4D Printing of Multicomponent Shape-Memory Polymer Formulations

Abstract

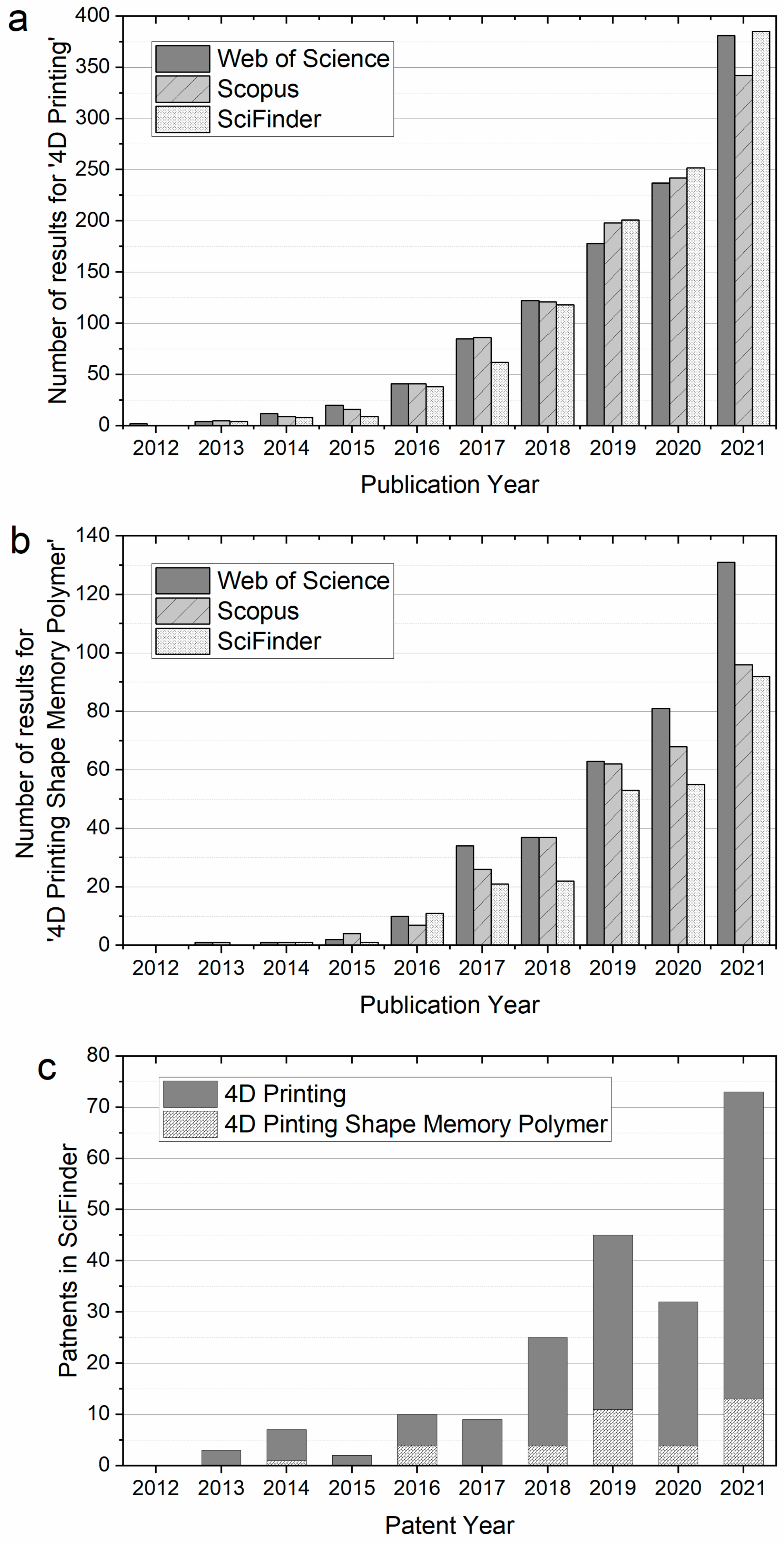

:1. Introduction

2. Multicomponent SMPs

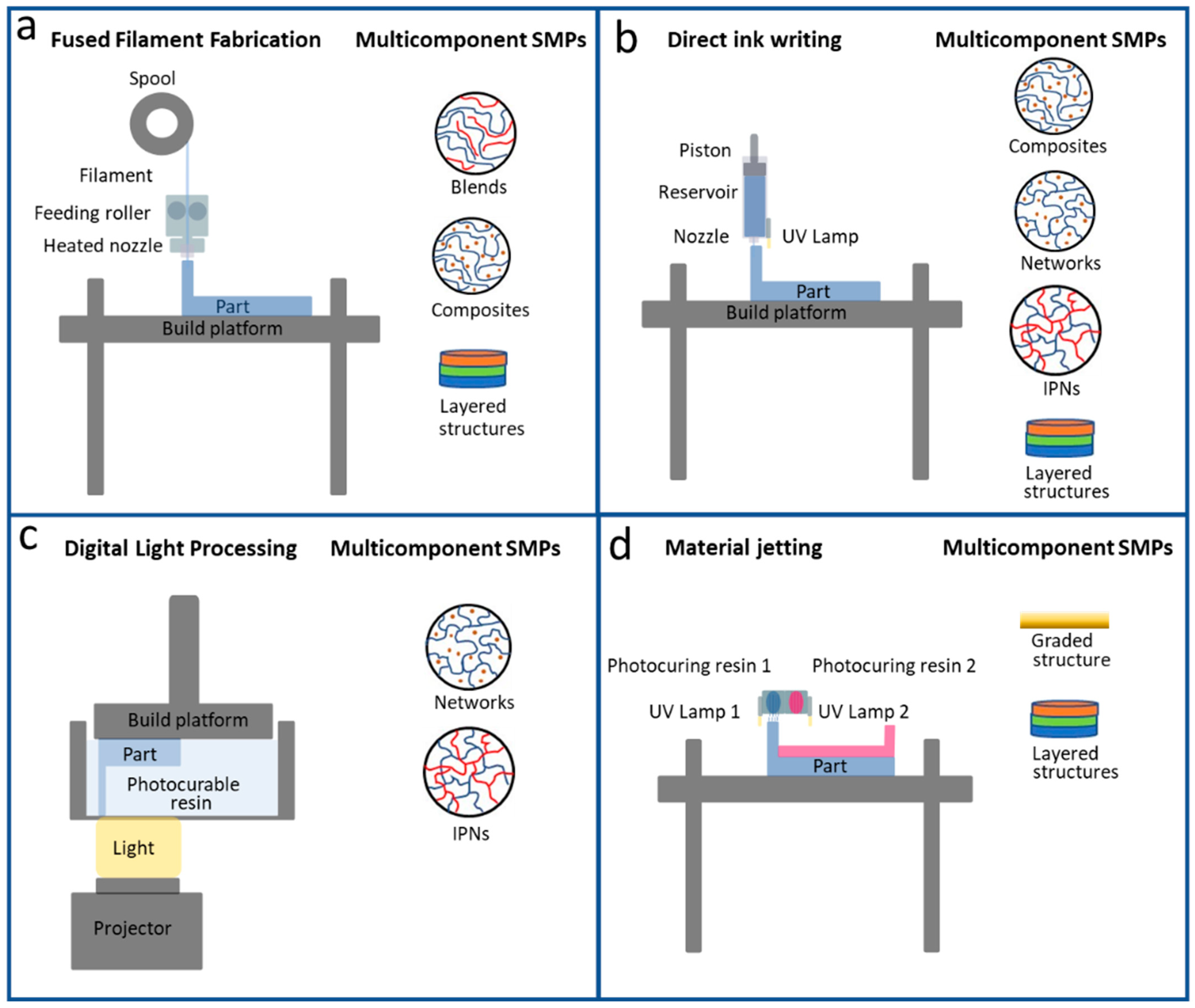

3. Extrusion Based 4D Printing

3.1. Fused Filament Fabrication (FFF)

3.1.1. FFF of Polymer–Polymer Blends

3.1.2. FFF of Polymer–Particulate Composites

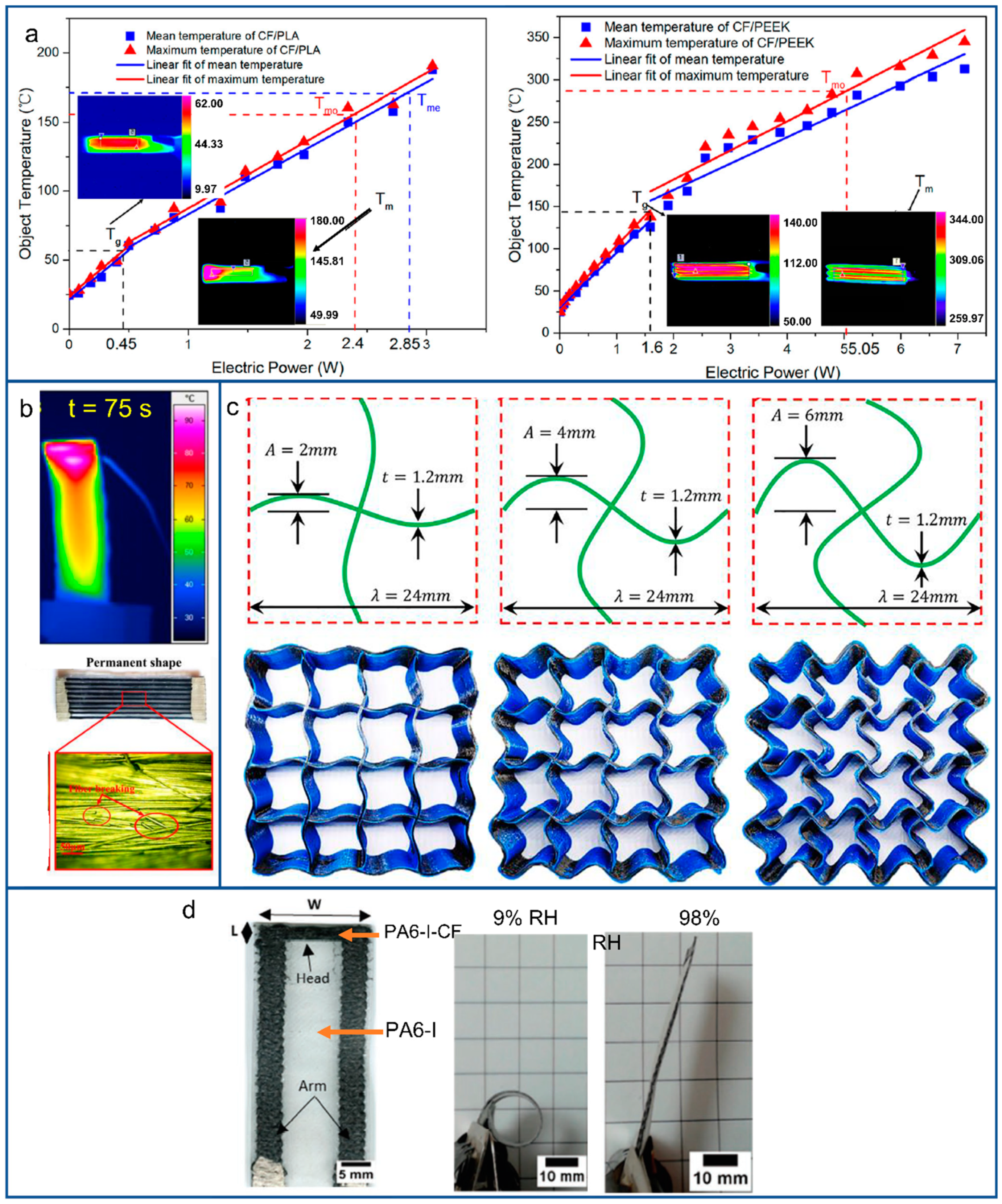

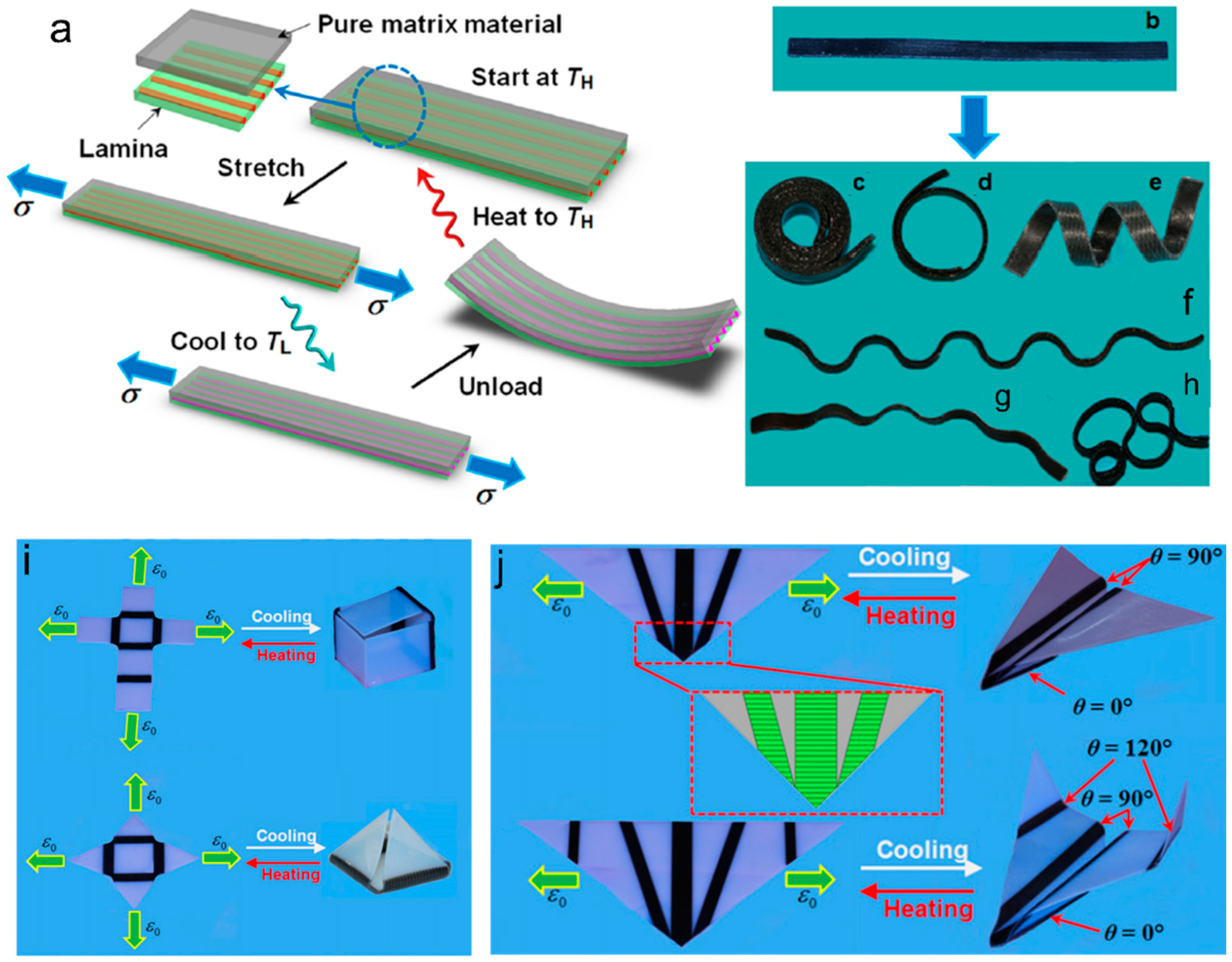

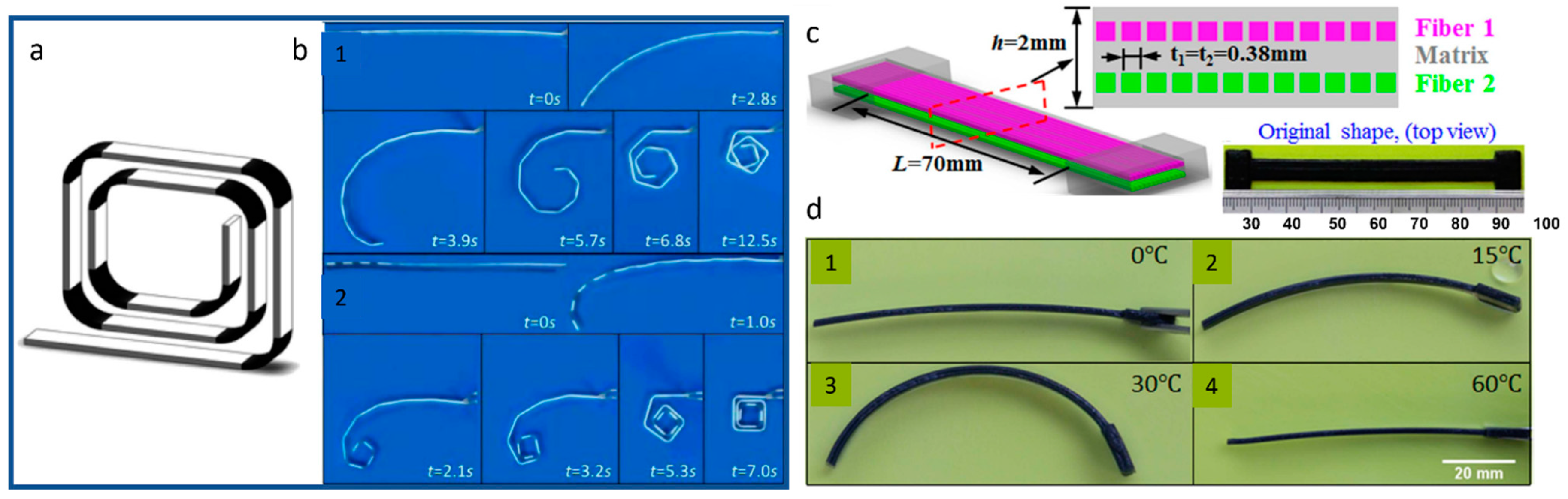

3.1.3. FFF of Continuous Fiber-Reinforced Composites

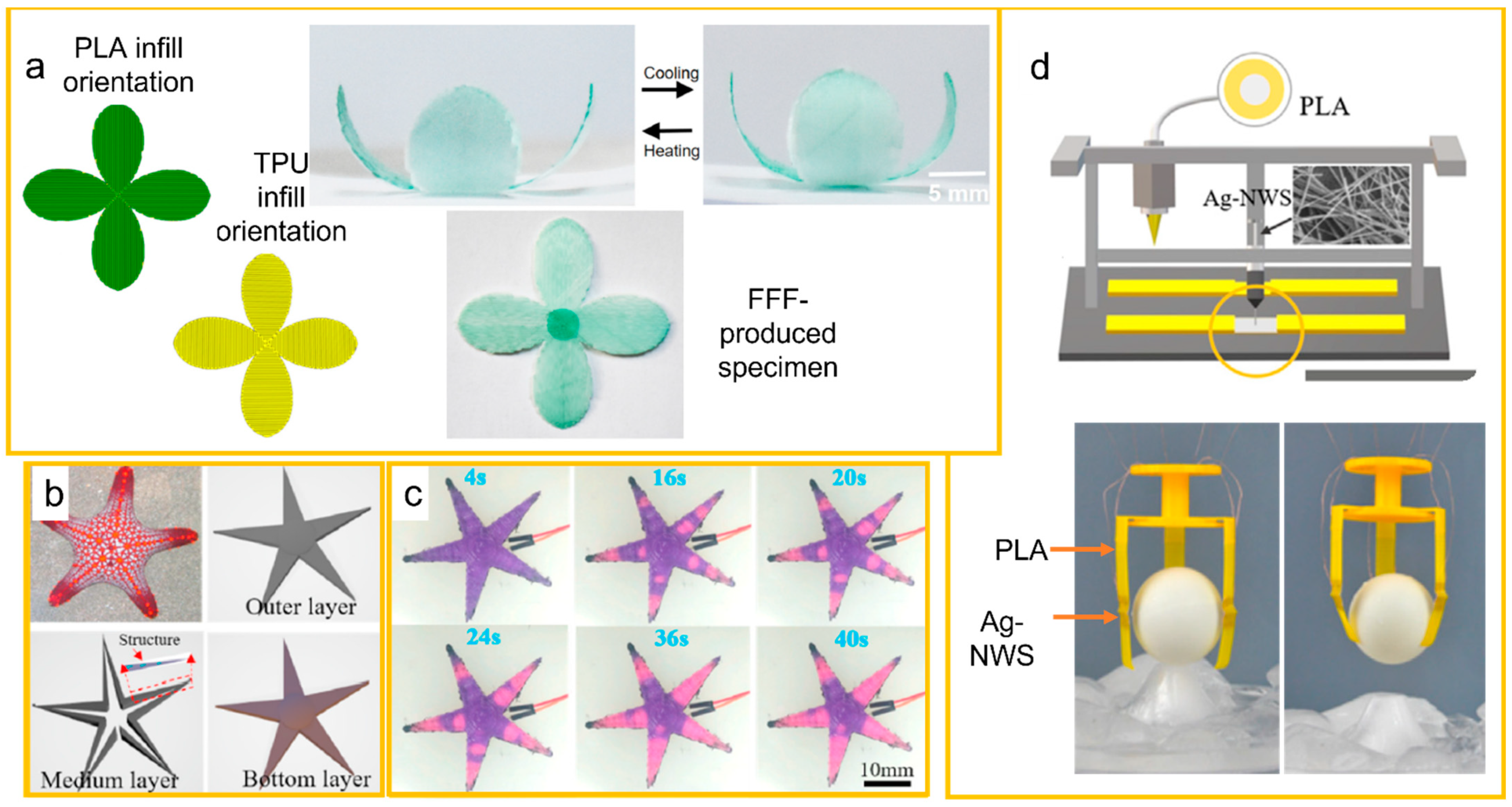

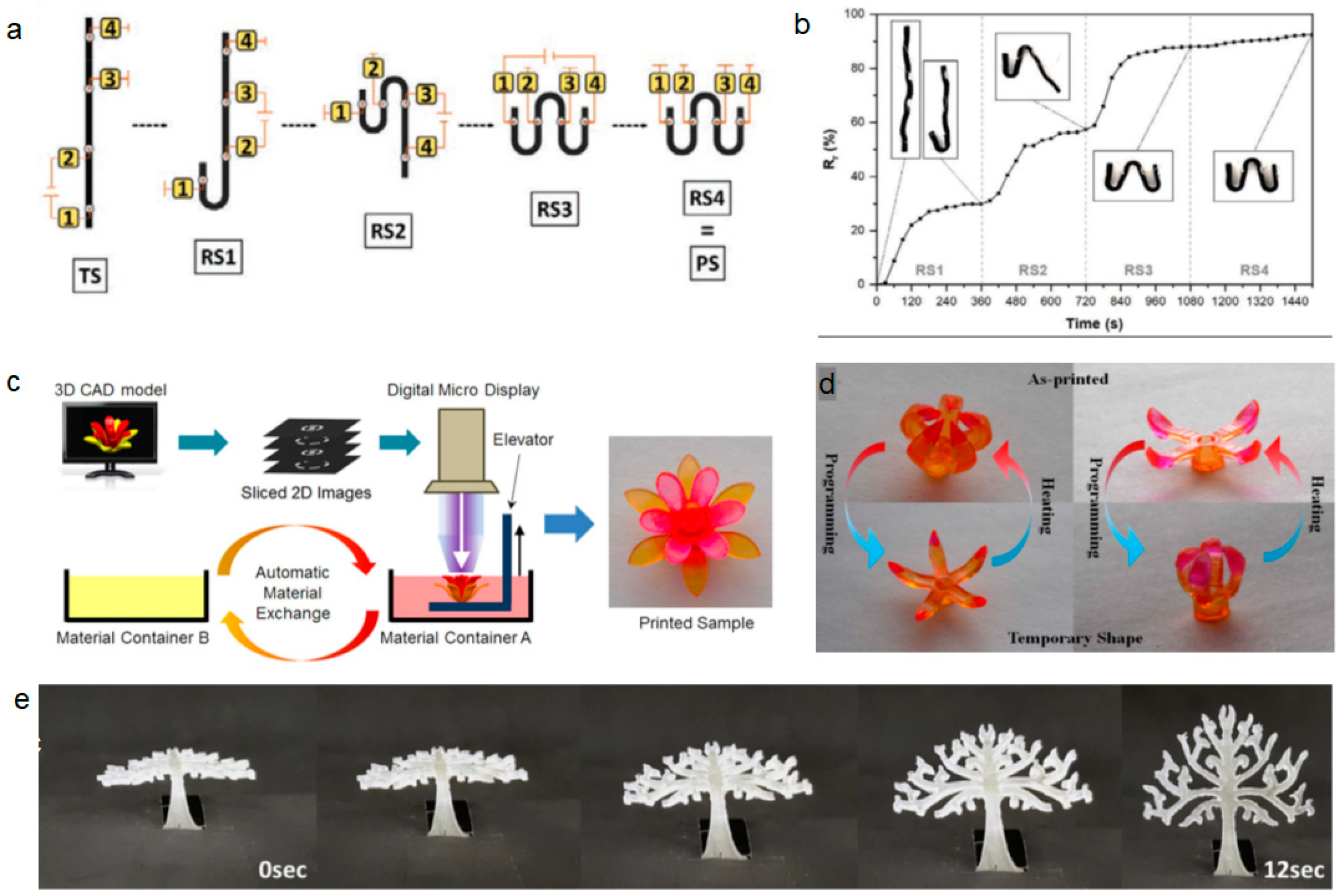

3.1.4. Three-Dimensional Objects Produced by Multiple Extrusion FFF

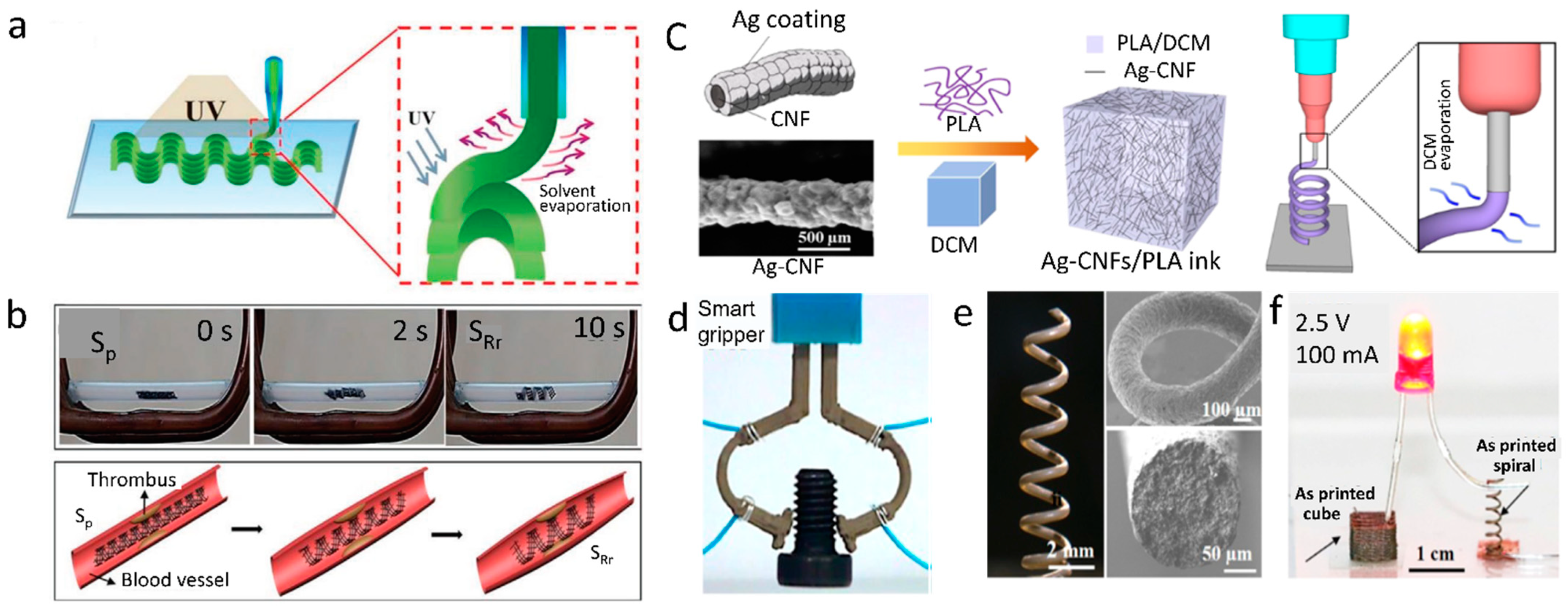

3.2. Direct Ink Writing

3.2.1. DIW of Thermoplastics in Solution

3.2.2. DIW of Liquid Pre-Polymers

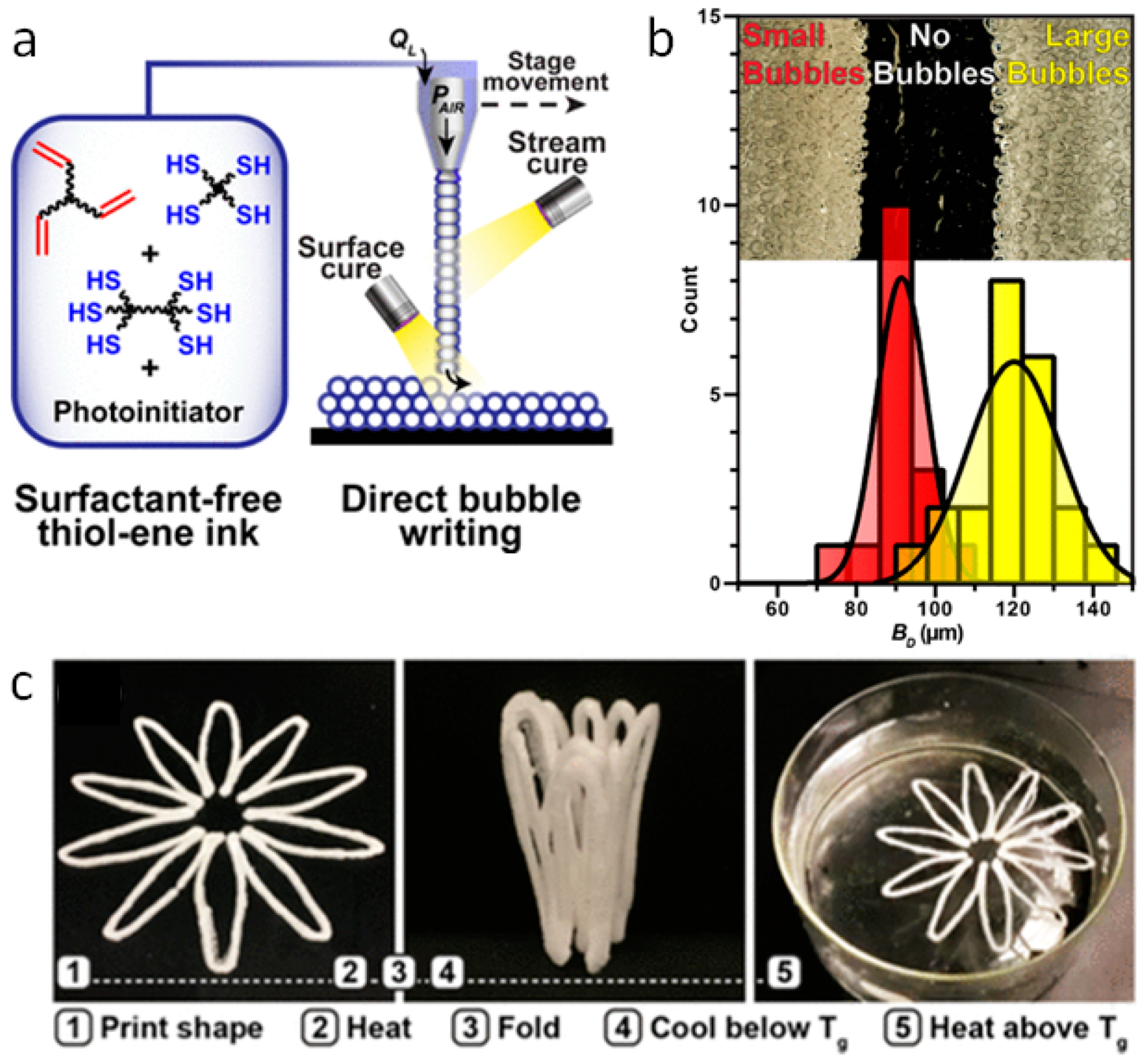

3.2.3. Generation of Porosity during DIW

4. Vat-Photopolymerization Based 4D Printing

4.1. Digital Light Processing (DLP) of trSMPs

4.2. Stereolithography (SLA) of trSMP

4.3. Multi-Photon Polymerization (MPP) of SMPs

5. Material Jetting (MJT) 4D Printing

6. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Behl, M.; Razzaq, M.Y.; Lendlein, A. Multifunctional Shape-Memory Polymers. Adv. Mater. 2010, 22, 3388–3410. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.; He, Y.; Zhang, F.; Liu, Y.; Leng, J. A Review of Shape Memory Polymers and Composites: Mechanisms, Materials, and Applications. Adv. Mater. 2020, 33, 2000713. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Liu, Y.; Leng, J. Recent developments in shape memory polymer nanocomposites: Actuation methods and mechanisms. Coord. Chem. Rev. 2016, 320–321, 38–52. [Google Scholar] [CrossRef]

