Steady State and Transient Vibration Analysis of an Exponentially Graded Rotor Bearing System Having a Slant Crack

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Gradation Based on Exponential Law

2.2. Exponential Temperature Distribution

3. Formulation of a Slant Crack in the EG Rotor Element

3.1. Formulation of Flexibility Matrix of a Slant Cracked Element

3.2. Stiffness Matrix of a Slant Cracked Element

3.3. Modelling of Breathing Phenomenon

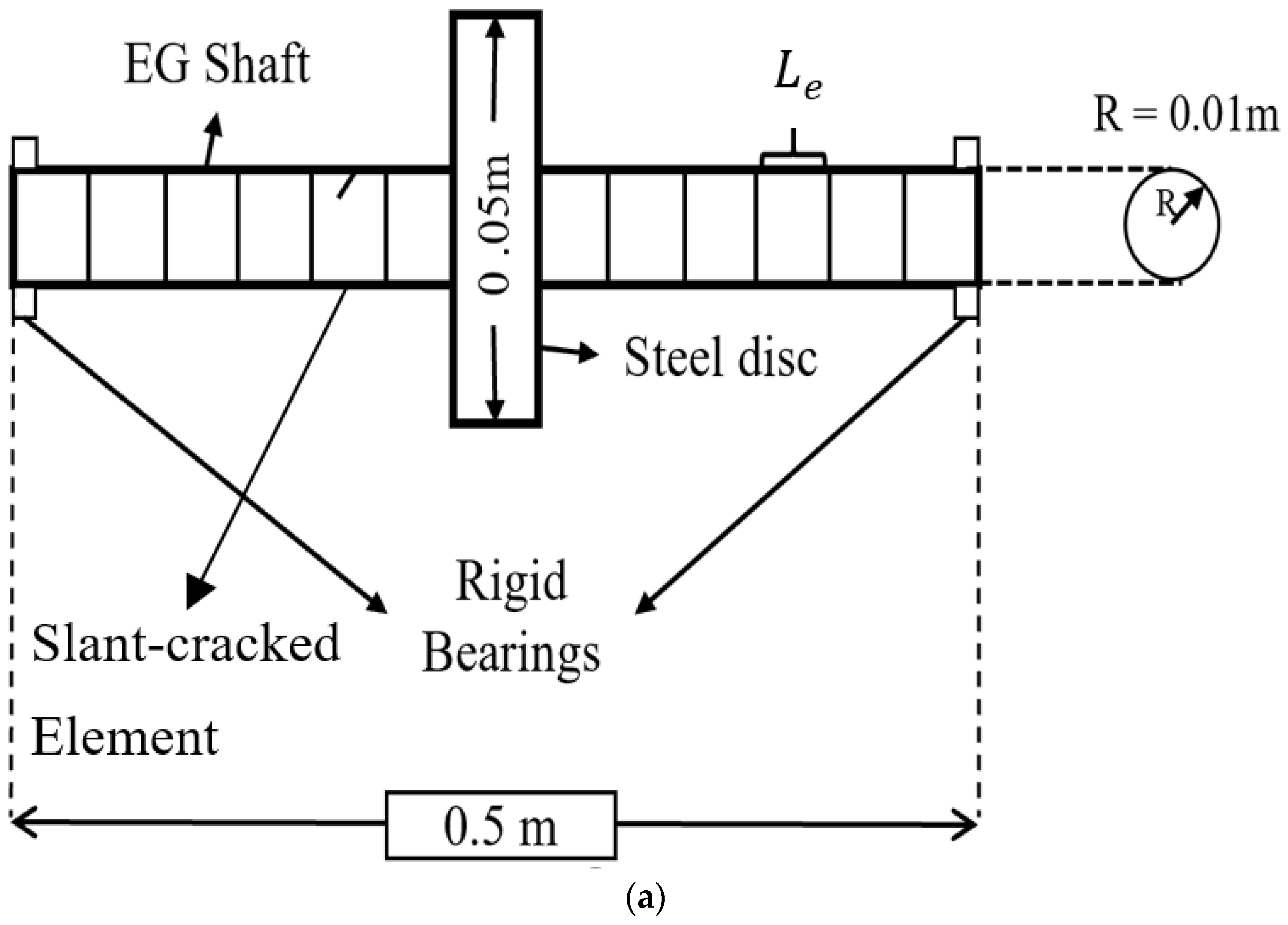

4. Finite Element Modelling of an EG Rotor-Bearing System

4.1. Finite EG Shaft Element without Crack

4.2. Global Equation of Motion and Solution Procedure to Compute Eigenfrequencies

5. Dynamic Response

6. Validations

6.1. Non-Dimensional Natural Frequencies of an Exponentially Graded Beam

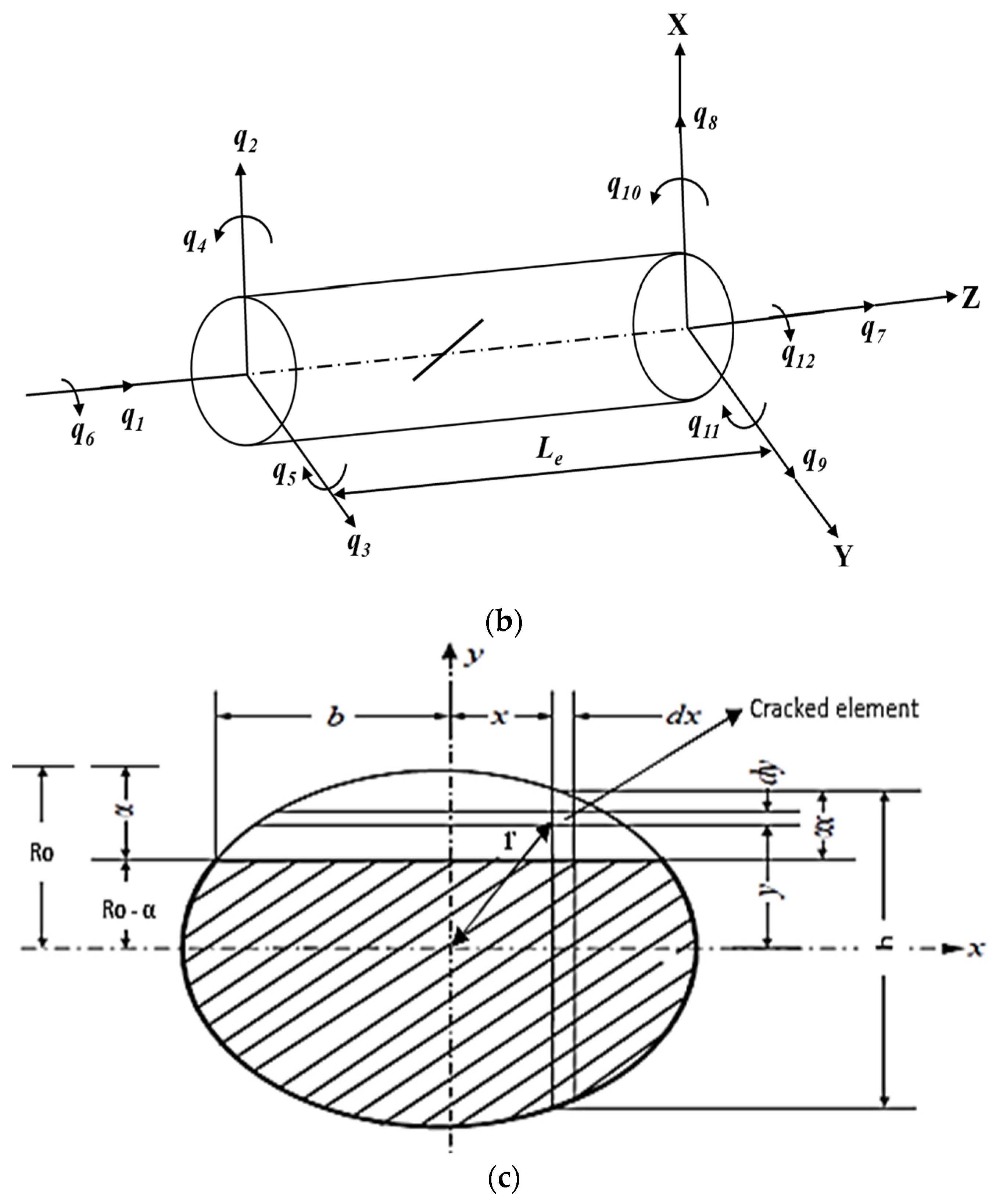

6.2. Normalised Natural Frequencies of a Slant-Cracked Steel Rotor-Bearing System

