Investigation of Behavior of Masonry Walls Constructed with Autoclaved Aerated Concrete Blocks under Blast Loading

Abstract

:1. Introduction

2. Materials and Methods

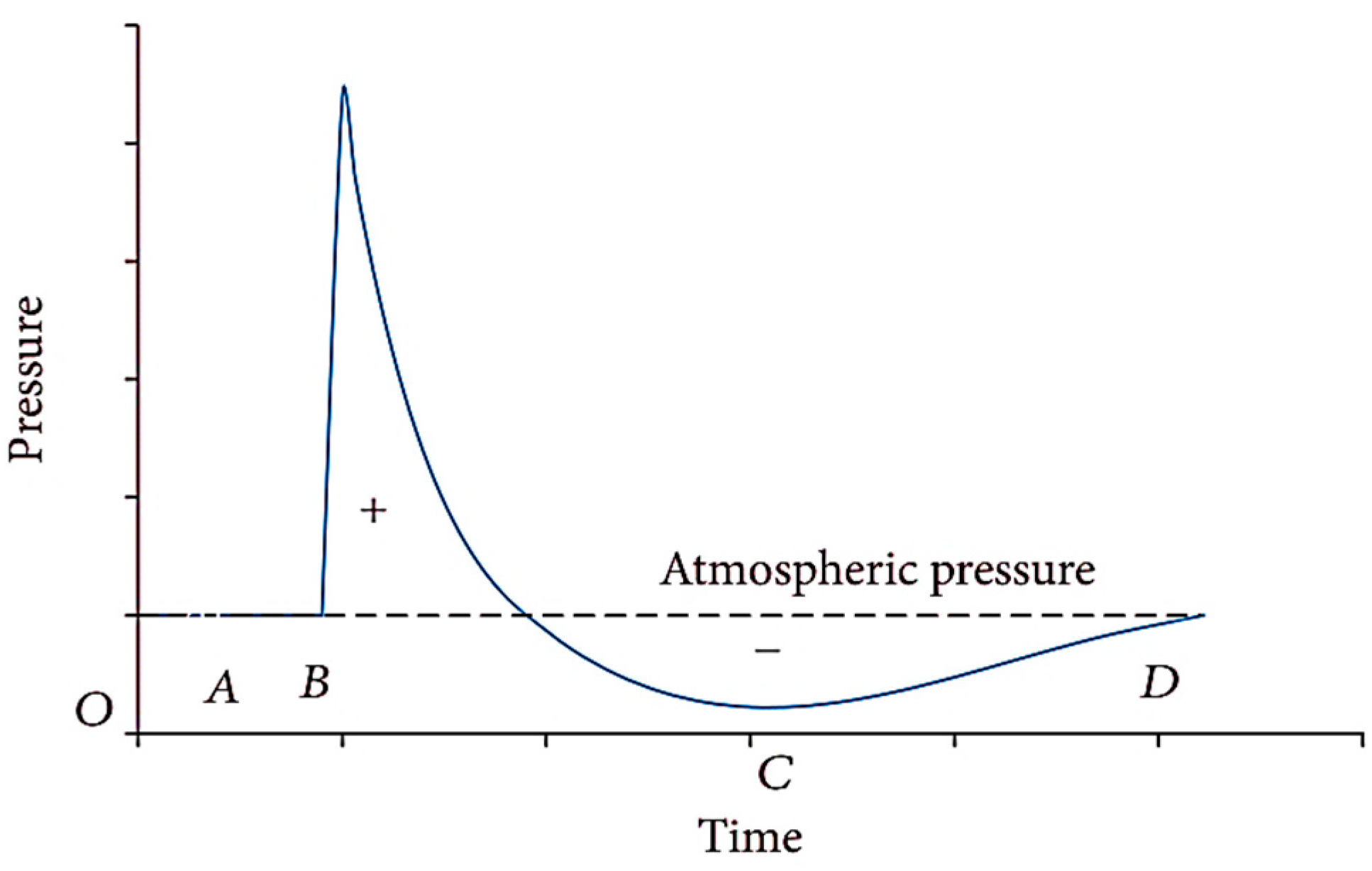

2.1. Blast Loading

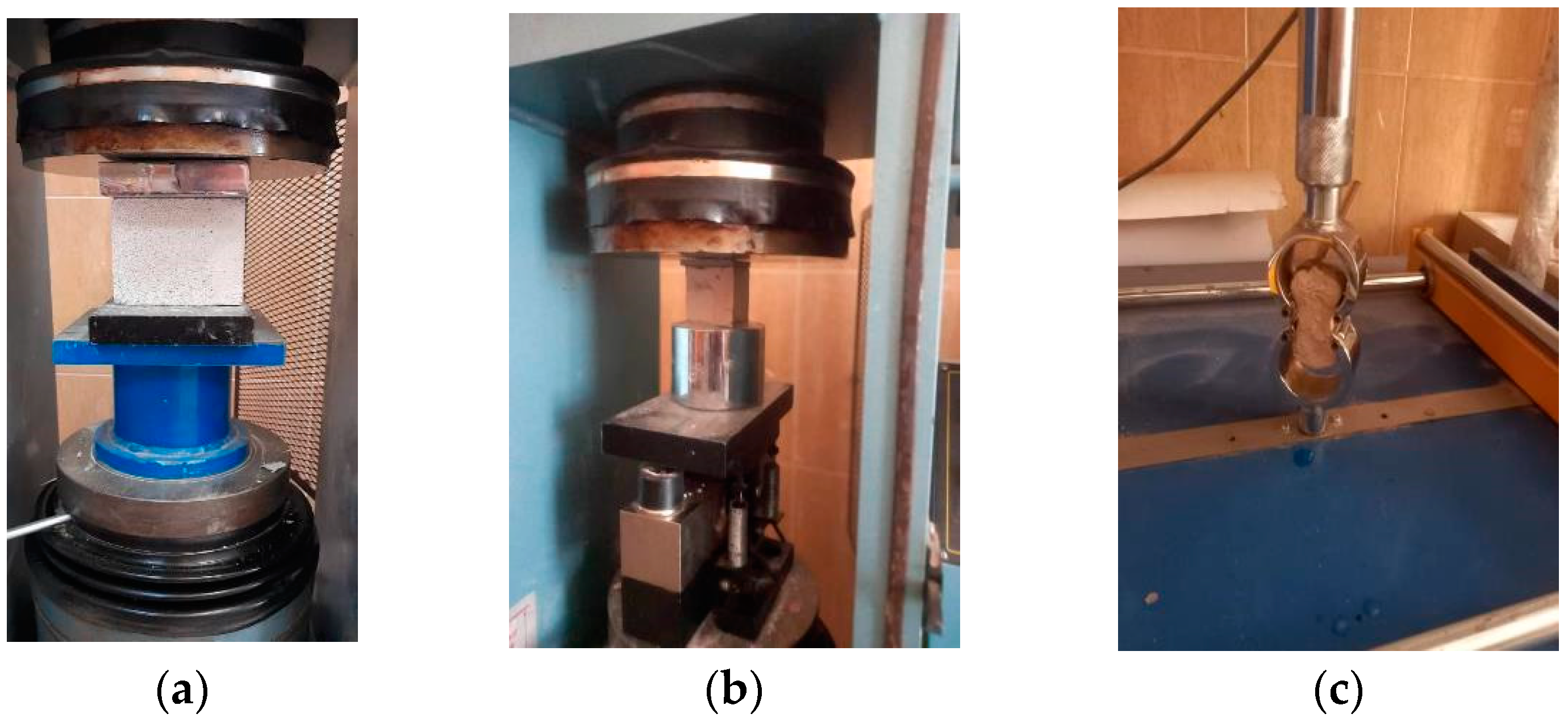

2.2. AAC and Grout Materials

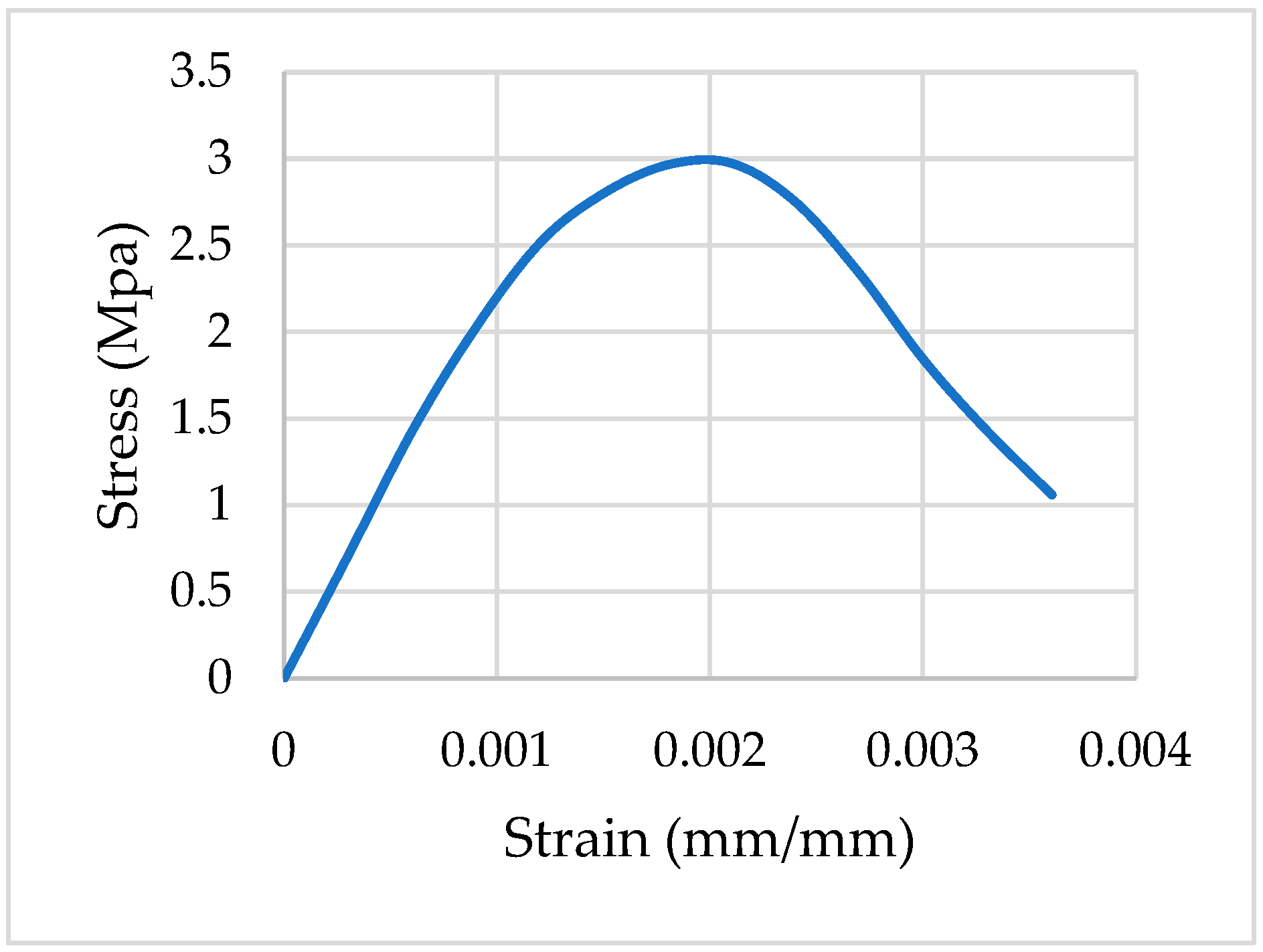

2.3. Numerical Modeling

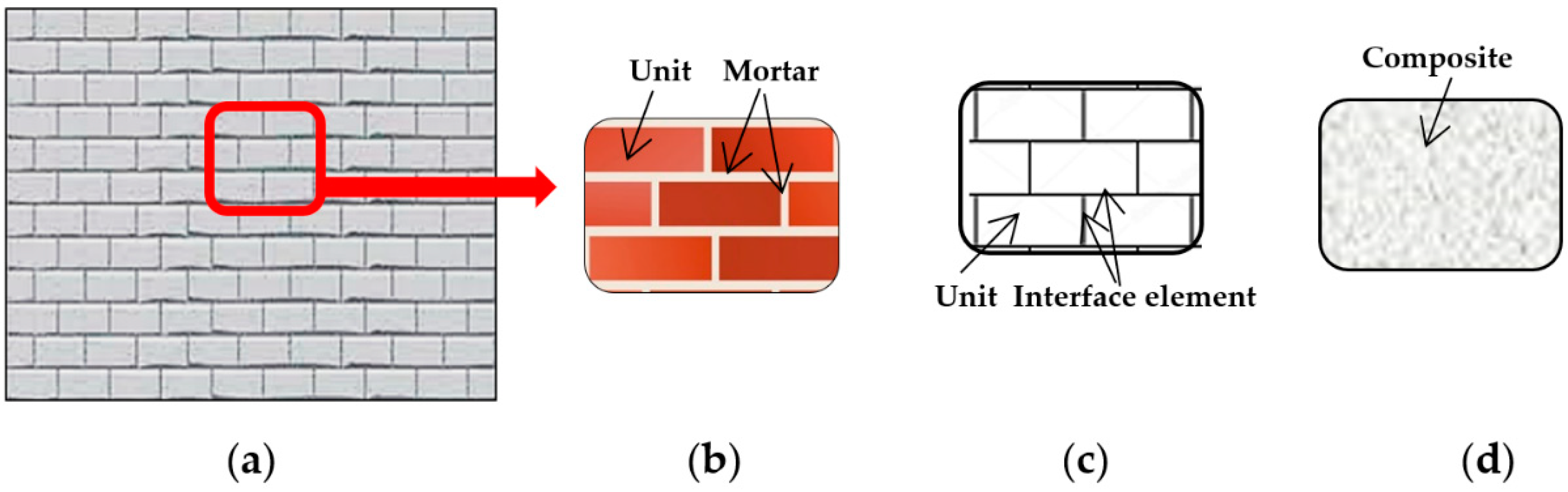

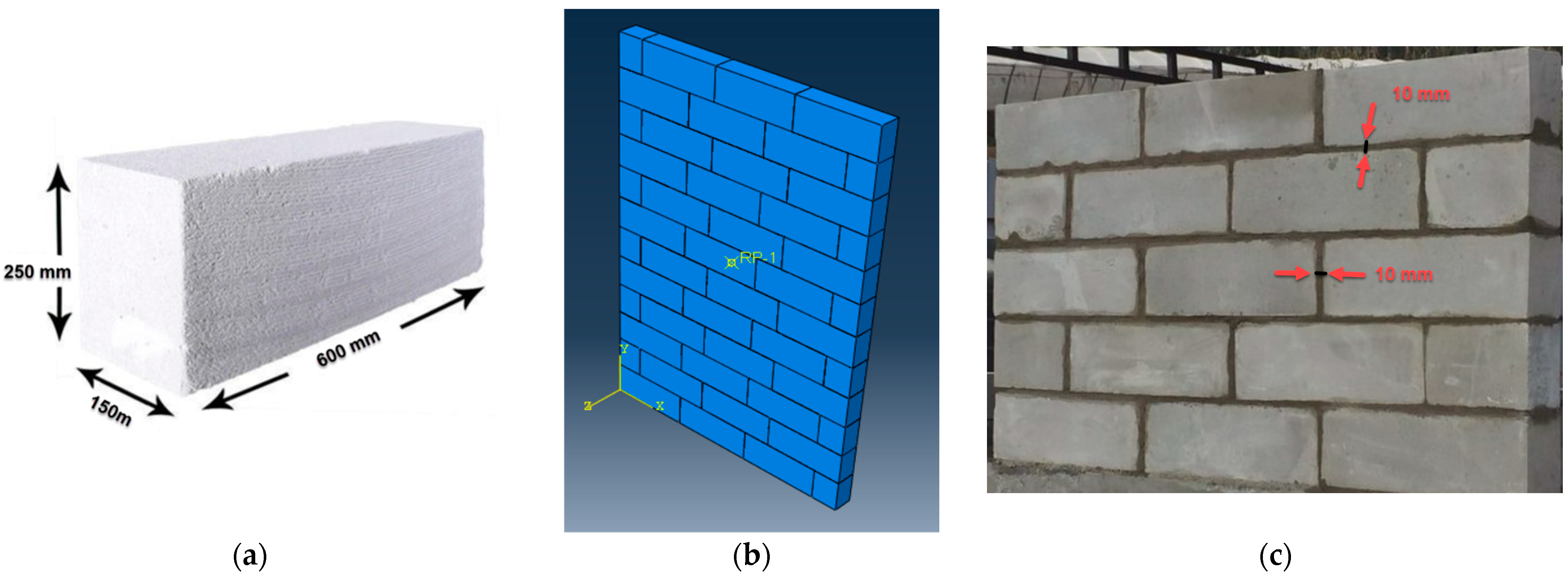

2.4. FE modeling of Masonry Walls

2.5. Properties of Interface Elements

