Stress Intensity Factor and Shape Coefficient Correction of Non-Penetrating Three-Dimensional Crack for Brittle Ampoule Bottle with V-Shaped Notch

Abstract

:1. Introduction

2. Theory and Method of Fracture Mechanics Based on the FEM

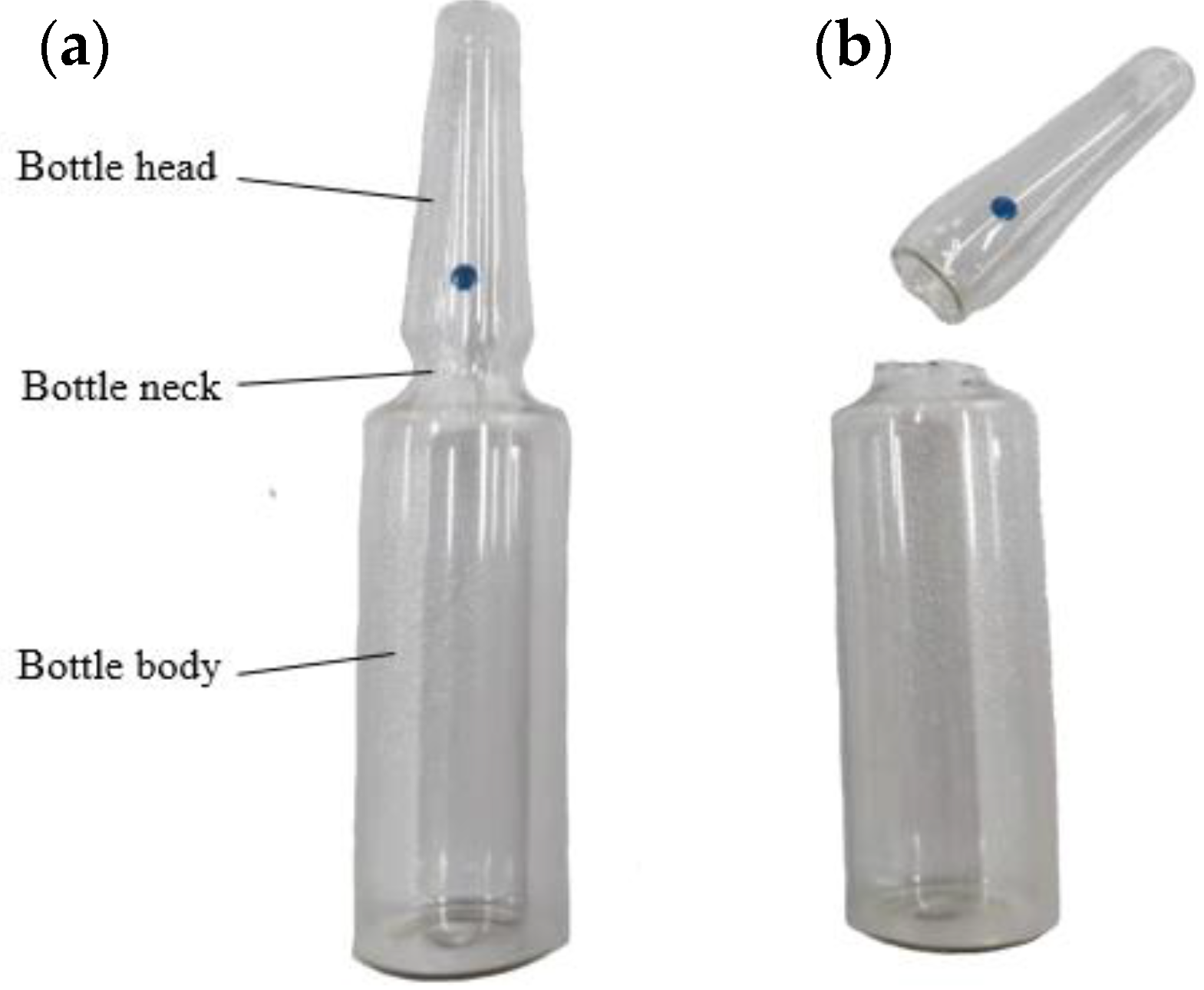

2.1. Mechanical Model of an Ampoule Bottle with the Crack on the Neck

2.2. Mesh Model of the FEM in Fracture Mechanics

2.3. Stress Intensity Factor and Shape Coefficient of the Crack

2.4. Calculation of the SIF Based on the FEM

2.5. Correction of Crack Shape Coefficient

2.6. Verification Method of Shape Coefficient Correction

3. Results and Discussion

3.1. The Influence of Mesh Size on the Coefficient K

3.2. Results and Analysis of the Coefficient K at the Crack Front

3.3. Corrected Shape Coefficient with a V-Shaped Notch

3.4. Verification of the Corrected Shape Coefficient

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Liang, Y. The New Version of GMP Tutorial; China Medical Science and Technology Press: Beijing, China, 2011. [Google Scholar]

