Abstract

Since underground structures such as tunnels are inevitably surrounded by rocks, their long-term safety and stability are primarily governed by the comportment of these materials. Being able to express the time-dependent behavior of rocks, creep is one of the most interesting mechanical properties considered in the study of tunnels. Based on relevant research efforts, this article aims to provide a comprehensive review of pertinent information on rock creep and its potential influencing factors. It also presents the latest progress in constitutive models of rock creep and discusses their applicability to the long-term stability of deep underground structures. The results show that rock creep is significantly influenced by various potential factors both external and internal. These are mainly hydraulic pressure, stress level, water content, temperature, damage, and time-to-failure. For instance, the creep lifetime of andesite is drastically reduced by the presence of water. It is about 180 times shorter in wet conditions than in dry conditions, under the same stress conditions. By the combined influence of high stresses, high pressures, and high temperatures, creep rupture occurs in a semi-brittle manner for most types of hard rocks. The characteristics and installation period of the lining structures also have a strong influence on the evolution of creep in the rocks surrounding the underground structures. It is suggested that despite the colossal research efforts already made in this area, more accurate creep constitutive models are still needed for more adequate applications to the long-term stability of deep rock tunnels. Accordingly, key perspectives for future investigations are highlighted. This work can serve as a good reference in the establishment of new constitutive models of rock creep aimed at improving their accuracy, and facilitate appropriate actions to predict the long-term stability of deep tunnels in realistic situations.

1. Introduction

The creep behavior of rocks plays a fundamental role in tunnel engineering and related sciences. It usually occurs under the action of stresses exerted over a long period of time [1]. This is the case of underground structures which are generally planned to be operational for decades or even more than a hundred years. However, the deformations of these structures initiate rapidly once their surrounding rocks are excavated. Due to the complex loading–unloading process that the rocks undergo in the vicinity of the generated openings [2,3], these are particularly softened and the extent of their deformation evolves as quickly as possible. As a result, there is formation of disturbed and damaged areas where the relevant properties of rocks are diminished. One of the most pronounced effects of rock excavations is that rock properties are lastingly altered in damaged zones. This is why one ordinarily observes considerable deformations and fractures around the tunnels [4]. In soft rocks particularly, large strain rates remain evident even after the installation of the initial supports of tunnels [5]. Nonetheless, depending on the relevant tunneling conditions and characteristics, any type of rock can present obvious deformations. In fact, with the evolution of time, the surrounding rocks always manifest their tendency to converge towards the interior of the tunnels. Such tendency is usually associated with the spread of fractures and damage in excavated areas. This is mainly due to the fact that natural rocks contain pre-existing discontinuities and cracks which are generally increased by the effect of excavations. Indeed, the time-dependent deformation of rocks which is amply expressed by rock creep is therefore inevitable [6]. Rock creep is strongly related to the long-term stability of rocks [7,8,9,10], and its effect on the long-term stability of structures is of great consequence [6,11,12]. Accordingly, its proper consideration is of paramount importance in assessing the long-term stability of tunnels [13]. Nevertheless, since rock creep is influenced by many factors that generally reduce its strength, the study of rock creep requires reasonable and thorough attention. Strong influencing factors include stress state, damage, water, and temperature. When these factors are not effectively considered in the assessment of rock creep parameters, the designed constitutive models may be ineffective in their actual applicability. For example, the accumulation of damage during creep can generally lead to rock failure [14,15]. Effectively predicting the long-term stability of rock engineering therefore requires proper consideration of factors that strongly influence rock creep.

Scholars and researchers have conducted numerous studies on creep behavior of rocks under different conditions. For instance, Challamel et al. [16] detailed creep failure of quasi-brittle materials such as rock and concrete subjected to high prolonged loads based on the development of a simple time-dependent continuous damage mechanics. Cao et al. [17] studied the viscoelasto-plastic properties of amphibolite to simulate the creep properties of these rock types via the method of loading and unloading staged by cyclic increment, under hydrous environment. They found that the rheological creep properties of amphibolite are strongly affected by water and can be represented by the general shape of the Kelvin model. Chen et al. [18] established the constitutive equations reflecting the time-dependent marble damage model based on experimental results. Their proposed mechanical model can describe the three stages of marble creep, which are essential to ensure the stability of underground structures both at the stage of their excavation and during their lifespan. From shear static test and shear creep test, Mei et al. [19] revealed that the shear creep properties of limestone can be normally depicted by the Poyting–Thomson model. For this, they fitted the gradual creep curves using the exponential empirical law and employing the method of polynomial regression analysis. Their study can be applied to engineering structures built on a steep rocky slope where the limestone is in low interlayer. For their part, Liu et al. [20] developed improved creep damage equations for soft rock based on the classical Nishihara model and superposition principle. In this model, the nonlinear least squares method is used to obtain the fitted expression. By reflecting three stages of soft rocks, this model can be applied in the stability study of soft rock tunnels where mica-quartz schist is predominant. By studying salt rocks and using segmentation simulation where segments are fitted using variable-order fractional calculus, Tang et al. [21] proposed an adapted creep model. In stress and time thresholds, continuous damage is considered in such a model describing the creep character of rock salt. Using the basis of factional derivatives and experimental data, Wu et al. [22] conceived a creep model for salt rocks. Their results can be used to judge the long-term stability of deep saline rocks serving as energy storage structures. Recently, to describe the overall rock creep behavior, Gao and Yin [23] conceived a new variable fractional order rheological model. Although their model could be applied to various rock types, not all factors influencing rock creep are taken into account. Li and Yin [24] analyzed the shear creep of sandstone, marble, and granite under fatigue loading provoked by seismic perturbations, and they suggest that their model can serve as a basis for studying the support of anchored rock mass subjected to dynamic disturbances. More recently, Qian et al. [25] carried out creep tests on granite at different confining pressures to study the deformation of an underground hydropower station in the Western Sichuan province of China, and then established an improved creep constitutive model based on the generalized Kelvin model, taking into account the ratio of deviatoric stress and the maximum strength of the rocks. It is therefore observed that, despite substantial research efforts, comprehensive reviews are lacking in the advancements of this salient field. In fact, the need to accurately select and estimate the creep characteristics of rocks are of utmost importance in order to properly predict the long-term stability of deep rock tunnels. This article summarizes relevant information on creep behavior of rocks. Moreover, it discusses the implication of such rock behavior in predicting the long-term stability of deep tunnels. Since the need to build such structures is remarkably increasing around the world, the accurate prediction of their long-term stability is a major concern. It is important to mention that this study has two main limitations. First, it is difficult to study the influence of individual factors on the obtained results without considering specific cases of deep tunnels. Second, as specific study cases are not presented, it is difficult to quantify the accuracy of the various creep constitutive models, and mechanical models are mainly discussed. These limitations could be addressed in future investigations.

2. General Creep Background

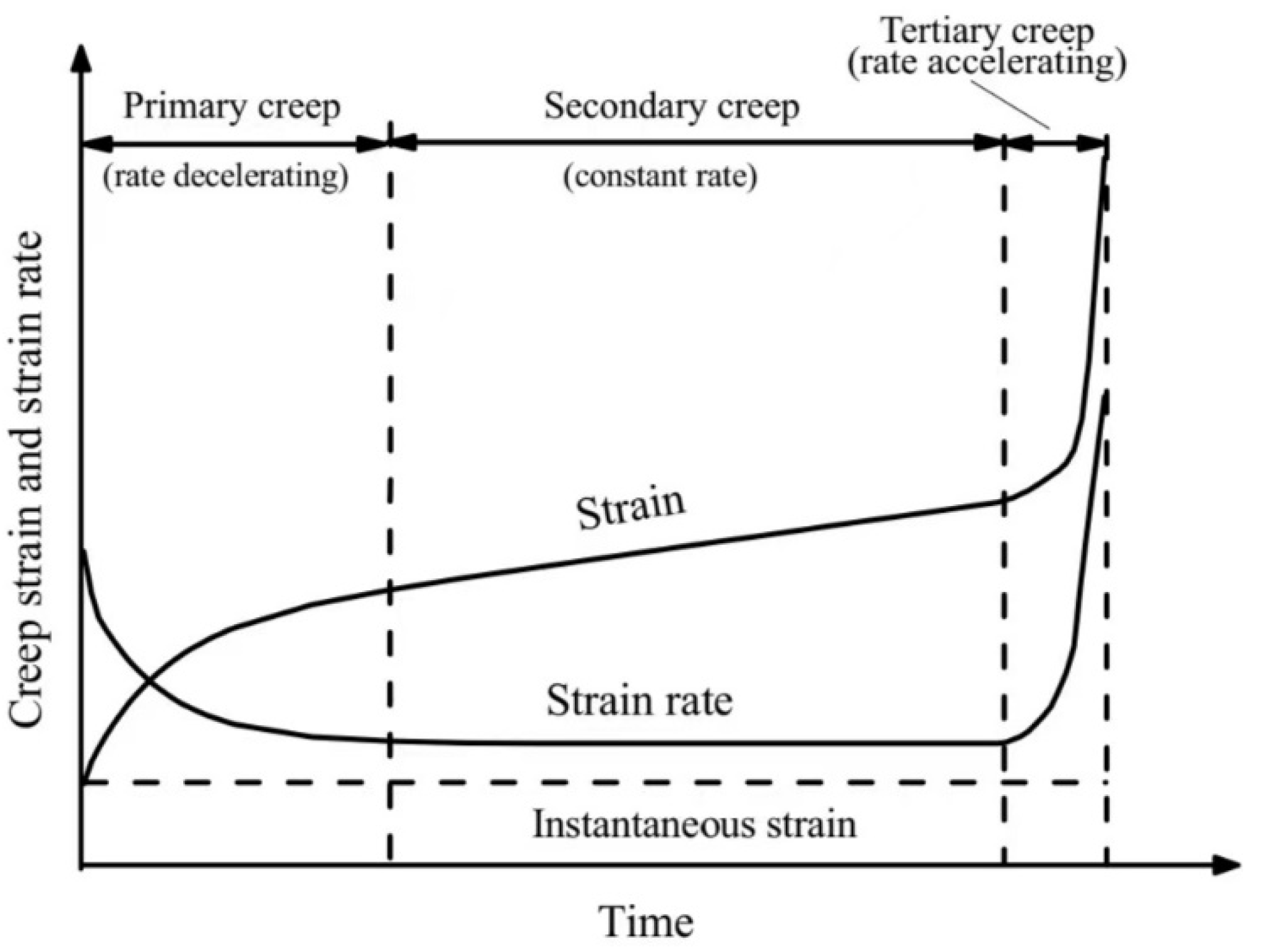

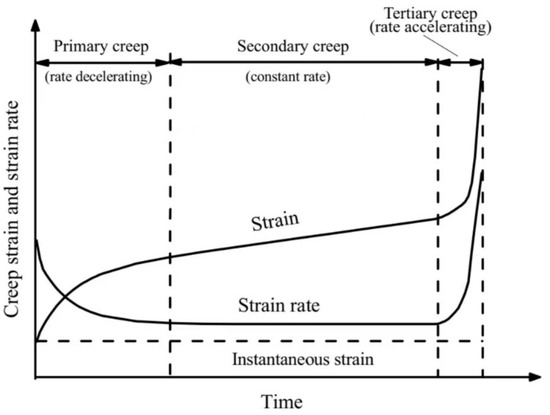

Under specific load influenced by time at constant temperature [26], the creep of rocks generally manifests in four traditional phases, namely instant elastic strain, primary creep, secondary creep, and tertiary creep [12,26,27,28,29,30,31,32,33]. The instant elastic strain is reversible and can takes place promptly when a constant load is applied. Primary creep is ephemeral and usually exhibits a decelerated strain rate. Secondary creep is the steady phase where the strain rate remains constant. Tertiary creep is the final phase which is generally characterized by an accelerated strain rate until the creep life is exhausted. Creep characteristics are observed in different types of rocks. The creep curves of the latter are basically similar despite their different strengths [34]. Figure 1 illustrates the creep behavior of rocks. Depending on the exposure conditions, exception can be made for certain rocks. In fact, at great depth, the rocks are generally subjected to high stresses. Under such stress levels, some hard rocks may display two-phase creep behavior and their failure can be brittle [11]. It should be noted, however, despite intact hard rocks generally deforming at low creep rates, their time-dependent behavior is considerable in many situations [35,36]. Depending on the magnitude of the confining pressures, even some soft rocks can be deformed without exhibiting all phases of creep. For example, it was experimented by Herrmann et al. [37] that only primary creep occurred during the deformation of shale rocks under high confining pressure. However, given the mechanical nature of creep, it is rare to observe soft rocks deforming without showing tertiary creep. In fact, one of the remarkable characteristics of soft rocks is that their creep deformation is significant [22].

