Comparative Study on Planar Type-II Strained-Layer Superlattice Infrared Photodetectors Fabricated by Ion-Implantation

Abstract

:1. Introduction

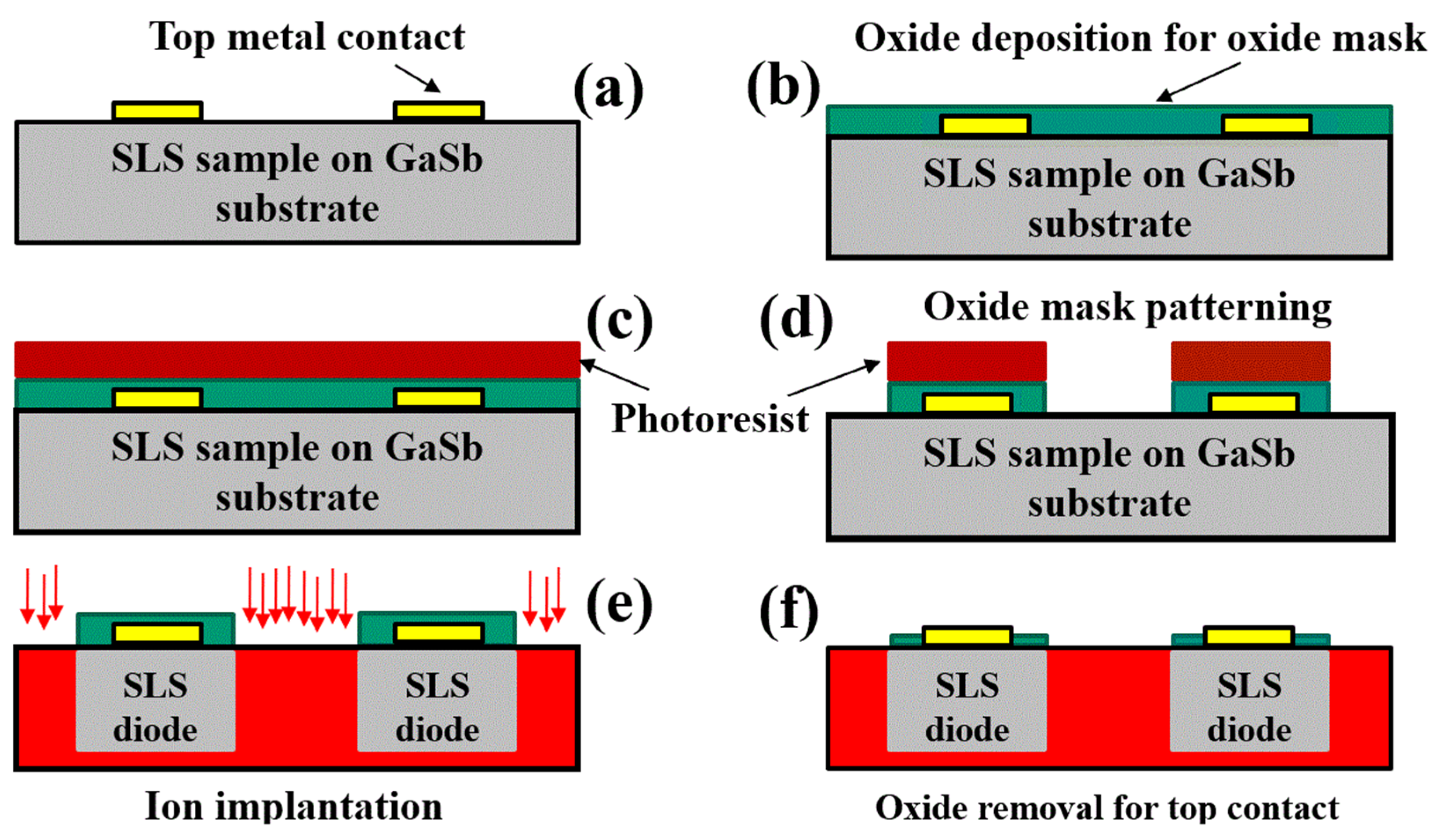

2. Materials and Methods

