Parameter Optimization and Experimental Study on Tool-Vibration-Assisted Pulsed Electrochemical Machining of γ-TiAl TNM Blades

Abstract

:1. Introduction

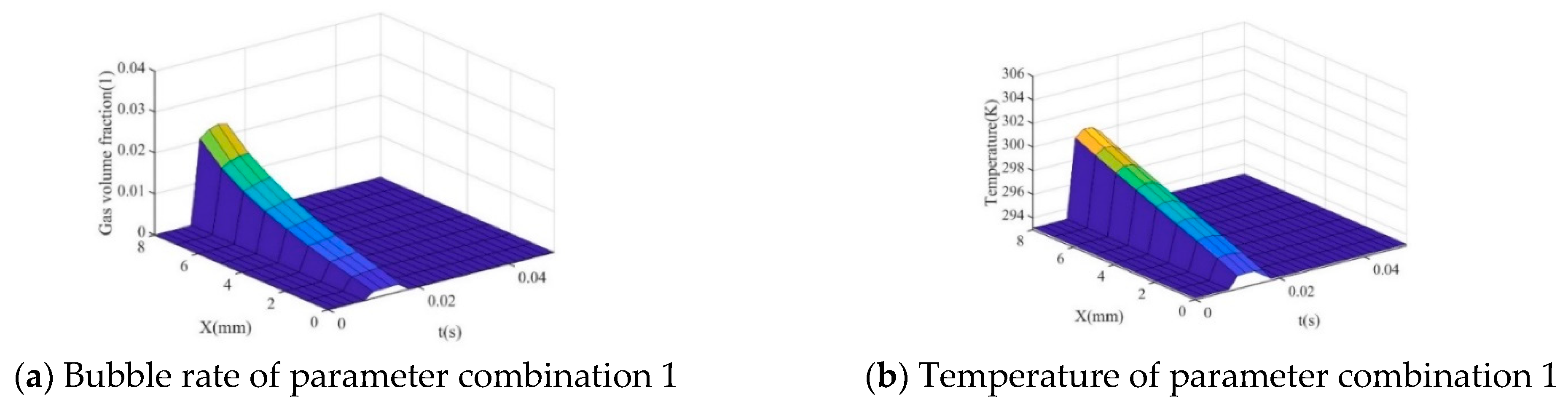

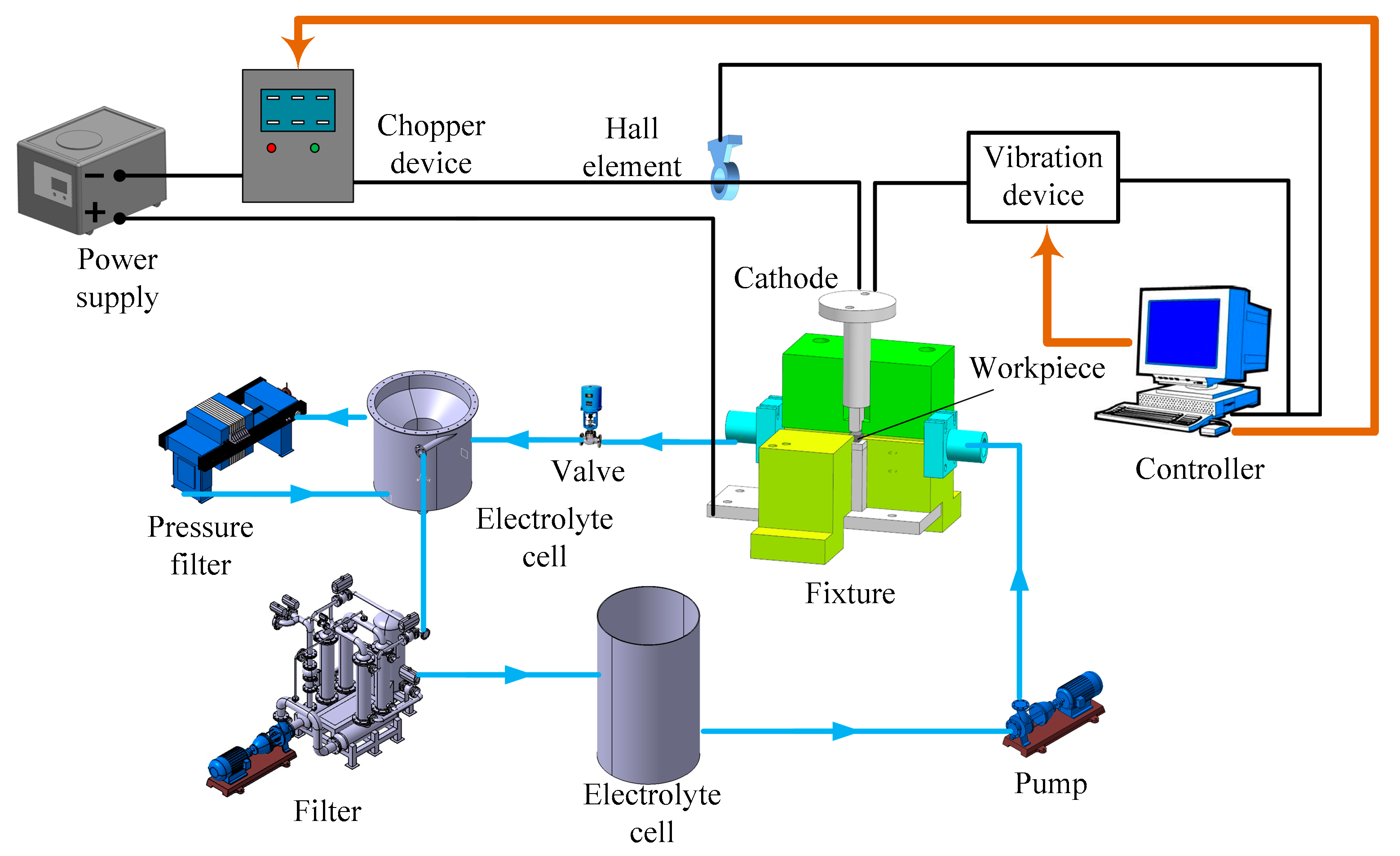

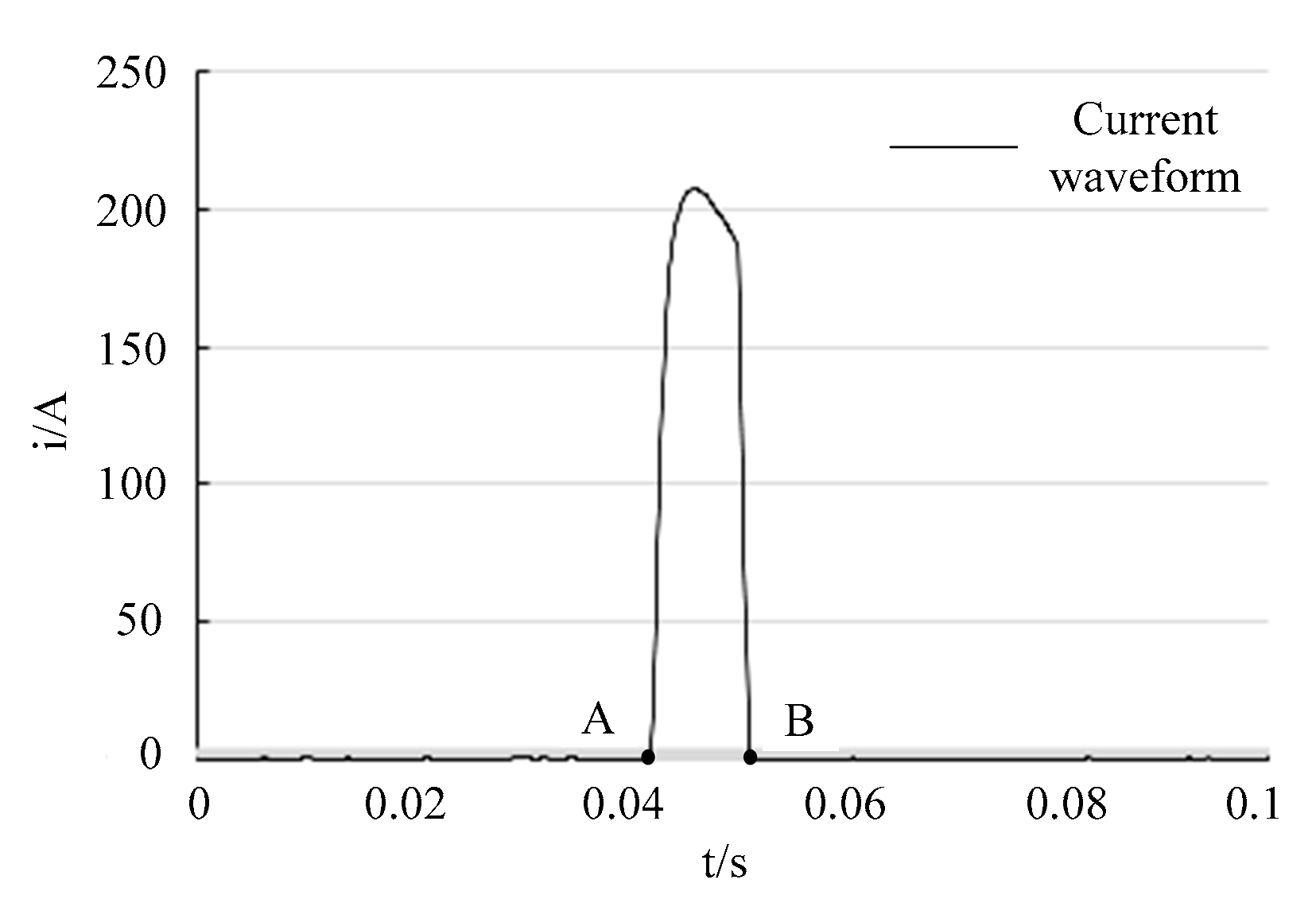

2. Principle and Multi-Field Simulation of VPECM

3. Experiments

3.1. Expreimental Equipment

3.2. Orthogonal Experiment

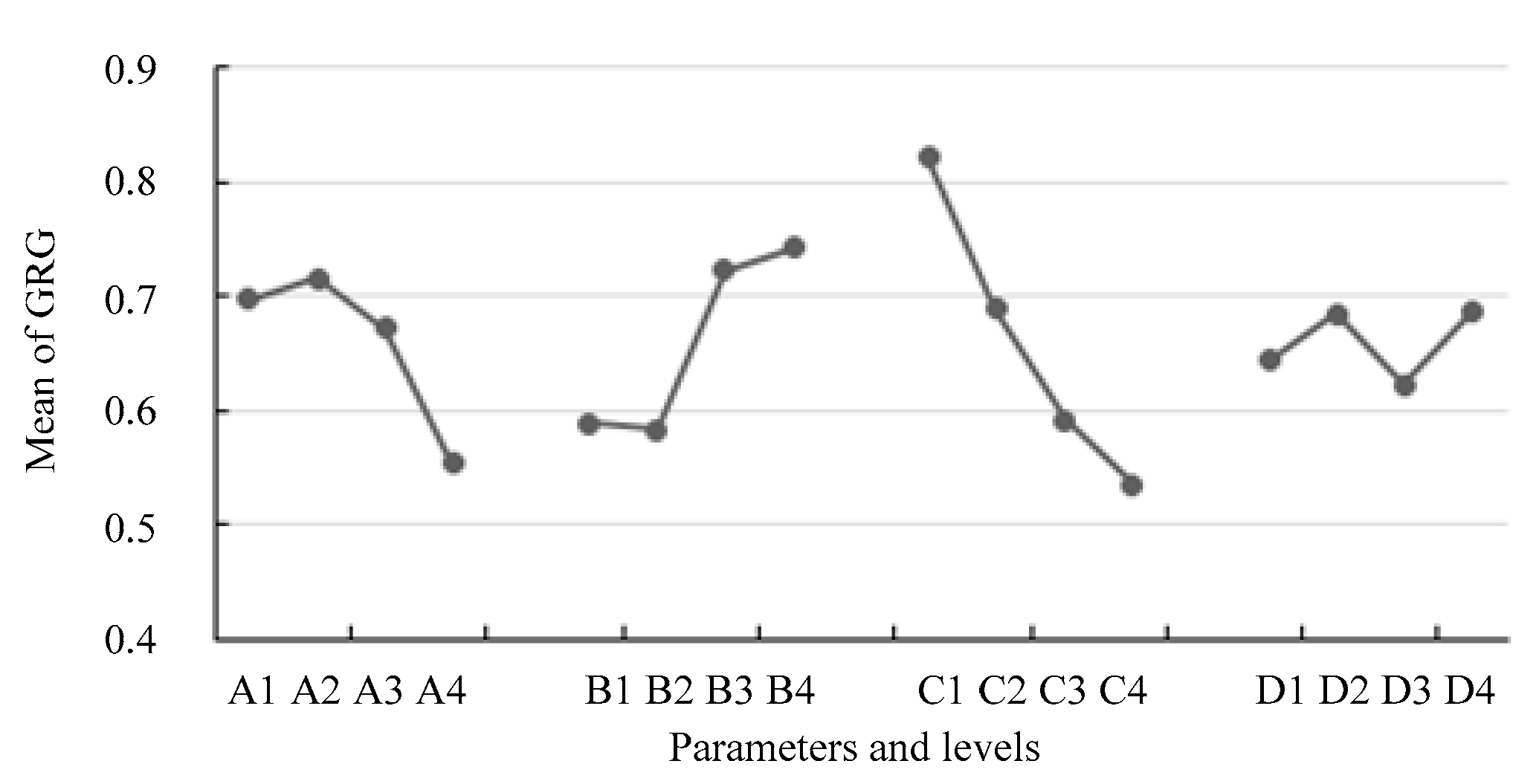

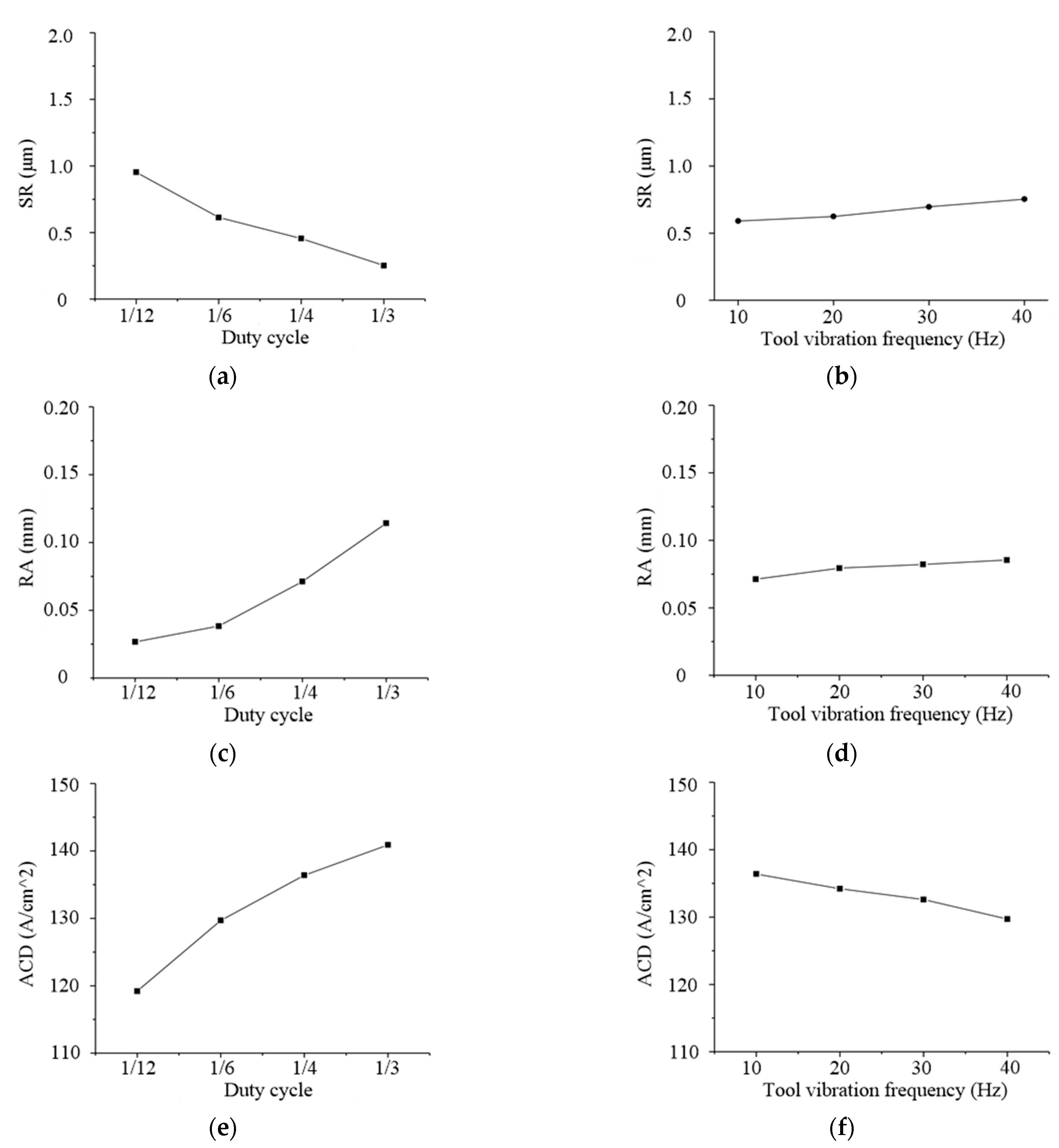

3.3. Experimental Results and Grey Relational Analysis

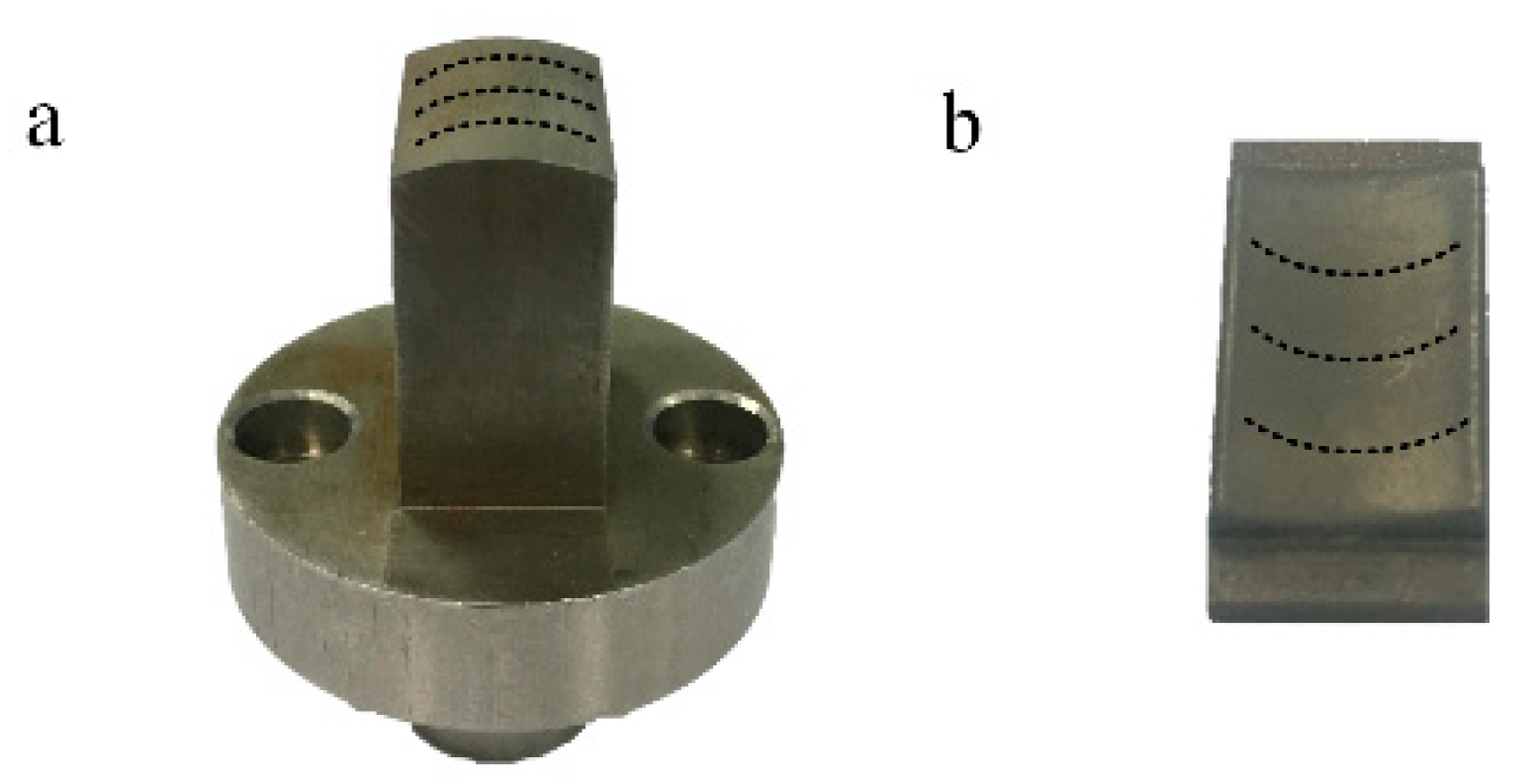

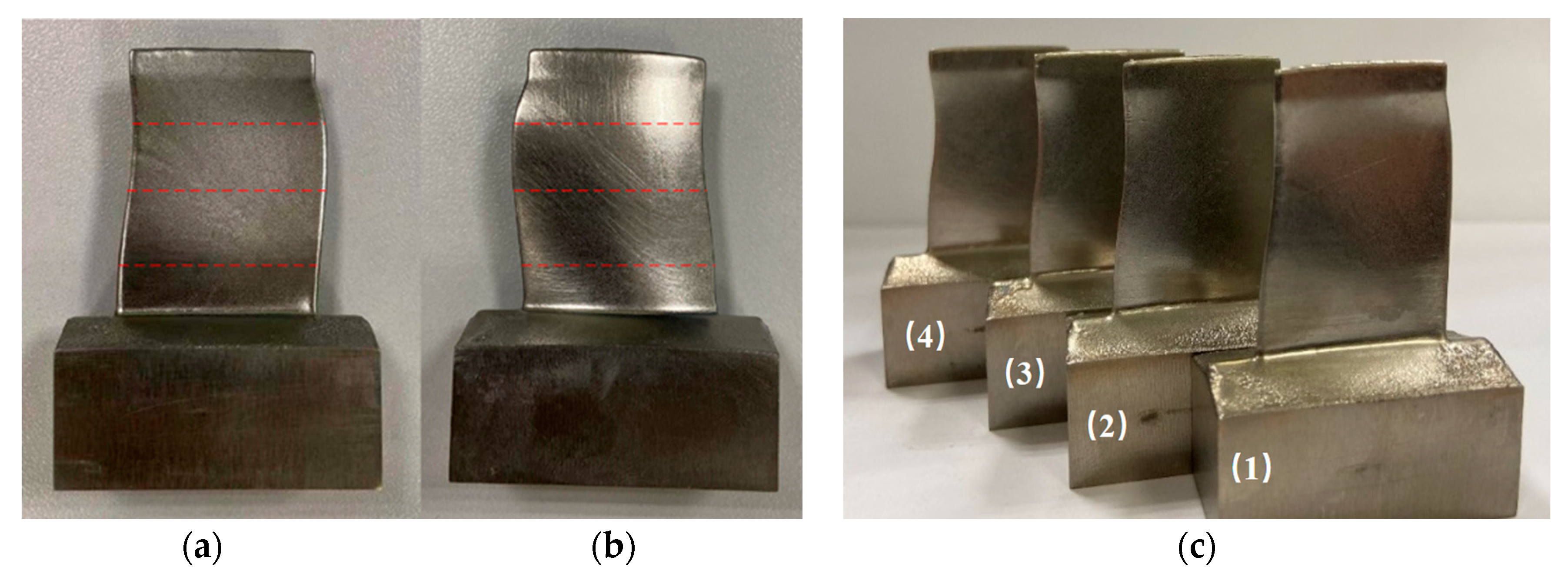

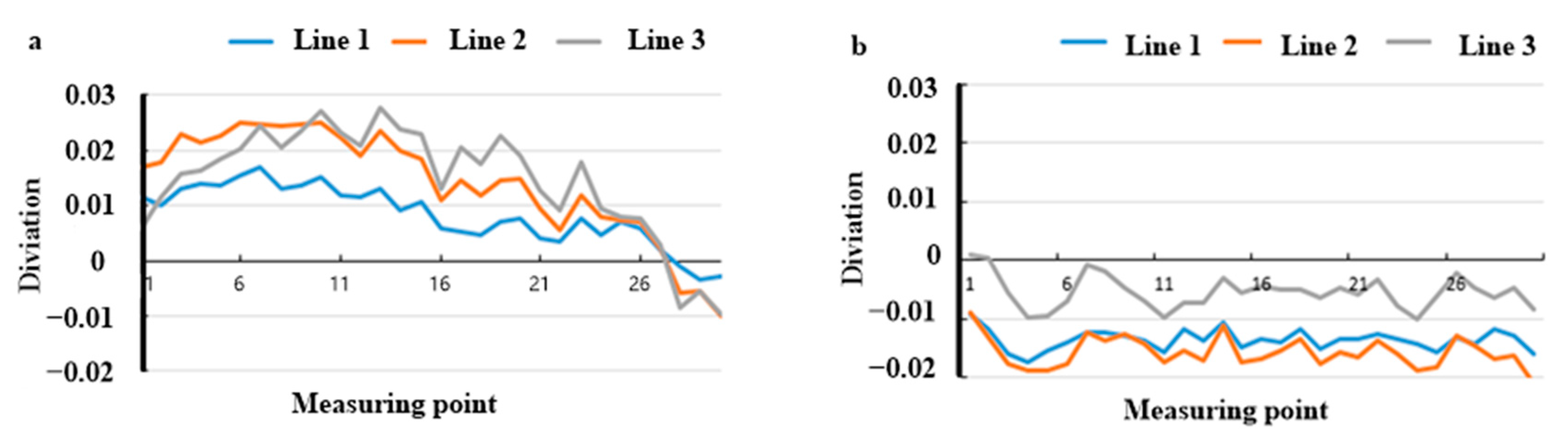

4. Processing Experiment of γ-TiAl TNM Blades

5. Conclusions

