Shear Strength Improvement of Clay Soil Stabilized by Coffee Husk Ash

Abstract

:1. Introduction

2. Materials and Methods

2.1. Clay Soil

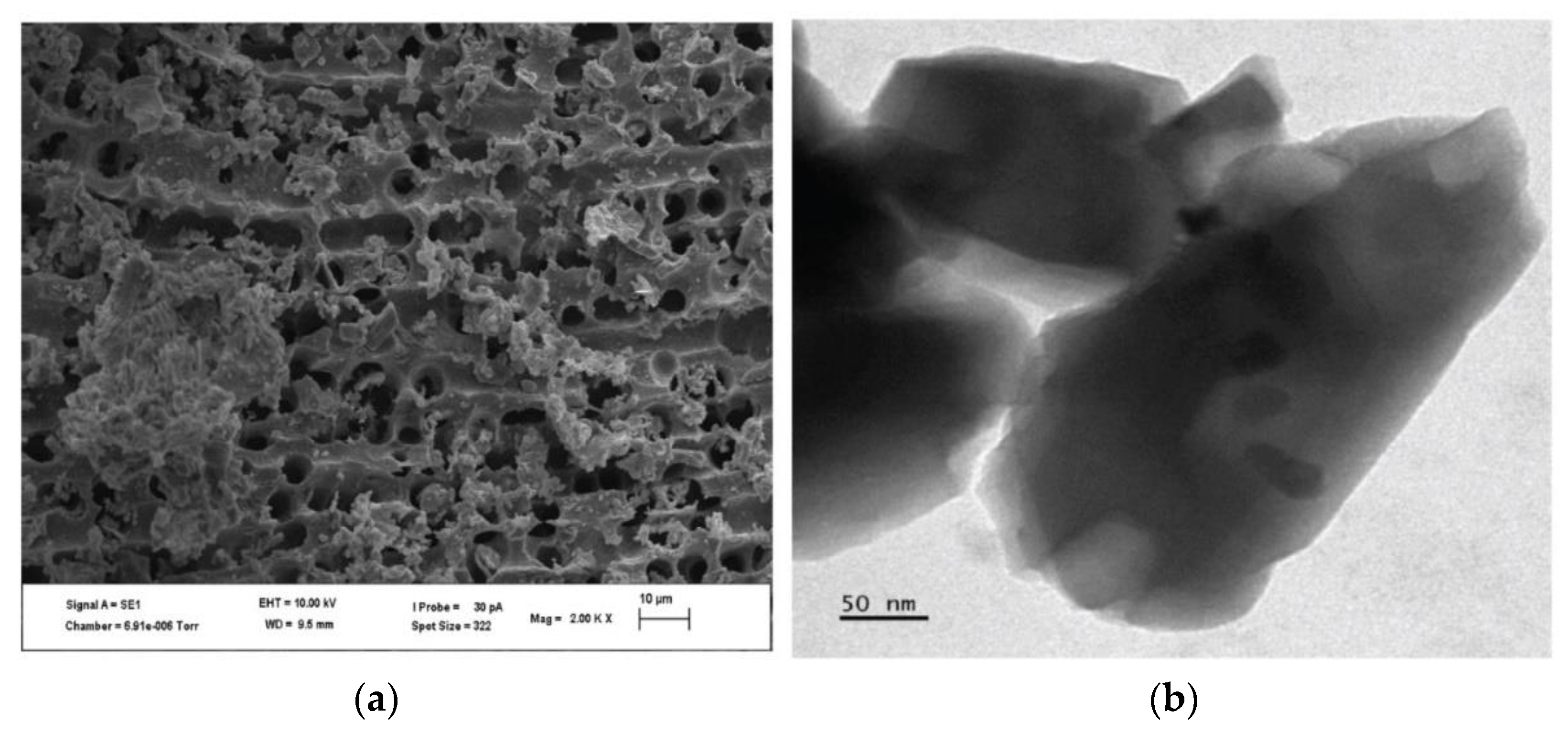

