Seismic Performance Evaluation of Highway Bridges under Scour and Chloride Ion Corrosion

Abstract

:1. Introduction

2. Earthquake and Scour Combination in the Failure Probability of Bridge

2.1. Calculation of Seismic Failure Probability of Bridges at Different Scour Depths

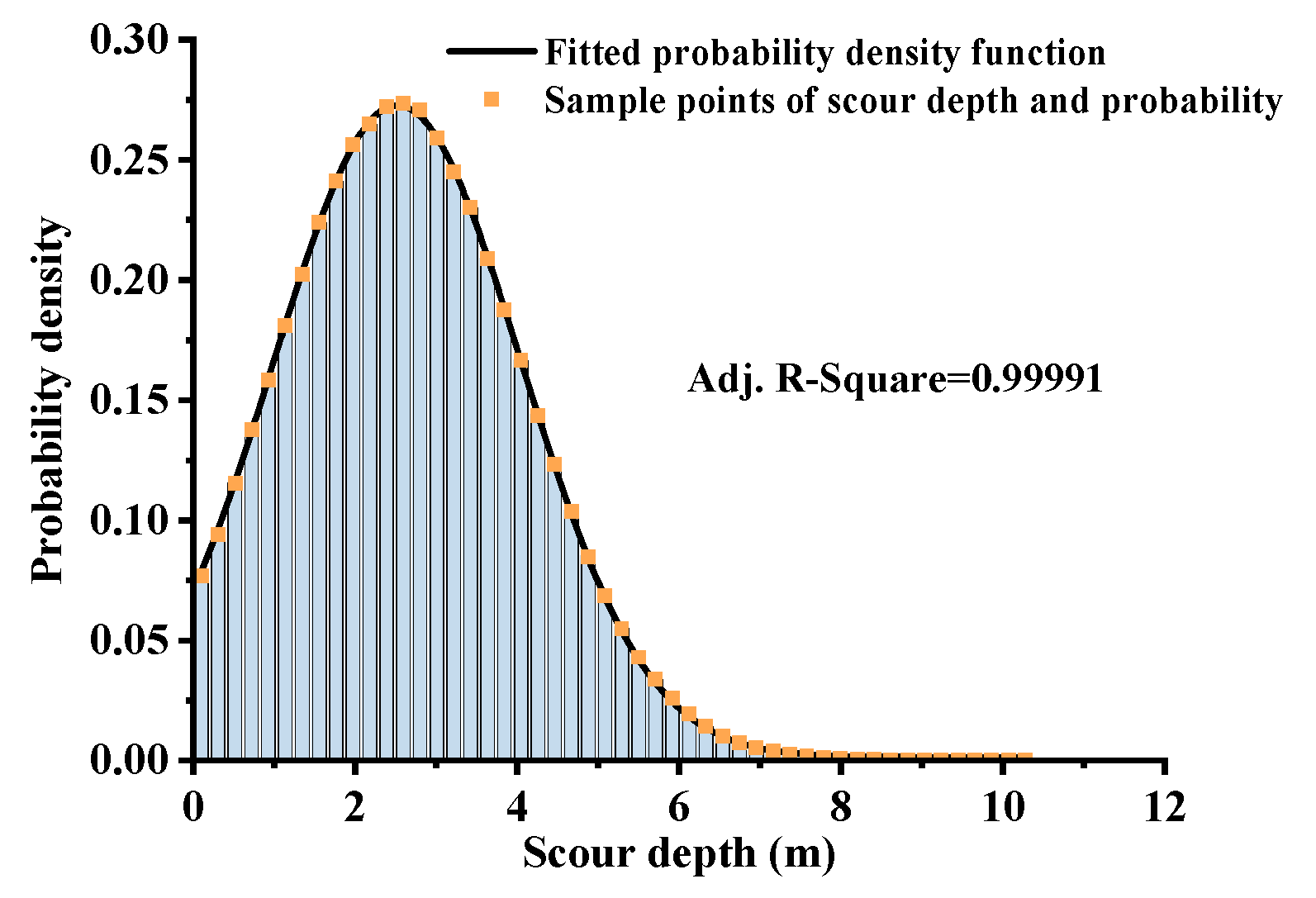

2.1.1. Scour Depth Distribution

2.1.2. Solution of Structural Failure Probability

2.2. Application for a Practical Project

2.2.1. The Introduction of Bridge Model and the Determination of Scour Depth Distribution

2.2.2. Determination of the Critical Section of Members and Structural Failure Mode

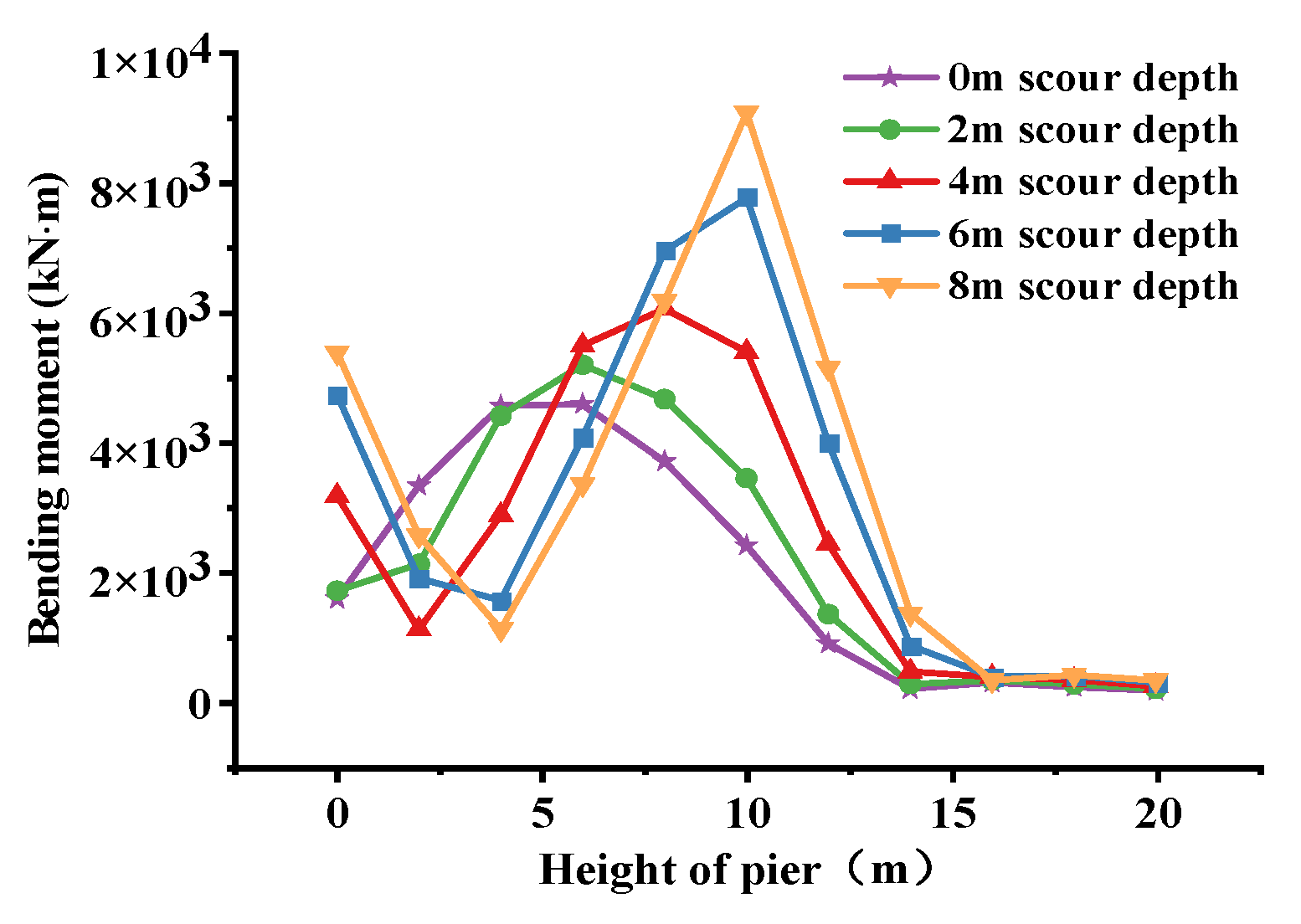

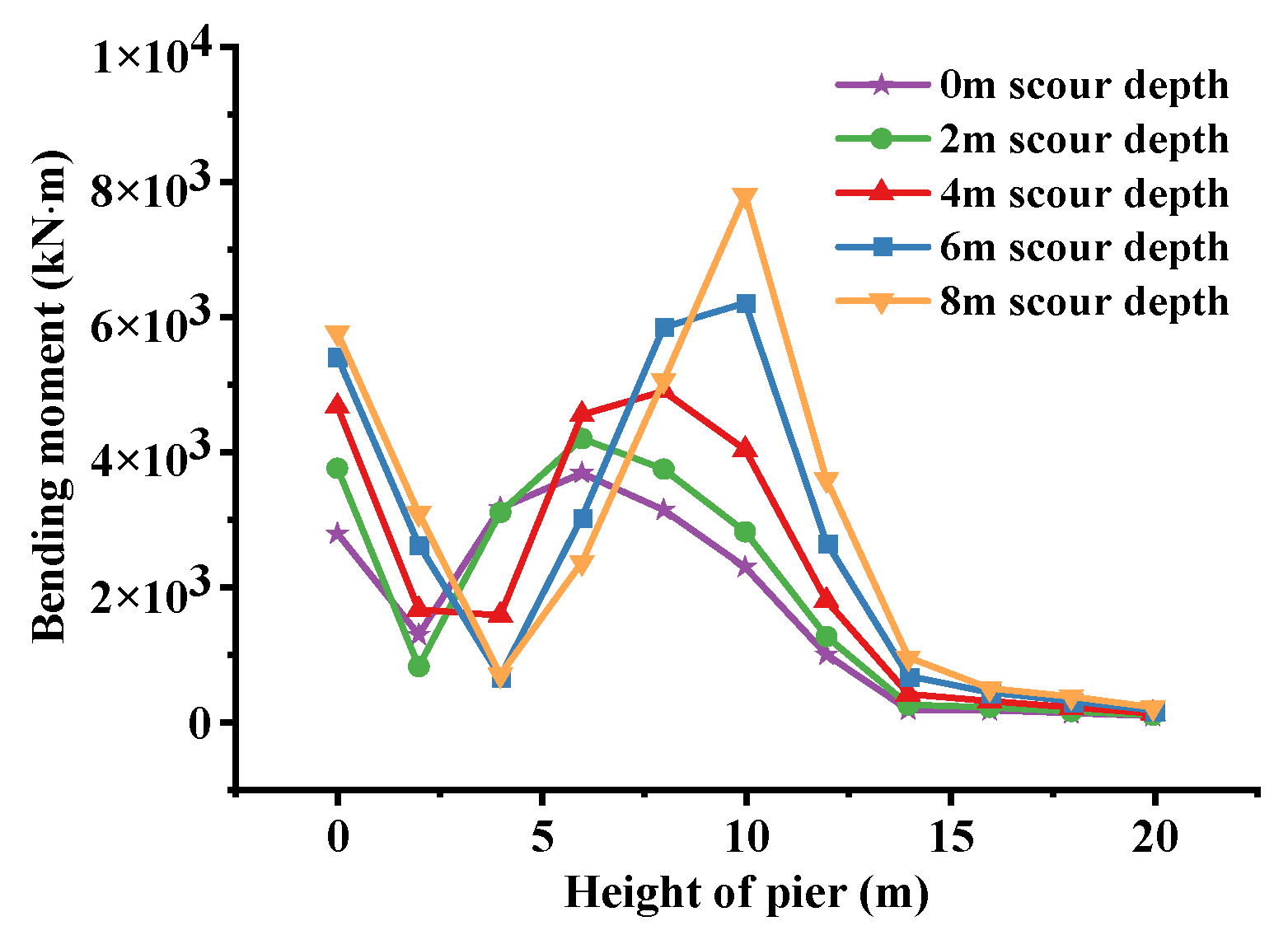

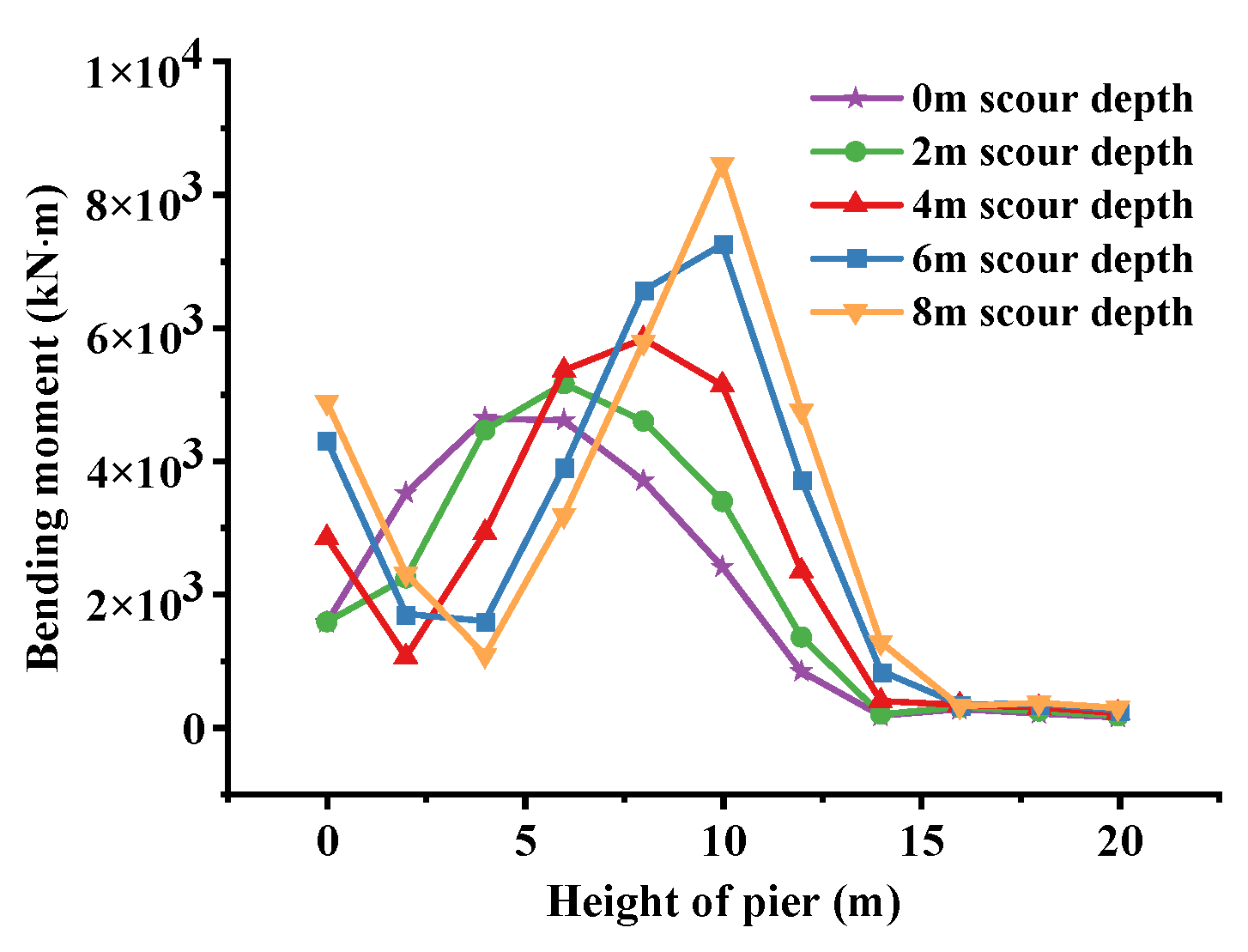

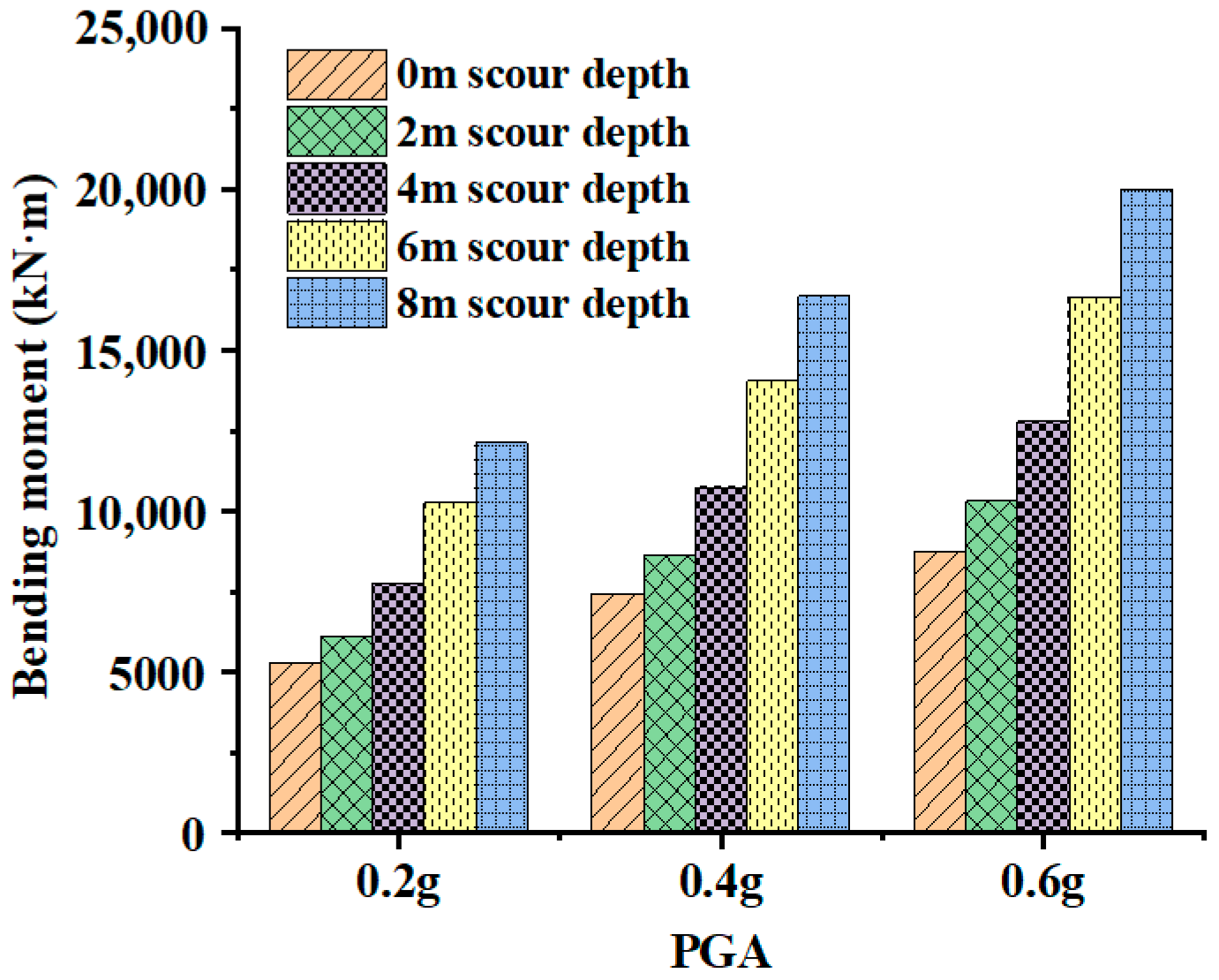

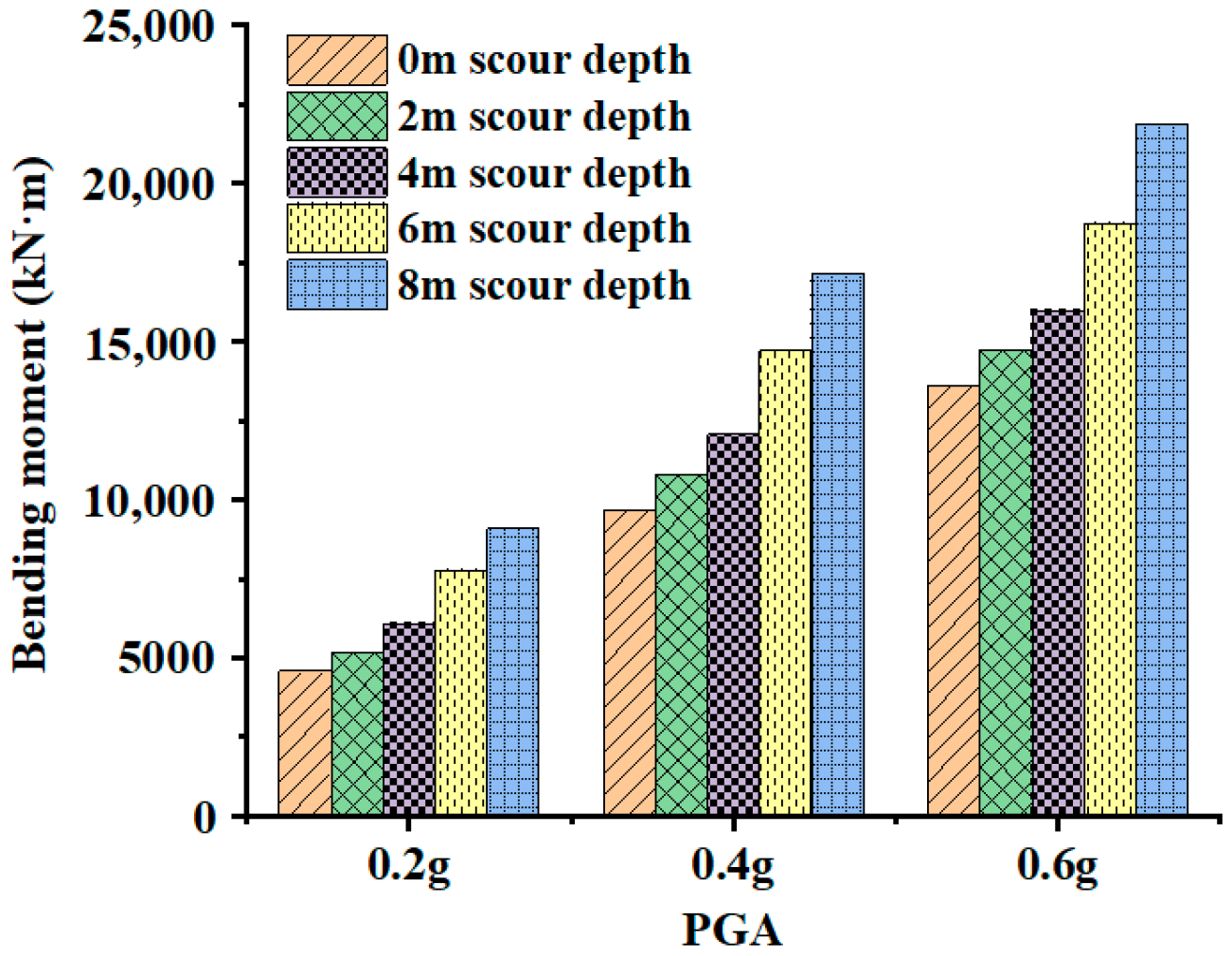

