Ultraviolet-Assisted Modified Delignified Wood with High Transparency

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

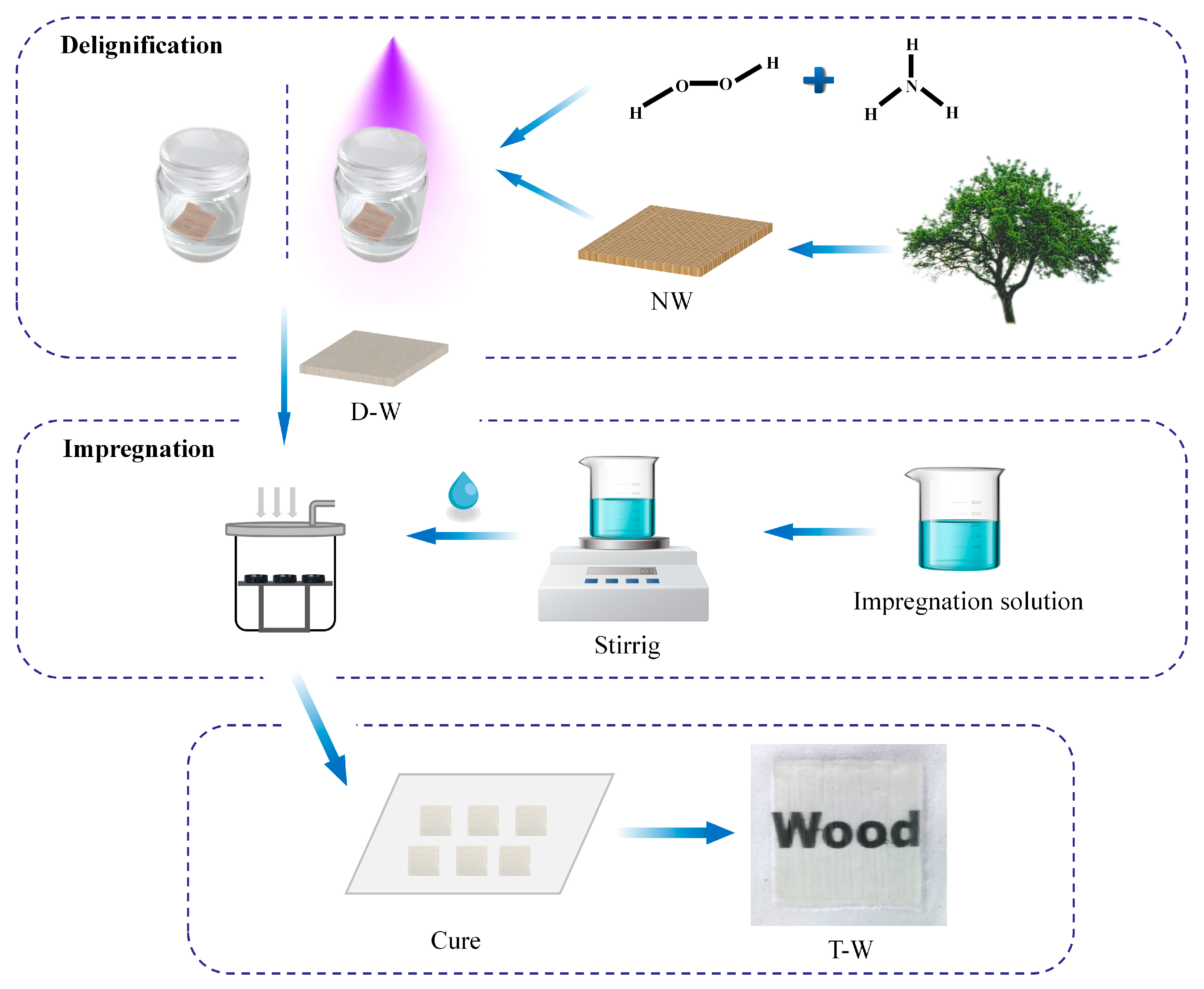

2.2. Preparation of Delignified Wood

