Dynamic Response of Reinforced Recycled Aggregate Concrete Pavement under Impact Loading

Abstract

:1. Introduction

- (1)

- To investigate the effect of steel reinforcement distribution and slab thickness on the impact force characteristics and impact behaviors of RCP;

- (2)

- To evaluate the applicability of reinforced recycled aggregate concrete pavement under impact loads compared to the reinforced natural aggregate concrete pavement.

2. Experimental Methods

2.1. Materials

- (1)

- Cement and Water

- (2)

- Fine Aggregate

- (3)

- Coarse Aggregate

- (4)

- Steel reinforcement

2.2. Concrete Mix Design

2.3. Description of RCP Specimens

2.4. Instrumentation

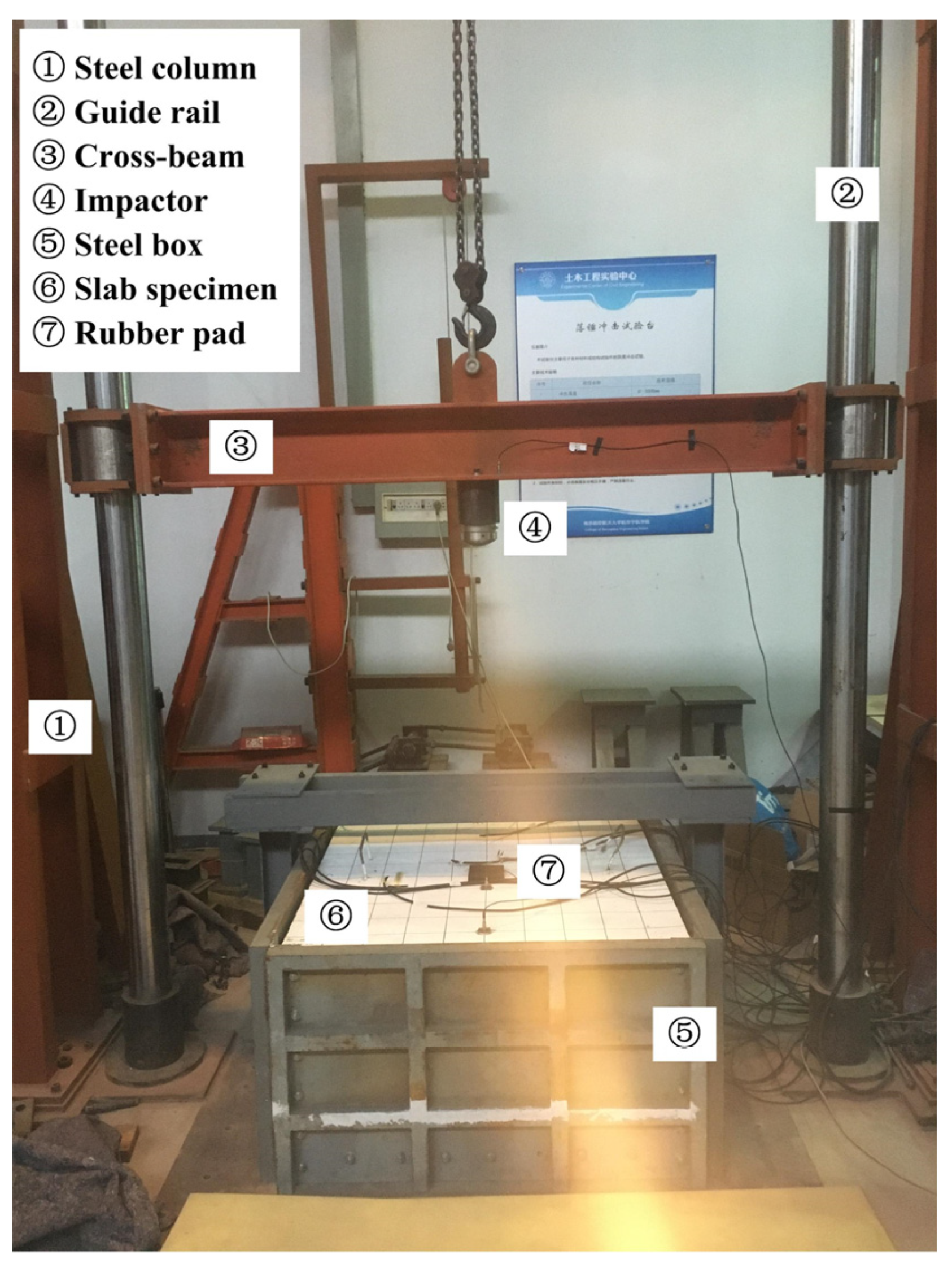

2.5. Test Program

3. Experimental Results and Discussion

3.1. Impact Force Characteristics

3.2. Damage Characteristics and Crack Patterns

3.3. Displacement Response

3.4. Strain Due to Impact Load

4. Conclusions

- (1)

- The peak impact force increased with the increase in reinforcement ratio. The impact force reached its peak value immediately after the impact, but the displacement, concrete strain and steel strain reached their peak value a few microseconds later. Therefore, the peak impact force cannot be directly considered the true impact resistance capacity.

- (2)

- The increase in slab thickness resulted in an increase in the peak inertia force, but it decreased the peak impact force. Moreover, the energy consumption ratio reached 91.5% in 6MR specimen, which been severely damaged.

- (3)

- All RCP specimens had similar crack patterns on the bottom surface, and the number of cracks decreased with the increase in the slab thickness. The reinforcement arrangement could affect the crack pattern; circumferential cracks on the top surface appeared in the 7M1R slab with 100 mm reinforced spacing, and similar cracks were not found in the 7MR slab with 150 mm reinforced spacing.

- (4)

