Optimization and Performance Analysis of a Distributed Energy System Considering the Coordination of the Operational Strategy and the Fluctuation of Annual Hourly Load

Abstract

:1. Introduction

2. Model and Method

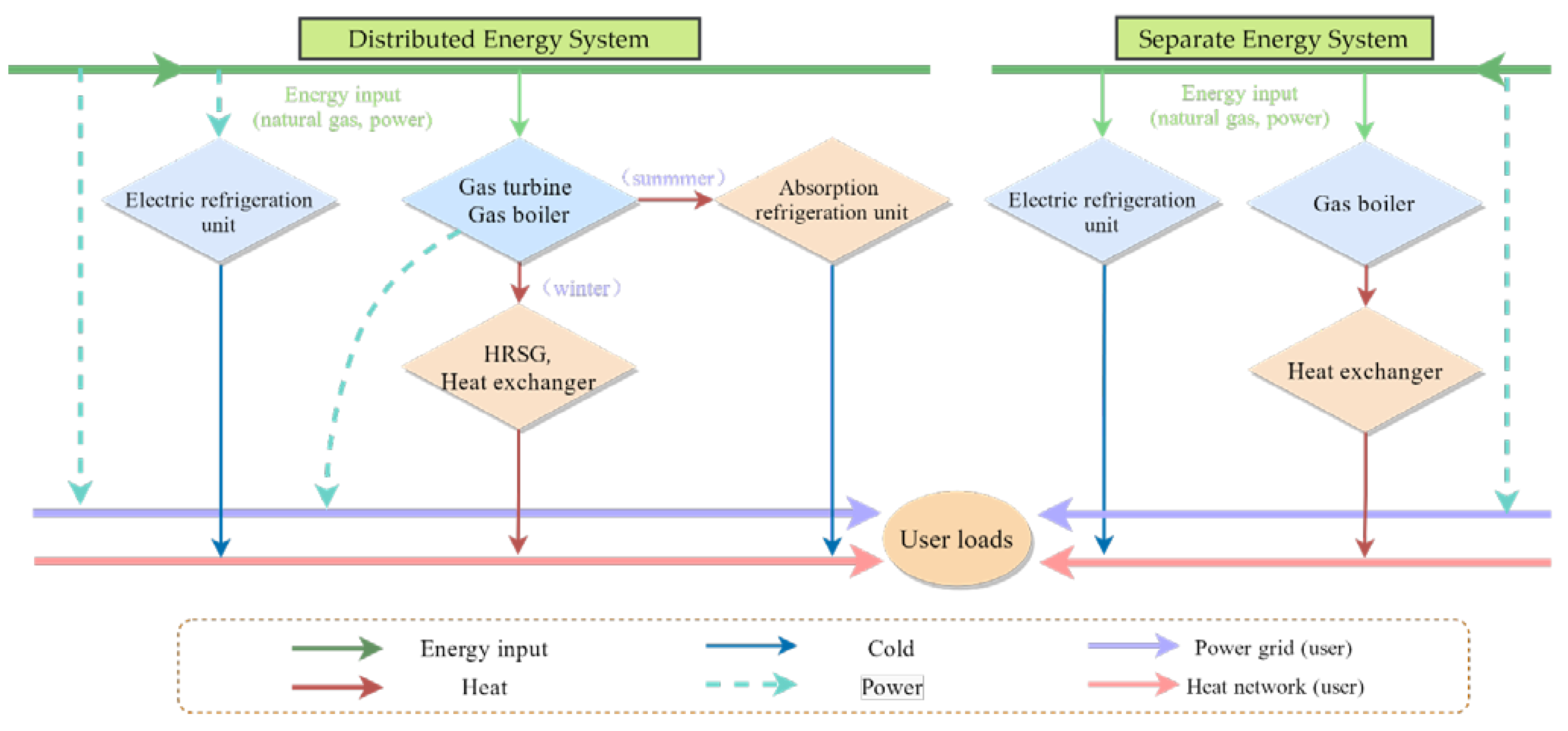

