Abstract

Plastic recycling is the most effective way to solve plastic pollution. Color recognition of plastic is a key step in the plastic recycling process, which is very important for improving the utilization rate of waste plastic. At present, the manual recognition method is inefficient and cannot meet the requirements of large-scale production, while the existing color recognition based on machine vision has problems such as low recognition accuracy of similar colors, complicated algorithm and high system cost. According to the above problems, a color recognition method based on multi-wavelength transmission spectrum was proposed in this paper for the color recognition of colorless, light blue, light green and apple green transparent plastic. For each transparent plastic, the transmission spectra at 381 nm, 439 nm, 620 nm and white transmission light source were obtained, and the ratios of R, G and B wavebands of the transmission spectra were used to set up a color feature, which was then used for color recognition. A color recognition model was established based on the color features and naive Bayes model. The 10-fold cross-validation results showed that the recognition accuracy of the four colors of transparent plastic reached 100%.

1. Introduction

Plastic materials play an important role in the modern world, but they also produce a large amount of plastic waste. It is estimated that by 2050, about 12 billion tons of plastic waste will accumulate in landfills and natural environments worldwide [1]. Plastic waste pollution poses imminent threats to the marine environment, food safety, human health and contributes to climate change [2,3,4,5]. From the perspective of environmental and socio-economic sustainability, recycling is the most effective way to solve plastic pollution, and it is the most dynamic area of the plastic industry today. Plastic recycling and utilization can reduce the demand for new plastic raw materials, thus reducing the consumption of resources and energy in the production process [6,7,8], which is consistent with the Sustainable Development Goals (SDGs) of the United Nations (UN). Many countries and regions have carried out a lot of practices in waste plastic recycling [9,10,11].

By sorting the plastics of different materials and colors, the utilization rate of plastic and the final product quality can be obviously improved [12], thus material and color recognitions are essential for plastic sorting and recycling. At present, researchers have carried out many studies on material recognition using spectroscopy, machine vision and other methods [13,14,15,16], while there are few studies on color recognition.

At present, there are two main plastic color recognition methods: manual recognition and machine recognition. The poor working environment of the manual recognition method poses a great threat to human health, and the low recognition efficiency makes it difficult to meet the needs of large-scale and efficient production [17]. Generally, the machine recognition method realizes automatic color recognition by using machine vision, and the method can be divided into two types: one is the traditional machine vision method, in which the color features are extracted based on red–green–blue (RGB), hue saturation value (HSV), hue intensity saturation (HIS) and other color models, and color recognition models are established using traditional machine learning algorithms such as support vector machine and K-nearest neighbor [18,19,20]; the other type is deep learning based machine vision method, in which the color recognition models are established using a large number of sample images and deep learning algorithms such as convolutional neural network [21,22]. The first type is simple to implement, but the accuracy is low and it is difficult to identify the transparent plastics with similar color. The second type has a good performance in distinguishing transparent plastic with similar color, but the deep learning algorithms are complex and require a large amount of training samples and high-performance computing resources, so the application cost is high. In addition, the image acquisition device in the machine recognition method mostly adopts single-wavelength lighting source, and the sample image is obtained by the camera that is located on the same side of the light source. This structure is susceptible to specular reflection interference, resulting in the degradation of image quality and color recognition effect.

According to the above problems, this paper proposes a color recognition method for transparent plastic based on multi-wavelength transmission spectrum. LEDs with different wavelengths were used as transmission light sources, and the transmission spectrum of the transparent plastic was obtained at each transmission light wavelength. The ratios of the R, G and B wavebands of each transmission spectrum were used to set up a color feature for color recognition. A color recognition model was established based on the color features and naive Bayes model, realizing the accurate color recognition of transparent plastics with similar color.