Figure 1.

Sketch showing the creep behavior of rocks (Reprinted from Qian et al. [25], Copyright©2022, with permission from the publisher, License No. 5352440395617).

Generally, rocks show their creep behavior when their creep threshold is reached [14]. It is therefore important to precisely estimate such a threshold in terms of load or stress for better control. The stress grade that generates the first cracks or fractures is usually considered as stress threshold grade [38]. More precisely, the stress threshold is regarded as the maximum load which engenders a non-severe creep deformation [39]. Depending on the rock type and conditions, rapid creep deformations may occur due to exceeding stress thresholds which may be different in the axial and lateral directions of the rocks [40]. Secondary and tertiary creep stages emerge to express plastic strain when the applied stress exceeds the threshold [14,41,42]. As an unstable creep stage, tertiary creep mainly appears when the secondary creep strain rate is greater than zero [43]. Ordinarily, as reported by Lyu et al. [44], the coupled effect of load and damage causes creep strain in the tertiary creep. Due to the unsteady behavior of tertiary creep that usually leads to failure in an accelerated manner, to ensure the long-term safety and stability of underground structures, the steady creep phase must be precisely controlled. The steady creep is viewed as the level of stress lower than the long-term resistance of rocks and which does not allow the triggering of tertiary creep [23]. Nevertheless, since tertiary creep is the nonlinear accelerated creep phase, the accurate prediction of its occurrence is extremely important to reveal the possible end of the long-term stability of underground openings.

3. Mechanism of Rock Creep

It is well known that rocks are heterogeneous materials that naturally have micro-voids or microcracks and discontinuities. Under load, micro-voids and microcracks spread, multiply, and become larger and larger. These defects facilitate the evolution of rock creep over time. The creep mechanism of rocks can be seen at both microscopic and macroscopic scales. In microscopic scale, the creep deformation is mainly governed by the propagation of initial cracks and dislocation networks, as well as by the deformation provoked between the internal constituents of rocks [45]. For instance, the displacement of a large number of dislocations leads generally to plastic deformations. According to Fabre and Pellet [46], mechanisms of rock creep from a microscopic point of view can be cataclastic creep (retarded weakening of microstructure) and granular creep (friction-induced grain repositioning). Macroscopically, creep is a continuous anelastic deformation under constant loading [47]. In fact, the macroscopic creep deformation widely depends on the evolution of microcracks. Habitually, these build up gradually even under low loads, and can become increasingly important over time. As expressed by Bikong et al. [48], macroscopic creep deformations are caused by the inevitable time-dependent propagation of microcracks, even under low loads. Under high loads, microcracks can grow faster to produce microscopic creep strains. Macroscopic deformation and microcracks evolution can be correlated as follows [49]:

where is axial strain; ; : constants related to the material; is initial damage; : radius of initial penny-shaped microcracks; : wing crack length; : cosine of the angle of crack concerned.

Two types of evolution mechanism can be distinguished for macro-cracks. The first one is that macro-cracks can accumulate rapidly and generate fracture surfaces reflecting the creep fracture mechanism which is generally transient. The second one can be the long-term development of macro-cracks describing the steady state of the rock creep mechanism.

It should be noted that the creep failure mechanism depends on the ductility and brittleness of rocks. In fact, such rock features evolve under the influence of embedding depth of the structures and geo-stress [50]. The spreading and coalescence of microcracks could be responsible for the failure triggered during brittle creep, while the ductile failure may be caused by dislocation-slip coupling where the exponential increase in steady creep rate is sudden [50]. In fact, brittle rocks involve quasi-linear axial deformation and non-linear lateral deformation [51], and they generally show no evident deformation at failure [52]. There is local stress concentration and relative crack concentration in the affected areas in brittle creep rupture [50]. However, it should be noted that such rocks are characterized by their ubiquitous dilatancy when compressed to failure [53]. According to Nicolas et al. [54], brittle failure, triggered by the growth of mode I subcritical cracks, can be time-dependent. In the case of coalescence of many microcracks, the propagation of the cracks is described as unstable, indicating that the rocks can no longer bear increased loads [51]. However, there is no failure if the current long-term strength of the rocks is not attacked [55]. The main mechanism of the time-dependent steady-state behavior of rock creep is subcritical crack extension due to stress corrosion, while that of tertiary creep is crack interaction [56]. At great depths, due to moisture and groundwater pressure, stress corrosion cracking is common and is responsible for the continued propagation of fractures and spalling of brittle rocks [57]. Crack evolution is triggered in brittle rocks when the mode I fracture toughness () is greater than the mode I stress intensity factor (), and its rate can be expressed as [49]:

where : wing crack length; : time; : index related to stress corrosion; and : velocity characteristic of cracks.

The ductile behavior of rocks is characterized by the exhibition of strong deformation before failure. It indicates the degree of plastic deformation of rocks. Generally, ductile creep provokes alteration of the stress state [58] and is characterized by a delocalized evolution [59]. Indeed, when closed microcracks develop by sliding friction and mode II failure, the deformation is ductile [60]. Specifically, over time, ductile deformation manifests as shear deformation and can be attributed to continuous events, namely the displacement of weak bonds in clay minerals, the displacement of interstitial atoms or atomic voids in crystals, or the sliding of dislocations [61]. A uniform stress distribution is generally observed in ductile creep rupture [50]. Ductile creep occurs mainly in soft rocks such as mudstone, sandstone, shale, or in other types of sedimentary rocks. Salt rocks are type of rocks that exhibit extraordinary ductile creep [22,62].

Another creep failure mechanism is semi-brittle. In fact, when the contributions of the brittle and viscous deformation mechanisms to the adjustment of the strains are contemporaneous and notable during the deformation, there is the appearance of a semi-brittle creep [63]. Specifically, semi-brittle creep deformation is a type of strain mainly triggered when the creep strain rate is governed by pressure, applied stress, and temperature [64]. Semi-brittle creep can be either compact creep enduring rigid compaction or dilatant creep dealing with the highest differential stresses [54]. It is one of the predominant mechanisms in some rock types such as carbonate rocks [54]. More broadly, the creep mechanism of natural rocks can be described by the transition between brittle and ductile behavior. As at such depths there are usually increased pressures and temperatures, the brittle–ductile mutation is very common [59,65]. The extent of microcracks inside rocks plays a key role in the brittle–ductile transition. Furthermore, as demonstrated by Hu et al. [66], when microcracks and frictional slips are sufficiently distributed under the influence of increased confining pressures, the appearance of brittle–ductile fractures is possible in hard rocks.

Basically, creep is a character common to any rock mass, but it is more prominent in clayey and organic rocks [67], as well as in weak rocks and in fractured rock masses [68]. As already mentioned, soft rocks, including salt rocks, exhibit high ductile creep deformation under loads. The creep deformations of these rocks are even greater with the complex general conditions of great depth. Furthermore, as reported by Zhang et al. [68], creep strain is large enough in jointed and fissured hard rocks. As the natural structure of rock masses usually contains many joints, fissures, fault zones [69], it can be understood that creep behavior is frequent in any type of rock mass. Therefore, understanding rock creep mechanism is essential for proper application in deep rock engineering.

4. Introduction to Creep Test Methods, Monitoring Methods, and Data Processing

According to the literature, creep properties of rocks are determined from different types of creep tests. Relaxation tests are also commonly employed to determine the creep properties of rocks [61]. All tests are performed under different experimental methods and conditions. The most widely employed experimental methods are indoor creep test methods which mainly include staged incremental loading, staged incremental loading and unloading, and separate loading methods. All the experimental methods are accompanied by monitoring methods. These aim to monitor the evolution of the characteristics of cracks and fractures, as well as the overall creep deformations of the rocks. Briefly, the most famous monitoring methods in this field are computed tomography, ultra-pulse wave velocity, scanning electron microscope, acoustic emission, etc. Each of these monitoring methods has particularities and limitations. The choice of a method mainly depends on the expected results and relevant conditions. For example, computed tomography is generally used to depict the microstructure and meso-structure of rock as well as to detect damage and fractures in rock specimens [70]. As the scan provided by computed tomography (CT) is a bit expensive, it is not commonly employed. Nevertheless, in order to detect experimental damage in rocks, most researchers mainly analyze rock samples before and after creep tests using CT scans. Rock degradation can be monitored using the ultra-pulse wave velocity by accumulating rock damage [71], but not in real time. Moreover, although scanning electron microscope method is quite accurate in detecting rock creep damage by analyzing the variation in rock microstructure [72], it cannot be used in real time. After a rupture due to rock creep, the characteristics of cracks and aperture can be recognized by means of scanning electron microscope [73]. Acoustic emission is typically used to track the progress of cracks and fractures in rocks, as well as to assess damage and strength [74]. Ordinarily, the creep characteristics of rocks are examined from different acoustic emission events. Thus, the acoustic emission method is widely used to study rock failure in different engineering applications [75]. However, despite the existence of several monitoring methods, it remains difficult to effectively monitor the characteristics and conditions of rock creep in real time.

The data are usually processed to interpret the results of creep tests. Different methods are usually used to this purpose. The most common are Boltzmann’s principle of superposition and viscoelastic-plastic stress separation. Boltzmann’s principle of superposition is especially utilized in staged incremental loading, while viscoelastic-plastic stress separation is particularly associated with staged incremental loading and unloading. These methods are briefly presented herein.

The Boltzmann principle of superposition consists in superimposing the deformations generated by different loads to obtain the total creep deformation. By applying to a rock specimen, a stress at the instant , its strain () is given as follows:

where is the creep compliance which represents the ratio between the creep strain and the applied differential stress [76,77,78].

As the experiment progresses, a supplemental stress is applied at . It should be noted that an additional strain is engendered when . In such situation, the total strain is accounted as follows:

According to Boltzmann’s superposition principle, the calculation of the total creep strain can be generalized as follows:

Stress is ordinarily considered a function ) because it is applied variably and repeatedly over time. The integral form is generally used in the situation where the time interval is infinitely small between different applied stresses.

In the viscoelastic-plastic stress separation method, the total strain is calculated as the sum of the instantaneous strain and the creep strain, for each stress level. The equation reflecting this calculation is as follows [79]:

where is the total strain; is the instantaneous strain which composes of the instantaneous elastic strain and the instantaneous plastic strain ; is the creep strain which is constituted of visco-elastic strain , and visco-plastic strain . They are determined under the application of the i-th stress level.