2.1. Operational Process and Structure

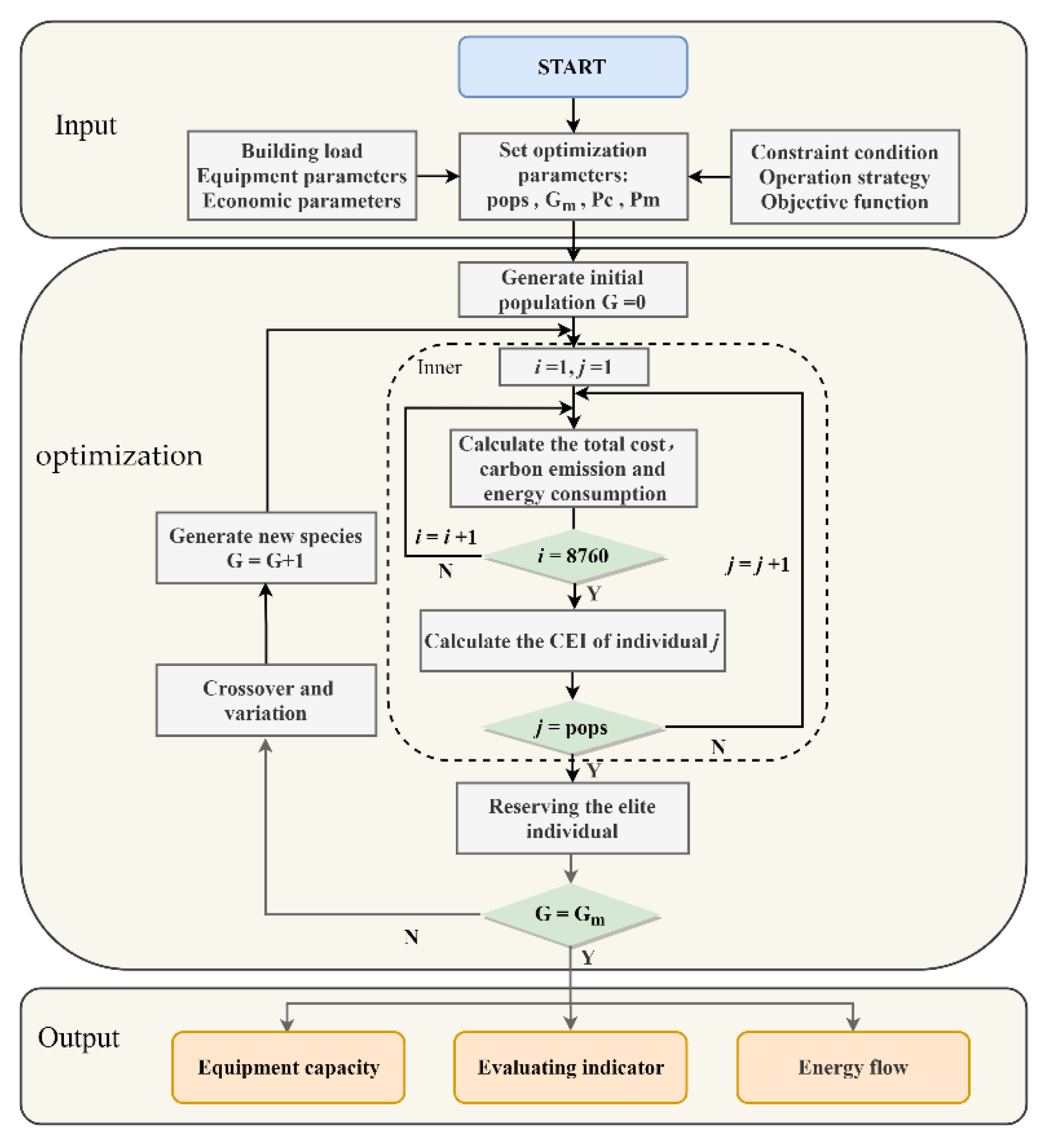

2.2. Process of Optimization

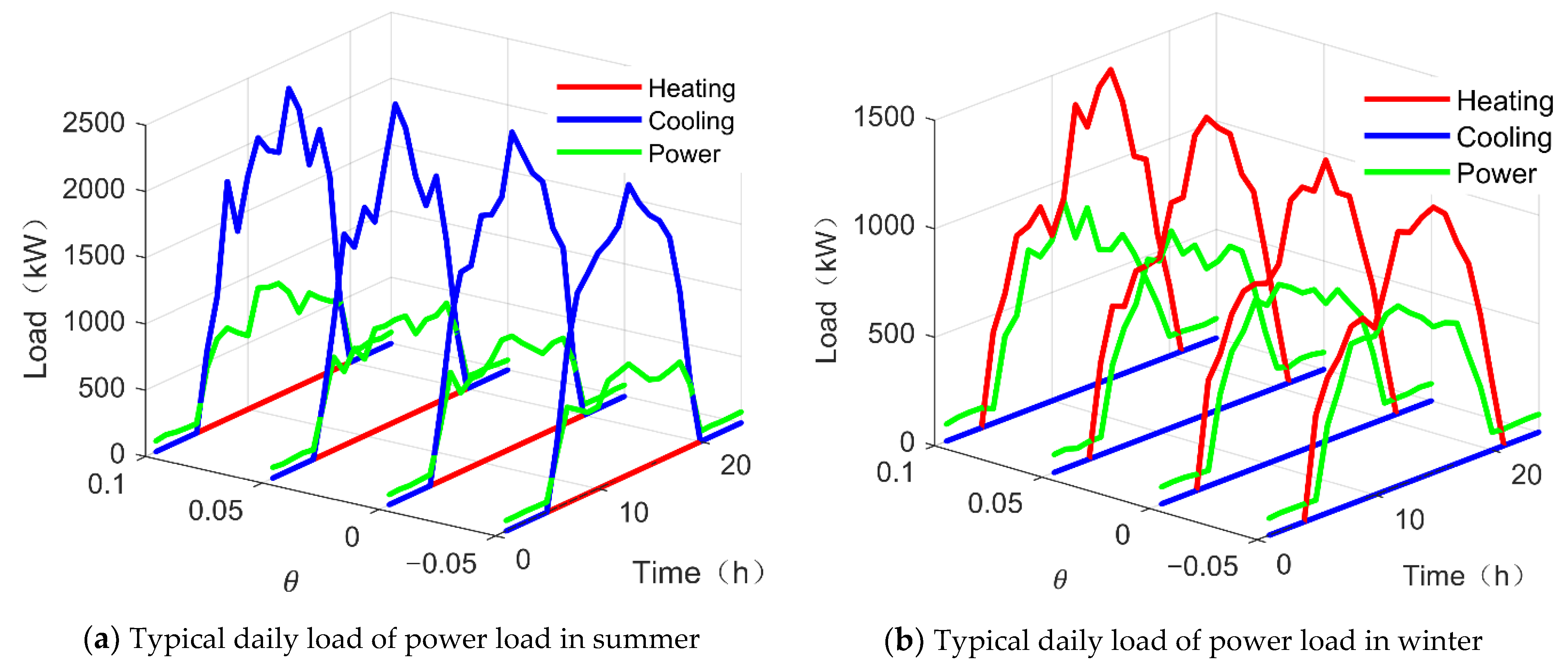

2.3. Load Calculation

2.4. Model of DES Optimization

2.4.1. Objective Function

2.4.2. Constraint Condition of DES

- (1)

