After the complete success of the first [

1], second [

2,

3], and third edition [

4,

5] of the Special Issues of the Manufacturing Engineering Society (SIMES), with a total of 118 contributions (94 in

Materials and 24 in

Applied Sciences) regarding emerging methods and technologies, the Special Issue of the Manufacturing Engineering Society—2021 (SIMES-2021) [

6,

7] was launched again as a joint issue of the same journals,

Materials and

Applied Sciences.

Once again, this Special Issue was promoted by the Manufacturing Engineering Society (MES) of Spain [

8], with the aim of covering a wide range of lines of research developed by the members and collaborators of the MES and other researchers within the field of manufacturing engineering. The Special Issue aims to explore the evolution of traditional manufacturing models toward the new requirements of the Manufacturing Industry 4.0 and how manufacturing professionals should face the resulting competitive challenges in the context of the ever-increasing use of digital information systems and communication technologies.

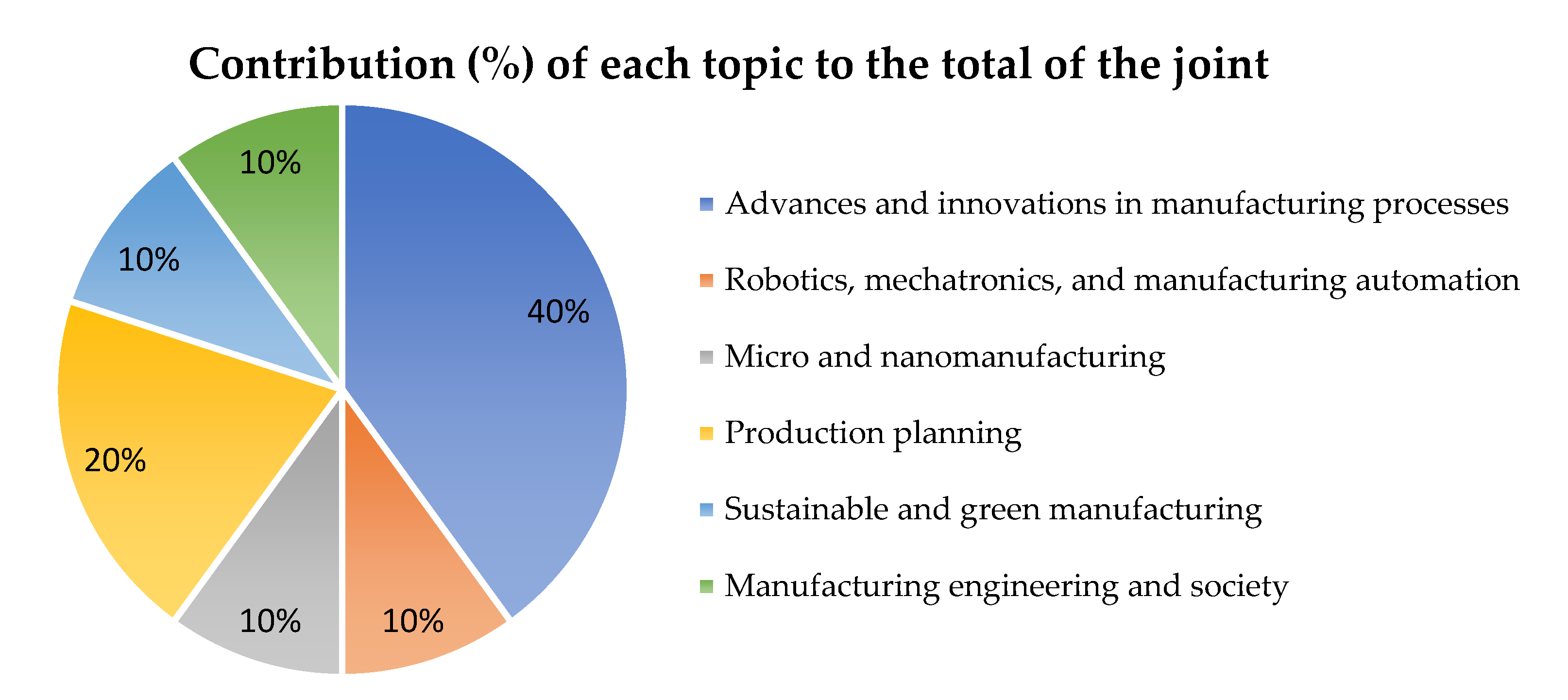

In this fourth edition, the joint issue gathered a total of 10 contributions (9 papers and 1 review) in the topics presented in

Figure 1, in which the percentage of the contribution of each topic to the Special Issue of the Manufacturing Engineering Society—2021 (SIMES-2021) is also shown.

Regarding the specific contributions to the Special Issue in the journal

Applied Sciences, four papers regarding cutting-edge advancements in different fields of manufacturing engineering were published after a rigorous review process. In particular, these papers covered the topics of production planning, sustainable and green manufacturing, and manufacturing engineering and society.

