1. Introduction

The application of robotic arms is widespread, including in industrial manufacturing automation applications [

1,

2], military security, disaster prevention and explosion removal [

3], medical rehabilitation [

4,

5,

6], and home entertainment [

7]. Robotic arms have been applied in many fields. The medical rehabilitation robots mentioned above have been important research topics. Patients with physical movement disabilities caused by accidents, surgery after injury or brain injury, stroke, etc., are unable to take care of themselves in daily life and need to be cared for long-term by others [

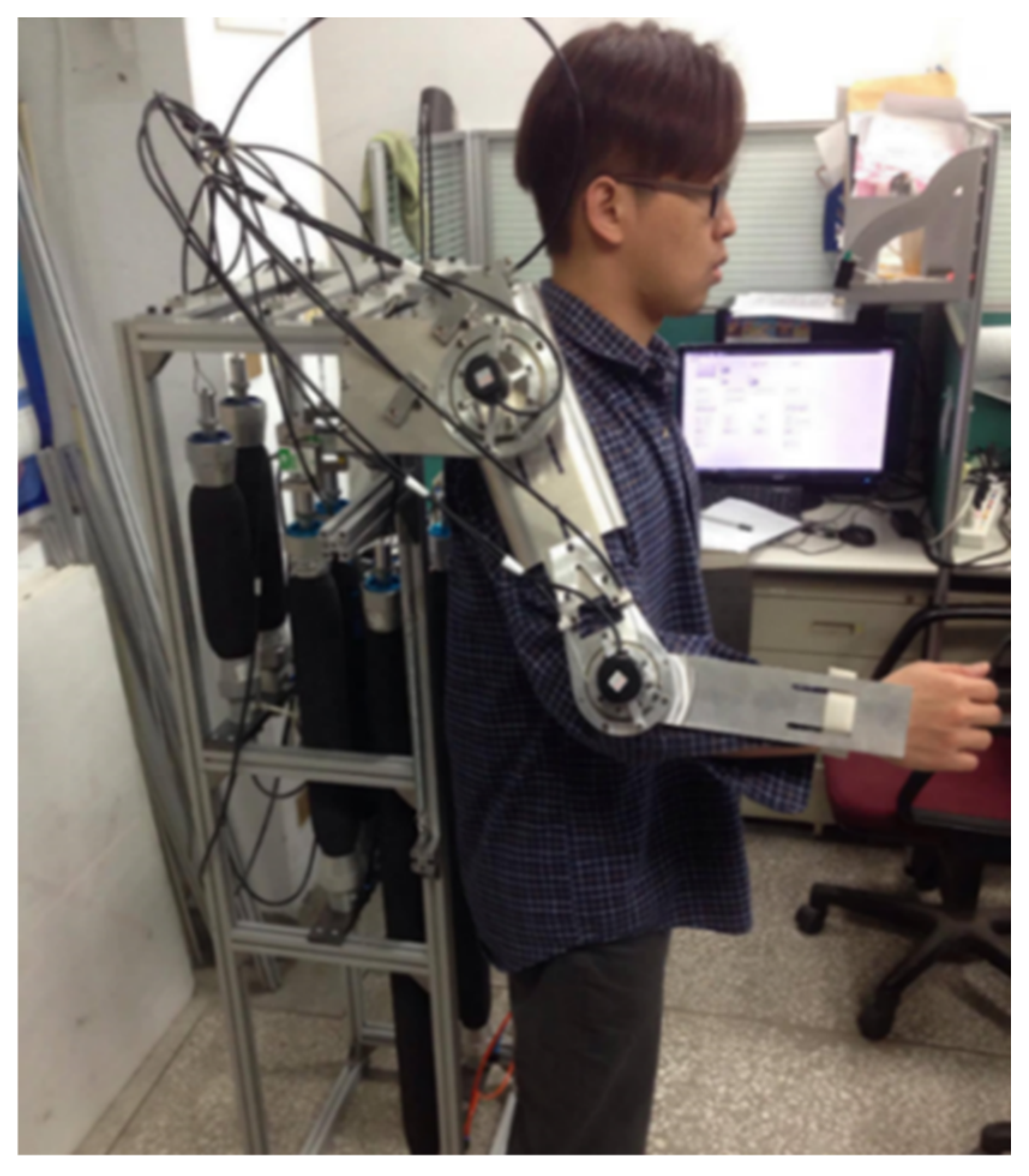

8]. Thus, this study aims to develop a multi-functional robotic arm and design a multi-degree of freedom robotic arm for patients who cannot lift their upper limbs by themselves and need to be assisted by devices for rehabilitation training. It is designed as a human-shaped exoskeleton with a wearable function so that the patient can perform rehabilitation exercises for the upper limbs with the help of the robotic arm while wearing it.