- Energy balance condition

- (2)

- Equipment capacity constraints

2.4.3. Device Model

2.5. Operational Strategy

2.5.1. FEL Operational Strategy

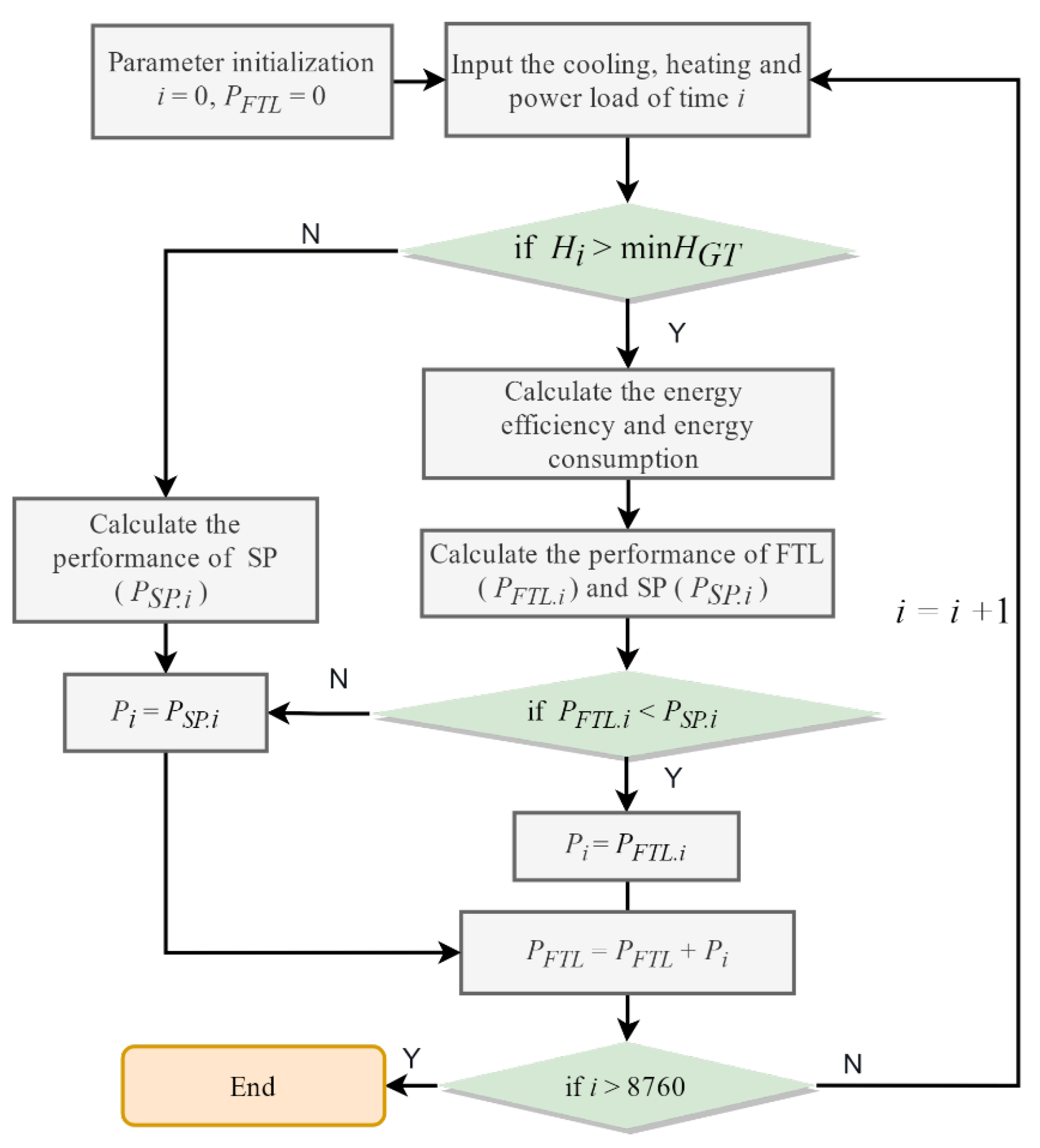

2.5.2. FTL Operational Strategy

2.5.3. HOS Operational Strategy

- (1)

- CERgt > CERi and Ci > Vgt.H·ηar

- (2)

- CERgt < CERi and Ci < Vgt.H·ηar

- (3)

- CERgt > CERi and Ei·ηer + Ci > Vgt.E·ηer + Vgt.H·ηar

- (4)

- CERgt < CERi and Ei·ηer + Ci < Vgt.E·ηer + Vgt.H·ηar

- (1)

- HERgt > HERi and Hi > Vgt.H

- (2)

- HERgt > HERi and Hi < Vgt.H

- (3)