- Gunes, I.S.; Jana, S.C. Shape memory polymers and their nanocomposites: A review of science and technology of new multifunctional materials. J. Nanosci. Nanotechnol. 2008, 8, 1616–1637. [Google Scholar] [CrossRef] [PubMed]

- Behl, M.; Lendlein, A. Shape-memory polymers. Mater. Today 2007, 10, 20–28. [Google Scholar] [CrossRef]

- Meng, Q.; Hu, J. A review of shape memory polymer composites and blends. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1661–1672. [Google Scholar] [CrossRef]

- Lendlein, A.; Kelch, S. Shape-memory polymers. Angew. Chem. Int. Ed. Engl. 2002, 41, 2035–2057. [Google Scholar] [CrossRef]

- Madbouly, S.A.; Lendlein, A. Shape-memory polymer composites. Shape-Mem. Polym. 2010, 226, 41–95. [Google Scholar]

- Zhao, Q.; Qi, H.J.; Xie, T. Recent progress in shape memory polymer: New behavior, enabling materials, and mechanistic understanding. Prog. Polym. Sci. 2015, 49–50, 79–120. [Google Scholar] [CrossRef] [Green Version]

- Meng, H.; Li, G. A review of stimuli-responsive shape memory polymer composites. Polymer 2013, 54, 2199–2221. [Google Scholar] [CrossRef] [Green Version]

- Sauter, T.; Heuchel, M.; Kratz, K.; Lendlein, A. Quantifying the Shape-Memory Effect of Polymers by Cyclic Thermomechanical Tests. Polym. Rev. 2013, 53, 6–40. [Google Scholar] [CrossRef]