- The reinforcement ratio played an important role in peak deflection and residual displacement. As the reinforcement ratio increased from 0.48% to 0.72%, the peak and residual displacements at D1 point decreased by 7.0% and 12.2%, respectively. The global flexural response could be observed in the RCP specimens. Microscopic punching shear failure modes were observed only in the 8MR and 7M1R specimens.

- (5)

- The 7MN specimen showed lower peak and residual displacement and higher peak impact force compared to the 7MR specimen, but no significant difference was observed between damage characteristics and crack patterns in the 7MR and 7MN specimens.

- (6)

- The influence of using RAC in RCP was relatively small, even at 100% RCA replacement ratio, and the impact of using RCA was diminished for RCP made with 100 mm longitudinal reinforcement spacing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Modarres, A.; Shabani, H. Investigating the effect of aircraft impact loading on the longitudinal top-down crack propagation parameters in asphalt runway pavement using fracture mechanics. Eng. Fract. Mech. 2015, 150, 28–46. [Google Scholar] [CrossRef]

- MH/T5004; Specifications for Airport Cement Concrete Pavement Design. CAAC (Civil Aviation Administration of China): Beijing, China, 2010.

- AC 150/5320-6E; Airport Pavement Design and Evaluation. FAA (Federal Aviation Administrator): Washington, DC, USA, 2009.

- Choi, P.; Kim, D.; Lee, B.; Won, M. Evaluation of structural responses of continuously reinforced concrete pavement (CRCP) using falling weight deflectometer. Can. J. Civ. Eng. 2016, 43, 28–39. [Google Scholar] [CrossRef]

- Salles, L.; Khazanovich, L.; Balbo, J. Structural analysis of transverse cracks in short continuously reinforced concrete pavements. Int. J. Pavement Eng. 2020, 21, 1853–1863. [Google Scholar] [CrossRef]

- Hertz, H. Uber das Gleichgewicht Schwinnender elastischer platten. Wiedermann’s Ann. Cler Phys. Und Chem. 1884, 22, 449–455. [Google Scholar]

- Westergaard, H.M. Stresses in concrete pavements computed by theoretical analysis. Public Roads 1921, 8, 54–60. [Google Scholar]