2.6. Mechanical Properties of AAC Materials and Grout

2.7. Considered Models

3. Results and Discussion

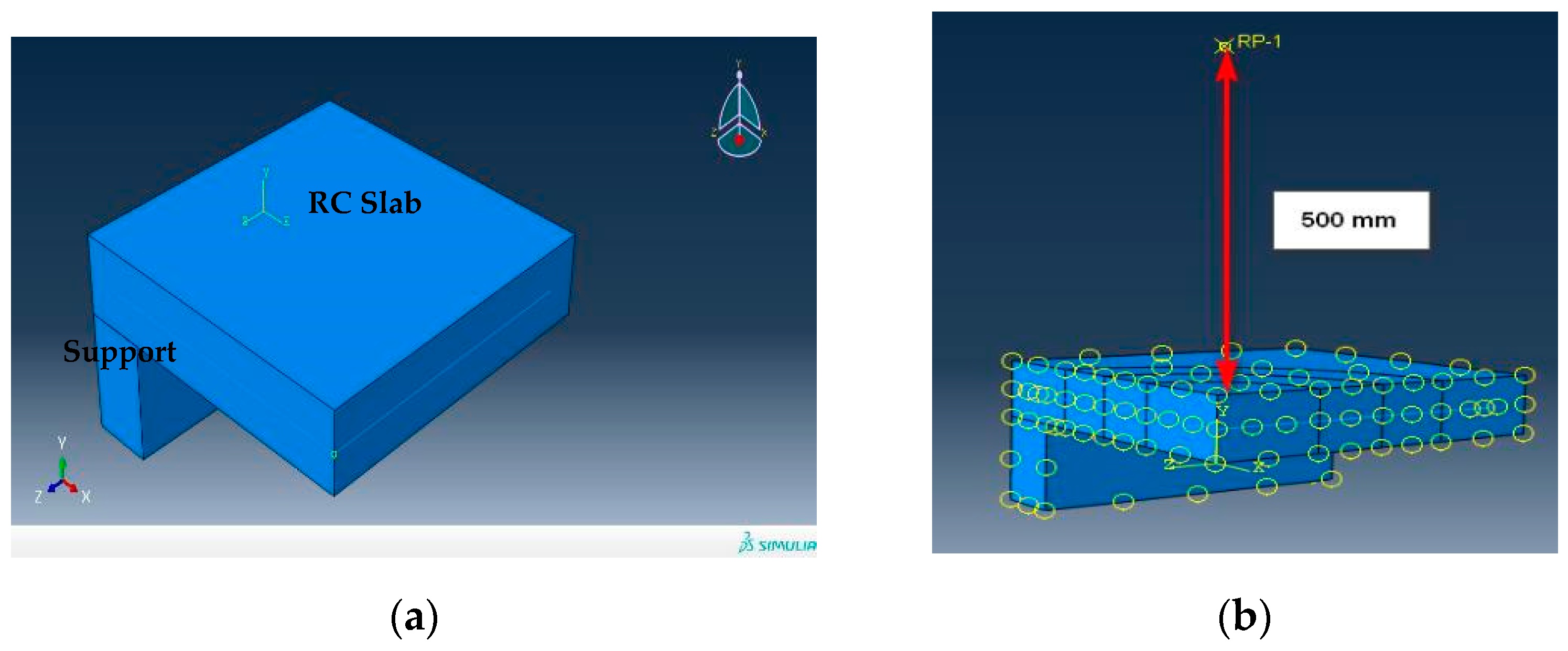

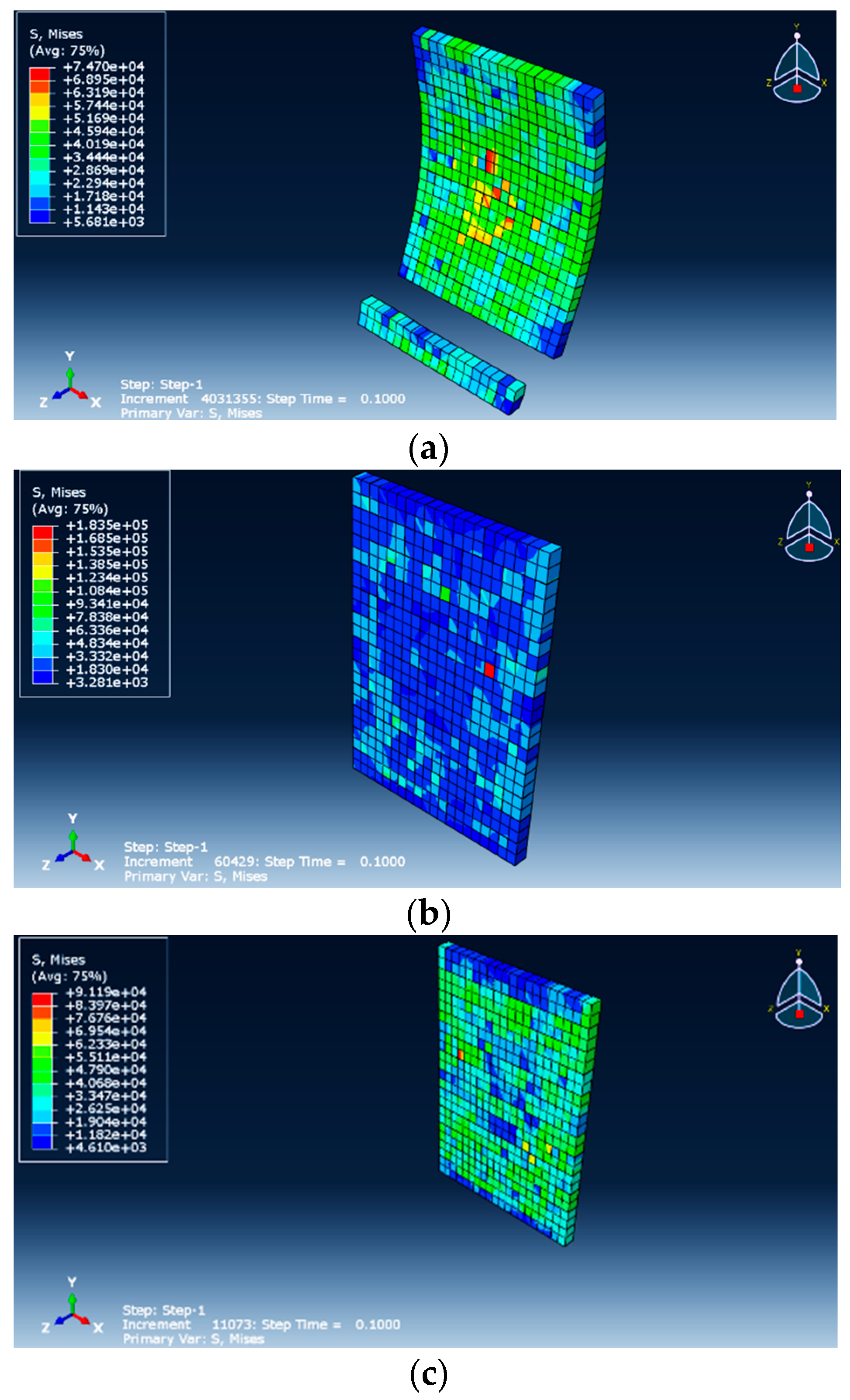

3.1. Validation

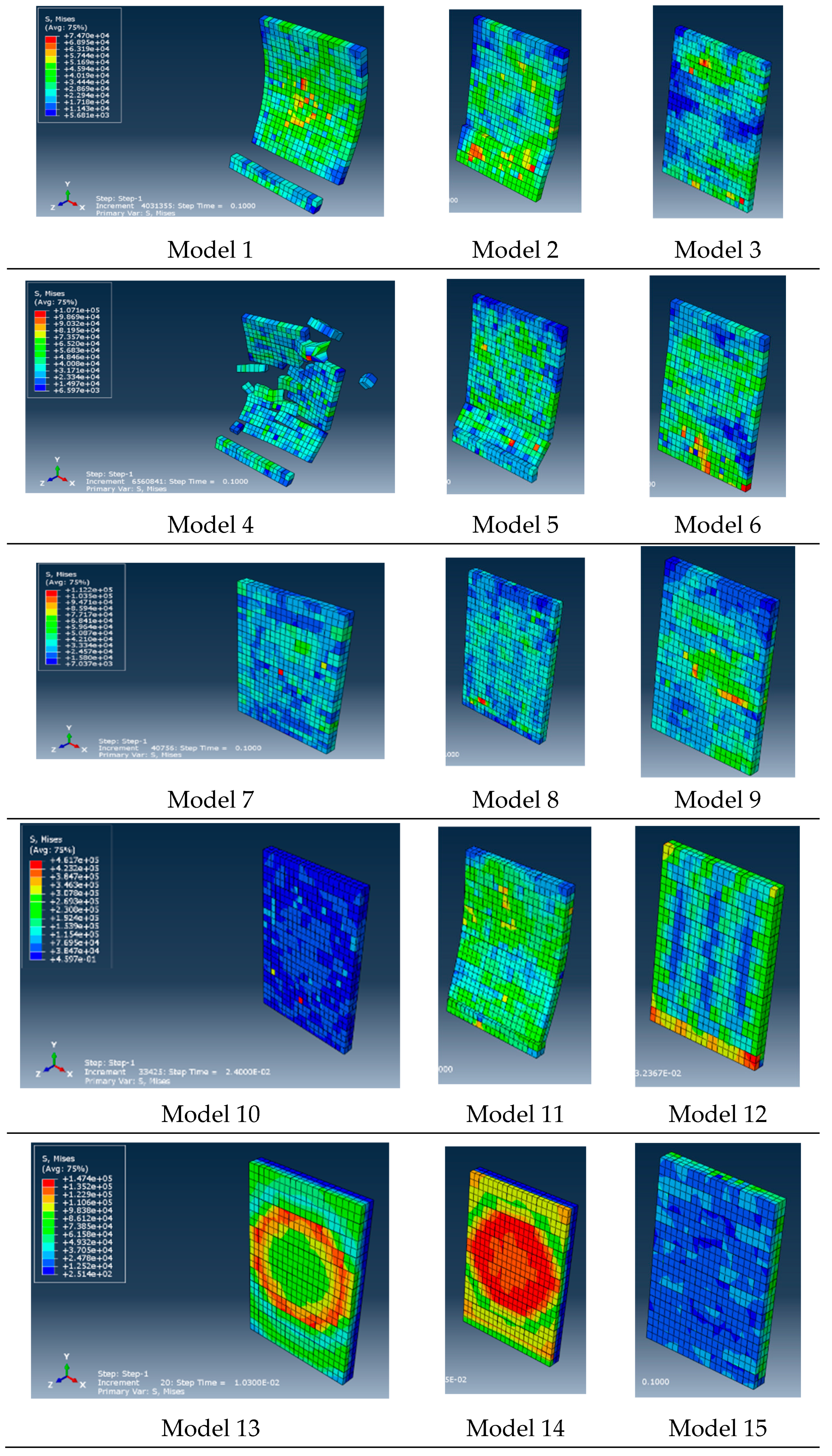

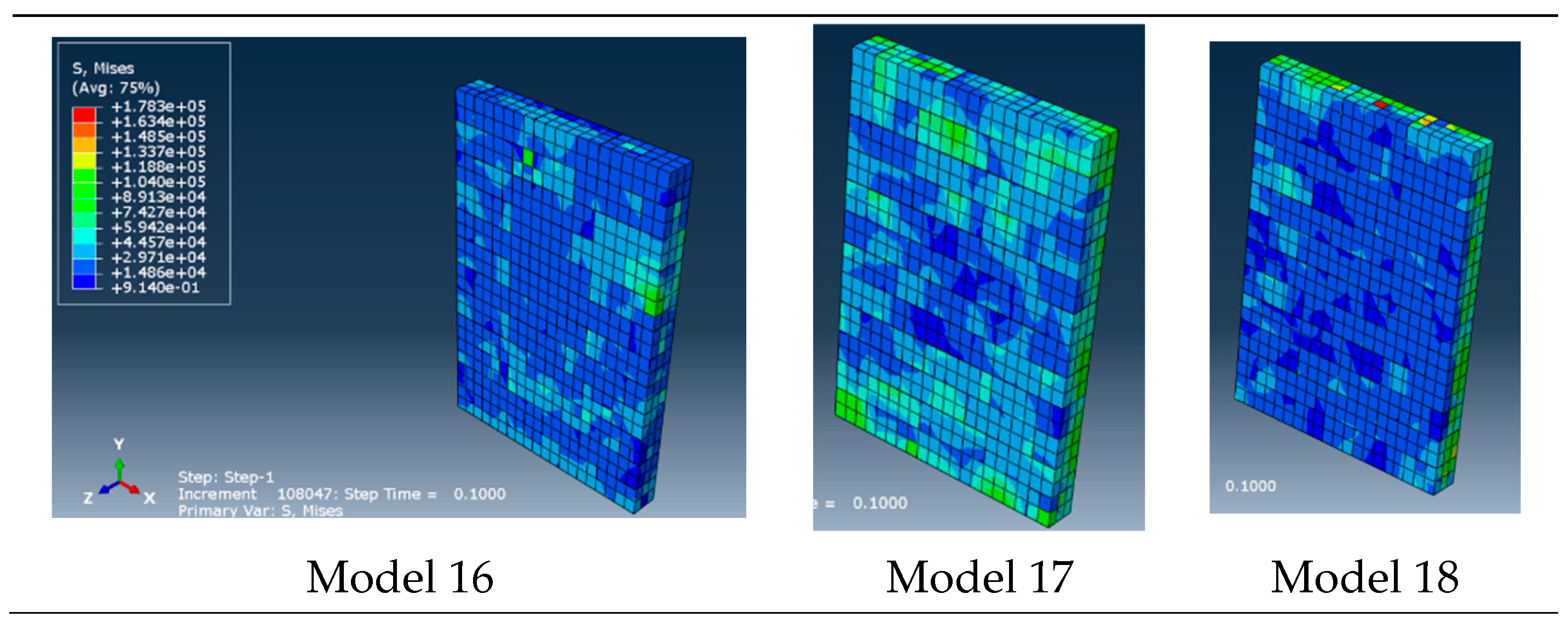

3.2. Von Mises Stress Distribution

3.3. Displacement Responses

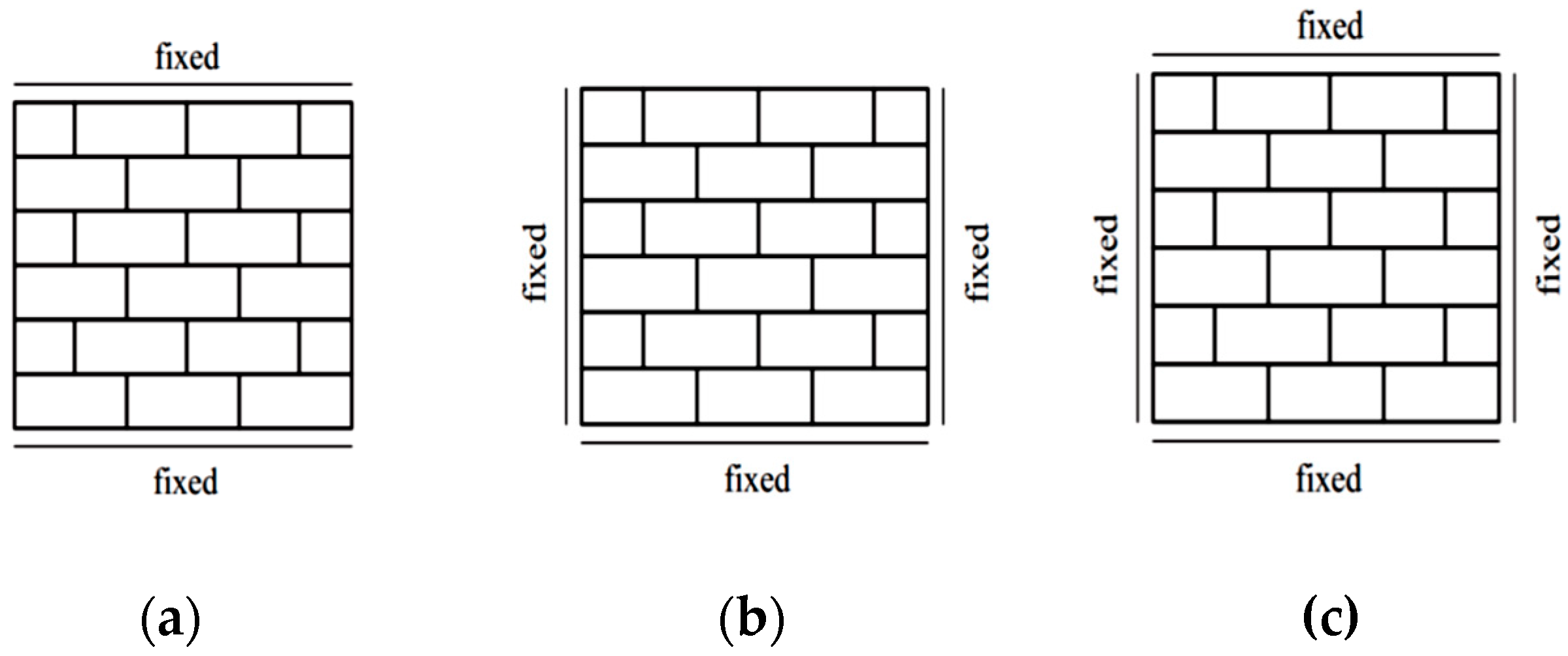

3.4. The Influence of the Boundary Conditions

3.5. Base Shear Force

4. Conclusions