2. Materials and Methods

2.1. Experimental System

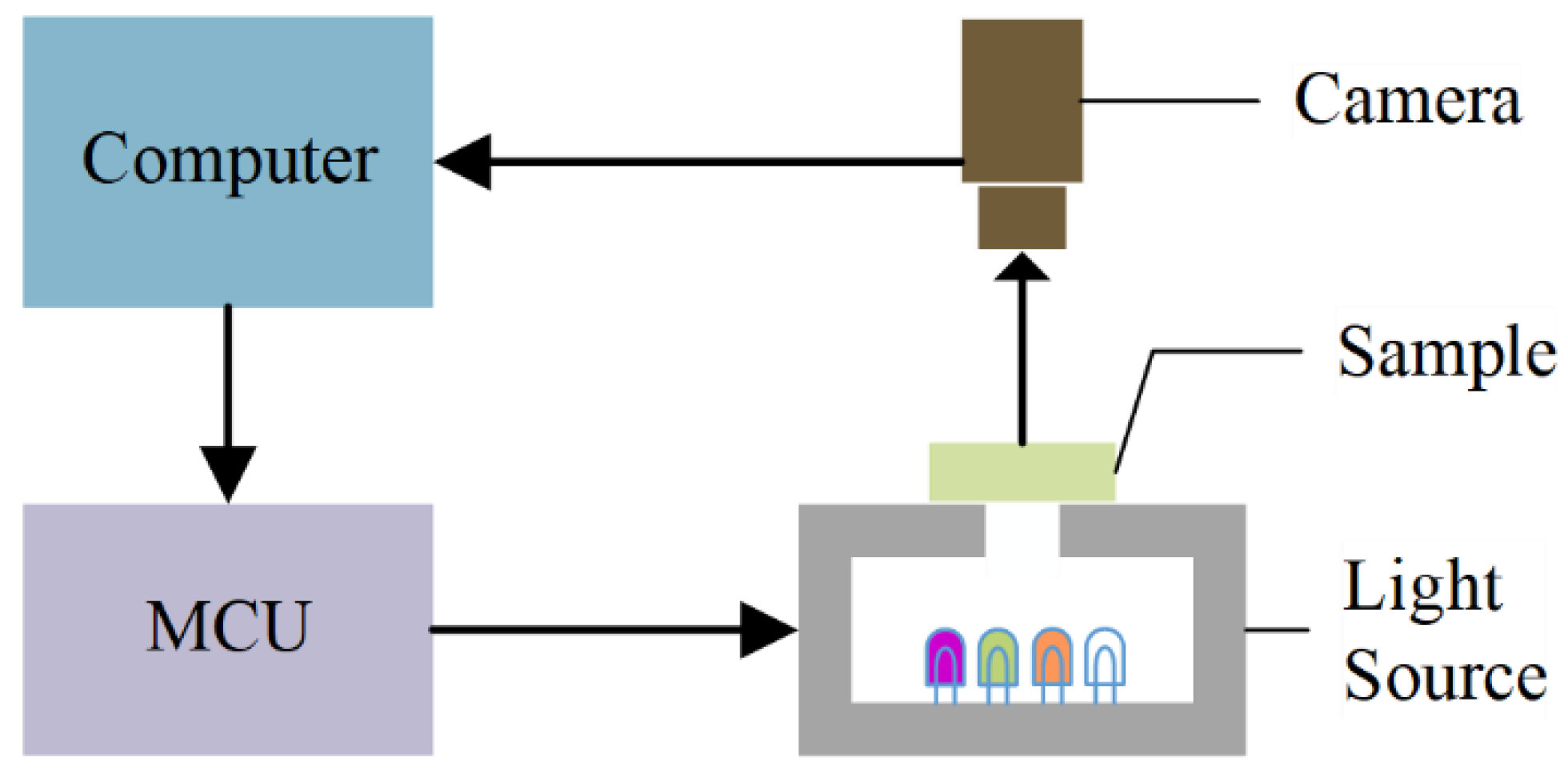

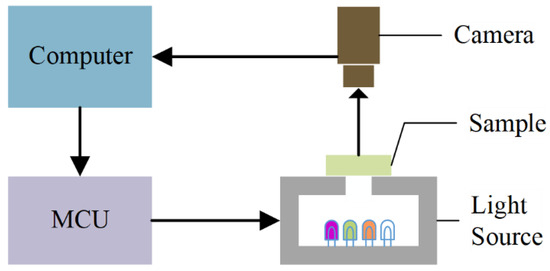

As shown in Figure 1, the experimental system is composed of LED transmission light source with 4 wavelengths (381 nm, 439 nm, 620 nm and white), transmission spectrum acquisition camera (DFK23GPO31, The Imaging Source Inc., Bremen, Germany), microcontroller control unit (MCU) and data processing unit (Computer). The 381 nm, 439 nm, 620 nm and white wavelengths of the LED transmission light source were selected from the existing wavelengths of 381 nm, 439 nm, 495 nm, 520 nm, 620 nm and white by the experiment based on the comprehensive consideration of recognition effect and data size. The LEDs of the 4 wavelengths successively irradiate the transparent plastic on one side, and the corresponding transmission spectrum is obtained by the camera that is located on the other side of the plastic. The obtained spectra are then processed by a computer for color recognition.

Figure 1.

Schematic diagram of color recognition system of transparent plastic based on multi- wavelength transmission spectrum.