- HERgt < HERi

2.6. Evaluating Indicator

3. Case Study

3.1. Model Parameter

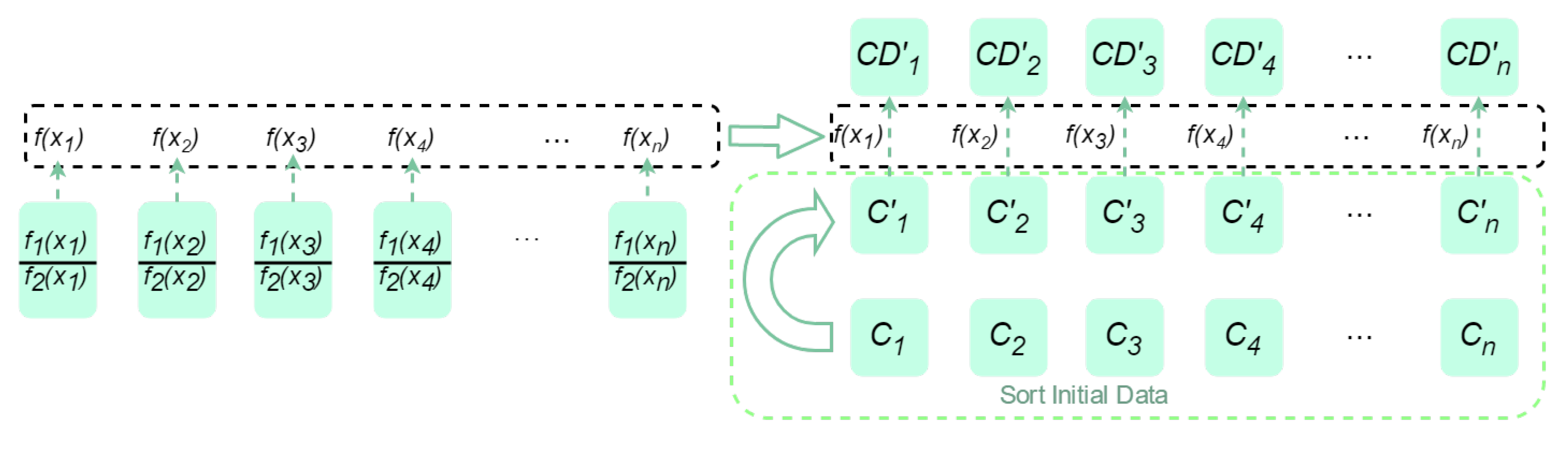

3.2. Load Discretization

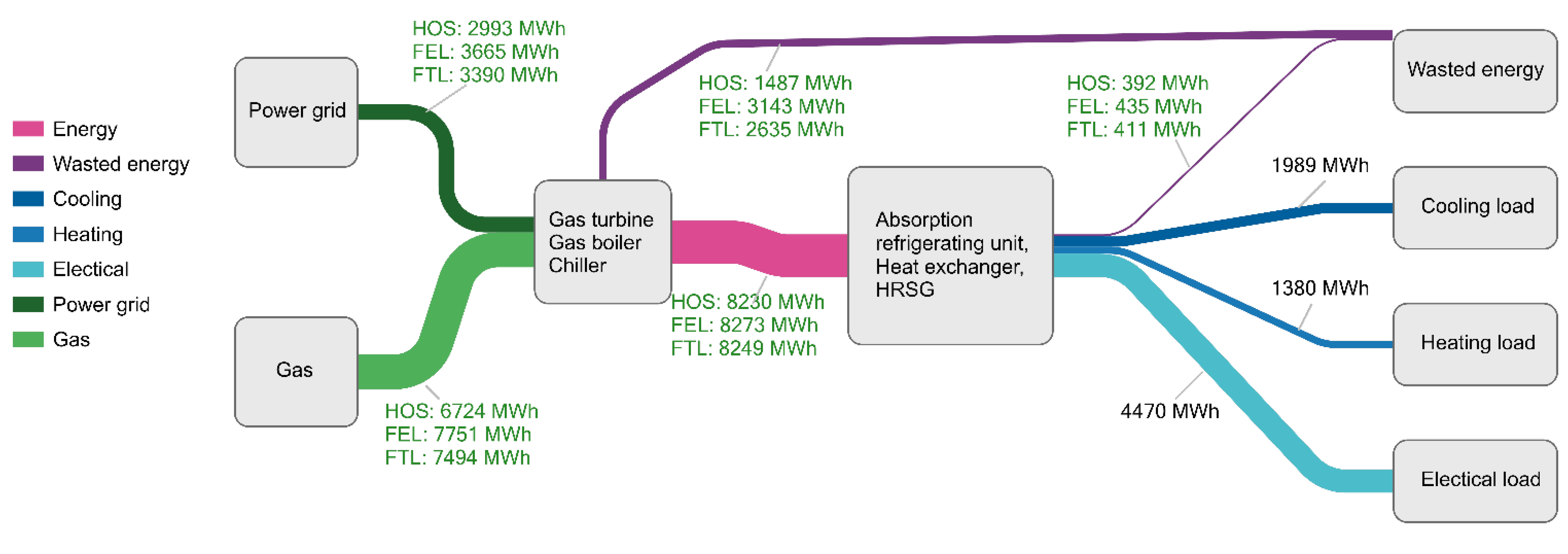

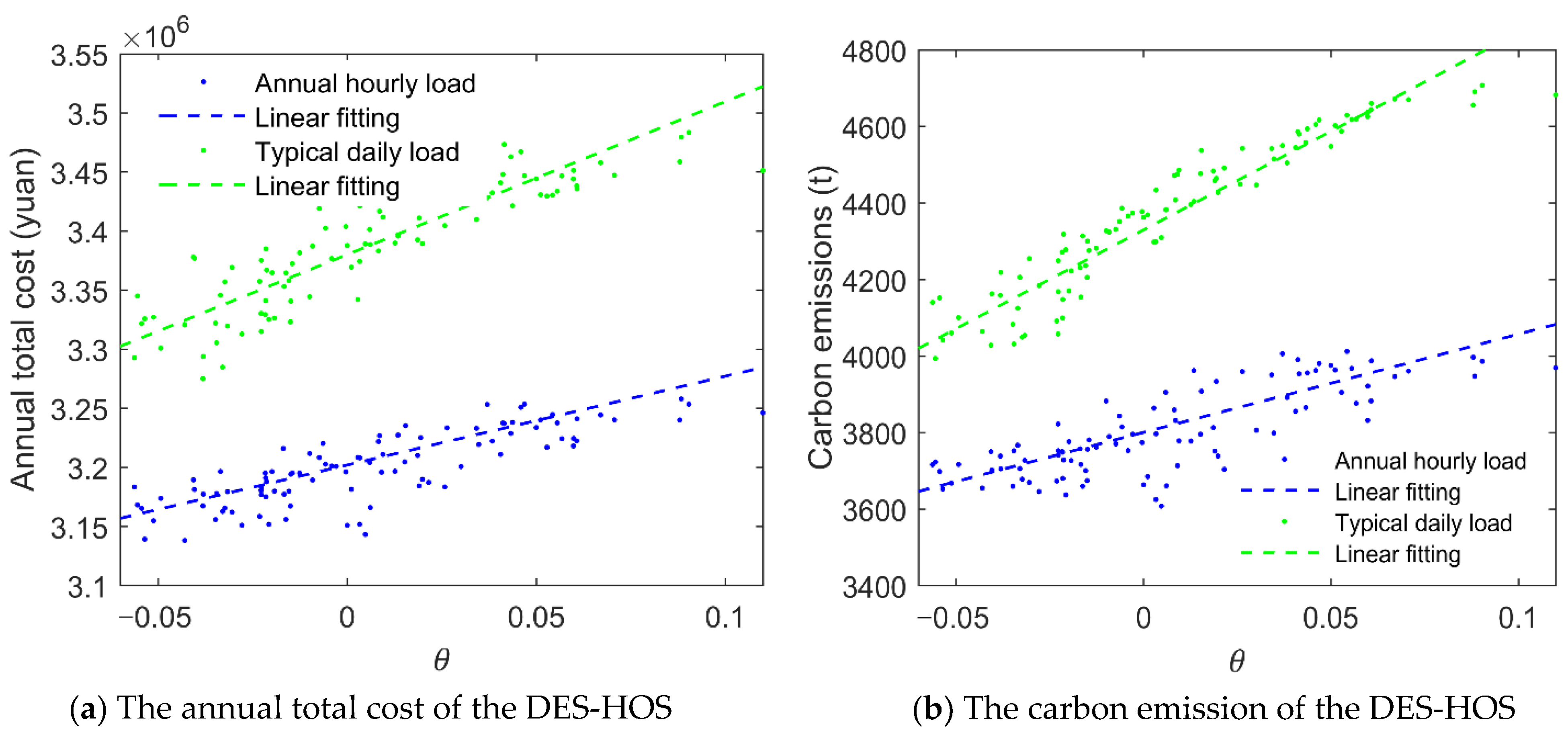

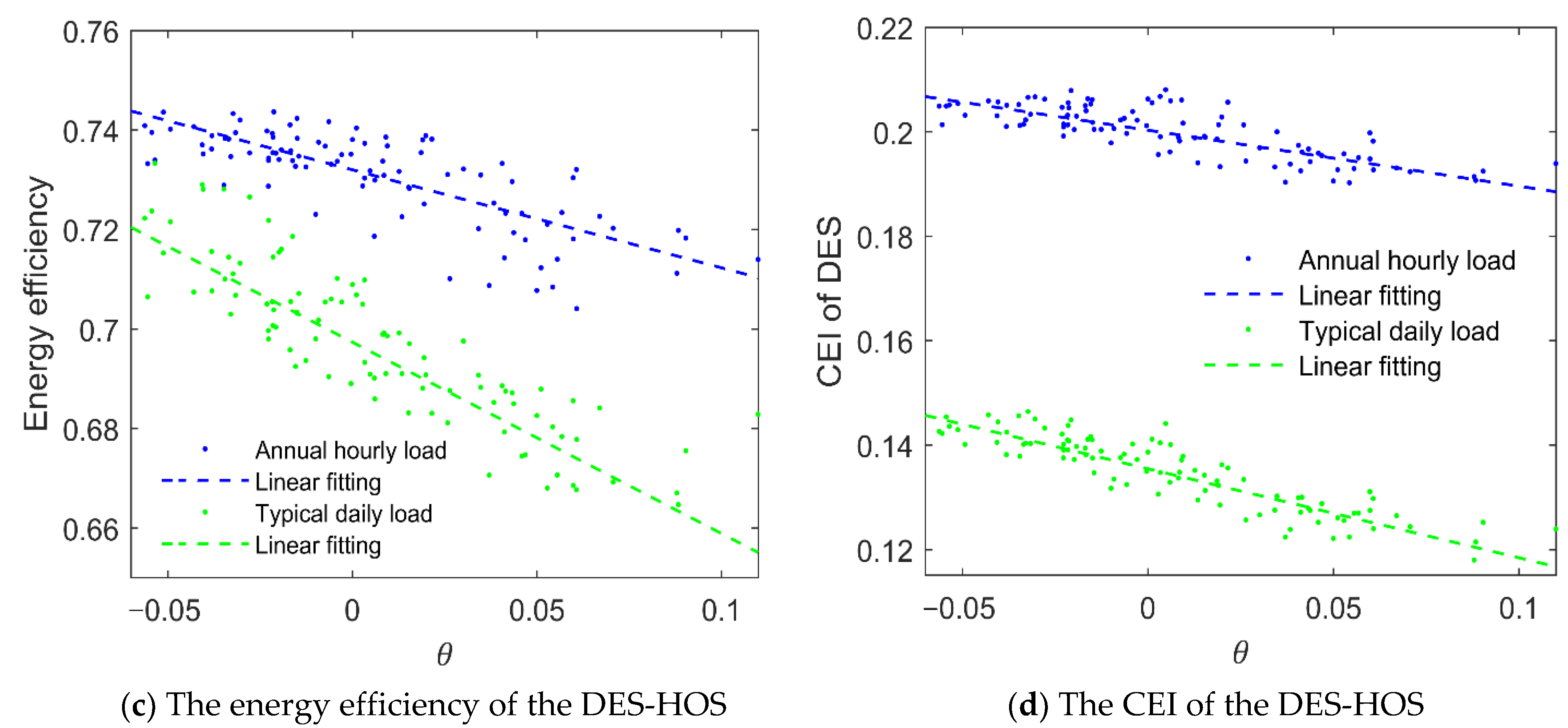

3.3. Optimization Results

4. Conclusions

- (1)

- Compared with the FEL and FTL operational strategies, the HOS reduced the energy waste of the DES by 19.7% and 15.5% and improved the comprehensive performance of the DES by 5.2% and 7.1%, respectively, through the cooperation between the annual hourly load characteristics and the equipment efficiency.

- (2)

- According to the performance analysis of the DES optimized based on multiple sets of discrete load with different fluctuations, it was found that the comprehensive performance of the DES-HOS decreased by 1.8% with the increase in the load fluctuation by 15%.

- (3)

- Compared with using a typical daily load, using the annual hourly load for DES-HOS optimization improved the accuracy of load forecasting and the comprehensive performance of the DES by about 5.2% and lowered the adverse impact derived from load fluctuations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ren, F.; Wei, Z.; Zhai, X. A review on the integration and optimization of distributed energy systems. Renew. Sustain. Energy Rev. 2022, 162, 112440. [Google Scholar] [CrossRef]