- Lendlein, A.; Langer, R. Biodegradable, Elastic Shape-Memory Polymers for Potential Biomedical Applications. Science 2002, 296, 1673–1676. [Google Scholar] [CrossRef] [PubMed]

- Mather, P.T.; Luo, X.; Rousseau, I.A. Shape memory polymer research. Annu. Rev. Mater. Res. 2009, 39, 445–471. [Google Scholar] [CrossRef]

- Lei, M.; Chen, Z.; Lu, H.; Yu, K. Recent progress in shape memory polymer composites: Methods, properties, applications and prospects. Nanotechnol. Rev. 2019, 8, 327–351. [Google Scholar] [CrossRef]

- Barletta, M.; Gisario, A.; Mehrpouya, M. 4D printing of shape memory polylactic acid (PLA) components: Investigating the role of the operational parameters in fused deposition modelling (FDM). J. Manuf. Process. 2020, 61, 473–480. [Google Scholar] [CrossRef]

- Falahati, M.; Ahmadvand, P.; Safaee, S.; Chang, Y.-C.; Lyu, Z.; Chen, R.; Li, L.; Lin, Y. Smart polymers and nanocomposites for 3D and 4D printing. Mater. Today 2020, 40, 215–245. [Google Scholar] [CrossRef]

- Tan, L.J.; Zhu, W.; Zhou, K. Recent Progress on Polymer Materials for Additive Manufacturing. Adv. Funct. Mater. 2020, 30, 2003062. [Google Scholar] [CrossRef]

- de Leon, A.C.; Chen, Q.; Palaganas, N.B.; Palaganas, J.O.; Manapat, J.; Advincula, R.C. High performance polymer nanocomposites for additive manufacturing applications. React. Funct. Polym. 2016, 103, 141–155. [Google Scholar] [CrossRef]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Kuang, X.; Roach, D.J.; Wu, J.; Hamel, C.M.; Ding, Z.; Wang, T.; Dunn, M.L.; Qi, H.J. Advances in 4D Printing: Materials and Applications. Adv. Funct. Mater. 2018, 29, 1805290. [Google Scholar] [CrossRef]