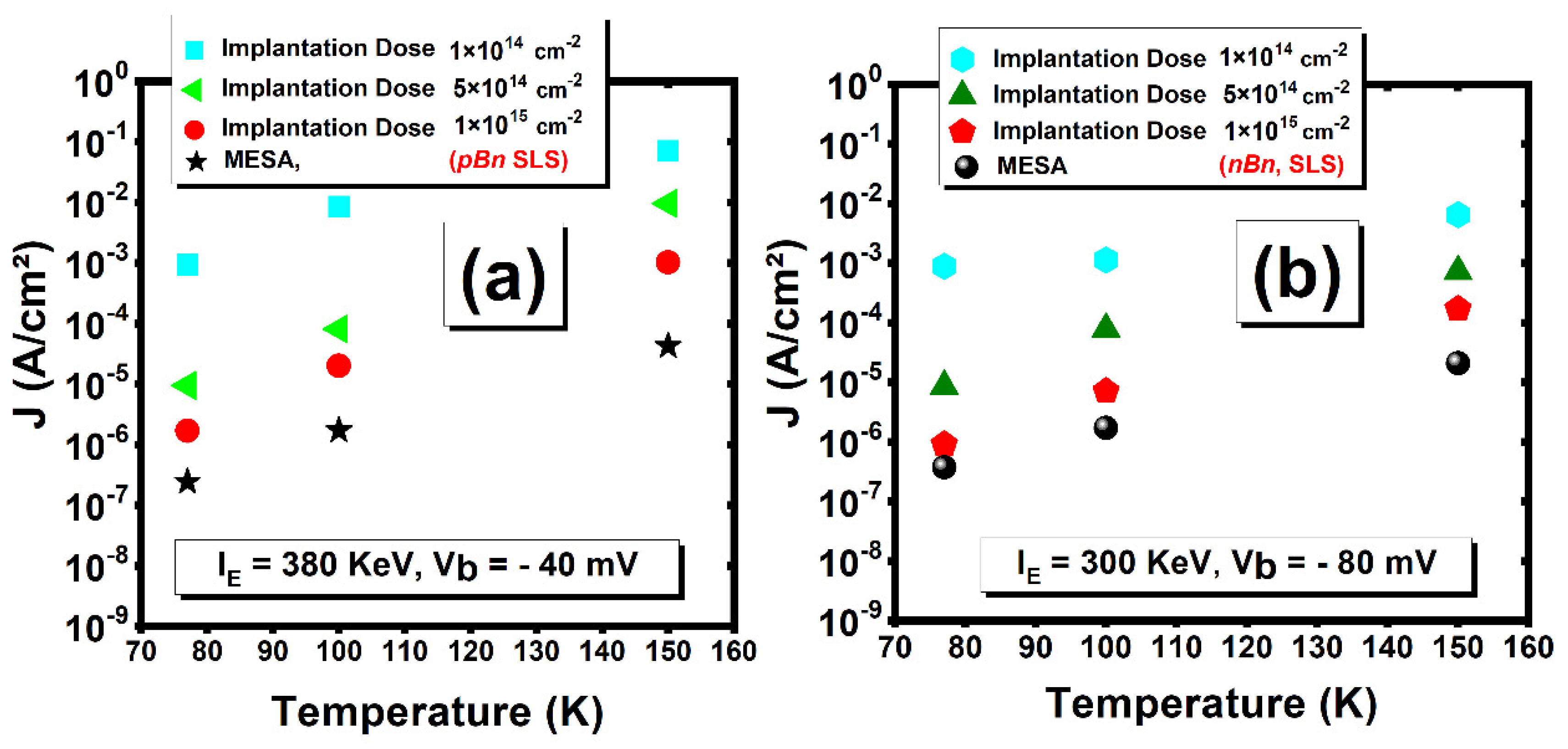

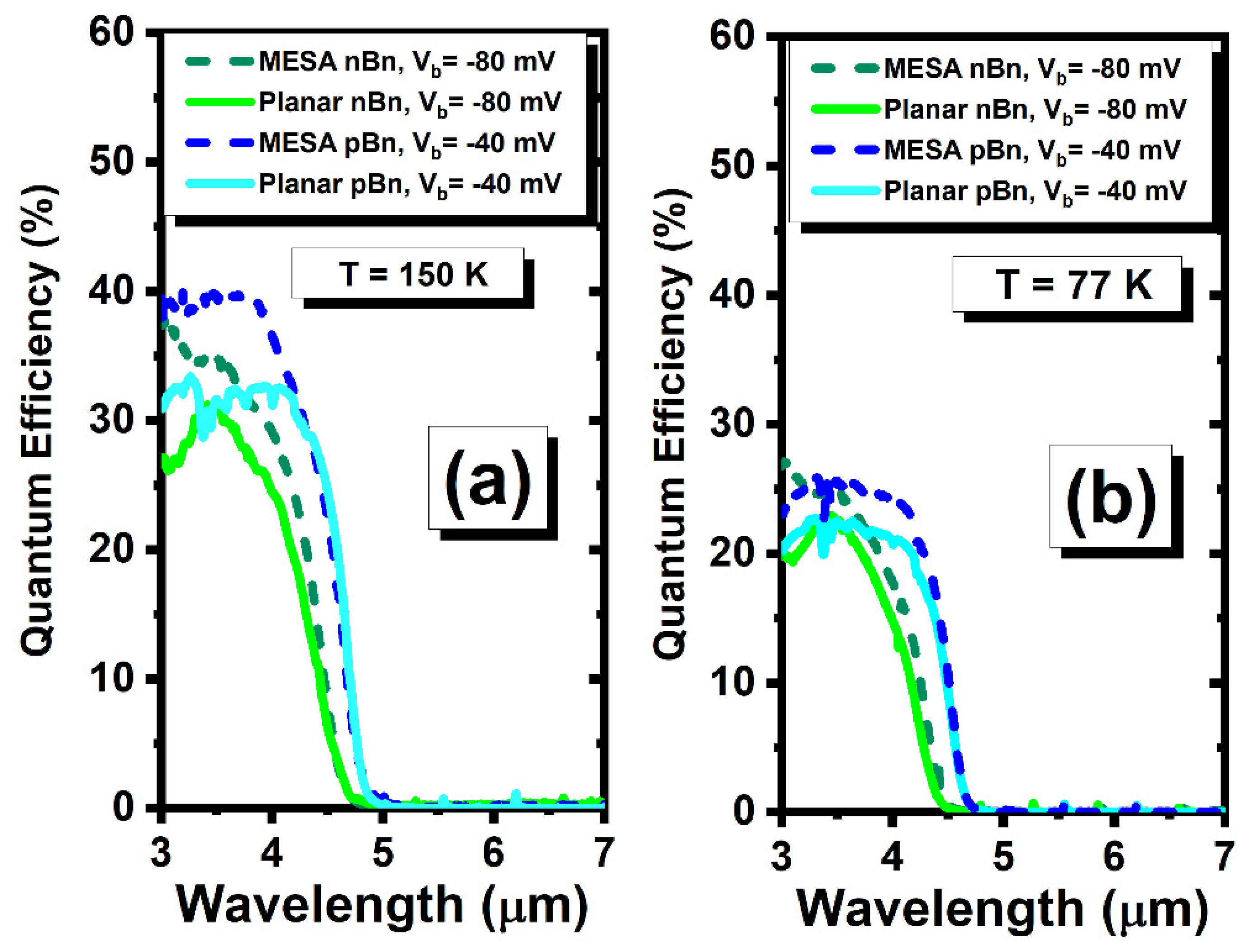

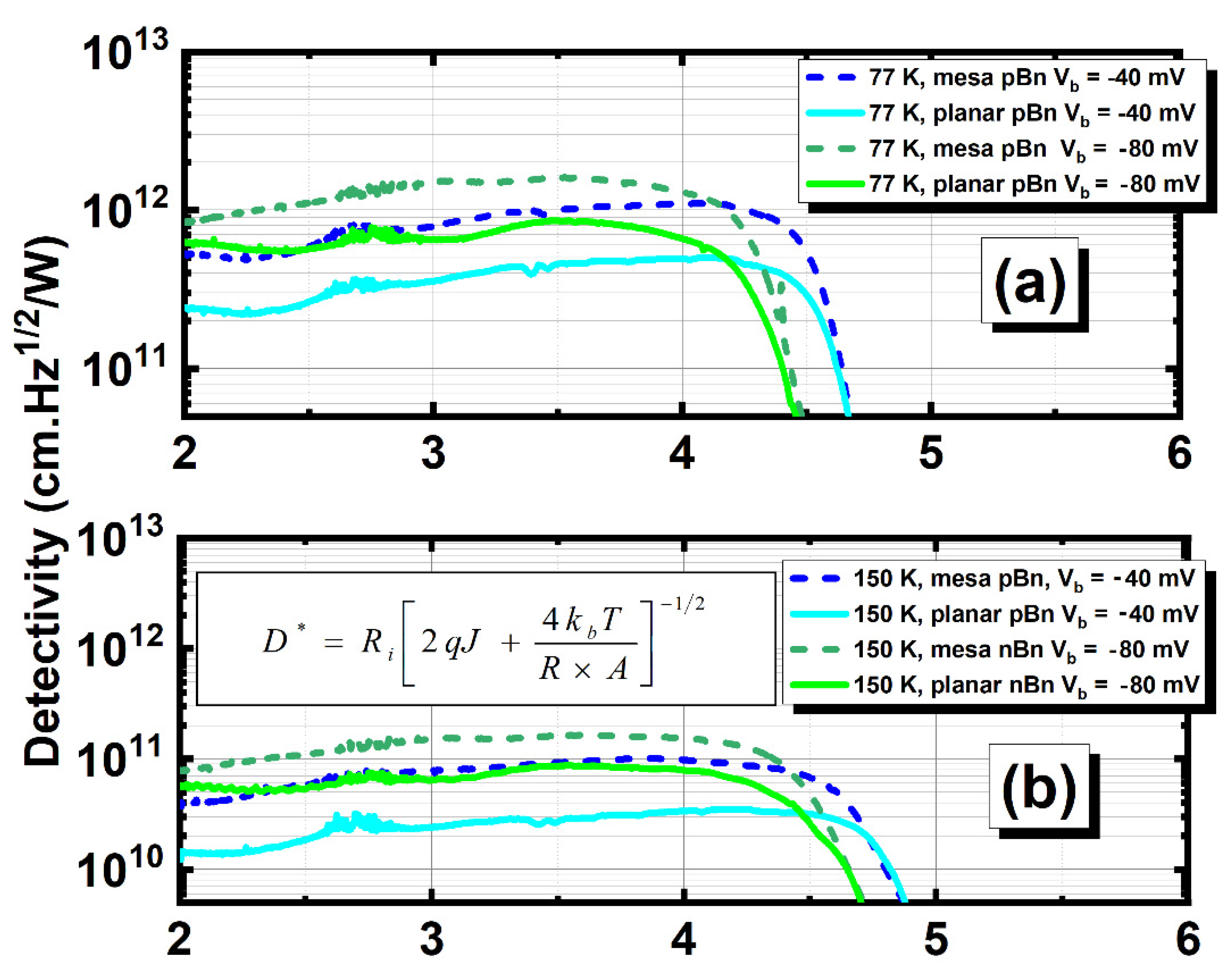

3. Results

4. Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rogalski, A.; Martyniuk, P.; Kopytko, M. Type-II superlattice photodetectors versus HgCdTe photodiodes. Prog. Quantum Electron. 2019, 68, 100228. [Google Scholar] [CrossRef]

- Razeghi, M.; Haddadi, A.; Dehzangi, A.; Chevallier, R.; Yang, T. Recent advances in InAs/InAs1-xSbx/AlAs1-xSbx gap-engineered type-II superlattice-based photodetectors. In Proceedings of the Infrared Technology and Applications XLIII, Anaheim, CA, USA, 9–13 April 2017; SPIE: Bellingham, WA, USA, 2017; Volume 10177, pp. 19–29. [Google Scholar]