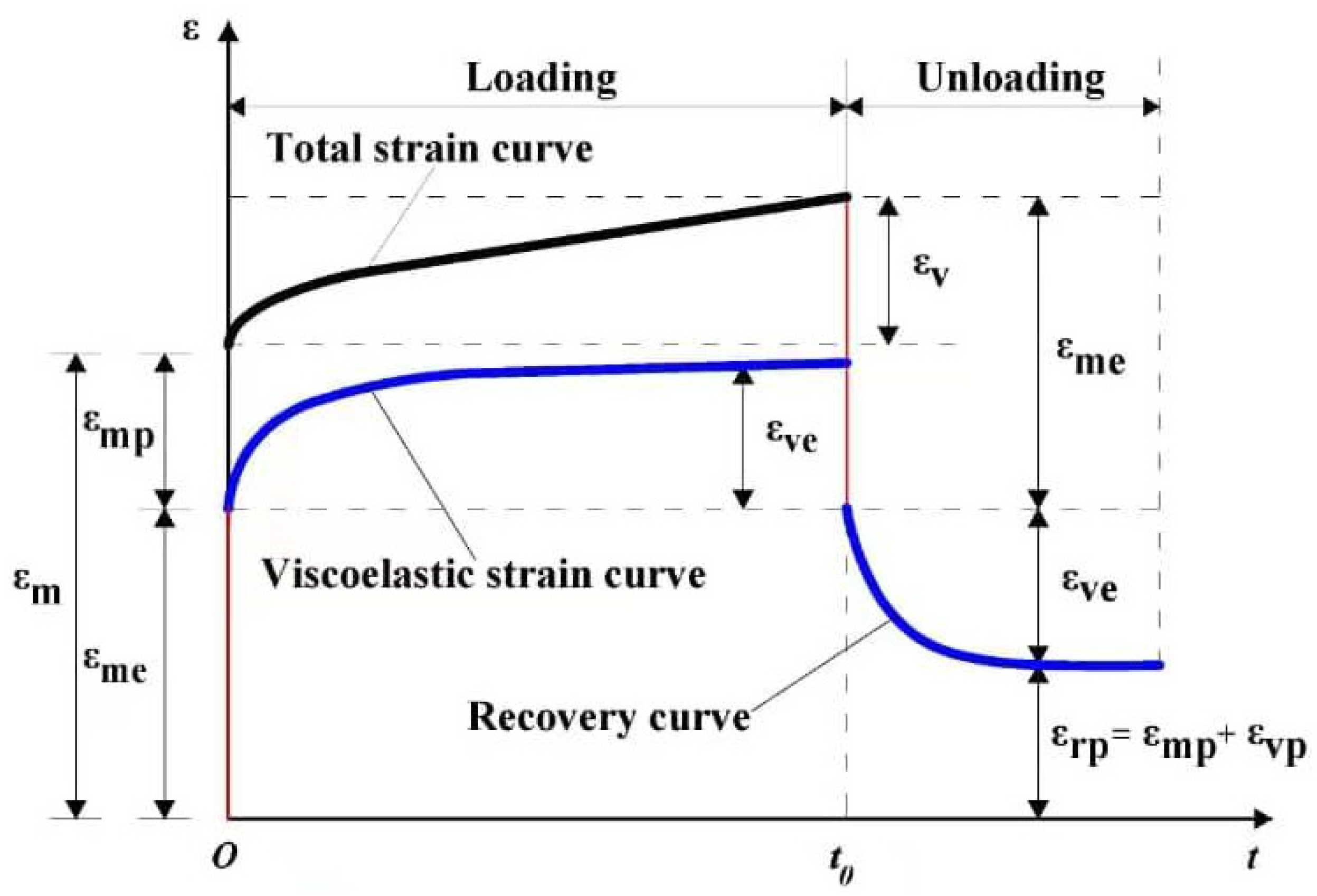

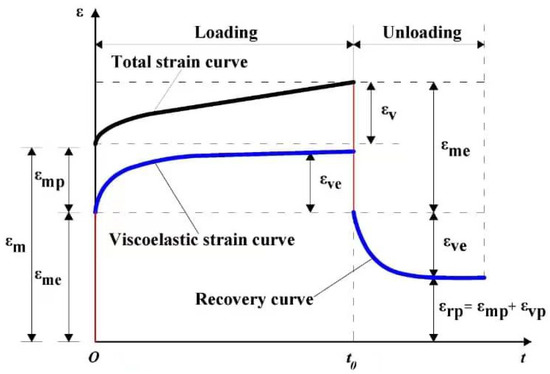

Figure 2 shows a typical rock creep curve in loading and unloading creep tests. The curve describing the unloading process is generally used to estimate and . Regarding and , they are especially calculated on the basis of the loading history according to:

where and are respectively the supplement instantaneous plastic strain and the supplement visco-plastic strain which are provoked during each additional deviatoric stress.

Figure 2.

Illustration of different strains by separation method during loading and unloading creep test (after Zhang and Wang, 2021 [80]).

It is important to note that currently most experimentally determined rock creep properties are primarily based on the rock loading process. However, most rocks continue to exhibit their creep behavior during the unloading process [81]. Additionally, compared to the actual rock deformation in the deep rock mass especially, the calculation of unloading deformation based on loading tests would be largely inaccurate [82]. The creep properties of rocks should therefore be studied much more.

5. Potential Factors Influencing Rock Creep

5.1. Hydraulic Pressure, Stress Level, Water Content, and Temperature

In addition to the internal factors mainly related to the composition and structure of rocks, the creep behavior is also influenced by several external potential factors that cannot be overlooked. It is very difficult to present in great detail all these factors in a single article, but the most relevant are reported herein. The most pronounced external factors are hydraulic pressure [82,83], stress level, water content, and temperature [23,30,84,85,86]. Hydraulic pressure itself can strongly affect the creep properties of rocks. In fact, the evolution of cracks and damage may facilitate rock failure under water seepage in existing rock discontinuities [83]. More broadly, hydraulic pressure can accelerate the evolution of cracks in rocks and thus affect the duration of creep phases. The increase of hydraulic confining pressure leads to the increase in creep deformation and also the increase in creep strain rate [83]. For its part, stress level is an obvious key factor influencing rock creep behavior. Generally, it governs the resistance of rocks. Stress level can justify the extent of creep phases over time and can affect both axial and shear creep of rocks. For instance, the creep strain and steady-state creep strain rate increase with the increase of the shear stress for the same elapsed time [87]. Moreover, the creep strain rate generally increases with the increase in deviatoric stress [86]. Rock creep is usually defined from a stress level. When the latter is modified, the creep parameters are also modified. Therefore, for fairer conclusions on any engineering applicability of rock creep behavior, it is strongly suggested to study rock creep under different stress levels.

Regarding the water content, its influence on the creep behavior of rocks is extremely significant. Generally speaking, water strongly weakens the mechanical properties of rocks. It dramatically affects the creep deformation of rocks. For instance, dry mudstones have their total cumulative volumetric strain 503% less than that of saturated mudstones [88]. This is one of the remarkable effects of water on the properties of rocks. Specifically, the creep resistance of rocks is generally reduced by the presence of water. Aggressive water has more adverse impacts on rocks due to its corrosive effects. Moreover, under prolonged exposure to water, soluble and carbonate rocks (such as limestone, dolomite, and gypsum) can even be karstified. Tunnel ruptures under the effects of water are frequent. In fact, the water content can easily be increased in the rocks surrounding the deep tunnels as a result of groundwater pressures and flows [89]. These are very common at great depth. Table 1 summarizes the relevant effects of water on creep behavior of different rock types.

Table 1.

Summary of the effects of water on the creep behavior of rocks (adapted from [89]). These data are taken into account given that the rock samples were mainly collected from deep rock tunnels, and also because of the available relevant studies. The maximum duration or duration range of the tests is provided to better understand the results.

Temperature is another key concern significantly affecting the creep behavior of rocks. Variation in the microstructure of rocks can be caused by changes in temperature [96]. This induces serious impacts on rock properties. Specifically, high temperatures usually deteriorate rock properties by debilitating the rock system, diminishing effective stress, and enhancing pore pressure [86]. Both short-term and long-term creep behaviors of rocks are influenced by increasing temperature. Tertiary creep as well as the breakage of rock can prematurely occur at high temperature [97]. This is generally due to the propagation of cracks which is favored by the increase in temperature. It is therefore important to take into account the range of temperatures to which the rocks are exposed. It is observed that nowadays, tunnels and mines are being built deeper and deeper and their surrounding rocks are experiencing complex conditions where temperatures are high [98]. Consequently, the effects of temperature fluctuations must be seriously considered in any study of rock creep aimed at effectively predicting the long-term stability of such structures. A summary of relevant temperature effects on the creep behavior of different rock types is presented in Table 2.

Table 2.

Summary of the effects of temperature on the creep behavior of rocks. Data are taken into account given that the rock samples were mainly collected from deep rock tunnels, and also because of the available relevant studies. The maximum duration or duration range of the tests is provided to better understand the results.

5.2. Damage and Time-to-Failure

Damage can be an internal factor that has an extreme influence on rock creep. Similarly, the time-to-failure of rocks, which is particularly associated with the scope of damage, affects the process of rock creep. Owing to the stress perturbations that impose stress redistributions around the rocks surrounding the excavated areas, rock damage is inevitable. Excavation-damaged zones (EDZ) and excavation-disturbed zones (EdZ) are therefore evident consequences of stress redistributions. Generally, there is lasting damage to pertinent rock properties in the EDZ [104,105]. It should be pointed out that most of the rocks contain pre-existing damage which is increased by that generated by the tunneling. Then, their extent increases with time due to the time-dependent behavior of natural rocks. According to Zhang et al. [106], it is even indispensable to determine the damage generated by different deformations of rocks. Due to the random distribution of microcracks in rocks [107], the evolution of damage mainly results in nonlinear deformations [108]. Indeed, tertiary creep and rock failure can be caused by the time-dependent damage of rocks [109]. More specifically, as related by Li et al. [85], critical damage triggers the appearance of the tertiary creep. Typically, damage accumulates in the secondary creep phase and then reaches the tertiary creep until it leads to rock failure [8,110]. Under the effect of damage, the spectacular reduction in the mechanical properties of rock usually corresponds to the failure [111]. Therefore, a correct description of rock creep cannot be made without adequate consideration of the damage factor. The accuracy of constitutive rock creep models is questionable when they do not take into account the actual rock damage. The damage variable (D) can be expressed as follows [8,14]:

where is the time initial; is the moment of the total damage of rocks; is a constant related to the rock material. Quantitatively, the damage factor can vary from 0 (intact rock) to 1 (rock totally damaged) during creep [8,14,21,32,101,112,113].

The damage effect on the overall creep process is considerable. It not only affects the rocks surrounding the tunnels, but also the linings. When these are not properly designed to resist rock creep deformation, they can be severely damaged over time [114]. As such, the damage severity to tunnel linings varies with the strength of the rocks. For tunnels located in weak rocks, the deformation of the linings can be uncontrollable and their failure may occur more quickly than expected. Even tunnels in high strength rocks can have their supports with a high extent of damage over time [115]. In this respect, selecting and developing rock constitutive creep models without evaluating and integrating the rock damage variable may be unrealistic.