- Based on the grey relational analysis, the optimal parameter combination was determined. The parameters were as follows: an applied voltage of 20 V, an electrode feed rate of 0.3 mm/min, a duty cycle of 1/12, and a tool vibration frequency of 20 Hz. In the four parameters, the duty cycle was the key factor to achieve the highest mean SR, RA, and ACD.

- Based on the analysis results of the orthogonal experiment, four γ-TiAl TNM blades were processed. The roughness values of the processed basin and back surface were determined to be Ra 0.295 μm and Ra 0.313 μm, and the tolerance machining error range was −0.019 mm to +0.028 mm. The specimens had good machining accuracy and surface quality.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, J.; Zhu, D.; Zhao, L.; Xu, Z.Y. Experimental investigation on clectrochemical machining of γ-TiAl intermetallic. Procedia CIRP 2015, 35, 20–24. [Google Scholar] [CrossRef]

- Klocke, F.; Klink, A.; Veselovac, D.; Aspinwall, D.K.; Soo, S.L.; Schmidt, M.; Schilp, J.; Levy, G.; Kruth, J.-P. Turbo machinery component manufacture by application of electrochemical, electro-physical and photonic processes. CIRP Ann. Manuf. Technol. 2014, 63, 703–726. [Google Scholar] [CrossRef]

- Beddoes, J.C.; Wallace, W.; Malherbe, M.C.D. The technology of titanium aluminides for aerospace applications. Adv. Manuf. Process. 1992, 7, 527–559. [Google Scholar] [CrossRef]

- Voice, W. The future use of gamma titanium aluminides by Rolls-Royce. Aircr. Eng. Aerosp. Technol. 1999, 71, 337–340. [Google Scholar] [CrossRef]