- Piotrowski, J.; Piotrowski, A. Room temperature IR photodetectors. Mercury Cadmium Telluride Growth Prop. Appl. 2010, 513–537. [Google Scholar] [CrossRef]

- Kinch, M.A. Fundamentals of Infrared Detector Materials; SPIE: Bellingham, WA, USA, 2007. [Google Scholar]

- Blanks, D.K.; Beck, J.D.; Kinch, M.A.; Colombo, L. Band-to-band tunnel processes in HgCdTe: Comparison of experimental and theoretical studies. J. Vac. Sci. Technol. A 1988, 6, 2790–2794. [Google Scholar] [CrossRef]

- Dehzangi, A.; Haddadi, A.; Adhikary, S.; Razeghi, M. Impact of scaling base thickness on the performance of heterojunction phototransistors. Nanotechnology 2017, 28, 10LT01. [Google Scholar] [CrossRef]

- Dehzangi, A.; McClintock, R.; Wu, D.; Li, J.; Johnson, S.M.; Dial, E.; Razeghi, M. High speed antimony-based superlattice photodetectors transferred on sapphire. Appl. Phys. Express 2019, 12, 116502. [Google Scholar] [CrossRef]

- Hoang, A.M.; Dehzangi, A.; Adhikary, S.; Razeghi, M. High performance bias-selectable three-color Short-wave/Mid-wave/Long-wave Infrared Photodetectors based on Type-II InAs/GaSb/AlSb superlattices. Sci. Rep. 2016, 6, 24144. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, B.-M.; Hoffman, D.; Delaunay, P.-Y.; Huang, E.K.-W.; Razeghi, M.; Pellegrino, J. Band edge tunability of M-structure for heterojunction design in Sb based type II superlattice photodiodes. Appl. Phys. Lett. 2008, 93, 163502. [Google Scholar] [CrossRef]

- Binh-Minh, N.; Guanxi, C.; Minh-Anh, H.; Razeghi, M. Growth and Characterization of Long-Wavelength Infrared Type-II Superlattice Photodiodes on a 3-in GaSb Wafer, Quantum Electronics. IEEE J. Quantum Electron. 2011, 47, 686–690. [Google Scholar] [CrossRef]

- Zegrya, G.G.; Andreev, A.D. Mechanism of suppression of Auger recombination processes in type-II heterostructures. Appl. Phys. Lett. 1995, 67, 2681–2683. [Google Scholar] [CrossRef]

- Ting, D.Z.; Soibel, A.; Khoshakhlagh, A.; Keo, S.A.; Rafol, B.; Fisher, A.M.; Pepper, B.J.; Luong, E.M.; Hill, C.J.; Gunapala, S.D. Advances in III-V semiconductor infrared absorbers and detectors. Infrared Phys. Technol. 2019, 97, 210–216. [Google Scholar] [CrossRef]

- Ting, D.Z.-Y.; Hill, C.J.; Soibel, A.; Keo, S.A.; Mumolo, J.M.; Nguyen, J.; Gunapala, S.D. A high-performance long wavelength superlattice complementary barrier infrared detector. Appl. Phys. Lett. 2009, 95, 023508. [Google Scholar] [CrossRef]

- Arias, J.M.; Pasko, J.G.; Zandian, M.; Shin, S.H.; Williams, G.M.; Bubulac, L.O.; DeWames, R.E.; Tennant, W.E. Planar p-on-n HgCdTe heterostructure photovoltaic detectors. Appl. Phys. Lett. 1993, 62, 976–978. [Google Scholar] [CrossRef]

- Musca, C.A.; Antoszewski, J.; Dell, J.M.; Faraone, L.; Terterian, S. Planar p-on-n HgCdTe heterojunction mid-wavelength infrared photodiodes formed using plasma-induced junction isolation. J. Electron. Mater. 2003, 32, 622–626. [Google Scholar] [CrossRef]

- Chang, S.-H.; Fang, Y.-K.; Ting, S.-F.; Chen, S.-F.; Lin, C.-Y.; Wu, C.-Y. Ultra high performance planar InGaAs PIN photodiodes for high speed optical fiber communication. Sens. Actuators A Phys. 2007, 133, 9–12. [Google Scholar] [CrossRef]

