Mechanical Behavior of Large-Diameter Adjacent Shield Tunnelling Bridge Piles: A Case Study of Chunfeng Tunnel

Abstract

:1. Introduction

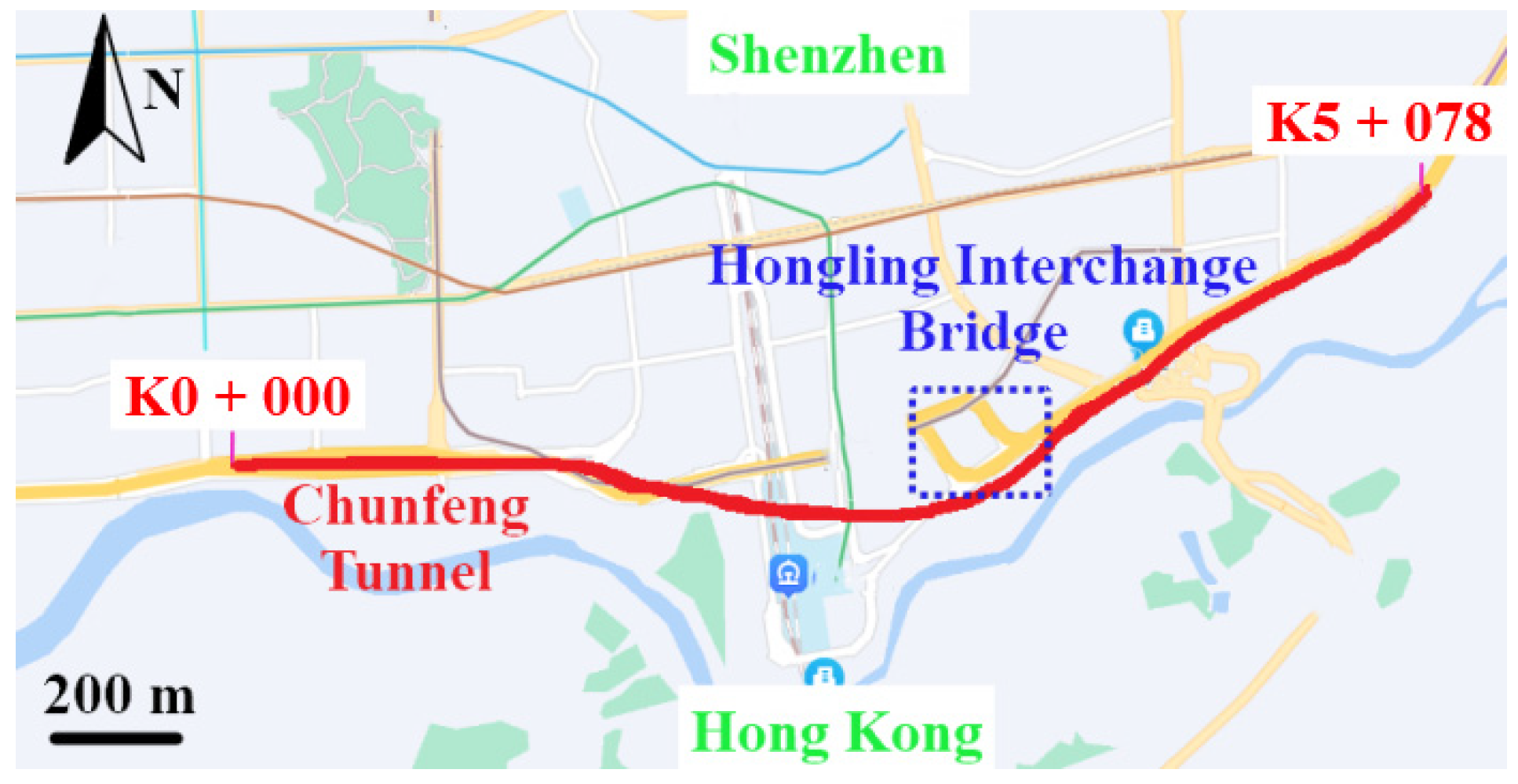

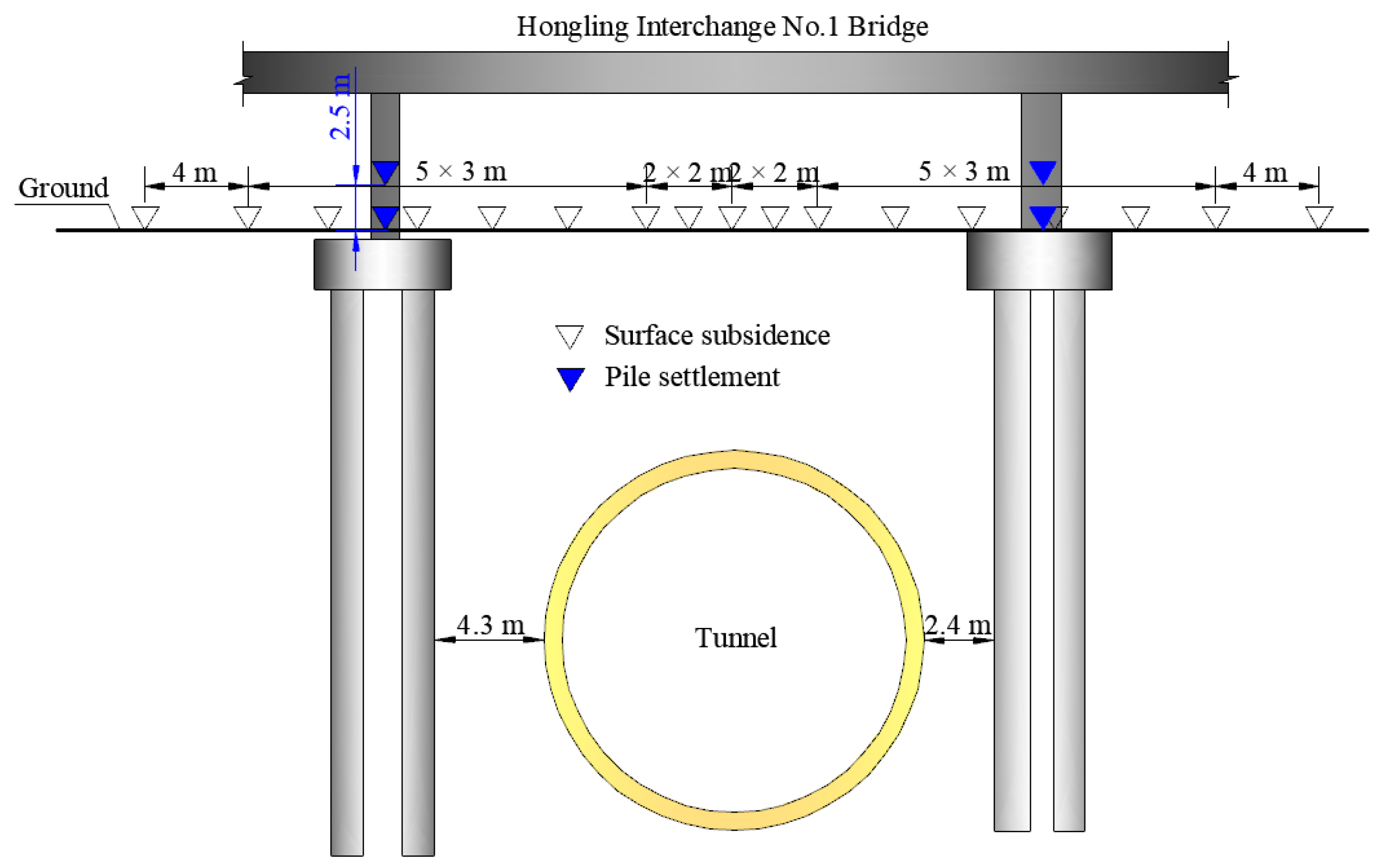

2. Engineering Background

2.1. Project Overview

2.2. Large-Diameter Slurry Shield

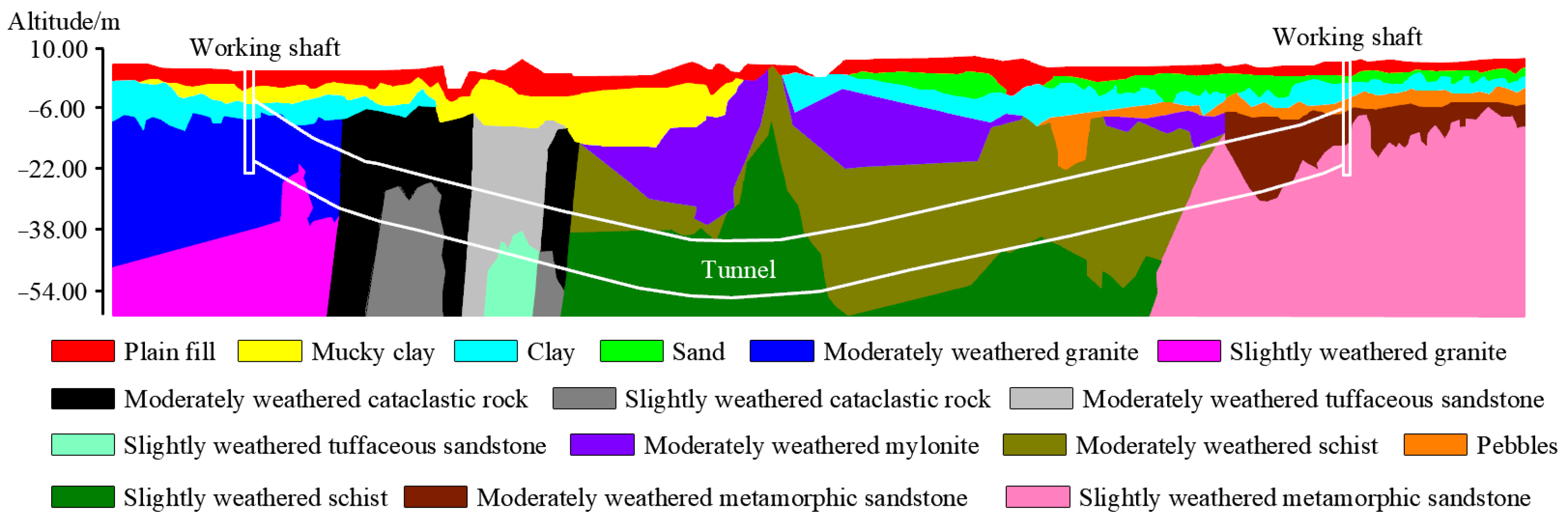

2.3. Engineering Geology