2.3. Preparation of the Impregnating Solution

2.4. Vacuum Impregnation

2.5. Characterisation

3. Results and Discussion

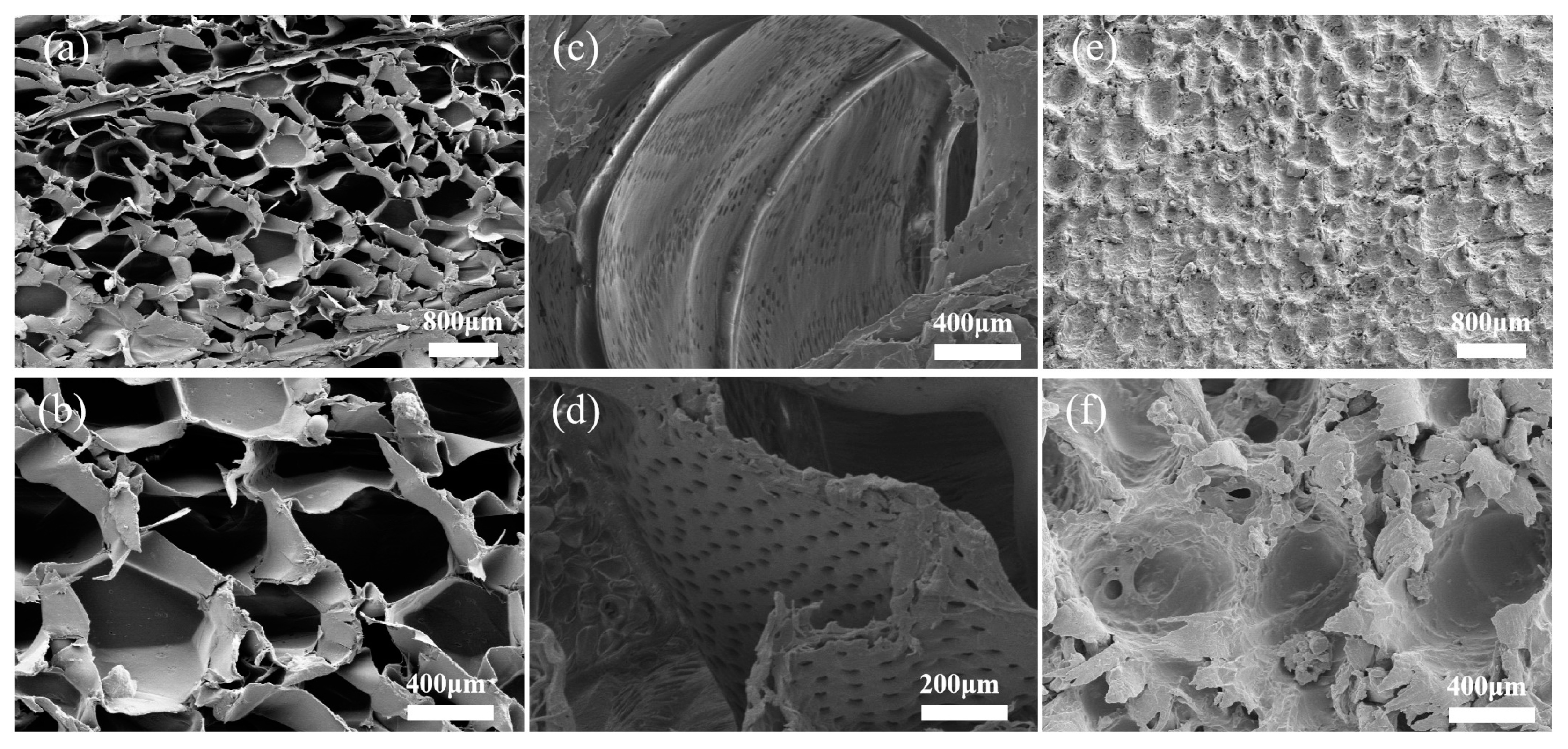