2.2. Coffee Husk Ash

2.3. Sample Preparation

2.4. Testing Procedures

2.4.1. Atterberg Limit and Standard Proctor

2.4.2. Unconfined Compression Test

2.4.3. Direct Shear

3. Result and Discussion

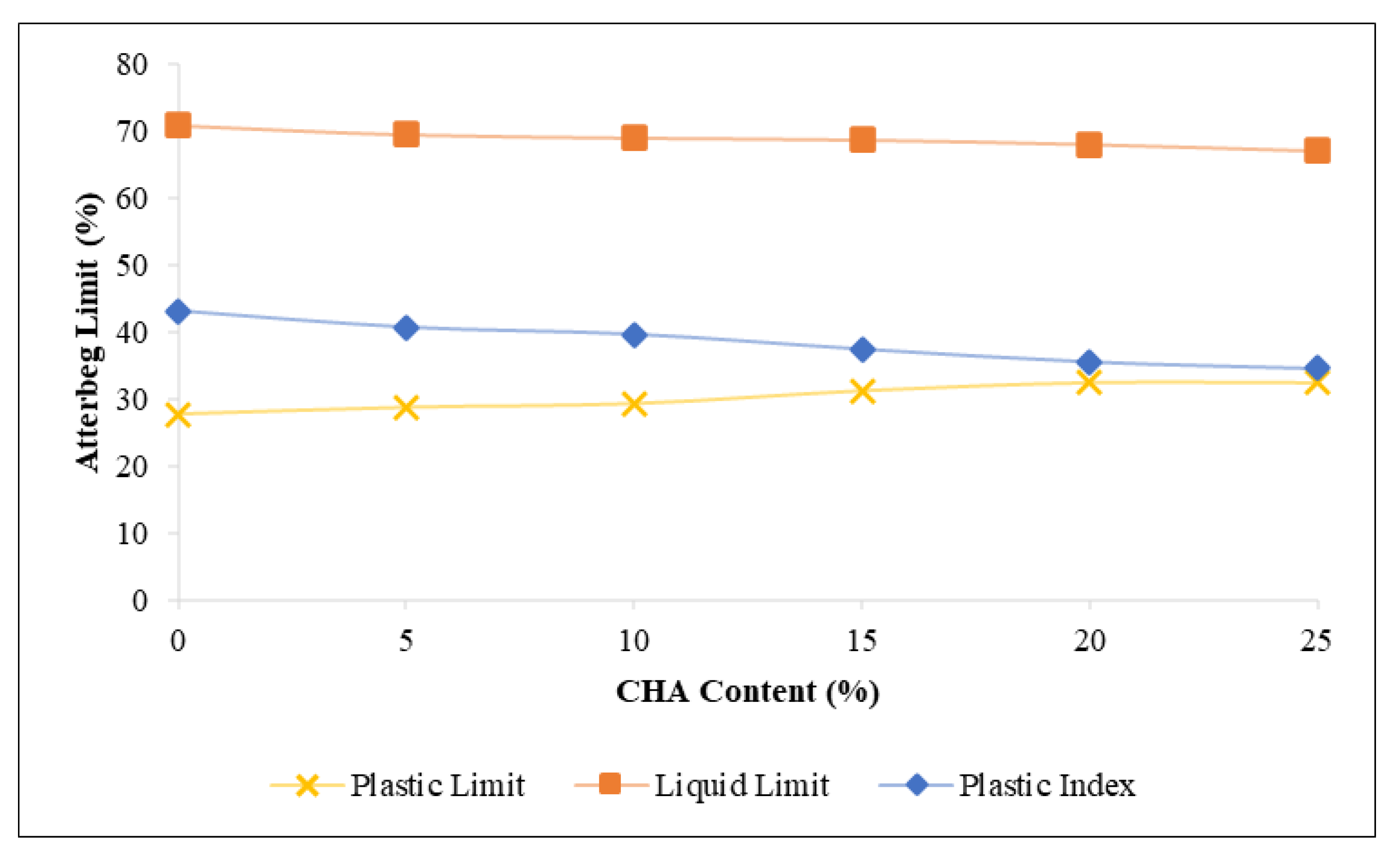

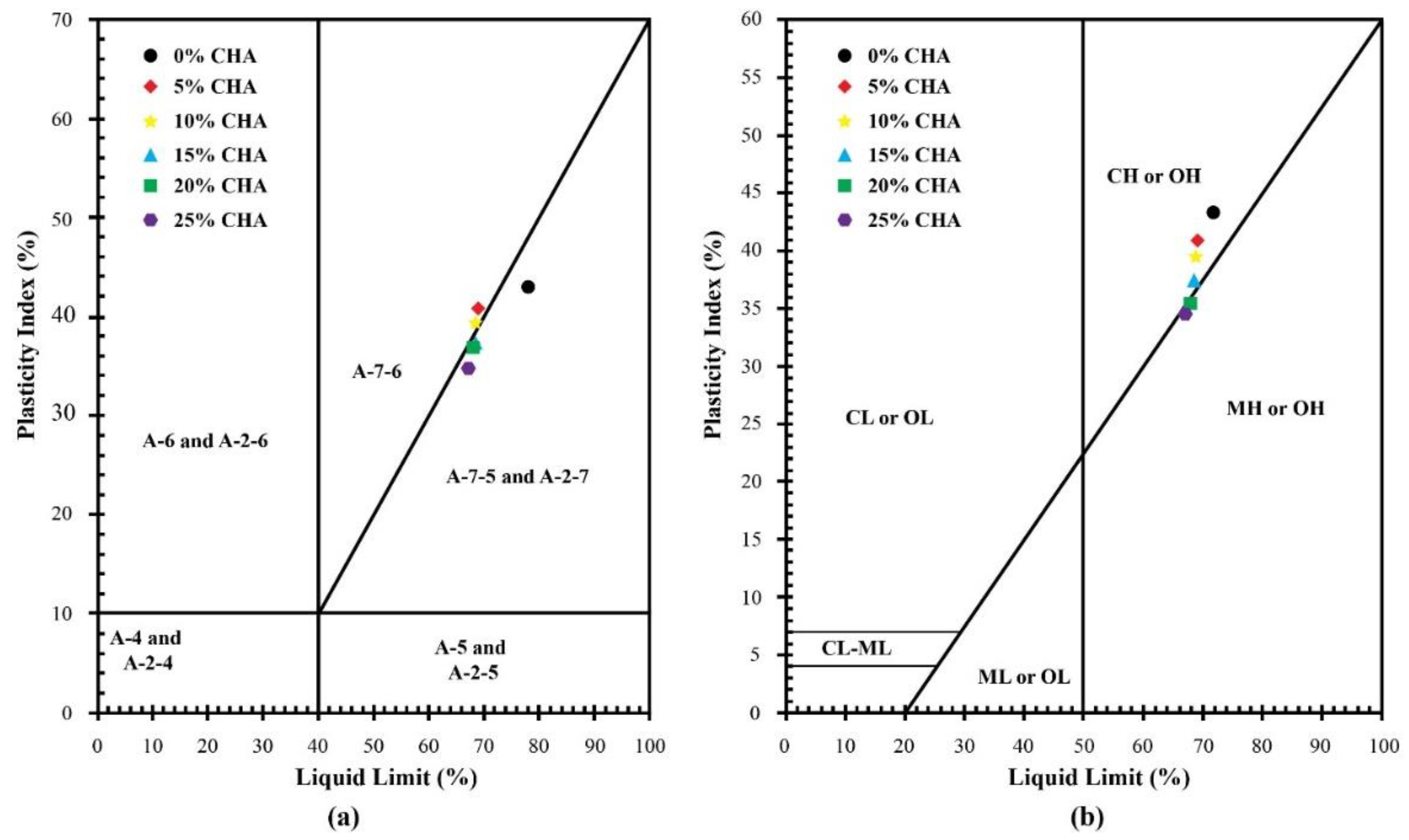

3.1. Physical Properties Test

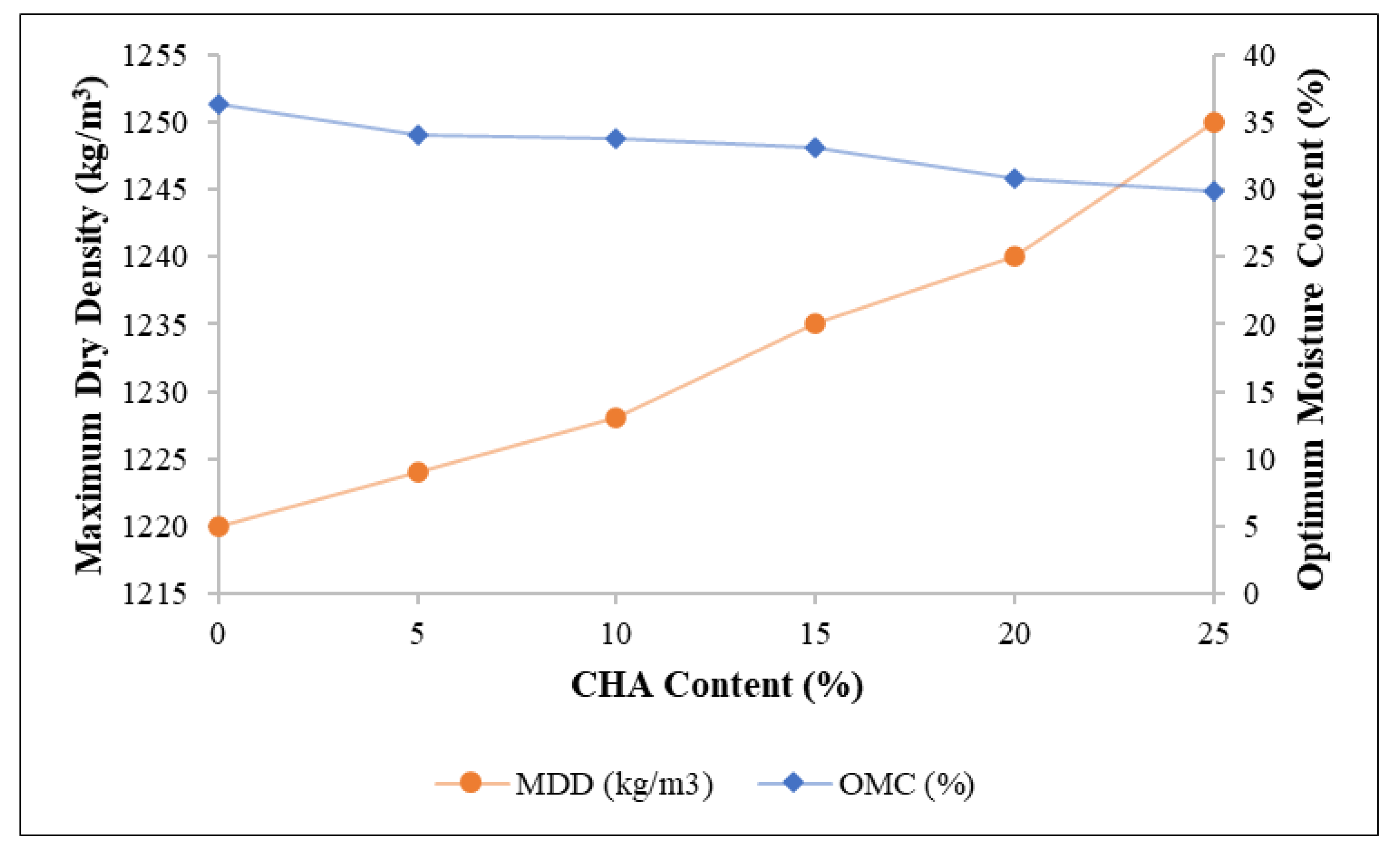