- Vaccari, M.; Mancuso, G.; Riccardi, J.; Cantù, M.; Pannocchia, G. A Sequential Linear Programming algorithm for economic optimization of Hybrid Renewable Energy Systems. J. Process Control 2017, 2017 74, 189–201. [Google Scholar] [CrossRef]

- Mago, P.J.; Fumo, N.; Chamra, L.M. Performance analysis of CCHP and CHP systems operating following the thermal and electric load. Int. J. Energy Res. 2010, 33, 852–864. [Google Scholar] [CrossRef]

- Wang, J.; Dong, F.; Ma, Z.; Chen, H.; Yan, R. Multi-objective optimization with thermodynamic analysis of an integrated energy system based on biomass and solar energies. J. Clean. Prod. 2021, 324, 129257. [Google Scholar] [CrossRef]

- Li, M.; Zhou, M.; Feng, Y.; Mu, H.; Ma, Q.; Ma, B. Integrated design and optimization of natural gas distributed energy system for regional building complex. Energy Build. 2017, 154, 81–95. [Google Scholar] [CrossRef]

- Ge, Y.; Han, J.; Ma, Q.; Feng, J. Optimal configuration and operation analysis of solar-assisted natural gas distributed energy system with energy storage. Energy 2022, 246, 123429. [Google Scholar] [CrossRef]

