3.1. Basis Modeling of Slug Flow

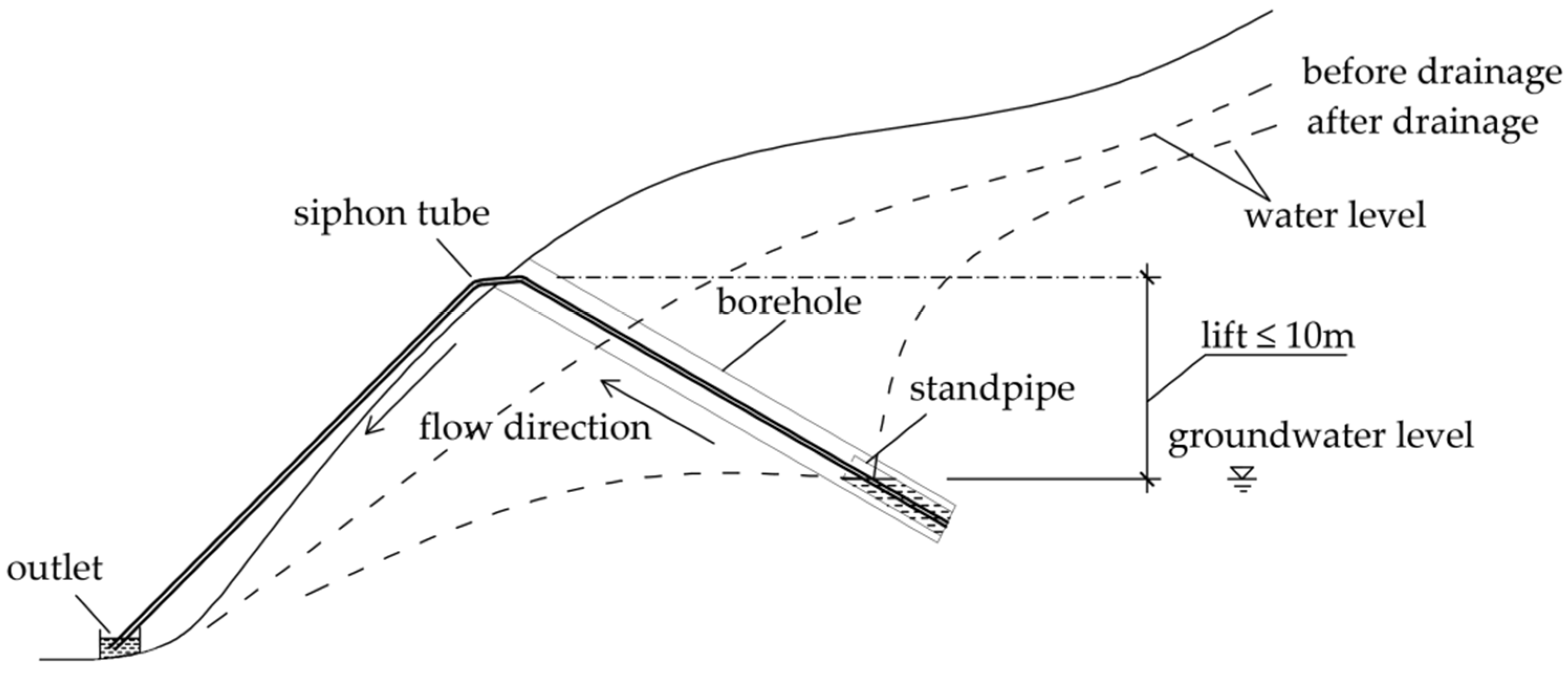

In a cylindrical pipe formed by a gas–liquid two-phase fluid mixture in a slug flow, the bubble can be approximated as a cylinder with two nearly hemispherical caps. As shown in

Figure 4, the middle section of the bubble can be approximated as consisting of a cylindrical cavity and a uniform thickness liquid film wrapped around the outside. The two ends of the bubble consist of a three-dimensional surface with a very complex shape and a nearly spherical surface at the top, as shown in

Figure 5. The slug bubble that can exist stably in the circular tube has a length several times the diameter of the circular tube, while the gas flow rate is mainly calculated based on the main body of the bubble. Therefore, the actual shape of the bubble ends has little effect on the calculation of the total volume flow rate of the gas.