3.2. Compaction Test

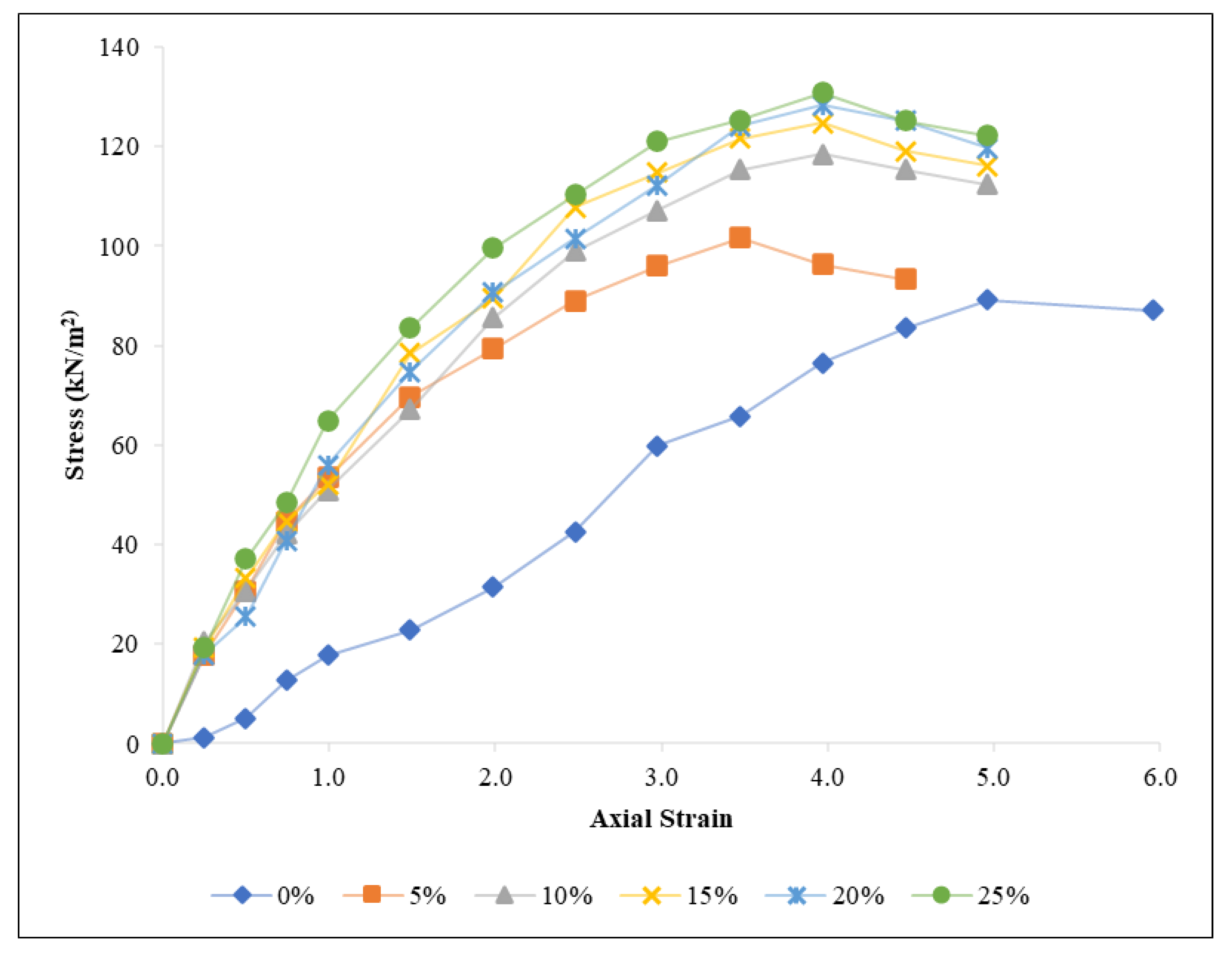

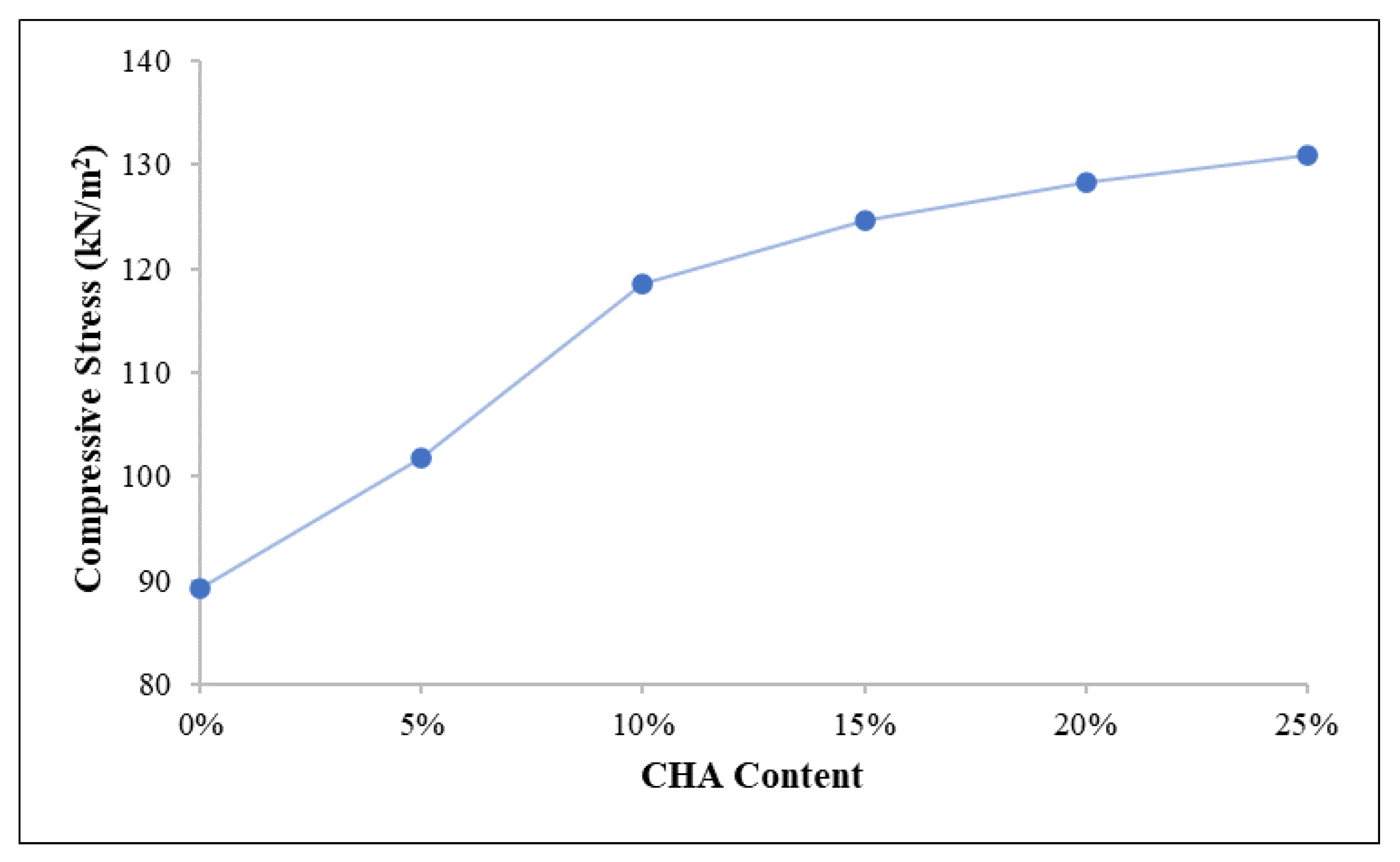

3.3. UCS Result

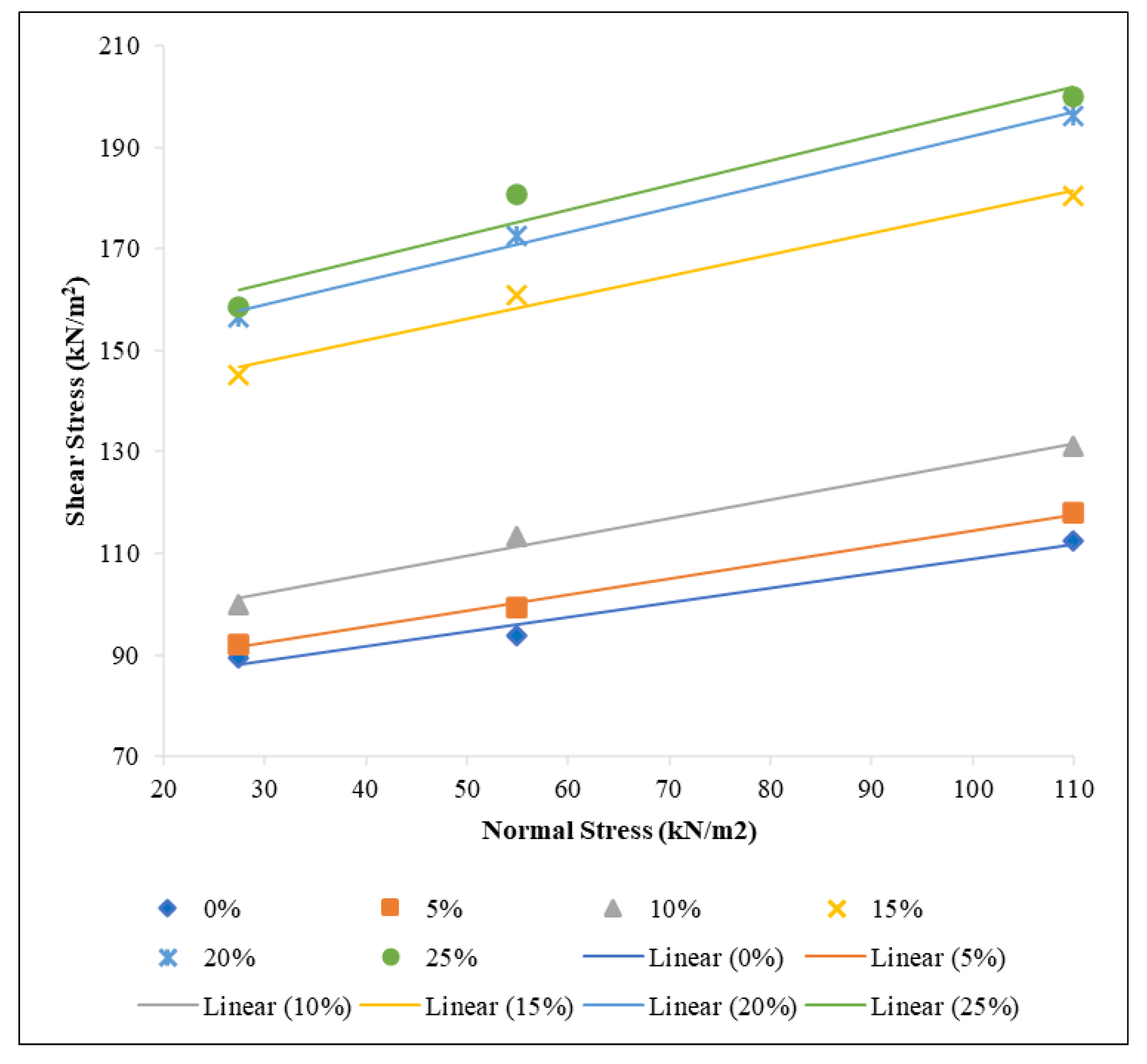