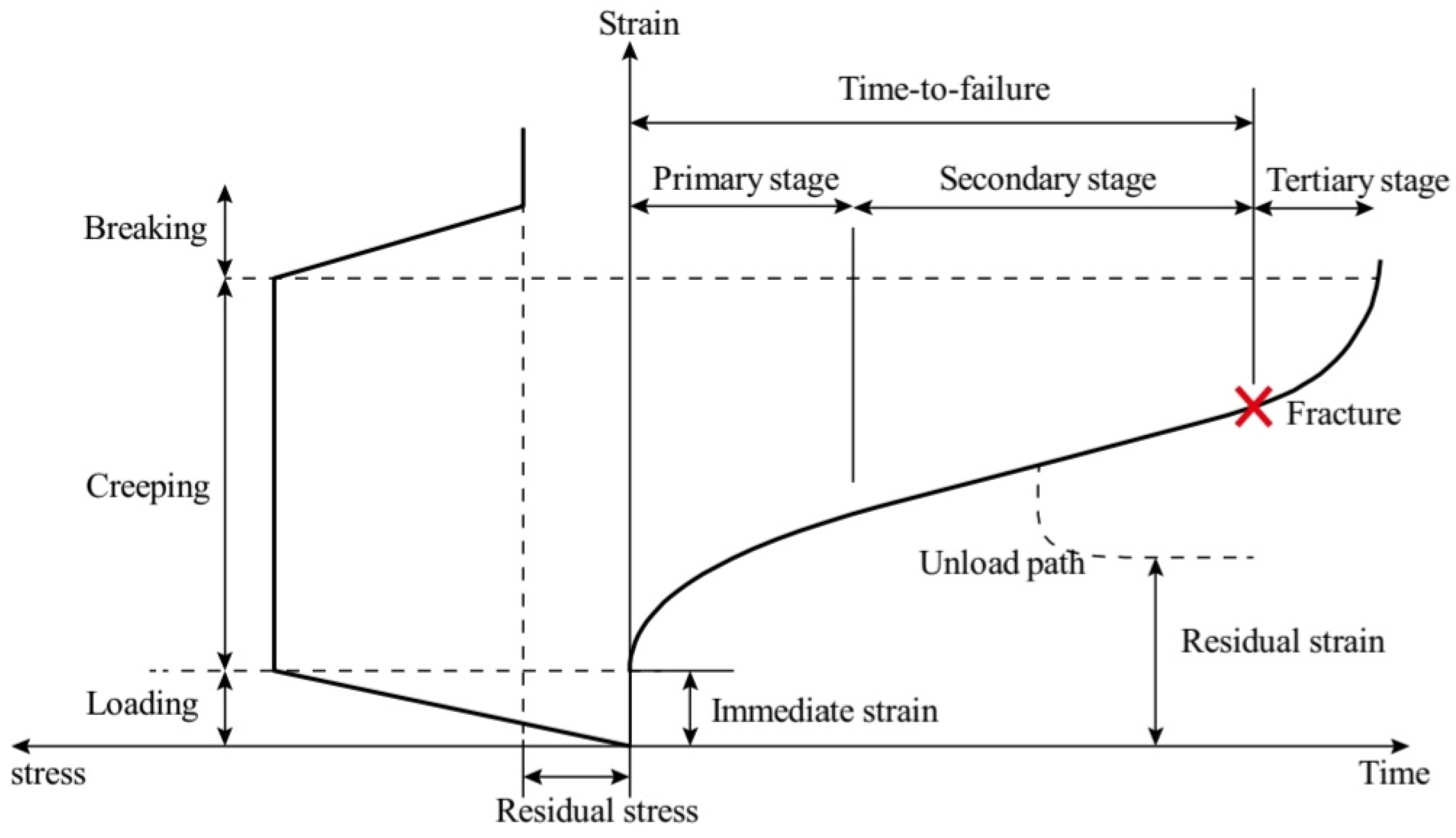

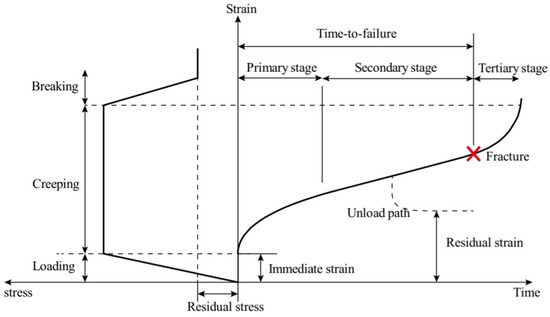

The time-to-failure of rocks is the time taken for rocks to be fractured during creep until failure. It varies with the type of rocks and the applied stress. Specifically, with the increase of the latter and of the secondary creep rate, the time-to-failure reduces [31]. Under the effect of loads, fractures which generally result from the evolution and coalescence of pre-existing cracks cause the rock to break [116]. The time-to-failure of rocks can be hastened at tertiary creep where damage and fractures are greater. Normally, it consists of the sum of the creep times in the three phases [28]. However, brittle rocks, for example, may exhibit short failure times which can be the duration of the first two creep stages (Figure 3). For each creep phase, the duration depends on the stress level [117]. If the environmental conditions of the surrounding rocks remain unchanged, the time-to-failure of rocks can only depend on the stress level [118]. Therefore, rock creep time is the lifetime of rocks under a given level of stress. Accordingly, it is of utmost consideration to predict the time-to-failure of rocks using the real stresses the rocks might be subjected to. The developed constitutive models of rock creep may also be adept at predicting the time-to-failure of rock [32]. The degree of damage of surrounding rocks generally has significant impact on the time-to-failure of rocks, and on the structural integrity of tunnels. In addition to damage generated by rock excavations, damage provoked by the triggering of rockbursts and earthquakes should also be taken into account. Indeed, the rocks near the tunnels can face such dynamic situations which considerably increase their level of damage and reduce the time-to-failure [6]. Specifically, earthquakes can cause extensive damage to tunnels, including water ingress into surrounding rocks and rupture of linings [119]. In other words, the more damaged the surrounding rocks, the shorter their time to failure [120], and therefore the faster the tunnels rupture. This can be illustrated for brittle rocks in Equation (9), referring to Brantut et al. [112]:

where is the macroscopic time-to-failure; is tertiary creep; is the applied stress; is the creep time; is a coefficient related to the evolution of damage; is elastic modulus of rocks.

Figure 3.

Illustration time-to-failure for brittle rocks from a standard creep curve (from [110]; Copyright©2022, with permission from the publisher, License No. 5333750843038).

Depending on the rock conditions involved, the time-to-failure may sometimes be delayed and failure may therefore occur somewhat later after the onset point of tertiary creep is reached, owing to the evolution of cracks [121]. However, when tertiary creep occurs, rock shear strength is significantly degraded and ultimate rock failure is imminent [8]. The time-to-failure is therefore a factor that influences the creep process. It should be taken into account in the models describing the creep behavior of rocks.

5.3. Consideration on Tunnel Lining Structures

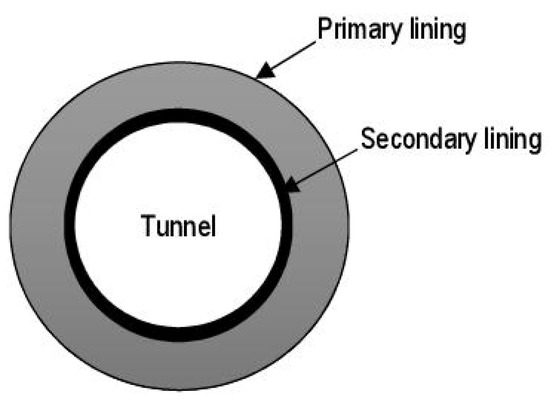

Tunnels are commonly supported by an initial lining which may be shotcrete, rock bolts, steel arch, and a secondary lining [122]. Figure 4 illustrates the typical position of tunnel linings. Such supports are necessary and must be put in place within a reasonable time to effectively limit the time-dependent behavior of the EDZ evolving in three phases, the third of which is the accelerated phase, especially in a contiguous rock mass [123]. The linings can be seriously impacted under various factors, including the creep effect of the surrounding rocks. As reported by Nie and Zhang [124], rock creep is the primary factor causing lining deformation. For example, due to severe creep deformation which occurred only after 3 years in the secondary lining of Erlangshan tunnel (China), new reinforcement was applied in an attempt to solve the problem [125]. Indeed, there is no fixed time for the appearance of severe creep deformations in the secondary lining of tunnels. This depends on several relevant factors including the strength of the linings.

Figure 4.

Typical positions of secondary and primary linings of tunnels, adapted from [126].

The mechanical properties of the secondary lining can be altered due to their general exposure conditions [127]. Moreover, such lining typically confronts the time-dependent creep behavior of its own materials and the effects of the tunnel construction process [128]. It is of the greatest consideration to install the secondary lining of tunnels as soon as possible [122,129,130]. This implies that the primary lining must previously be installed more rapidly. Indeed, a significant reduction in ground deformation is a great advantage of placing the primary lining very early [131].

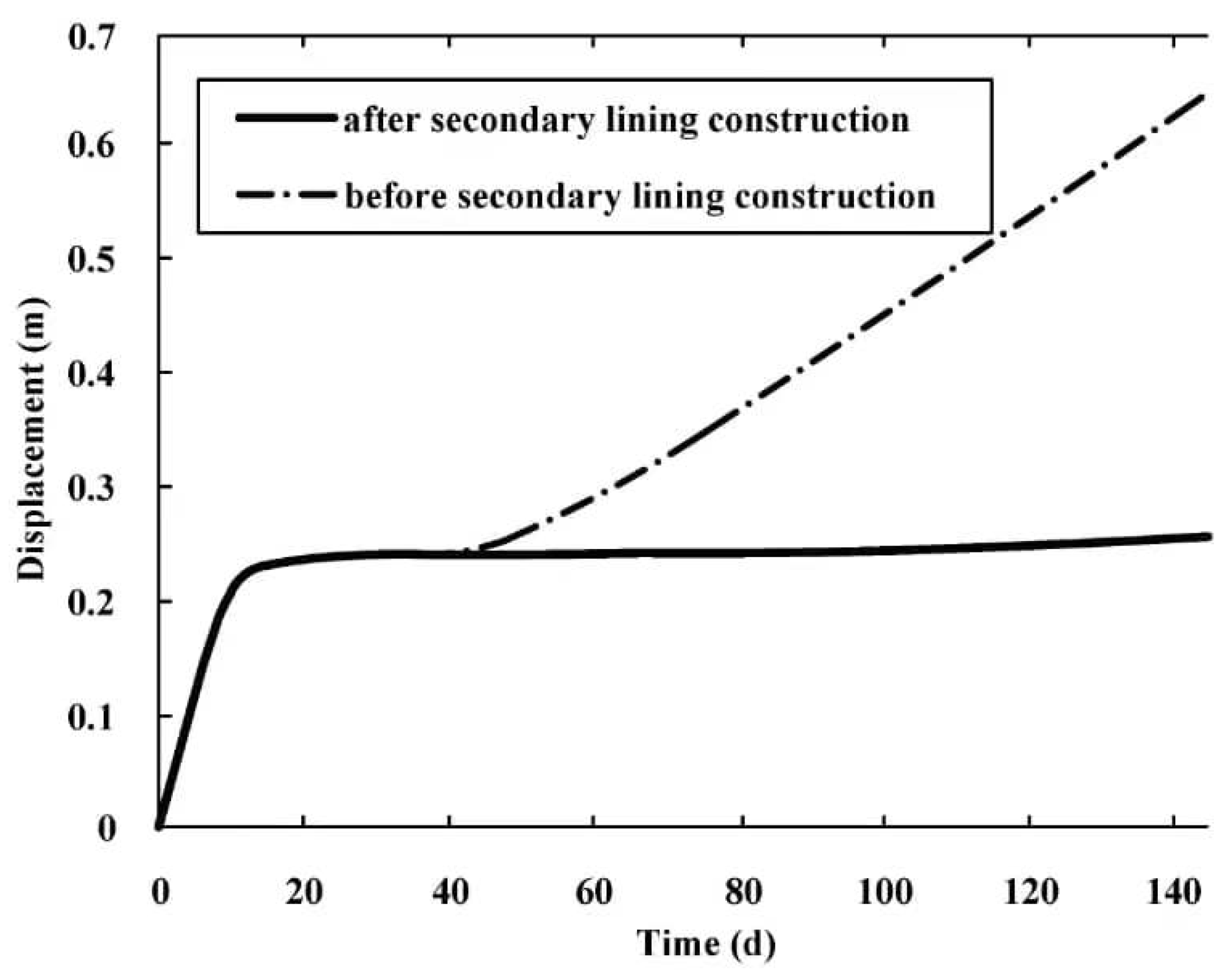

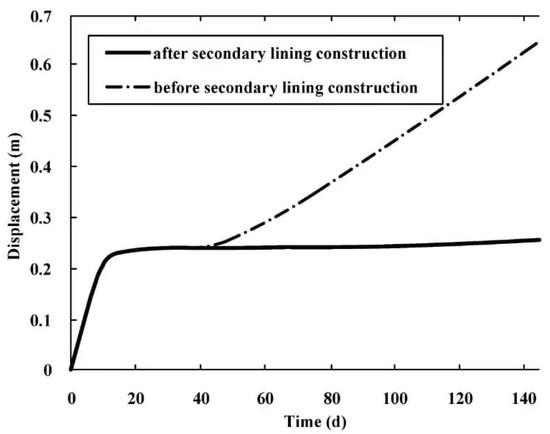

Tunnel excavations are usually done in different phases or sections [132], and usually only after a few minutes of excavation, the rocks start their deformation which will evolve continuously [41]. The application time of the secondary lining should be in accordance with the time of the excavation sequence. This can prevent the rapid evolution of rock creep and thus ensure the stability of the rocks near the tunnels. In addition, referring to Chu et al. [133], the earlier the lining is installed, the lower the ultimate support and rheological pressures. More explicitly, for tunnels built in soft rocks where large deformations usually occur, their secondary lining must be put in place within a period not exceeding 40 days after excavation [129]. Such a practice makes it possible to limit the creep rate of the host rocks and to keep their creep behavior in the secondary stage for as long as possible (Figure 5). Additionally, the limitation of the time for placing the secondary lining is necessary to stabilize the pressure of the rock mass around the tunnels. As an example, the rock mass pressure was stabilized after 35 days of secondary lining installation in Lianchengshan highway tunnel, Hanzhong City, Shaanxi Province, China [134]. Stabilizing rock pressure as quickly as possible is essential for the lining stability. In fact, one of the causes of lining rupture is the exorbitant pressure of rocks engendering uncontrollable deformations in the tunnels [135]. Under such circumstances, squeezing rock behavior is common. From a constant deviatoric stress, the triggering of such behavior can also be favored by the increase in shear strain [136], which can eventuate during the evolution of creep strain and before failure [8]. As related by Barla et al. [137], squeezing rock can strongly appear in tunnel constructions and its effects are considerable. Such behavior, jeopardizing tunnel stability, is also frequent in weak rocks under high stress, and its extent reflects tunnel deformations [138]. As reported by Yadav and Sharan [139], squeezing may last for a long-time and is basically related to creep. It is of extreme consideration to stabilize rock pressure and creep by placing the linings as soon as possible. Since the long-term stability of tunnels depends largely on the long-term safety of its secondary lining [127,140], the control of deformations of the surrounding rocks and those of the secondary lining is of paramount importance. The resistance of the linings and especially their installation time are therefore also factors influencing the evolution of rock creep.

Figure 5.

Influence of the installation time of the secondary lining in maintaining surrounding rocks at their steady creep state for a tunnel built in soft rocks. “d” refers to days (reprinted from Huang et al. [129], Copyright©2022, with permission from the publisher, License ID 1238703-1).