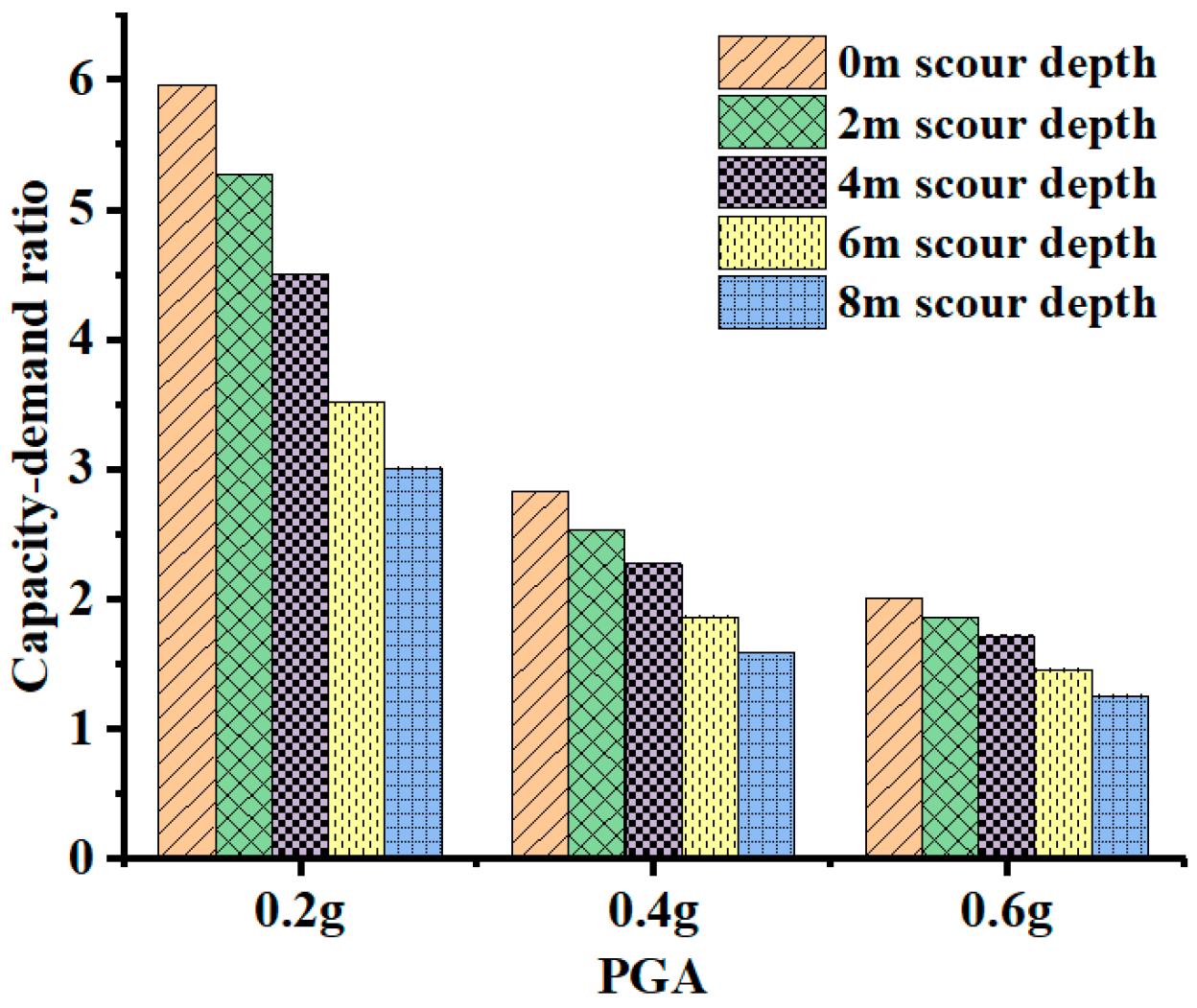

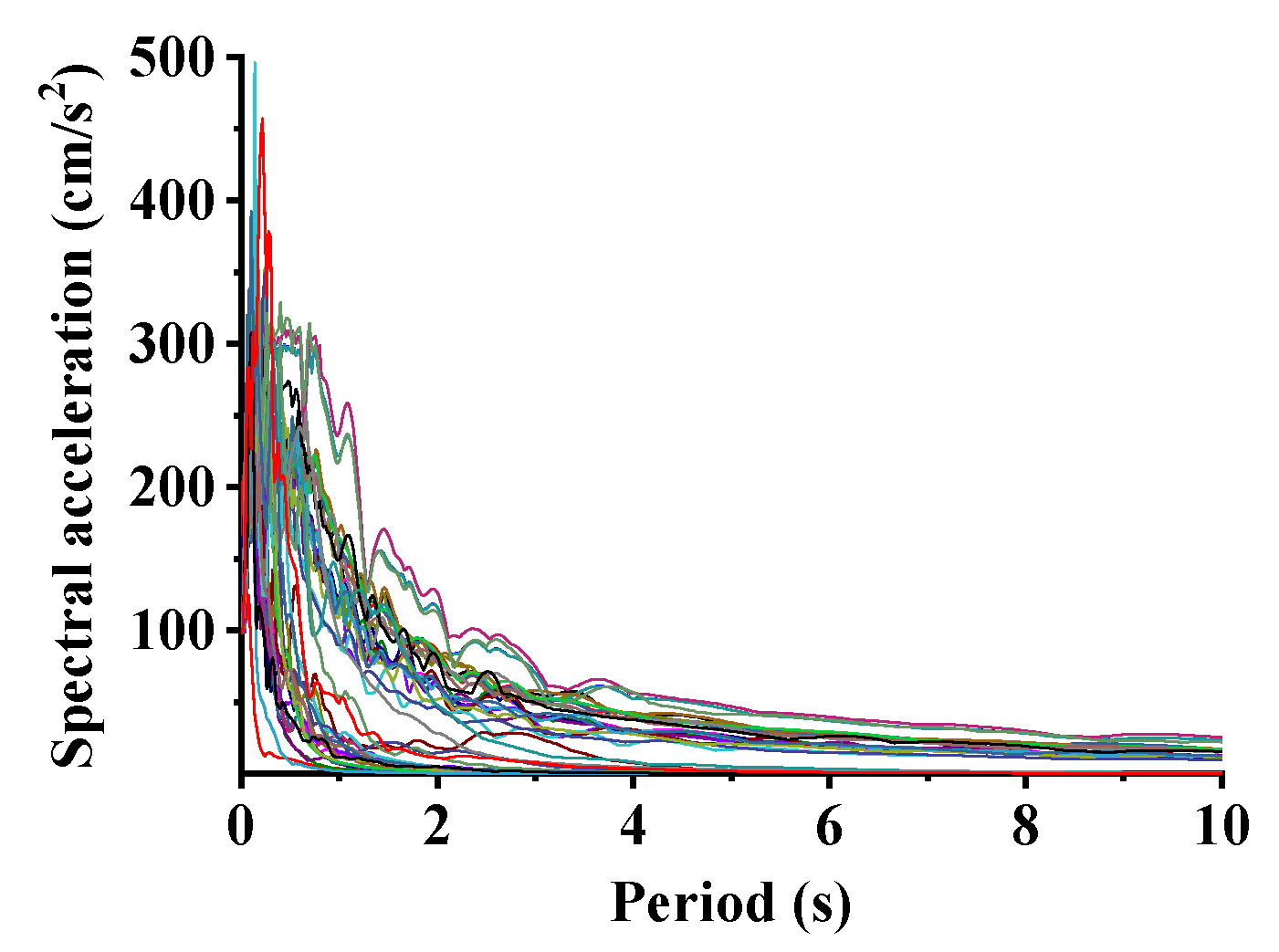

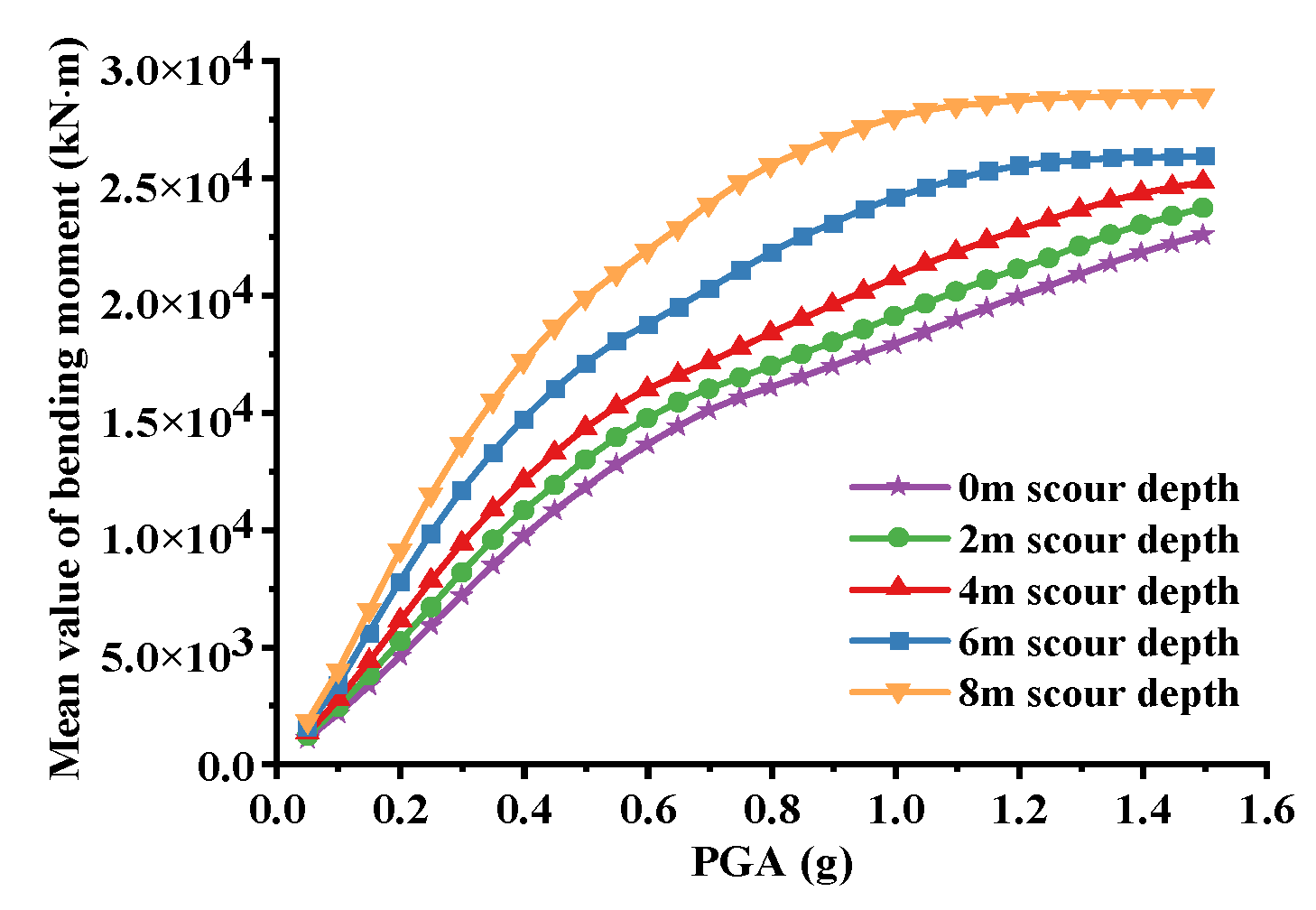

2.2.3. IDA Analysis under the Combined Action of Earthquake and Scour

2.2.4. Determination of the Distribution of Seismic Bending Moment under Scour Conditions

2.2.5. Distribution Function of Structural Resistance

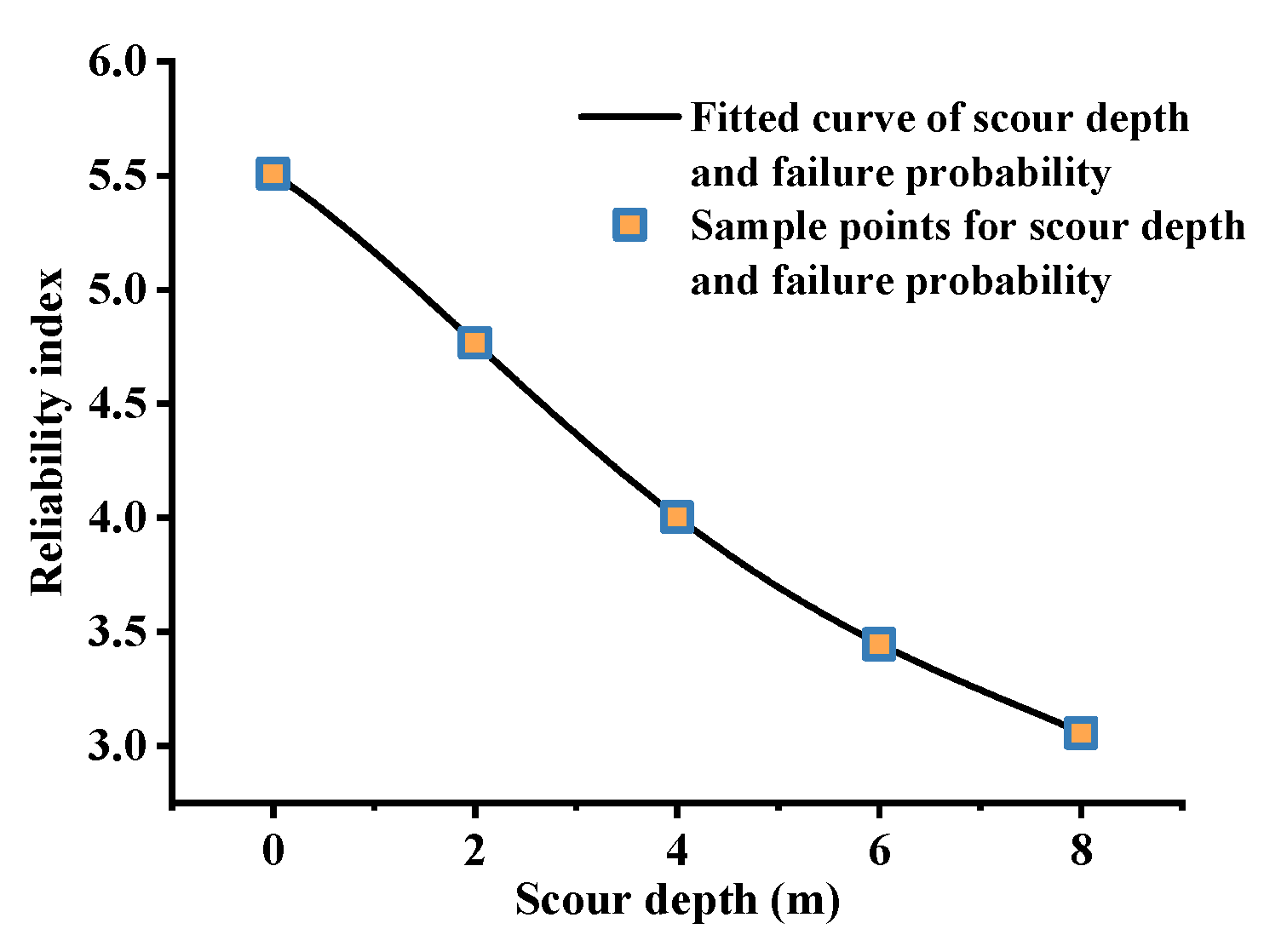

2.2.6. Solution of Structural Failure Probability and Reliability Index

2.2.7. Determination of Combined Partial Coefficient of Scour Action

2.2.8. Optimal Resistance Value under the Combined Partial Coefficient of Scour Action

3. Effect of Corrosion on the Seismic Performance of Bridge Column

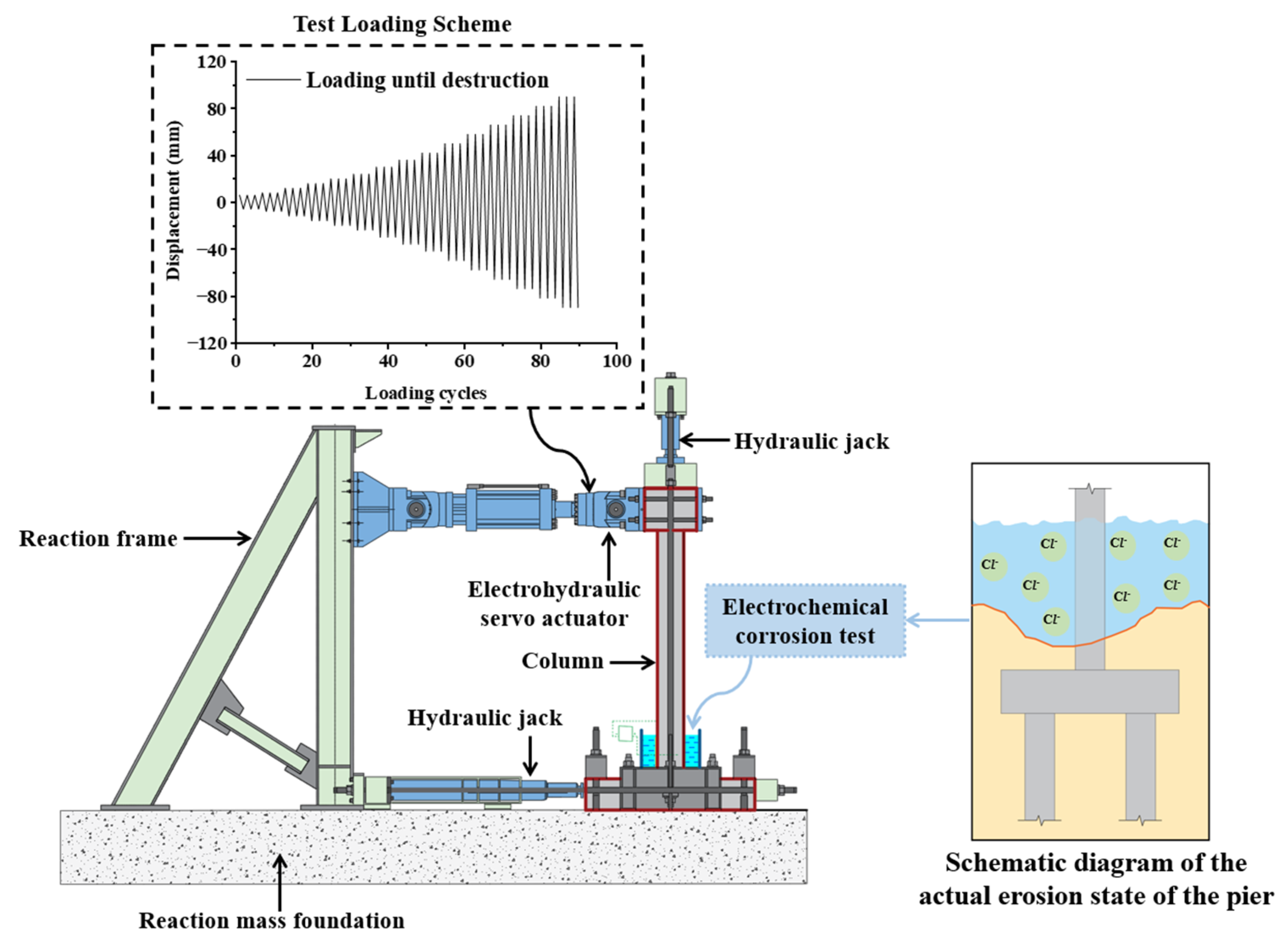

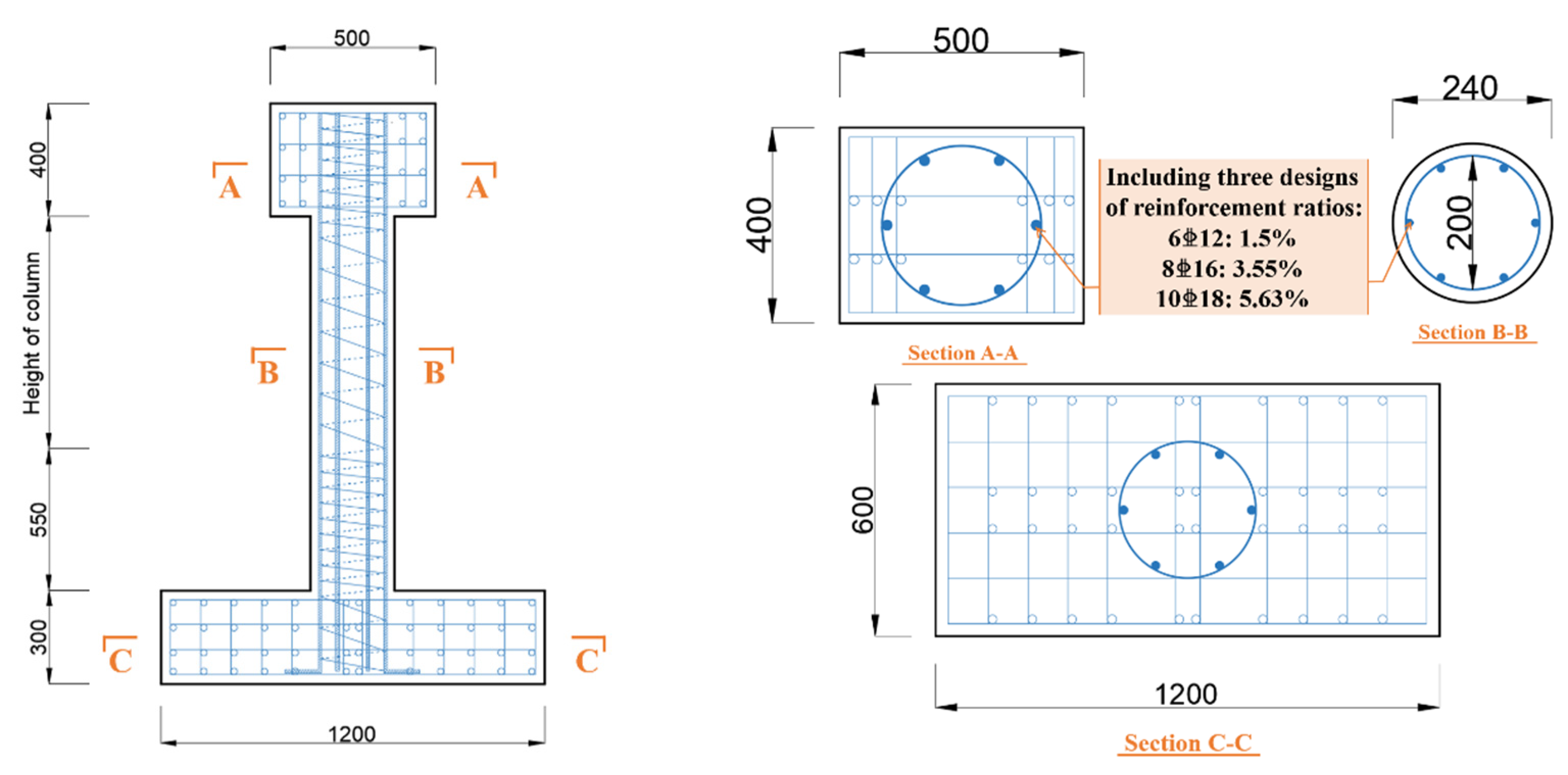

3.1. Specimen Design and Quasi-Static Test