2.2. Sample and Spectrum Acquisition

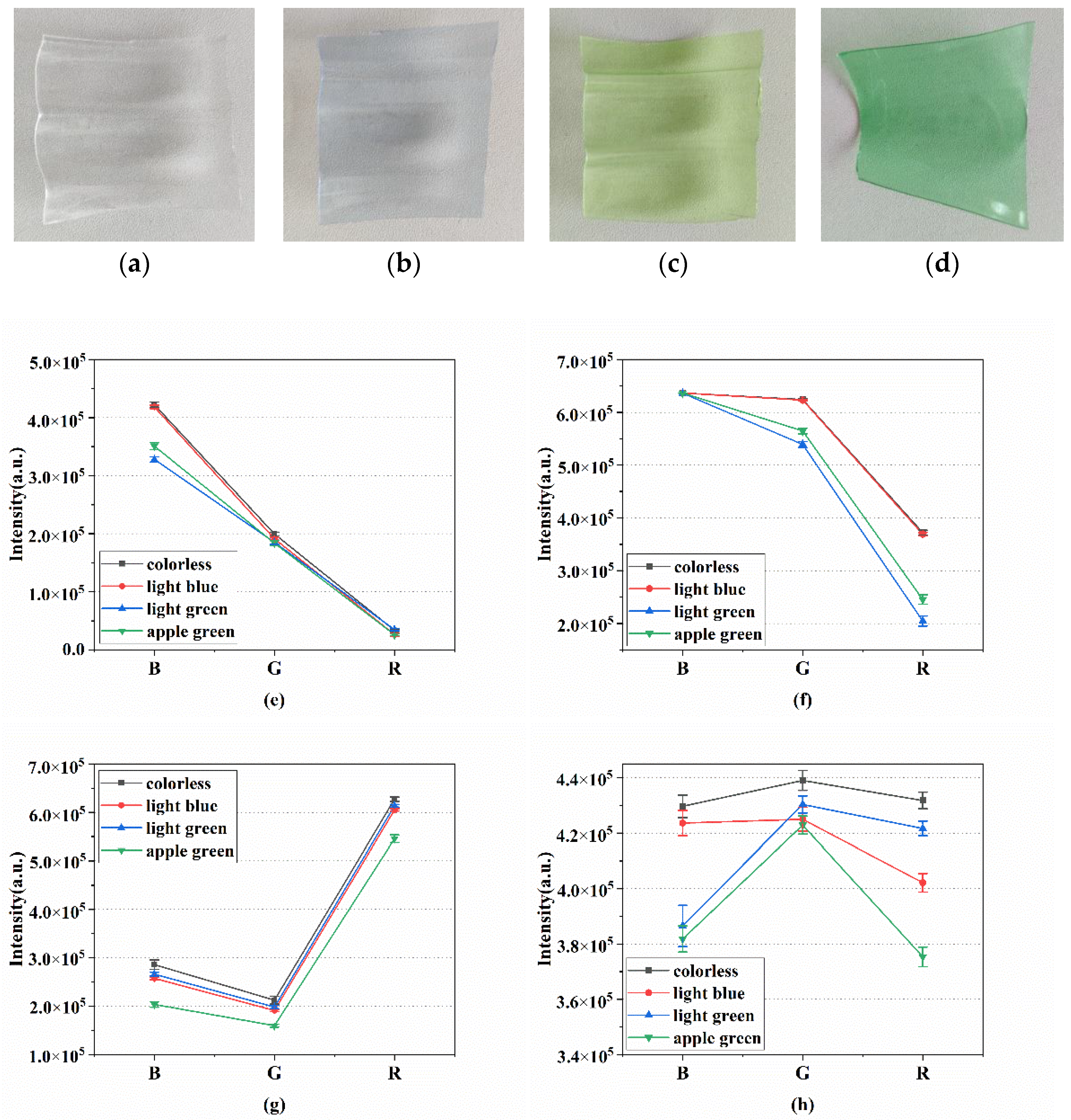

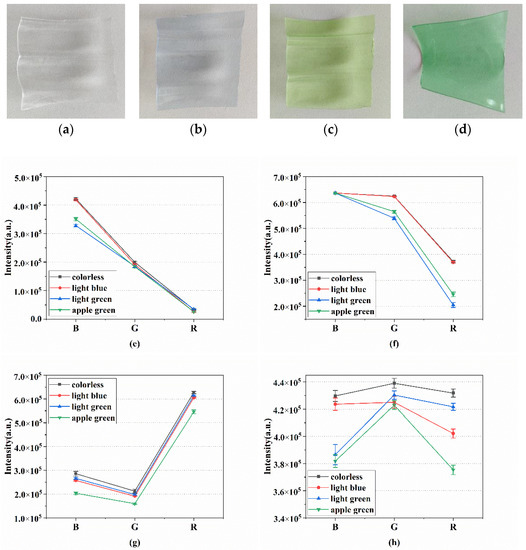

Colorless, light blue, light green and apple green transparent plastics, which are commonly used in daily life, were used as the experimental samples. The material of the samples was Polyethylene Terephthalate (PET) because the PET material is widely used in consumer goods packaging and is of the highest scrap value for its environmental friendliness, low cost and ease of recycling [23,24]. As shown in Figure 2a–d, the samples were taken from PET plastic bottles, thus the samples were arc-shaped and the size of the samples was about 3 cm × 3 cm.

Figure 2.

The colorless (a), light blue (b), light green (c) and apple green (d) transparent plastic used in the experiment and the transmission spectra of the transparent plastics at transmission light sources of 381 nm (e), 439 nm (f), 620 nm (g) and white (h).

There were 40 samples for each color of plastic and each sample was, respectively, measured at 381 nm, 439 nm, 620 nm and white transmission light source to obtain the corresponding transmission spectrum. Shown in Figure 2e–h are the transmission spectra for the plastics of the 4 colors at each transmission light source. The transmission spectrum is described by R, G and B wavebands [25], and each shown spectrum is the mean of the 40 transmission spectra of the 40 samples of the same color.