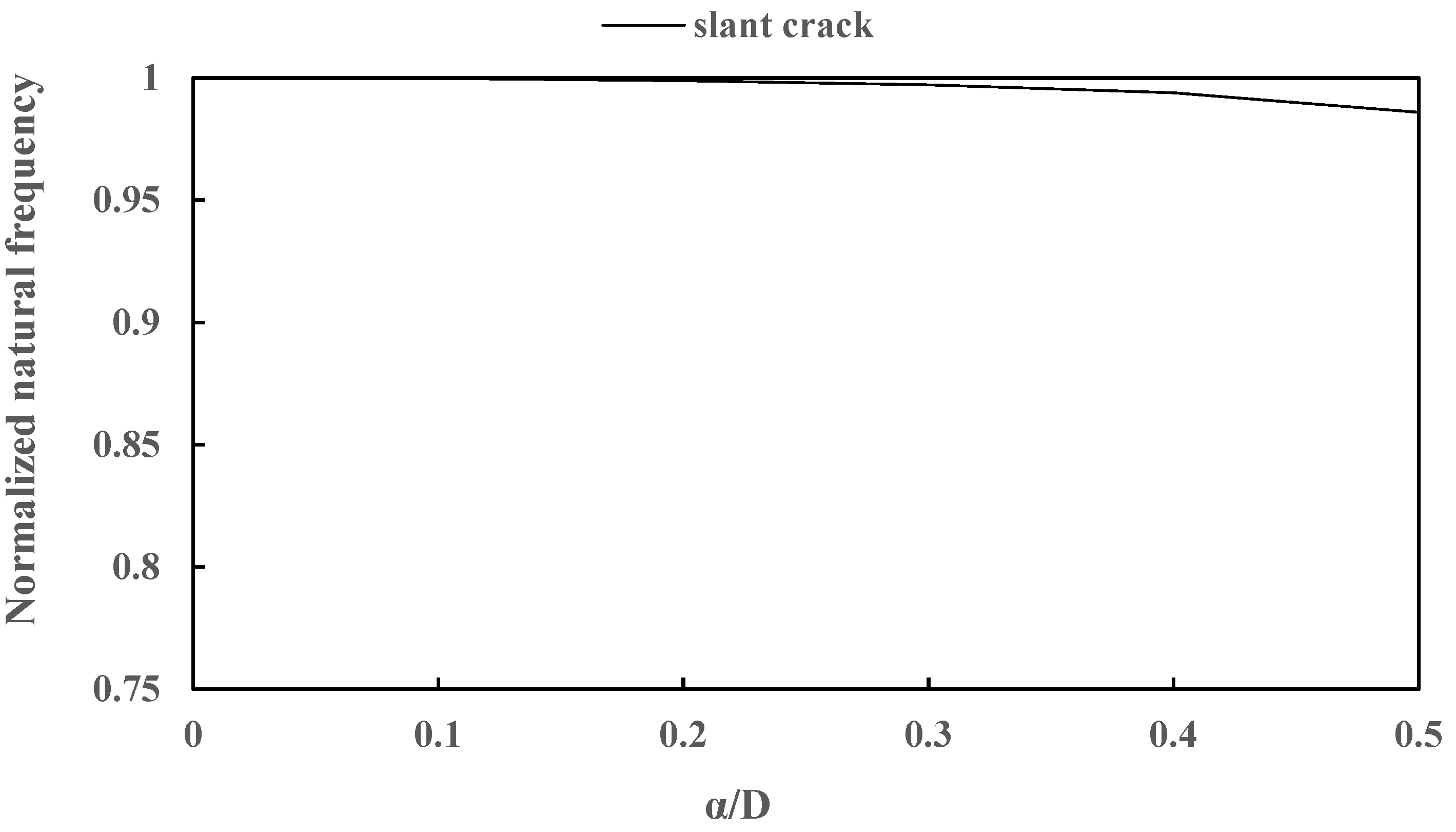

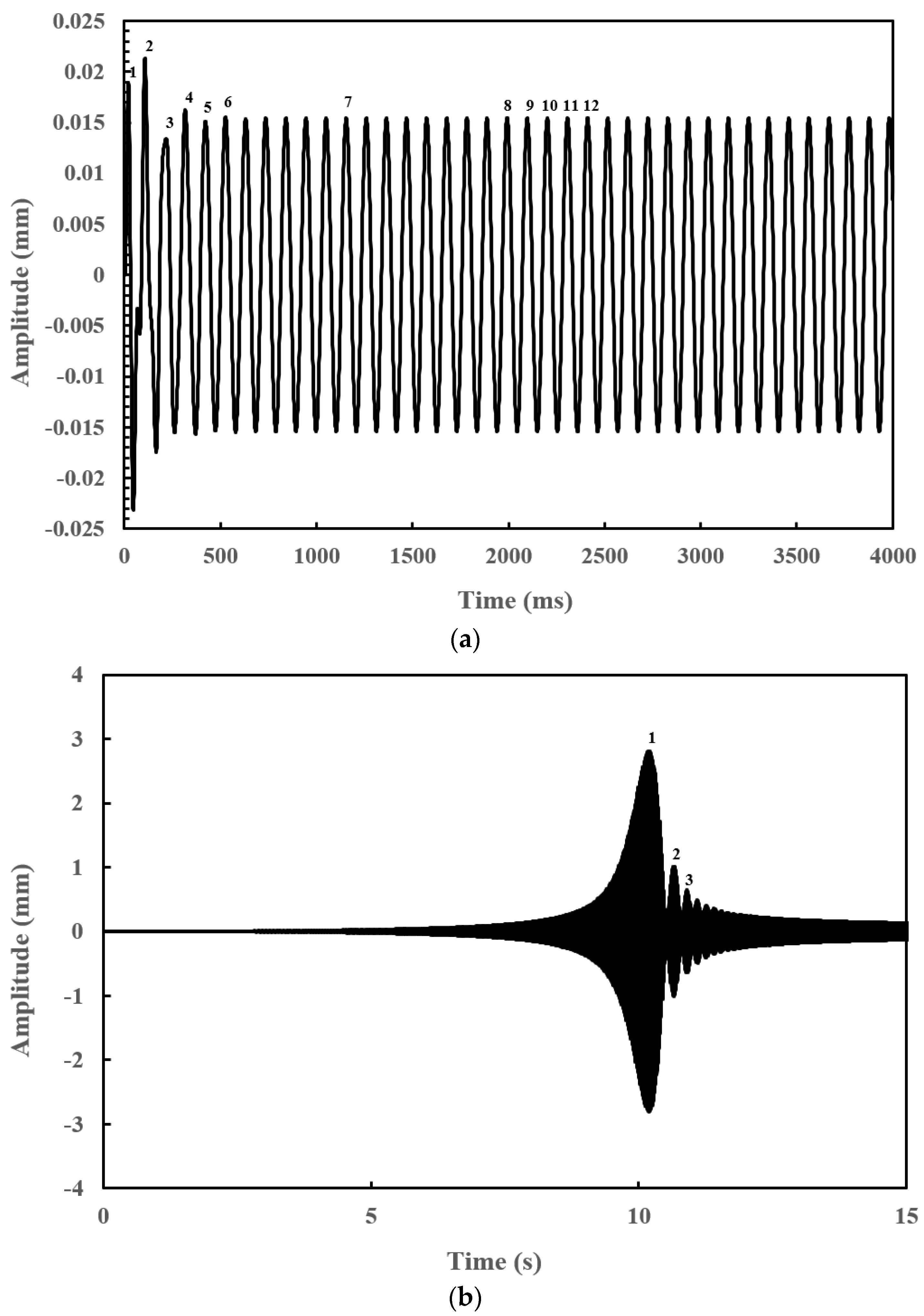

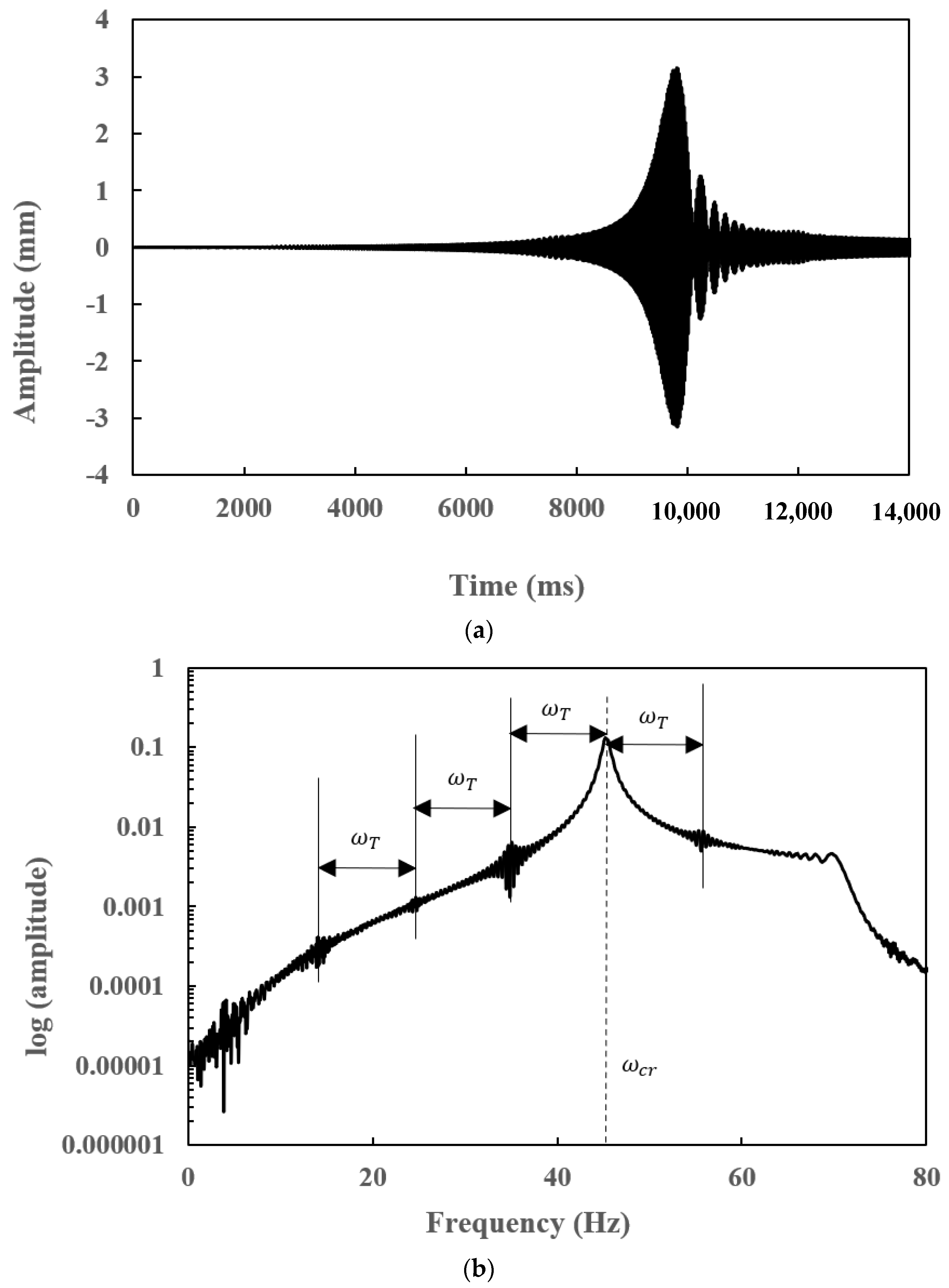

6.3. Dynamic Response of a Steel Rotor with a Breathing Crack

7. Results and Discussions

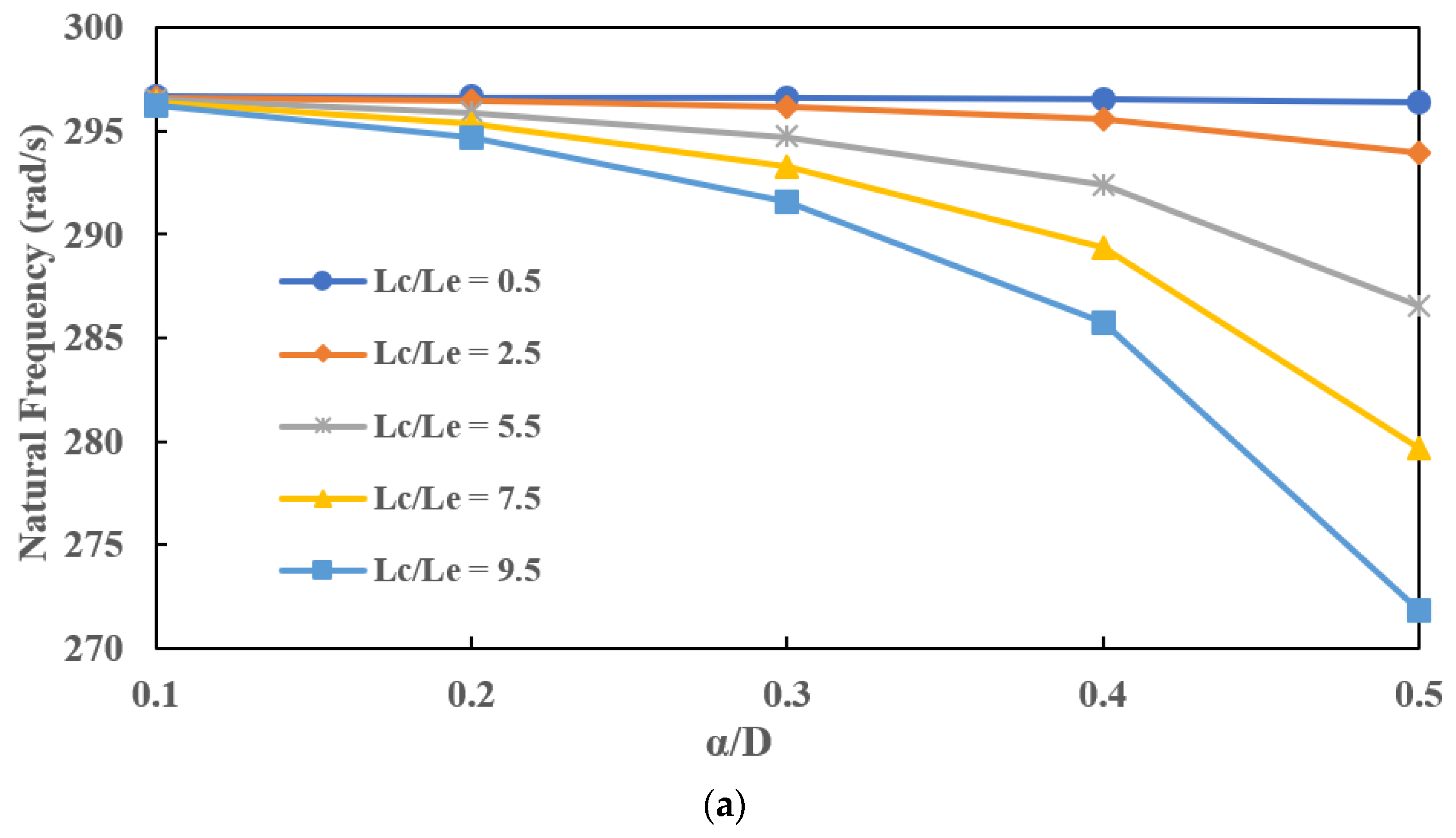

7.1. Effect of Crack Depth () on Natural Frequencies for Different Crack Locations ()

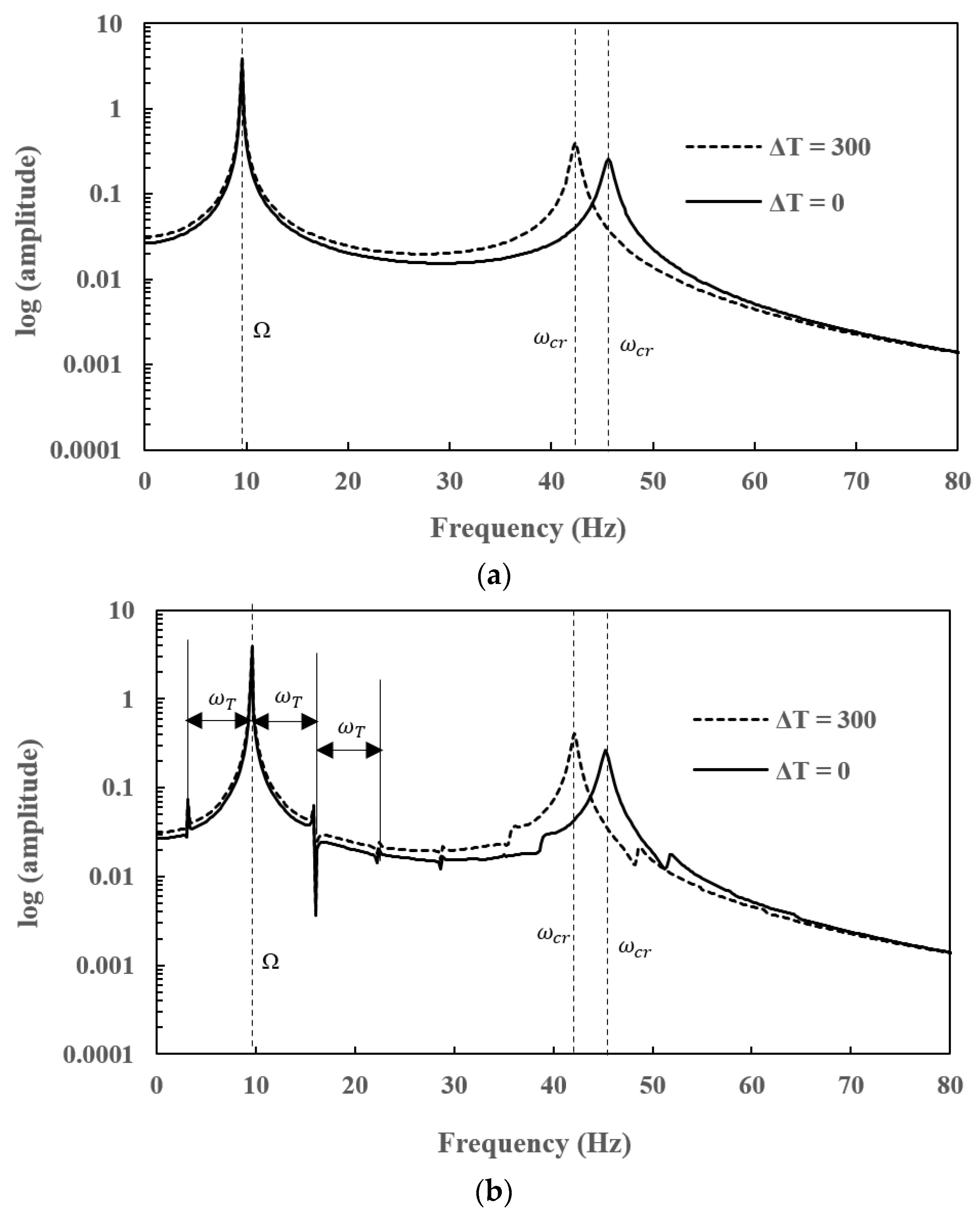

7.2. Effect of Temperature Gradients (ΔT) on Natural Frequencies for Different Crack Depths

7.3. Steady-State Responses of a Slant-Cracked EG Rotor-Bearing System

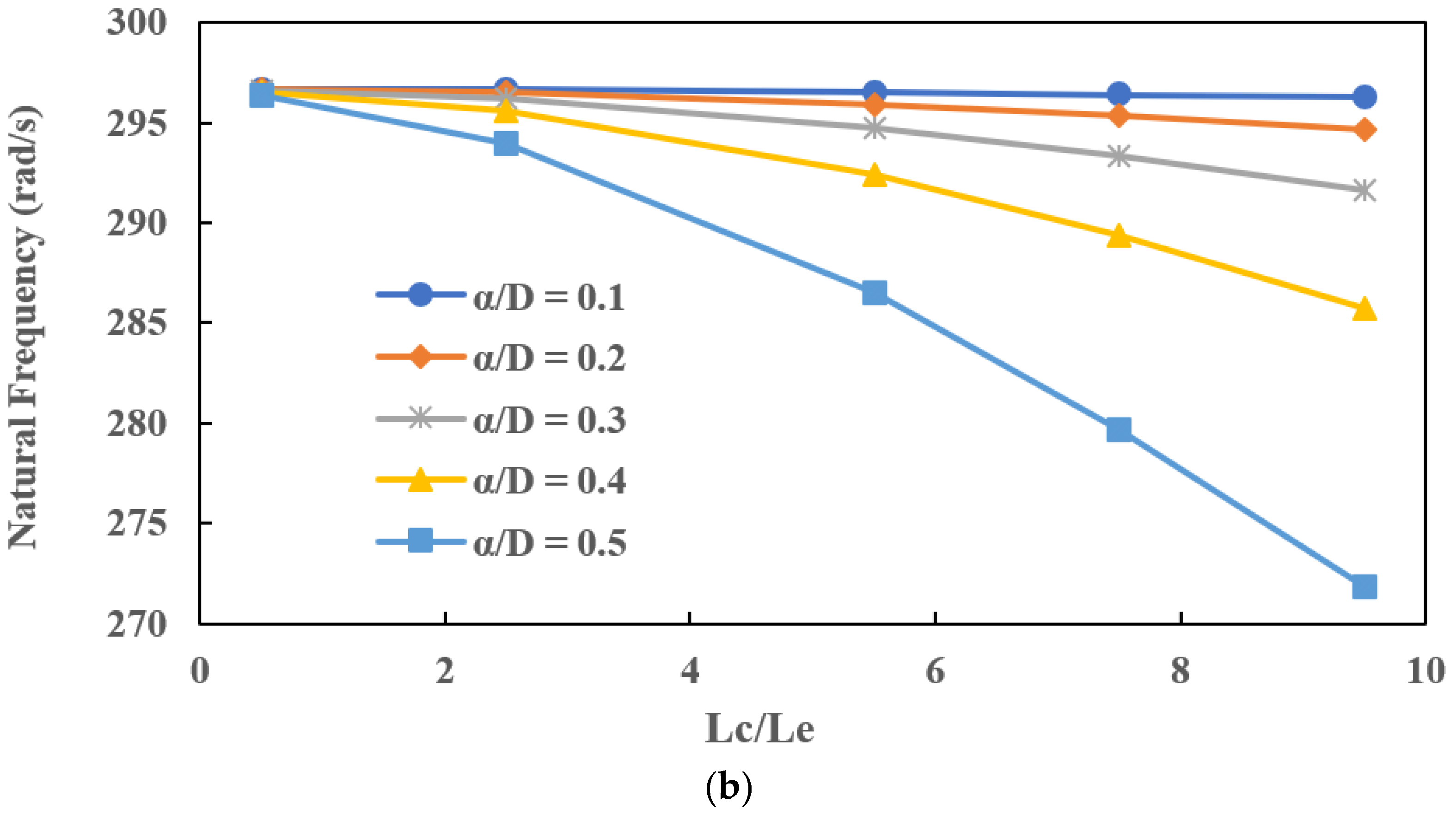

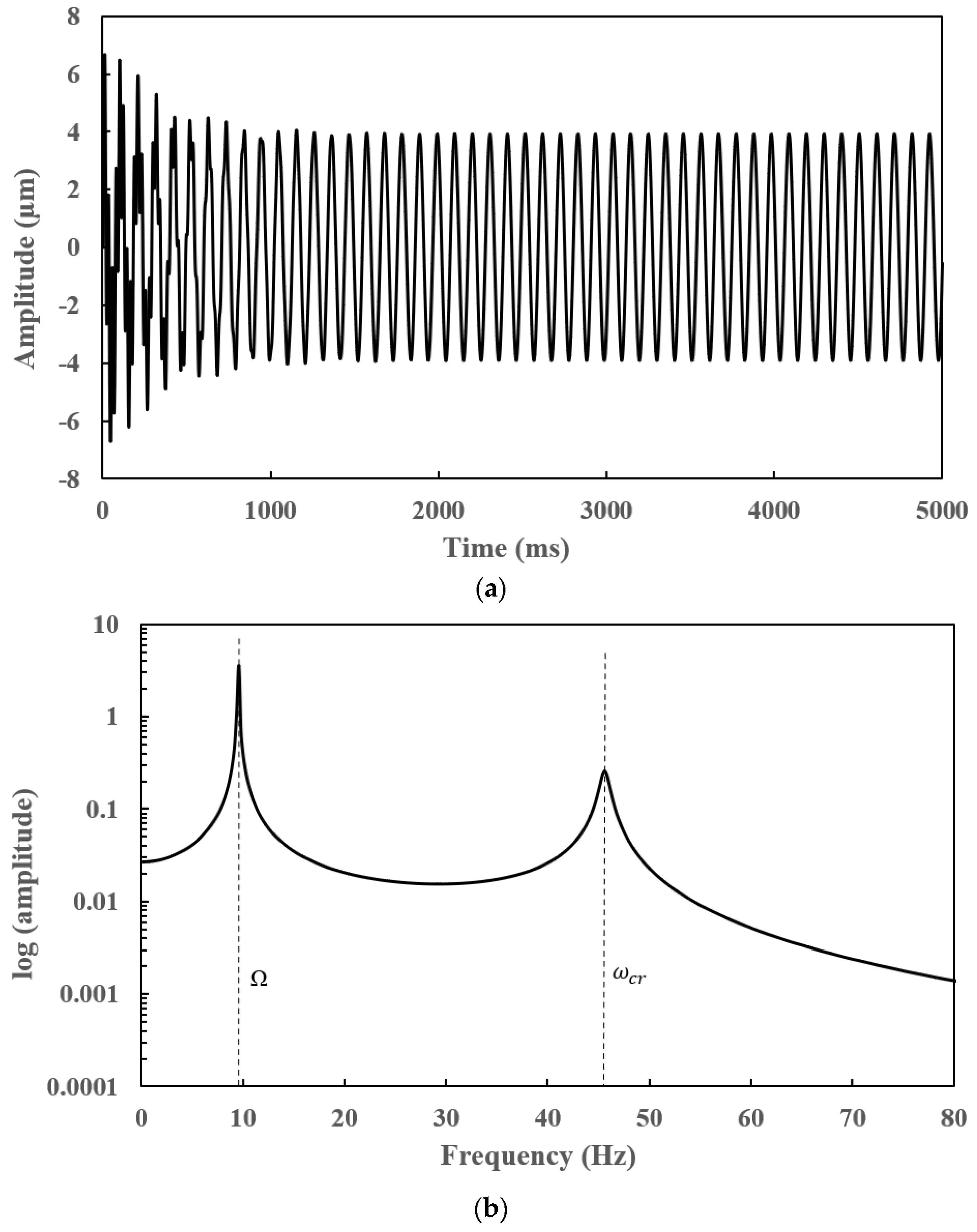

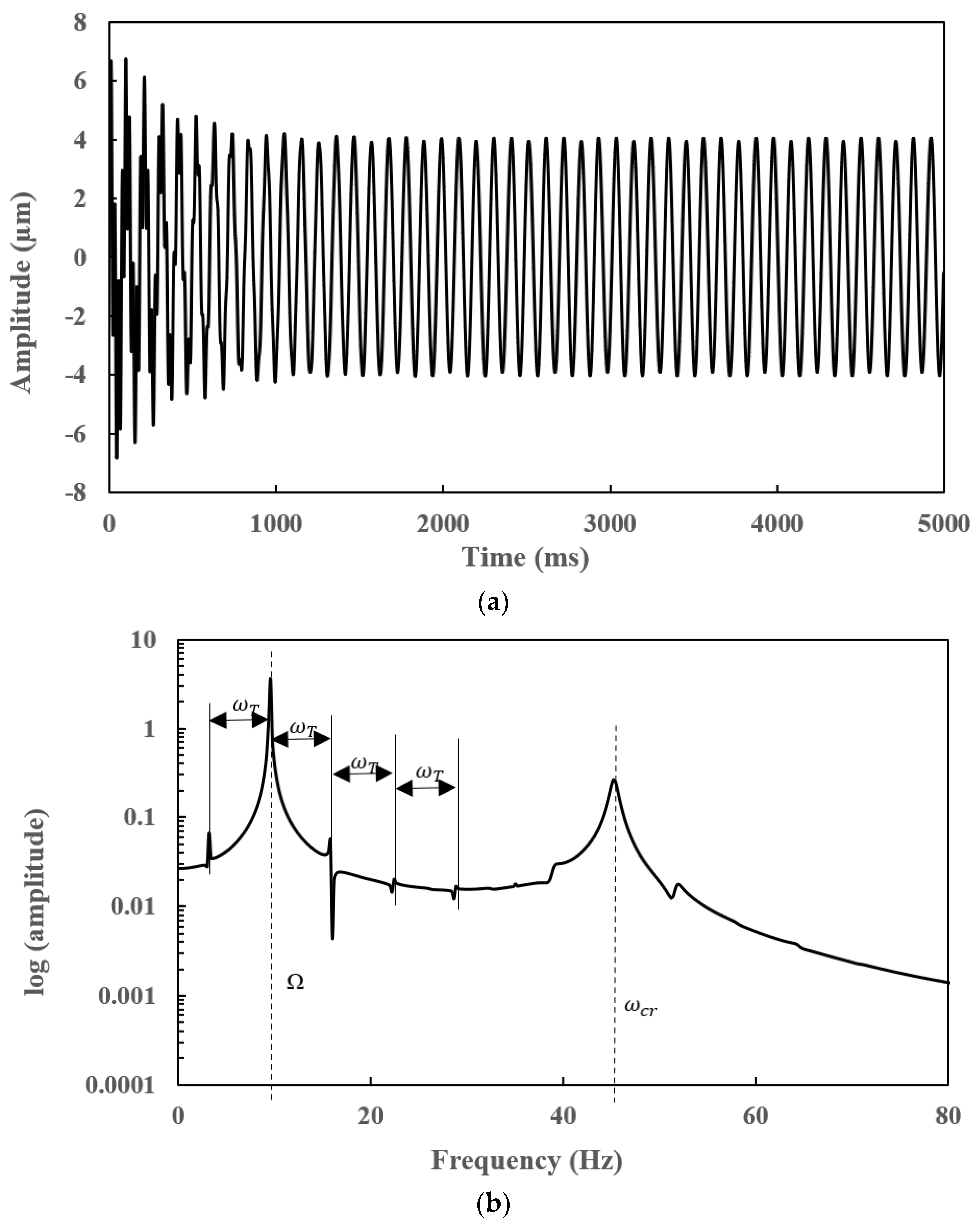

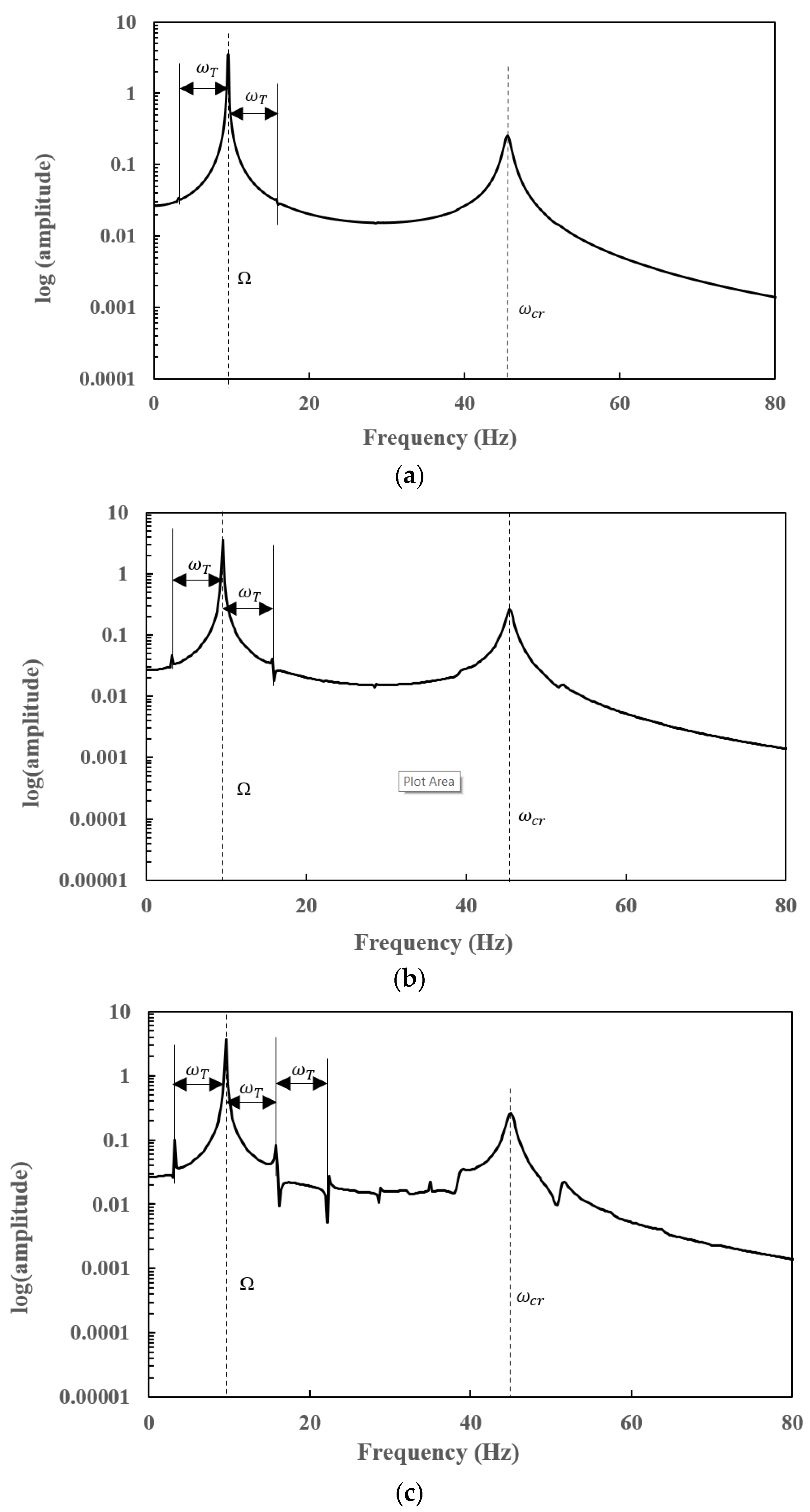

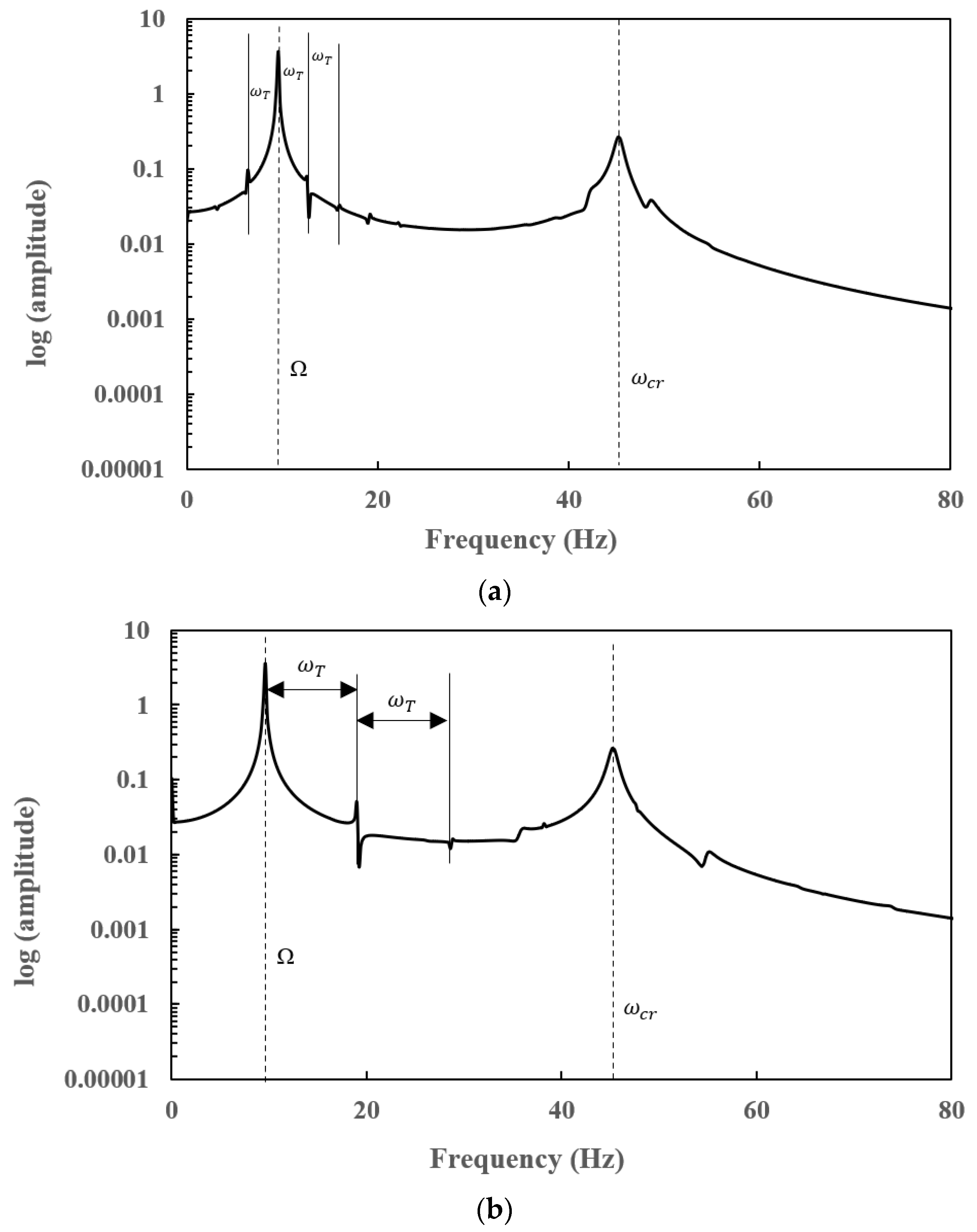

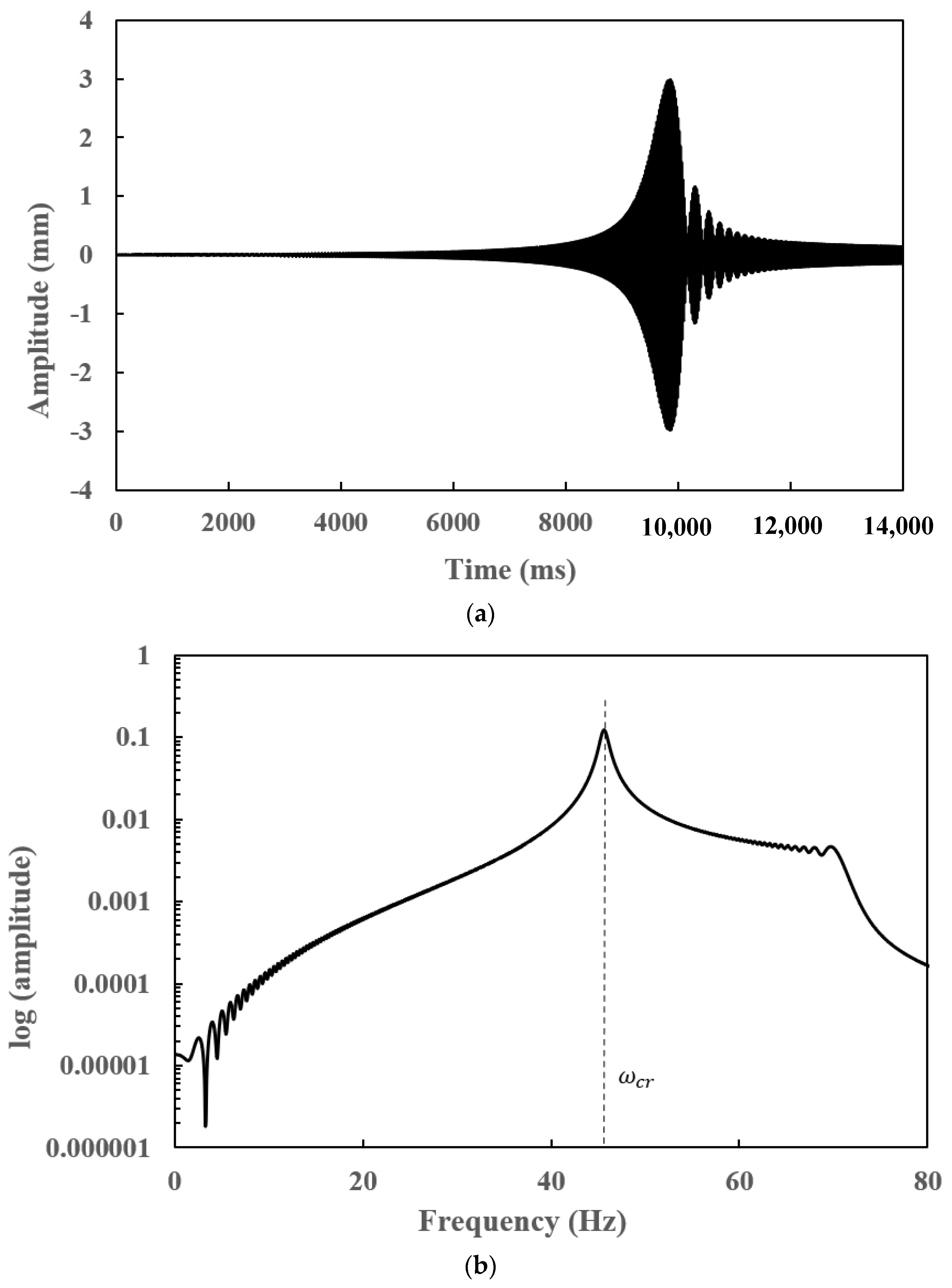

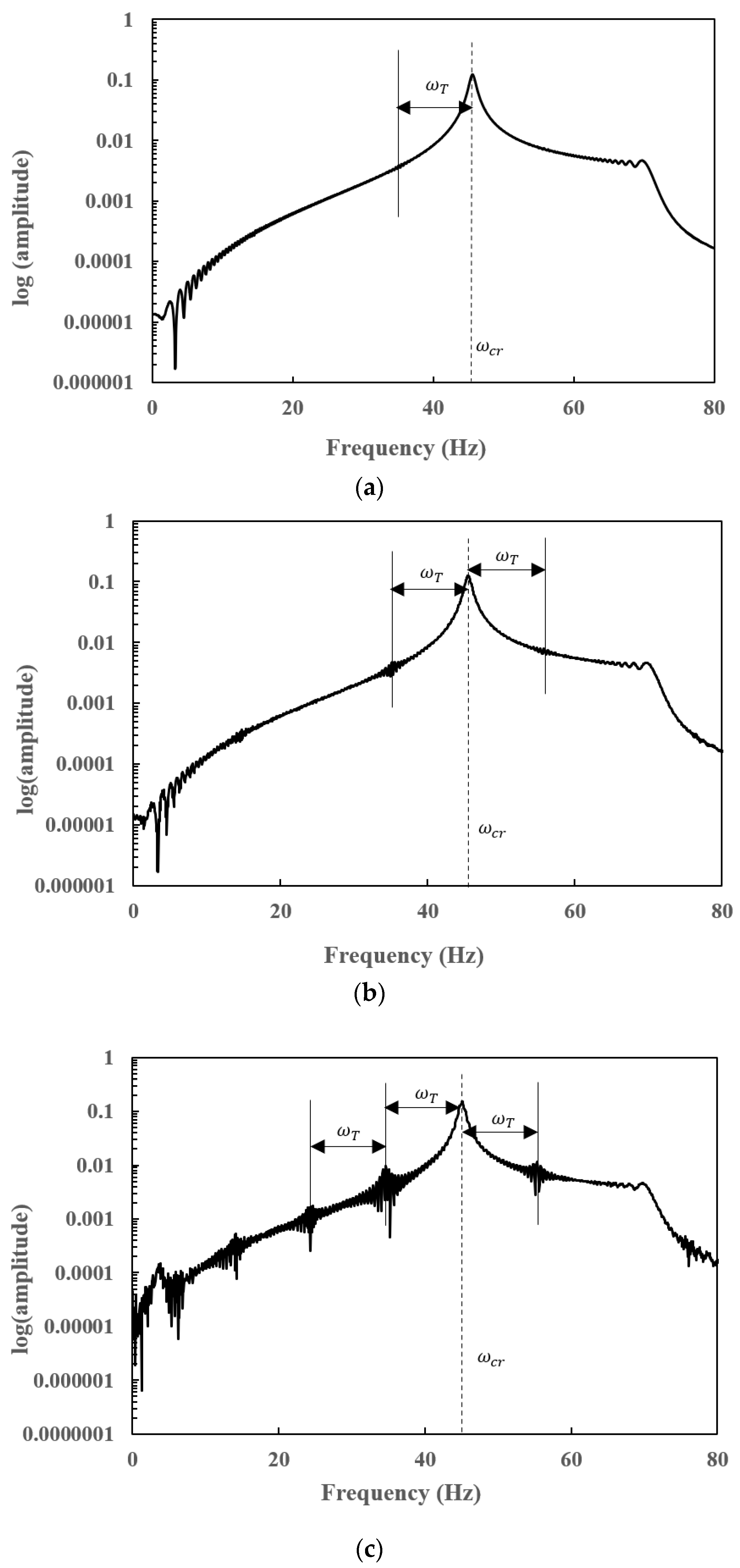

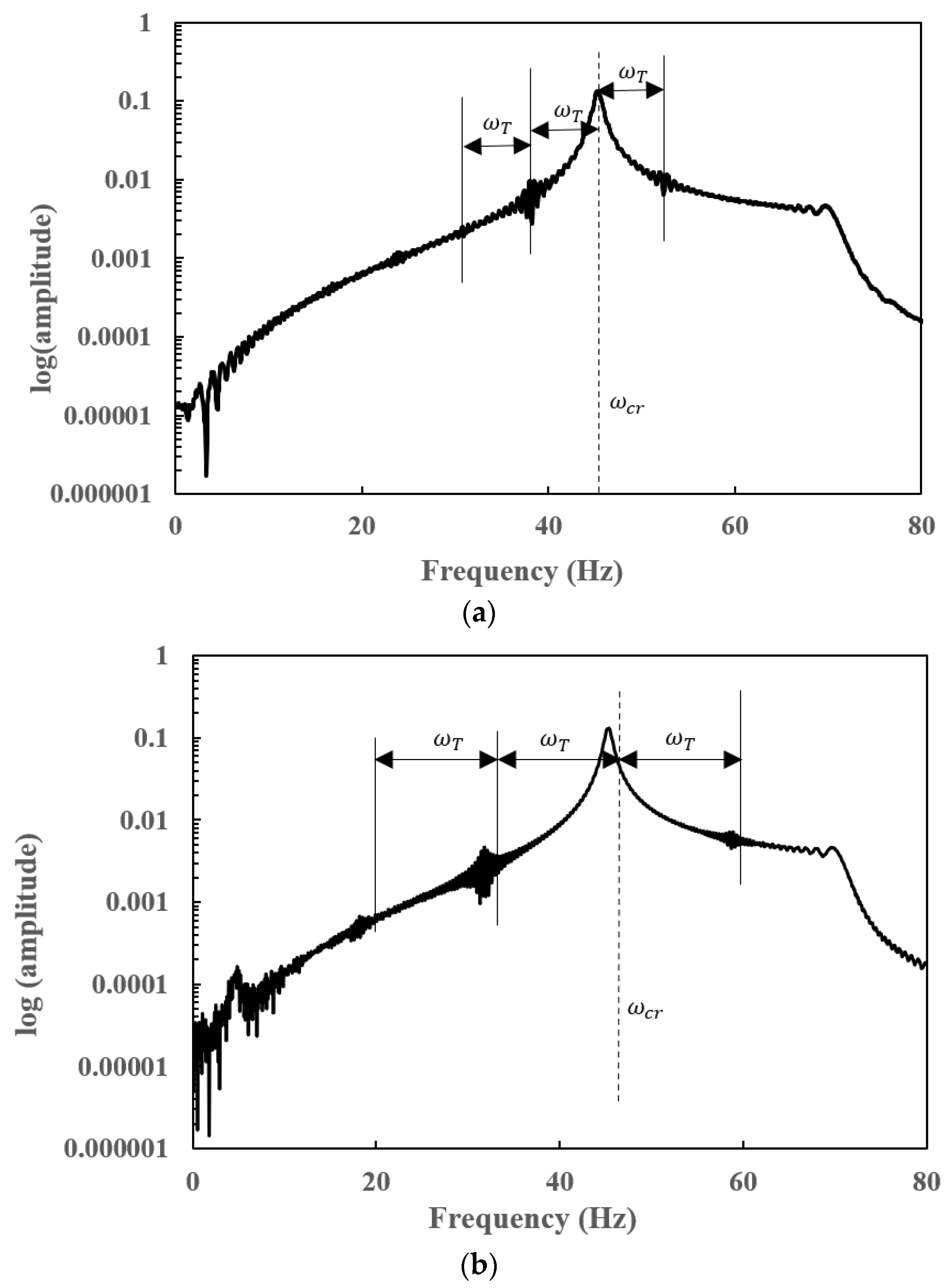

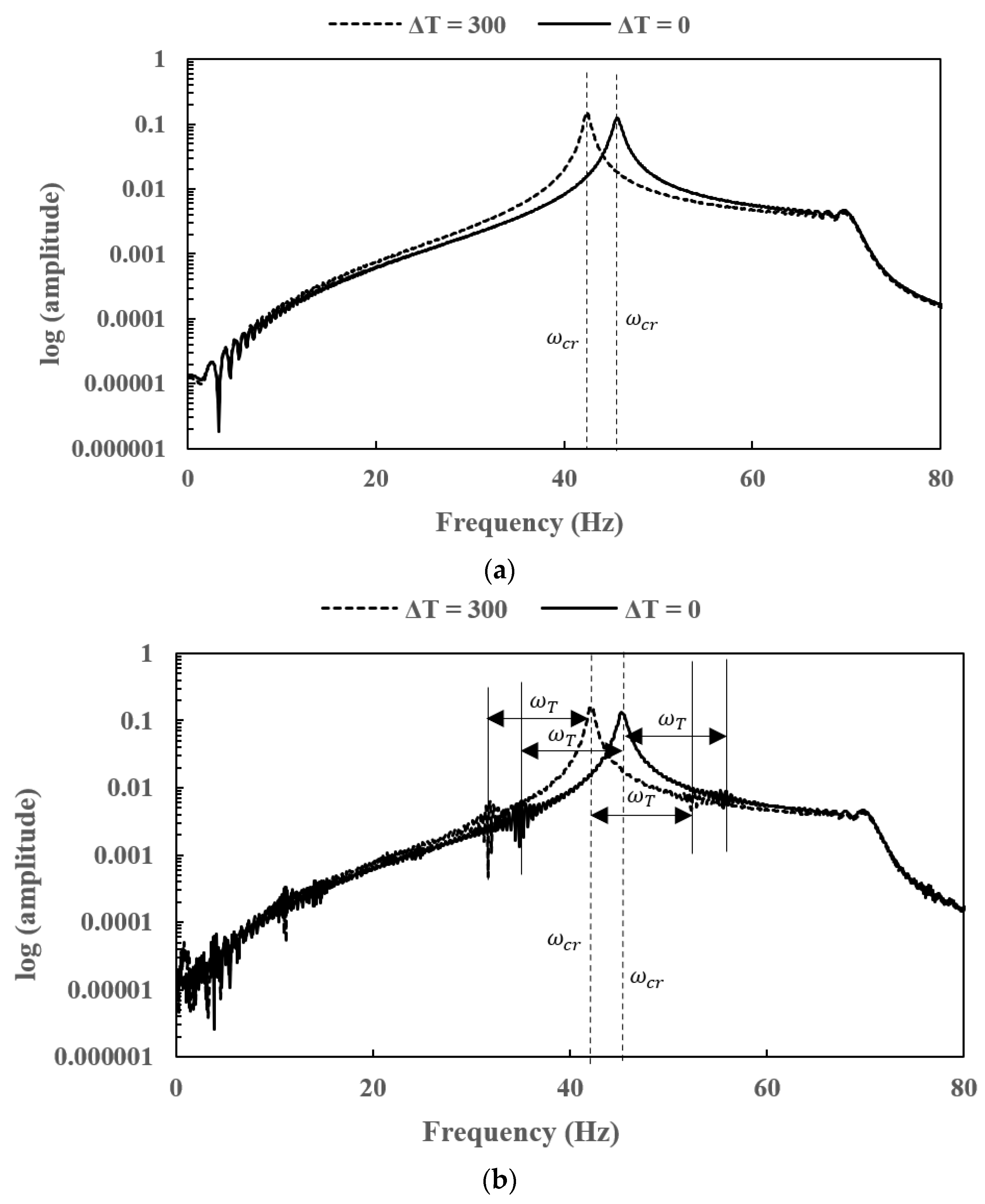

7.4. Transient Responses of a Slant-Cracked EG Rotor-Bearing System