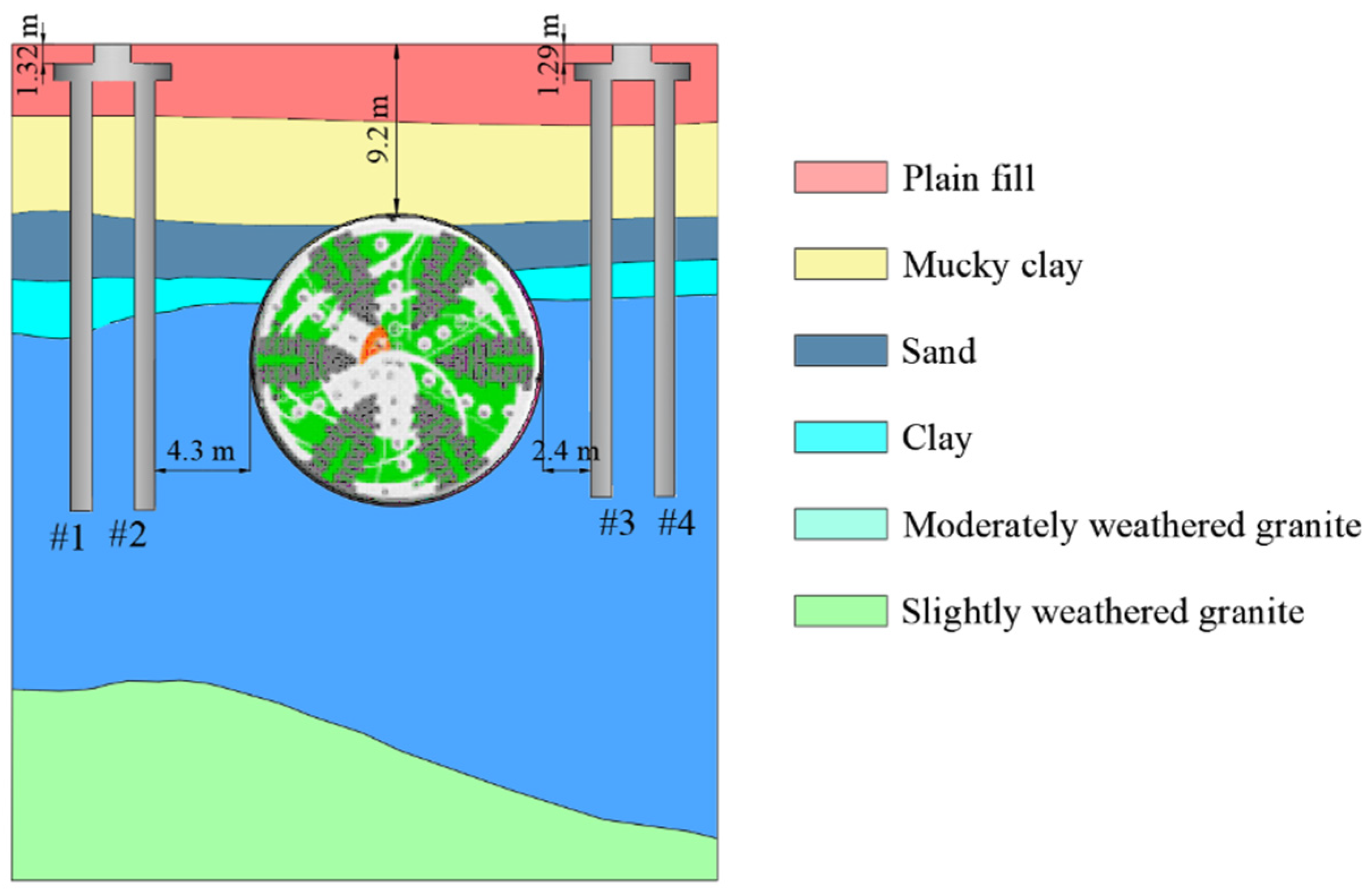

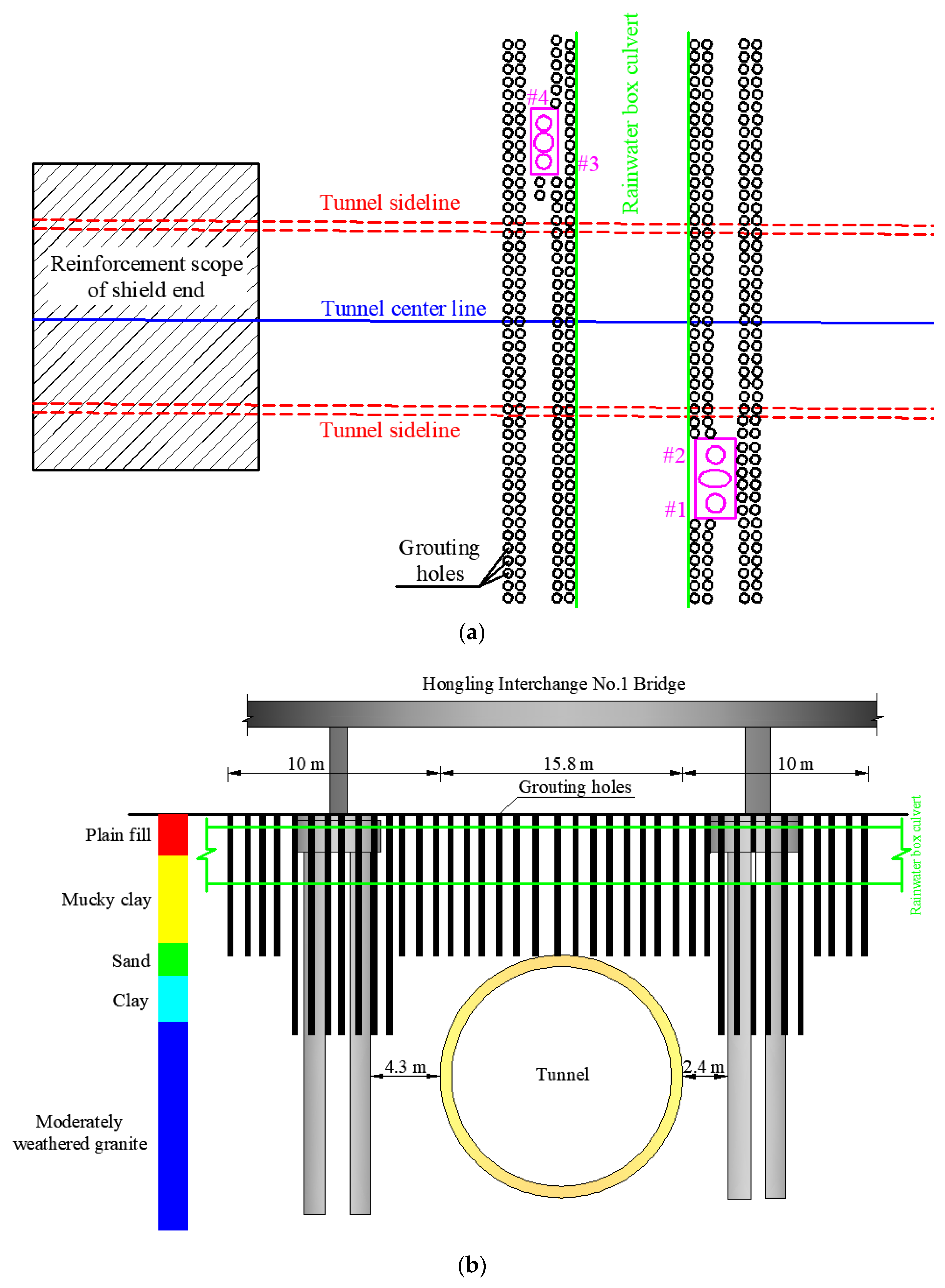

2.4. Problems and Solutions Encountered in Tunnel Excavation

3. Numerical Simulation of Mechanical Behaviour of Large-Diameter Adjacent Shield Tunnelling Bridge Piles

3.1. Bridge Piles Deformation Control Standard

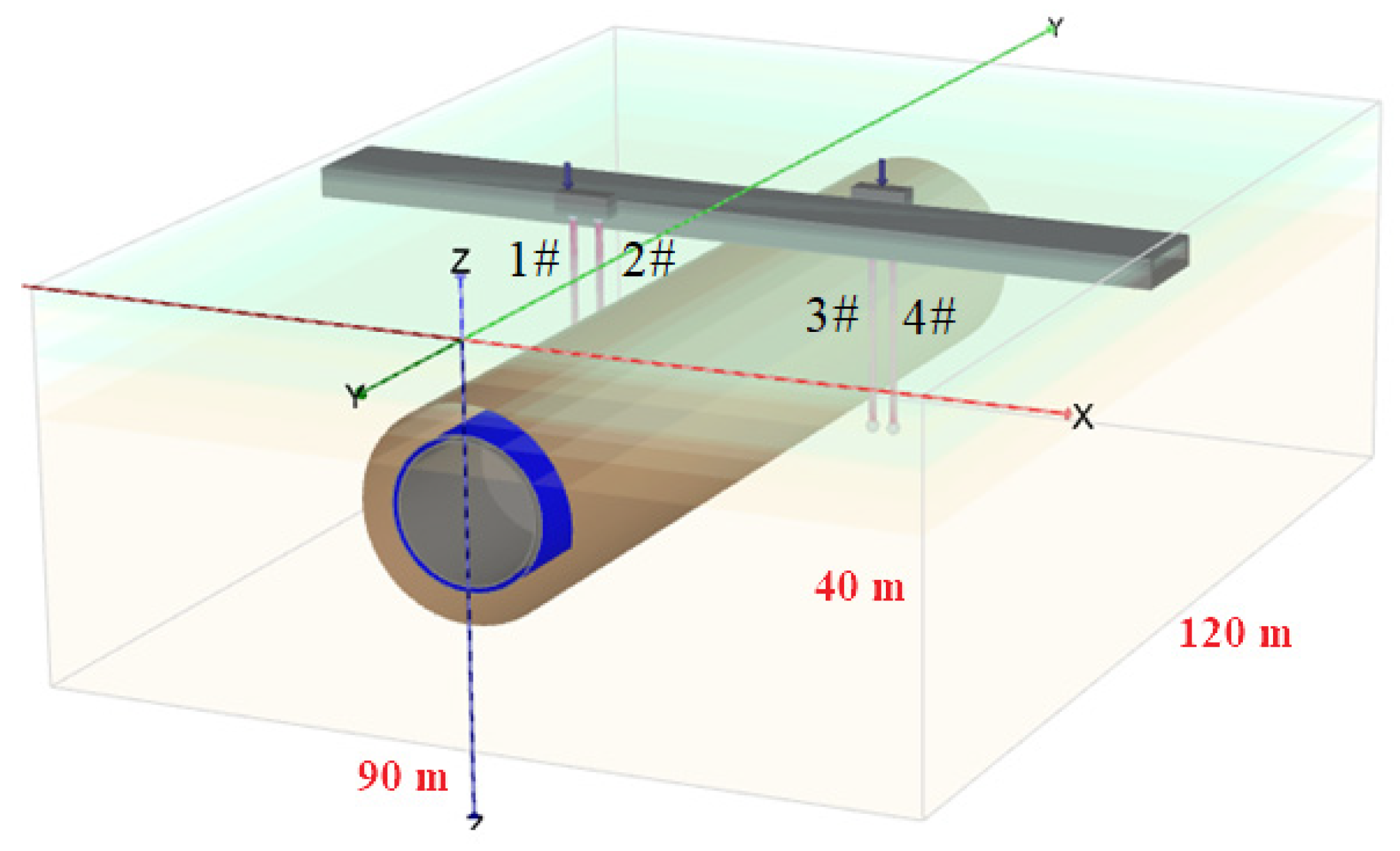