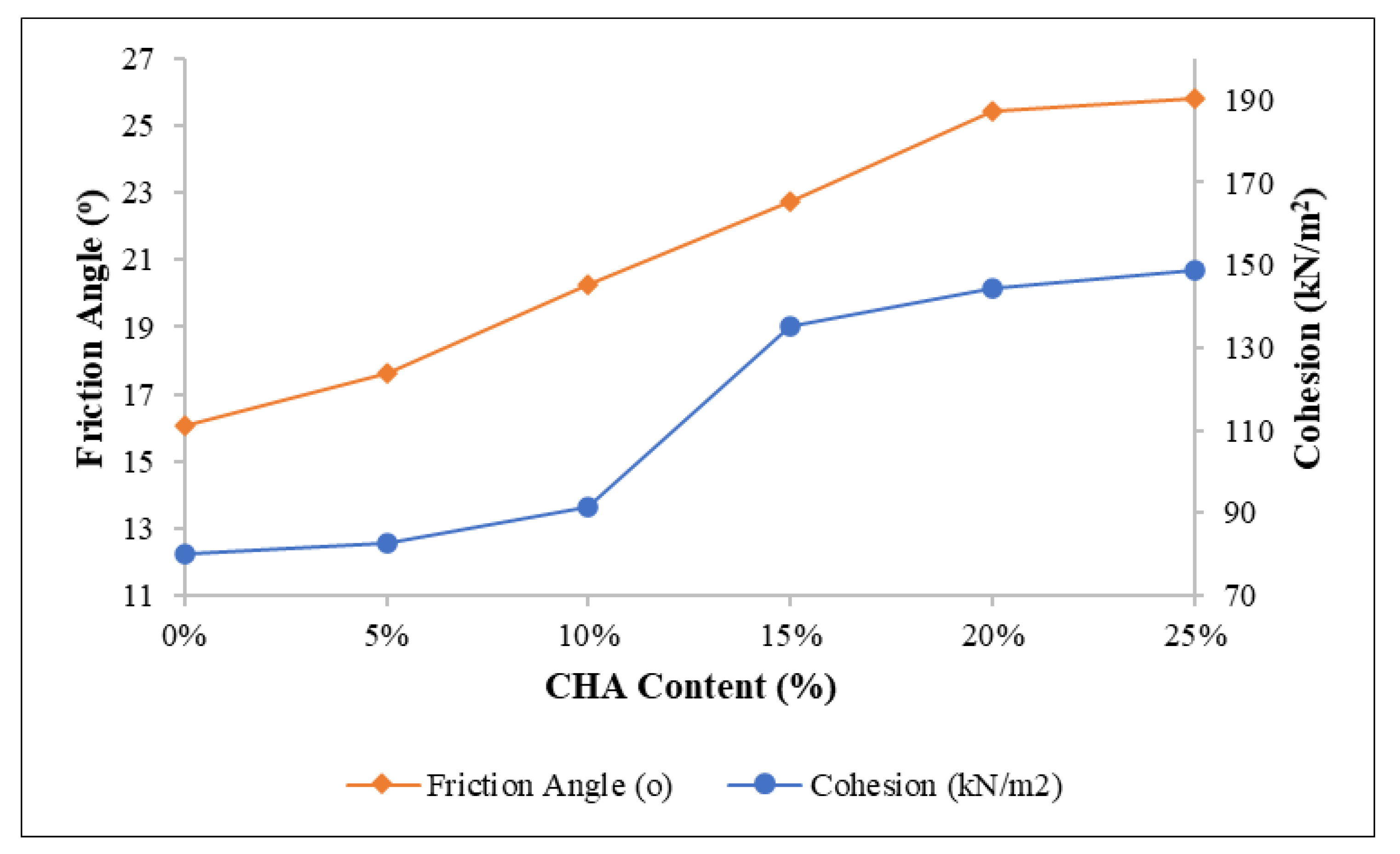

3.4. Direct Shear Result

4. Conclusions

- The principal mineral components of CHA are potassium oxide, silica, iron oxide, and phosphor pentoxide.