- Considering the weight of TNT used in a short distance (R = 2 m), it was observed that very large local stresses were created in the wall, which caused the wall to collapse in a very short time. It should be noted that at distances of less than 2 m, the wall models diverged at the very first moments. Therefore, the analysis and presentation of their results were avoided here.

- With the increasing charge weight, wall performance degraded. The stress level in the case of an explosive charge weight of 7 kg TNT increased by about 10% compared to that for 5 kg TNT. It is important to note that the walls modeled in this study under a charge larger than 7 kg TNT had a rapid failure in the initial moments. Therefore, considering the typical values of charge weight in the explosion events of hand grenades and suitcase bombs (about 20 kg-TNT) [72], it can be stated that masonry walls made with AAC do not have a good explosion resistance and would need retrofitting.

- Some retrofitting methods in masonry walls could involve using CFRP coating, steel wire mesh, and laminating. In addition, polyurea and polyurethane coatings, using steel sheets, aluminum foam, and engineered cementitious composites, are suggested for masonry units that can be applied to walls made with AAC.

- With the increasing charge weight and decreasing stand-off distance, the wall displacement increased significantly, so that at a distance of 2 m, the displacement was several times that for the 5- and 10-m distances. In the walls with thicknesses of 15, 20, and 25 cm, the performance was also observed to be the same. As the amount of TNT increased, the stress values increased, and more damage was observed in the walls.