Electrochemical Corrosion of Bridge Columns

3.2. Degradation of Material Properties by Corrosion

3.2.1. Effect of Corrosion on Concrete Materials

3.2.2. Effect of Corrosion on the Material Properties of Steel Reinforcement

3.3. Comparison of Quasi-Static Test Results of Columns before and after Corrosion

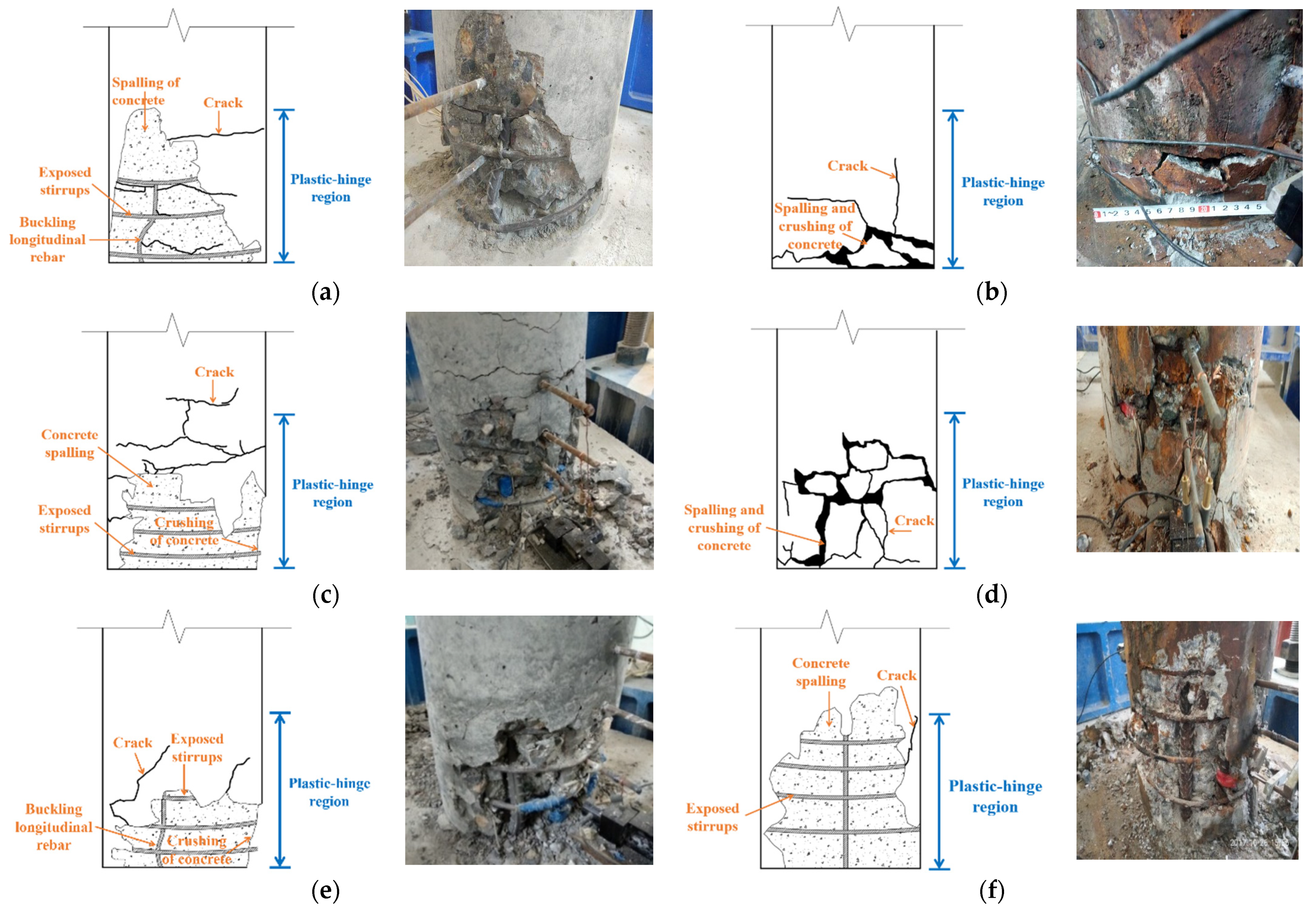

3.3.1. Specimen Damage Phenomenon

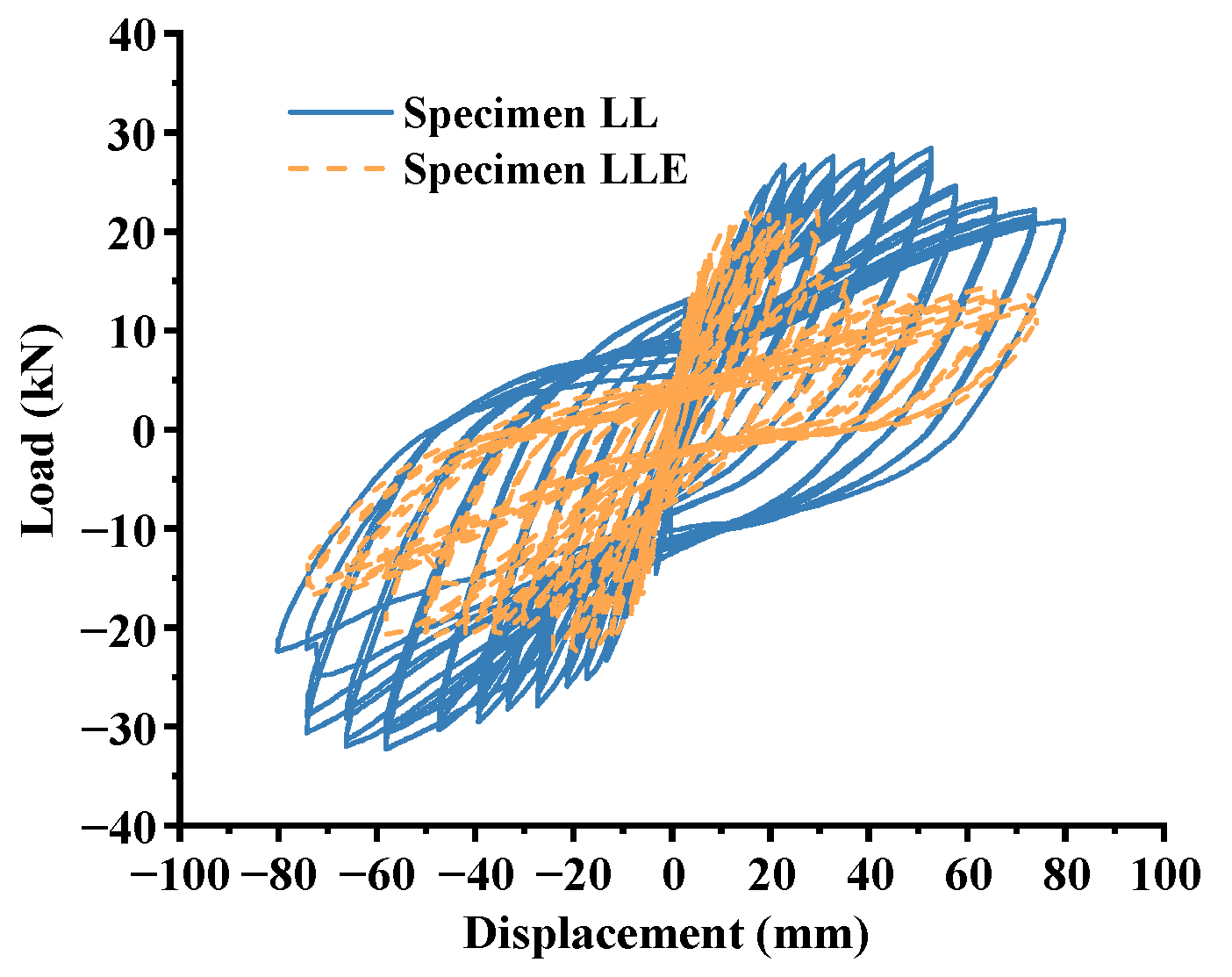

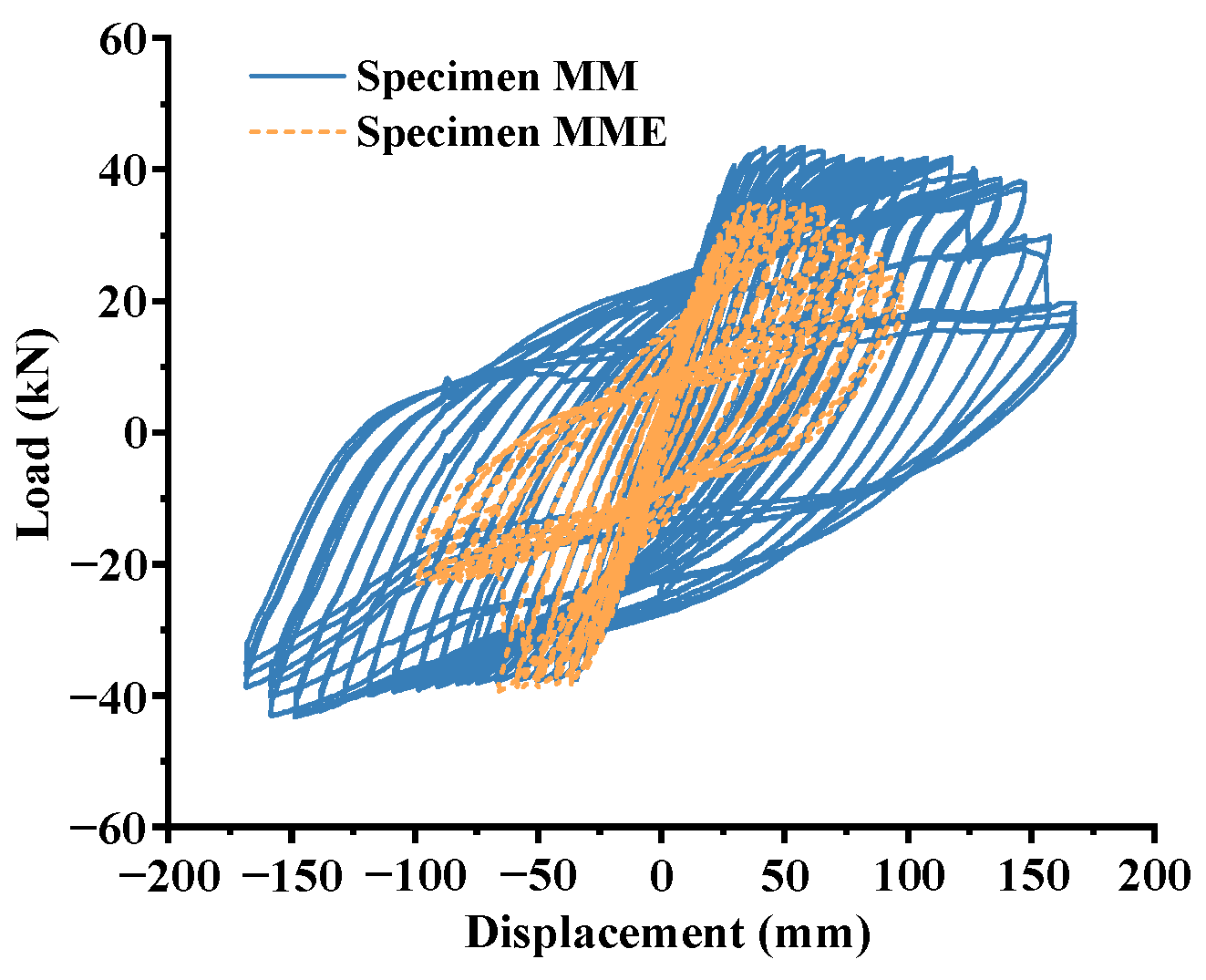

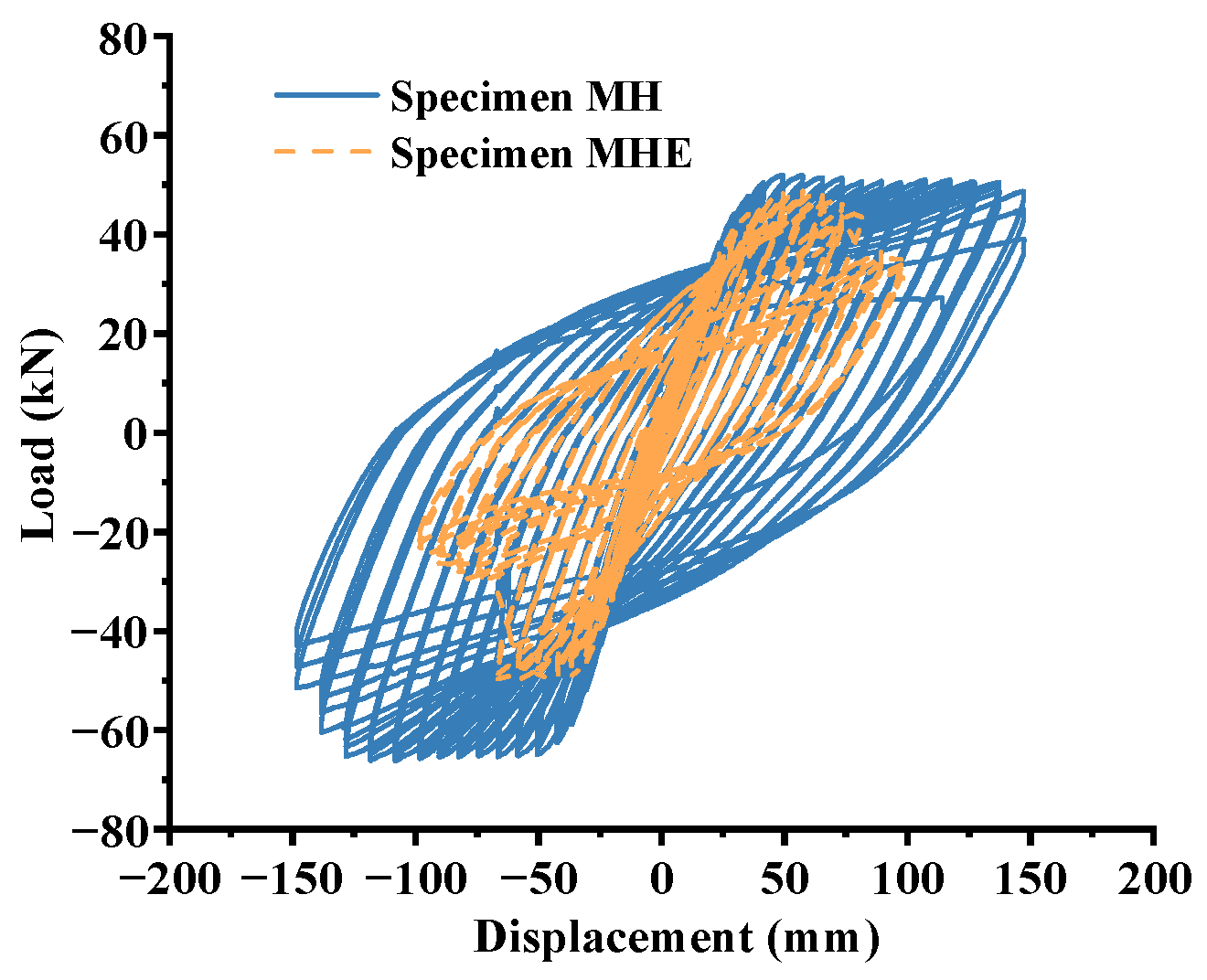

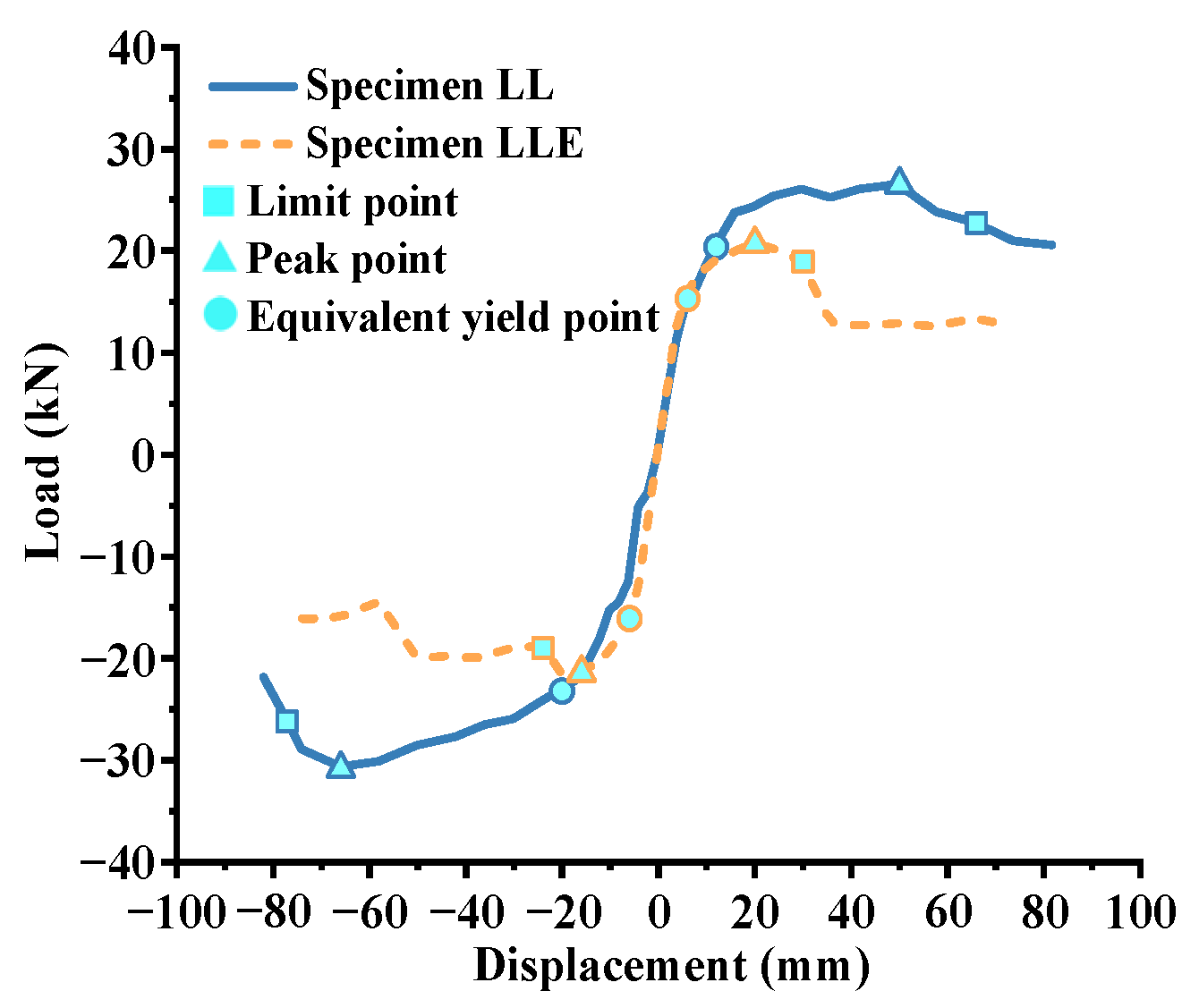

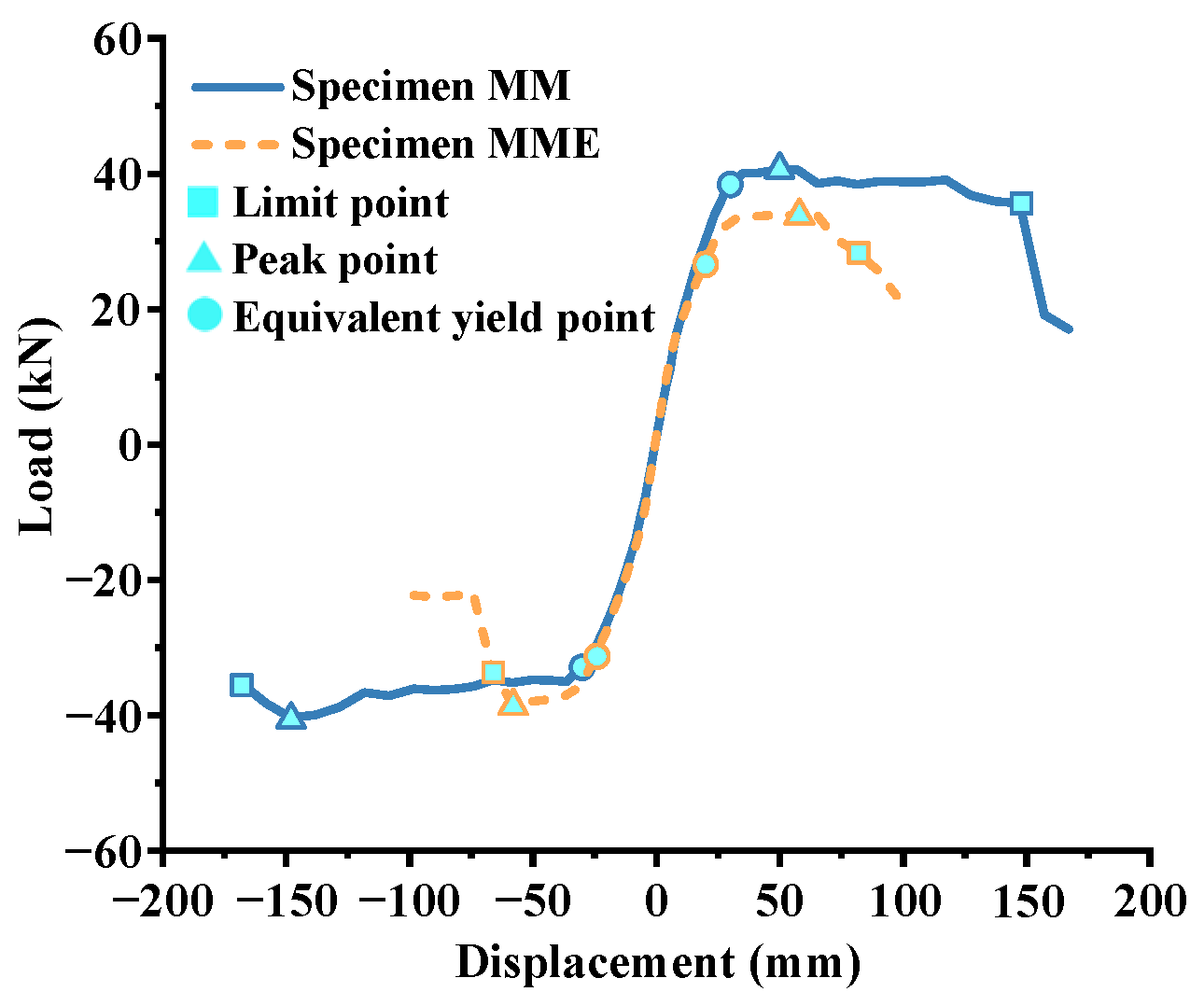

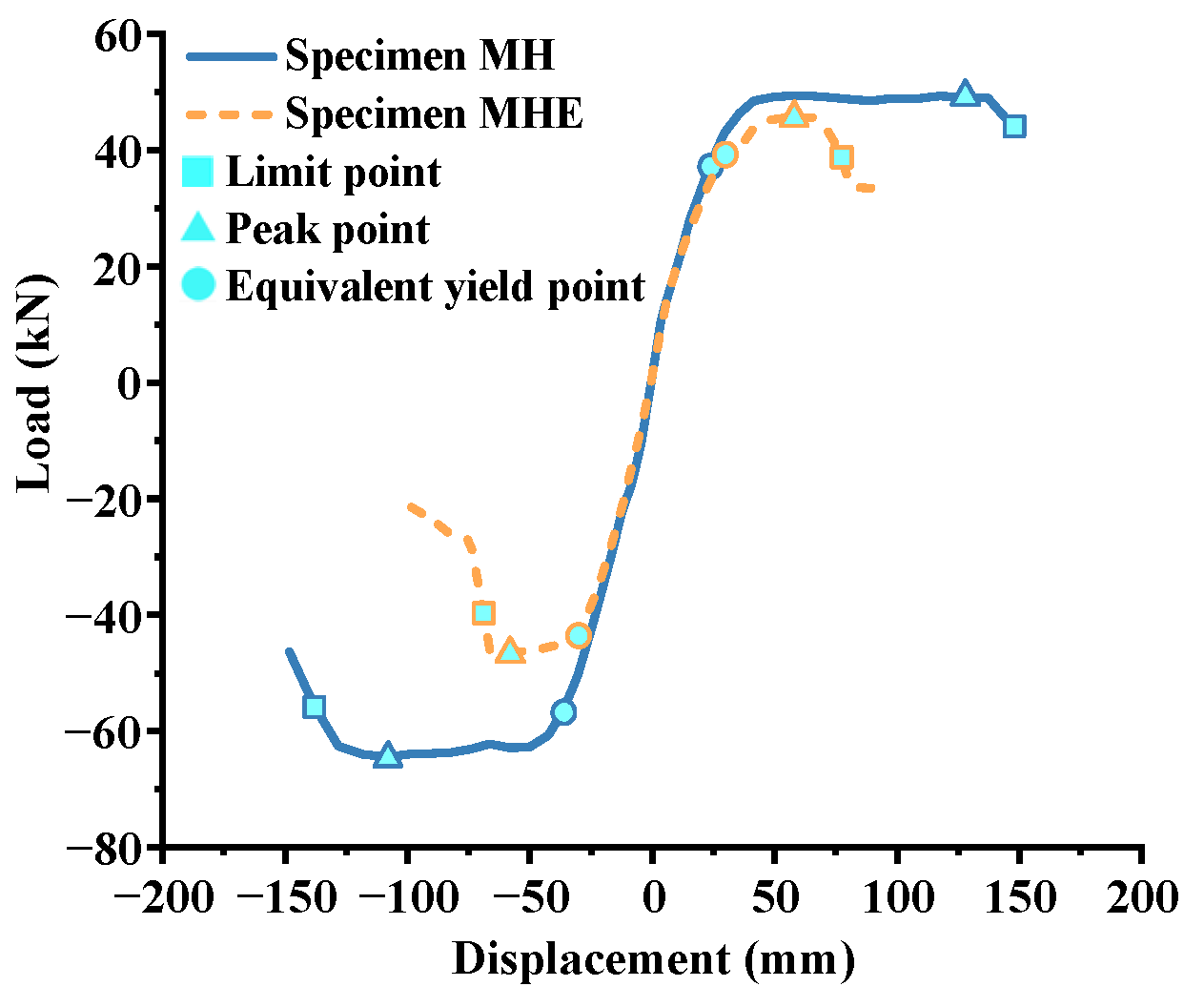

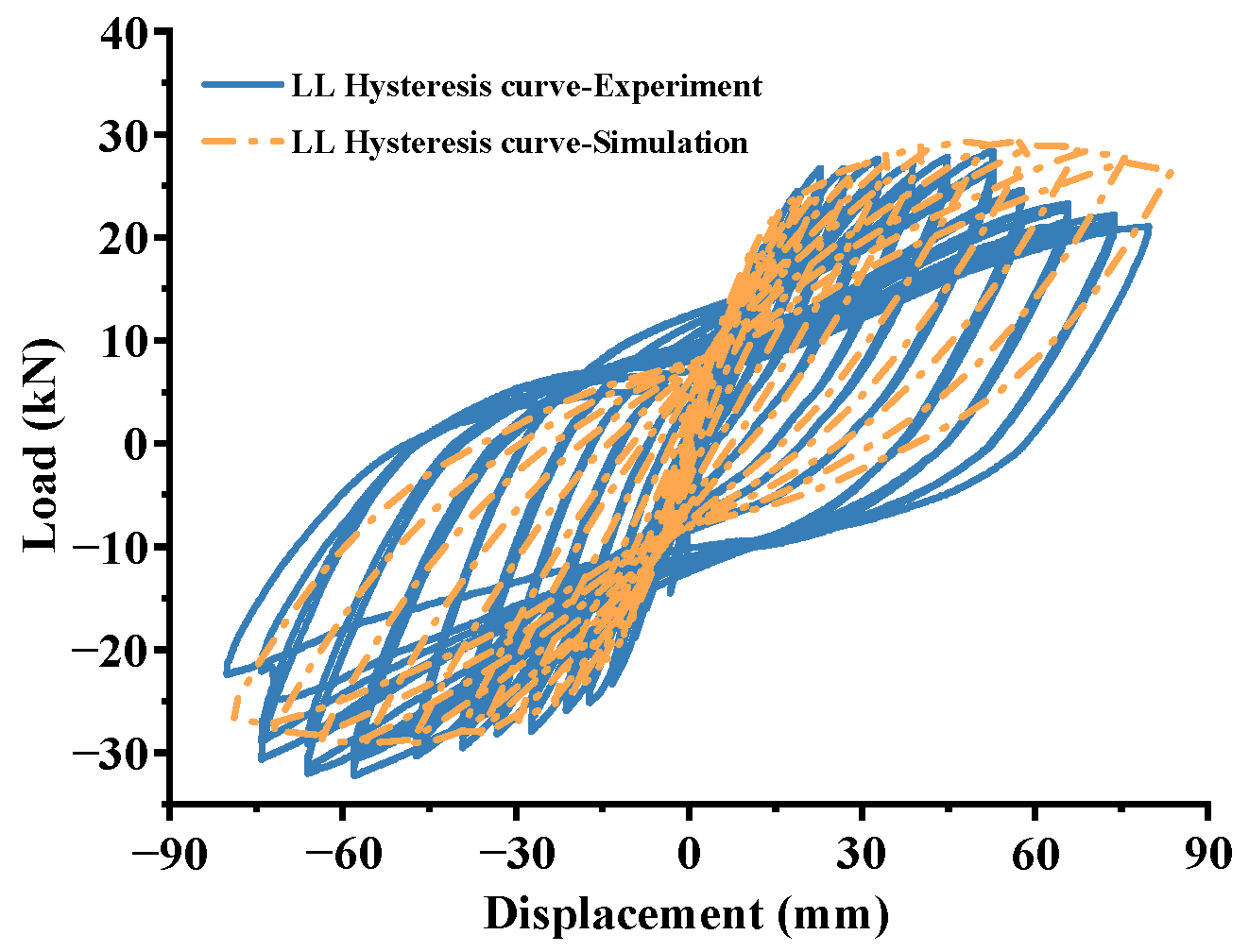

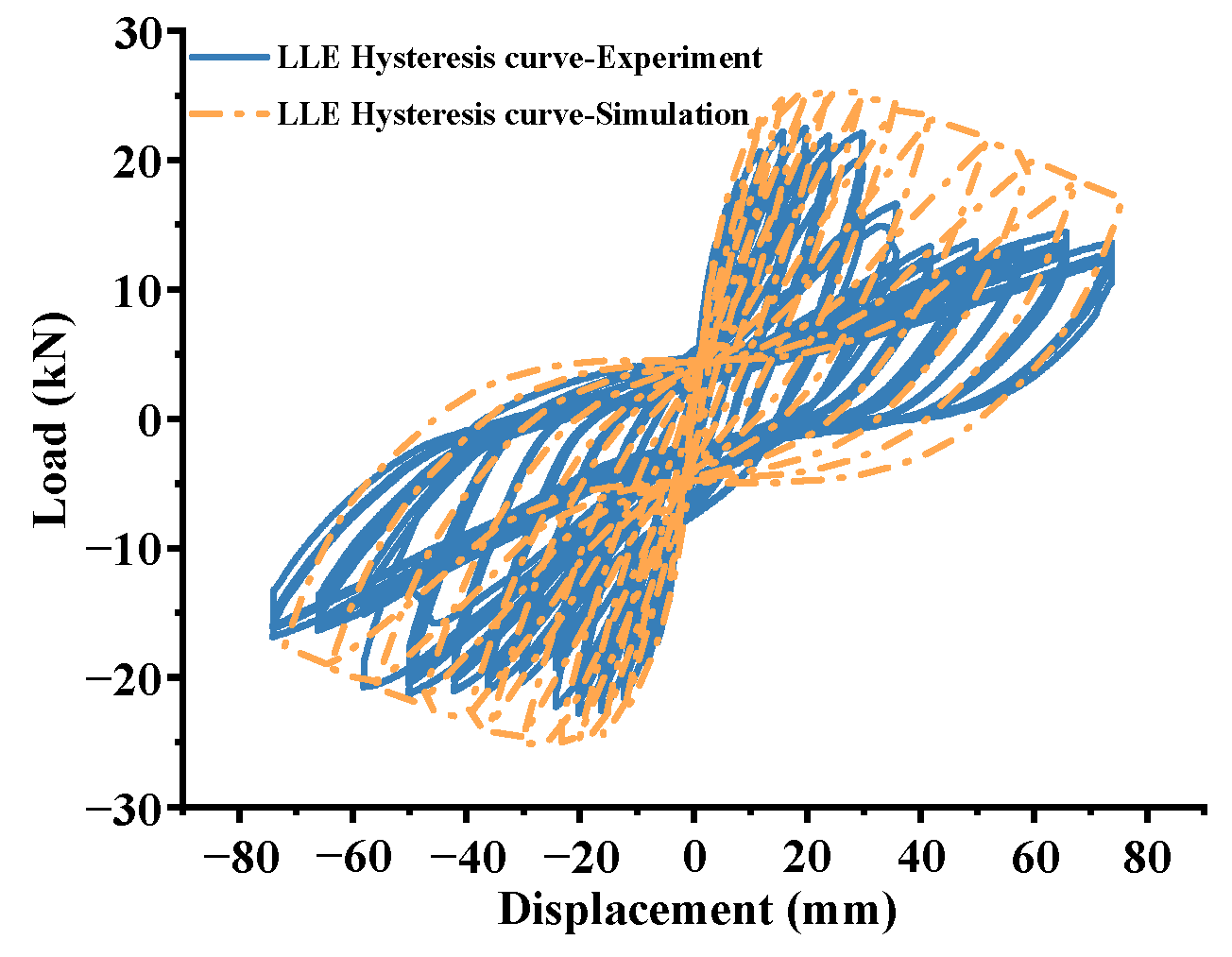

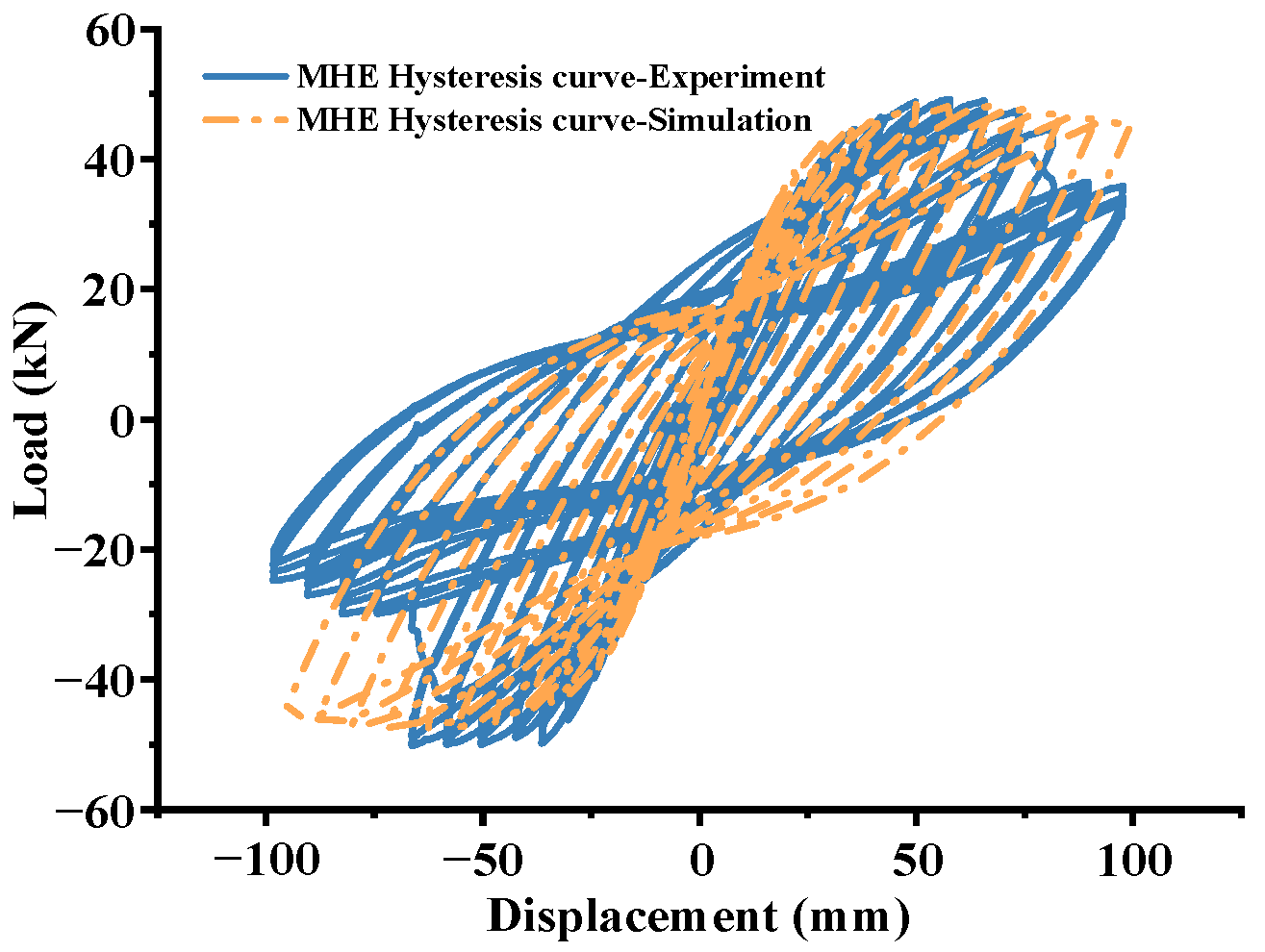

3.3.2. Load–Displacement Hysteretic Curve and Skeleton Curve of Column