3.1. Microstructural Analysis

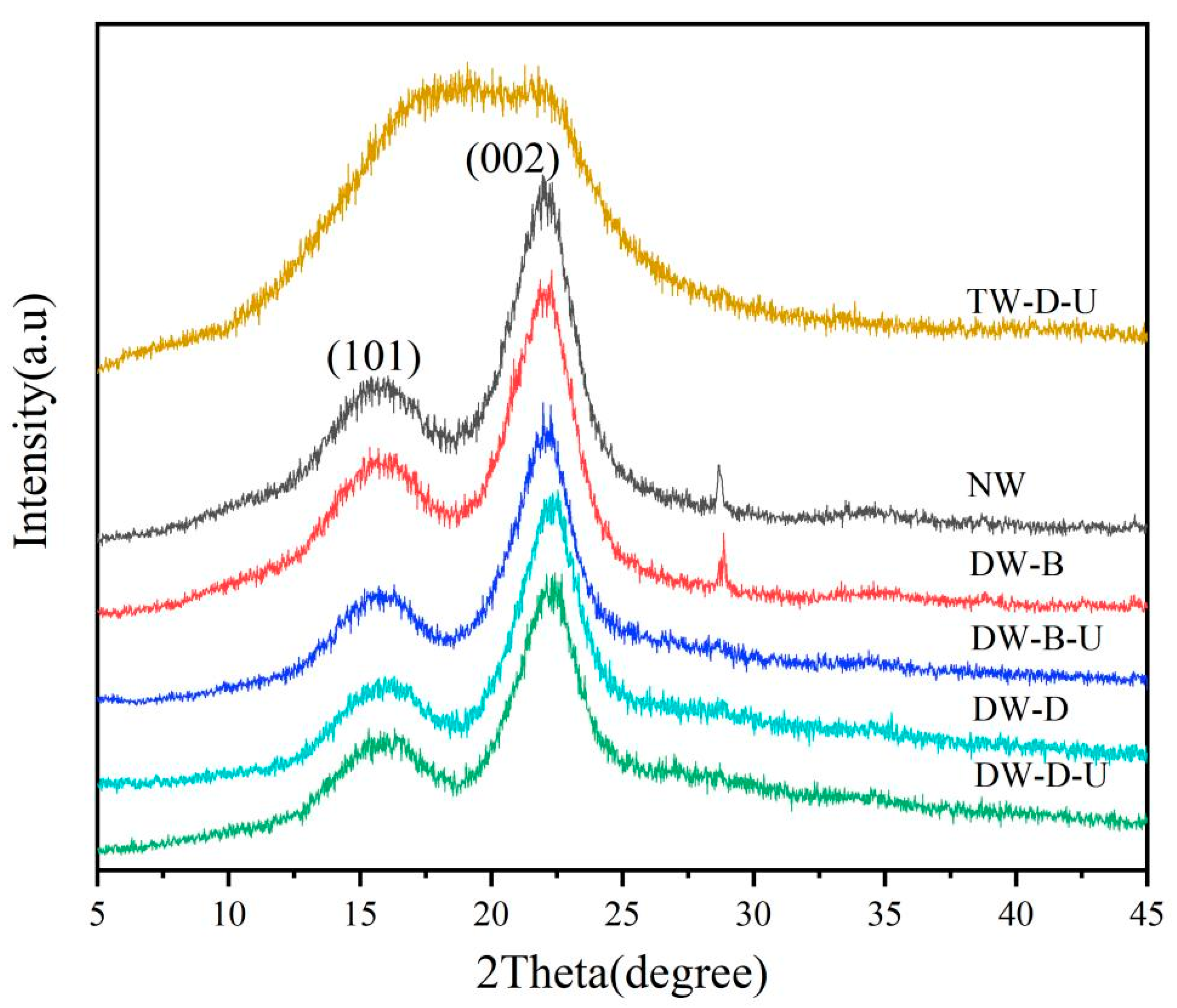

3.2. Analysis of XRD Image

3.3. Analysis of Transmittance and Haze

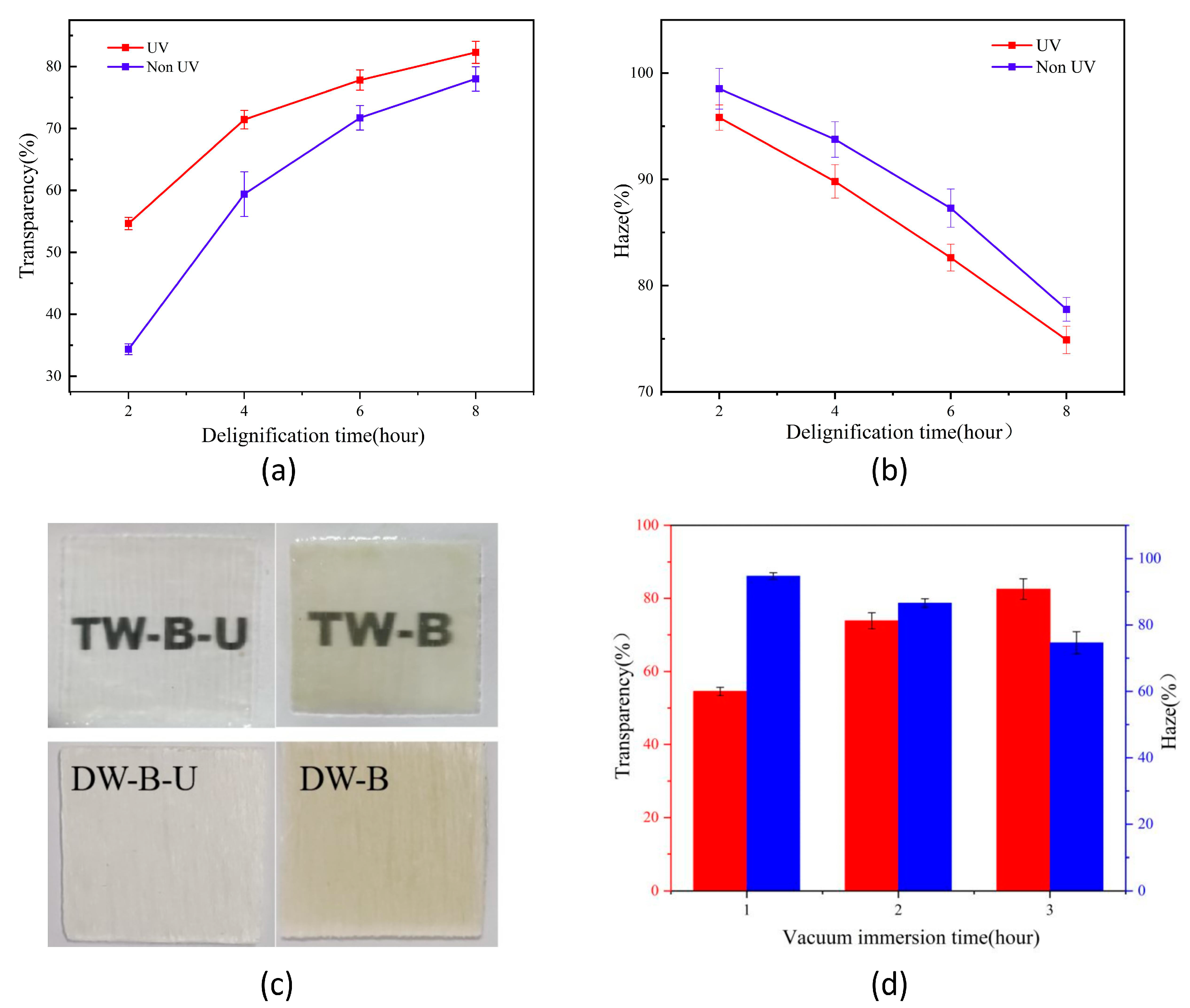