- Helmut, C.; Svea, M. Advanced intermetallic TiAl alloys. Mater. Sci. Forum 2016, 879, 113–118. [Google Scholar]

- Wallgram, W.; Schmölzer, T.; Cha, L.; Das, G.; Güther, V.; Clemens, H. Technology and mechanical properties of advanced γ-TiAl based alloys. Int. J. Mater. Res. 2009, 100, 1021–1030. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Chen, Y.F.; Kong, F.T.; Xiao, S.L. Fabrication and processing of gamma titanium aluminides—A Review. Mater. Sci. Forum 2010, 638–642, 128–1287. [Google Scholar] [CrossRef]

- Aspinwall, D.; Dewes, R.; Mantle, A. The machining of gamma-TiAl intermetallic alloys. CIRP Ann. Manuf. Technol. 2005, 54, 99–104. [Google Scholar] [CrossRef]

- Priarone, P.C.; Stefania, R. Drilling experiments on a gamma titanium aluminide obtained via electron beam melting. Int. J. Adv. Manuf. Technol. 2013, 69, 483–490. [Google Scholar] [CrossRef]

- Rajurkar, K.P.; Zhu, D.; McGeough, J.A. New development of electrochemical machining. CIRP Ann. Manuf. Technol. 1999, 48, 48–56. [Google Scholar] [CrossRef]

- Klocke, F.; Zeis, M.; Klink, A.; Veselovac, D. Technological and economical comparison of roughing strategies via milling, EDM and ECM for titanium- and nickel-based blisks. Procedia CIRP 2012, 2, 98–101. [Google Scholar] [CrossRef]

- Clifton, D.; Mount, A.R.; Jardine, D.J.; Roth, R. Electrochemical machining of gamma titanium aluminide intermetallics. J. Mater. Process. Technol. 2001, 108, 338–348. [Google Scholar] [CrossRef]

- Klocke, F.; Herrig, T.; Zeis, M.; Klink, A. Experimental research on the electrochemical machinability of selected γ-TiAl alloys for the manufacture of future aero engine components. Procedia CIRP 2015, 35, 50–54. [Google Scholar] [CrossRef]

- Wang, Y.D.; Xu, Z.Y.; Zhang, A. Anodic characteristics and electrochemical machining of two typical gamma-TiAl alloys and its quantitative dissolution model in NaNO3 solution. Electrochim. Acta 2020, 331, 135429. [Google Scholar] [CrossRef]

- Wang, H.; Liu, J.; Gu, D.W.; Zhu, D. Electrochemical dissolution behavior of Ti-48A1-2Nb-2Cr in NaNO3 and NaCl electrolytes. Int. J. Electrochem. Sci. 2020, 15, 9313–9324. [Google Scholar] [CrossRef]