- Joshi, S.; Rawat, K.; Karunakaran, C.; Rajamohan, V.; Mathew, A.T.; Koziol, K.; Thakur, V.K.; Balan, A. 4D printing of materials for the future: Opportunities and challenges. Appl. Mater. Today 2019, 18, 100490. [Google Scholar] [CrossRef]

- Simske, S.; Vans, M.; Loucks, B. Incremental information objects and progressive barcodes. In Proceedings of the NIP & Digital Fabrication Conference, Quebec City, QC, Canada, 9–13 September 2012; pp. 375–377. [Google Scholar]

- Ge, Q.; Qi, H.J.; Dunn, M.L. Active materials by four-dimension printing. Appl. Phys. Lett. 2013, 103, 131901. [Google Scholar] [CrossRef]

- Alshebly, Y.S.; Nafea, M.; Ali, M.S.M.; Almurib, H.A. Review on recent advances in 4D printing of shape memory polymers. Eur. Polym. J. 2021, 159, 110708. [Google Scholar] [CrossRef]

- Leist, S.K.; Gao, D.; Chiou, R.; Zhou, J. Investigating the shape memory properties of 4D printed polylactic acid (PLA) and the concept of 4D printing onto nylon fabrics for the creation of smart textiles. Virtual Phys. Prototyp. 2017, 12, 290–300. [Google Scholar] [CrossRef]

- Monzón, M.D.; Paz, R.; Pei, E.; Ortega, F.; Suárez, L.A.; Ortega, Z.; Alemán, M.E.; Plucinski, T.; Clow, N. 4D printing: Processability and measurement of recovery force in shape memory polymers. Int. J. Adv. Manuf. Technol. 2016, 89, 1827–1836. [Google Scholar] [CrossRef] [Green Version]