3.2. Establishment of Numerical Model

3.3. Analysis of Numerical Simulation Results

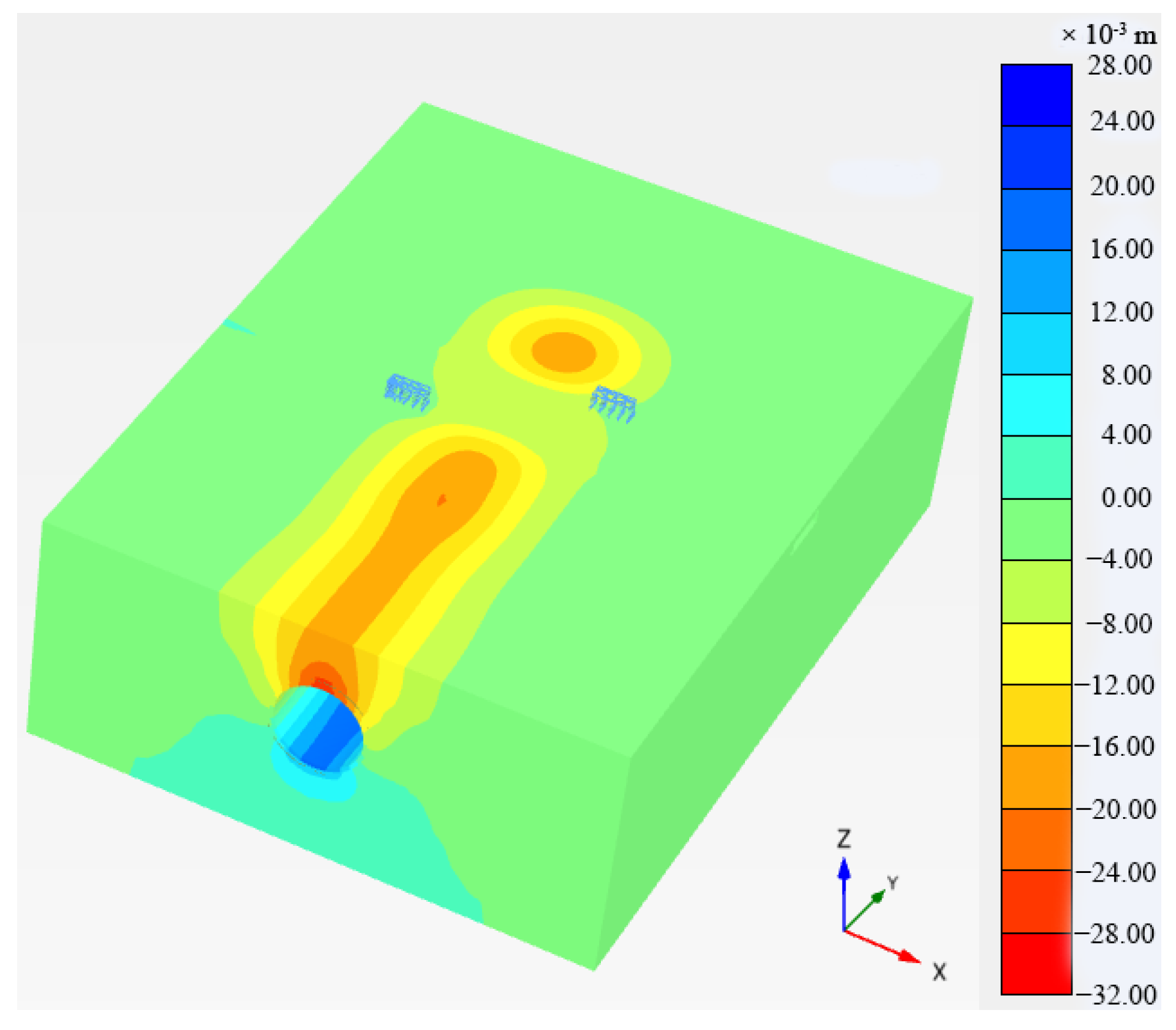

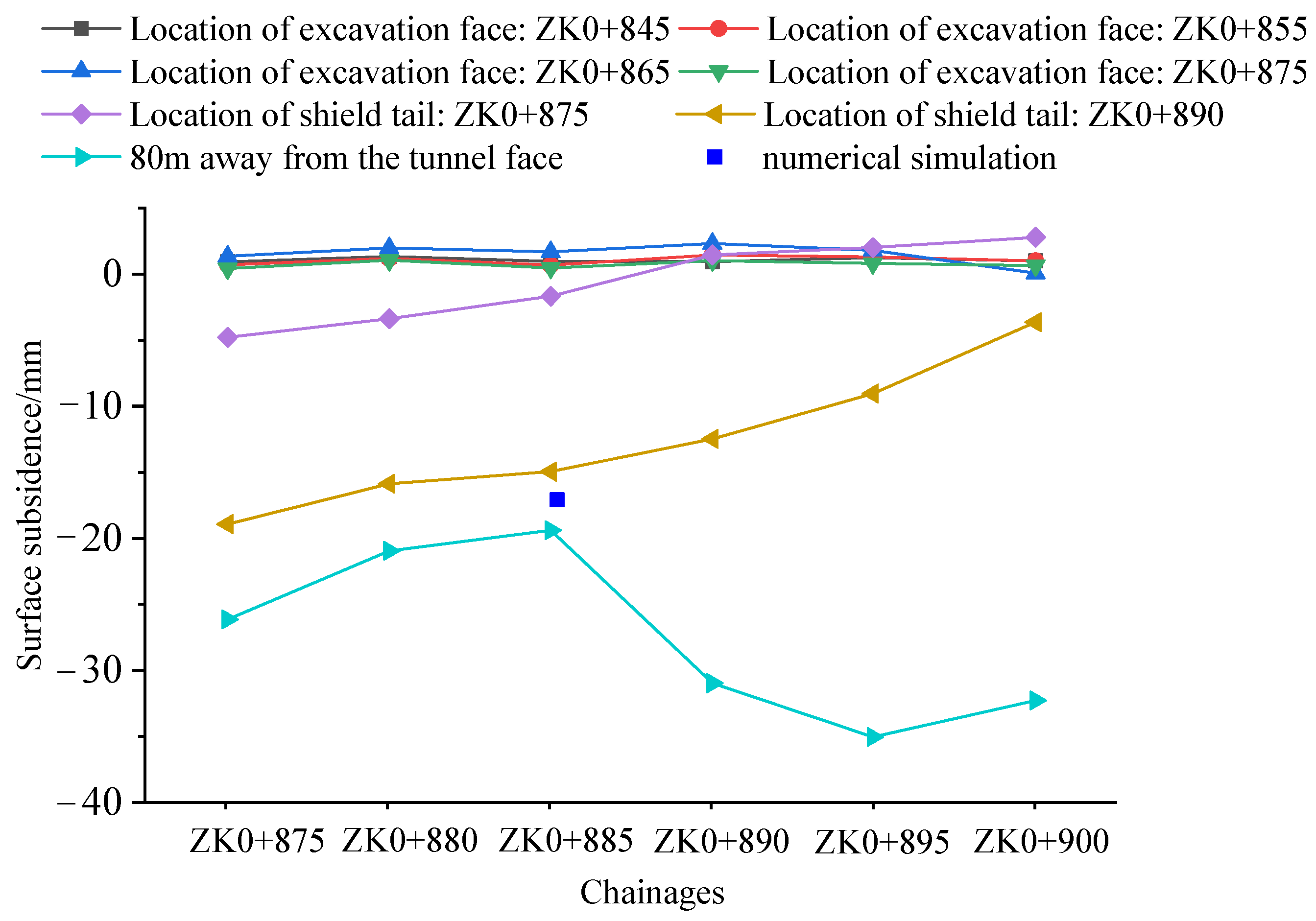

3.3.1. Surface Settlement

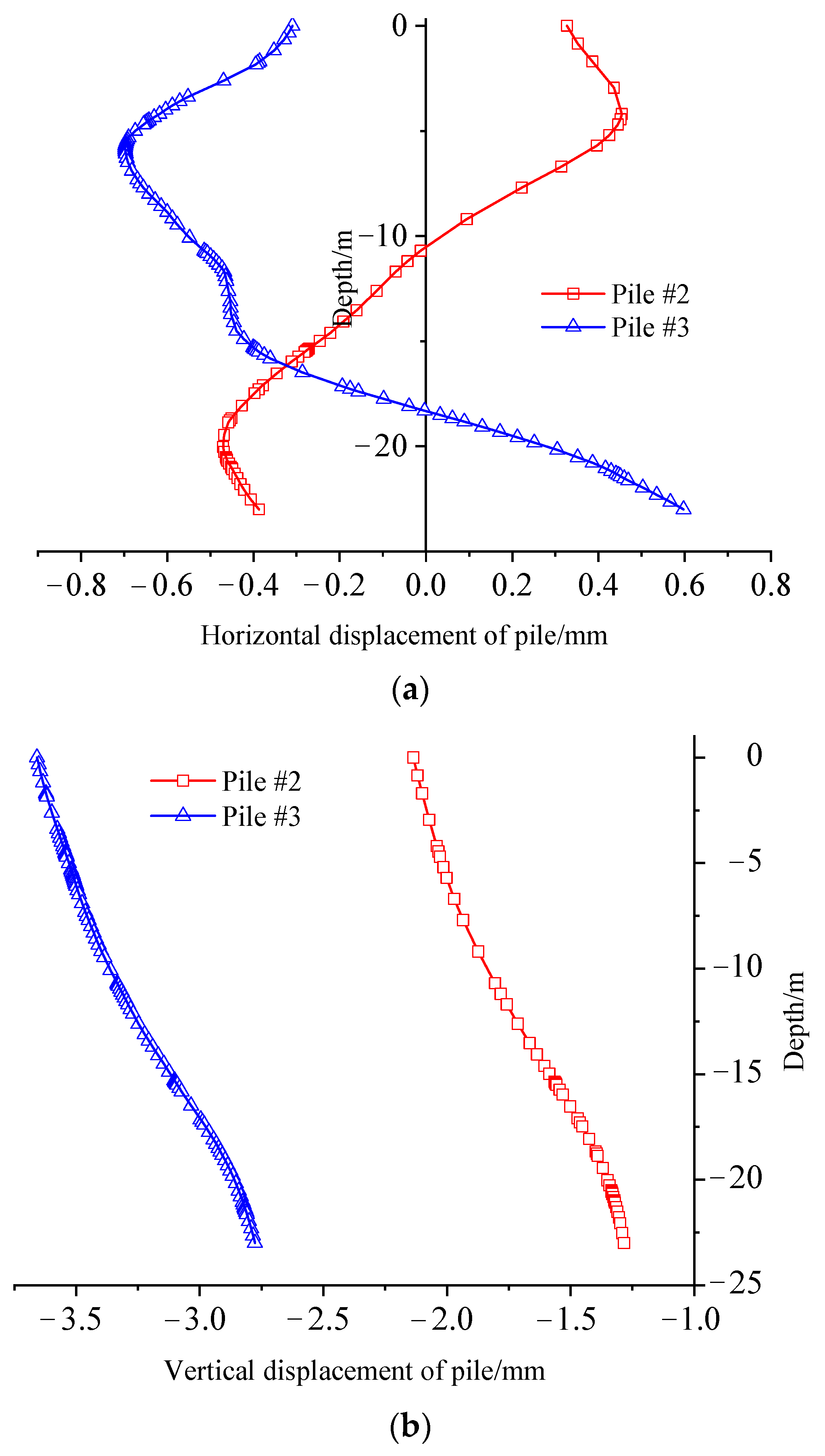

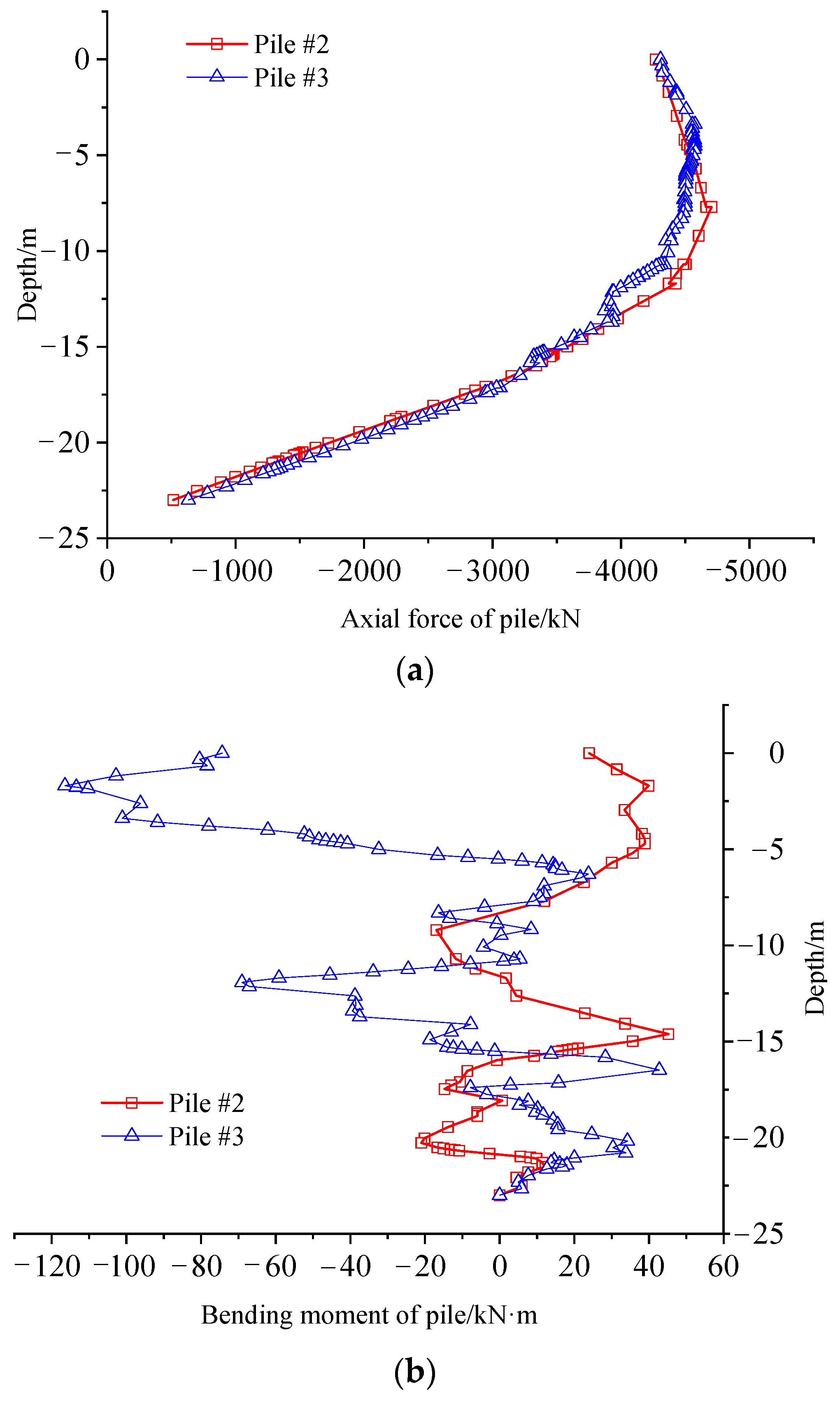

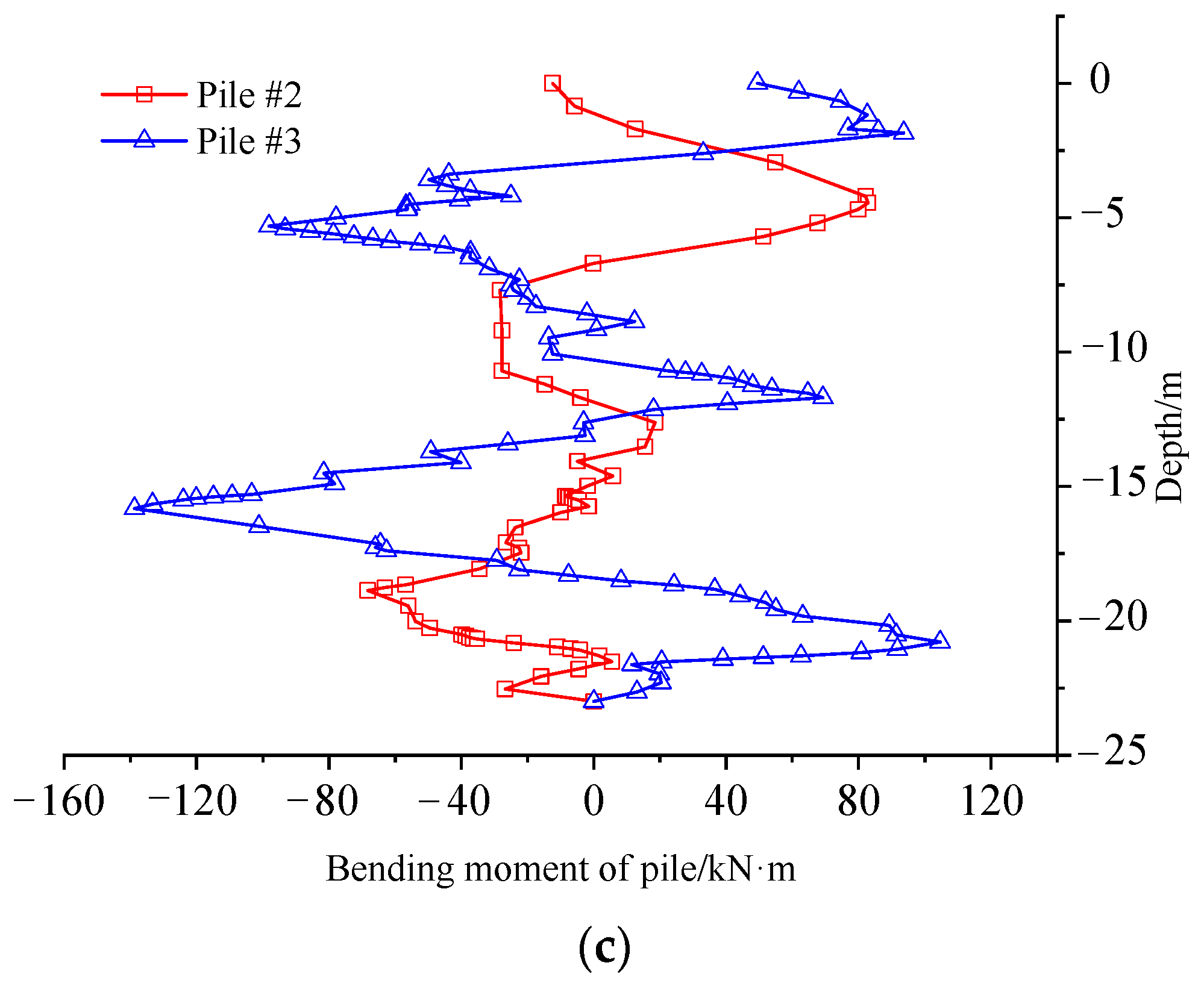

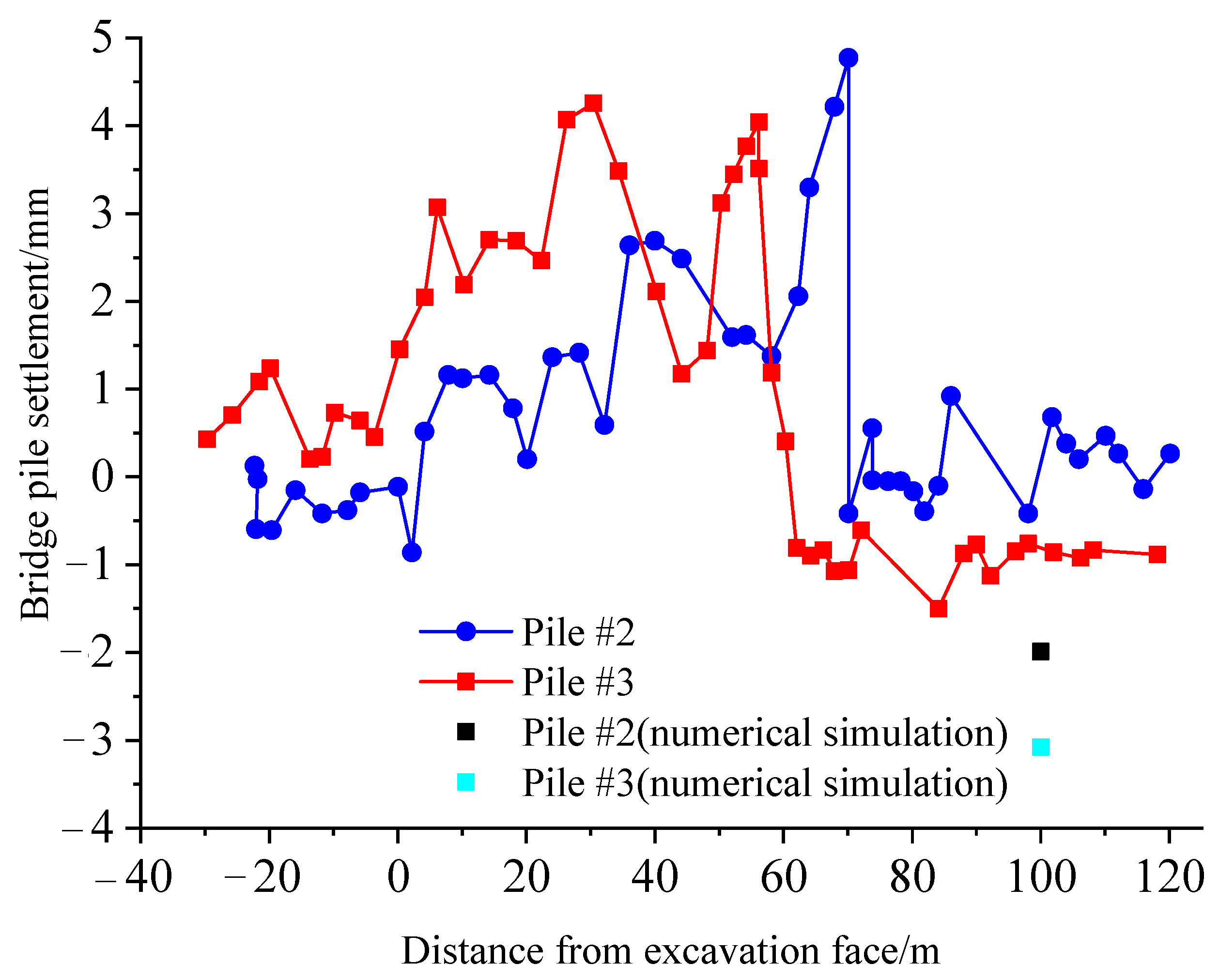