- Arias, J.; Pasko, J.G.; Zandian, M.; Shin, S.H.; Williams, G.M.; Bubulac, L.O.; De Wames, R.E.; Tennant, W.E. MBE HgCdTe heterostructure p-on-n planar infrared photodiodes. J. Electron. Mater. 1993, 22, 1049–1053. [Google Scholar] [CrossRef]

- Kinch, M. HDVIP FPA Technology at DRS Infrared Technologies (Aerospace/Defense Sensing, Simulation, and Controls); SPIE: Bellingham, WA, USA, 2001. [Google Scholar]

- Dehzangi, A.; Wu, D.; McClintock, R.; Li, J.; Razeghi, M. Planar nBn type-II superlattice mid-wavelength infrared photodetectors using zinc ion-implantation. Appl. Phys. Lett. 2020, 116, 221103. [Google Scholar] [CrossRef]

- Dehzangi, A.; Wu, D.; McClintock, R.; Li, J.; Jaud, A.; Razeghi, M. Demonstration of Planar Type-II Superlattice-Based Photodetectors Using Silicon Ion-Implantation. Photonics 2020, 7, 68. [Google Scholar] [CrossRef]

- Wu, D.; Dehzangi, A.; Li, J.; Razeghi, M. High performance Zn-diffused planar mid-wavelength infrared type-II InAs/InAs1−xSbx superlattice photodetector by MOCVD. Appl. Phys. Lett. 2020, 116, 161108. [Google Scholar] [CrossRef] [Green Version]

- Dehzangi, A. Planar strained layer superlattice infrared photodetector using ion implantation. In Proceedings of the Image Sensing Technologies: Materials, Devices, Systems, and Applications IX, Orlando, FL, USA, 3 April–13 June 2022; SPIE: Bellingham, WA, USA, 2022; Volume 12091, pp. 9–15. [Google Scholar]

- Pearton, S.J. Ion implantation for isolation of III–V semiconductors. Mater. Sci. Rep. 1990, 4, 313–363. [Google Scholar] [CrossRef]

- Eisen, F.H. Ion implantation in III–V compounds. Radiat. Eff. 1980, 47, 99–115. [Google Scholar] [CrossRef]

- Donnelly, J.P. The electrical characteristics of ion implanted compound semiconductors. Nucl. Instrum. Methods 1981, 182–183, 553–571. [Google Scholar] [CrossRef]

- Steenbergen, E.H.; Connelly, B.C.; Metcalfe, G.D.; Shen, H.; Wraback, M.; Lubyshev, D.; Qiu, Y.; Fastenau, J.M.; Liu, A.W.K.; Elhamri, S.; et al. Significantly improved minority carrier lifetime observed in a long-wavelength infrared III–V type-II superlattice comprised of InAs/InAsSb. Appl. Phys. Lett. 2011, 99, 251110. [Google Scholar] [CrossRef]

- Razeghi, M.; Haddadi, A.; Hoang, A.M.; Chevallier, R.; Adhikary, S.; Dehzangi, A. InAs/InAs1−xSbx type-II superlattices for high performance long wavelength infrared detection. In Proceedings of the Infrared Technology and Applications XLII, Baltimore, MD, USA, 18–21 April 2016; Volume 9819, p. 981909. [Google Scholar]

- Wu, D.; Li, J.; Dehzangi, A.; Razeghi, M. Mid-wavelength infrared high operating temperature pBn photodetectors based on type-II InAs/InAsSb superlattice. AIP Adv. 2020, 10, 025018. [Google Scholar] [CrossRef] [Green Version]

- Soibel, A.; Ting, D.Z.; Rafol, S.B.; Fisher, A.M.; Keo, S.A.; Khoshakhlagh, A.; Gunapala, S.D. Mid-wavelength infrared InAsSb/InAs nBn detectors and FPAs with very low dark current density. Appl. Phys. Lett. 2019, 114, 161103. [Google Scholar] [CrossRef]