- Khazanovich, L.; Selezneva, O.; Yu, H.T.; Darter, M.I. Development of Rapid Solutions for Prediction of Critical Continuously Reinforced Concrete Pavement Stresses. Transp. Res. Rec. J. Transp. Res. Board 2001, 1778, 64–72. [Google Scholar] [CrossRef]

- William, G.W.; Shoukry, S.N. 3D Finite Element Analysis of Temperature-Induced Stresses in Dowel Jointed Concrete Pavements. Int. J. Geomech. 2001, 3, 291–308. [Google Scholar] [CrossRef]

- Davids, W.; Wang, Z.; Turkiyyah, G.; Mahoney, J.P.; Bush, D. Three-Dimensional finite element analysis of jointed plain concrete pavement with everfe2.2. Transp. Res. Rec. J. Transp. Res. Board 2003, 1853, 92–99. [Google Scholar] [CrossRef]

- Yang, G.; Bradford, M.A. A refined modelling for thermal-induced upheaval buckling of continuously reinforced concrete pavements. Eng. Struct. 2017, 150, 256–270. [Google Scholar] [CrossRef]

- Rahal, K. Mechanical properties of concrete with recycled coarse aggregate. Build. Environ. 2007, 42, 407–415. [Google Scholar] [CrossRef]

- Li, J.; Xiao, H.; Zhou, Y. Influence of coating RA surface with pozzolanic powder on properties of RAC. Build. Environ. 2009, 23, 1287–1291. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, Z.; Xu, J.; Lui, E.M.; Wu, B. Performance evaluation of recycled aggregate concrete under multiaxial compression. Constr. Build. Mater. 2019, 229, 116935. [Google Scholar] [CrossRef]

- Mas, B.; Cladera, A.; Olmo, T.; Pitarch, F. Influence of the amount of mixed RAs on the properties of concrete for non-structural use. Constr. Build. Mater. 2017, 27, 612–622. [Google Scholar] [CrossRef]

- Francesconi, L.; Pani, L.; Stochino, F. Punching shear strength of reinforced recycled concrete slabs. Constr. Build. Mater. 2016, 127, 248–263. [Google Scholar] [CrossRef]

- Rahal, K.; Alrefaei, Y. Shear strength of longitudinally reinforced recycled aggregate concrete beams. Eng. Struct. 2017, 145, 273–282. [Google Scholar] [CrossRef]

- Arezoumandi, M.; Drury, J.; Volz, J.S.; Khayat, K.H. Effect of recycled concrete aggregate replacement level on shear strength of reinforced concrete beams. Mater. J. 2015, 112, 559–567. [Google Scholar] [CrossRef]

- Schubert, S.; Hoffmann, C.; Leemann, A.; Moser, K.; Motavalli, M. Recycled aggregate concrete: Experimental shear resistance of slabs without shear reinforcement. Eng. Struct. 2012, 41, 490–497. [Google Scholar] [CrossRef]

- Brandes, M.R.; Kurama, Y.C. Behavior of shear-critical prestressed concrete beams with recycled concrete aggregates under ultimate loads. Eng. Struct. 2018, 165, 237–246. [Google Scholar] [CrossRef]

- Alnahhal, W.; Aljidda, O. Flexural behavior of basalt fiber reinforced concrete beams with recycled concrete coarse aggregates. Constr. Build. Mater. 2018, 169, 165–178. [Google Scholar] [CrossRef]

- Kantar, E.; Yuen, T.; Kobya, V.; Kuang, J. Impact dynamics and energy dissipation capacity of fibre-reinforced self-compacting concrete plates. Constr. Build. Mater. 2017, 138, 383–397. [Google Scholar] [CrossRef]

- Zineddin, M.; Krauthammer, T. Dynamic response and behavior of reinforced concrete slabs under impact loading. Int. J. Impact Eng. 2007, 34, 1517–1534. [Google Scholar] [CrossRef]

- Zineddin, M. Behavior of Structural Concrete Slabs under Localized Impact. Ph.D. Thesis, The Pennsylvania State University, State College, PA, USA, 2002. [Google Scholar]