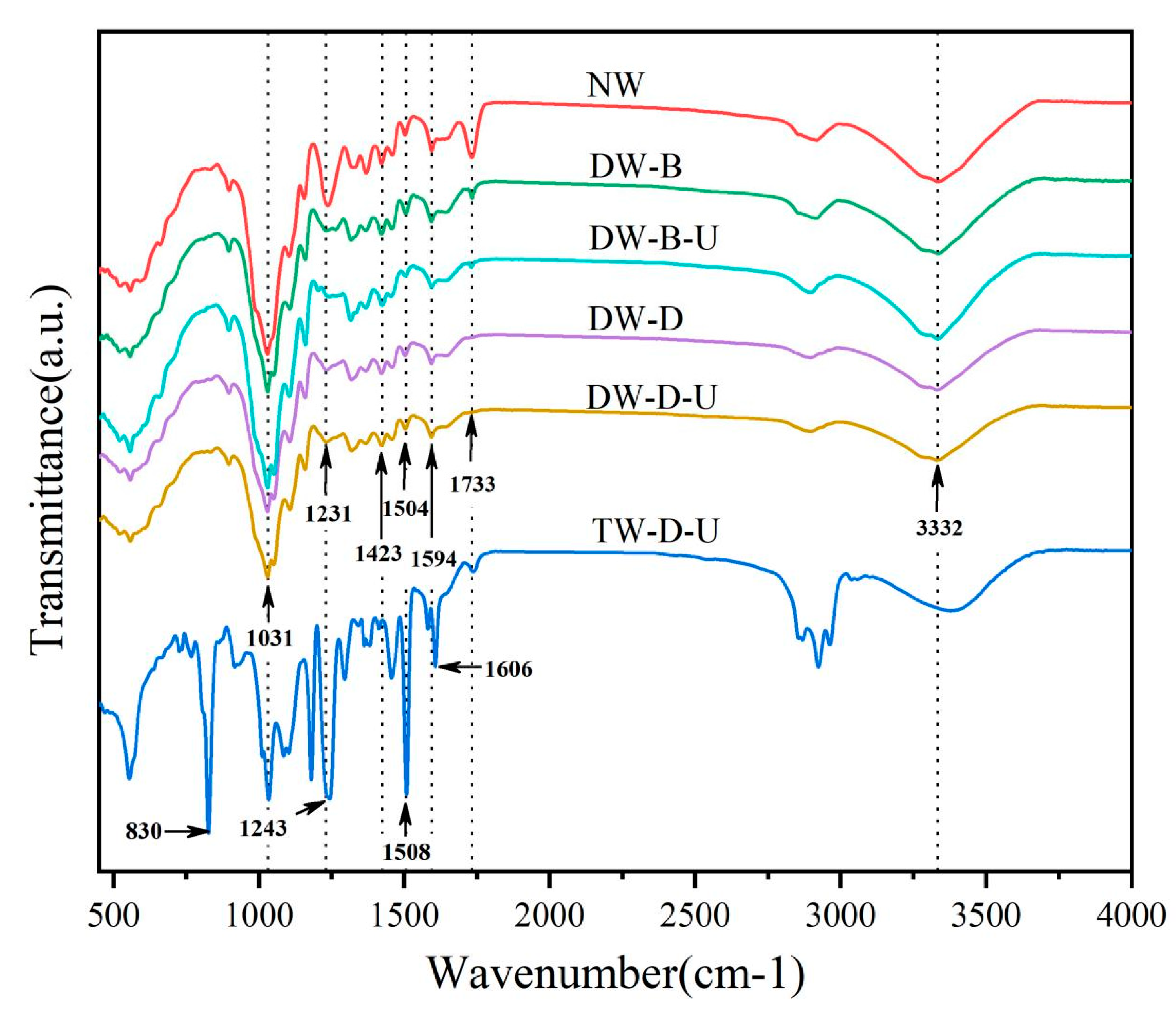

3.4. Fourier Transform Infrared Spectroscopy Analysis

3.5. Analysis of Lignin Content

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kamau-Devers, K.; Miller, S.A. The environmental attributes of wood fiber composites with bio-based or petroleum-based plastics. Int. J. Life Cycle Assess. 2020, 25, 1145–1159. [Google Scholar] [CrossRef]