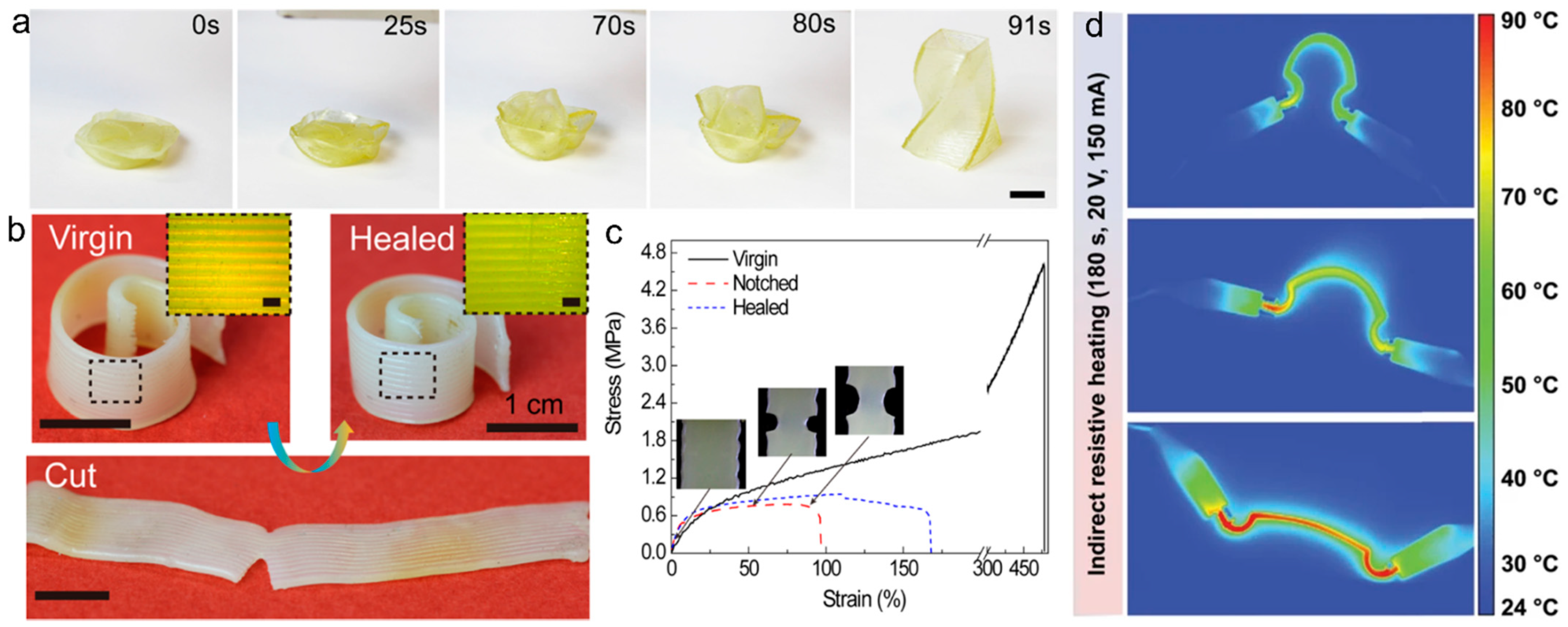

- Peng, B.; Yang, Y.; Ju, T.; Cavicchi, K.A. Fused Filament Fabrication 4D Printing of a Highly Extensible, Self-Healing, Shape Memory Elastomer Based on Thermoplastic Polymer Blends. ACS Appl. Mater. Interfaces 2020, 13, 12777–12788. [Google Scholar] [CrossRef]

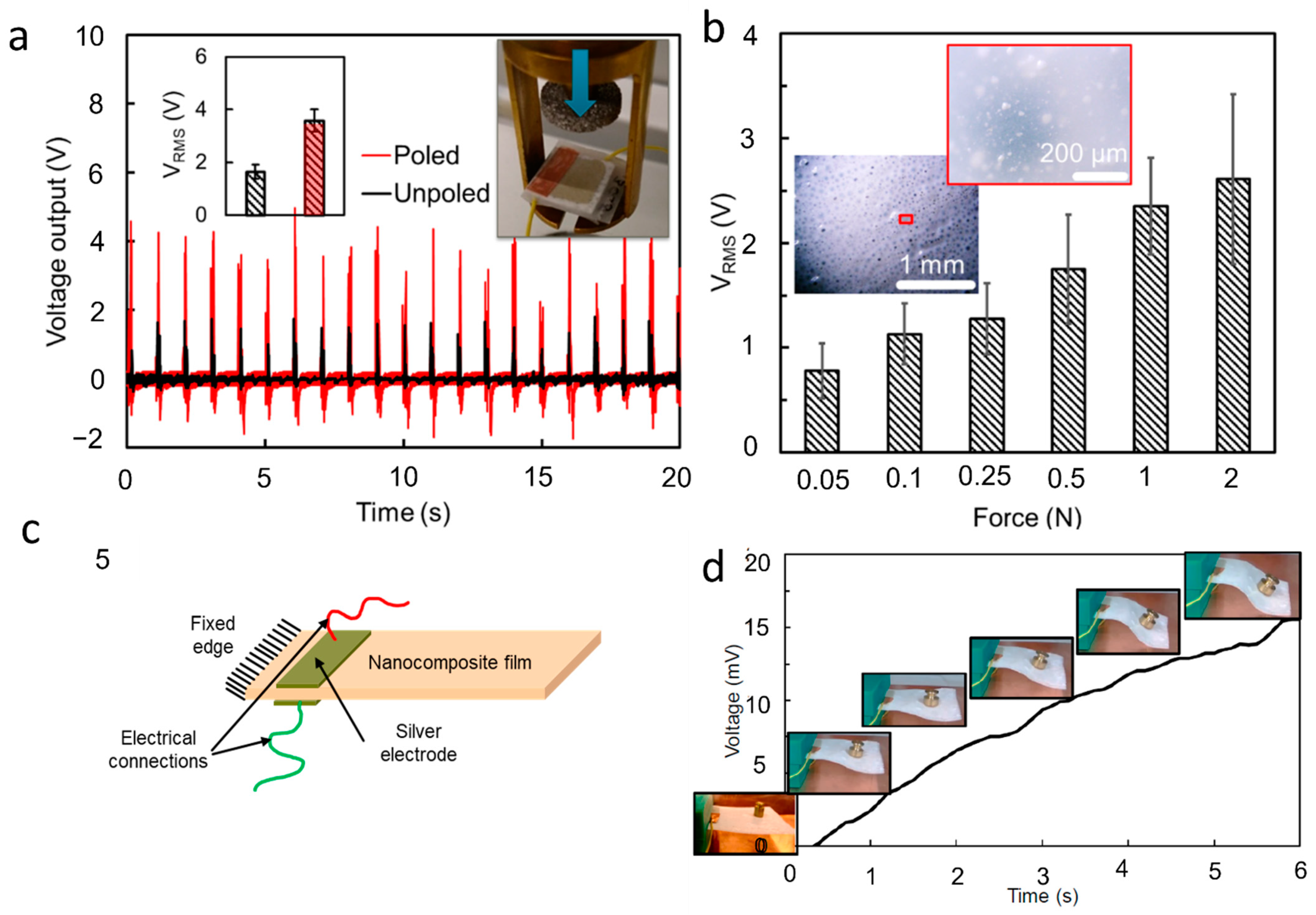

- Bodkhe, S.; Ermanni, P. 3D printing of multifunctional materials for sensing and actuation: Merging piezoelectricity with shape memory. Eur. Polym. J. 2020, 132, 109738. [Google Scholar] [CrossRef]

- Chen, K.; Zhang, L.; Kuang, X.; Li, V.; Lei, M.; Kang, G.; Wang, Z.L.; Qi, H.J. Dynamic Photomask-Assisted Direct Ink Writing Multimaterial for Multilevel Triboelectric Nanogenerator. Adv. Funct. Mater. 2019, 29, 1903568. [Google Scholar] [CrossRef]

- Goo, B.; Hong, C.-H.; Park, K. 4D printing using anisotropic thermal deformation of 3D-printed thermoplastic parts. Mater. Des. 2020, 188, 108485. [Google Scholar] [CrossRef]

- Mao, Y.; Yu, K.; Isakov, M.S.; Wu, J.; Dunn, M.L.; Qi, H.J. Sequential Self-Folding Structures by 3D Printed Digital Shape Memory Polymers. Sci. Rep. 2015, 5, 13616. [Google Scholar] [CrossRef]

- Yang, H.; Leow, W.R.; Wang, T.; Wang, J.; Yu, J.; He, K.; Qi, D.; Wan, C.; Chen, X. 3D Printed Photoresponsive Devices Based on Shape Memory Composites. Adv. Mater. 2017, 29, 1701627. [Google Scholar] [CrossRef] [PubMed]

- Zeng, C.; Liu, L.; Bian, W.; Liu, Y.; Leng, J. 4D printed electro-induced continuous carbon fiber reinforced shape memory polymer composites with excellent bending resistance. Compos. Part B Eng. 2020, 194, 108034. [Google Scholar] [CrossRef]

- Razzaq, M.Y.; Behl, M.; Kratz, K.; Lendlein, A. Multifunctional Hybrid Nanocomposites with Magnetically Controlled Reversible Shape-Memory Effect. Adv. Mater. 2013, 25, 5730–5733. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.; Zhang, H.; Xu, S.; Gui, X.; Wei, H.; Leng, J.; Koratkar, N.; Zhong, J. Fast Triggering of Shape Memory Polymers using an Embedded Carbon Nanotube Sponge Network. Sci. Rep. 2016, 6, 24148. [Google Scholar] [CrossRef] [PubMed]

- Salimon, A.; Senatov, F.; Kalyaev, V.; Korsunsky, A. Shape memory polymer blends and composites for 3D and 4D printing applications. In 3D and 4D Printing of Polymer Nanocomposite Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 161–189. [Google Scholar] [CrossRef]

- Keneth, E.S.; Lieberman, R.; Rednor, M.; Scalet, G.; Auricchio, F.; Magdassi, S. Multi-Material 3D Printed Shape Memory Polymer with Tunable Melting and Glass Transition Temperature Activated by Heat or Light. Polymers 2020, 12, 710. [Google Scholar] [CrossRef] [Green Version]

- Rafiee, M.; Farahani, R.D.; Therriault, D. Multi-material 3D and 4D printing: A survey. Adv. Sci. 2020, 7, 1902307. [Google Scholar] [CrossRef]

- Li, Z.; Esling, C. Multifunctional behaviors in meta-magnetic shape-memory microwires. IUCrJ 2019, 6, 784–785. [Google Scholar] [CrossRef] [Green Version]

- Ma, L.; Wang, J.; He, J.; Yao, Y.; Zhu, X.; Peng, L.; Yang, J.; Liu, X.; Qu, M. Biotemplated Fabrication of a Multifunctional Superwettable Shape Memory Film for Wearable Sensing Electronics and Smart Liquid Droplet Manipulation. ACS Appl. Mater. Interfaces 2021, 13, 31285–31297. [Google Scholar] [CrossRef]