8. Conclusions

- The decrease in natural frequencies with an increase in crack depth is significant when a crack is located near the disc or far from the bearings. The stiffness of the cracked EG rotor is reduced due to the presence of a slant crack.

- The percentage decrease in the natural frequency is less when a slant crack is present near the bearings compared to the percentage decrease in natural frequency when a slant crack is near the disc. The reduction in stiffness of the EG shaft is compensated by the bearing stiffness when a crack is present near the bearings. Therefore, the natural frequencies of an EG rotor-bearing system are hardly affected when a slant crack is present near the bearings.

- Natural frequencies of the EG rotor-bearing system decrease with the increase in the crack depth as the stiffness is affected. The increase in temperature gradient of the EG rotor decreases the stiffness as the Young’s modulus is affected. Therefore, the stiffness of a cracked EG rotor-bearing system is furthermore reduced due to an increase in the thermal gradients. The sudden drop in the natural frequencies for different crack depths at higher thermal gradients has also been observed for this reason.

- Subharmonic peaks are found to be centred on the operational speed at an interval frequency corresponding to the torsional crack breathing frequency in steady-state frequency spectra of a slant-cracked EG rotor-bearing system. The amplitude of the harmonic peaks is increased with an increase in crack depth. Hence the severity of the crack could be identified through the sub-harmonic peaks.

- The frequency spectrum of the transient response of a slant-cracked EG rotor-bearing system is found to have the subharmonic frequencies centred on the critical speed of the rotor system at an interval frequency corresponding to the