Due to the random nature of the gas–liquid two-phase flow, the lengths of both bubbles and liquid slugs were not identical. It was assumed that all bubbles had the same length and were multiples of the diameter of the circular tube. Similarly, it was assumed that all liquid slugs were of the same length. The object of calculation and analysis was a cell consisting of a bubble and a slug. Based on the theory of multiphase media, a mathematical model of slug flow in a circular tube section in axisymmetric form was established. Firstly, it can be assumed that the computational domain of a single fluid based on the mass conservation equation can be obtained as the continuity equation in column coordinates (

x,

r,

θ) [

28]

The Navier–Stokes equation projected onto the

x-axis in the column coordinate system can be written in the following form

Equations (11) and (12) describe the flow of bubbles and liquid films. Since the liquid was incompressible and the volume of the bubble remained almost constant, it can be assumed that the density

ρ of each phase was constant. Since

and

characterized the axisymmetric model,

can be obtained from Equation (11), and further

. Therefore, Equation (12) can be simplified to the following form

where

and

denote the velocity components of the continuous phase (liquid film or liquid) and the dispersed phase (bubble or droplet) along the

x-axis, respectively, and

is the effective gravitational acceleration component of the gravity and pressure gradient acting on the dispersed or continuous phase along the

x-axis.

The conventional view is that the low viscosity properties of the gas result in minimal shear stress on the bubble surface, which can be neglected in calculations. However, the effect of shear stress on bubbles and droplets in slug flows can be substantial due to the small transverse dimensions of bubbles and liquid films in small-diameter circular tubes. At the axis of the circular tube (

r = 0), the shear stress in the bubble is zero.

This equation can be combined with Equation (11) to obtain

Meanwhile, the tube wall obeys the no-slip boundary condition at

r =

RAt the gas–liquid interface (

), the mixed boundary condition is used to characterize the continuity of the velocity and shear stress distribution in the system,

The above equation can be further written as

Double integration of the gas–liquid phase in Equation (13) yields

where the integration constants

and

can be calculated by the boundary conditions (Equations (16)–(19)). The velocity and stress distribution of the continuous phase (liquid film) in the velocity distribution of each phase of the mixture is shown below

The velocity and stress distribution in the dispersed phase (bubbles or droplets) are shown below

Each parameter in the formula is calculated as follows

The instantaneous flow rate of the liquid in the liquid film can be obtained by integrating Equation (22)

The instantaneous flow rate of the gas in the bubble can be found by integrating Equation (24)

Thulasidas [

29] provided the instantaneous flow rate relationship for a gas–liquid two-phase mixture in a tube during flow based on the assumption that the direction of flow through the liquid film is always opposite to the direction of the bubble velocity

The difference is that Aditya extends the assumptions to

The expressions (17)–(19) have the meaning of balanced equations: the left side of its equal sign is the sum of the volume fluxes of each phase entering or leaving the control volume V through the cross-section x = 0, while the right side is the sum of the volume fluxes of each phase entering or leaving the control volume V through the cross-section x = L.

Equation (31) assumes that the flow direction of the film should always be opposite to the flow direction of the bubbles. It is known that the velocity of the bubble is higher than the velocity of the liquid in the slug, i.e., . It can be seen from Equation (30) that, depending on the area of the bubble cross-section, the flow direction of the liquid in the film may be the same as the movement direction of the bubble when the area of the bubble cross-section is small. However, the film flow direction is opposite when the bubble occupies most of the cross-section of the pipe.

After a simple algebraic operation using Equations (27)–(29), the pressure gradient along the bubble axis in the liquid film can be written as

The following equation can calculate the constants

However, when the fluid velocity or siphon diameter decreases, the film thickness decreases until it disappears, and the pressure drop of the fluid inside the tube can no longer be calculated using such equations based on the film thickness.

3.2. Mechanism and Calculation for Pressure Drop of Dry Slug Flow

Unlike single-phase flow motion, the mechanical properties of slug flow depend heavily on the bubble-liquid interaction. The mechanical transfer properties of wet slug flow have been discussed when a liquid film is present, while the calculation of dry slug flow is more intuitive.