- Abdellah, A.; Noordin, M.I.; Ismail, W.A.W. Importance and globalization status of good manufacturing practice (GMP) requirements for pharmaceutical excipients. Saudi Pharm. J. 2015, 23, 9–13. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Arayne, M.S.; Sultana, N.; Zaman, M.K. Historical incidents leading to the evolution of good manufacturing practice. Accredit. Qual. Assur. 2008, 13, 431–432. [Google Scholar] [CrossRef]

- National Pharmacopoeia Commission. Pharmacopoeia of the People’s Republic of China: 2015 Edition; China Pharmaceutical Science and Technology Press: Beijing, China, 2015. [Google Scholar]

- Gad, S.C. United States Pharmacopoeia (USP). In Encyclopedia of Toxicology, 3rd ed.; Academic Press: Waltham, MA, USA, 2014; pp. 881–882. [Google Scholar]

- Yin, H.; Qi, H.J.; Fan, F.; Zhu, T.; Wang, B.; Wei, Y. Griffith criterion for brittle fracture in graphene. Nano Lett. 2015, 15, 1918–1924. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, K.; Takahiro, S.; Ozaki, N.; Hagiwara, Y.; Sumigawa, T.; Guo, L.; Kitamura, T. A unified and universal Griffith-based criterion for brittle fracture. Int. J. Solids Struct. 2017, 128, 67–72. [Google Scholar] [CrossRef]

- Guo, X.; Zhou, H.; Zhang, L.; Wu, W.; Zhang, J.; Huang, Y. Investigation on the crack healing effect in dimethyl phthalate series glassy materials. Acta Phys. Sin. 2010, 59, 417–421. [Google Scholar]

- Zhao, J.X.; Qu, R.T.; Wu, F.F.; Zhang, Z.F.; Shen, B.L.; Stoica, M. Fracture mechanism of some brittle metallic glasses. J. Appl. Phys. 2009, 105, 1505. [Google Scholar] [CrossRef]

- Richard, C.B. Applying fractography and fracture mechanics to the energy and mass of crack growth for glass in the mirror region. J. Eur. Ceram. Soc. 2014, 34, 3255–3262. [Google Scholar]

- Pourmoghaddam, N.; Kraus, M.A.; Schneider, J.; Siebert, G. Relationship between strain energy and fracture pattern morphology of thermally tempered glass for the prediction of the 2D macro-scale fragmentation of glass. Glass Struct. Eng. 2019, 4, 257–275. [Google Scholar] [CrossRef] [Green Version]

- Pourmoghaddam, N.; Kraus, M.; Schneider, J.; Siebert, G. The geometrical properties of random 2D Voronoi tesselations for the prediction of the tempered glass fracture pattern. Ce/Papers 2018, 2, 325–339. [Google Scholar] [CrossRef]

- Ameri, M.; Mansourian, A.; Khavas, M.H.; Aliha, M.; Ayatollahi, M. Cracked asphalt pavement under traffic loading—A 3D finite element analysis. Eng. Fract. Mech. 2011, 78, 1817–1826. [Google Scholar] [CrossRef]

- Yang, S.; Li, C.Q.; Yang, W. Analytical model of elastic fracture toughness for steel pipes with internal cracks. Eng. Fract. Mech. 2016, 153, 50–60. [Google Scholar] [CrossRef] [Green Version]

- Qin, T.Y.; Yu, Y.S.; Noda, N.A. Finite-part integral and boundary element method to solve three-dimensional crack problems in piezoelectric materials. Int. J. Solids Struct. 2007, 44, 4770–4783. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Qi, Y.; Feng, D.; Shi, X.; Wan, T. Numerical analysis of a single-sided cracked plate with elliptical holes. Chin. J. Mech. Eng.-Eng. 2012, 48, 86–90. [Google Scholar] [CrossRef]