Figure 2 shows the main topics and the percentages of their contribution in this journal.

Among them, most contributions regarded the topic “production planning” (representing 50% of the submissions), followed by the topics “sustainable and green manufacturing” and “manufacturing engineering and society” (each representing 25% of the submissions).

Concretely, within the topic “production planning”, in the field of quality in the manufacturing sector, the work by Pérez-Fernández et al. [

9] presented an innovative decision support system to analyze intangible quality costs. The system was developed with an empirical base, applying the Analytical Hierarchy Process (AHP), the Analytical Network Process (ANP), and Lean methodology to efficiently reduce all quality-related costs. In this study, an innovative methodology that allows one to measure and control intangible costs (perceptions, thoughts, and judgments) in quality departments was developed. Another major innovation was the application of both multi-criteria methodologies to obtain the best combined result for decision making and the optimization of this result, developing an effort–impact matrix based on Lean manufacturing methodology. It was shown that this system speeds up the decision-making process and ensures its efficiency in quality department applications. Moreover, this decision support system may be applicable to any manufacturing sector.

Another interesting article on this topic, in the field of management systems, was submitted by Brocal et al. [

10]. The objective of this work was to identify and classify leading indicators which facilitate the dynamic analyses of emerging risks in Integrated management systems (IMSs) for quality, environment, and safety. To achieve this, the indicator analysis was based on a bibliographic analysis. Firstly, a structure of indicators, which was configured by three categories organized in two levels, emerged. In the first level, it was established which categories can be integrated by the indicators of the IMS. The second level was configured by two categories of interrelated indicators, that is, process integrity indicators and occupational risks indicators. Each of these three categories had two dimensions. The first dimension represented the direction of the indicator, which made it either a leading or lagging indicator. The second dimension represented the risk nature, which was either an emerging or traditional risk. Then, the classification of the leading indicators was derived according to the categories of the indicators and the risk nature. This classification showed the direction of the leading indicators as well as the qualitative graduation of the potential associated consequences. This theoretical framework was applied to a real manufacturing process. This methodology represents the first step towards a more in-depth and detailed identification and definition of specific leading indicators within an IMS from a dynamic and emerging risk perspective.

Related to the topic of “sustainable and green manufacturing”, Benito et al. [

11] developed an article focused on the use of Bayesian networks to address the industrial thermal comfort issue, specifically in industries in northern Argentina. Mined data sets were analyzed and exploited with WEKA and ELVIRA tools. Thus, networks giving the predictive value of thermal comfort for different pairs of indoor temperature and humidity values according to activity, time, and season, verified in the workplace, were obtained. The results obtained were compared to other statistical models of linear regression used for thermal comfort, and thus, it was observed that comfort temperature values were within the same range, yet the network offered more information, as a range of options for interior design parameters (temperature/relative humidity) was offered for different work, time, and season conditions. Additionally, a comparison with static models of heat exchange revealed that the contribution of Bayesian networks was noted when considering a context of actual operability and adaptability conditions to the environment. This fact is promising for the development of thermal comfort intelligent systems, especially for the development of sustainable settings within the “Industry 4.0” paradigm.

Finally, regarding the topic of “manufacturing and society”, López et al. [

12] submitted an article within the field of teaching methodologies in engineering. This paper focused on the analysis of the effect of the global pandemic on the acquisition of competencies by students in specific technological disciplines, such as manufacturing engineering. This environment of uncertainty, joined to the health and safety measures applied during the pandemic, led to a different type of teaching: synchronous and asynchronous methodologies. Hence, face-to-face and online methodologies coexisted in the same academic year. In this paper, the results achieved in this uncertain environment were studied, with reference to students enrolled in Manufacturing Processes 2 at the Centro Universitario de Mérida within the bachelor’s degree in Design Engineering and New Product Development (Grado en Ingeniería en Diseño y Desarrollo de Nuevos Productos -GIDIDP-). An analysis of variance (ANOVA) was applied to the data obtained to locate the significant differences between the samples taken in the first year with online and face-to-face teaching methodologies and those taken in the second year with an exclusively face-to-face methodology. In the comparison of the results, maintaining face-to-face teaching proved essential, as it contributed towards students achieving better marks or maintaining the marks they previously achieved. However, online methodologies also help as an additional tool for students to acquire other knowledge and specific skills in these technical engineering subjects, specifically those dealing with the manufacturing processes addressed in this study.

Just seven months after the publication of the first work [

10], all of the papers now present prominent activity in their “article metrics”; it is remarkable that some of the papers belonging to this Special Issue currently have more than 1.300 abstract and full-text views, which is a clear evidence of the interest of all these topics in readers of the journal

Applied Sciences, in general, and scientists and professionals from the industry in particular.