- The liquid limit, plasticity index, and optimum water content all decrease as the CHA content increases; however, the plastic limit and maximum dry density increase.

- According to soil classification, following the addition of the CHA, the clay soil turns to be coarser.

- With the addition of CHA content, the OMC decrease and the MDD increase.

- The optimal concentration of CHA for improving the shear strength of clay soil is 25%.

- Increased mechanical properties of soil can be related to the pozzolanic and hydration reaction between CHA and soil, which fills void space and binds the particles together, hence increasing the performance of the soil.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nasiri, H.; Khayat, N.; Mirzababaei, M. Simple yet quick stabilization of clay using a waste by-product. Transp. Geotech. 2021, 28, 100531. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Onyia, M.E.; Van, D.B.; Baykara, H.; Ugwu, H.U. Pozzolanic Reaction in Clayey Soils for Stabilization Purposes: A Classical Overview of Sustainable Transport Geotechnics. Adv. Mater. Sci. Eng. 2021, 2021, 6632171. [Google Scholar] [CrossRef]

- Taib, A.M.; Taha, M.R.; Hasbollah, D.Z.A. Validation of Numerical Modelling Techniques in Unsaturated Slope Behaviour. J. Kejuruter. 2018, 1, 29–35. [Google Scholar]

- Taib, A.M.; Taha, M.R.; Hasbollah, D.Z.A. Influence of Initial Conditions on Unsaturated Groundwater Flow Models. Int. J. Eng. Technol. 2019, 8, 34–40. [Google Scholar]

- Soundara, B.; Robinson, R.G. Hyperbolic model to evaluate uplift force on pile in expansive soils. KSCE J. Civ. Eng. 2016, 21, 746–751. [Google Scholar] [CrossRef]

- Taha, O.M.E.; Taha, M.R. Volume Change and Hydraulic Conductivity of Soil-Bentonite Mixture. Jordan J. Civ. Eng. 2015, 9, 43–58. [Google Scholar] [CrossRef] [Green Version]

- Beck, R.; Gravina, C.; Maurício, A.; Caicedo, L.; Cesar, N. Technical and environmental performance of eggshell lime for soil stabilization. Constr. Build. Mater. 2021, 298, 123648. [Google Scholar]

- Hamzani, H.; Munirwansyah, M.; Hasan, M.; Sugiarto, S. Determining the properties of semi-flexible pavement using waste tire rubber powder and natural zeolite. Constr. Build. Mater. 2021, 266, 121199. [Google Scholar] [CrossRef]

- Hasan, M.; Syamsul, M.; Zaini, I.; Sin, L.; Azman, K.; Putra, R. Effect of optimum utilization of silica fume and eggshell ash to the engineering properties of expansive soil. J. Mater. Res. Technol. 2021, 14, 1401–1418. [Google Scholar] [CrossRef]

- Choobbasti, A.J.; Samakoosh, M.A.; Kutanaei, S.S. Mechanical properties soil stabilized with nano calcium carbonate and reinforced with carpet waste fibers. Constr. Build. Mater. 2019, 211, 1094–1104. [Google Scholar] [CrossRef]

- Rahgozar, M.A.; Saberian, M.; Li, J. Soil stabilization with non-conventional eco-friendly agricultural waste materials: An experimental study. Transp. Geotech. 2018, 14, 52–60. [Google Scholar] [CrossRef]

- Latifi, N.; Eisazadeh, A.; Marto, A.; Meehan, C.L. Tropical residual soil stabilization: A powder form material for increasing soil strength. Constr. Build. Mater. 2017, 147, 827–836. [Google Scholar] [CrossRef]

- Sabzi, Z. Environmental Friendly Soil Stabilization Materials Available in Iran. J. Environ. Friendly Mater. 2018, 2, 33–39. [Google Scholar]

- Rosales, J.; Agrela, F.; Diaz, L. Use of Nanomaterials in the Stabilization of Expansive Soils into a Road Real-Scale Application. Materials 2020, 13, 3058. [Google Scholar] [CrossRef]

- Jawad, I.T.; Taha, M.R.; Majeed, Z.H.; Khan, T.A. Soil Stabilization Using Lime: Advantages, Disadvantages and Proposing a Potential Alternative. Res. J. Appl. Sci. Eng. Technol. 2014, 8, 510–520. [Google Scholar] [CrossRef]

- Zahraalsadat, E.; Norsyahariati, N.D.N.; Yusoff, Z.M.; Rostami, V. Evaluation of the Effects of Cement and Lime with Rice Husk Ash as an Additive on Strength Behavior of Coastal Soil. Materials 2021, 14, 1140. [Google Scholar]

- Hassan, H.J.A.; Rasul, J.; Samin, M. Effects of Plastic Waste Materials on Geotechnical Properties of Clayey Soil. Transp. Infrastruct. Geotechnol. 2021, 8, 390–413. [Google Scholar] [CrossRef]

- Ahmad, A.; Sutanto, M.H.; Rosmawati, N.; Bujang, M.; Mohamad, M.E. The Implementation of Industrial Byproduct in Malaysian Peat Improvement: A Sustainable Soil Stabilization Approach. Materials 2021, 14, 7315. [Google Scholar] [CrossRef]

- Shekhawat, P.; Sharma, G.; Martand, R. Microstructural and morphological development of eggshell powder and flyash-based geopolymers. Constr. Build. Mater. 2020, 260, 119886. [Google Scholar] [CrossRef]

- Ma, J.; Su, Y.; Liu, Y.; Tao, X. Strength and Microfabric of Expansive Soil Improved with Rice Husk Ash and Lime. Adv. Civ. Eng. 2020, 2020, 9646205. [Google Scholar] [CrossRef]

- Ahmadi, H.; Hamid, S.; Molaabasi, H.; Zeighami, E. The effect of zeolite and cement stabilization on the mechanical behavior of expansive soils. Constr. Build. Mater. 2020, 272, 121630. [Google Scholar] [CrossRef]