- The thickness of the walls was very effective in reducing the explosive demand force. For example, for a wall with a thickness of 15 cm, compared to that with a thickness of 25 cm, the base shear values induced by the same explosion were about 10 times higher.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Korniyenko, S.V.; Vatin, N.I.; Gorshkov, A.S. Heat and power characteristics analysis carried out for the residential building made of autoclaved aerated concrete blocks. Constr. Unique Build. Struct. 2016, 12, 45–60. [Google Scholar] [CrossRef]

- Winkels, B.; Nebel, H.; Raupach, M. Carbonation of autoclaved aerated concrete containing fly ash. ce/papers 2018, 2, 47–51. [Google Scholar] [CrossRef]

- Gyurkó, Z.; Jankus, B.; Fenyvesi, O.; Nemes, R. Sustainable applications for utilization the construction waste of aerated concrete. J. Clean. Prod. 2019, 230, 430–444. [Google Scholar] [CrossRef]

- Saghi, H.; Arefizadeh, N. Quantitative and Qualitatively Evaluation of New Technologies in Perspective of Construction Optimization. Am. J. Civ. Eng. 2015, 3, 64–68. [Google Scholar] [CrossRef]

- Hammond, G.P.; Jones, C.I. Embodied energy and carbon in construction materials. Proc. Inst. Civ. Eng. Energy 2008, 161, 87–98. [Google Scholar] [CrossRef]

- Sherin, K.; Saurabh, J.K. Review of autoclaved aerated concrete: Advantages and disadvantages. In Proceedings of the National Conference of Advanced Structures, Materials and Methodology in Civil Engineering-ASMMCE-2018, Punjab, India, 3–4 November 2018. [Google Scholar]

- Momeni, M.; Hadianfard, M.A.; Bedon, C.; Baghlani, A. Damage evaluation of H-section steel columns under impulsive blast loads via gene expression programming. Eng. Struct. 2020, 219, 110909. [Google Scholar] [CrossRef]

- Momeni, M.; Hadianfard, M.A.; Bedon, C.; Baghlani, A. Numerical damage evaluation assessment of blast loaded steel columns with similar section properties. Structures 2019, 20, 189–203. [Google Scholar] [CrossRef]

- Esameelnia Omran, M.; Mollaei, S. Investigation of Axial Strengthened Reinforced Concrete Columns under Lateral Blast Loading. Shock Vib. 2017, 2017, 94–113. [Google Scholar] [CrossRef]

- Mollaei, S.; Babaei, M.; JalilKhani, M. Assessment of Damage and Residual Load Capacity of the Normal and Retrofitted RC Columns against the Impact Loading. J. Rehab. Civ. Eng. 2021, 9, 29–51. [Google Scholar] [CrossRef]

- Deyazada, M.; Vandoren, B.; Dragan, D.; Degée, H. Experimental investigations on the resistance of masonry walls with AAC thermal break layer. Constr. Build. Mater. 2019, 224, 474–492. [Google Scholar] [CrossRef]

- Yankelevsky, D.Z.; Avnon, I. Autoclaved aerated concrete behavior under explosive action. Constr. Build. Mater. 1998, 12, 359–364. [Google Scholar] [CrossRef]

- Tanner, J.E.; Varela, J.L.; Klingner, R.E.; Brightman, M.J.; Cancino, U. Seismic testing of autoclaved aerated concrete shear walls: A comprehensive review. ACI Struct. J. 2005, 102, 374. [Google Scholar]

- Tanner, J.E.; Varela, J.L.; Klingner, R.E. Design and seismic testing of two-story, full-scale autoclaved aerated concrete assemblage specimen. ACI Struct. J. 2005, 102, 114. [Google Scholar]

- ACI Committee 523. Guide for Design and Construction with Autoclaved Aerated Concrete Panels (ACI 523.4R-09); American Concrete Institute: Farmington Hills, MI, USA, 2009. [Google Scholar]

- Uddin, N.; Shelar, K.V.; Fouad, F. Impact response of autoclave aerated concrete/FRP sandwich structures. In Proceedings of the Structures Congress 2006: Structural Engineering and Public Safety, ASCE, St. Louis, MO, USA, 18–21 May 2006. [Google Scholar] [CrossRef]

- Tomaževič, M.; Gams, M. Shaking table study and modelling of seismic behaviour of confined AAC masonry buildings. Bull. Earthq. Eng. 2012, 10, 863–893. [Google Scholar] [CrossRef]

- Bayat, A.; Liaghat, G.H.; Ghalami-Choobar, M.; Ashkezari, G.D.; Sabouri, H. Analytical modeling of the high-velocity impact of autoclaved aerated concrete (AAC) blocks and some experimental results. Int. J. Mech. Sci. 2019, 159, 315–324. [Google Scholar] [CrossRef]

- U.S. Department of the Army, the Navy and Air Force. Fundamental of Protective Design for Conventional Weapons-Technical Manual (TM 5-855-1); U.S. Department of the Army: Washington, DC, USA, 1986. [Google Scholar]

- U.S. Department of the Army, the Navy and Air Force. The Design of Structures to Resist the Effects of Accidental Explosions-Technical Manual (TM 5-1300); U.S. Department of the Army: Washington, DC, USA, 1990. [Google Scholar]

- U.S. Department of Defense (DOD). Structures to Resist the Effects of Accidental Explosions (UFC 3-340-02); DOD: Washington, DC, USA, 2008. [Google Scholar]

- Hao, H.; Wu, C. Numerical simulation of damage of low-rise RC frame structures with infilled masonry walls to explosive loads. Aust. J. Struct. Eng. 2006, 7, 13–22. [Google Scholar] [CrossRef]

- Wu, C.; Hao, H. Safe scaled distance for masonry infilled RC frame structures subjected to airblast loads. J. Perform. Constr. Facil. 2007, 21, 422–431. [Google Scholar] [CrossRef]

- Wei, X.; Stewart, M.G. Model validation and parametric study on the blast response of unreinforced brick masonry walls. Int. J. Impact Eng. 2010, 37, 1150–1159. [Google Scholar] [CrossRef]

- Ahmad, S.; Elahi, A.; Pervaiz, H.; Rahman, A.G.A.; Barbhuiya, S. Experimental study of masonry wall exposed to blast loading. Mater. Constr. 2014, 64, e007. [Google Scholar] [CrossRef]

- Pandey, A.; Bisht, R. Numerical modelling of infilled clay brick masonry under blast loading. Adv. Struct. Eng. 2014, 17, 591–606. [Google Scholar] [CrossRef]

- Pereira, J.M.; Campos, J.; Lourenço, P.B. Experimental study on masonry infill walls under blast loading. In Proceedings of the 9th International Masonry Conference, Guimarães, Portugal, 7–9 July 2014. [Google Scholar]

- Shi, Y.; Xiong, W.; Li, Z.X.; Xu, Q. Experimental studies on the local damage and fragments of unreinforced masonry walls under close-in explosions. Int. J. Impact Eng. 2016, 90, 122–131. [Google Scholar] [CrossRef]

- Parisi, F.; Balestrieri, C.; Asprone, D. Blast resistance of tuff stone masonry walls. Eng. Struct. 2016, 113, 233–244. [Google Scholar] [CrossRef]

- Keys, R.A.; Clubley, S.K. Experimental analysis of debris distribution of masonry panels subjected to long duration blast loading. Eng. Struct. 2017, 130, 229–241. [Google Scholar] [CrossRef]

- Badshah, E.; Naseer, A.; Ashraf, M.; Ahmad, T. Response of masonry systems against blast loading. Def. Technol. 2021, 17, 1326–1337. [Google Scholar] [CrossRef]

- Zeng, B.; Li, Y.; Noguez, C.C. Modeling and parameter importance investigation for simulating in-plane and out-of-plane behaviors of un-reinforced masonry walls. Eng. Struct. 2021, 248, 113233. [Google Scholar] [CrossRef]

- ASCE/SEI 59-11; Blast Protection of Buildings. American Society of Civil Engineers: Reston, VA, USA, 2011.