6. Mechanical Models and Creep Constitutive Models

6.1. Mechanical Models

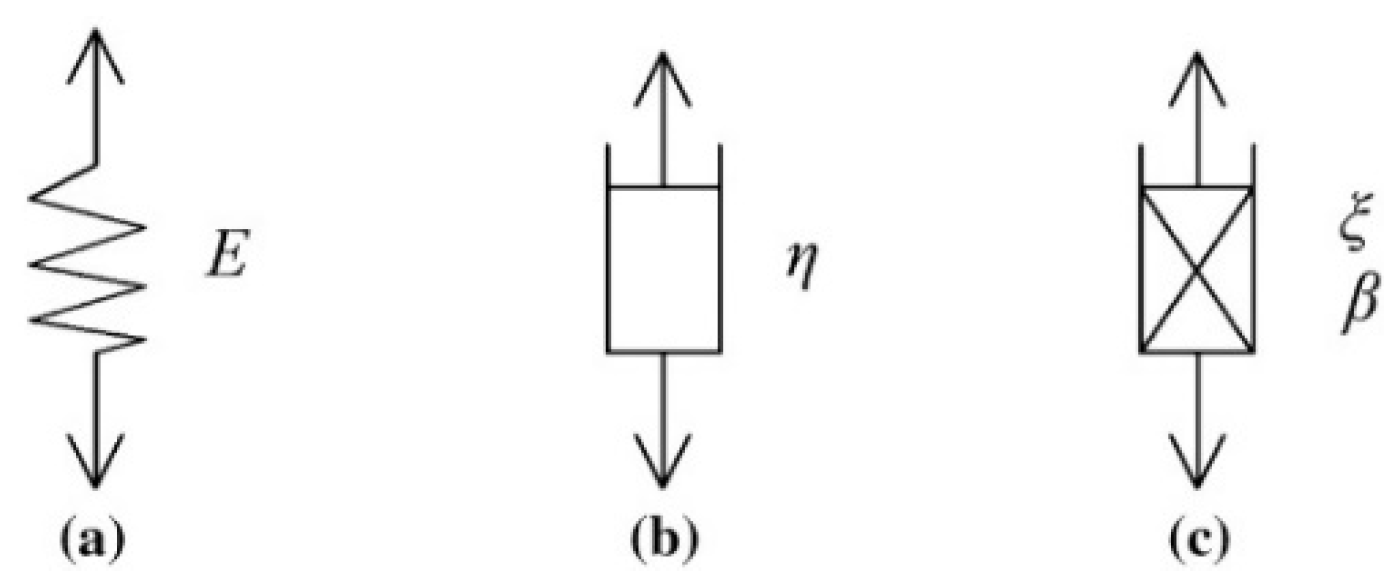

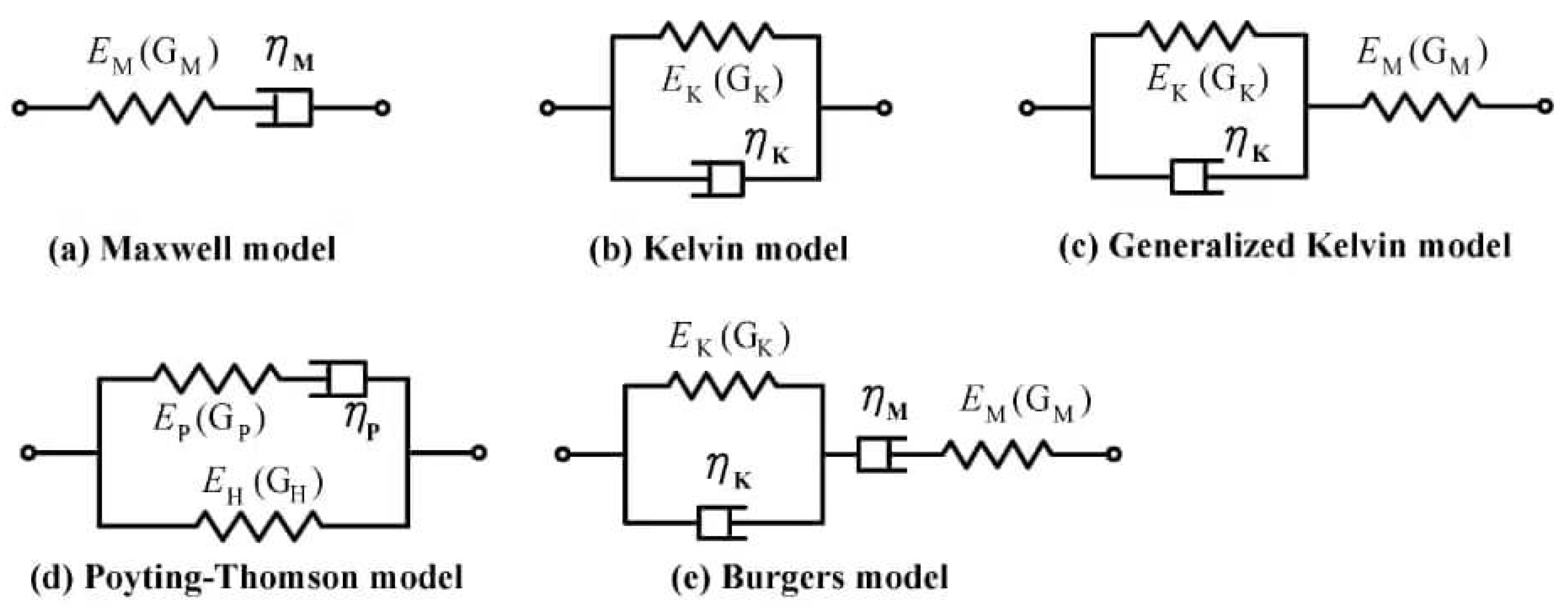

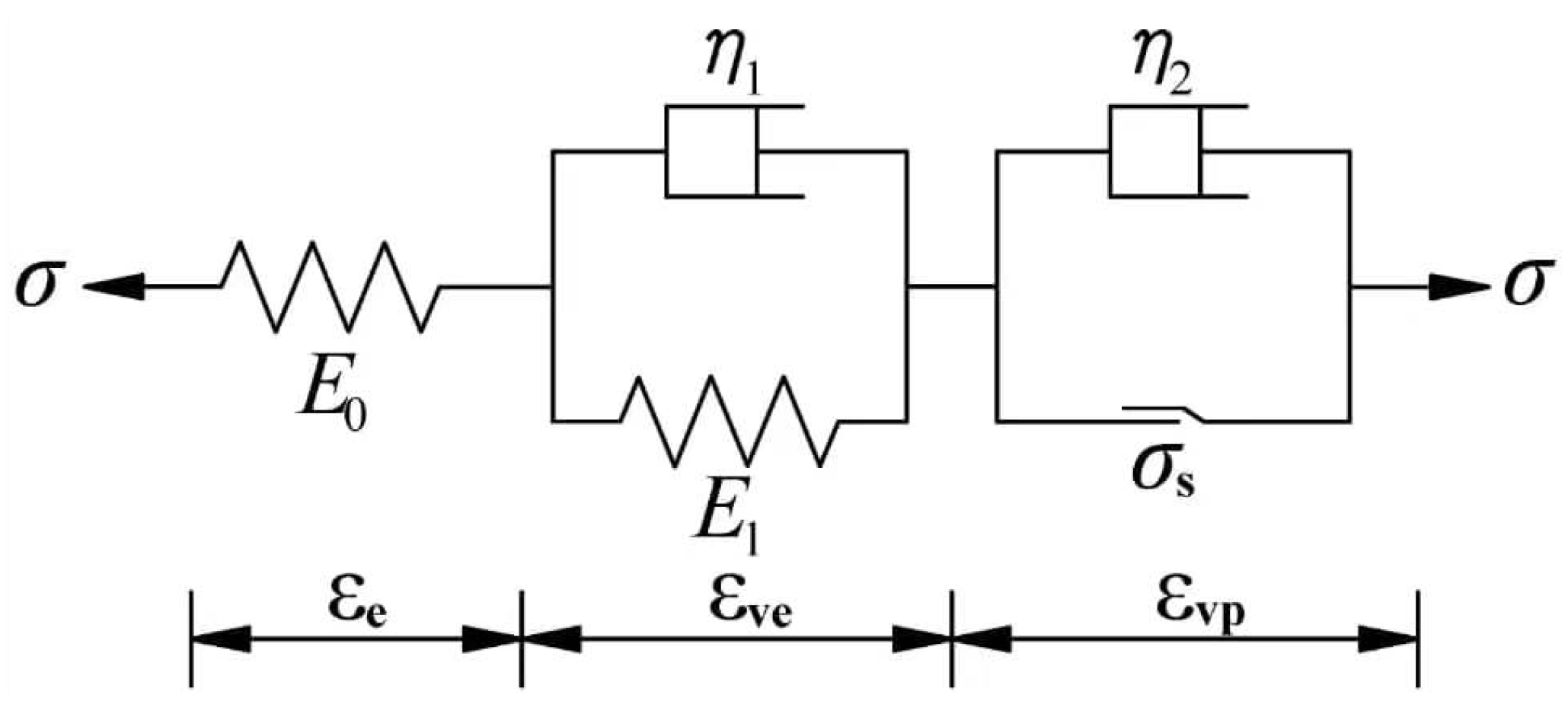

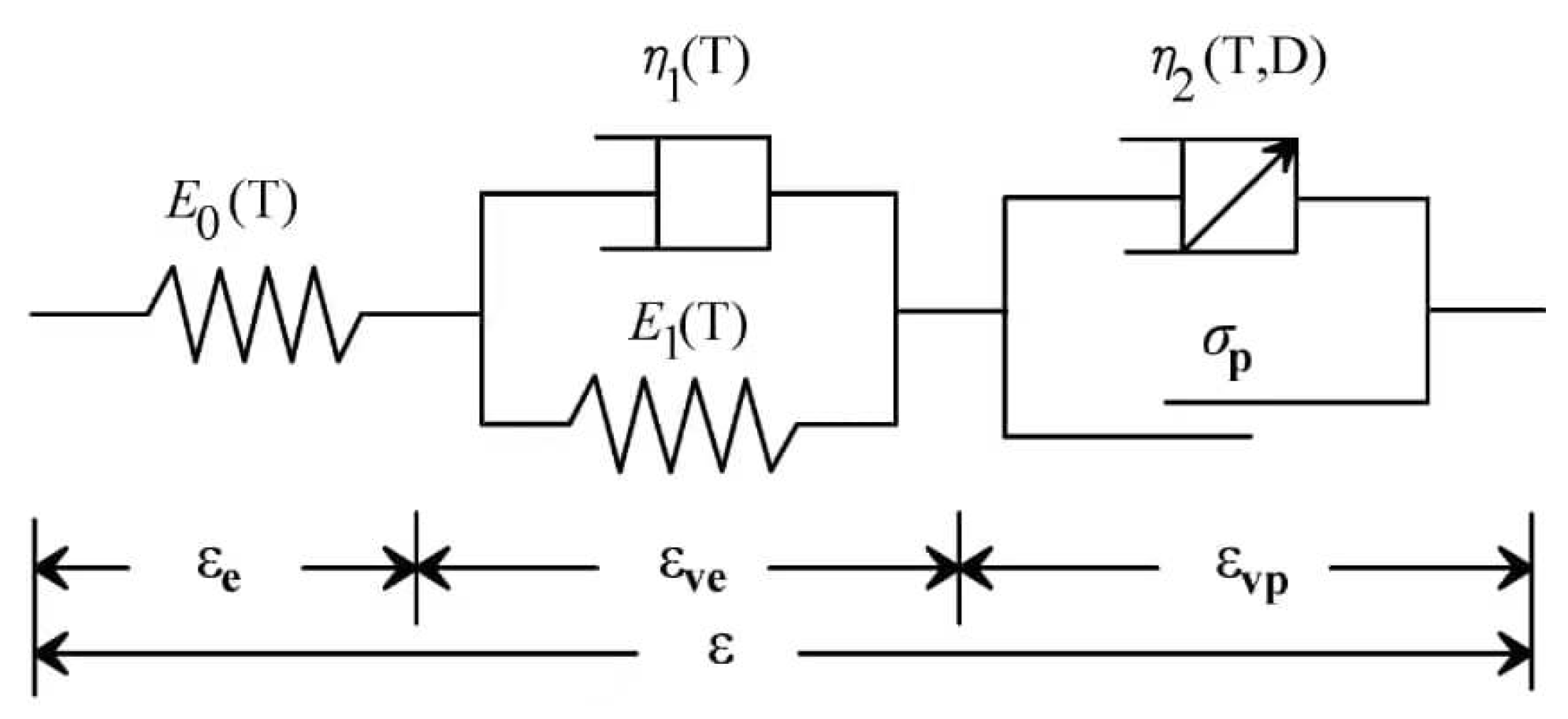

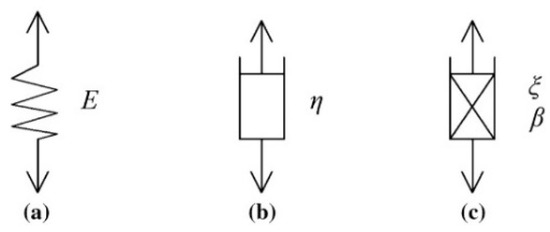

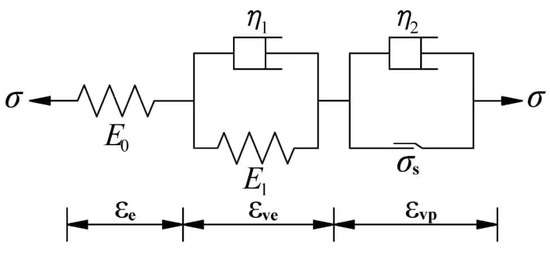

Mechanical models are habitually employed to concretely represent the creep behavior of rocks under well-defined conditions. A mechanical model consists of springs, dashpots, and frictional-cohesive elements [141]. Springs are usually represented by Hooke’s body to reflect elastic behavior (Figure 6a), dashpots are illustrated by Newton’s body to reflect viscous behavior (Figure 6b), while friction-cohesive by St Venant’s body to express plastic behavior (Figure 6c). Since rocks are generally complex, combinations of mechanical models are usually appropriate to better represent their creep behavior. These combinations can be linear or nonlinear depending on the relationship between stress and strain. In such combinations, elements can be associated in series and/or in parallel [41]. Above all, the modes of association must express the creep characteristic of the rocks as precisely as possible. Table 3 reports details of the most relevant mechanical models based on the works of Kabwe et al. [32] and Yang et al. [142].