3.3.3. Displacement Ductility Coefficient of Specimen

3.3.4. Energy Dissipation Capacity of Specimen

3.3.5. Equivalent Viscous Damping Coefficient of Specimens

3.3.6. Finite Element Analysis (FEA)

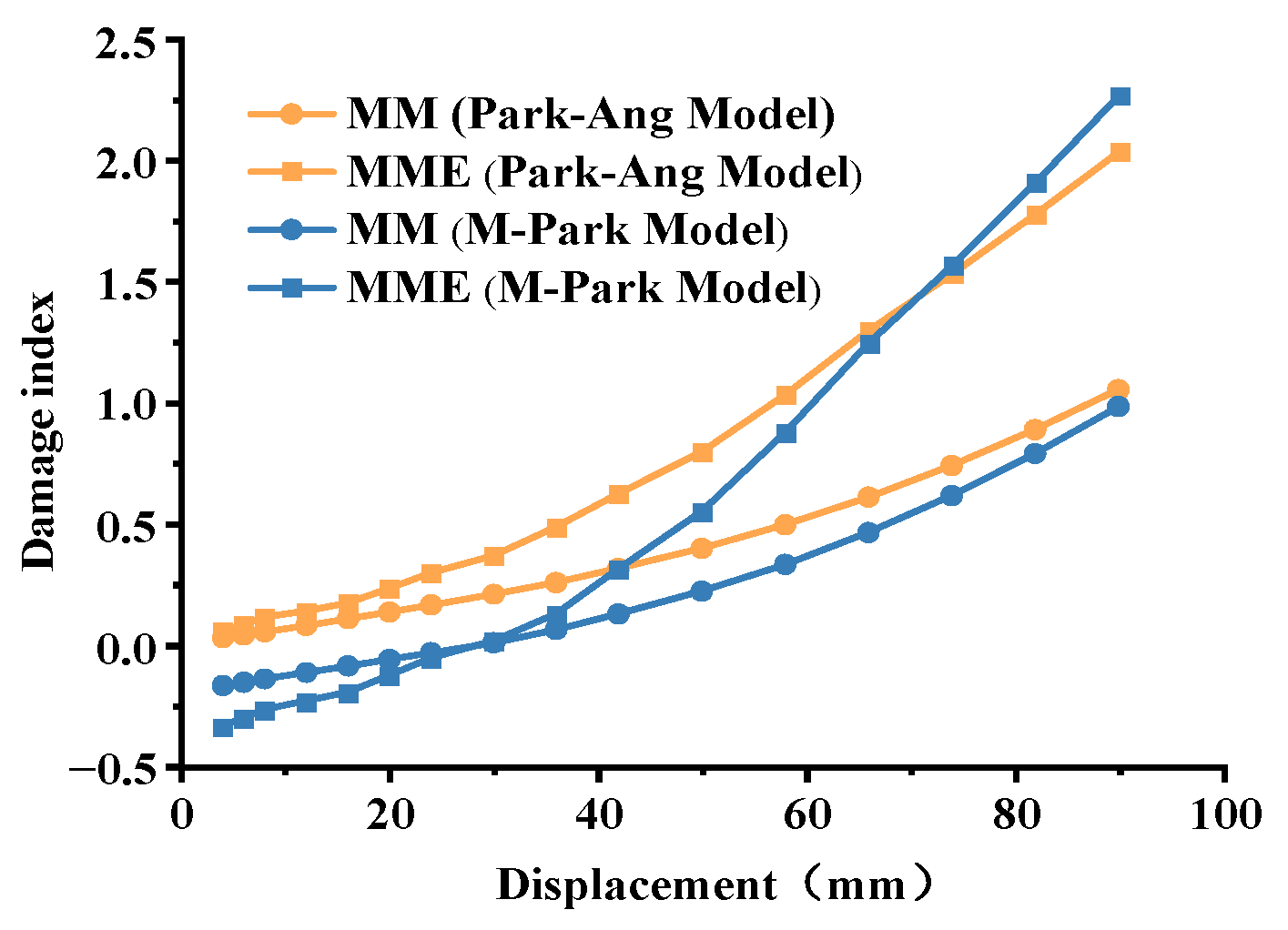

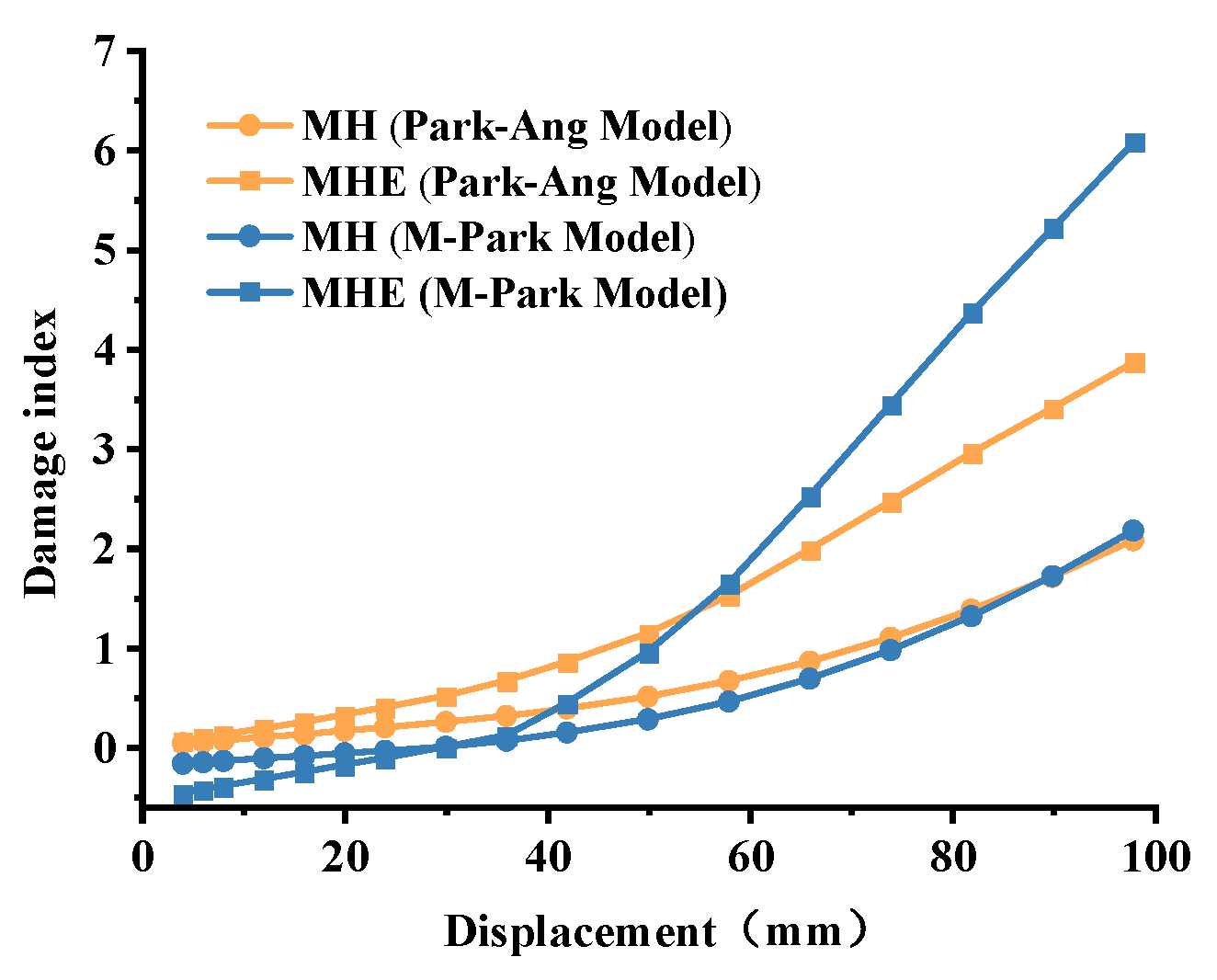

3.4. Two-Parameter Seismic Damage Index

4. Conclusions

- (1)

- The restraining effect of soil on the pile foundation was weakened due to scour action. It was found that the fragility of bridge columns decreased while the fragility of pile foundation increased with the increase of scour depth. The non-linear relationship between scour depth and failure probability of pile foundation could be determined by vulnerability analysis under the combined action of scour and earthquake.

- (2)