3. Results and Discussion

3.1. Characteristics of Transmission Spectrum

The color of the transparent plastic depends on the wavelength of the light that is passing through the plastic [26,27,28], as shown in Figure 2e–h, the plastics of the four colors possess different transmission spectra at a same transmission light source. However, because the four colors of the plastics are similar, the transmission spectra of the plastics may also be similar at certain wavelengths of light source. The ratios of the R, G and B wavebands can magnify the difference in the transmission spectra, and furthermore, the ratios are stable for a certain color because they are only related to the color and are not affected by other factors such as light intensity. Therefore, the ratios of the R, G and B wavebands were used as color parameters to describe the difference in the transmission spectra of transparent plastics with different colors. The ratios of the R, G and B wavebands, that are BG, GR and RB, were calculated using Equations (1)–(3). Each transmission spectrum contributes a set of color parameters BG, GR and RB.

where (B/G)plastic, (G/R)plastic and (R/B)plastic are calculated from the transmission spectrum of the plastic, and (B/G)light, (G/R)light and (R/B)light are calculated from the spectrum of the light source that is acquired by the camera when there is no plastic sample. By dividing the parameters calculated from the light source spectrum, the influence of the light source can be eliminated in the color parameter calculation.

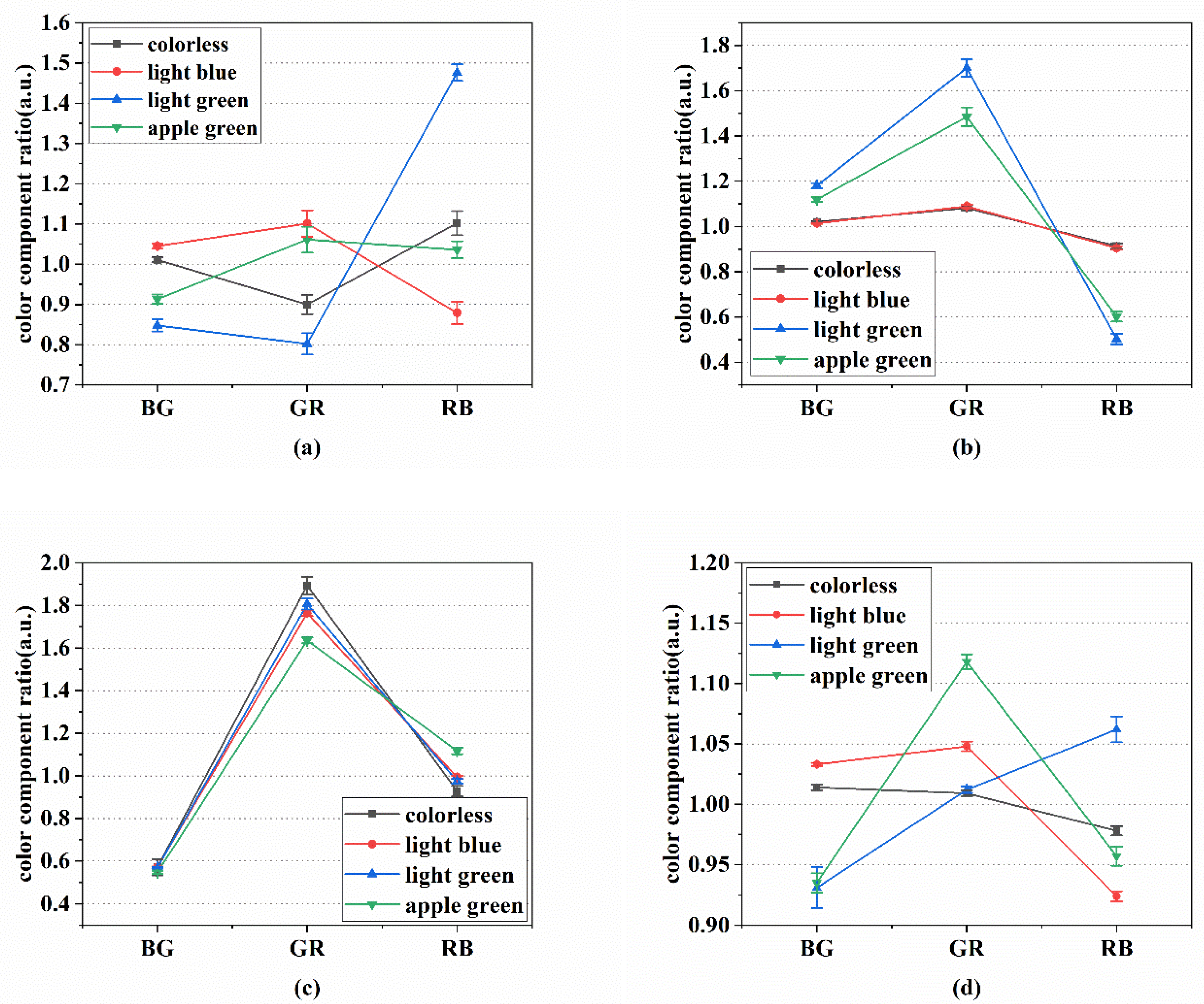

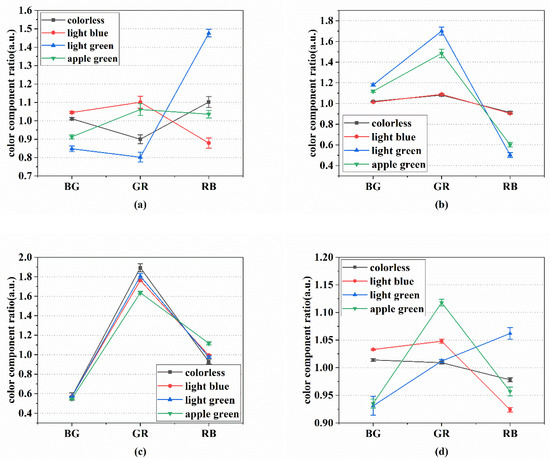

For each sample, the color parameters BG, GR and RB were calculated from the transmission spectra that were obtained at the 381 nm, 439 nm, 620 nm and white transmission light sources. As described in Section 2.2, for each color of plastic, there were 40 samples, thus there were 40 sets of color parameters BG, GR and RB at each wavelength of transmission light source. The mean values of the 40 sets of color parameters were, respectively, calculated for each color of plastic at each wavelength of transmission light source, as shown in Table 1 and Figure 3.

