Review of Flexible Piezoresistive Strain Sensors in Civil Structural Health Monitoring

Abstract

1. Introduction

2. Piezoresistive Mechanisms

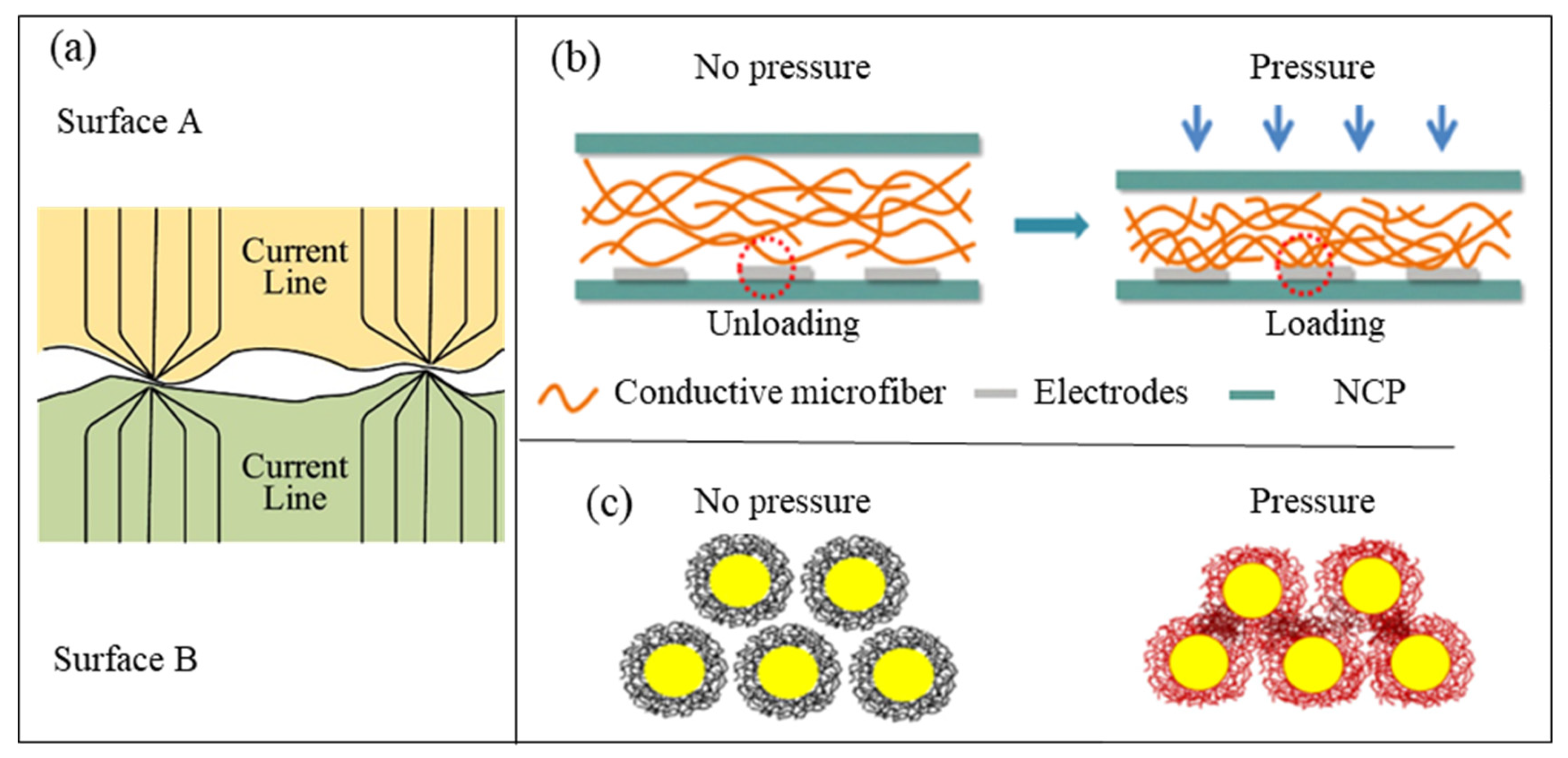

2.1. Interface Contact Effect

2.2. Tunneling Effect