- de Doile, G.N.; Junior, P.R.; Rocha, L.C.; Janda, K.; Aquila, G.; Peruchi, R.S.; Balestrassi, P.P. Feasibility of Hybrid Wind and Photovoltaic Distributed Generation and Battery Energy Storage Systems Under Techno-Economic Regulation. Renew. Energy 2022, 195, 1310–1323. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, J.; Wu, D.; Fan, G.; Zhang, S.; Yang, X.; Ge, H. Two-phase collaborative optimization and operation strategy for a new distributed energy system that combines multi-energy storage for a nearly zero energy community. Energy Convers. Manag. 2021, 230, 113800. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Y.; Fan, G.; Wu, D.; Guo, J.; Jin, G.; Zhang, S.; Yang, X. Co-optimization of a novel distributed energy system integrated with hybrid energy storage in different nearly zero energy community scenarios. Energy 2022, 247, 123553. [Google Scholar] [CrossRef]

- Wen, Q.; Liu, G.; Rao, Z.; Liao, S. Applications, evaluations and supportive strategies of distributed energy systems: A review. Energy Build. 2020, 225, 110314. [Google Scholar] [CrossRef]

- Jan, J.; Broesicke, O.; Tong, X.; Wang, D.; Li, D.; Crittenden, J.C. Multidisciplinary design optimization of distributed energy generation systems: The trade-offs between life cycle environmental and economic impacts. Appl. Energy 2020, 284, 116197. [Google Scholar]