torsional frequency corresponds to crack breathing frequency. The presence of subharmonics on the frequency spectra confirms the presence of the crack in the EG rotor.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Birman, V.; Byrd, L. Modeling and Analysis of Functionally Graded Materials and Structures. Appl. Mech. Rev. 2007, 60, 195–216. [Google Scholar] [CrossRef]

- Koizumi, M. FGM activities in Japan. Compos. Part B Eng. 1997, 28, 1–4. [Google Scholar] [CrossRef]

- Jha, D.; Kant, T.; Singh, R. A critical review of recent research on functionally graded plates. Compos. Struct. 2013, 96, 833–849. [Google Scholar] [CrossRef]

- Nejad, M.; Jabbari, M.; Hadi, A. A review of functionally graded thick cylindrical and conical shells. J. Comput. Appl. Mech. 2017, 48, 357–370. [Google Scholar]

- Simsek, M. Static analysis of a functionally graded beam under a uniformly distributed load by Ritz method. Int. J. Eng. Appl. Sci. 2009, 1, 1–11. [Google Scholar]

- Aydogdu, M.; Taskin, V. Free vibration analysis of functionally graded beams with simply supported edges. Mater. Des. 2007, 5, 1651–1656. [Google Scholar] [CrossRef]

- Nguyen, T.; Vo, T.; Thai, H. Static and free vibration of axially loaded functionally graded beams based on the first-order shear deformation theory. Compos. Part B Eng. 2013, 55, 147–157. [Google Scholar] [CrossRef] [Green Version]

- Pradhan, K.; Chakraverty, S. Free vibration of Euler and Timoshenko functionally graded beams by Rayleigh–Ritz method. Compos. Part B Eng. 2013, 51, 175–184. [Google Scholar] [CrossRef]

- Şimşek, M. Fundamental frequency analysis of functionally graded beams by using different higher-order beam theories. Nucl. Eng. Des. 2010, 240, 697–705. [Google Scholar] [CrossRef]

- Azadi, M. Free and forced vibration analysis of FG beam considering temperature dependency of material properties. J. Mech. Sci. Technol. 2011, 25, 69–80. [Google Scholar] [CrossRef]

- Nelson, H.; McVaugh, J. The Dynamics of Rotor-Bearing Systems Using Finite Elements. J. Eng. Ind. 1976, 98, 593–600. [Google Scholar] [CrossRef]

- Nelson, H. A Finite Rotating Shaft Element Using Timoshenko Beam Theory. J. Mech. Des. 1980, 102, 793–803. [Google Scholar] [CrossRef]

- Bose, A.; Sathujoda, P. Natural frequency analysis of a functionally graded rotor system using three-dimensional finite element method. Vibroeng. Procedia 2019, 29, 70–75. [Google Scholar] [CrossRef]

- Kiani, Y.; Eslami, M. Thermal buckling analysis of functionally graded material beams. Int. J. Mech. Mater. Des. 2010, 6, 229–238. [Google Scholar] [CrossRef]

- Mahi, A.; Bedia, E.A.; Tounsi, A.; Mechab, I. An analytical method for temperature-dependent free vibration analysis of functionally graded beams with general boundary conditions. Compos. Struct. 2010, 92, 1877–1887. [Google Scholar] [CrossRef]