To design an upper limb wearable robotic arm, it is necessary to consider the design process and validation issues [

9,

10]. An upper limb wearable robotic arm is an assistive device in direct contact with the user’s body, and its safety and flexibility are very important. Rehabilitation tasks require stability and comfort. At present, most robotic arms are driven by motors, where the advantages of motors are high-speed response time, high precision, and high linearity, but because of the direct action on the rotary axis, improper control will make patients feel pain and cause secondary injury. Thus, Festo’s pneumatic muscle cylinder is used as the actuator in this study. In comparison with motors or pneumatic cylinder actuators, it has the following advantages: slower reaction speed, limited movement stroke, and higher output force. Additionally, flexible material is used to make the pneumatic artificial muscle cylinder, and the rotation of the rotary axis is a little flexible during the robotic arm’s rehabilitation tasks. Hence, it is more suitable for human–computer interaction robotic arm development than rigid material actuators such as motors and pneumatic cylinders.

Pneumatic artificial muscle (PAM) was first designed in 1961 by Joseph L. McKibben, an American physicist, as his daughter was suffering from osteomyelitis and McKibben was looking for an actuator with flexible material that could be used as a prosthesis [

11]. McKibben invented PAM in order to obtain a material that was flexible and could be used as an actuator for a prosthesis, and thus, PAM was also called McKibben muscle [

12]. From the perspective of PAM and biological muscle, PAM has the advantages of higher output force, high energy-conversion efficiency, faster dynamic characteristics, compact structure, light weight, flexibility, easy control of extension position through pressure valve control, and less heat, noise, and harmful substances during operation. On the other hand, the disadvantages are that the displacement change of PAM is time-varying and non-linear compared to the input pressure, and there is some friction between the inner elastic rubber tube and the outer fiber mesh of PAM when the displacement change occurs due to the internal pressure change, thus causing a hysteresis phenomenon [

13,

14].

In recent years, the German Festo team has been developing the application of PAM in robotics. The ZAR5, developed by the Festo team, uses PAM as an actuator, and its mechanism consists of a rotatable base, two upper limb arms, and a total of ten fingers on both hands. By controlling the flow valve to change the air flow in the pneumatic artificial muscles, it can perform the action of bending the fingers with the arms together and can track the action of simulated human hands [

15]. A UK-based shadow company also designed a bionic arm using PAMs, with each group of PAMs installed in the same position as the corresponding muscles of the human arm, which can realize the same bending elbow and arm forward and extension movements as human hands [

16]. Tondu et al. [

17] published a seven-degrees-of-freedom humanoid robotic arm with PAM as the actuator to drive each axis of the arm in remote control mode, allowing the arm to perform the task of picking up and dropping objects. Caldwell et al. [

18] designed an exoskeleton device for upper limb and lower limb rehabilitation with seven degrees of freedom for the upper limb exoskeleton and five degrees of freedom for the lower limb exoskeleton, which is driven by a PAM. The upper limb exoskeleton is equipped with a torque sensor at the end of the hand, which can sense the force signal applied at the end of the hand and use the force signal to achieve the desired movement position of the patient through control.

PAMs are applied to control robotic arms, which can be generally classified as single PAM control or dual PAMs operating in linear or rotary motion; the use of pneumatic control valves is also different from pressure control valves or flow-control flow servo valves. Minh et al. [

19] used a proportional flow-control PAM, but because the PAM produced hysteresis during operation, the hysteresis was modeled by isometric, isobaric, and isotropic experiments to perform feed-forward compensation so that the system could achieve better control results. Shen [

20] proposed using sliding mode control (SMC) to control the linear motion of a proportional flow servo valve with dual PAMs, and established a nonlinear model of the PAMs, with ideal gas equation and air flow equation to derive the relationship between the control command parameters and the dual PAMs, and designed the sliding plane to calculate the control commands through the equivalent control law and switching control law to control the system. Andrikopoulos et al. [

21] used a nonlinear proportional–integral–derivative (PID) structure to simplify the modeling process and provide pneumatic artificial muscles to compensate for nonlinear hysteresis phenomena and increase the robustness of the system.