- Ma, W.; Fang, S.; Liu, G. Hybrid optimization method and seasonal operation strategy for distributed energy system integrating CCHP, photovoltaic and ground source heat pump. Energy 2017, 141, 1439–1455. [Google Scholar] [CrossRef]

- Gou, X.; Chen, Q.; Sun, Y.; Ma, H.; Li, B.-J. Holistic analysis and optimization of distributed energy system considering different transport characteristics of multi-energy and component efficiency variation. Energy 2021, 228, 120586. [Google Scholar] [CrossRef]

- Vaccari, M.; di Capaci, R.B.; Brunazzi, E.; Tognotti, L.; Pierno, P.; Vagheggi, R.; Pannocchia, G. Optimally Managing Chemical Plant Operations: An Example Oriented by Industry 4.0 Paradigms. Ind. Eng. Chem. Res. 2021, 60, 7853–7867. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, J.; Li, Y.; Wu, D.; Zhang, S.; Yang, X.; Ge, H.; Cai, Z. Multi-scenario analysis and collaborative optimization of a novel distributed energy system coupled with hybrid energy storage for a nearly zero-energy community. J. Energy Storage 2021, 41, 102992. [Google Scholar] [CrossRef]

- Huang, D.; Zhou, D.; Jia, X.; Yan, S.; Li, T.; Huang, D.; Zhang, C. A mixed integer optimization method with double penalties for the complete consumption of renewable energy in distributed energy systems. Sustain. Energy Technol. Assess. 2022, 52, 102061. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, P.; Wu, D.; Liu, Z.; Ge, H.; Zhang, S.; Yang, X. A new collaborative optimization method for a distributed energy system combining hybrid energy storage. Sustain. Cities Soc. 2021, 75, 103330. [Google Scholar] [CrossRef]

- Huang, Y.; Xu, P.; Wu, Q.; Ren, H.; Li, Q.; Yang, Y. Optimization of regional distributed energy system under discrete demand distribution. Energy Rep. 2022, 8, 634–640. [Google Scholar] [CrossRef]

- Li, L.; Mu, H.; Li, N.; Li, M. Analysis of the integrated performance and redundant energy of CCHP systems under different operation strategies. Energy Build. 2015, 99, 231–242. [Google Scholar] [CrossRef]

- Wu, J.-Y.; Wang, J.-L.; Li, S. Multi-objective optimal operation strategy study of micro-CCHP system. Energy 2012, 48, 472–483. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, J.; Dong, F.; Qin, Y.; Ma, Z.; Ma, Y.; Li, J. Novel flexibility evaluation of hybrid combined cooling, heating and power system with an improved operation strategy. Appl. Energy 2021, 300, 117358. [Google Scholar] [CrossRef]

- Peng, X.; Bhattacharya, T.; Cao, T.; Mao, J.; Tekreeti, T.; Qin, X. Exploiting Renewable Energy and UPS Systems to Reduce Power Consumption in Data Centers. Big Data Res. 2021, 27, 100306. [Google Scholar] [CrossRef]

- Wang, Y.; Zou, C.; Li, W.; Zou, Y.; Huang, H. Improving stability and thermal properties of TiO2 nanofluids by supramolecular modification: High energy efficiency heat transfer medium for data center cooling system. Int. J. Heat Mass Transf. 2020, 156, 119735. [Google Scholar] [CrossRef]

- Cao, Y.; Wu, Y.; Fu, L.; Jermsittiparsert, K.; Razmjooy, N. Multi-objective optimization of a PEMFC based CCHP system by meta-heuristics. Energy Rep. 2019, 5, 1551–1559. [Google Scholar] [CrossRef]

- Mu, Y.; Wang, C.; Sun, M.; He, W.; Wei, W. CVaR-based operation optimization method of community integrated energy system considering the uncertainty of integrated demand response. Energy Rep. 2022, 8, 1216–1223. [Google Scholar] [CrossRef]

- Rajamand, S. Probabilistic Power Distribution Considering Power Uncertainty of Load and Distributed Generators Using Cumulant and Truncated Versatile Distribution. Sustain. Energy Grids Netw. 2022, 30, 100608. [Google Scholar] [CrossRef]

- Li, L.; Cao, X.; Wang, P. Optimal coordination strategy for multiple distributed energy systems considering supply, demand, and price uncertainties. Energy 2021, 227, 120460. [Google Scholar] [CrossRef]

- Lu, C.; Wang, J.; Yan, R. Multi-objective optimization of combined cooling, heating and power system considering the collaboration of thermal energy storage with load uncertainties. J. Energy Storage 2021, 40, 102819. [Google Scholar] [CrossRef]

- Liu, Z.; Cui, Y.; Wang, J.; Yue, C.; Agbodjan, Y.S.; Yang, Y. Multi-objective optimization of multi-energy complementary integrated energy systems considering load prediction and renewable energy production uncertainties. Energy 2022, 254, 124399. [Google Scholar] [CrossRef]

- Hou, J.; Wang, J.; Zhou, Y.; Lu, X. Distributed energy systems: Multi-objective optimization and evaluation under different operational strategies. J. Clean. Prod. 2020, 280, 124050. [Google Scholar] [CrossRef]

- Lee, D.; Kim, B.J. Different environmental conditions in genetic algorithm. Phys. A Stat. Mech. Its Appl. 2022, 602, 127604. [Google Scholar] [CrossRef]

- Zakaria, A.; Ismail, F.B.; Lipu, M.H.; Hannan, M. Uncertainty models for stochastic optimization in renewable energy applications. Renew. Energy 2020, 145, 1543–1571. [Google Scholar] [CrossRef]