3.3.2. Displacement of Bridge Piles

4. Field Measurement and Verification of Large Diameter Adjacent Shield Tunnelling Bridge Piles

4.1. Monitoring Scheme

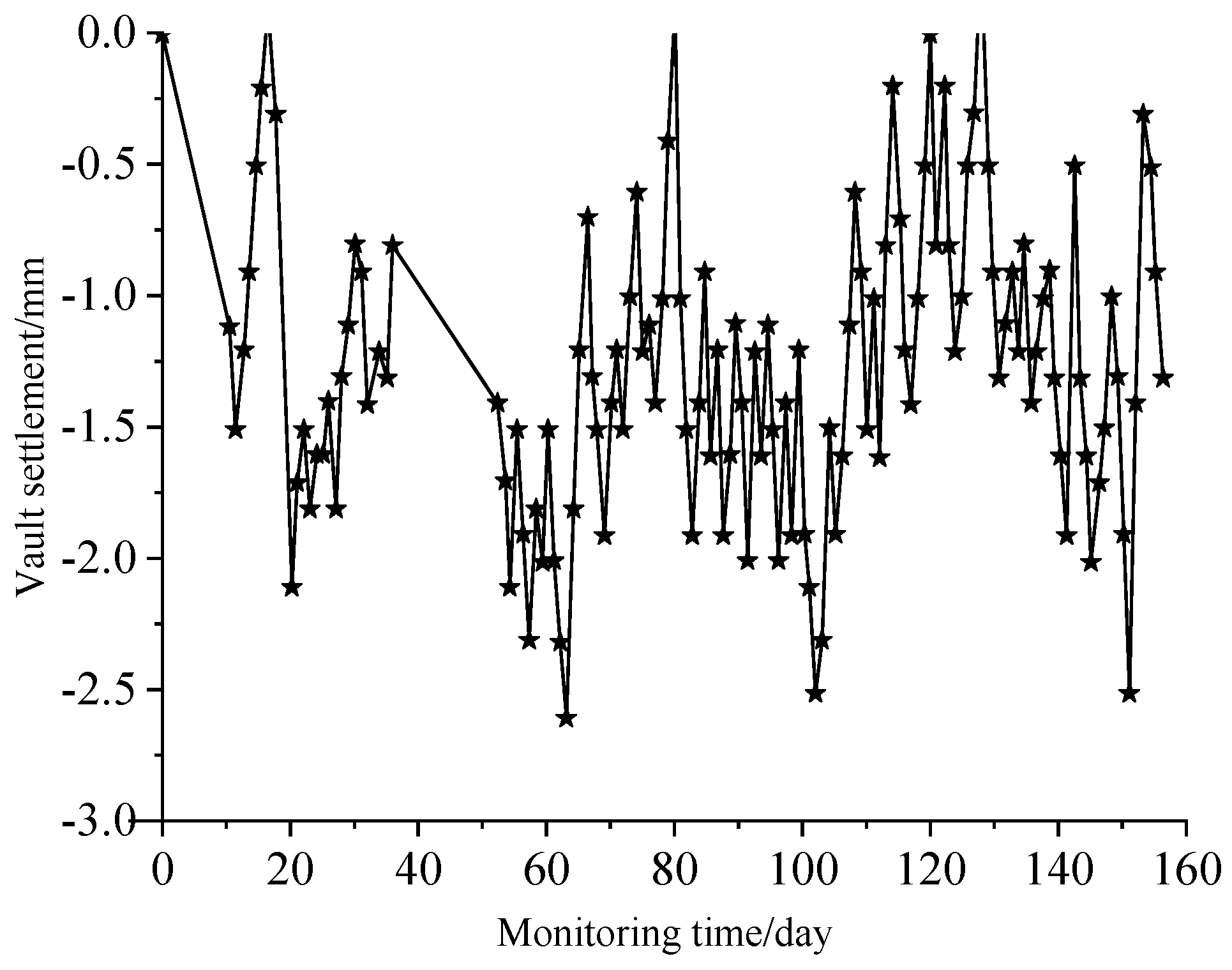

4.2. Analysis of In-Site Monitoring Results

4.3. Control of Tunnelling Parameters during Shield Machine Crossing Bridge Piles

5. Conclusions

- (1)

- Sleeve valve pipe pre-grouting reinforcement between shield tunnel and bridge pile foundation. After shield tunnelling to strengthen the stratum, the maximum simulated surface settlement was 19.4 mm, and the influence range of the settlement groove was about 60 m. According to the field data of shield tunnelling monitoring points, the surface settlement of the pre reinforced stratum around the bridge pile was about 25 mm, which is slightly larger than the simulation value but meets the requirements of surface settlement control. The maximum surface settlement was 35 mm at the position of the unreinforced stratum near the bridge pile, indicating that the stratum reinforcement significantly reduced the impact of shield construction on the soil.