In order to improve the control accuracy of the trajectory tracking, this study uses iterative learning control. The initial idea of iterative learning control was to make a relevant correction to the control of mechanical motion through the implementation error in the mechanical system, but the analysis of learning control was still insufficient at that time [

22]. Arimoto et al. [

23] proposed a learning algorithm called the PID-type, which can guarantee the convergence of the system without initial error and specially defined norm limits. Since then, different definitions of iterative learning control and modified learning algorithms have been proposed; these learning algorithms require several iterations to achieve a certain control accuracy [

24,

25]. Kurek and Zaremba [

26] proposed a theoretical algorithm that can adjust the control error to zero in just one learning session, but this method is obtained from the system state generated by the new control input. Geng et al. [

27] introduced iterative learning control (ILC) with a two-dimensional system theory and introduced a suitable mathematical model to clearly describe the dynamics of the control system and the learning process behavior. However, their proposed method must be full-state feedback and can only be applied to first-order systems. They also applied two-dimensional system theory to propose an iterative learning control method for continuous-time and discrete-time systems [

28,

29].

To sum up, the purpose of this study is to develop a robotic arm with a rehabilitation function and to conduct various experimental validations. This study involves designing a single-axis robotic arm controller, a robotic arm on a multi-axis recovery trajectory, a multi-axis robotic tracking experiment on a rehabilitation trajectory, and a robotic arm joining/loading experiment.

4. Conclusions

This study developed a multi-functional redundant robotic arm with four degrees of freedom using PAM as the main actuator to allow patients with upper limb mobility impairment to perform rehabilitation trajectory tasks in the future while wearing the robotic arm. The exoskeleton robot arm is designed based on the structure of the joints of the human arm due to the need to wear it on the human body. Since the mechanism may collide with the user when it is in motion, an actuator and control commands are used to limit the space available for each rotary axis during the movement of the robot arm so as not to exceed the limit of human arm joints. The rotary axis control part is controlled by PAM. Therefore, the mathematical model of the single-axis robot arm driven by two PAMs was firstly developed, followed by the design of the PID, feedback (LMS-PID), and feed-forward (ILC) controllers. Because of the complexity of the nonlinear characteristics of the PAM actuator, the model and control parameters are uncertain when performing the tracking experiment of the PID controller by simulating the parameters, which leads to the ineffective control of the parameters.

Therefore, this study used a self-adaptive (LMS-PID) controller and an iterative learning controller (ILC) to compensate; the ILC performs the feed-forward compensation by iteratively modifying the control commands, while the LMS-PID controller is an adaptive feedback controller using the LMS algorithm. The parameters obtained from the LMS-PID combined with the iterative learning control can produce a better control effect, especially the phase lag and transient parts, which cannot be solved by the PID controller. Iterative learning control can reduce the error of the system to a certain range within a limited number of learning times, which can greatly improve the control effect of the robot arm.

Overall, in the single-axis robotic arm controller experiment, the results showed that LMS-PID was superior to the conventional PID control method. In the control experiment of the robotic arm under multi-axis recovery trajectory, the experimental results showed that the study can plan the training of drawing a circle on the wall, which can effectively train the shoulder joint area. In the multi-axis robotic tracking experiment under the rehabilitation trajectory, the results showed that the LMS-PID controller reduced the RMSE of the tracking trajectory to 0.2444 and 0.2853. In the robotic arm joining/loading experiment, the results showed that the tracking accuracy was still accurate after the loading.

Finally, the robotic arm in the rehabilitation mode was only used by people without impairments, but the purpose of this development is for patients with arm injuries. It is hoped that we can cooperate with hospitals in the future so that patients with arm disabilities can use the robotic arm developed by this study to perform rehabilitation exercises.