- The distribution of PGA corresponding to basic intensity of earthquake in the bridge site area was studied, according to which the distribution of seismic effect could finally be determined. The IDA curve of the seismic effect was established. Both a quantitative description of seismic input and a definite functional expression for the output of the seismic effect could be achieved.

- (3)

- The joint distribution of scour depth and seismic failure probability was established to determine the reasonable scour depth. The sub-factor considering the combination of scour action was calculated so that the combined expression for the joint action could be obtained as shown in Equation (16).

- (4)

- Strength and bulk stability of the concrete were affected by corrosion as the result of severe corrosion of the reinforcement, which had a serious impact on the performance and durability of the reinforced concrete columns.

- (5)

- corrosion caused a remarkable reduction in yield resistance, peak resistance, and ultimate resistance of columns. A decrease of 56.35%, 88.01%, and 75.2% in cumulative hysteretic energy dissipation of columns at ultimate displacement occurred, respectively, due to corrosion. The equivalent viscous damping coefficient of corroded columns was always greater than the corresponding un-corroded columns before ultimate displacement. At the same stage, plasticity development of the corroded columns was larger, which indicates that corroded columns were more prone to damage.

- (6)

- Ductility properties of medium-high columns with medium and high reinforcement ratios could be significantly weakened by corrosion, whose displacement ductility coefficients dropped by 41.56% and 46.85%, respectively. For columns with low reinforcement ratios and low heights, the displacement ductility coefficient increased by 3.91% while the hysteresis loop area shrunk by 56.35%, which indicated that there is a limitation in judging seismic performance of columns by ductility coefficient only.

- (7)

- Through the two-parameter model, it was found that the aggravation degree of seismic damage on columns caused by corrosion rose linearly with the increase of displacement, which eventually resulted in the damage index of corroded columns growing to twice that of the uncorroded columns at ultimate displacement. Indexes of displacement and energy dissipation should be taken into account in selecting reinforcement ratio for ductile columns simultaneously.