- (2)

- After the super large diameter shield tunnel passed through the reinforced stratum, the vertical displacement of the pile decreased with the deepening of the pile body. The maximum vertical displacement of the simulated bridge pile was 3.0 mm at the pile top and 0.7 mm at 5~6 m of the pile body, and the stress of the bridge pile met the strength requirements. During the construction, settlement monitoring points were set on the bridge pile. During shield crossing, the final settlement of the bridge pile was stable to 1.48 mm after a small settlement before crossing, and floated for a short time, which is less than the numerical simulation analysis value, indicating that the grouting reinforcement between the tunnel and the pile foundation had a noticeable control effect on the pile displacement and achieved a good reinforcement effect.

- (3)

- Through the pre reinforcement of Shield Crossing front sleeve valve pipe, the surface and bridge pile displacement met the deformation control standard, and the risk of short-distance crossing bridge pile was generally controllable. If it is necessary to set reasonable tunnelling parameters before crossing, to strictly control the tunnelling attitude of the shield, pay attention to control the tunnel face pressure, adjust the slurry pressure in a timely manner, reduce disturbance to the soil, and achieve continuous, balanced and stable advancement.

- (4)

- The successful crossing of the Hongling Interchange No. 1 bridge provides a theoretical basis and engineering practice for the 16 m super-large diameter shield to cross an existing bridge pile foundation in a short distance in composite stratum with uneven, soft and hard features. This has significance reference value for similar projects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jin, D.; Zhang, Z.; Yuan, D. Effect of dynamic cutterhead on face stability in EPB shield tunnelling. Tunn. Undergr. Space Technol. 2021, 110, 103827. [Google Scholar] [CrossRef]

- Jin, D.; Yuan, D.; Li, X.; Su, W. Probabilistic analysis of the disc cutter failure during TBM tunnelling in hard rock. Tunn. Undergr. Space Technol. 2021, 109, 103744. [Google Scholar] [CrossRef]

- Marshall, A.M. Tunnel-Pile Interaction Analysis Using Cavity Expansion Methods. J. Geotech. Geoenviron. Eng. 2012, 138, 1237–1246. [Google Scholar] [CrossRef]

- Franza, A.; Losacco, N.; Ledesma, A.; Viggiani, G.M.B.; Jimenez, R. Protecting surface and buried structures from tunnelling using pile walls: A prediction model. Can. Geotech. J. 2020, 58, 1590–1602. [Google Scholar] [CrossRef]

- Sirivachiraporn, A.; Phienwej, N. Ground movements in EPB shield tunnelling of Bangkok subway project and impacts on adjacent buildings. Tunn. Undergr. Space Technol. 2012, 30, 10–24. [Google Scholar] [CrossRef]

- Jeon, Y.J.; Jeon, S.C.; Jeon, S.J.; Lee, C.J. Study on the behaviour of pre-existing single piles to adjacent shield tunnelling by considering the changes in the tunnel face pressures and the locations of the pile tips. Geomech. Eng. 2020, 21, 187–200. [Google Scholar]

- Huang, K.; Sun, Y.-W.; Zhou, D.-Q.; Li, Y.-J.; Jiang, M.; Huang, X.-Q. Influence of water-rich tunnel by shield tunnelling on existing bridge pile foundation in layered soils. J. Cent. South Univ. 2021, 28, 2574–2588. [Google Scholar] [CrossRef]

- Huang, F.; Wang, Z.; Zhang, M.; Li, S. Failure Mechanism of the Bearing Stratum at the End of a Pile Induced by Shield Tunnel Excavation Beneath a Piled Building. KSCE J. Civ. Eng. 2022, 26, 942–954. [Google Scholar] [CrossRef]

- Berthoz, N.; Branque, D.; Wong, H.; Subrin, D. TBM soft ground interaction: Experimental study on a 1 g reduced-scale EPBS model. Tunn. Undergr. Space Technol. 2018, 72, 189–209. [Google Scholar] [CrossRef]

- Song, G.; Marshall, A.M. Tunnel–piled structure interaction: Numerical simulation of hybrid centrifuge tests. Comput. Geotech. 2021, 140, 104477. [Google Scholar] [CrossRef]

- Chaipanna, P.; Jongpradist, P. 3D response analysis of a shield tunnel segmental lining during construction and a parametric study using the ground-spring model. Tunn. Undergr. Space Technol. 2019, 90, 369–382. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, K.-W.; Wei, G.; Li, B.; Li, Q.; Yao, W.-J. Field measurement analysis of the influence of double shield tunnel construction on reinforced bridge. Tunn. Undergr. Space Technol. 2018, 81, 252–264. [Google Scholar] [CrossRef]

- Nematollahi, M.; Dias, D. Three-dimensional numerical simulation of pile-twin tunnels interaction—Case of the Shiraz subway line. Tunn. Undergr. Space Technol. 2019, 86, 75–88. [Google Scholar] [CrossRef]

- He, S.; Lai, J.; Li, Y.; Wang, K.; Wang, L.; Zhang, W. Pile group response induced by adjacent shield tunnelling in clay: Scale model test and numerical simulation. Tunn. Undergr. Space Technol. 2022, 120, 104039. [Google Scholar] [CrossRef]

- Wang, J.; Wen, Z. Analysis of Construction Impact of a Large Diameter Shield Tunnelling Side-Crossing Viaduct Pile Foundations in Short Distance. Geotech. Geol. Eng. 2021, 39, 5587–5598. [Google Scholar] [CrossRef]

- Professional Standards Compilation Group of People’s Republic of China. Code for Design of Road Tunnel (JTG D70-2004); China Communications Press: Beijing, China, 2004. [Google Scholar]

- Xiong, Q.; Mo, Y. Discussion on the Key Technologies for Survey of Super Large Diameter Urban Shield Tunnel Under Complex Conditions—Taking Chunfeng Tunnel as an Example. Constr. Des. Proj. 2019, 16, 90–91. (In Chinese) [Google Scholar]

- Zhang, W. Research on Deformation and Control of Bridge Pile Structure of Large Diameter Shield Tunnel under Airport Line of Beijing Metro Line 14. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2012. [Google Scholar]

- Lueprasert, P.; Jongpradist, P.; Jongpradist, P.; Suwansawat, S. Numerical investigation of tunnel deformation due to adjacent loaded pile and pile-soil-tunnel interaction. Tunn. Undergr. Space Technol. 2017, 70, 166–181. [Google Scholar] [CrossRef]

- Vu, M.N.; Broere, W.; Bosch, J. Effects of cover depth on ground movements induced by shallow tunnelling. Tunn. Undergr. Space Technol. 2015, 50, 499–506. [Google Scholar] [CrossRef] [Green Version]

- Sheng, M.; Gao, J.; Guo, P.; Cao, R.; Wang, Y. Temporal-Spatial Characteristics of Ground and Pile Responses to Twin Shield Tunnelling in Clays. Geofluids 2021, 2021, 2373456. [Google Scholar] [CrossRef]

- Xu, Q.; Zhu, H.; Ma, X.; Ma, Z.; Li, X.; Tang, Z.; Zhuo, K. A case history of shield tun-nel crossing through group pile foundation of a road bridge with pile underpinning technologies in Shanghai. Tunn. Undergr. Space Technol. 2015, 45, 20–33. [Google Scholar] [CrossRef]