- Othman, H.; Marzouk, H. An experimental investigation on the effect of steel reinforcement on impact response of reinforced concrete plates. Int. J. Impact Eng. 2016, 88, 12–21. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, B.; Fujikake, K. Experimental Study of Reinforced Concrete Slabs under Different Loading Rates. ACI Struct. J. 2016, 113, 157–168. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, B.; Fujikake, K. Behavior of Reinforced Concrete Slabs under Low-Velocity Impact. ACI Struct. J. 2017, 114, 643–658. [Google Scholar] [CrossRef]

- Özgür Anil Kantar, E.; Yilmaz, M.C. Low velocity impact behavior of RC slabs with different support types. Constr. Build. Mater. 2015, 93, 1078–1088. [Google Scholar] [CrossRef]

- Chiaia, B.; Kumpyak, O.; Placidi, L.; Maksimov, V. Experimental analysis and modeling of two-way reinforced concrete slabs over different kinds of yielding supports under short-term dynamic loading. Eng. Struct. 2015, 96, 88–99. [Google Scholar] [CrossRef]

- Husem, M.; Cosgun, S.I. Behavior of reinforced concrete plates under impact loading: Different support conditions and sizes. Comput. Concrete. 2016, 18, 389–404. [Google Scholar] [CrossRef]

- Hrynyk, T.; Vecchio, F. Behavior of steel fiber-reinforced concrete slabs under impact load. ACI Struct. J. 2014, 111, 1213–1223. [Google Scholar] [CrossRef]

- Beckmann, B.; Hummeltenberg, A.; Weber, T.; Curbach, M. Strain Behaviour of Concrete Slabs under Impact Load. Struct. Eng. Int. 2018, 22, 562–568. [Google Scholar] [CrossRef]

- Al-Rousan, R.Z.; Alhassan, M.A.; Al-Salman, H. Impact resistance of polypropylene fiber reinforced concrete two-way slabs. Struct. Eng. Mech. 2017, 62, 373–380. [Google Scholar] [CrossRef]

- Ong, K.C.G.; Basheerkhan, M.; Paramasivam, P. Resistance of fibre concrete slabs to low velocity projectile impact. Cem. Concr. Compos. 1999, 21, 391–401. [Google Scholar] [CrossRef]

- Wu, J. Development of Advanced Pavement Materials System for Blast Load. Ph.D. Thesis, National University of Singapore, Singapore, 2012. [Google Scholar]

- Cai, J.; Wong, L.N.Y.; Hua, W.Y. Dynamic response of airport concrete pavement to impact loading. Adv. Mater. Res. 2012, 594, 1395–1401. [Google Scholar] [CrossRef]

- Guo, J. Research on Dynamic Response of Recycled Aggregate Concrete Beam under Impact Action. Ph.D. Thesis, South China University of Technology, Guangzhou, China, 2016. [Google Scholar]

- Vali, N.M.; Babu, B.M. Impact strength assessment of recycle aggregate concrete slabs. Int. J. Sci. Res. Dev. 2016, 9, 225–228. [Google Scholar]

- Ramana NVSubbareddy, Y.V.; Sashidhar, C. Impact resistance of steel fiber reinforced recycle aggregate concrete beams. Int. J. Res. Appl. Sci. Eng. Technol. 2017, 5, 1919–1927. [Google Scholar]

- Zhou, C.; He, W.C.; Kong, X.Q.; Zheng, Z.Y.; Wang, X.Z. Study on impact behavior of steel fiber recycled concrete. Concrete 2021, 379, 36–41. [Google Scholar]

- Weng, X.H. Design of Airport Pavement; Communications Press Co. Ltd.: Beijing, China, 2017. [Google Scholar]

- Isaac, P.; Darby, A.; Ibell, T.; Evernden, M. Experimental investigation into the force propagation velocity due to hard impacts on reinforced concrete members. Int. J. Impact Eng. 2017, 100, 131–138. [Google Scholar] [CrossRef]