Table 1.

The mean values of the color parameters BG, GR and RB of the colorless, light blue, light green and apple green plastics at 381 nm, 439 nm, 620 nm and white transmission light sources.

Figure 3.

The mean values of the color parameters BG, GR and RB of the colorless, light blue, light green and apple green plastic at 381 nm (a), 439 nm (b), 620 nm (c) and white (d) transmission light sources.

As can be seen from Figure 3, on the whole, the color parameters BG, GR and RB of the transparent plastics of the four colors show differences both in patterns and values at each light source. Therefore, color parameters BG, GR and RB can be used for color recognition of transparent plastic. However, it should be pointed out that at 439 nm light source, the color parameters of the colorless and light blue transparent plastics were almost the same (Figure 3b), and at 620 nm light source, the color parameters of light blue and light green had little difference (Figure 3c). Therefore, in some application scenarios, there may be difficulties in accurate recognition of similar colors when only using the color parameters obtained at a single wavelength transmission light source. According to the above analysis, the color parameters obtained at multi-wavelength transmission light sources were used in this paper to set up a stable and effective color feature to ensure the accurate recognition of similar colors.

3.2. Color Feature

Based on the analysis in Section 3.1, the color feature F for each sample was set up using color parameters BG, GR and RB that were obtained at 381 nm, 439 nm, 620 nm and white light sources, as described in Equation (4).

where the subscript of BG, GR and RB indicates that the parameter is calculated from the transmission spectrum acquired at the light source with that wavelength. α, β and γ are, respectively, the weights of the color parameters BG, GR and RB.