- Stanley, M.; Metzger, J.; Martinez, R.; Koenig, J. UL-Like Testing of Commercial Off-the-Shelf Products That Enhance the Blast and Ballistic Resistance of Structures, Quick Look Report 2; New Mexico Tech, Energetic Materials Research and Testing Center, Karagozian & Case: Burbank, CA, USA, 2005. [Google Scholar]

- Tan, K.H.; Patoary, M.K.H. Blast resistance of FRP-strengthened masonry walls. I: Approximate analysis and field explosion tests. J. Compos. Constr. 2009, 13, 422–430. [Google Scholar] [CrossRef]

- Baylot, J.T.; Bullock, B.; Slawson, T.R.; Woodson, S.C. Blast response of lightly attached concrete masonry unit walls. J. Struct. Eng. 2005, 131, 1186–1193. [Google Scholar] [CrossRef]

- Alsayed, S.H.; Elsanadedy, H.M.; Al-Zaheri, Z.M.; Al-Salloum, Y.A.; Abbas, H. Blast response of GFRP-strengthened infill masonry walls. Constr. Build. Mater. 2016, 115, 438–451. [Google Scholar] [CrossRef]

- Bui, T.T.; Limam, A. Out-of-plane behaviour of hollow concrete block masonry walls unstrengthened and strengthened with CFRP composite. Compos. Part B Eng. 2014, 67, 527–542. [Google Scholar] [CrossRef]

- Chen, L.; Fang, Q.; Fan, J.; Zhang, Y.; Hao, H.; Liu, J. Responses of masonry infill walls retrofitted with CFRP, steel wire mesh and laminated bars to blast loadings. Adv. Struct. Eng. 2014, 17, 817–836. [Google Scholar] [CrossRef]

- Ghaderi, M.; Maleki, V.A.; Andalibi, K. Retrofitting of unreinforced masonry walls under blast loading by FRP and spray on polyurea. Cumhur. Üniversitesi Fen Fakültesi Fen Bilimleri Derg. 2015, 36, 462–477. [Google Scholar] [CrossRef]

- Urgessa, G.S.; Maji, A.K. Dynamic response of retrofitted masonry walls for blast loading. J. Eng. Mech. 2010, 136, 858–864. [Google Scholar] [CrossRef]

- Xu, W.X.; Bao, Q.; Li, Z.; Fan, J.Y. Numerical Analysis on the Behavior of Autoclaved Aerated Concrete Block Infilled Wall Subjected to Gas Explosion. Appl. Mech. Mater. 2015, 723, 259–265. [Google Scholar] [CrossRef]

- Li, Z.; Chen, L.; Fang, Q.; Hao, H.; Zhang, Y.; Chen, W.; Xiang, H.; Bao, Q. Study of autoclaved aerated concrete masonry walls under vented gas explosions. Eng. Struct. 2017, 141, 444–460. [Google Scholar] [CrossRef]

- Wang, J.; Ren, H.; Wu, X.; Cai, C. Blast response of polymer-retrofitted masonry unit walls. Compos. Part B Eng. 2017, 128, 174–181. [Google Scholar] [CrossRef]

- Liu, C.; Hou, J.; Hao, Y.; Hao, H.; Meng, X. Effect of high strain rate and confinement on the compressive properties of autoclaved aerated concrete. Int. J. Impact Eng. 2021, 156, 103943. [Google Scholar] [CrossRef]

- Sovják, R.; Koutný, O.; Hála, P. Penetration Resistance of Building Materials against 7.62-mm Armor-Piercing Projectile. J. Mater. Civ. Eng. 2021, 33, 04021224. [Google Scholar] [CrossRef]

- Stepinac, M.; Kisicek, T.; Renić, T.; Hafner, I.; Bedon, C. Methods for the Assessment of Critical Properties in Existing Masonry Structures under Seismic Loads—The ARES Project. Appl. Sci. 2020, 10, 1576. [Google Scholar] [CrossRef]

- Hinman, E. Primer for Design of Commercial Buildings to Mitigate Terrorist Attacks; Federal Emergency Management Agency (FEMA): Washington, DC, USA, 2003. [Google Scholar]

- Cormie, D.; Mays, G.; Smith, P.D. Blast Effects on Buildings, 2nd ed.; Thomas Telford: London, UK, 2009. [Google Scholar]

- Brode, H.L. Numerical Solutions of Spherical Blast Waves. J. Appl. Phys. 1955, 26, 766–775. [Google Scholar] [CrossRef]

- Newmark, N.M.; Hansen, R.J. Design of blast resistant structures. Shock. Vib. Handb. 1961, 3, 04014007. [Google Scholar]

- Mills, C.A. The design of concrete structure to resist explosions and weapon effects. In Proceedings of the 1st International Conference on Concrete for Hazard Protections, Edinburgh, UK, 27–30 September 1987; 1987. [Google Scholar]

- Baker, W.E.; Cox, P.A.; Westine, P.S.; Kulesz, J.J.; Strehlow, R.A. Explosion Hazards and Evaluation; Elsevier Scientific: New York, NY, USA, 1983. [Google Scholar]

- Hyde, D. User’s Guide for Microcomputer Programs CONWEP and FUNPRO, Applications of TM 5-855-1: Fundamentals of Protective Design for Conventional Weapons; USA Army Engineers Waterways Experimentation: Vicksburg, MS, USA, 1988. [Google Scholar]

- Masonry Standards Joint Committee. Building Code Requirements and Specification for Masonry Structures: Containing Building Code Requirements for Masonry Structures (TMS 402-11/ACI 530-11/ASCE 5-11), and Specification for Masonry Structures TMS 402-11/ACI 530-11/ASCE 6-11), and Companion Commentaries; ASCE: Reston, VA, USA, 2016. [Google Scholar]

- Entezari, A.; Esmaili, J. Investigation on the Stress Distribution and Flexural Strength of Structural Lightweight Aggregate Concrete. Concr. Res. 2010, 3, 61–72. [Google Scholar]

- Abaqus v. 6.14 Documentation; Dassault Systemes Simulia Corporation: Providence, RI, USA, 2011.