- Atahu, M.K.; Saathoff, F.; Gebissa, A. Strength and compressibility behaviors of expansive soil treated with coffee husk ash. J. Rock Mech. Geotech. Eng. 2019, 11, 337–348. [Google Scholar] [CrossRef]

- Shahsavani, S.; Vakili, A.H.; Mokhberi, M. The effect of wetting and drying cycles on the swelling-shrinkage behavior of the expansive soils improved by nanosilica and industrial waste. Bull. Eng. Geol. Environ. 2020, 79, 4765–4781. [Google Scholar] [CrossRef]

- Alsharef, J.M.A.; Taha, M.R.; Firoozi, A.A.; Govindasamy, P. Potential of Using Nanocarbons to Stabilize Weak Soils. Appl. Environ. Soil Sci. 2016, 2016, 5060531. [Google Scholar] [CrossRef] [Green Version]

- Taha, M.R.; Alsharef, J.M.A.; Khan, T.A.; Al-Mansob, R.A.; Gaber, M. Ultrasonic Dispersion of Nanocarbons in Soil-water Mixture. Mater. Sci. 2020, 26, 3–9. [Google Scholar] [CrossRef] [Green Version]

- Taha, M.R.; Alsharef, J.M.A. Performance of Soil Stabilized with Carbon Nanomaterials. Chem. Eng. Trans. 2018, 63, 757–762. [Google Scholar]

- Siang, D.; Chandra, S.; Anggraini, V.; Ying, S.; Shams, T.; Romero, C. Influence of SiO2, TiO2 and Fe2O3 nanoparticles on the properties of fly ash blended cement mortars. Constr. Build. Mater. 2020, 258, 119627. [Google Scholar] [CrossRef]

- Eyo, E.U.; Ng, S.; Abbey, S.J. Incorporation of a nanotechnology-based additive in cementitious products for clay stabilisation. J. Rock. Mech. Geotech. Eng. 2020, 12, 1056–1069. [Google Scholar] [CrossRef]

- James, J.; Pandian, P.K. Industrial Wastes as Auxiliary Additives to Cement / Lime Stabilization of Soils. Adv. Civ. Eng. 2016, 2016, 1267391. [Google Scholar] [CrossRef] [Green Version]

- Phanikumar, B.R.; Raju, E.R. Compaction and strength characteristics of an expansive clay stabilised with lime sludge and cement. Soils. Found. 2020, 60, 129–138. [Google Scholar] [CrossRef]

- Paula, A.; Razakamanantsoa, A.; Ranaivomanana, H.; Levacher, D. Shear strength performance of marine sediments stabilized using cement, lime and fly ash. Constr. Build. Mater. 2018, 184, 454–463. [Google Scholar]

- Pourakbar, S.; Asadi, A.; Huat, B.B.K.; Fasihnikoutalab, M.H. Soil stabilisation with alkali-activated agro-waste. Environ. Geotech. 2015, 2, 359–370. [Google Scholar] [CrossRef]

- De Jesús, J.; Baldovino, A.; Luis, R.; Moreira, E.B.; Rose, J.L. Optimizing the evolution of strength for lime-stabilized rammed soil. J. Rock Mech. Geotech. Eng. 2019, 11, 882–891. [Google Scholar]

- Vukicevic, M.; Marjanovic, M.; Pujevic, V.; Jockovic, S. The Alternatives to Traditional Materials for Subsoil Stabilization and Embankments. Materials 2019, 12, 3018. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pourakbar, S.; Asadi, A.; Huat, B.B.K.; Fasihnikoutalab, M.H. Stabilization of clayey soil using ultrafine palm oil fuel ash (POFA) and cement. Transp. Geotech. 2015, 3, 24–35. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y.; Hao, H.; Guo, W.; Wen, H.; Zhang, D. Characterization and sulfonamide antibiotics adsorption capacity of spent coffee grounds based biochar and hydrochar. Sci. Total Environ. J. 2020, 716, 137015. [Google Scholar] [CrossRef]

- Acchar, W.; Avelino, K.A.; Segadães, A.M. Granite waste and coffee husk ash synergistic effect on clay-based ceramics. Adv. Appl. Ceram. 2016, 6753, 236–242. [Google Scholar] [CrossRef]

- Mamuye, Y.; Geremew, A. Improving Strength of Expansive Soil using Coffee Husk Ash for Subgrade Soil Formation: A Case Study in Jimma Town. Int. J. Eng. Res. Technol. 2018, 7, 120–126. [Google Scholar]

- Munirwan, R.P.; Sundary, D.; Munirwansyah, M.; Bunyamin, B. Study of coffee husk ash addition for clay soil stabilization. In Proceedings of the 10th Annual International Conference on Science and Engineering (10th AIC 2020), Banda Aceh, Indonesia, 15–16 October 2020; Volume 1087. [Google Scholar]

- Woldegiorgis, A.D. Effect of Coffee Husk Ash on Index and Strength Properties of Expansive Soils. Master’s Thesis, Department of Geotechnical Engineering, Addis Ababa Science and Technology University, Addis Ababa, Ethiopia, 2019. [Google Scholar]

- Wahab, N.A.; Roshan, M.J.; Rashid, A.S.A.; Hezmi, M.A.; Jusoh, S.N.; Norsyahariati, N.D.N. Strength and Durability of Cement-Treated Lateritic Soil. Sustainability 2021, 13, 6430. [Google Scholar] [CrossRef]

- ASTM D422-63(2007)e2; Standard Test Method for Particle-Size Analysis of Soils (Withdrawn 2016). ASTM International: West Conshohocken, PA, USA, 2007.