- Ready, S.; Whiting, G.; Ng, T.N. Multi-material 3D printing. In Proceedings of the NIP & Digital Fabrication Conference, Philadelphia, PA, USA, 7–11 September 2014; pp. 120–123. [Google Scholar]

- Lopes, L.; Silva, A.; Carneiro, O. Multi-material 3D printing: The relevance of materials affinity on the boundary interface performance. Addit. Manuf. 2018, 23, 45–52. [Google Scholar] [CrossRef]

- Skylar-Scott, M.A.; Mueller, J.; Visser, C.W.; Lewis, J.A. Voxelated soft matter via multimaterial multinozzle 3D printing. Nature 2019, 575, 330–335. [Google Scholar] [CrossRef]

- Patadiya, J.; Gawande, A.; Joshi, G.; Kandasubramanian, B. Additive Manufacturing of Shape Memory Polymer Composites for Futuristic Technology. Ind. Eng. Chem. Res. 2021, 60, 15885–15912. [Google Scholar] [CrossRef]

- Demoly, F.; Dunn, M.L.; Wood, K.L.; Qi, H.J.; André, J.-C. The status, barriers, challenges, and future in design for 4D printing. Mater. Des. 2021, 212, 110193. [Google Scholar] [CrossRef]

- Chowdhury, J.; Anirudh, P.V.; Karunakaran, C.; Rajmohan, V.; Mathew, A.T.; Koziol, K.; Alsanie, W.F.; Kannan, C.; Balan, A.S.S.; Thakur, V.K. 4D Printing of Smart Polymer Nanocomposites: Integrating Graphene and Acrylate Based Shape Memory Polymers. Polymers 2021, 13, 3660. [Google Scholar] [CrossRef] [PubMed]

- Kuang, X.; Chen, K.; Dunn, C.K.; Wu, J.; Li, V.C.F.; Qi, H.J. 3D Printing of Highly Stretchable, Shape-Memory, and Self-Healing Elastomer toward Novel 4D Printing. ACS Appl. Mater. Interfaces 2018, 10, 7381–7388. [Google Scholar] [CrossRef] [PubMed]

- Platzer, N. Multicomponent Polymer Systems. In Applied Polymer Science; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 1985; Volume 285, pp. 219–237. [Google Scholar]

- Miles, I.S.; Rostami, S. Multicomponent Polymer Systems; Longman Scientific & Technical: London, UK, 1992. [Google Scholar]

- Ze, Q.; Kuang, X.; Wu, S.; Wong, J.; Montgomery, S.M.; Zhang, R.; Kovitz, J.M.; Yang, F.; Qi, H.J.; Zhao, R. Magnetic Shape Memory Polymers with Integrated Multifunctional Shape Manipulation. Adv. Mater. 2019, 32, e1906657. [Google Scholar] [CrossRef] [PubMed]

- Leng, J.; Du, S. Shape-Memory Polymers and Multifunctional Composites; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Razzaq, M.Y.; Anhalt, M.; Frormann, L.; Weidenfeller, B. Thermal, electrical and magnetic studies of magnetite filled polyurethane shape memory polymers. Mater. Sci. Eng. A 2007, 444, 227–235. [Google Scholar] [CrossRef]

- Leng, J.; Lau, A.K.-T. Multifunctional Polymer Nanocomposites; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- He, Y.-J.; Shao, Y.-W.; Xiao, Y.-Y.; Yang, J.-H.; Qi, X.-D.; Wang, Y. Multifunctional Phase Change Composites Based on Elastic MXene/Silver Nanowire Sponges for Excellent Thermal/Solar/Electric Energy Storage, Shape Memory, and Adjustable Electromagnetic Interference Shielding Functions. ACS Appl. Mater. Interfaces 2022, 14, 6057–6070. [Google Scholar] [CrossRef]

- Curtis, P. Multifunctional polymer composites. Adv. Perform. Mater. 1996, 3, 279–293. [Google Scholar] [CrossRef]

- Kulshreshtha, A.K.; Vasile, C. Handbook of Polymer Blends and Composites; iSmithers Rapra Publishing: Akron, OH, USA, 2002; Volume 1. [Google Scholar]

- Lipatov, Y.S. Polymer blends and interpenetrating polymer networks at the interface with solids. Prog. Polym. Sci. 2002, 27, 1721–1801. [Google Scholar] [CrossRef]

- Kuila, B.K.; Formanek, P.; Stamm, M. Multilayer polymer thin films for fabrication of ordered multifunctional polymer nanocomposites. Nanoscale 2013, 5, 10849–10852. [Google Scholar] [CrossRef]

- Zheng, Y.; Dong, R.; Shen, J.; Guo, S. Tunable Shape Memory Performances via Multilayer Assembly of Thermoplastic Polyurethane and Polycaprolactone. ACS Appl. Mater. Interfaces 2016, 8, 1371–1380. [Google Scholar] [CrossRef] [PubMed]

- Sadasivuni, K.K.; Deshmukh, K.; Al-Maadeed, M.A.S. 3D and 4D Printing of Polymer Nanocomposite Materials: Processes, Applications, and Challenges; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Roudbarian, N.; Baniasadi, M.; Nayyeri, P.; Ansari, M.; Hedayati, R.; Baghani, M. Enhancing shape memory properties of multi-layered and multi-material polymer composites in 4D printing. Smart Mater. Struct. 2021, 30, 105006. [Google Scholar] [CrossRef]

- Cao, L.; Wang, L.; Zhou, C.; Chunhua, L.; Fang, L.; Ni, Y.; Lu, C.; Xu, Z. Surface Structures, Particles, and Fibers of Shape-Memory Polymers at Micro-/Nanoscale. Adv. Polym. Technol. 2020, 2020, 7639724. [Google Scholar] [CrossRef]

- Lee, W.L.; Low, H.Y. Geometry- and Length Scale-Dependent Deformation and Recovery on Micro- and Nanopatterned Shape Memory Polymer Surfaces. Sci. Rep. 2016, 6, 23686. [Google Scholar] [CrossRef]

- Chen, D.; Liu, Q.; Geng, P.; Tang, S.; Zhang, J.; Wen, S.; Zhou, Y.; Yan, C.; Han, Z.; Shi, Y. A 4D printing strategy and integrated design for programmable electroactive shape-color double-responsive bionic functions. Compos. Sci. Technol. 2021, 208, 108746. [Google Scholar] [CrossRef]

- Garces, I.T.; Ayranci, C. Advances in additive manufacturing of shape memory polymer composites. Rapid Prototyp. J. 2021, 27, 379–398. [Google Scholar] [CrossRef]

- Singh, S.; Singh, G.; Prakash, C.; Ramakrishna, S. Current status and future directions of fused filament fabrication. J. Manuf. Process. 2020, 55, 288–306. [Google Scholar] [CrossRef]

- Valvez, S.; Reis, P.; Susmel, L.; Berto, F. Fused Filament Fabrication-4D-Printed Shape Memory Polymers: A Review. Polymers 2021, 13, 701. [Google Scholar] [CrossRef]

- He, F.; Khan, M. Effects of Printing Parameters on the Fatigue Behaviour of 3D-Printed ABS under Dynamic Thermo-Mechanical Loads. Polymers 2021, 13, 2362. [Google Scholar] [CrossRef] [PubMed]

- Gibson, I.; Rosen, D.; Stucker, B. Vat photopolymerization processes. In Additive Manufacturing Technologies; Springer: Berlin, Germany, 2015; pp. 63–106. [Google Scholar]

- Elomaa, L.; Teixeira, S.; Hakala, R.; Korhonen, H.; Grijpma, D.W.; Seppälä, J.V. Preparation of poly(ε-caprolactone)-based tissue engineering scaffolds by stereolithography. Acta Biomater. 2011, 7, 3850–3856. [Google Scholar] [CrossRef]

- Cortés, A.; Cosola, A.; Sangermano, M.; Campo, M.; Prolongo, S.G.; Pirri, C.F.; Jiménez-Suárez, A.; Chiappone, A. DLP 4D-Printing of Remotely, Modularly, and Selectively Controllable Shape Memory Polymer Nanocomposites Embedding Carbon Nanotubes. Adv. Funct. Mater. 2021, 31, 2106774. [Google Scholar] [CrossRef]

- Al Rashid, A.; Ahmed, W.; Khalid, M.Y.; Koç, M. Vat photopolymerization of polymers and polymer composites: Processes and applications. Addit. Manuf. 2021, 47, 102279. [Google Scholar] [CrossRef]

- Malas, A.; Isakov, D.; Couling, K.; Gibbons, G.J. Fabrication of High Permittivity Resin Composite for Vat Photopolymerization 3D Printing: Morphology, Thermal, Dynamic Mechanical and Dielectric Properties. Materials 2019, 12, 3818. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, F.; Zhu, L.; Li, Z.; Wang, S.; Shi, J.; Tang, W.; Li, N.; Yang, J. The recent development of vat photopolymerization: A review. Addit. Manuf. 2021, 48, 102423. [Google Scholar] [CrossRef]

- Kamble, P.P.; Chavan, S.; Hodgir, R.; Gote, G.; Karunakaran, K. Multi-jet ice 3D printing. Rapid Prototyp. J. 2021, 28, 989–1004. [Google Scholar] [CrossRef]

- Udroiu, R.; Braga, I.C. Polyjet technology applications for rapid tooling. In Proceedings of the MATEC Web of Conferences, Sibiu, Romania, 7–9 June 2017; p. 03011. [Google Scholar] [CrossRef] [Green Version]

- Ge, Q.; Dunn, C.K.; Qi, H.J.; Dunn, M.L. Active origami by 4D printing. Smart Mater. Struct. 2014, 23, 094007. [Google Scholar] [CrossRef]

- Crump, S. Apparatus and Method for Creating Three-Dimensional Objects. U.S. Patent 5121329, 2 March 1989. [Google Scholar]

- Stratasys. Legal Documents-Legal Information. Stratasys.com. 2021. Available online: https://www.stratasys.com/legal/legal-information (accessed on 7 December 2021).