- Liu, J.; Wang, H.; Zhu, D. Electrochemical machining of γ-TiAl intermetallic blades by using the stainless steel anti-copied tool electrodes. Procedia CIRP 2018, 68, 757–761. [Google Scholar] [CrossRef]

- Feng, Z.; Granda, E.; Hung, W. Experimental investigation of vibration-assisted pulsed electrochemical machining. Procedia Manuf. 2016, 5, 798–814. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Wang, Y.D. Electrochemical machining of complex components of aero-engines: Developments, trends, and technological advances. Chin. J. Aeronaut. 2019, 34, 28–53. [Google Scholar] [CrossRef]

- Schaarschmidt, I.; Zinecker, M.; Hackert-Oschätzchen, M.; Meichsner, G.; Schubert, A. Multiscale multiphysics simulation of a pulsed electrochemical machining process with oscillating cathode for microstructuring of impact extrusion punches. Procedia CIRP 2017, 58, 257–262. [Google Scholar] [CrossRef]

- Zhao, J.S.; Feng, W.; Zhang, X.; Yang, Z.; Lv, Y.; He, Y. Experimental research on improving ECM accuracy and stability for diamond-hole grilles. Procedia CIRP 2018, 68, 684–689. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, D.; Liu, J. Improving the accuracy of the blade leading/trailing edges by electrochemical machining with tangential feeding. CIRP Ann. 2019, 68, 165–168. [Google Scholar] [CrossRef]

- Zong, Y.W.; Liu, J.; Zhu, D. Study of voltage regulation strategy in electrochemical machining of blisk channels using tube electrodes. Int. J. Adv. Manuf. Technol. 2021, 114, 3489–3501. [Google Scholar] [CrossRef]

- Tomoyuki, S.; Masanori, K. Study on influences of bubbles on ECM gap phenomena using transparent electrode. CIRP Ann. 2016, 65, 225–228. [Google Scholar]

- Hackert-Oschätzchen, M.; Paul, R.; Kowalick, M.; Kuhn, D.; Meichsner, G.; Zinecker, M.; Schubert, A. Characterization of an Electrochemical Machining Process for Precise Internal Geometries by Multiphysics Simulation. Procedia CIRP 2017, 58, 175–180. [Google Scholar] [CrossRef]

| Parameters | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Applied peak voltage (V) | 20 | 30 | 20 | 20 |

| Feed rate (mm/min) | 0.25 | 0.25 | 0.35 | 0.25 |

| Duty cycle | 1/6 | 1/6 | 1/6 | 1/3 |

| Vibration frequency (Hz) | 20 | 20 | 20 | 40 |

| Parameters | Simulation Parameters |

|---|---|

| Vibration amplitude (mm) | 0.3 |

| Electrolyte temperature (°C) | 30 |

| Electrolyte | 200 g/L NaNO3 |

| Inlet pressure (MPa) | 0.8 |

| Outlet pressure (MPa) | 0.2 |

| Composition | Ti | Al | Nb | Mo | B | Fe | C | N | H | O |

|---|---|---|---|---|---|---|---|---|---|---|

| At.% | Bal. | 43.3 | 4.02 | 0.96 | 0.21 | 0.03 | 0.02 | 0.03 | 0.11 | 0.16 |

| Symbol | Parameters | Levels | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||

| A | Applied voltage (V) | 15 | 20 | 25 | 30 |

| B | Feed rate (mm/min) | 0.2 | 0.25 | 0.3 | 0.35 |

| C | Duty cycle | 1/12 | 1/6 | 1/4 | 1/3 |

| D | Tool vibration frequency (Hz) | 10 | 20 | 30 | 40 |

| Parameter Type | Processing Parameters |

|---|---|

| Feed length | 2 mm |

| Initial gap | 0.15 mm |

| Electrolyte temperature | 30 °C |

| Electrolyte | 200 g/L NaNO3 |

| Inlet pressure | 0.8 MPa |

| Experiment | Parameters | Observed Performance | |||||

|---|---|---|---|---|---|---|---|

| A | B | C | D | SR (μm) | RA (mm) | ACD (A/cm2) | |

| 1 | 1 | 1 | 1 | 1 | 0.59 | 0.0233 | 117.8 |

| 2 | 1 | 2 | 2 | 2 | 1.43 | 0.0304 | 72.8 |

| 3 | 1 | 3 | 3 | 3 | 0.27 | 0.0312 | 58.5 |

| 4 | 1 | 4 | 4 | 4 | 0.52 | 0.0405 | 51.6 |

| 5 | 2 | 1 | 2 | 3 | 0.58 | 0.0653 | 58.9 |

| 6 | 2 | 2 | 1 | 4 | 0.23 | 0.0187 | 136.2 |

| 7 | 2 | 3 | 4 | 1 | 0.77 | 0.0729 | 48.6 |

| 8 | 2 | 4 | 3 | 2 | 0.21 | 0.0306 | 70.7 |

| 9 | 3 | 1 | 3 | 4 | 0.70 | 0.1722 | 43.7 |

| 10 | 3 | 2 | 4 | 3 | 0.86 | 0.2582 | 40.1 |

| 11 | 3 | 3 | 1 | 2 | 0.63 | 0.0208 | 153 |

| 12 | 3 | 4 | 2 | 1 | 0.16 | 0.0226 | 109.1 |

| 13 | 4 | 1 | 4 | 2 | 0.86 | 0.1882 | 35.9 |

| 14 | 4 | 2 | 3 | 1 | 2.68 | 0.1852 | 54.9 |

| 15 | 4 | 3 | 2 | 4 | 0.70 | 0.0401 | 91.4 |

| 16 | 4 | 4 | 1 | 3 | 0.54 | 0.0375 | 82.4 |

| No. | Normalized Value for SR | Normalized Value for RA | Normalized Value for ACD |