When the bubble is composed of the gas–liquid interface at both ends and the tube wall, instead of only the gas–liquid interface, this flow type can be considered a dry slug flow, while the gas–liquid interface and the tube wall form a gas–liquid–solid three-phase contact line. The most widely used theoretical models regarding the relationship between contact angle and contact line velocity are fluid dynamics [

30] and molecular dynamics theory [

31]. Among them, the molecular dynamics theory model suggests that the motion of the contact line is determined by the statistical dynamics of collisions between gas, solid, and liquid molecules in the three-phase region [

31], as defined by

where

ϑ is the average displacement length,

is Boltzmann’s constant,

h is Planck’s constant,

T is temperature;

is the equilibrium frequency of random displacement of molecules, which can be expressed in terms of the activation energy of the wetting process

where

N is Avogadro’s constant.

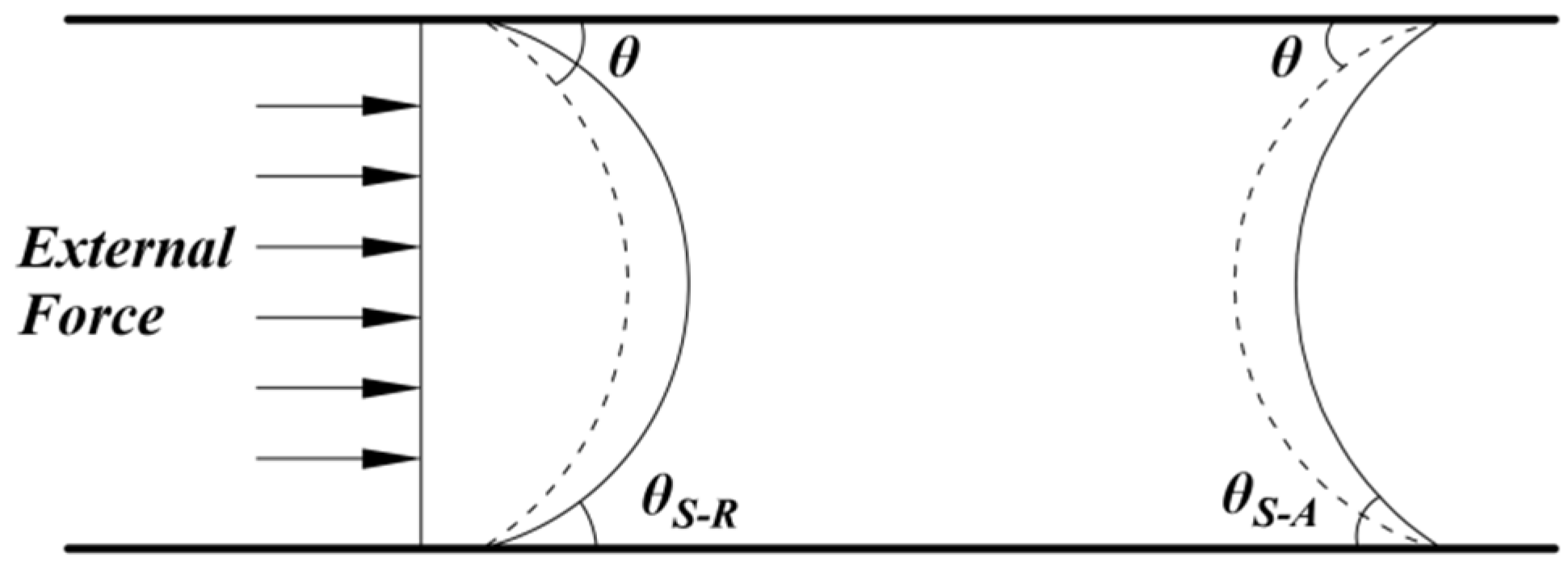

During the siphon drainage process, the fluid in the rising section pushes the fluid in the horizontal section toward the drain. In a millimeter-diameter siphon, the horizontal segment fluid undergoes a discontinuous motion under the action of thrust. Assuming that the fluid does not compress, the forces during the entire motion include fluid thrust, slug bubble interface pressure, resistance along the wall, and negative pressure on the drain side of the slug bubble. Further, the primary energy conversion process of its motion process is gravitational potential energy → kinetic energy → pressure potential energy, → kinetic energy … finally transformed into pressure potential energy, pushing the horizontal segment terminal fluid to vertical segment drop, forming a continuous siphon flow. For siphons in this size range, in the process of resuming siphoning through water level lift, the thrust provided by the lift change is consumed step-by-step by the slug bubble and liquid slug in the horizontal section, plus the resistance effect of the interface between the two ends of the slug bubble and the pipe wall, resulting in a certain degree of reduction in the critical lift that causes siphon restart. A simplified force model of the dry slug flow unit is shown in

Figure 6. In this form of flow, the bubbles have the same velocity as the liquid and flow alternately through the pipe without forming a liquid film on the pipe wall. According to the simplified model, it is known that the pressure drop of the slug flow can be divided into three parts, namely, the frictional pressure drop of the bubble and fluid movement and the frictional pressure drop generated by the movement of the gas–liquid–solid three-phase contact line, as shown in

Figure 7 for the simplified pressure drop model.