- Rojas, C.; Troubetzkoy, S. Coding discretizations of continuous functions. Discret. Math. 2011, 311, 620–627. [Google Scholar] [CrossRef]

- Lai, J.Z.; Huang, T.-J. An agglomerative clustering algorithm using a dynamic k-nearest-neighbor list. Inf. Sci. 2011, 181, 1722–1734. [Google Scholar] [CrossRef]

- Gou, X.; Zhang, H.; Li, G.; Cao, Y.; Zhang, Q. Dynamic simulation of a gas turbine for heat recovery at varying load and environment conditions. Appl. Therm. Eng. 2021, 195, 117014. [Google Scholar] [CrossRef]

- Momeni, M.; Soltani, M.; Hosseinpour, M.; Nathwani, J. A comprehensive analysis of a power-to-gas energy storage unit utilizing captured carbon dioxide as a raw material in a large-scale power plant. Energy Convers. Manag. 2021, 227, 113613. [Google Scholar] [CrossRef]

- Azam, A.; Rafiq, M.; Shafique, M.; Zhang, H.; Yuan, J. Analyzing the effect of natural gas, nuclear energy and renewable energy on GDP and carbon emissions: A multi-variate panel data analysis. Energy 2021, 219, 119592. [Google Scholar] [CrossRef]

| Time | Price (Yuan·(kWh)−1) | |

|---|---|---|

| Peak period | 8:00~11:00 18:00~21:00 | 1.074 |

| Intermediate period | 6:00~8:00 11:00~18:00 21:00~22:00 | 0.671 |

| Valley period | 0:00~6:00 22:00~24:00 | 0.316 |

| Equipment | Equipment Cost (Yuan·(kWh)−1) | Maintenance Cost (Yuan·(kWh)−1) | Efficiency | Life (Year) |

|---|---|---|---|---|

| GT | 6500 | 0.0472 | * | 30 |

| ** | ||||

| HRSG | 800 | 0.0022 | 0.85 | 20 |

| GB | 900 | 0.0022 | 0.90 | 20 |

| ER | 900 | 0.0087 | 4.5 | 20 |

| ARU | 1228 | 0.008 | 1.2 | 20 |

| HE | 100 | 0 | 0.95 | 20 |

| Operational Strategy | CEI | ATC (Yuan) | CE (t) | EE |

|---|---|---|---|---|

| HOS | 0.151 | 3.22 × 106 | 3854 | 0.83 |

| FEL | 0.103 | 3.39 × 106 | 4056 | 0.79 |

| FTL | 0.076 | 3.42 × 106 | 4112 | 0.77 |

| Operational Strategy | GT (kW) | ER (kW) | GB (kW) | HRSG (kW) | ARU (kW) | HE (kW) |

|---|---|---|---|---|---|---|

| HOS | 643 | 1334 | 2159 | 1922 | 2189 | 1762 |

| FEL | 704 | 1112 | 1865 | 2154 | 2320 | 1966 |

| FTL | 603 | 1224 | 2112 | 1789 | 1974 | 1523 |

| θ | GT (kW) | ER (kW) | GB (kW) | HRSG (kW) | ARU (kW) | HE (kW) |

|---|---|---|---|---|---|---|

| −0.05 | 723 | 1121 | 1974 | 2120 | 2354 | 1862 |

| 0 | 643 | 1334 | 2159 | 1922 | 2189 | 1762 |

| 0.05 | 594 | 1485 | 2310 | 1781 | 1910 | 1642 |

| 0.1 | 550 | 1610 | 2521 | 1665 | 1759 | 1519 |

| θ | Gas (×105 m3) | Power * (MWh) | Waste (MWh) |

|---|---|---|---|

| −0.05 | 6.94 | 3021 | 1811 |

| 0 | 6.74 | 2993 | 1924 |

| 0.05 | 6.51 | 3710 | 2045 |

| 0.1 | 6.22 | 4156 | 2141 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quan, X.; Xie, H.; Wang, X.; Zhang, J.; Wei, J.; Zhang, Z.; Liu, M. Optimization and Performance Analysis of a Distributed Energy System Considering the Coordination of the Operational Strategy and the Fluctuation of Annual Hourly Load. Appl. Sci. 2022, 12, 9449. https://doi.org/10.3390/app12199449

Quan X, Xie H, Wang X, Zhang J, Wei J, Zhang Z, Liu M. Optimization and Performance Analysis of a Distributed Energy System Considering the Coordination of the Operational Strategy and the Fluctuation of Annual Hourly Load. Applied Sciences. 2022; 12(19):9449. https://doi.org/10.3390/app12199449

Chicago/Turabian StyleQuan, Xibin, Hao Xie, Xinye Wang, Jubing Zhang, Jiayu Wei, Zhicong Zhang, and Meijing Liu. 2022. "Optimization and Performance Analysis of a Distributed Energy System Considering the Coordination of the Operational Strategy and the Fluctuation of Annual Hourly Load" Applied Sciences 12, no. 19: 9449. https://doi.org/10.3390/app12199449

APA StyleQuan, X., Xie, H., Wang, X., Zhang, J., Wei, J., Zhang, Z., & Liu, M. (2022). Optimization and Performance Analysis of a Distributed Energy System Considering the Coordination of the Operational Strategy and the Fluctuation of Annual Hourly Load. Applied Sciences, 12(19), 9449. https://doi.org/10.3390/app12199449