- Soleimani, S.; Banthia, N. A novel drop weight impact setup for testing reinforced concrete beams. Exp. Tech. 2014, 38, 72–79. [Google Scholar] [CrossRef]

- Christoforou, A.; Yigit, A. Effect of flexibility on low velocity impact response. J. Sound Vibration 1998, 217, 563–578. [Google Scholar] [CrossRef]

- Wang, Y.; Qian, X.; Liew, J.; Zhang, M. Impact of cement composite filled steel tubes: An experimental, numerical and theoretical treatise. Thin-Walled Struct. 2015, 87, 76–88. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985; pp. 119–124. [Google Scholar]

- Othman, H.; Marzouk, H. Impact response of Ultra-High-Performance reinforced concrete plates. ACI Struct. J. 2016, 113, 1–10. [Google Scholar] [CrossRef]

- Micallef, K.; Sagaseta, J.; Ruiz, M.F.; Muttoni, A. Assessing punching shear failure in reinforced concrete flat slabs subjected to localised impact loading. Int. J. Impact Eng. 2014, 71, 17–33. [Google Scholar] [CrossRef]

- Martín-Morales, M.; Zamorano, M.; Ruiz-Moyano, A.; Valverde-Espinosa, A. Characterization of recycled aggregates construction and demolition waste for concrete production following the Spanish Structural Concrete Code EHE-08. Constr. Build. Mater. 2011, 25, 742–748. [Google Scholar] [CrossRef]

- Chen, Y.; May, I. Reinforced concrete members under drop-weight impacts. Proc. Inst. Civ. Eng. Struct. Build. 2009, 162, 45–56. [Google Scholar] [CrossRef]

- Fonseca, N.; de Brito, J.; Evangelista, L. The influence of curing conditions on the mechanical performance of concrete made with recycled concrete waste. Cem. Concr. Compos. 2011, 33, 637–643. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C. Long-term mechanical and durability properties of RAC prepared with the incorporation of fly ash. Cem. Concr. Compos. 2012, 37, 12–19. [Google Scholar] [CrossRef]

- Clough, R.; Penzien, J. Dynamics of Structures, 2nd ed.; McGraw-Hill: New York, NY, USA, 1995. [Google Scholar]

| Loss on Ignition (%) | Initial Setting Time (min) | Final Setting Time (min) | Specific Surface Area (m2/kg) | Compressive Strength (Mpa) | Flexural Strength (Mpa) | ||

|---|---|---|---|---|---|---|---|

| 7 Days | 28 Days | 7 Days | 28 Days | ||||

| 2.35 | 170 | 290 | 337 | 27.3 | 45.6 | 5.6 | 8.2 |

| Type of Coarse Aggregate | Apparent Density (g/m3) | Clay Content (%) | Water Absorption (%) | Crushing Value Index (%) |

|---|---|---|---|---|

| NCA | 2644 | 0.6 | 0.9 | 8.2 |

| RCA | 2567 | 1.2 | 3.4 | 14.5 |

| Type of Concrete | Cement (kg/m3) | Fine Aggregate (kg/m3) | Coarse Aggregate(kg/m3) | Water (kg/m3) | Water-Cement Ratio | Sand Rate (%) |

|---|---|---|---|---|---|---|

| NAC | 18.57 | 22.10 | 46.96 | 7.80 | 0.42 | 32 |

| RAC | 22.29 | 21.03 | 44.69 | 7.80 | 0.35 | 32 |

| Type of Concrete | Compressive Strength, 28 Days | Split Tensile Strength, 28 Days | Flexural Strength, 28 Days | |||

|---|---|---|---|---|---|---|

| Mean (Mpa) | Standard Deviation | Mean (Mpa) | Standard Deviation | Mean (Mpa) | Standard Deviation | |

| NAC | 46.80 | 1.694 | 3.55 | 0.141 | 5.64 | 0.303 |

| RAC | 48.28 | 1.236 | 3.21 | 0.172 | 5.44 | 0.376 |

| RCP Specimen | Thickness (mm) | Type of Concrete | Bar Spacing (mm) | Average Compressive Strength (Mpa) | Maturing Age |