In the dry slug flow mode, the gas, liquid, and solid phases are entirely separated by the gas–liquid interface and moving contact line, and the bubbles have the same velocity as the liquid and flow alternately through the pipe and do not form a liquid film on the pipe wall. Therefore, to satisfy the continuity equation, the velocities of bubbles and slugs should be equal, as shown in the following equation.

The subscripts L and G denote the liquid and gas phases, respectively. In this section, we study the velocity of bubbles and liquid slugs based on the average interfacial velocity of liquid slugs based on the visualized data.

Under experimental conditions, the two-phase flow is dry slug flow when the liquid slug passes through a small diameter channel with hydrophobic properties. According to previous studies, the pressure drop of the two-phase flow consists of the pressure drop of the liquid slug, the bubble, and the moving contact line [

32] as follows

where Δ

P is the pressure drop, the subscripts

TP,

G,

L, and

MCL are the two-phase integrated gas phase, liquid phase, and contact line, respectively. As the measured flow velocities at each lift of the 200 m length siphon involved in the test and at the medium and high lift of the 100 m length siphon proved that the siphon flow in the 3~8 mm diameter tube is laminar, the frictional pressure drop of each single phase bubble or liquid slug can be calculated by the following equation

The following equation can express the pressure drop of the slug flow

In addition, pressure loss is also induced when the gas–liquid–solid three-phase contact line moves, i.e., the third term on the right-hand side of the Equation (38). The difference in density and surface tension between different fluids will create a curved interface, and any curved interface between the two phases of the fluid will create a pressure difference that depends on the exact shape of the interface. However, in many cases, the gas–liquid interface can be assumed to be a curved lunar surface described using only the contact angle and the hydraulic diameter. The contact angle depends on the hydrodynamics at the contact line; thus, that part of the pressure drop can be referred to as the contact angle or the pressure drop due to the contact line. The pressure drop at the contact line of the “bubble-liquid slug” cell can be expressed by applying Young’s equation to the contact line

where

and

are the forward and backward contact angles, respectively. Therefore, as long as the forward and backward contact angles differ, a net pressure drop is generated in the contact line. Moreover, the difference between the forward and backward contact angles is caused by two phenomena, i.e., contact angle hysteresis and the effect of contact line velocity on contact angle. Although previous models considered the effect of contact line velocity, the pressure drop caused by contact angle hysteresis was not considered.