Author Contributions

Funding

Conflicts of Interest

References

- Koks, E.E.; Rozenberg, J.; Zorn, C.; Tariverdi, M.; Vousdoukas, M.; Fraser, S.A.; Hall, J.W.; Hallegatte, S. A global multi-hazard risk analysis of road and railway infrastructure assets. Nat. Commun. 2019, 10, 2677. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, G.C.; Tong, M.; Yen, W.P. Design of Highway Bridges Against Extreme Hazard Events: Issues, Principles and Approaches; MCEER, University at Buffalo, State University of New York, the United States of America: Buffalo, NY, USA, 2008. [Google Scholar]

- Ettouney, M.M.; Alampalli, S.; Agrawal, A.K. Theory of multihazards for bridge structures. Bridge Struct. 2005, 1, 281–291. [Google Scholar] [CrossRef]

- Wen, Y.K. Minimum lifecycle cost design under multiple hazards. Reliab. Eng. Syst. Saf. 2001, 73, 223–231. [Google Scholar] [CrossRef]

- Adey, B.; Hajdin, R.; Brühwiler, E. Risk-based approach to the determination of optimal interventions for bridges affected by multiple hazards. Eng. Struct. 2003, 25, 903–912. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.Q.; Fang, D.J.; Zhao, L.J. Reflection on earthquake damage of buildings in 2015 Nepal earthquake and seismic measures for post-earthquake reconstruction. Structures 2021, 30, 647–658. [Google Scholar] [CrossRef]

- Liu, C.Q.; Fang, D.J.; Yan, Z.X. Seismic fragility analysis of base isolated structure subjected to near-fault ground motions. Period. Polytech. Civ. Eng. 2021, 65, 768–783. [Google Scholar] [CrossRef]

- Crespi, P.; Zucca, M.; Longarini, N.; Giordano, N. Seismic assessment of six typologies of existing RC bridges. Infrastructures 2020, 5, 52. [Google Scholar] [CrossRef]

- Causevic, M.; Mitrovic, S. Comparison between non-linear dynamic and static seismic analysis of structures according to European and US provisions. Bull. Earthq. Eng. 2011, 9, 467–489. [Google Scholar] [CrossRef]

- Valente, M.; Milani, G. Alternative retrofitting strategies to prevent the failure of an under-designed reinforced concrete frame. Eng. Fail. Anal. 2018, 89, 271–285. [Google Scholar] [CrossRef]

- Ma, Y.; Che, Y.; Gong, J.X. Behavior of corrosion damaged circular reinforced concrete columns under cyclic loading. Constr. Build. Mater. 2012, 29, 548–556. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, D.S.; Cheng, H.; Shi, Y. Bayesian theory-based seismic failure modes identification of reinforced concrete columns. J. Earthq. Eng. 2021, 1–12. [Google Scholar] [CrossRef]

- Zhou, M. Design Methods for Extreme Loads on Bridges with High Pile Bearing Systems; Jilin University Press: Changchun, China, 2018. [Google Scholar]

- You, D.; Dan, M.F.; Duygu, S. Time variation sustainability assessment of seismically vulnerable bridges to multiple hazards. Earthq. Eng. Struct. Dyn. 2013, 42, 1451–1467. [Google Scholar]

- Prasad, G.G.; Banerjee, S. The impact of flood–induced scour on seismic fragility characteristics of bridges. J. Earthq. Eng. 2013, 17, 803–828. [Google Scholar] [CrossRef]

- Wang, Z.H.; Leonardo, D.O.; Jamie, E.P. Influence of scour effects on the seismic response of reinforced concrete bridges. Eng. Struct. 2014, 76, 202–214. [Google Scholar] [CrossRef]

- Yang, Y.K.; Ma, R.J.; Chen, A.R. Risk-based reasonable scouring depth for multi-hazard bridges. J. South China Univ. Technol. 2016, 44, 103–109. [Google Scholar]

- Zhao, S.C. Failure probability analysis of steel concrete bridge durability induced by chloride ingress compared with that by concrete carbonization in marine environment. Highway 2008, 4, 163–166. [Google Scholar]

- Liu, X.L. Fundamental research on safety and durability of major structures in civil and hydraulic engineering. China Civ. Eng. J. 2001, 34, 1–7. [Google Scholar]

- Zhang, W.; Niu, D.T.; Li, Q. Stirrups corrosion of concrete column with axial compression for numerical simulation. Build. Sci. Res. Sichuan 2013, 39, 94–97, 111. [Google Scholar]

- Zhang, W.P.; Shang, D.F.; Gu, X.L. Study on stress-strain relationship of corroded reinforcement. J. Tongji Univ. Nat. Sci. 2006, 34, 586–592. [Google Scholar]

- Ou, Y.C.; Nguyen, N.D. Influences of location of reinforcement corrosion on seismic performance of corroded reinforced concrete beams. Eng. Struct. 2016, 126, 210–223. [Google Scholar] [CrossRef]

- Ou, Y.C.; Susanto, Y.T.T.; Roh, H. Tensile behavior of naturally and artificially corroded steel bars. Constr. Build. Mater. 2016, 103, 93–104. [Google Scholar] [CrossRef]

- Simon, J.; Bracci, J.M.; Gardoni, P. Seismic response and fragility of deteriorated reinforced concrete bridges. J. Struct. Eng. 2010, 136, 1273–1281. [Google Scholar] [CrossRef]

- Ghosh, J.; Padgett, J.E. Aging considerations in the development of time-dependent seismic fragility curves. J. Struct. Eng. 2011, 136, 1497–1511. [Google Scholar] [CrossRef]

- Biondini, F.; Camnasio, E.; Palermo, A. Lifetime seismic performance of concrete bridges exposed to corrosion. Struct. Infrastruct. Eng. 2014, 10, 880–900. [Google Scholar] [CrossRef]

- Guo, A.; Yuan, W.; Lan, C.; Guan, X.; Li, H. Time-dependent seismic demand and fragility of deteriorating bridges for their residual service life. Bull. Earthq. Eng. 2015, 13, 2389–2409. [Google Scholar] [CrossRef]

- Sun, Y.Z.; Niu, D.T.; Jiang, L. Analysis of sulfate attack damage of concrete under dry and wet cycling conditions. Silic. Bull. 2013, 7, 1405–1409. [Google Scholar]

- Zhao, G.F.; Jin, W.L.; Gong, J.X. Structural Reliability Theory; China Building Industry Press: Beijing, China, 2000. [Google Scholar]

- Wang, S.H.; Zhang, H.X.; Zhou, M. Model of bridge pile-soil dynamic interaction in sandy area. Road Mach. Constr. Mech. 2018, 35, 94–101. [Google Scholar]

- Rneso, L.A.; Zevenbe, R.L.W.; Lagasse, P.F. Evaluating Scour at Bridge; Department of Transportation Federal Highway Administration: Washington, DC, USA, 2012. [Google Scholar]

- Johnson, P.A.; Dock, D.A. Probabilistic bridge scour estimates. J. Hydraul. Eng. 1998, 124, 750–754. [Google Scholar] [CrossRef]

- Liu, H.L. Research on software for moment-curvature analysis of sections of arbitrary reinforced concrete. J. Highw. Transp. Res. Dev. 2015, 31, 69–73. [Google Scholar]

- GB50011-2010; Seismic Design Code for Buildings. China Construction Industry Press: Beijing, China, 2016.

- American Petroleum Institute. API Recommended Practice for Planning, Designing and Constructing Fixed Offshore Platforms; American Petroleum Institute: Washington, DC, USA, 1977. [Google Scholar]

- Feng, Q.H. Analysis of Seismic Vulnerability and Risk Probability of Super-Large Bridges; Tongji University: Shanghai, China, 2008. [Google Scholar]

- Gao, X.W.; Bao, Y.B. Probability model of earthquake action and its statistical parameters. Earthq. Eng. Eng. Vib. 1985, 1, 13–22. [Google Scholar]

- Ellingwood, B.; Galambos, T.V.; Macgregor, J.G.; Cornell, C.A. Development of a Probability-Based Load Criterion for American National Standard A58: Building Code Requirements for Minimum Design Loads in Buildings and Other Structures; National Bureau of Standards: Washington, DC, USA, 1980. [Google Scholar]

- Wen, Y.K. A clustering model for correlated load processes. ASCE J. Struct. Eng. 1981, 107, 965–983. [Google Scholar] [CrossRef]

- Zhang, M. Structural Reliability Analysis-Methods and Procedures; Science Press: Beijing, China, 2009. [Google Scholar]

- Chen, J.; Pan, Q.Q.; Wang, W.X. Matlab implementation of monte-carlo method for reliability in box girder construction. J. Chongqing Technol. Bus. Univ. 2011, 28, 90–93. [Google Scholar]

- Liu, L.D.; Yan, Q.S.; Li, J.W.; Wang, X.W. Analysis of seismic vulnerability of single tower cable-stayed bridge based on incremental dynamic analysis method. Railw. Constr. 2018, 58, 17–21. [Google Scholar]

- Yang, K.; Tian, S.Z.; Zhang, C. Evaluation of RC frame structure collapses based on IDA method. Build. Struct. 2018, 48, 106–109. [Google Scholar]

- Zhao, R.D.; Gao, N.; Jia, Y.; Qiu, X.L. Analysis of seismic vulnerability of long-span continuous beam bridge based on IDA. J. Shenyang Jianzhu Univ. 2017, 33, 672–679. [Google Scholar]

- GB/T 50283-1999; Uniform Standards for Structural Reliability Design for Highway Engineering. China Planning Press: Beijing, China, 1999.

- Leeg, C.; Rzhevsky, V. From the WTC Tragedy to the Development of Disaster Engineering for Landmark Buildings—An Extension of the Performance-Based Earthquake Engineering Approach: MCEER-03-SP04; University at Buffalo, State University of New York, the United States of America: Buffalo, NY, USA, 2003. [Google Scholar]

- Caltrans Seismic Design Criteria Version 1.6; California Department of Transportation: Sacramento, CA, USA, 2010.

- American Association of State Highway and Transportation Officials. AASHTO LRFD Bridge Design Specifications; Customary U.S. Unit; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2012. [Google Scholar]

- Specifications for Seismic Design of Highway Bridges; Ministry of Transport of the People’s Republic of China: Beijing, China, 2020.

- Code for Seismic Design of Urban Rail Transit Structures; Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2014.

- Yin, S.P.; Li, Y.; Li, H.D.; Peng, C. Axial compression performance of reinforced concrete column strengthened with TRC under chloride dry-wet cycles. China J. Highw. Transp. 2017, 30, 230–238. [Google Scholar]

- Filippou, F.C.; Popov, E.P.; Bertero, V.V. Effects of Bond Deterioration on Hysteretic Behavior of Reinforced Concrete Joints; Report EERC 83-19; Earthquake Engineering Research Center, University of California, Berkeley: Berkeley, CA, USA, 1983. [Google Scholar]

- Mohd, H.M.Y. Nonlinear Analysis of Prestressed Concrete Structures under Monotonic and Cycling Loads; University of California, Berkeley: Berkeley, CA, USA, 1994. [Google Scholar]

- Lei, C.; Fang, C.Q.; Hu, R.; Yang, S.; Xue, W. Corrosive crack analysis of reinforced concrete columns under wet-dry cycles and corrosive environment. Concrete 2017, 6, 24–27. [Google Scholar]

- Park, Y.J.; Ang, H.S. Mechanistic Seismic Damage Model for Reinforced Concrete. J. Struct. Eng. ASCE 1985, 111, 722–739. [Google Scholar] [CrossRef]

- Zhu, H.B.; Miao, C.Q.; Bai, L.T.; Shao, Y.F. Park-Ang damage correction model for reinforced concrete columns with low cycle fatigue damage effect. J. Southeast Univ. 2020, 50, 71–80. [Google Scholar]

- Wang, D.S.; Feng, Q.M.; Wang, G.X. An improved Park-Ang earthquake damage model with low cycle fatigue life. Chin. J. Civ. Eng. 2004, 37, 41–49. [Google Scholar]

| Variable | Average Value | Coefficient of Variation | Probability Distribution |

|---|---|---|---|

| 0.57 | 0.6 | Normal distribution | |

| 1 | 0.05 | ||

| 1.1 | 0.05 |

| Order | Period of Vibration/s | Frequency/Hz | Vibration Mode |

|---|---|---|---|

| 1 | 0.79288 | 1.26122 | Longitudinal drift of main beam and longitudinal vibration of main pier |

| 2 | 0.76576 | 1.30589 | Lateral bending of main beam and transverse bending of main pier |

| 3 | 0.632 | 1.58227 | Lateral bending of main beam and transverse positive symmetrical bending of main pier |

| 4 | 0.62516 | 1.59958 | Lateral bending of main beam and transverse antisymmetric bending of main pier |

| 5 | 0.58152 | 1.71962 | Lateral bending of main beam and longitudinal antisymmetric vibration of main pier |

| Average Value | Standard Deviation | Probability Distribution |

|---|---|---|

| 33,548.8 | 4743.8 | Lognormal distribution |

| Specimen Number | Diameter/m | Height of Column/m | Longitudinal Reinforcement Ratio | Concrete Type | Rebar Type | Scale Ratio | Ratio of Axial Compression Stress to Strength | Thickness of Protective Layer/mm |

|---|---|---|---|---|---|---|---|---|

| LL | 0.24 | 1.4 | 1.50% | C40 | HRB335 | 1:6.25 | 0.057 | 20 |

| LLE | 0.24 | 1.4 | 1.50% | C40 | HRB335 | 1:6.25 | 0.057 | |

| MM | 0.24 | 1.8 | 3.55% | C40 | HRB400 | 1:8.33 | 0.071 | |

| MME | 0.24 | 1.8 | 3.55% | C40 | HRB400 | 1:8.33 | 0.071 | |

| MH | 0.24 | 1.8 | 5.63% | C40 | HRB400 | 1:8.33 | 0.071 | |

| MHE | 0.24 | 1.8 | 5.63% | C40 | HRB400 | 1:8.33 | 0.071 |

| Specimen Number | LL | LLE | MM | MME | MH | MHE |

|---|---|---|---|---|---|---|

| Cumulative hysteresis energy consumption (kN·mm) | 43,936.51 | 19,178.79 | 255,771.10 | 52,148.20 | 308,940.90 | 76,602.51 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, M.; Yin, S.; Zhu, G.; Fu, J. Seismic Performance Evaluation of Highway Bridges under Scour and Chloride Ion Corrosion. Appl. Sci. 2022, 12, 6680. https://doi.org/10.3390/app12136680

Zhou M, Yin S, Zhu G, Fu J. Seismic Performance Evaluation of Highway Bridges under Scour and Chloride Ion Corrosion. Applied Sciences. 2022; 12(13):6680. https://doi.org/10.3390/app12136680

Chicago/Turabian StyleZhou, Mi, Shujun Yin, Guoqiang Zhu, and Jiafei Fu. 2022. "Seismic Performance Evaluation of Highway Bridges under Scour and Chloride Ion Corrosion" Applied Sciences 12, no. 13: 6680. https://doi.org/10.3390/app12136680