- Bose, A.; Sathujoda, P. Effect of Thermal Gradient on Vibration Characteristics of a Functionally Graded Shaft System. Math. Model. Eng. Probl. 2020, 7, 212–222. [Google Scholar] [CrossRef]

- Dimarogonas, A. Vibration for Engineers; Prentice-Hall: Upper Saddle River, NJ, USA, 1996. [Google Scholar]

- Mayes, I.; Davies, W. Analysis of the Response of a Multi-Rotor-Bearing System Containing a Transverse Crack in a Rotor. J. Vib. Acoust. 1984, 106, 139–145. [Google Scholar] [CrossRef]

- Dimarogonas, A.; Papadopoulos, C. Vibration of cracked shafts in bending. J. Sound Vib. 1983, 91, 583–593. [Google Scholar] [CrossRef]

- Papadopoulos, C. Torsional vibrations of rotors with transverse surface cracks. Comput. Struct. 1994, 51, 713–718. [Google Scholar] [CrossRef]

- Papadopoulos, C.; Dimarogonas, A. Coupling of bending and torsional vibration of a cracked Timoshenko shaft. Ing. Arch. 1987, 57, 257–266. [Google Scholar] [CrossRef]

- Darpe, A.; Chawla, A.; Gupta, K. Analysis of the response of a cracked Jeffcott rotor to axial excitation. J. Sound Vib. 2002, 249, 429–445. [Google Scholar] [CrossRef] [Green Version]

- Ichimonji, M.; Watanabe, S. The dynamics of a rotor system with a shaft having a slant crack: A qualitative analysis using a simple rotor model. JSME Int. J. Ser. 3 Vib. Control Eng. Eng. Ind. 1988, 31, 712–718. [Google Scholar] [CrossRef] [Green Version]

- Dias-da-Costa, D.; Valenca, J.; Julio, E.; Araujo, H. Crack propagation monitoring using an image deformation approach. Struct. Control Health Monit. 2016, 24, 1973. [Google Scholar] [CrossRef]

- Yao, Y.; Ellen, S.T.; Glisic, B. Crack detection and characterization techniques-An overview. Struct. Control Health Monit. 2014, 21, 1387–1413. [Google Scholar] [CrossRef]

- Sekhar, A.; Prasad, P.B. Dynamic analysis of a rotor system considering a slant crack in the shaft. J. Sound Vib. 1997, 208, 457–474. [Google Scholar] [CrossRef]

- Sekhar, A.; Mohanty, A.; Prabhakar, S. Vibrations of cracked rotor system: Transverse crack versus slant crack. J. Sound Vib. 2005, 279, 1203–1217. [Google Scholar] [CrossRef]

- Prabhakar, S.; Sekhar, A.; Mohanty, A. Detection and monitoring of cracks in a rotor-bearing system using wavelet transforms. Mech. Syst. Signal Process. 2001, 15, 447–450. [Google Scholar] [CrossRef]

- Prabhakar, S.; Sekhar, A.; Mohanty, A. Transient lateral analysis of a slant-cracked rotor passing through its flexural critical speed. Mech. Mach. Theory 2002, 37, 1007–1020. [Google Scholar] [CrossRef]

- Sathujoda, P.; Batchu, A.; Obalareddy, B.; Canale, G.; Maligno, A.; Citarella, R. Free Vibration Analysis of a Thermally Loaded Porous Functionally Graded Rotor–Bearing System. Appl. Sci. 2020, 10, 8197. [Google Scholar] [CrossRef]

- Sathujoda, P.; Obalareddy, B.; Batchu, A.; Canale, G.; Maligno, A.; Citarella, R. Effect of Corrosion on the Natural and Whirl Frequencies of a Functionally Graded Rotor-Bearing System Subjected to Thermal Gradients. Materials 2020, 13, 4546. [Google Scholar] [CrossRef]

- Gayen, D.; Chakraborty, D.; Tiwari, R. Whirl frequencies and critical speeds of a rotor-bearing system with a cracked functionally graded shaft–Finite element analysis. Eur. J. Mech. A/Solids 2017, 61, 47–58. [Google Scholar] [CrossRef]

- Gayen, D.; Chakraborty, D.; Tiwari, R. Free Vibration Analysis of Functionally Graded Shaft System with a Surface Crack. J. Vib. Eng. Technol. 2018, 6, 483–494. [Google Scholar] [CrossRef]

- Bose, A.; Sathujoda, P.; Canale, G. Natural frequency analysis of a functionally graded rotor-bearing system with a slant crack subjected to thermal gradients. Int. J. Turbo Jet-Engines 2021. [Google Scholar] [CrossRef]

- Shen, H. Functionally Graded Materials; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Touloukian, Y. Thermophysical Properties of High Temperature Solid Materials; Macmillan: New York, NY, USA, 1967. [Google Scholar]

- Reddy, J.; Chin, C. Thermomechanical analysis of functionally graded cylinders and plates. J. Therm. Stresses 1998, 21, 593–626. [Google Scholar] [CrossRef]

- Qian, G.; Gu, S.; Jiang, J. The dynamic behaviour and crack detection of a beam with a crack. J. Sound Vib. 1990, 138, 233–243. [Google Scholar] [CrossRef]

- Tada, H.; Paris, P.; Irwin, G. The stress analysis of cracks handbook. Del. Res. Corp. 1973, 34, 635. [Google Scholar]

| L/h | Non-Dimensional Natural Frequencies | ||

|---|---|---|---|

| Present | Mahi et al. [15] | Error% | |

| 5 | 3.547 | 3.543 | 0.11 |

| 20 | 3.589 | 3.584 | 0.14 |

| α/D | Present | Digitized Values [26] | |Difference| |

|---|---|---|---|

| 0.1 | 0.999 | 0.999 | 0 |

| 0.2 | 0.998 | 0.998 | 0 |

| 0.3 | 0.997 | 0.995 | 0.002 |

| 0.4 | 0.993 | 0.991 | 0.002 |

| 0.5 | 0.986 | 0.985 | 0.001 |

| Points | Present | Digitised Values [26] | |Difference| |

|---|---|---|---|

| 1 | 0.019 | 0.020 | 0.001 |

| 2 | 0.021 | 0.021 | 0 |

| 3 | 0.013 | 0.014 | 0.001 |

| 4 | 0.016 | 0.017 | 0.001 |

| 5 | 0.015 | 0.015 | 0 |

| 6 | 0.015 | 0.016 | 0.001 |

| 7 | 0.015 | 0.015 | 0 |

| 8 | 0.015 | 0.015 | 0 |

| 9 | 0.015 | 0.015 | 0 |

| 10 | 0.015 | 0.015 | 0 |

| 11 | 0.015 | 0.015 | 0 |

| 12 | 0.015 | 0.015 | 0 |

| Points | Present | Digitised Values [29] | |Difference| |

|---|---|---|---|

| 1 | 2.839 | 2.842 | 0.003 |

| 2 | 1.059 | 1.063 | 0.004 |

| 3 | 0.652 | 0.652 | 0 |

| Shaft | ||

|---|---|---|

| Length (L) | 0.5 m | |

| Diameter (D) | 0.02 m | |

| Disc | ||

| Location | Mid-span | |

| Mass (m) | 5.5 kg | |

| Polar moment of inertia (Ip) | 0.01546 kg m2 | |

| Diametral moment of inertia (Id) | 0.00773 kg m2 | |

| Unbalance eccentricity () | 0.0001 m | |

| Bearing | ||

| Bearing Stiffness (Rigid bearings) | 1010 N/m | |

| Damping | 100 Ns/m | |

| Crack depth () | ||

| Crack location () | ||

| Material Properties | Stainless Steel (SS) | Zirconia (ZrO2) |

| Young’s Modulus (GPa) | 207.8 | 168 |

| Density (kg/m3) | 8166 | 5700 |

| Poisson’s ratio | 0.3 | 0.24 |

| No. of Finite Elements | Uncracked (Hz) | α/D = 0.1 (Hz) | α/D = 0.3 (Hz) |

|---|---|---|---|

| 10 | 47.2127 | 47.2212 | 47.2214 |

| 14 | 47.2127 | 47.1955 | 46.9362 |

| 18 | 47.2127 | 47.1637 | 46.5665 |

| 20 | 47.2127 | 47.1637 | 46.5672 |

| 22 | 47.2127 | 47.1637 | 46.5672 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sathujoda, P.; Batchu, A.; Canale, G.; Citarella, R. Steady State and Transient Vibration Analysis of an Exponentially Graded Rotor Bearing System Having a Slant Crack. Appl. Sci. 2022, 12, 6900. https://doi.org/10.3390/app12146900

Sathujoda P, Batchu A, Canale G, Citarella R. Steady State and Transient Vibration Analysis of an Exponentially Graded Rotor Bearing System Having a Slant Crack. Applied Sciences. 2022; 12(14):6900. https://doi.org/10.3390/app12146900

Chicago/Turabian StyleSathujoda, Prabhakar, Aneesh Batchu, Giacomo Canale, and Roberto Citarella. 2022. "Steady State and Transient Vibration Analysis of an Exponentially Graded Rotor Bearing System Having a Slant Crack" Applied Sciences 12, no. 14: 6900. https://doi.org/10.3390/app12146900

APA StyleSathujoda, P., Batchu, A., Canale, G., & Citarella, R. (2022). Steady State and Transient Vibration Analysis of an Exponentially Graded Rotor Bearing System Having a Slant Crack. Applied Sciences, 12(14), 6900. https://doi.org/10.3390/app12146900