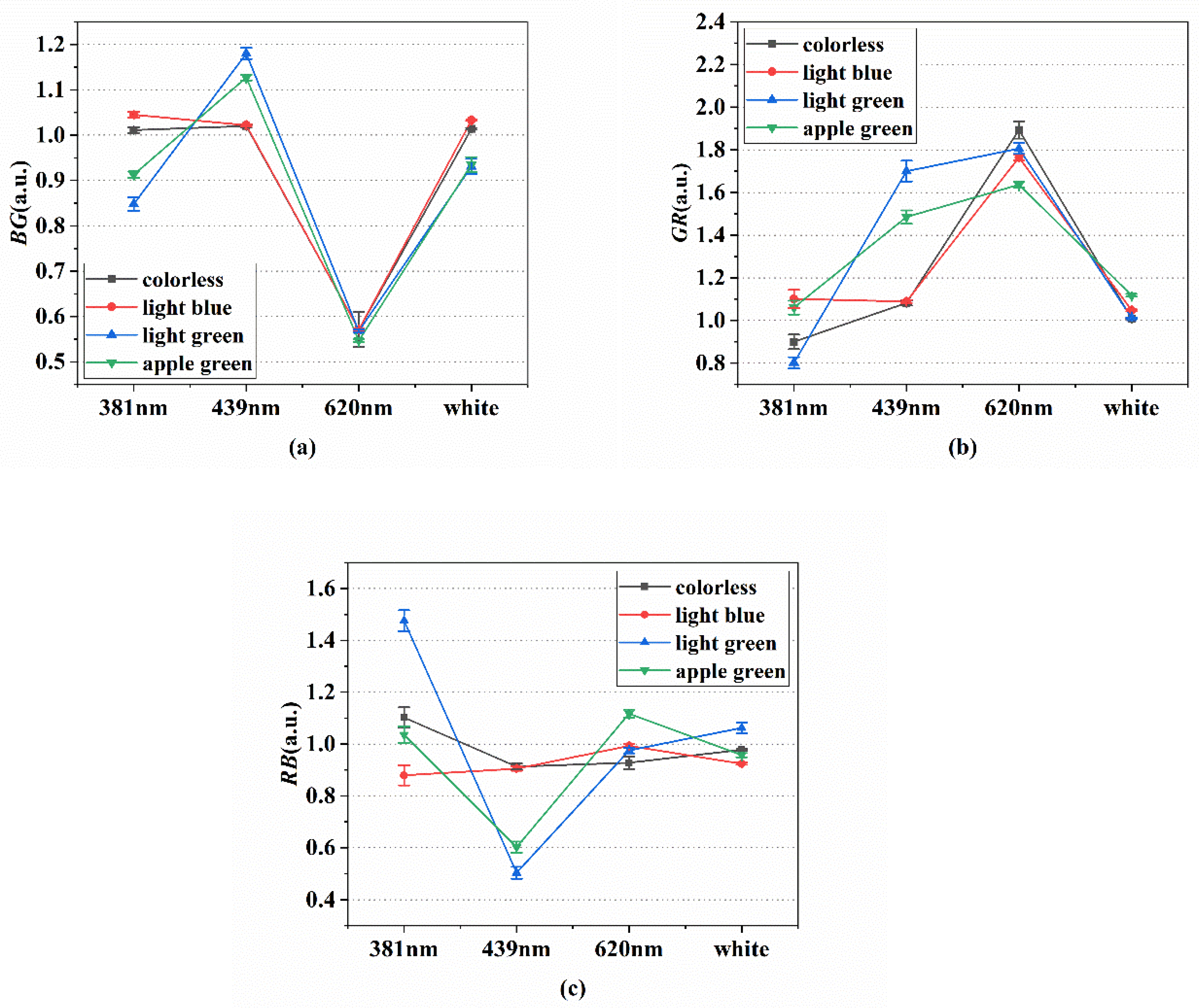

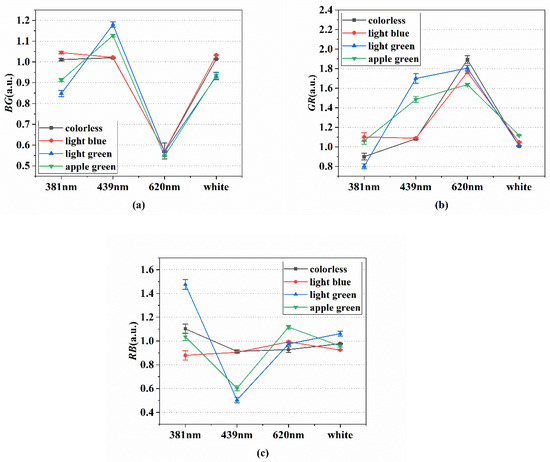

The values of α, β and γ depend on the ability of the parameters BG, GR and RB to reflect the color difference. As shown in Figure 4, the ability of the color parameters BG, GR and RB to reflect the color difference is different, and the coefficient of variation was employed to evaluate the ability of the color parameters BG, GR and RB to reflect color difference. For each color parameter, the coefficient of variation of the values at each transmission wavelength was calculated, and four coefficients of variation were obtained and then the mean of the four coefficients of variation was calculated, as shown in Table 2. The ratio of the mean values of the coefficients of variation of BG, GR and RB was about 1:2.2:2.4, consequently, α:β:γ was initially set to 1:2.2:2.4. However, further analysis showed that although the mean of the coefficient of variation of BG was small, the coefficients of variation at the wavelength of 381 nm and 439 nm were relatively large, which can reflect the color difference. Therefore, the proportion of α should be appropriately increased. Multiple groups of α:β:γ were analyzed by the experiment, and the results showed that the color recognition effect was the best when α:β:γ was about 1:2:2. Generally, the sum of α, β and γ was set to 1, therefore, α = 0.2, β = 0.4, γ = 0.4. It should be pointed out that the sum of α, β and γ can be set to other values as long as the ratio of the weights is not changed.

Figure 4.

The color parameters BG (a), GR (b) and RB (c) of colorless, light blue, light green and apple green plastic.

Table 2.

Coefficient of variation of the color parameters BG, GR and RB.

As there were 40 samples, respectively, for the colorless, light blue, light green and apple green plastic, 40 sets of color features were obtained for each color category and were labeled by 1, 2, 3 and 4, respectively. Finally, a sample set containing 160 sets of color features was established.

3.3. Establishment and Validation of Color Recognition Model

Naive Bayes model is one of the most widely used classification models in machine learning due to its simplicity, high efficiency and effectiveness [29,30]. In this paper, a color recognition model was established by training the naïve Bayes model using the labeled color features. The training and validation process of the model is as follows:

Step 1, the 160 sets of color features were divided into a training set and validation set.