Yu et al. [

33] proposed that the magnitude of the dynamic contact angle is related to the capillary number Ca, and these correlations have the following form.

where

and

are the static advancing contact angle, and dynamic advancing contact angle, respectively, and both

c and

d are constants. Therefore, the dynamic advancing contact angle can be calculated as

Regarding the values of

c and

d, according to Seebergh [

34], the way the dynamic contact angle varies and the values of the relevant constants are obtained, as follows Equation

Although the model does not contain any empirical parameters, it only applies to the forward contact line velocity solution, i.e., the dynamic forward contact angle. In order to be able to apply the above equation to the dynamic backward contact angle, in previous work on the model calculation, it was assumed that the difference between the static and dynamic backward contact angle is the same as the difference between the static and dynamic forward contact angle. Thus, the dynamic backward contact angle can be calculated according to the following equation

where

and

are the static and dynamic backward contact angles, and

and

are the static and dynamic forward contact angles, respectively. According to the above formula, it is known that the larger the flow velocity is, the more significant difference between the static contact angle and dynamic contact angle is; conversely, the smaller it is. Combined with the formula of the critical radius, the calculation results within the application range of this formula show a monotonic decreasing trend with the increase of the contact angle. Therefore, during siphon drainage with a low lift and high flow rate, the end of the liquid slug in the horizontal section of the siphon (corresponding to the head of the slug bubble) is prone to rupture, while the head of the liquid slug is relatively intact, and this phenomenon is also observed in the experiment.

The relationships between the four dynamic static contact angles were obtained from Equation (42) to Equation (45) can be further combined with experimental correlations. First, to eliminate the empirical parameters in the molecular dynamics equations, the independent variables of hyperbolic sine are assumed to be minor, and then the hyperbolic sine function is substituted into its Taylor expansion to reduce Equation (35) to a linear equation

Using Equations (35) and (45) to find U, respectively, and joint, the same equation can be written for the backward contact angle (i.e., −U) to obtain the relationship equation for the contact angle, respectively.

The single contact line pressure drop is solved by substituting the dynamic contact angle correlation Equation (44) into Equation (47) and then substituting the resulting dynamic forward and backward contact angles into Equation (41), which obtains the contact line pressure drop associated with the capillary number.

Thus, with the pipe material and fluid type determined, the pressure drop of the moving contact line is then determined by the speed and number of its movements. The slug frequency is the number of fluid slugs that flow through a specific pipe location during a specific time interval. The primary defining equation for slug frequency is

Heywood [

35] obtained an improved formula for calculating the slug frequency

where

.