- Mohamad, W.; Bourgeois, E.; Le Kouby, A.; Szymkiewicz, F.; Michalski, A.; Branque, D.; Berthoz, N.; Soyez, L.; Kreziak, C. Full scale study of pile response to EPBS tunnel-ling on a Grand Paris Express site. Tunn. Undergr. Space Technol. 2022, 124, 104492. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Z.; Regueiro, R.A. Pile and pile group response to tunnelling using a large diameter slurry shield—Case study in Shanghai. Comput. Geotech. 2014, 59, 21–43. [Google Scholar] [CrossRef]

- Liu, B.; Yu, Z.; Yao, B.; Han, Y.; Liu, H.; Wang, S. Responses of the ground and adja-cent pile to excavation of U-shaped tunnel. Comput. Geotech. 2021, 130, 103919. [Google Scholar] [CrossRef]

- Andreotti, G.; Calvi, G.M.; Soga, K.; Gong, C.; Ding, W. Cyclic model with damage assessment of longitudinal joints in segmental tunnel linings. Tunn. Undergr. Space Technol. 2020, 103, 103472. [Google Scholar] [CrossRef]

- Tvede-Jensen, B.; Faurschou, M.; Kasper, T. A modelling approach for joint rotations of segmental concrete tunnel linings. Tunn. Undergr. Space Technol. 2017, 67, 61–67. [Google Scholar] [CrossRef]

- Schanz, T. Formulation and verification of the Hardening-Soil Model. RBJ Brinkgreve Beyond 2000 Comput. Geotech. 1999, 281–290. [Google Scholar]

- Benz, T. Small-Strain Stiffness of Soils and Its Numerical Consequences. Ph.D. Thesis, University of Stuttgart, Baden-Württemberg, Germany, 2007. [Google Scholar]

- Honkanadavar, N.P.; Sharma, K.G. Modeling the triaxial behavior of riverbed and blasted quarried rockfill materials using hardening soil model. J. Rock Mech. Geotech. Eng. 2016, 8, 350–365. [Google Scholar] [CrossRef] [Green Version]

- Sukkarak, R.; Likitlersuang, S.; Jongpradist, P.; Jamsawang, P. Strength and stiffness parameters for hardening soil model of rockfill materials. Soils Found. 2021, 61, 1597–1614. [Google Scholar] [CrossRef]

- Seyedan, S.; Sołowski, W.T. Enhancing Constitutive Models for Soils: Adding the Capability to Model Nonlinear Small Strain in Shear. Adv. Civ. Eng. 2019, 2019, 6016350. [Google Scholar] [CrossRef]

- Beijing General Municipal Engineering Design & Research Insititute Co., Ltd. Geological Exploration Report of Chunfeng Tunnel; Beijing General Municipal Engineering Design & Research Insititute Co., Ltd.: Beijing, China, 2018. [Google Scholar]

- Brinkgreve, R.B.J.; Broere, W. Plaxis Material Models Manual; PLAXIS B V: Delft, The Netherlands, 2006. [Google Scholar]

- Zhou, Z.; Zhao, J.; Tan, Z.; Zhou, X. Mechanical responses in the construction process of super-large cross-section tunnel: A case study of Gongbei tunnel. Tunn. Undergr. Space Technol. 2021, 115, 104044. [Google Scholar] [CrossRef]

- Russo, G. Evaluating the Required Face-Support Pressure in Epbs Advance Mode. Gallerie E Grandi Opere Sotter. 2003, 71, 1–14. [Google Scholar]

- Oh, J.Y.; Park, H.; Kim, D.; Chang, S.; Lee, S.; Choi, H. Study on the effect of tail void grouting on the short-and long-term surface settlement in the shield TBM Tunnelling using numerical analysis. J. Korean Tunn. Undergr. Space Assoc. 2017, 19, 265–281. [Google Scholar] [CrossRef]

| Control Items | Range of Control Items | References |

|---|---|---|

| Surface settlement | +10 mm~−30 mm | Sheng et al., [21] |

| Pier settlement | ≤15 mm | Xu et al., [22]; He et al., [14] |

| Pier settlement speed | ±3 mm/day | |

| Differential settlement between longitudinal adjacent piers | ≤2 mm | Mohamad et al., [23]; Liu et al., [24]; Liu et al., [25] |

| Differential settlement between transverse adjacent piers | ≤3 mm |

| Model Parameters | Plain Fill | Clay | Medium Sand | Gravel Sand | Moderately Weathered Granite | Slightly Weathered Granite | |

|---|---|---|---|---|---|---|---|

| Secant modulus corresponding to partial stress of 0.5 times shear strength under reference stress | (MPa) | 8 | 6 | 17 | 24 | 100 | 120 |

| Unloading and reloading modulus under | (MPa) | 24 | 18 | 51 | 72 | 300 | 360 |

| Gravity of unsaturated soil | (kN/m3) | 18.4 | 17.2 | 19 | 20 | 19.7 | 20.9 |

| Gravity of saturated soil | (kN/m3) | 20 | 20.3 | 20 | 20 | 23.3 | 24.5 |

| Poisson’s ratio | 0.3 | 0.46 | 0.28 | 0.25 | 0.22 | 0.20 | |

| Cohesion | c (kPa) | 28 | 25 | 0 | 0 | 35 | 100 |

| Friction angle | φ (°) | 19 | 21 | 28 | 30 | 33 | 35 |

| Power exponent of stiffness stress level correlation | m | 0.6 | 0.8 | 0.5 | 0.5 | 0.5 | 0.5 |

| Shear strain corresponding to the secant shear modulus attenuation of 0.7 times of the initial shear modulus | (10−4) | 2.1 | 2.5 | 2.7 | 1.5 | 1.2 | 1.0 |

| Reference initial shear modulus of small strain | (MPa) | 65 | 74 | 85 | 120 | 500 | 750 |

| Damage ratio | Rf | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Model Parameters | Shield Shell | |

|---|---|---|

| Modulus of elasticity | E1 (GPa) | 210 |

| Poisson’s ratio | ν1 | 0.20 |

| Gravity | γ1 (kN/m3) | 76.5 |

| Model Parameters | Shield Shell | |

|---|---|---|

| External diameter | D (m) | 15.2 |

| Internal diameter | d (m) | 13.9 |

| Thickness | t (m) | 0.65 |

| Gravity | γ2 (kN/m3) | 27 |

| Modulus of elasticity | E2 (GPa) | 31.0 |

| Poisson’s ratio | ν2 | 0.1 |

| Top Pressure of Slurry Silo (Bar) | Total Thrust (kN) | Advance Rate (mm/min) | Cutter Head Speed (rad/min) | Cutter Head Torque (kN·m) |

|---|---|---|---|---|

| 1.18~1.12 | 52,920~62,600 | 6~13 | 1.2 | 11,200~16,110 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Zhao, J.; Tan, Z.; Liu, X.; Wang, X.; Liu, M. Mechanical Behavior of Large-Diameter Adjacent Shield Tunnelling Bridge Piles: A Case Study of Chunfeng Tunnel. Appl. Sci. 2022, 12, 5418. https://doi.org/10.3390/app12115418

Wu J, Zhao J, Tan Z, Liu X, Wang X, Liu M. Mechanical Behavior of Large-Diameter Adjacent Shield Tunnelling Bridge Piles: A Case Study of Chunfeng Tunnel. Applied Sciences. 2022; 12(11):5418. https://doi.org/10.3390/app12115418

Chicago/Turabian StyleWu, Jingang, Jinpeng Zhao, Zhongsheng Tan, Xiangyu Liu, Xia Wang, and Minggao Liu. 2022. "Mechanical Behavior of Large-Diameter Adjacent Shield Tunnelling Bridge Piles: A Case Study of Chunfeng Tunnel" Applied Sciences 12, no. 11: 5418. https://doi.org/10.3390/app12115418

APA StyleWu, J., Zhao, J., Tan, Z., Liu, X., Wang, X., & Liu, M. (2022). Mechanical Behavior of Large-Diameter Adjacent Shield Tunnelling Bridge Piles: A Case Study of Chunfeng Tunnel. Applied Sciences, 12(11), 5418. https://doi.org/10.3390/app12115418