Figure 6.

Fundamental mechanical elements with their characteristic parameters: (a) Spring element represented by Hooke’s body to reflect the elastic behavior of rocks, is elastic modulus; (b) Dashpot element illustrated by Newton’s body to reflect the viscous behavior of rocks, is viscosity coefficient; (c) Friction-cohesive element represented by St Venant’s body to express the plastic behavior of rocks, is viscosity coefficient; is fractional order. (Reprinted from [21], Copyright©2022, with permission from the publisher, License No. 5333740277281).

Table 3.

Common mechanical models interpreting the creep behavior of rocks.

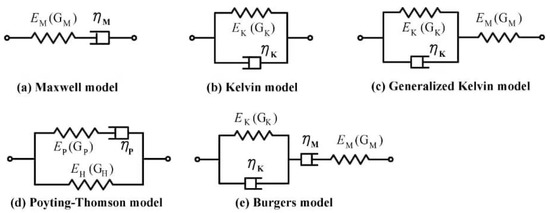

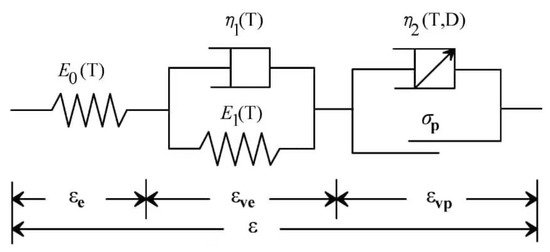

Figure 7, Figure 8 and Figure 9 illustrate some of these models with their characteristic parameters.

Figure 7.

Common creep models with their characteristic parameters (from [143], Copyright©2022, with permission from the publisher, License No. 5333760872972).

Figure 8.

Classical Nishihara model (after Liu et al. [20], Copyright©2022, with permission from the publisher, License No. 5333750232228).

Figure 9.

A mechanical model integrating thermo-damage effect (after Chen et al. [97], Copyright©2022, with permission from the publisher, License No. 5333771474409).

6.2. Constitutive Creep Models of Rocks

Creep constitutive models are usually conceived to predict long-term deformations of rocks. They are roughly classified into two types such as empirical equations and differential creep equations [98]. The differential creep equations can be linear and nonlinear. Nonlinear models are generally established to overcome the limitations of common mechanical models which are characterized by linear components [79]. The empirical creep equations are generally in the forms of power-law, exponential, logarithmic, and are commonly derived from typical creep curves. Empirical equations can also be a mixture of the three mentioned forms. The equation reflecting the empirical law of rock creep is as follows [14,31]:

where is the total creep strain; is instant elastic strain; is ephemeral creep strain; is stable creep strain; and is creep strain at the final stage.

With the need to outrival the basic limits of the empirical creep law [80], many creep constitutive models are developed to better represent the rock properties from combinations of mechanical models. Since rheological problems in rocks are complex and are caused by many factors, most scholars extend the one-dimensional rheological model to three-dimensional (3D) with the intention of better describing rock creep. Indeed, in 3D representations, the deviatoric stress tensor () and the spherical stress tensor () are the constituents of stress tensor (). They are generally expressed as follows from Hooke’s law [32,144]:

where and are respectively deviatoric strain and spherical strain tensors; is the elastic bulk modulus.

where is the Kronecker coefficient; is the strain tensor; is the sum of the principal stresses , and such as .

Table 4 and Table 5 show relevant information on existing constitutive creep models for various specific and general rock types. They can also illustrate the considerable progress made in this area.

Table 4.

Summary of relevant details of creep constitutive models for various specific rock types.

Table 5.

Summary of relevant details of creep constitutive models for various general rock types.

It is important to present existing constitutive creep models for specific rock types and general rock types. In fact, creep constitutive models for specific rock types can be applied in specific situations. That is, the long-term stability of a given tunnel can be studied using an appropriate creep constitutive model of the specific rock type which is the most predominant in the surrounding rocks. However, constitutive creep models of general rock types can be used to study the long-term stability of tunnels when various rock types that exist in the surroundings can be classified as one of the general rock types. For any choice between creep constitutive models of specific rock types and those of general rock types, the suitability is required. It should be noted that usually, to establish the constitutive creep models of a general rock type, the specimens used for the experiments are most often specific rock types that may represent the rock types of the studied rocky media. For instance, to propose creep constitutive models of soft rocks, Liu et al. [20] used mica-quartz schist for experiments. Similarly, Cao et al. [17] study the creep constitutive models of hard rocks from experiments carried out on amphibolite samples.

6.3. Creep Constitutive Models in Deep Mines and Caverns

It is also of great interest to ensure the long-term stability of mines and caverns. However, it remains a difficult task due to the continuous increase in the depth of such underground structures. Coal mines, for instance, are operated at depths that can surpass 1000 m [98,154]. As caverns are usually used for long-term energy storage, their burial depth is usually very deep and can exceed 1500 m or even more. For example, a salt cavern in the Hebei province of China is expected to be located at an exceptional depth of 2700 m [155]. Nevertheless, at deeper and deeper depth, rock characteristics and conditions are increasingly complex [156]. At the same time, ensuring the long-term stability of deep mines and caverns is vital. To this purpose, creep constitutive models are widely employed as essential means [157]. In the case of hard rocks and harder rocks, the task is more challenging. For instance, despite their low creep deformation, hard rocks such as granite are often utilized to host geothermal systems and highly radioactive waste [158]. Therefore, an accurate assessment of the creep behavior of any rock type is of paramount importance. Indeed, the effects of potential factors (temperature and stress level for example) on rock creep cannot be neglected in deep mines and caverns [22,157]. It is suggested to house these structures in rocky environments which have excellent creep properties. The notable creep properties of salt rocks allow them to be the best choice for positioning energy storage structures [22,159,160]. More appropriate mechanical creep models are therefore needed for the safety of structures located in the complex environments of salt rocks [160], whose creep properties are greatly impacted by the presence of water [161,162]. In fact, mining extraction decisions can be made based on the creep properties of the rocky media concerned [163], which are ordinarily significantly affected by water [164]. Importantly, properly ensuring the long-term stability of deep mines and caverns relies on adequate and accurate constitutive creep models. This is of extreme consideration to prevent financial and human life losses that can be caused by any early brutal failure of deep mines and caverns. Rough failure can be encountered in deep coal mines owing to the creep behavior of coal which endures strong stress conditions at great depth [154]. Partial or complete destruction of deep salt rock caverns is usually caused by the deformation of rocks over time [159]. Table 6 shows some creep constitutive models established for deep mines and caverns. In all situations, it is crucial to select and design the most appropriate creep constitutive models to ensure the long-term safety and stability of deep mines and caverns.

Table 6.

Some existing creep constitutive models for mines and caverns.

7. On the Applicability of Constitutive Models of Rock Creep to Deep Tunnels

A constitutive model of rock creep is extremely important in deep rock engineering. It can generally indicate the total creep strain of a given rock type. It is mainly used as a basis for designing appropriate support systems to ensure the long-term stability of host rocks of deep underground structures such as tunnels, mines, and caverns. Therefore, constitutive rock creep models should reflect rock characteristics and conditions as closely as possible. Otherwise, these models will not be effective in engineering applications. According to Nadimi et al. [166], constitutive models of rock creep must be reliable. In fact, premature tunnel failures can be caused by inaccurate estimation of the rock’s constitutive creep models. Consequently, it is important to continually revise the existing creep models in order to adopt the necessary considerations for their suitable applications. As examples, based on the creep constitutive model of deep sandy mudstone, Xuyang et al. [167] proposed a robust mixed support system to resist the overwhelming deformation of deep soft rock roadway located at the coal mines in Pingdingshan mining area of Henan province, China. Similarly, to solve creep hazards generating considerable instability on a siltstone roadway, Yang et al. [168] proposed a strong support system. Nonetheless, such propositions can be improved if the creep constitutive modeling is improved. In ultra-exaggerated deformations, tunnel support systems must be ultra-efficient and highly adapted to the real situations they face. To achieve such objectives, the constitutive creep models must be as accurate as possible. In fact, the need to improve the degree of precision according to their applicability should be prioritized. Note that significant losses are generally related to rock creep and to their constitutive models that are inappropriately characterized in underground structures [30]. Therefore, an ongoing review of pertinent existing equations that interpret and reflect such models is of tremendous importance.

As presented in Table 4 and Table 5, researchers have developed more and more sophisticated constitutive models of rock creep based on certain assumptions and conditions, but as pointed out by [7], their suitability is required. It can be noticed that the mathematical expressions are particularly complex for the majority of such models. Their applicability may therefore be difficult. Additionally, due to the complexity of rock behavior, the actual rock properties and conditions are very difficult to be determined and represented with extreme accuracy. Thus, scholars often utilize simplifying assumptions and conditions to study and establish constitutive models of rock creep. However, the exactness of such assumptions is rarely discussed. For convenient applications to deep rock tunnels which are substantial engineering structures and which are mostly expected to have long lifespans, it is worth questioning these assumptions. The following are the most commonly used assumptions or considerations.

7.1. Homogeneity and Isotropy of Rocks

Owing to the difficulties in capturing the exact nature of deep rocks, these are assumed to be homogeneous and isotropic. It is, however, accepted that such an assumption can be considered. In reality, natural rocks are heterogeneous and have many interstices [107,169,170]. Moreover, as revealed by Barton and Quadros [171], the anisotropic character of rocks is very frequent. This character is mainly due to the existence of micro-fissures which cause directional evolutions in the damage [108,172]. Remarkably, the evolution of the damage cannot be correctly controlled and determined by considering the homogeneity of rocks. Creep and rock damage are inseparable. As already mentioned, the evolution of rock damage is essential for properly estimating creep deformation.

7.2. Isothermal Conditions

Most laboratory experiments on rocks are carried out under isothermal conditions and the results are used to establish constitutive creep equations. However, throughout the life of a deep tunnel, the host rocks are confronted with often considerable temperature fluctuations. Temperature rise is one of the most adverse conditions typically faced by deep rocky environments [156,173]. Indeed, geothermal gradient cannot be ignored in deep rocky media. Generally, the temperature increases by /100 m depth [156]. However, at the same depths, it can be varied in different rock formations [156]. For example, located at a depth of 1347 m, the host rocks of the Sangzhuling tunnel (Lhasa–Linzhi Railway) face temperature variations, the highest of which is 89.9 °C, which seriously affects the longevity of its structures [173]. As already expressed (Table 2), temperature changes have considerable effects on rock creep. Moreover, the coupling effects of temperature gradients and the evolution of damage are very unfavorable for maintaining the long-term stability of underground structures. Therefore, it is crucial to expose rock specimens to strong temperature gradients for a long period of time in order to adequately interpret their behavior. Thus, isothermal conditions cannot accurately reflect the actual behavior of deep rocks. This is another reason why constitutive creep models established under such conditions cannot be applied as they stand to ensure the long-term stability of deep rock tunnels.