- Naser, A.Z.; Deiab, I.; Darras, B.M. Poly (lactic acid) (PLA) and polyhydroxyalkanoates (PHAs), green alternatives to petroleum-based plastics: A review. RSC Adv. 2021, 11, 17151–17196. [Google Scholar] [CrossRef] [PubMed]

- Changwichan, K.; Silalertruksa, T.; Gheewala, S.H. Eco-efficiency assessment of bioplastics production systems and end-of-life options. Sustainability 2018, 10, 952. [Google Scholar] [CrossRef] [Green Version]

- Silva, F.A.G.S.; Dourado, F.; Gama, M.; Poças, F. Nanocellulose bio-based composites for food packaging. Nanomaterials 2020, 10, 2041. [Google Scholar] [CrossRef]

- Cabane, E.; Keplinger, T.; Künniger, T.; Merk, V.; Burgert, I. Functional lignocellulosic materials prepared by ATRP from a wood scaffold. Sci. Rep. 2016, 6, 31287. [Google Scholar] [CrossRef] [Green Version]

- Johnston, C.M.T.; Guo, J.; Prestemon, J.P. US and Global Wood Energy Outlook under Alternative Shared Socioeconomic Pathways. Forests 2022, 13, 786. [Google Scholar] [CrossRef]

- Yang, X.; You, Z.; Dai, Q.; Mills-Beale, J. Mechanical performance of asphalt mixtures modified by bio-oils derived from waste wood resources. Constr. Build. Mater. 2014, 51, 424–431. [Google Scholar] [CrossRef]

- Polman, A.; Knight, M.; Garnett, E.C.; Ehrler, B.; Sinke, W.C. Photovoltaic materials: Present efficiencies and future challenges. Science 2016, 352, aad4424. [Google Scholar] [CrossRef] [Green Version]

- Zhu, M.; Song, J.; Li, T.; Gong, A.; Wang, Y.; Dai, J.; Yao, Y.; Luo, W.; Henderson, D.; Hu, L. Highly anisotropic, highly transparent wood composites. Adv. Mater. 2016, 28, 5181–5187. [Google Scholar] [CrossRef]

- Wan, C.; Liu, X.; Huang, Q.; Cheng, W.; Su, J.; Wu, Y. A Brief Review of Transparent Wood: Synthetic Strategy, Functionalization and Applications. Curr. Org. Synth. 2021, 18, 615–623. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, J.; Yang, F.; Wang, Y.; Wang, J.; Zhang, J. A strong multilayered transparent wood with natural wood color and texture. J. Mater. Sci. 2021, 56, 8000–8013. [Google Scholar] [CrossRef]

- Yaddanapudi, H.S.; Hickerson, N.; Saini, S.; Tiwari, A. Fabrication and characterization of transparent wood for next generation smart building applications. Vacuum 2017, 146, 649–654. [Google Scholar] [CrossRef]

- Wang, X.; Zhan, T.; Liu, Y.; Shi, J.; Pan, B.; Zhang, Y.; Cai, L.; Shi, S.Q. Large-size transparent wood for energy-saving building applications. ChemSusChem 2018, 11, 4086–4093. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Wu, Y.; Yang, F.; Tang, C.; Huang, Q.; Zhang, J. Impact of delignification on morphological, optical and mechanical properties of transparent wood. Compos. Part. A Appl. Sci. Manuf. 2019, 117, 324–331. [Google Scholar] [CrossRef]