Step 2, the prior probability of each color category P(Cj) (j = 1, 2, 3, 4) was calculated using the labeled color features in the training set (Equation (5)).

where Cj (j = 1, 2, 3, 4) is the color category, which is colorless, light blue, light green and apple green in order. NCj is the number of color features belonging to the color category Cj in the training set and Nall is the total number of color features in the training set.

Step 3, the conditional probabilities of the color parameters in each color category in the training set were calculated using Equation (6).

where F(i) (i = 1, 2, …, 12) is the color parameter in the color feature, which is αBG381nm, αBG439nm, αBG620nm, αBGwhite, βGR381nm, βGR439nm, βGR620nm, βGRwhite, γRB381nm, γRB439nm, γRB620nm and γRBwhite in order. Each color parameter possessed a conditional probability curve.

Step 4, for a color feature F′ in the validation set, the posterior probability P(Cj|F′) of F′ belonging to the color category Cj (j = 1, 2, 3, 4) was calculated using Equations (7) and (8), and the color category with the largest posterior probability estimate value was the final category.

where P(F’(i)|Cj) (i = 1, 2, 3, …, 12, j = 1, 2, 3, 4) is the conditional probability of the color parameter of color feature F’ in each color category, and it was calculated from the corresponding conditional probability curve obtained in step 3. P(Cj) is the prior probability that was obtained in step 2. P(F’) is a constant, thus the largest posterior probability can be obtained by comparing the numerator of Equation (7) without calculating P(F’).

A 10-fold cross validation was performed to evaluate the average recognition performance of the model, and the average confusion matrix is shown in Table 3, where colorless, light blue, light green and apple green transparent plastic are, respectively, labeled 1 to 4, and rows and columns represent actual and predicted values, respectively. It can be seen from the confusion matrix that the color recognition accuracy was 100%.

Table 3.

Confusion matrix of the color recognition results.

4. Conclusions

In this paper, a color recognition method for transparent plastics with similar colors was proposed based on the ratios of R, G and B wavebands of the transmission spectra obtained at multiple wavelength light sources. A color recognition model was established based on the naive Bayes classification model, and the color recognition accuracy for colorless, light blue, light green and apple green transparent plastic reached 100%. The proposed method solves the problem of the traditional machine vision method that is unable to accurately recognize similar colors, while the algorithm complex and cost of the proposed method are much lower than the deep-learning-based machine vision method. The work of this paper provides theoretical and technical support for the establishment of an accurate and rapid online sorting technique for transparent plastics with similar colors. At the same time, it should be pointed out that, according to different color recognition requirements, the weights of the color parameters BG, GR and RB may need to be adjusted to achieve the optimal color recognition effect.

Author Contributions

Conceptualization, C.S., F.D. and X.G.; Methodology, C.S., C.L. and S.Y.; Software, F.D. and M.L.; Validation, F.D.; Formal Analysis, M.L. and S.Y.; Investigation, F.D., C.S. and C.L.; Resources, S.Z. and Z.W.; Data Curation, M.L. and S.Y.; Writing—Original Draft Preparation, F.D.; Writing—Review and Editing, C.S. and C.L.; Visualization, F.D. and C.S.; Supervision, C.L. and C.S.; Project Administration, X.G.; Funding Acquisition, C.S., Z.W. and S.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Excellent Young Talents Fund Program of Higher Education Institutions of Anhui Province (Nos. gxyq2021229, gxyqZD2018071), the Natural Science Foundation of Higher Education Institutions of Anhui Province (Nos. KJ2021A0979, KJ2021A0981) and the Key Discipline Construction Project of Hefei University (No. 2018XK03).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhu, B.; Wang, D.; Wei, N. Enzyme discovery and engineering for sustainable plastic recycling. Trends Biotechnol. 2022, 40, 22–37. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; You, F. Waste high-density polyethylene recycling process systems for mitigating plastic pollution through a sustainable design and synthesis paradigm. AIChE J. 2022, 67, e17127. [Google Scholar] [CrossRef]

- Nelms, S.E.; Easman, E.; Anderson, N.; Berg, M.; Coates, S.; Crosby, A.; Eisfeld-Pierantonio, S.; Eyles, L.; Flux, T.; Gilford, E.; et al. The role of citizen science in addressing plastic pollution: Challenges and opportunities. Environ. Sci. Policy 2022, 128, 14–23. [Google Scholar] [CrossRef]

- Horton, A.A. Plastic pollution: When do we know enough? J. Hazard. Mater. 2022, 422, 126885. [Google Scholar] [CrossRef] [PubMed]

- Fakirov, S. A new approach to plastic recycling via the concept of microfibrillar composites. Adv. Ind. Eng. Polym. Res. 2021, 4, 187–198. [Google Scholar] [CrossRef]

- Sebastian, J.; Lijo, P. Plastic recycling and regeneration. In Sustainable Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 339–365. [Google Scholar]