- Haddadi, A.; Dehzangi, A.; Chevallier, R.; Adhikary, S.; Razeghi, M. Bias–selectable nBn dual–band long–/very long–wavelength infrared photodetectors based on InAs/InAs1−xSbx/AlAs1−xSbx type–II superlattices. Sci. Rep. 2017, 7, 3379. [Google Scholar] [CrossRef] [Green Version]

- Wu, D.; Dehzangi, A.; Razeghi, M. Demonstration of mid-wavelength infrared nBn photodetectors based on type-II InAs/InAs1−xSbx superlattice grown by metal-organic chemical vapor deposition. Appl. Phys. Lett. 2019, 115, 061102. [Google Scholar] [CrossRef]

- Asano, T.; Atanassov, R.D.; Ishiwara, H.; Furukawa, S. Formation of Thick, Thermally-Stable High-Resistivity-Layers in GaAs by Oxygen Ion Implantation. Jpn. J. Appl. Phys. 1981, 20, 901–907. [Google Scholar] [CrossRef]

- Dehzangi, A.; McClintock, R.; Haddadi, A.; Wu, D.; Chevallier, R.; Razeghi, M. Type–II superlattices base visible/extended short–wavelength infrared photodetectors with a bandstructure–engineered photo–generated carrier extractor. Sci. Rep. 2019, 9, 5003. [Google Scholar] [CrossRef] [Green Version]

- Matsubara, M.; Kyrtsos, A.; Bellotti, E. Phase diagrams and critical temperatures for coherent and incoherent mixtures of InAs1−xSbx alloys using first-principles calculations. J. Appl. Phys. 2022, 131, 215102. [Google Scholar] [CrossRef]

- Ting, D.Z.; Fisher, A.M.; Pepper, B.J.; Hill, C.J.; Keo, S.A.; Khoshakhlagh, A.; Soibel, A.; Rafol, B.; Maruyama, Y.; Gunapala, S.D.; et al. Progress in InAs/InAsSb superlattice barrier infrared detectors. In Proceedings of the Infrared Technology and Applications XLVIII, Orlando, FL, USA, 3 April–13 June 2022; Volume 12107, pp. 167–175. [Google Scholar]

| Design | Implantation Energy | Implantation Dose | Depth of Ion Concentration Peak | Straggling |

|---|---|---|---|---|

| pBn | 300 KeV | 1 × 1015 cm−2 | 900 nm | 100 nm |

| nBn | 380 KeV | 1 × 1015 cm−2 | 1000 nm | 115 nm |

| Design | Fabrication Approach | QE @ 150 K | QE @ 77 K |

|---|---|---|---|

| nBn λ = 3.35 µm | Mesa | 36.4% | 25.0% |

| Planar | 31.5% | 23.5% | |

| pBn λ = 3.80 µm | Mesa | 39.2% | 24.4% |

| Planar | 32.6% | 21.5% |

| Design | Fabrication Approach | D* @ 150 K cm⸱Hz1/2/W | D* @ 77 K cm⸱Hz1/2/W |

|---|---|---|---|

| nBn λ = 3.35 µm | Mesa | 1.86 × 1011 | 1.52 × 1012 |

| Planar | 8.54 × 1010 | 9.12 × 1011 | |

| pBn λ = 3.80 µm | Mesa | 3.37 × 1010 | 1.52 × 1012 |

| Planar | 4.95 × 1011 | 1.10 × 1012 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dehzangi, A. Comparative Study on Planar Type-II Strained-Layer Superlattice Infrared Photodetectors Fabricated by Ion-Implantation. Appl. Sci. 2022, 12, 6114. https://doi.org/10.3390/app12126114

Dehzangi A. Comparative Study on Planar Type-II Strained-Layer Superlattice Infrared Photodetectors Fabricated by Ion-Implantation. Applied Sciences. 2022; 12(12):6114. https://doi.org/10.3390/app12126114

Chicago/Turabian StyleDehzangi, Arash. 2022. "Comparative Study on Planar Type-II Strained-Layer Superlattice Infrared Photodetectors Fabricated by Ion-Implantation" Applied Sciences 12, no. 12: 6114. https://doi.org/10.3390/app12126114