- Müller, U.; Rätzsch, M.; Schwanninger, M.; Steiner, M.; Zöbl, H. Yellowing and IR-changes of spruce wood as result of UV-irradiation. J. Photochem. Photobiol. B Biol. 2003, 69, 97–105. [Google Scholar] [CrossRef]

- Li, Y.; Vasileva, E.; Sychugov, I.; Popov, S.; Berglund, L. Optically transparent wood: Recent progress, opportunities, and challenges. Adv. Opt. Mater. 2018, 6, 1800059. [Google Scholar] [CrossRef]

- Fink, S. Transparent Wood—A New Approach in the Functional Study of Wood Structure. Holzforschung 1992, 46, 403–408. [Google Scholar] [CrossRef]

- Li, Y.; Fu, Q.; Yu, S.; Yan, M.; Berglund, L. Optically transparent wood from a nanoporous cellulosic template: Combining functional and structural performance. Biomacromolecules 2016, 17, 1358–1364. [Google Scholar] [CrossRef]

- Yano, H. Potential strength for resin-impregnated compressed wood. J. Mater. Sci. Lett. 2001, 20, 1127–1129. [Google Scholar] [CrossRef]

- Gan, W.; Xiao, S.; Gao, L.; Gao, R.; Li, J. Luminescent and transparent wood composites fabricated by poly (methyl methacrylate) and γ-Fe2O3@ YVO4: Eu3+ nanoparticle impregnation. ACS Sustain. Chem. Eng. 2017, 5, 3855–3862. [Google Scholar] [CrossRef]

- Zhu, M.; Wang, Y.; Zhu, S.; Xu, L.; Jia, C.; Dai, J.; Song, J.; Yao, Y.; Wang, Y.; Li, Y.; et al. Anisotropic, transparent films with aligned cellulose nanofibers. Adv. Mater. 2017, 29, 1606284. [Google Scholar] [CrossRef] [PubMed]

- Qiu, Z.; Wang, S.; Wang, Y.; Li, J.; Xiao, Z.; Wang, H.; Liang, D.; Xie, Y. Transparent wood with thermo-reversible optical properties based on phase-change material. Compos. Sci. Technol. 2020, 200, 108407. [Google Scholar] [CrossRef]

- Fang, Z.; Zhu, H.; Bao, W.; Preston, C.; Liu, Z.; Dai, J.; Li, Y.; Hu, L. Highly transparent paper with tunable haze for green electronics. Energy Environ. Sci. 2014, 7, 3313–3319. [Google Scholar] [CrossRef]

- Xia, Q.; Chen, C.; Li, T.; He, S.; Gao, J.; Wang, X.; Hu, L. Solar-assisted fabrication of large-scale, patternable transparent wood. Sci. Adv. 2021, 7, eabd7342. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Fu, Q.; Rojas, R.; Yan, M.; Lawoko, M.; Berglund, L. Lignin-retaining transparent wood. ChemSusChem 2017, 10, 3445–3451. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Y.; Cheng, M.; Jungstedt, E.; Xu, B.; Sun, L.; Berglund, L.A. Optically transparent wood substrate for perovskite solar cells. ACS Sustain. Chem. Eng. 2019, 7, 6061–6067. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Y.; Yang, F. Comparison of multilayer transparent wood and single layer transparent wood with the same thickness. Front. Mater. 2021, 8, 41. [Google Scholar] [CrossRef]

- Yin, Q.; Liu, H.H. Drying stress and strain of wood: A Review. Appl. Sci. 2021, 11, 5023. [Google Scholar] [CrossRef]

- Makarov, I.S.; Golova, L.K.; Bondarenko, G.N.; Anokhina, T.S.; Dmitrieva, E.S.; Levin, I.S.; Makhatova, V.E.; Galimova, N.Z.; Shambilova, G.K. Structure, morphology, and permeability of cellulose films. Membranes 2022, 12, 297. [Google Scholar] [CrossRef]