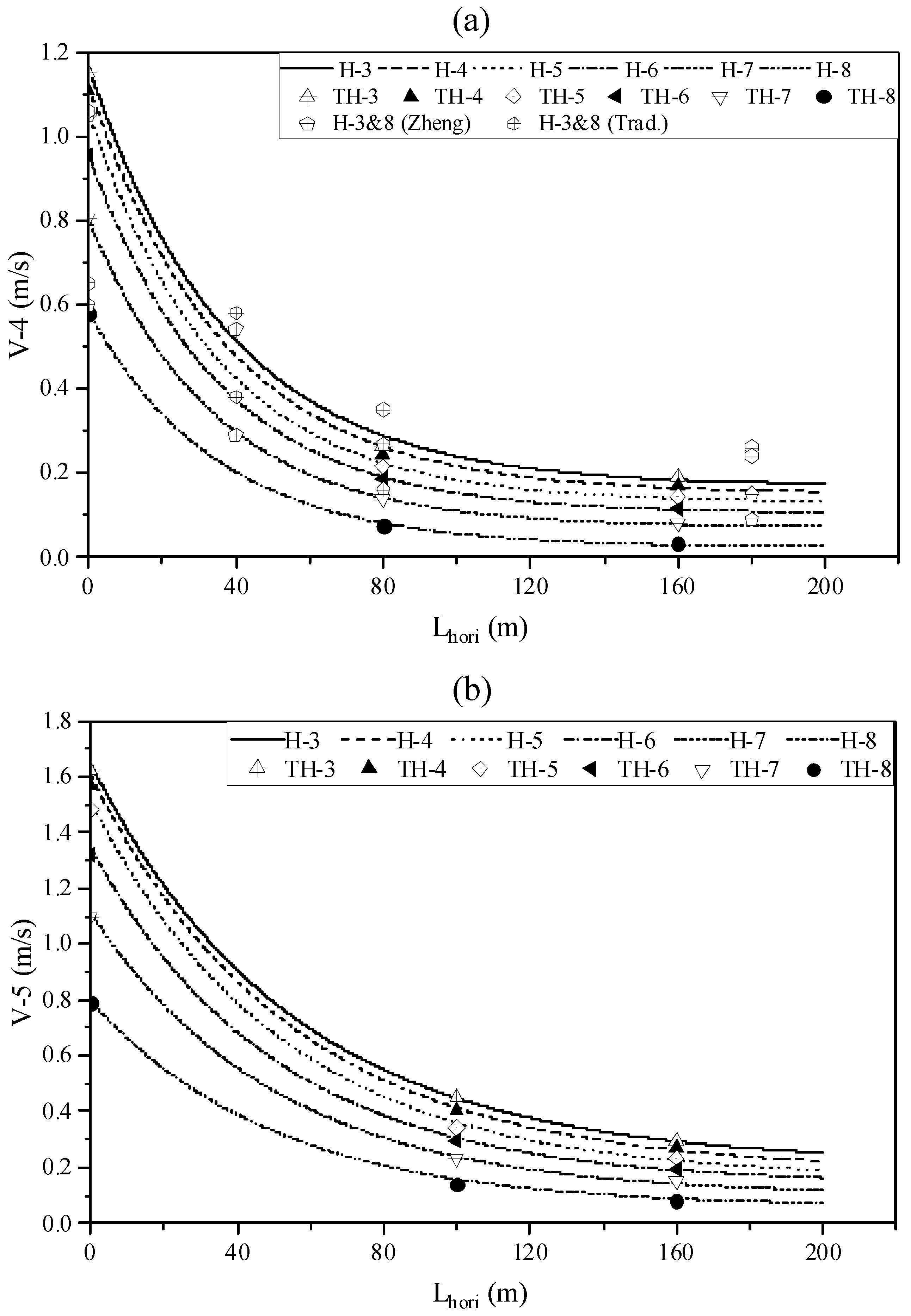

3.3. Improved Calculation Method for Siphon Flow Rate with Long Horizontal Pipe Sections

The standard siphon velocity calculation is based on Bernoulli’s equation,

which is based on the assumption of continuous single-phase flow and shows that the siphon velocity was influenced by frictional resistance, including along-stream and local lift losses. The effect of lift and height difference on the selection of siphon velocity parameters was further demonstrated by Mei’s study [

36], but only a semi-empirical solution was given without a more detailed explanation of the mechanism. The different force transfer characteristics of the fluid in the siphon were analyzed separately by setting the apex of the siphon as the critical analysis plane by Zheng [

37]. Different calculation lengths were selected according to the acceleration direction of fluid motion around the critical analysis surface, and smaller values were taken in the results to control the calculation error between 3% and 19%.

Although the calculation errors were significantly reduced, the research focused on the flow velocity calculation of “straight-up- straight-down” siphon drainage systems. Although in long or short siphon systems with a high lift, the fluid will precipitate much air due to the reduction of air pressure. However, in a siphon with a long horizontal section, the effect of frictional resistance from air precipitation increases with the length of the top horizontal section. Therefore, it is urgent and necessary to study the mechanism of siphon flow velocity in siphons with extended horizontal sections and to calculate it accurately in engineering practice.

In his study of short pipe siphoning, Zheng found that the magnitude of the fluid thrust at the top of the siphon plays a crucial role in how the flow velocity is calculated. That is, the ability to maintain continuous flow when the fluid moves to the highest position determines Bernoulli’s equation’s scope of application. However, long horizontal siphons have more complex and stochastic fluid motion than short siphons and have different velocity loss characteristics. For short siphons, the critical analysis surface can be intuitively chosen from the highest point of the siphon based on the energy loss characteristics, but for long horizontal siphons, the fluid will be in a state of continuous energy loss at its highest horizontal position. Therefore, in the process of calculating the siphon flow velocity in the long horizontal section, although the process of air pressure change in the rising section is similar to that in the short tube, the interaction between the fluid and the tube wall in the horizontal section has a considerable effect on the change of flow velocity. Therefore, to extend the formula of siphon flow velocity to the operating mode of long siphons, the analytical calculation of the siphon drainage velocity for the horizontal section should be added to the original formula of segmental integration. Therefore, the siphon velocity loss in the “horizontal section” should be added to the siphon velocity equation considering the effect of the long horizontal section. Based on the above reasoning, and assuming that the siphoned fluid in the horizontal section is a segmental slug flow, i.e., a cross-section at any location with a single-phase composition, this simplifies the computational model to simulate the movement of a homogeneous fluid in the pipe. Similarly, to simulate the most unfavorable state, the calculated length of the horizontal section of the siphon is taken to be the entire length of the horizontal section, as follows.