- Fadhil, R.; Maarif, M.S.; Bantacut, T.; Hermawan, A. A prospective strategy for institutional development of Gayo coffee agroindustry in Aceh province, Indonesia. Bulg. J. Agric. Sci. 2018, 24, 959–966. [Google Scholar]

- Almqvist, A.C. Coffee, a Fair Trade?—A study about Fairtrade certified Gayo Coffee Farmers in Aceh, Indonesia. Master’s Thesis, Swedish University of Agricultural Sciences (SLU), Uppsala, Sweden, 2011. [Google Scholar]

- Ortiz-barajas, D.L.; Arevalo-Prada, J.A.; Fenollar, O.; Rueda-Ordonez, Y.J.; Torres-Giner, S. Torrefaction of Coffee Husk Flour for the Development of Injection-Molded Green Composite Pieces of Polylactide with High Sustainability. Appl. Sci. 2020, 10, 6468. [Google Scholar] [CrossRef]

- Ramirez, N.; Sardella, F.; Deiana, C.; Schlosser, A.; Kißling, P.A.; Klepzig, L.F. Capacitive behavior of activated carbons obtained from coffee husk. RSC Adv. 2020, 10, 38097–38106. [Google Scholar] [CrossRef] [PubMed]

- Miito, G.J.; Banadda, N. A short review on the potential of coffee husk gasification for sustainable energy in Uganda. F1000Research 2017, 6, 1809. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rebollo-hernanz, M.; Cañas, S.; Taladrid, D.; Benitez, V.; Bartolome, B.; Aguilera, Y. Revalorization of Coffee Husk: Modeling and Optimizing the Green Sustainable Extraction of Phenolic Compounds. Foods 2021, 10, 653. [Google Scholar] [CrossRef]

- Acchar, W.; Dultra, E.J.V.; Segadães, A.M. Untreated coffee husk ashes used as fl ux in ceramic tiles. Appl. Clay Sci. 2013, 75, 141–147. [Google Scholar] [CrossRef]

- Samuel, Z.A. Technological Viability of Coffee Husk Ash, Soil Rich in Kaolinite-Ferrinatrite and Kaolinite-Geothite for The Adsorptive Removal of Chromium (VI) from Industrial Wastewater. Ph.D. Thesis, School of Engineering, College of Agriculture, Engineering and Science, University of KuaZulu Natal, Durban, South Africa, 2017. [Google Scholar]

- ASTM D4318-17e1; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D698-12(2021); Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft3 (600 kN-m/m3)). ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D2166 / D2166M-16; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM International: West Conshohocken, PA, USA, 2016.

- Praveen, G.V.; Kurre, P. Influence of coir fiber reinforcement on shear strength parameters of cement modified marginal soil mixed with fly ash. Mater. Today Proc. 2020, 39, 504–507. [Google Scholar] [CrossRef]

- ASTM D3080/D3080M-11; Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions (Withdrawn 2020). ASTM International: West Conshohocken, PA, USA, 2011.

- Tanzadeh, R.; Vafaeian, M.; Yusefzadeh, M. Effects of micro-nano-lime (CaCO3) particles on the strength and resilience of road clay beds. Constr. Build. Mater. 2019, 217, 193–201. [Google Scholar] [CrossRef]

- Sefene, S.S. Determination of Effective Wood Ash Proportion for Black Cotton Soil Improvement. Geotech. Geol. Eng. 2020, 39, 617–625. [Google Scholar] [CrossRef]

- Nath, B.D.; Sarkar, G.; Siddiqua, S.; Rokunuzzaman, M.; Islam, M.R. Geotechnical Properties of Wood Ash-Based Composite Fine-Grained Soil. Adv. Civ. Eng. 2018, 2018, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Alo, B.A.; Ayodele, F.O.; Adekanmi, J.S. Effect of Abattoir Wastewater on Geotechnical Properties of Lateritic Soil. J. Eng. Sci. Technol. 2021, 16, 2114–2127. [Google Scholar]

- Atahu, M.K.; Saathoff, F.; Gebissa, A. Effect of coffee husk ash on geotechnical properties of expansive soil. Int. J. Curr. Res. 2017, 9, 46401–46406. [Google Scholar]

- Rababah, S.; Aldeeky, H.; Qasrawi, H.; Hattamleh, O.A.; Rababah, S.; Aldeeky, H. Performance of subgrade soil stabilised with by-product recycled mill scale and cementitous materials. Int. J. Pavement Eng. 2020, 23, 708–718. [Google Scholar] [CrossRef]

- Oluwatuyi, O.E.; Adeola, B.O.; Alhassan, E.A.; Nnochiri, E.S.; Modupe, A.E.; Elemile, O.O. Ameliorating effect of milled eggshell on cement stabilized lateritic soil for highway construction. Case Stud. Constr. Mater. 2018, 9, e00191. [Google Scholar] [CrossRef]

- Chavali, R.V.P.; Reshmarani, B. Characterization of expansive soils treated with lignosulfonate. Int. J. Geo Eng. 2020, 11, 17. [Google Scholar] [CrossRef]

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | K2O | MnO | P2O5 | LOI |

|---|---|---|---|---|---|---|---|---|---|

| 42.99 | 5.63 | 2.67 | 3.01 | 1.69 | 0.05 | 0.10 | 0.03 | 0.28 | 1.50 |

| Properties | Symbol | Value |

|---|---|---|

| Liquid Limit (%) | LL | 70.90 |

| Plastic Limit (%) | PL | 27.77 |

| Plasticity Index (%) | PI | 43.13 |

| Soil Classification: | ||

| USCS | CH | |

| AASHTO | A-7-6 | |

| Maximum Dry Density (kg/m3) | MDD | 1220 |

| Optimum Moisture Content (%) | OMC | 36.3 |

| Specific Gravity | Gs | 2.67 |

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | K2O | MnO | P2O5 | LOI |

|---|---|---|---|---|---|---|---|---|---|

| 8.30 | 0.04 | 5.10 | 5.22 | 1.03 | 0.03 | 60.09 | 0.05 | 4.98 | 2.83 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Munirwan, R.P.; Taha, M.R.; Mohd Taib, A.; Munirwansyah, M. Shear Strength Improvement of Clay Soil Stabilized by Coffee Husk Ash. Appl. Sci. 2022, 12, 5542. https://doi.org/10.3390/app12115542

Munirwan RP, Taha MR, Mohd Taib A, Munirwansyah M. Shear Strength Improvement of Clay Soil Stabilized by Coffee Husk Ash. Applied Sciences. 2022; 12(11):5542. https://doi.org/10.3390/app12115542

Chicago/Turabian StyleMunirwan, Reza Pahlevi, Mohd Raihan Taha, Aizat Mohd Taib, and Munirwansyah Munirwansyah. 2022. "Shear Strength Improvement of Clay Soil Stabilized by Coffee Husk Ash" Applied Sciences 12, no. 11: 5542. https://doi.org/10.3390/app12115542