|---|---|---|---|

| 1 | 0.8294 | 0.9808 | 0.6994 |

| 2 | 0.4960 | 0.9511 | 0.3151 |

| 3 | 0.9563 | 0.9478 | 0.1930 |

| 4 | 0.8571 | 0.9090 | 0.1341 |

| 5 | 0.8333 | 0.8054 | 0.1964 |

| 6 | 0.9722 | 1.0000 | 0.8565 |

| 7 | 0.7579 | 0.7737 | 0.1085 |

| 8 | 0.9802 | 0.9503 | 0.2972 |

| 9 | 0.7857 | 0.3591 | 0.0666 |

| 10 | 0.7222 | 0.0000 | 0.0359 |

| 11 | 0.8135 | 0.9912 | 1.0000 |

| 12 | 1.0000 | 0.9837 | 0.6251 |

| 13 | 0.7222 | 0.2923 | 0.0000 |

| 14 | 0.0000 | 0.3048 | 0.1623 |

| 15 | 0.7857 | 0.9106 | 0.4740 |

| 16 | 0.8492 | 0.9215 | 0.3971 |

| No. | Grey Relational Coefficients | Grey Relational Grades | |||

|---|---|---|---|---|---|

| SR | RA | ACD | Average Value | Order | |

| 1 | 0.7456 | 0.9630 | 0.6245 | 0.7777 | 4 |

| 2 | 0.4980 | 0.9109 | 0.4220 | 0.6103 | 11 |

| 3 | 0.9196 | 0.9055 | 0.3826 | 0.7359 | 6 |

| 4 | 0.7777 | 0.8460 | 0.3661 | 0.6633 | 9 |

| 5 | 0.7500 | 0.7198 | 0.3836 | 0.6178 | 10 |

| 6 | 0.9473 | 1.0000 | 0.7770 | 0.9081 | 1 |

| 7 | 0.6738 | 0.6884 | 0.3593 | 0.5738 | 12 |

| 8 | 0.9619 | 0.9096 | 0.4157 | 0.7624 | 5 |

| 9 | 0.7000 | 0.4383 | 0.3488 | 0.4957 | 13 |

| 10 | 0.6428 | 0.3333 | 0.3415 | 0.4392 | 15 |

| 11 | 0.7283 | 0.9827 | 1.0000 | 0.9037 | 2 |

| 12 | 1.0000 | 0.9684 | 0.5715 | 0.8466 | 3 |

| 13 | 0.6428 | 0.4140 | 0.3333 | 0.4634 | 14 |

| 14 | 0.3333 | 0.4183 | 0.3738 | 0.3751 | 16 |

| 15 | 0.7000 | 0.8483 | 0.4873 | 0.6785 | 8 |

| 16 | 0.7683 | 0.8643 | 0.4533 | 0.6953 | 7 |

| Parameter Type | Processing Parameters |

|---|---|

| Applied voltage (V) | 20 |

| Feed rate (mm/min) | 0.2 |

| Duty cycle | 1/4 |

| Tool vibration frequency (Hz) | 10 |

| Electrolyte temperature | 30 °C |

| Inlet pressure | 0.8 MPa |

| Parameters | Parameter Values | |||

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |

| Duty cycle | 1/12 | 1/6 | 1/4 | 1/3 |

| Tool vibration frequency (Hz) | 10 | 20 | 30 | 40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Liu, Y.; Zhang, Z.; Wang, H. Parameter Optimization and Experimental Study on Tool-Vibration-Assisted Pulsed Electrochemical Machining of γ-TiAl TNM Blades. Appl. Sci. 2022, 12, 8042. https://doi.org/10.3390/app12168042

Liu J, Liu Y, Zhang Z, Wang H. Parameter Optimization and Experimental Study on Tool-Vibration-Assisted Pulsed Electrochemical Machining of γ-TiAl TNM Blades. Applied Sciences. 2022; 12(16):8042. https://doi.org/10.3390/app12168042

Chicago/Turabian StyleLiu, Jia, Yan Liu, Zhe Zhang, and Hao Wang. 2022. "Parameter Optimization and Experimental Study on Tool-Vibration-Assisted Pulsed Electrochemical Machining of γ-TiAl TNM Blades" Applied Sciences 12, no. 16: 8042. https://doi.org/10.3390/app12168042

APA StyleLiu, J., Liu, Y., Zhang, Z., & Wang, H. (2022). Parameter Optimization and Experimental Study on Tool-Vibration-Assisted Pulsed Electrochemical Machining of γ-TiAl TNM Blades. Applied Sciences, 12(16), 8042. https://doi.org/10.3390/app12168042