The calculation of siphon drainage with a long horizontal section can be divided into two parts: the vertical upward section (whose main feature is the decrease in air pressure with increasing height) and the horizontal section (whose main feature is the accumulation of losses along the range). In the vertical upward section of the siphon, the air pressure increases with the height of the position and a “parabolic” type decline occurs, the fluid kinetic energy is converted to gravitational potential energy, and the fluid moves from acceleration to deceleration, but still maintains a significant flow rate. When the fluid moves to the horizontal section, the air pressure value inside shows a state of height, while the change in air pressure is significantly reduced. Based on this, in the fluid motion formula, if we continue to use the calculation of the vertical section of the air pressure, then the value of will continue to decrease, which is not in line with the actual situation. Therefore, to simplify the calculation, the air pressure at the initial position of the horizontal section was approximated by taking the air pressure at the top of the vertical section. Take , where is a constant value approximately equal to the air pressure at the top of the vertical section, as shown in Equation (51).

In this study, since there was no applied pressure throughout, the air pressure fluctuation inside the tube did not exceed two times the atmospheric pressure, so the air could be precipitated by default with the liquid out of the siphon and no longer dissolved in water. Therefore, when calculating the void ratio and the total length of the air slug, the descending section length of the tube should be included in the calculation of the equation. Therefore,

in Equation (51) can be expressed as

Before starting the calculation, some known data need to be given. The input data include the diameter of the circular tube D; the physical properties of each phase

,

,

,

,

; and the projection of gravitational acceleration in the flow direction

. The calculation algorithm is described as follows, and the calculation flow chart is given in

Figure 8.

First, we calculated the value of the siphon flow rate in the ideal state without considering air release by using the whole tube as the calculation segment, assigned it to the initial value of the flow rate, and calculated the instantaneous flow rate at the corresponding position according to Equation (51) combined with the change of air pressure occurring in the tube with height up to the horizontal segment. When the iteration proceeds to the horizontal section, a determination of the type of dry or wet slug flow is required. It can be seen that the pressure drop at both ends of the bubble decreased sharply when the capillary number was less than

from

Figure 3 as well as Equation (44). Therefore, to simplify the calculation, the wet slug flow or dry slug flow can be judged according to whether the

Ca is greater than

.

When

Ca >

, it can be judged as a wet slug flow, and the mathematical models given in Equations (26)–(32) were used to calculate the velocity of each gas–liquid phase, the volume fraction of the gas, and the length of the bubble slug when the bubble size is known. The calculated flow velocity was used as the liquid velocity, i.e.,

, and the equation proposed by Thulasidas [

18] was used to determine the initial approximation of the bubble velocity

Then, the capillary number was calculated by using the bubble velocity, and the liquid film thickness

δ was determined using

[

38]. The pressure gradient could be calculated after n iterations of Equations (31) and (32), while the gas flow rate in the bubble, the liquid flow rate in the liquid film, and the bubble motion velocity could be obtained after n iterations of Equations (26) and (27). The relative error

can be used to compare the liquid flow rate in the film and the calculated error ϖ specified value can be used to decide whether to terminate the calculation (when

ψ ≤ ϖ) or return to re-substitute the calculated capillary number and repeat the step (when

ψ > ϖ).

When Ca < 0.001, it can be judged as dry slug flow. Take the calculated flow velocity as the gas–liquid two-phase velocity , and calculate the moving friction loss of the gas–liquid–solid three-phase contact line according to Equation (41). The value of the slug frequency in the tube at the corresponding flow rate was obtained by Equation (49). In addition, the air pressure, gas precipitation, gas motion velocity, and liquid motion velocity in the tube after n iterations were determined using Equation (52). Comparing the values of the selected parameters, i.e., , the specified value of the calculation error Δ determines whether to terminate the calculation (when ) or to return and repeat the previous ones.