- Sassu, M.; Andreini, M.; Casapulla, C.; De Falco, A. Archaeological consolidation of UNESCO masonry structures in Oman: The Sumhuram Citadel of Khor Rori and the Al Balid Fortress. Int. J. Archit. Herit. 2013, 7, 339–374. [Google Scholar] [CrossRef]

- Pantò, B.; Casapulla, C.; Caliò, I. Discrete rotating links model for the non-linear torsion−shear behaviour of masonry joints. Proc. Inst. Civ. Eng. Eng. Comput. Mech. 2021, 174, 215–235. [Google Scholar] [CrossRef]

- Zucchini, A.; Lourenço, P.B. A micro-mechanical model for the homogenisation of masonry. Int. J. Solids Struct. 2002, 39, 3233–3255. [Google Scholar] [CrossRef]

- Casapulla, C.; Giresini, L.; Argiento, L.U.; Maione, A. Nonlinear static and dynamic analysis of rocking masonry corners using rigid macro-block modeling. Int. J. Struct. Stab. Dyn. 2019, 19, 1950137. [Google Scholar] [CrossRef]

- Maheri, M.R.; Najafgholipour, M.A.; Rajabi, A.R. The influence of mortar head joints on the in-plane and out-of-plane seismic strength of brick masonry walls. Iran. J. Sci. Technol. Trans. Civ. Eng. 2011, 35, 63–79. [Google Scholar]

- Gabor, A.; Bennani, A.; Jacquelin, E.; Lebon, F. Modelling approaches of the in-plane shear behaviour of unreinforced and FRP strengthened masonry panels. Compos. Struct. 2006, 74, 277–288. [Google Scholar] [CrossRef]

- Lourenço, P.B.; Rots, J. Analysis of Masonry Structures with Interface Elements-Report No. 03-21-22-0; Delft University of Technology: Delft, The Netherlands, 1994. [Google Scholar]

- Lourenço, P.B. Computations on historic masonry structures. Prog. Struct. Eng. Mater. 2002, 4, 301–319. [Google Scholar] [CrossRef]

- Vecchio, F.J.; Collins, M.P. The modified compression-field theory for reinforced concrete elements subjected to shear. ACI J. 1986, 83, 219–231. [Google Scholar]

- Korany, Y.; EL-Haggar, S. Mechanics and modeling of URM structures. In Proceedings of the International Short Course on Architectural and Structural Design of Masonry, Dresden, Germany, 7–18 December 2003. [Google Scholar]

- ASTM C495; Standard Test Method for Compressive Strength of Lightweight Insulating Concrete. American Society for Testing and Materials (ASTM): Philadelphia, PA, USA, 2002.

- ASTM, C109; Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or 50-mm Cube Specimens). ASTM International: West Conshohocken, PA, USA, 1999; Volume 4.

- ASTM C307-03; Standard Test Method for Tensile Strength of Chemical-Resistant Mortar, Grouts and Monolithic Surfacing. ASTM International: West Conshohocken, PA, USA, 2012.

- Kumar, V.; Kartik, K.V.; Iqbal, M.A. Experimental and numerical investigation of reinforced concrete slabs under blast loading. Eng. Struct. 2020, 206, 110125. [Google Scholar] [CrossRef]

- National Research Council. ISC Security Design Criteria for New Federal Office Buildings and Major Modernization Projects: A Review and Commentary; The National Academies Press: Washington, DC, USA, 2003. [Google Scholar] [CrossRef]

| Parameter | Dilation Angle | Eccentricity | Biaxial-to-Uniaxial Compressive Strength Ratio | Shape Factor Function | Viscoelastic Parameter |

|---|---|---|---|---|---|

| Quantity | 20 | 0.1 | 1.16 | 0.66 | 0.001 |

| Materials | Amounts (kg/m3) |

|---|---|

| silica sand | 350 |

| lime | 100 |

| cement | 25 |

| aluminum powder | 0.5 |

| water | 330 |

| Model | Thickness (cm) | Stand-Off Distance (m) | Charge Weight (kg) | Scaled Distance (m/kg1/3) |

|---|---|---|---|---|

| Model-1 | 15 | 2 | 5 | 1.170 |

| Model-2 | 15 | 5 | 5 | 2.924 |

| Model-3 | 15 | 10 | 5 | 5.848 |

| Model-4 | 15 | 2 | 7 | 1.046 |

| Model-5 | 15 | 5 | 7 | 2.614 |

| Model-6 | 15 | 10 | 7 | 5.228 |

| Model-7 | 20 | 2 | 5 | 1.170 |

| Model-8 | 20 | 5 | 5 | 2.924 |

| Model-9 | 20 | 10 | 5 | 5.848 |

| Model-10 | 20 | 2 | 7 | 1.046 |

| Model-11 | 20 | 5 | 7 | 2.614 |

| Model-12 | 20 | 10 | 7 | 5.228 |

| Model-13 | 25 | 2 | 5 | 1.170 |

| Model-14 | 25 | 5 | 5 | 2.924 |

| Model-15 | 25 | 10 | 5 | 5.848 |

| Model-16 | 25 | 2 | 7 | 1.046 |

| Model-17 | 25 | 5 | 7 | 2.614 |

| Model-18 | 25 | 10 | 7 | 5.228 |

| Model | Thickness (cm) | Stand-Off Distance (m) | Charge Weight (kg) | Maximum Stress (kgf/m2) |

|---|---|---|---|---|

| Model-1 | 15 | 2 | 5 | 7.470 × 104 |

| Model-2 | 15 | 5 | 5 | 6.261 × 104 |

| Model-3 | 15 | 10 | 5 | 5.494 × 104 |

| Model-4 | 15 | 2 | 7 | 1.071 × 105 |

| Model-5 | 15 | 5 | 7 | 9.522 × 104 |

| Model-6 | 15 | 10 | 7 | 5.793 × 104 |

| Model-7 | 20 | 2 | 5 | 1.122 × 105 |

| Model-8 | 20 | 5 | 5 | 6.234 × 104 |

| Model-9 | 20 | 10 | 5 | 9.829 × 104 |

| Model-10 | 20 | 2 | 7 | 4.617 × 105 |

| Model-11 | 20 | 5 | 7 | 6.715 × 104 |

| Model-12 | 20 | 10 | 7 | 1.367 × 104 |

| Model-13 | 25 | 2 | 5 | 1.474 × 105 |

| Model-14 | 25 | 5 | 5 | 3.933 × 104 |

| Model-15 | 25 | 10 | 5 | 6.075 × 104 |

| Model-16 | 25 | 2 | 7 | 1.783 × 105 |

| Model-17 | 25 | 5 | 7 | 5.638 × 104 |

| Model-18 | 25 | 10 | 7 | 6.591 × 104 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mollaei, S.; Babaei Ghazijahani, R.; Noroozinejad Farsangi, E.; Jahani, D. Investigation of Behavior of Masonry Walls Constructed with Autoclaved Aerated Concrete Blocks under Blast Loading. Appl. Sci. 2022, 12, 8725. https://doi.org/10.3390/app12178725

Mollaei S, Babaei Ghazijahani R, Noroozinejad Farsangi E, Jahani D. Investigation of Behavior of Masonry Walls Constructed with Autoclaved Aerated Concrete Blocks under Blast Loading. Applied Sciences. 2022; 12(17):8725. https://doi.org/10.3390/app12178725

Chicago/Turabian StyleMollaei, Somayeh, Reza Babaei Ghazijahani, Ehsan Noroozinejad Farsangi, and Davoud Jahani. 2022. "Investigation of Behavior of Masonry Walls Constructed with Autoclaved Aerated Concrete Blocks under Blast Loading" Applied Sciences 12, no. 17: 8725. https://doi.org/10.3390/app12178725

APA StyleMollaei, S., Babaei Ghazijahani, R., Noroozinejad Farsangi, E., & Jahani, D. (2022). Investigation of Behavior of Masonry Walls Constructed with Autoclaved Aerated Concrete Blocks under Blast Loading. Applied Sciences, 12(17), 8725. https://doi.org/10.3390/app12178725