- Schwabl, D.; Markus, B.; Markus, L. Advancing plastic recycling by wet-mechanical processing of mixed waste fractions. Processes 2021, 9, 493. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Siddique, R.; Mendis, P.; Zhuge, Y.; Wong, S.H.; Lokuge, W.; Aravinthan, T.; Schubel, P. Recycling of landfill wastes (tyres, plastics and glass) in construction—A review on global waste generation, performance, application and future opportunities. Resour. Conserv. Recycl. 2021, 173, 105745. [Google Scholar] [CrossRef]

- Burgess, M.; Holmes, H.; Sharmina, M.; Shaver, M.P. The future of UK plastics recycling: One bin to rule them all. Resour. Conserv. Recycl. 2021, 164, 105191. [Google Scholar] [CrossRef]

- Baran, B. Plastic recycling in Poland—A transformation towards a circular economy? Pr. Nauk. Uniw. Ekon. We Wrocławiu 2021, 65, 1–10. [Google Scholar] [CrossRef]

- Shamsuyeva, M.; Endres, H.-J. Plastics in the context of the circular economy and sustainable plastics recycling: Comprehensive review on research development, standardization and market. Compos. Part C Open Access 2021, 6, 100168. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef] [PubMed]

- Henriksen, M.L.; Karlsen, C.B.; Klarskov, P.; Hinge, M. Plastic classification via in-line hyperspectral camera analysis and unsupervised machine learning. Vib. Spectrosc. 2021, 118, 103329. [Google Scholar] [CrossRef]

- Tan, Z.; Fei, Z.; Zhao, B.; Yang, J. Identification for recycling polyethylene terephthalate (pet) plastic bottles by polarization vision. IEEE Access 2021, 9, 27510–27517. [Google Scholar] [CrossRef]

- Chen, X.; Kroell, N.; Wickel, J.; Feil, A. Determining the composition of post-consumer flexible multilayer plastic packaging with near-infrared spectroscopy. Waste Manag. 2021, 123, 33–41. [Google Scholar] [CrossRef]

- Srigul, W.; Inrawong, P.; Kupimai, M. Plastic classification base on correlation of RGB color. In Proceedings of the 2016 13th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Chiang Mai, Thailand, 28 June–1 July 2016. [Google Scholar]

- Zhou, X.; Chen, J.; Zhu, K. Intelligent Sorting Method of Plastic Bottles Based on Convolution Neural Network. Digit. Manuf. Sci. 2021, 19, 227–232. [Google Scholar]

- Peršak, T.; Viltužnik, B.; Hernavs, J.; Klančnik, S. Vision-based sorting systems for transparent plastic granulate. Appl. Sci. 2020, 10, 4269. [Google Scholar] [CrossRef]

- Wang, Z.; Peng, B.; Huang, Y.; Sun, G. Classification for plastic bottles recycling based on image recognition. Waste Manag. 2019, 88, 170–181. [Google Scholar] [CrossRef]

- Mouli, C.C.; Jyothi, P.; Pradeep, K.P.J.; Raju, K.N. Design, Implementation and Comparative Study of Supervised Classification Algorithms for Object Sorting. IOSR J. Electr. Electron. Eng. 2014, 9, 51–60. [Google Scholar] [CrossRef]

- Erkinay Ozdemir, M.; Ali, Z.; Subeshan, B.; Asmatulu, E. Applying machine learning approach in recycling. J. Mater. Cycles Waste Manag. 2021, 23, 855–871. [Google Scholar] [CrossRef]

- Pelletier, M.G.; Holt, G.A.; Wanjura, J.D. A plastic contamination image dataset for deep learning model development and training. AgriEngineering 2020, 2, 317–321. [Google Scholar] [CrossRef]

- Zulkifley, M.A.; Mustafa, M.M.; Hussain, A.; Mustapha, A.; Ramli, S. Robust Identification of Polyethylene Terephthalate (PET) Plastics through Bayesian Decision. PLoS ONE 2014, 9, e114518. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, R.; Ma, X.; Shen, X.; Zhai, Y.; Zhang, T.; Ji, C.; Hong, J. PET bottles recycling in China: An LCA coupled with LCC case study of blanket production made of waste PET bottles. J. Environ. Manag. 2020, 260, 110062. [Google Scholar] [CrossRef] [PubMed]

- Singh, Y.K. Detection of Fire Regions Using RGB Color Variance. Int. J. Res. Eng. Sci. 2021, 9, 10–14. [Google Scholar]

- Wu, L. Fundamental Principle of Plastic Colouring. Plastics 1989, 5, 42–44+55. [Google Scholar]

- Xu, H. Color technical principle and its application to dyeing and finishing (II). China Dye. Finish. 2005, 19, 40–44. [Google Scholar]

- Berns, R.S. Billmeyer and Saltzman’s Principles of Color Technology; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- He, W. Research on Text Classification Algorithm Based on Naive Bayes. Master’s Thesis, Nanjing University of Posts and Telecommunications, Nanjing, China, 2018. [Google Scholar]

- Theodoridis, S. Machine Learning: A Bayesian and Optimization Perspective; Academic Press: Cambridge, MA, USA, 2015. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).