- Lin, X.B.; Smith, R.A. Finite element modelling of fatigue crack growth of surface cracked plates. Eng. Fract. Mech. 1999, 63, 503–522. [Google Scholar] [CrossRef]

- Diamantoudis, A.T.H.; Labeas, G.N. Stress intensity factors of semi-elliptical surface cracks in pressure vessels by global-local finite element methodology. Eng. Fract. Mech. 2004, 72, 1299–1312. [Google Scholar] [CrossRef]

- Kamaya, M.; Kitamura, T. Stress intensity factors of microstructurally small crack. Int. J. Fract. 2003, 124, 201–213. [Google Scholar] [CrossRef]

- Newman, J.C.; Raju, I.S. An empirical stress-intensity factor equation for the surface crack. Eng. Fract. Mech. 1976, 15, 185–192. [Google Scholar] [CrossRef]

- Miyazaki, K.; Mochizuk, M. The Effects of Residual Stress Distribution and Geometry of Component on the Stress Intensity Factor of Surface Crack. In Proceedings of the Pressure Vessels and Piping Division, Proceedings of the ASME Pressure Vessels and Piping Conference, Denver, CO, USA, 17–21 July 2005. [Google Scholar]

- Predan, J.; Močilnik, V.; Gubeljak, N. Stress intensity factors for circumferential semi-elliptical surface cracks in a hollow cylinder subjected to pure torsion. Eng. Fract. Mech. 2013, 105, 152–168. [Google Scholar] [CrossRef]

- Carpinteri, A.; Vantadori, S. Sickle-shaped surface crack in a notched round bar under cyclic tension and bending. Fatigue Fract. Eng. Mater. Struct. 2009, 32, 223–232. [Google Scholar] [CrossRef]

- Yazdanmehr, A.; Soltani, N. Evaluation of stress intensity factors of rounded V and U notches under mixed mode loading, using the experimental method of caustics. Theor. Appl. Fract. Mec. 2014, 74, 79–85. [Google Scholar] [CrossRef]

- Zhang, J.; Dong, Y.; Ju, C.; Lin, W. A new singular element for evaluating stress intensity factors of V-shaped notches under mixed-mode load. Eng. Anal. Bound. Elem. 2018, 93, 161–166. [Google Scholar] [CrossRef]

- Barry, D.F.; Kevin, Z.T. An evaluation of fracture mechanics quarter-point displacement techniques used for computing stress intensity factors. Eng. Struct. 1999, 21, 406–415. [Google Scholar]

- Zhang, X.; Hu, R.; Kang, S.; Zhang, R.; Wang, P.; Zuo, F.; Wang, Y.; Wang, Y.; Liu, C.; Wang, M.; et al. Ansys 14.0 Finite Element Analysis from Entry to Proficiency, 2nd ed.; Machinery Industry Press: Beijing, China, 2012; pp. 91–136. [Google Scholar]

- China Academy of Aeronautics and Astronautics. Handbook of Stress Intensity Factors; Science Press: Beijing, China, 1993. [Google Scholar]

- Zhang, H. ANSYS 14.0 Theoretical Analysis and Engineering Application Examples; Mechanical Industry Press: Beijing, China, 2013. [Google Scholar]

- Walters, M.C.; Paulino, G.H.; Dodds, R.H. Interaction integral procedures for 3-D curved cracks including surface tractions. Eng. Fract. Mech. 2005, 72, 1635–1663. [Google Scholar] [CrossRef]

- He, J.; Cheng, G.; Wei, W.; Zhu, X.; Lu, Y.; Wu, J.; Zhu, G. Numerical study on stress intensity factors of elliptical cracks on cylindrical surface. J. Xi’An Jiaotong Univ. 2009, 43, 63–68. [Google Scholar]

- Meng, B.; Yu, C. Finite element analysis of stress intensity factor of V-notch root crack. J. Nanjing Univ. Aeronaut. Astronaut. 2009, 41, 126–129. [Google Scholar]

- Filippi, S.; Lazzarin, P.; Tovo, R. Developments of some explicit formulas useful to describe elastic stress fields ahead of notches in plates. Int. J. Solids Struct. 2002, 39, 4543–4565. [Google Scholar] [CrossRef]

- Nabavi, S.M.; Shahani, A.R. Calculation of stress intensity factors for a longitudinal semi-elliptical crack in a finite-length thick-walled cylinder. Fatigue Fract. Eng. Mater. Struct. 2010, 31, 85–94. [Google Scholar] [CrossRef]