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap–the replicating rapid prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef] [Green Version]

- Ecker, J.V.; Dobrezberger, K.; Gonzalez-Gutierrez, J.; Spoerk, M.; Gierl-Mayer, C.; Danninger, H. Additive Manufacturing of Steel and Copper Using Fused Layer Modelling: Material and Process Development. Powder Met. Prog. 2019, 19, 63–81. [Google Scholar] [CrossRef]

- Nastase-Dan, C.; Paul, S.; Ion, G.G. 3D Complex Structures through Layer Plastic Deposition Designed for Carbon Material Impregnation. INCAS Bull. 2018, 10, 65–74. [Google Scholar] [CrossRef]

- van Manen, T.; Janbaz, S.; Zadpoor, A.A. Programming 2D/3D shape-shifting with hobbyist 3D printers. Mater. Horiz. 2017, 4, 1064–1069. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Zhang, F.; Leng, J.; Chou, T.-W. Microstructural design of 4D printed angle-ply laminated strips with tunable shape memory properties. Mater. Lett. 2020, 285, 129197. [Google Scholar] [CrossRef]

- Hua, D.; Zhang, X.; Ji, Z.; Yan, C.; Yu, B.; Li, Y.; Wang, X.; Zhou, F. 3D printing of shape changing composites for constructing flexible paper-based photothermal bilayer actuators. J. Mater. Chem. C 2018, 6, 2123–2131. [Google Scholar] [CrossRef]

- Melocchi, A.; Inverardi, N.; Uboldi, M.; Baldi, F.; Maroni, A.; Pandini, S.; Briatico-Vangosa, F.; Zema, L.; Gazzaniga, A. Retentive device for intravesical drug delivery based on water-induced shape memory response of poly(vinyl alcohol): Design concept and 4D printing feasibility. Int. J. Pharm. 2019, 559, 299–311. [Google Scholar] [CrossRef]

- Loh, G.H.; Pei, E.; Gonzalez-Gutierrez, J.; Monzón, M. An Overview of Material Extrusion Troubleshooting. Appl. Sci. 2020, 10, 4776. [Google Scholar] [CrossRef]

- Spoerk, M.; Holzer, C.; Gonzalez-Gutierrez, J. Material extrusion-based additive manufacturing of polypropylene: A review on how to improve dimensional inaccuracy and warpage. J. Appl. Polym. Sci. 2019, 137, 48545. [Google Scholar] [CrossRef]

- Liu, J.; Li, W.; Guo, Y.; Zhang, H.; Zhang, Z. Improved thermal conductivity of thermoplastic polyurethane via aligned boron nitride platelets assisted by 3D printing. Compos. Part A Appl. Sci. Manuf. 2019, 120, 140–146. [Google Scholar] [CrossRef]

- Kwok, S.W.; Hin, K.; Goh, H.; Tan, Z.D.; Tan, S.T.M.; Tjiu, W.W.; Soh, J.Y.; Ng, Z.J.G.; Chan, Y.Z.; Hui, H.K.; et al. Electrically conductive filament for 3D-printed circuits and sensors. Appl. Mater. Today 2017, 9, 167–175. [Google Scholar] [CrossRef]

- Huber, C.; Cano, S.; Teliban, I.; Schuschnigg, S.; Groenefeld, M.; Suess, D. Polymer-bonded anisotropic SrFe12O19filaments for fused filament fabrication. J. Appl. Phys. 2020, 127, 063904. [Google Scholar] [CrossRef] [Green Version]

- Le Duigou, A.; Correa, D.; Ueda, M.; Matsuzaki, R.; Castro, M. A review of 3D and 4D printing of natural fibre biocomposites. Mater. Des. 2020, 194, 108911. [Google Scholar] [CrossRef]

- Viidik, L.; Vesala, J.; Laitinen, R.; Korhonen, O.; Ketolainen, J.; Aruväli, J.; Kirsimäe, K.; Kogermann, K.; Heinämäki, J.; Laidmäe, I.; et al. Preparation and characterization of hot-melt extruded polycaprolactone-based filaments intended for 3D-printing of tablets. Eur. J. Pharm. Sci. 2020, 158, 105619. [Google Scholar] [CrossRef]

- Jing, X.; Mi, H.-Y.; Peng, X.-F.; Turng, L.-S. The morphology, properties, and shape memory behavior of polylactic acid/thermoplastic polyurethane blends. Polym. Eng. Sci. 2014, 55, 70–80. [Google Scholar] [CrossRef]

- Leng, J.; Wu, J.; Zhang, J. Preparation of Thermoplastic Polyurethane Parts Reinforced with in Situ Polylactic Acid Microfibers during Fused Deposition Modeling: The Influences of Deposition-Induced Effects. Ind. Eng. Chem. Res. 2019, 58, 21476–21484. [Google Scholar] [CrossRef]

- Jiang, Y.; Leng, J.; Zhang, J. A high-efficiency way to improve the shape memory property of 4D-printed polyurethane/polylactide composite by forming in situ microfibers during extrusion-based additive manufacturing. Addit. Manuf. 2020, 38, 101718. [Google Scholar] [CrossRef]

- Lin, C.; Liu, L.; Liu, Y.; Leng, J. 4D printing of shape memory polybutylene succinate/polylactic acid (PBS/PLA) and its potential applications. Compos. Struct. 2021, 279, 114729. [Google Scholar] [CrossRef]

- Wang, G.; Cheng, T.; Do, Y.; Yang, H.; Tao, Y.; Gu, J.; An, B.; Yao, L. Printed paper actuator: A low-cost reversible actuation and sensing method for shape changing interfaces. In Proceedings of the Conference on Human Factors in Computing Systems, Montreal, QC, Canada, 21–26 April 2018; pp. 1–12. [Google Scholar] [CrossRef]

- Al-Rubaiai, M.; Pinto, T.; Qian, C.; Tan, X. Soft Actuators with Stiffness and Shape Modulation Using 3D-Printed Conductive Polylactic Acid Material. Soft Robot. 2019, 6, 318–332. [Google Scholar] [CrossRef]

- Tirado-Garcia, I.; Garcia-Gonzalez, D.; Garzon-Hernandez, S.; Rusinek, A.; Robles, G.; Martinez-Tarifa, J.; Arias, A. Conductive 3D printed PLA composites: On the interplay of mechanical, electrical and thermal behaviours. Compos. Struct. 2021, 265, 113744. [Google Scholar] [CrossRef]

- Lin, C.; Lv, J.; Li, Y.; Zhang, F.; Li, J.; Liu, Y.; Liu, L.; Leng, J. 4D-Printed Biodegradable and Remotely Controllable Shape Memory Occlusion Devices. Adv. Funct. Mater. 2019, 29, 1906569. [Google Scholar] [CrossRef]

- Zhao, W.; Zhang, F.; Leng, J.; Liu, Y. Personalized 4D printing of bioinspired tracheal scaffold concept based on magnetic stimulated shape memory composites. Compos. Sci. Technol. 2019, 184, 107866. [Google Scholar] [CrossRef]

- Hosseinnezhad, R.; Vozniak, I.; Zaïri, F. In Situ Generation of Green Hybrid Nanofibrillar Polymer-Polymer Composites—A Novel Approach to the Triple Shape Memory Polymer Formation. Polymers 2021, 13, 1900. [Google Scholar] [CrossRef]

- Yang, C.; Wang, B.; Li, D.; Tian, X. Modelling and characterisation for the responsive performance of CF/PLA and CF/PEEK smart materials fabricated by 4D printing. Virtual Phys. Prototyp. 2017, 12, 69–76. [Google Scholar] [CrossRef]

- Pu, J.; Saleh, E.; Ashcroft, I.; Jones, A. Technique for processing of continuous carbon fibre reinforced peek for fused filament fabrication. In Proceedings of the 2019 Annual International Solid Freeform Fabrication, Austin, TX, USA, 12–14 August 2019; pp. 1041–1053. [Google Scholar]

- Zeng, C.; Liu, L.; Bian, W.; Leng, J.; Liu, Y. Temperature-dependent mechanical response of 4D printed composite lattice structures reinforced by continuous fiber. Compos. Struct. 2021, 280, 114952. [Google Scholar] [CrossRef]

- Le Duigou, A.; Chabaud, G.; Scarpa, F.; Castro, M. Bioinspired Electro-Thermo-Hygro Reversible Shape-Changing Materials by 4D Printing. Adv. Funct. Mater. 2019, 29, 1903280. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X. 4D-printed bi-material composite laminate for manufacturing reversible shape-change structures. Compos. Part B Eng. 2021, 219, 108918. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Z.; Song, Z.; Ren, L.; Liu, Q.; Ren, L. Biomimetic Shape–Color Double-Responsive 4D Printing. Adv. Mater. Technol. 2019, 4, 1900293. [Google Scholar] [CrossRef]

- Shao, L.-H.; Zhao, B.; Zhang, Q.; Xing, Y.; Zhang, K. 4D printing composite with electrically controlled local deformation. Extrem. Mech. Lett. 2020, 39, 100793. [Google Scholar] [CrossRef]

- Wan, X.; Luo, L.; Liu, Y.; Leng, J. Direct Ink Writing Based 4D Printing of Materials and Their Applications. Adv. Sci. 2020, 7, 2001000. [Google Scholar] [CrossRef]

- Pinargote, N.; Smirnov, A.; Peretyagin, N.; Seleznev, A.; Peretyagin, P. Direct Ink Writing Technology (3D Printing) of Graphene-Based Ceramic Nanocomposites: A Review. Nanomaterials 2020, 10, 1300. [Google Scholar] [CrossRef]

- Choong, Y.Y.C.; Maleksaeedi, S.; Eng, H.; Wei, J.; Su, P.-C. 4D printing of high performance shape memory polymer using stereolithography. Mater. Des. 2017, 126, 219–225. [Google Scholar] [CrossRef]

- Guo, S.-Z.; Gosselin, F.; Guerin, N.; Lanouette, A.-M.; Heuzey, M.-C.; Therriault, D. Solvent-Cast Three-Dimensional Printing of Multifunctional Microsystems. Small 2013, 9, 4118–4122. [Google Scholar] [CrossRef]