7.3. Static or Quasi-Static Conditions

During most creep experiments, static or quasi-static conditions are mainly considered to determine rock creep parameters. However, rock creep is strongly affected by dynamic disturbances which imply additional damage and shorten the time-to-failure [6]. Deep tunnels often experience serious dynamic events during their excavation such as rockbursts, or during their operation such as earthquakes, etc. Dynamic loads affect tunnel support systems, making them unstable if they have not been designed to cope with such events. If the dynamic creep properties of rocks are unknown, then the associated constitutive models are unrealistic to be applied to deep rock tunnels. In fact, as demonstrated by Qin et al. [174], dynamic pressure and creep coupling can increase the deformation of deep soft rock roadway 11 times more. It should be noted that tunnel support systems usually fail when they cease to perform their functions properly.

7.4. Specific Stress Conditions

As already mentioned, stress level has obvious influences on the creep behavior of rocks. However, in most of the existing constitutive creep models of rocks, the constant stress level is mainly considered. As pointed out by Cao et al. [118], when the extent of stress varies, such models are no longer applicable unless all related parameters are re-evaluated. During the service life of a tunnel, the possibility of variation of the stress level remains high. Thus, suitable models that can simulate different stress levels are required for safe applications. Importantly, to establish a rational support principle of underground structures, the creep of rocks must be studied in detail under different states of stress [175].

8. Simple Example for a Specific Case

Considering the creep model (Burgers model) proposed by Mansouri and Ajalloeian [152] in Equation (26), a simple calculation is made in order to attract more attention. Burgers’ model strongly reflects the creep behavior of salt rocks which are widely utilized to be the host medium for deep mines and caverns [152,163]. Creep parameters of salt rocks at three stress levels are used for the calculation. Table 7 shows these parameters.

Table 7.

Creep parameters of salt rocks. (Data are taken from Mansouri and Ajalloeian [152], Copyright©2022, with permission from the publisher, License No. 5361920269706).

If we use the model mentioned above to predict the long-term stability of a deep salt mine or cavern, the evolution of creep strain can be a guide. Table 8 provides simple calculation results for different years.

Table 8.

Creep strain results for a deep salt mine or cavern based on Equation (26).

Table 8 shows the evolution of creep strain of a deep salt mine or cavern. Normally, such results could help in designing adequate support systems and judging the stability of the concerned deep salt cavern expected to be safely operated after 1 year, 2 years, 3 years, 10 years, 50 years, or 100 years. However, the obtained results based on Equation (26) cannot be properly exploited to accurately predict the long-term stability of the real salt cavern for the following main reasons:

- -

- Potential factors such as water content and temperature that strongly influence the creep behavior of salt rocks seem not to be taken into account in the model.

- -

- Tertiary creep is not introduced in the model. In fact, the modeling of the tertiary creep requires to take into account damage variables or nonlinear elements [98].

Although this example is a simple calculation, it may illustrate the need to develop more appropriate creep constitutive models that satisfy realistic situations for more accurate applications to the long-term stability of deep underground structures.

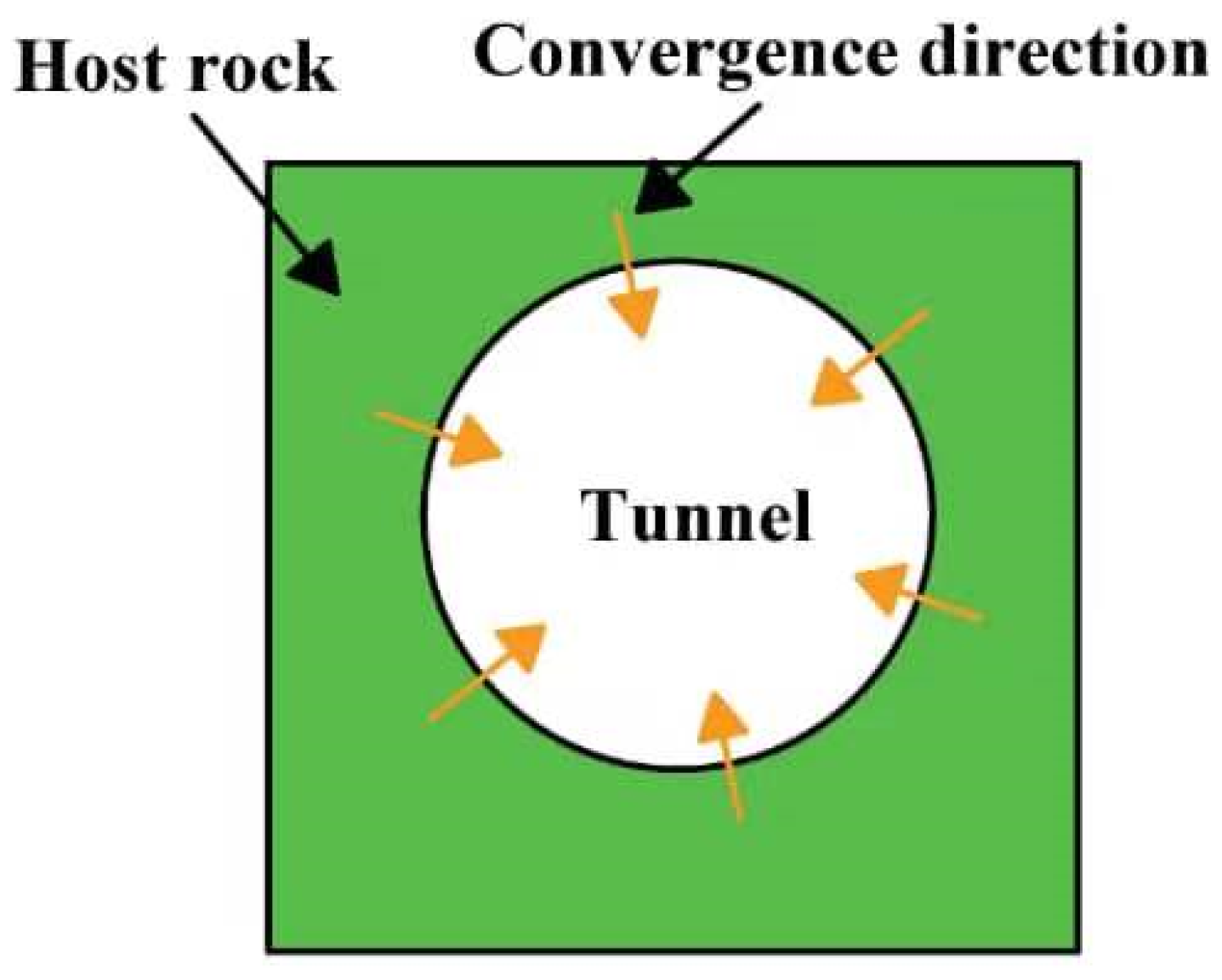

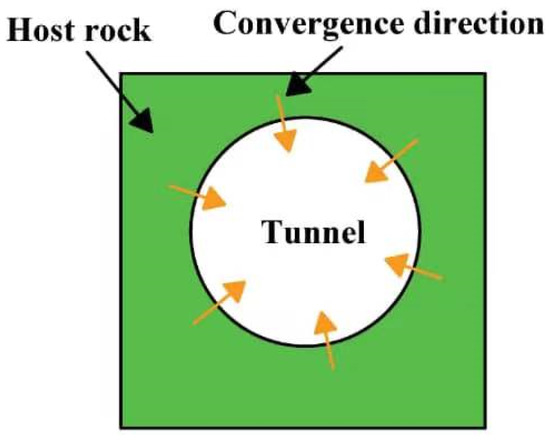

9. Convergence and Post-Creep Behavior of Rocks Surrounding the Tunnels

Convergence of tunnels is the gradual closing of the openings with the evolution of time. It is caused by two types of deformations of surrounding rocks. The first one is the deformation provoked by the tunnel front advance and the second is that generated by the effect of rock creep [176,177,178]. However, the major contribution to tunnel convergence is that due to rock creep. Therefore, the creep behavior of rocks really has the merit of reflecting and describing the long-term life of tunnels. According to Do et al. [130], reduction of tunnel convergence is possible by two technical measures such as low tunneling sequence or increased thickness of linings and early placement of supports. However, under the influence of time and aging of the supports, the convergence deformation can become considerable. The rate of convergence evolves according to the type of rocks located around the underground openings. It is generally faster in soft rocks than in hard rocks. To improve understanding, an illustration of convergence tendency is presented through Figure 10 for a circular tunnel.

Figure 10.

Illustration of tunnel convergence.

Ideally, the convergence is severe when the rocks surrounding the openings exhaust their stable creep phase. When it reaches 400 cm, the tunnels are said to have large deformations [179]. As associated with rock creep, large deformations are time-dependent [180], and are greater at great depth [181], where they can be strongly influenced by groundwater [182]. Unacceptable convergences are generally observed in deep tunnels located in soft and weak rocks under the action of strong in situ stresses [183]. The extent of tunnel convergence increases over time if security and stability conditions are no longer guaranteed. Indeed, when the accelerated creep is reached, the tendency to convergence become more and more severe. At that time, the tunnels will no longer be able to perform their functions because the risks of considerable closure are enormous. In fact, ensuring the long-term stability of tunnels is linked to major difficulties with the occurrence of tertiary creep [23]. The evolution of tertiary creep will then be followed by the final rupture of the rocks, and the tunnels will be completely collapsed. As a result, there is appearance of the post-creep behavior of the rocks surrounding the tunnels. According to Deleruyelle et al. [184], the life cycle of deep tunnels can be composed of four stages, the ultimate of which is total destruction where the natural water pressure slowly repairs itself and seeps through the existing cavities. It is therefore essential to accurately predict the life of tunnels by developing accurate and suitable constitutive creep models in order to prevent any early post-creep behavior of rocks near the underground openings.

10. Discussions

In this article, relevant information about rock creep is highlighted. It can be seen that scholars and researchers have devoted substantial research to rock creep. The properties of the latter are widely applied in different types of underground structures. However, because of its predominant feature of governing the long-term stability of rock engineering [113], rock creep should be much more studied and discussed as it still represents a key research area. In fact, rock creep impacts are increasingly significant at great depth. Under such circumstances, all rock types generally experience time-dependent deformations. There are no exceptions even for high strength hard and brittle rocks [115]. For long deep tunnels that pass through rock media with varying properties, rock creep control can be much more difficult. Therefore, precise information on the types of rocks traversed by these tunnels is necessary for a better assessment of their long-term stability.

It is indispensable to ensure the stability of deep tunnels [87], regardless of their function (water conveyance, sanitary drainage, transport systems, hydro-power stations, irrigation, mining, energy storage). The long-term stability of such structures is mainly governed by the secondary creep phase [185,186]. As stated by Herrmann et al. [37], at the smallest creep strain rate, secondary creep is considered a long duration transient creep event. It is essential to take adequate measures to keep it as durable as possible. Particular attention should be given to deep soft rocks which can quickly reach their tertiary creep under high stress [187]. In such stress ranges, the existence time of the secondary creep can be shortened, which is very detrimental to the stability and durability of tunnels built in the aforesaid rock types. It is important to emphasize that, whatever the nature of the rocks, high stress coupled to extreme geological conditions are very harmful to tunnel stability. Such conditions have great effects on rock creep life. Information on the extent of loads or stresses that trigger the steady creep stage and the period of reaching this stage is crucial to ensure the stability of tunnels [188]. Although laboratory experiments can reveal the magnitude of stress that causes secondary creep to end and tertiary creep to begin, extensive on-site monitoring is strongly necessary to better control and interpret the creep behavior of rocks. This is very important as the duration of real engineering projects is not exactly reflected in experimental study of rocks [39,102,129,185]. To accurately predict the long-term deformations of rocks, the duration of laboratory experiments should be reasonable. It can be observed that there is no universally accepted duration for laboratory creep experiments. As reported by Yang et al. [142], such tests can last a few hours, days, or months, and rarely a few years. It remains a difficult task to determine the duration of these experiments for the long-term prediction of rock deformation [77].