- Chen, J.; Pan, H. Stress intensity factor of semi-elliptical surface crack in a cylinder with hoop wrapped composite layer. Int. J. Press. Vessel. Pip. 2013, 110, 77–81. [Google Scholar] [CrossRef]

- Yu, D.; Chen, Y. Three-dimensional finite element analysis of stress intensity factors of cracked screw joints. Chin. J. Mech. Eng.-Eng. 2011, 47, 121–126. [Google Scholar] [CrossRef]

- Song, Z.; Fang, S.; Xie, J. Research on the stress intensity factor of the root cracks of T-shaped welded joints. Chin. J. Mech. Eng.-Eng. 2013, 49, 87–94. [Google Scholar] [CrossRef]

| Items | Material | Density | Elastic Young’s Modulus | Poisson’s Ratio |

|---|---|---|---|---|

| Ampoule bottle | High borosilicate glass | 2.23 g/cm3 | 67 GPa | 0.2 |

| a/t | a/c | |||||||

|---|---|---|---|---|---|---|---|---|

| 0.2 | 0.4 | 0.6 | 0.8 | |||||

| 0.2 | 821.02 | +∞ | 1000.00 | +∞ | 35.71 | +∞ | 25.71 | +∞ |

| 0.3 | 77.50 | +∞ | 40.00 | +∞ | 1500.00 | +∞ | 50.26 | +∞ |

| 0.4 | 51.65 | +∞ | 38.60 | +∞ | 56.25 | +∞ | 1351.35 | +∞ |

| 0.5 | 49.29 | +∞ | 34.67 | +∞ | 39.23 | +∞ | 60.52 | +∞ |

| 0.6 | 43.88 | +∞ | 29.11 | +∞ | 30.66 | +∞ | 32.96 | +∞ |

| 0.7 | 34.67 | +∞ | 30.16 | +∞ | 25.21 | +∞ | 22.73 | +∞ |

| 0.8 | 28.57 | +∞ | 29.23 | +∞ | 23.33 | +∞ | 21.53 | +∞ |

| a/c | R/r | |||

|---|---|---|---|---|

| 1.2 | 1.4 | 1.6 | 1.8 | |

| 0.2 | 1.90357(a/t)2+ 0.02693(a/t)+ 3.65907 | 2.52857(a/t)2− 0.63657(a/t)+ 3.84057 | 2.47716(a/t)2− 0.35966(a/t)+ 3.66329 | 2.73214(a/t)2− 0.49364(a/t)+ 3.69364 |

| 0.4 | 1.6(a/t)2− 0.291(a/t)+ 3.3385 | 1.03571(a/t)2+ 0.28429(a/t)+ 3.26621 | 1.92857(a/t)2− 0.49857(a/t)+ 3.38957 | 2.20714(a/t)2− 0.39214(a/t)+ 3.36914 |

| 0.6 | 1.44286(a/t)2− 0.430(a/t)+ 2.95586 | 0.175(a/t)2+ 0.5125(a/t)+ 2.926 | 0.2(a/t)2+ 0.46(a/t)+ 2.915 | 1.15357(a/t)2+ 0.09493(a/t)+ 2.97157 |

| 0.8 | −0.125(a/t)2+ 0.5925(a/t)+ 2.475 | 0.52143(a/t)2 0.09243(a/t)+ 2.68243 | 0.35(a/t)2+ 0.189(a/t)+ 2.618 | 0.55714(a/t)2+ 0.27886(a/t)+ 2.63214 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, P.; Huang, X.; Gong, Y.; Li, S. Stress Intensity Factor and Shape Coefficient Correction of Non-Penetrating Three-Dimensional Crack for Brittle Ampoule Bottle with V-Shaped Notch. Appl. Sci. 2022, 12, 5246. https://doi.org/10.3390/app12105246

Yu P, Huang X, Gong Y, Li S. Stress Intensity Factor and Shape Coefficient Correction of Non-Penetrating Three-Dimensional Crack for Brittle Ampoule Bottle with V-Shaped Notch. Applied Sciences. 2022; 12(10):5246. https://doi.org/10.3390/app12105246

Chicago/Turabian StyleYu, Peng, Xuefeng Huang, Youping Gong, and Shengji Li. 2022. "Stress Intensity Factor and Shape Coefficient Correction of Non-Penetrating Three-Dimensional Crack for Brittle Ampoule Bottle with V-Shaped Notch" Applied Sciences 12, no. 10: 5246. https://doi.org/10.3390/app12105246