|---|---|---|---|---|---|

| 6MR | 60 | RAC | 150 | 48.67 | 1 year, 11 days |

| 7MR | 70 | RAC | 150 | 48.73 | 1 year, 8 days |

| 8MR | 80 | RAC | 150 | 47.78 | 1 year, 9 days |

| 7MN | 70 | NAC | 150 | 47.21 | 1 year, 11 days |

| 7M1R | 70 | RAC | 100 | 49.43 | 1 year, 11 days |

| RCP Specimen | Fim,p (kN) | Fin,p (kN) | Ip (kN.s) | Vr (m/s) | Eim (J) | Eab (J) | Eab/Eim (%) |

|---|---|---|---|---|---|---|---|

| 6MR | 206.1 | 85.9 | 1143.4 | 1.292 | 1960.0 | 1793.0 | 91.5 |

| 7MR | 175.9 | 110.7 | 1148.5 | 1.315 | 1960.0 | 1787.0 | 91.2 |

| 8MR | 150.9 | 116.1 | 1153.0 | 1.338 | 1960.0 | 1781.0 | 90.9 |

| 7MN | 200.2 | 105.1 | 1151.1 | 1.328 | 1960.0 | 1783.5 | 91.0 |

| 7M1R | 220.5 | 111.7 | 1198.5 | 1.565 | 1960.0 | 1715.0 | 87.5 |

| RCP Specimen | Bottom Surface | Top Surface | ||||

|---|---|---|---|---|---|---|

| Crack Pattern | Num of Crack | Maximum Crack Widths | Crack Pattern | Num of Cack | Maximum Crack Widths | |

| 6MR | radial crack, diagonal crack | 21 | 1.60 | radial crack | 1 | 0.08 |

| 7MR | radial crack, diagonal crack | 9 | 1.80 | radial crack | 1 | 0.12 |

| 8MR | radial crack, diagonal crack | 7 | 1.80 | circumferential crack radial crack | 2 | 0.08 |

| 7MN | radial crack, diagonal crack | 8 | 1.46 | radial crack | 2 | 0.06 |

| 7M1R | radial crack, diagonal crack | 14 | 1.50 | circumferential crack radial crack | 2 | 0.04 |

| RCP Specimen | D1 | D2 | ||||

|---|---|---|---|---|---|---|

| ωp1 | ωr1 | ωfr1 | ωp2 | ωr2 | ωfr2 | |

| 6MR | 15.87 | 7.46 | 9.24 | 9.80 | 5.04 | 6.83 |

| 7MR | 16.40 | 7.54 | 9.67 | 9.75 | 4.67 | 5.83 |

| 8MR | 17.10 | 8.47 | 10.42 | 11.61 | 5.91 | 7.89 |

| 7MN | 14.60 | 6.84 | 8.50 | 10.55 | 5.27 | 6.23 |

| 7M1R | 15.25 | 6.63 | 8.16 | 11.53 | 5.34 | 6.66 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, J.; Wu, J.; Su, T.; Lin, D. Dynamic Response of Reinforced Recycled Aggregate Concrete Pavement under Impact Loading. Appl. Sci. 2022, 12, 8804. https://doi.org/10.3390/app12178804

Yuan J, Wu J, Su T, Lin D. Dynamic Response of Reinforced Recycled Aggregate Concrete Pavement under Impact Loading. Applied Sciences. 2022; 12(17):8804. https://doi.org/10.3390/app12178804

Chicago/Turabian StyleYuan, Jifeng, Jin Wu, Tian Su, and Dadi Lin. 2022. "Dynamic Response of Reinforced Recycled Aggregate Concrete Pavement under Impact Loading" Applied Sciences 12, no. 17: 8804. https://doi.org/10.3390/app12178804

APA StyleYuan, J., Wu, J., Su, T., & Lin, D. (2022). Dynamic Response of Reinforced Recycled Aggregate Concrete Pavement under Impact Loading. Applied Sciences, 12(17), 8804. https://doi.org/10.3390/app12178804