- Makarov, I.S.; Golova, L.K.; Smyslov, A.G.; Vinogradov, M.I.; Palchikova, E.E.; Legkov, S.A. Flax Noils as a Source of Cellulose for the Production of Lyocell Fibers. Fibers 2022, 10, 45. [Google Scholar] [CrossRef]

- French, A.D. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 2014, 21, 885–896. [Google Scholar] [CrossRef]

- Paulsson, M.; Simonson, R. Acetylation of lignin and photostabilization of lignin-rich mechanical wood pulp and paper. In Chemical Modification, Properties, and Usage of Lignin; Springer: Boston, MA, USA, 2002; pp. 221–245. [Google Scholar]

- Reyes-Rivera, J.; Terrazas, T. Lignin analysis by HPLC and FTIR. In Xylem; Humana Press: New York, NY, USA, 2017; pp. 193–211. [Google Scholar]

- Gierlinger, N.; Goswami, L.; Schmidt, M.; Burgert, I.; Coutand, C.; Rogge, T.; Schwanninger, M. In situ FT-IR microscopic study on enzymatic treatment of poplar wood cross-sections. Biomacromolecules 2008, 9, 2194–2201. [Google Scholar] [CrossRef] [PubMed]

- Derkacheva, O.; Sukhov, D. Investigation of lignins by FTIR spectroscopy. In Macromolecular Symposia; WILEY-VCH Verlag: Weinheim, Germany, 2008; Volume 265, pp. 61–68. [Google Scholar]

- González, M.G.; Cabanelas, J.C.; Baselga, J. Applications of FTIR on epoxy resins-identification, monitoring the curing process, phase separation and water uptake. Infrared Spectrosc.-Mater. Sci. Eng. Technol. 2012, 2, 261–284. [Google Scholar]

| Materials | Value | Properties |

|---|---|---|

| deionised water | - | - |

| ethanol | 99% | weight ratio |

| H2O2 | 30% | weight ratio |

| NH3 | 25% | weight ratio |

| resin | #128 | model |

| hardener | D230 | model |

| UV lamp | 30 W | power |

| UV lamp | 385–395 nm | wavelength |

| Groups | LC (wt %) | CC (wt %) | HC (wt %) |

|---|---|---|---|

| NW | 23.30 | 42.36 | 20.15 |

| DW-B | 17.63 | 43.50 | 18.69 |

| DW-B-U | 14.58 | 44.01 | 17.36 |

| DW-D | 7.78 | 45.22 | 17.94 |

| DW-D-U | 7.26 | 45.19 | 18.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Ge-Zhang, S.; Han, Y.; Yang, H.; Ou-Yang, W.; Zhu, H.; Hao, J.; Wang, J. Ultraviolet-Assisted Modified Delignified Wood with High Transparency. Appl. Sci. 2022, 12, 7406. https://doi.org/10.3390/app12157406

Chen X, Ge-Zhang S, Han Y, Yang H, Ou-Yang W, Zhu H, Hao J, Wang J. Ultraviolet-Assisted Modified Delignified Wood with High Transparency. Applied Sciences. 2022; 12(15):7406. https://doi.org/10.3390/app12157406

Chicago/Turabian StyleChen, Xiaoli, Shangjie Ge-Zhang, Yu Han, Hong Yang, Wenao Ou-Yang, Haotong Zhu, Junyi Hao, and Jinxin Wang. 2022. "Ultraviolet-Assisted Modified Delignified Wood with High Transparency" Applied Sciences 12, no. 15: 7406. https://doi.org/10.3390/app12157406

APA StyleChen, X., Ge-Zhang, S., Han, Y., Yang, H., Ou-Yang, W., Zhu, H., Hao, J., & Wang, J. (2022). Ultraviolet-Assisted Modified Delignified Wood with High Transparency. Applied Sciences, 12(15), 7406. https://doi.org/10.3390/app12157406