0.5 nm) |

| 0-BIOS | 48.5 (±1.7) | 47.9 (±0.6) | 0.298 (±0.034) | 0.351 (±0.004) | 19 |

| 5-BIOS | 28.8 (±1.6) | 28.3 (±0.3) | 0.166 (±0.017) | 0.124 (±0.002) | 10 |

| 20-BIOS | 19.6 (±1.5) | 18.7 (±0.2) | 0.066 (±0.005) | 0.086 (±0.003) | 4 |

| 40-BIOS | 22.6 (±3.5) | 20.2 (±0.1) | 0.077 (±0.011) | 0.097 (±0.003) | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Finlayson, C.E.; Rosetta, G.; Tomes, J.J. Spectroscopic Ellipsometry and Optical Modelling of Structurally Colored Opaline Thin-Films. Appl. Sci. 2022, 12, 4888. https://doi.org/10.3390/app12104888

Finlayson CE, Rosetta G, Tomes JJ. Spectroscopic Ellipsometry and Optical Modelling of Structurally Colored Opaline Thin-Films. Applied Sciences. 2022; 12(10):4888. https://doi.org/10.3390/app12104888

Chicago/Turabian StyleFinlayson, Chris E., Giselle Rosetta, and John J. Tomes. 2022. "Spectroscopic Ellipsometry and Optical Modelling of Structurally Colored Opaline Thin-Films" Applied Sciences 12, no. 10: 4888. https://doi.org/10.3390/app12104888