Tunnel instability can be predicted as soon as it is known that the second creep stage is about to end, and the third stage begins very soon. Consequently, maintaining the creep behavior of the surrounding rocks in its secondary phase is the optimal option. It is certain that the rocks surrounding the tunnels alone cannot maintain this phase for long. It is why that it is strongly recommended that the tunnel linings be installed at soon as possible according to the excavation sequences. Even after the installation of the secondary lining, adequate monitoring is required to control the appearance of cracks and deformations which will evolve slowly [179], and to ensure that the rock deformations still remain stable, avoiding any unexpected failure. In fact, given that failure usually results from reaching maximum crack propagation, careful monitoring is of paramount importance, especially at great depth where large rock deformations typically occur. The safety conditions of the secondary lining can signal the creep evolution of the rocks surrounding the tunnels. In fact, the visible growth of cracks and damage in the secondary lining can be taken as an indication that the deformations of the rocks near the tunnels are significant and therefore the creep strain rate could be high. As a result, the phases of rock creep may last less than expected when the host rocks are initially cracked and damaged by the excavations. Then, tunnels could then fail prematurely due to the shortening of the time-to-failure of rocks. With suitable and reliable monitoring systems, adequate measures can be taken in time and serious accidents can be prevented. For instance, after a short operating period of three years, the Xuecheng Tunnel of China was taken out of service due to the development of numerous cracks in its lining and it took two years to restore [122].

Although countless research efforts have already been conducted, the ideal constitutive models of rock creep are not yet precisely determined. Therefore, predicting long-term stability of tunnels remains arduous in spite of many advances in the field [189]. This is mainly due to the complexity associated with deep rocks. Consequently, rock creep is strongly influenced by many factors which are very difficult to account for accurately. On top of that, in many existing creep constitutive models, all these factors are not even taken into account and simplifying assumptions are mostly employed. Another important issue to address is the modeling of tertiary creep. As most of the existing constitutive models do not take into account the time-to-failure which reflects the lifetime of the creep and which is a potential internal influencing factor, the modeling of the tertiary creep needs to be studied much more. Despite most of the existing models having been designed by combining nonlinear models intending to better describe the nonlinear behavior of the accelerated creep, they are limited by not properly considering the three-dimensional characteristics of the rocky media. Such situations should therefore be further investigated. Consequently, the applicability of such models cannot be rigorous under real conditions.

Furthermore, it is also observed that the existing creep models mainly concern the rock masses. Only few of them take into account the rocks surrounding the tunnels. Moreover, it remains difficult to assess the actual rheological properties of the surrounding rocks in complex geological conditions [182,190]. In both cases (rock mass and surrounding rocks), all the factors that strongly influence the creep behavior of the rocks are not taken into account. In addition to this, as the linings or components of tunnels integrate the surroundings rocks and deform with them, they should also be considered in the development of creep models of rocks surrounding the tunnels. For example, the combination of rock bolts and rocks is always expected to behave as a new material with upgraded properties [191]. The control of the creep deformation of the complex generated by the surrounding rocks and the support systems is necessary. Importantly, for instance, depending on the type of surrounding rocks, the tunnel may be deformed even though it is reinforced [192,193,194,195,196,197,198]. However, rock bolt and cable bolt properties are rarely incorporated into the creep models of the rocks surrounding the tunnels. Convinced of such a shortcoming, Liu et al. [199] proposed a creep model for the rocks surrounding the tunnel considering the combined effect of anchor bolts, cable bolts, and rock mass as follows:

where is the total creep strain; is the prestressing force; is the diameter of bolt or cable; is the elastic modulus of the bolt or cable; is the elastic modulus of surrounding rocks; : time; : viscoelastic coefficient of surrounding rocks.

Equation (33) can be used for rocky media supposedly homogeneous, persistent, and isotropic [199]. Although it incorporates some properties of the surrounding rocks and those of the rock bolts, it might be inaccurate in realistic situations where the rocks are generally heterogeneous with numerous anisotropic flaws. The anisotropic character of rocks is so common that it cannot be neglected [171].

Accurate constitutive models of rock creep are fundamental for accurate predictions of the long-term stability of underground structures where rocks are typically the host materials. In fact, the occurrence of each stage should be forecasted accurately in order to properly ensure tunnel safety and stability. For instance, the failure of tunnels under creep effect is very common. It should be noted that when tertiary creep occurs, rock necking is reached, depending on the rock types and relevant conditions, failure may be delayed a bit, but it will happen anyway. There is an increase in the extent of the damaged zone of the host rocks at the accelerated creep stage leading to the large, broadened deformations [98]. Life losses usually result from the appearance of accelerated creep and unsteady damage [170]. The control of the tertiary creep of rocks is very delicate. Sub-stages could constitute the tertiary creep stages of rocks. Failure can occur when the tertiary creep is in its most ultimate sub-stage which is usually perilous. However, it can be accelerated when creep is affected by potential factors such as damage, water, and temperature [200]. However, such situation cannot be predicted with precision without precise rock creep models.

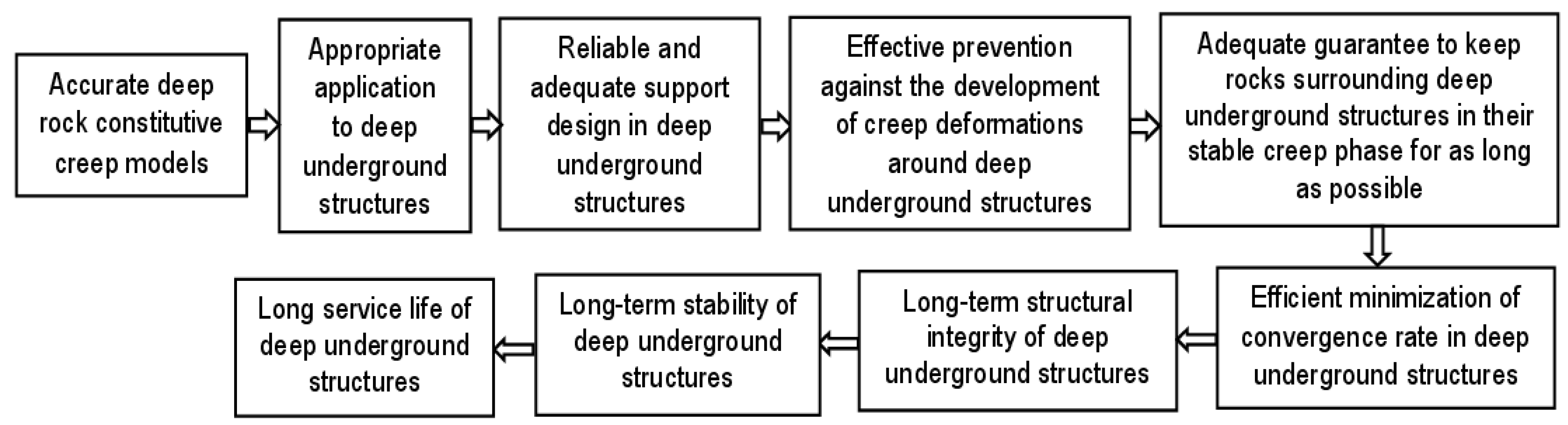

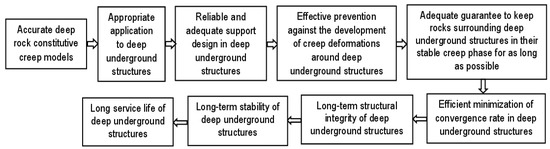

The correct applicability of constitutive rock creep models is strongly required to ensure the reliability of the design of the support systems, as well as the overall structural integrity of the tunnels. Figure 11 shows why accurate constitutive creep models are essential in ensuring long-term service life of deep tunnels, including deep caverns and mines.

Figure 11.

Diagram showing the importance of accurate constitutive rock creep models to ensure the long-term life of deep tunnels, including deep caverns and mines.

11. Conclusions and Perspectives for Future Research

11.1. Conclusions

Relevant information on rock creep and its potential influencing factors has been described throughout this article. Moreover, the article presented the latest advances in constitutive models of rock creep and discussed their applicability to the long-term stability of deep underground structures such as tunnels, mines, and caverns. The main conclusions drawn from this paper are as follows:

- Regardless of the rock type, creep character is very common and is influenced by several potential factors which are mainly stress level, hydraulic pressure, water content, temperature, damage, and time-to-failure. The creep deformation mechanisms of rocks are mainly brittle, ductile, and semi-brittle. Under the long-term action of stresses, brittle failure is mostly common in hard rocks, while soft rocks mostly fail in a ductile manner. Semi-brittle failure is predominant in many hard rock types in deep rocky environments when there are combined influences of high stresses, high pressures, and high temperatures.

- Rock creep properties are usually determined through different laboratory experiments accompanied by monitoring methods. The collected data are adequately processed and used as the basis for decision-making in the early stages of deep rock engineering projects as well as for studying the long-term stability of different types of deep underground structures such as tunnels, mines and caverns. However, one of the key concerns with evaluating the creep properties of rocks is the duration considered in laboratory experiments which does not truly reflect the full exposure duration of rocks in realistic situations. To this end, compared to the exposure times in the field, the observation times in laboratory are too short to detect with great precision the characteristics and conditions of rock creep. To explore more broadly and more concretely the creep properties of rocks, it is suggested to combine their microscopic and macroscopic characteristics. Furthermore, as each monitoring method has its limitations, to achieve more accurate results, it is suggested that these methods be combined appropriately. Importantly, long-term monitoring is necessary to effectively ensure long-term performance of host rocks and therefore long-term stability of the underground structures.

- Many constitutive models of rock creep have been devised. They are habitually used to design support systems that must keep stable the surrounding rocks of the underground structures over a long period of time. However, much effort is still needed for the rigorous applicability of such models to deep tunnels. In fact, most of such models are established on the basis of simplifying assumptions that do not fully express the characteristics and conditions of actual deep rocks. For instance, since the coupling of many internal factors is unclear, most scholars extend the one-dimensional models to three-dimensional creep models, despite the fact that rocks are naturally three-dimensional stress media. Then, for the external factors, despite their significant individual influences on rock creep, additional investigations on their coupling effects are necessary. Nonetheless, precise and appropriate correction factors can be applied to these models to enhance their suitability to deep tunnels. Therefore, tunnel support systems generally designed to cope with total creep deformation can be more responsive and more efficient. Note that only accurate creep constitutive models can properly represent the overall contribution of rock creep to the time-dependent behavior of rocks.

- It is also noticed that, until now, numerous constitutive models of rock creep have been designed on the basis of parameters estimated from loading process of rock mechanical properties. However, the long-term safety and stability of deep excavations cannot be minutely described by the loading process alone, but rather by the combined loading-unloading process of rock mechanical properties. Indeed, if only one process is considered, the unloading can be more suitable to reflect the long-term states of underground structures. Nevertheless, little research takes into account the unloading process of rock masses to design constitutive models of rock creep. The need to thoroughly study the creep properties of rock during the unloading process is essential to properly ensure the long-term safety and stability of tunnels.

- To avoid large convergence deformations and premature failures of deep tunnels, effective measures must be adopted to maintain stable rock creep for as long as possible. Tunnel support systems must have sufficient resistance, but above all they must be put in place quickly according to the excavation sequences, in order to decrease and stabilize adequately rock pressure. Stabilization of rock pressure is extremely important to prevent any rapid evolution of rock creep. The secondary lining of the deep tunnels must be installed within a quick and reasonable time after excavation, without exceeding 40 days.

- When the entire existence time of the secondary creep phase is over, tertiary creep begins, and long-term stability is no longer guaranteed. Tertiary creep control remains difficult because the degree of rock damage therein is very high. However, it is crucial to accurately estimate the remaining lifetime of deep tunnels after the onset of the tertiary creep conditions. In case of lack of precise data, the tunnels should be automatically decommissioned. This can prevent casualties resulting from partial or total failure of tunnels. Indeed, the extent of damage and the creep deformations being generally uncontrollable during the accelerated creep phase, the recovery of the tunnels is very rarely possible. The best solution to ensure the long-term stability of tunnels is therefore to adopt effective measures that maintain rock creep at its stable stage as durable as possible.

11.2. Perspectives for Future Research

One can notice throughout this article that the study of rock creep still represents salient areas of research, despite the enormous efforts already made by many scholars. Although it is very difficult, based on rock creep, improving the accuracy of prediction of the long-term stability of deep tunnels should be continuously investigated. Future research could focus on the following:

- -

- The effects of potential influencing factors on rock creep need further investigation. In fact, it is noteworthy to study the simultaneous effects of the hydraulic pressure, water content, stress level, temperature, and damage factor on long-term stability of deep tunnels built in heterogeneous rocky environments and subject to high stress.

- -

- Based on different specific case studies, it is extremely important to compare the accuracy of different existing creep constitutive models for stronger conclusions. The influence of individual factors on different creep constitutive models can also be further investigated.

- -

- Based on the heterogeneity and anisotropy of the rocky media, quantify the creep life of deep rock tunnels considering the effects of the potential influencing factors. It is also of high interest to accurately estimate the level of damage that can trigger accelerated creep for various rock types.

- -