- Wei, H.; Zhang, Q.; Yao, Y.; Liu, L.; Liu, Y.; Leng, J. Direct-Write Fabrication of 4D Active Shape-Changing Structures Based on a Shape Memory Polymer and Its Nanocomposite. ACS Appl. Mater. Interfaces 2016, 9, 876–883. [Google Scholar] [CrossRef]

- Wei, H.; Cauchy, X.; Navas, I.O.; Abderrafai, Y.; Chizari, K.; Sundararaj, U.; Liu, Y.; Leng, J.; Therriault, D. Direct 3D Printing of Hybrid Nanofiber-Based Nanocomposites for Highly Conductive and Shape Memory Applications. ACS Appl. Mater. Interfaces 2019, 11, 24523–24532. [Google Scholar] [CrossRef] [PubMed]

- Wan, X.; Zhang, F.; Liu, Y.; Leng, J. CNT-based electro-responsive shape memory functionalized 3D printed nanocomposites for liquid sensors. Carbon 2019, 155, 77–87. [Google Scholar] [CrossRef]

- Wang, Y.-J.; Jeng, U.-S.; Hsu, S.-H. Biodegradable Water-Based Polyurethane Shape Memory Elastomers for Bone Tissue Engineering. ACS Biomater. Sci. Eng. 2018, 4, 1397–1406. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, J.N.; Zhu, C.; Duoss, E.B.; Wilson, T.; Spadaccini, C.M.; Lewicki, J.P. Shape-morphing composites with designed micro-architectures. Sci. Rep. 2016, 6, 27933. [Google Scholar] [CrossRef] [Green Version]

- Chen, K.; Kuang, X.; Li, V.; Kang, G.; Qi, H.J. Fabrication of tough epoxy with shape memory effects by UV-assisted direct-ink write printing. Soft Matter 2018, 14, 1879–1886. [Google Scholar] [CrossRef]

- Tang, Z.; Gong, J.; Cao, P.; Tao, L.; Pei, X.; Wang, T.; Zhang, Y.; Wang, Q.; Zhang, J. 3D printing of a versatile applicability shape memory polymer with high strength and high transition temperature. Chem. Eng. J. 2021, 431, 134211. [Google Scholar] [CrossRef]

- Amato, D.N.; Amato, D.V.; Sandoz, M.; Weigand, J.; Patton, D.L.; Visser, C.W. Programmable Porous Polymers via Direct Bubble Writing with Surfactant-Free Inks. ACS Appl. Mater. Interfaces 2020, 12, 42048–42055. [Google Scholar] [CrossRef] [PubMed]

- Wu, A.S.; Small IV, W.; Bryson, T.M.; Cheng, E.; Metz, T.R.; Schulze, S.E.; Duoss, E.B.; Wilson, T.S. 3D printed silicones with shape memory. Sci. Rep. 2017, 7, 4664. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ng, W.L.; Lee, J.M.; Zhou, M.; Chen, Y.-W.; Lee, K.-X.A.; Yeong, W.Y.; Shen, Y.-F. Vat polymerization-based bioprinting—process, materials, applications and regulatory challenges. Biofabrication 2019, 12, 022001. [Google Scholar] [CrossRef]

- González, G.; Baruffaldi, D.; Martinengo, C.; Angelini, A.; Chiappone, A.; Roppolo, I.; Pirri, C.; Frascella, F. Materials Testing for the Development of Biocompatible Devices through Vat-Polymerization 3D Printing. Nanomaterials 2020, 10, 1788. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, L.; Song, H.; Ni, C.; Wu, J.; Zhao, Q.; Xie, T. 4D Printing of a Digital Shape Memory Polymer with Tunable High Performance. ACS Appl. Mater. Interfaces 2019, 11, 32408–32413. [Google Scholar] [CrossRef]

- Ge, Q.; Sakhaei, A.H.; Lee, H.; Dunn, C.K.; Fang, N.X.; Dunn, M.L. Multimaterial 4D Printing with Tailorable Shape Memory Polymers. Sci. Rep. 2016, 6, 31110. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Choong, Y.Y.C.; Maleksaeedi, S.; Eng, H.; Yu, S.; Wei, J.; Su, P.-C. High speed 4D printing of shape memory polymers with nanosilica. Appl. Mater. Today 2019, 18, 100515. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, W.; Zhang, Z.; Zhang, Y.-F.; Hingorani, H.; Liu, Z.; Liu, J.; Ge, Q. Self-Healing Four-Dimensional Printing with an Ultraviolet Curable Double-Network Shape Memory Polymer System. ACS Appl. Mater. Interfaces 2019, 11, 10328–10336. [Google Scholar] [CrossRef]

- Medellin, A.; Du, W.; Miao, G.; Zou, J.; Pei, Z.; Ma, C. Vat Photopolymerization 3D Printing of Nanocomposites: A Literature Review. J. Micro Nano-Manuf. 2019, 7, 031006. [Google Scholar] [CrossRef]

- Miao, S.; Zhu, W.; Castro, N.J.; Nowicki, M.; Zhou, X.; Cui, H.; Fisher, J.P.; Zhang, L.G. 4D printing smart biomedical scaffolds with novel soybean oil epoxidized acrylate. Sci. Rep. 2016, 6, 27226. [Google Scholar] [CrossRef] [Green Version]

- Selimis, A.; Mironov, V.; Farsari, M. Direct laser writing: Principles and materials for scaffold 3D printing. Microelectron. Eng. 2015, 132, 83–89. [Google Scholar] [CrossRef]

- Kuebler, S.M.; Xia, C.; Yang, G.; Sharma, R.; Martinez, N.P.; Rumpf, R.C.; Touma, J. 3D printing functional nano-photonic devices by multi-photon lithography. In Proceedings of the Conference: Novel Patterning Technologies for Semiconductors, MEMS/NEMS and MOEMS 2019, San Jose, CA, USA, 25–28 February 2019; pp. 8–15. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, H.; Wang, H.; Chan, J.Y.E.; Liu, H.; Zhang, B.; Zhang, Y.-F.; Agarwal, K.; Yang, X.; Ranganath, A.S.; et al. Structural multi-colour invisible inks with submicron 4D printing of shape memory polymers. Nat. Commun. 2021, 12, 112. [Google Scholar] [CrossRef] [PubMed]

- De Marco, C.; Alcântara, C.C.J.; Kim, S.; Briatico, F.; Kadioglu, A.; De Bernardis, G.; Chen, X.; Marano, C.; Nelson, B.J.; Pané, S. Indirect 3D and 4D Printing of Soft Robotic Microstructures. Adv. Mater. Technol. 2019, 4, 1900332. [Google Scholar] [CrossRef] [Green Version]

- Maniruzzaman, M. 3D and 4D Printing in Biomedical Applications: Process Engineering and Additive Manufacturing; John Wiley & Sons: New York, NY, USA, 2019. [Google Scholar]

- Keating, S.J.; Gariboldi, M.I.; Patrick, W.G.; Sharma, S.; Kong, D.S.; Oxman, N. 3D Printed Multimaterial Microfluidic Valve. PLoS ONE 2016, 11, e0160624. [Google Scholar] [CrossRef]

- Ubaid, J.; Wardle, B.L.; Kumar, S. Strength and Performance Enhancement of Multilayers by Spatial Tailoring of Adherend Compliance and Morphology via Multimaterial Jetting Additive Manufacturing. Sci. Rep. 2018, 8, 13592. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, J.; Yuan, C.; Ding, Z.; Isakov, M.; Mao, Y.; Wang, T.; Dunn, M.L.; Qi, H.J. Multi-shape active composites by 3D printing of digital shape memory polymers. Sci. Rep. 2016, 6, 24224. [Google Scholar] [CrossRef] [PubMed]

- Biswas, M.C.; Chakraborty, S.; Bhattacharjee, A.; Mohammed, Z. 4D Printing of Shape Memory Materials for Textiles: Mechanism, Mathematical Modeling, and Challenges. Adv. Funct. Mater. 2021, 31, 2100257. [Google Scholar] [CrossRef]

- Behl, M.; Kratz, K.; Zotzmann, J.; Nöchel, U.; Lendlein, A. Reversible Bidirectional Shape-Memory Polymers. Adv. Mater. 2013, 25, 4466–4469. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Lu, X.; Fei, G.; Wang, Z.; Xia, H.; Zhao, Y. 4D Printing of a Liquid Crystal Elastomer with a Controllable Orientation Gradient. ACS Appl. Mater. Interfaces 2019, 11, 44774–44782. [Google Scholar] [CrossRef]

- Piedra-Cascón, W.; Krishnamurthy, V.R.; Att, W.; Revilla-León, M. 3D printing parameters, supporting structures, slicing, and post-processing procedures of vat-polymerization additive manufacturing technologies: A narrative review. J. Dent. 2021, 109, 103630. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Razzaq, M.Y.; Gonzalez-Gutierrez, J.; Mertz, G.; Ruch, D.; Schmidt, D.F.; Westermann, S. 4D Printing of Multicomponent Shape-Memory Polymer Formulations. Appl. Sci. 2022, 12, 7880. https://doi.org/10.3390/app12157880

Razzaq MY, Gonzalez-Gutierrez J, Mertz G, Ruch D, Schmidt DF, Westermann S. 4D Printing of Multicomponent Shape-Memory Polymer Formulations. Applied Sciences. 2022; 12(15):7880. https://doi.org/10.3390/app12157880

Chicago/Turabian StyleRazzaq, Muhammad Yasar, Joamin Gonzalez-Gutierrez, Gregory Mertz, David Ruch, Daniel F. Schmidt, and Stephan Westermann. 2022. "4D Printing of Multicomponent Shape-Memory Polymer Formulations" Applied Sciences 12, no. 15: 7880. https://doi.org/10.3390/app12157880

APA StyleRazzaq, M. Y., Gonzalez-Gutierrez, J., Mertz, G., Ruch, D., Schmidt, D. F., & Westermann, S. (2022). 4D Printing of Multicomponent Shape-Memory Polymer Formulations. Applied Sciences, 12(15), 7880. https://doi.org/10.3390/app12157880