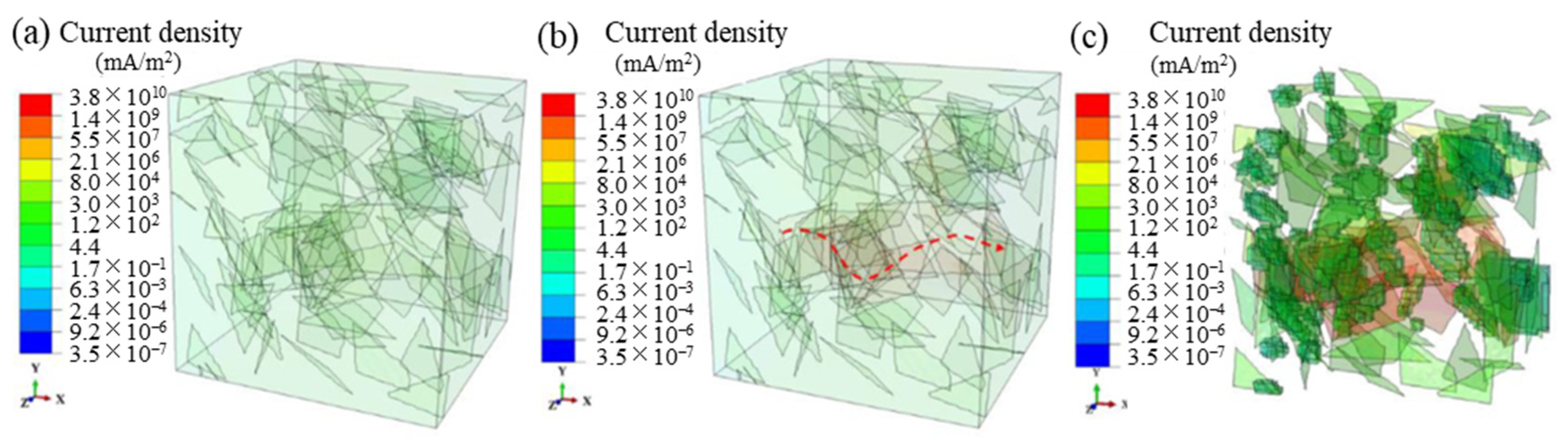

2.3. Percolation Network

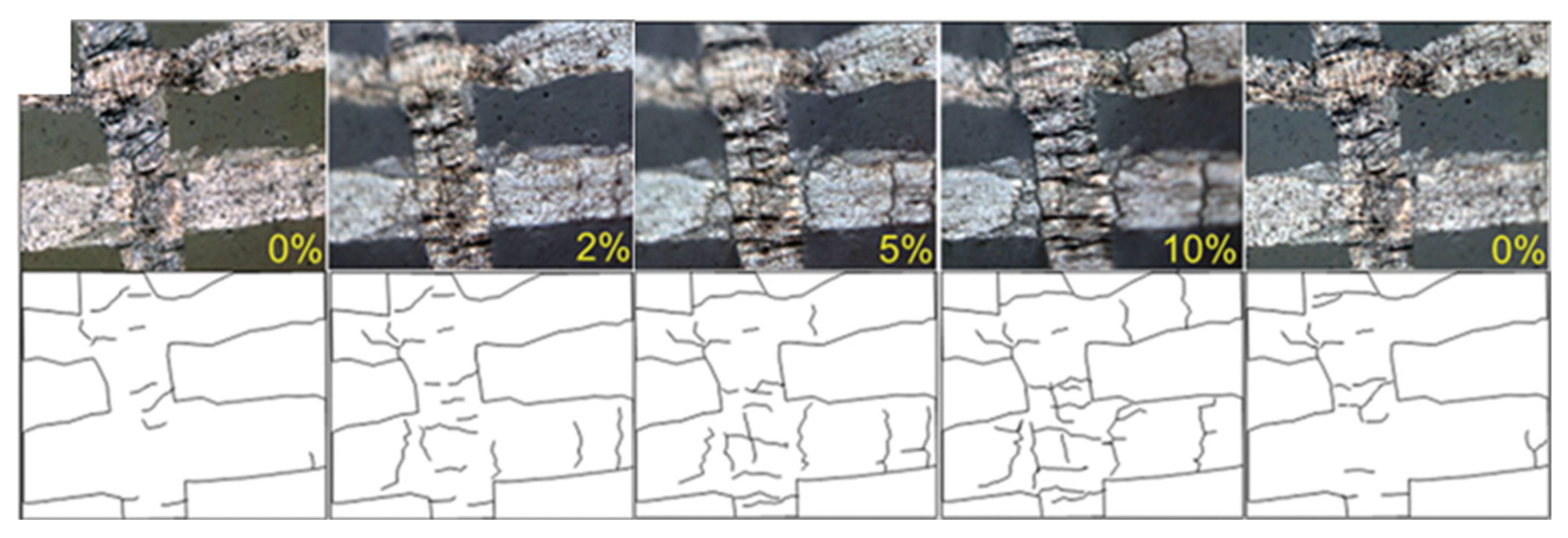

2.4. Crack Propagation

3. Elaboration of Sensor Materials

3.1. Conductive Materials

3.1.1. Metallic Materials

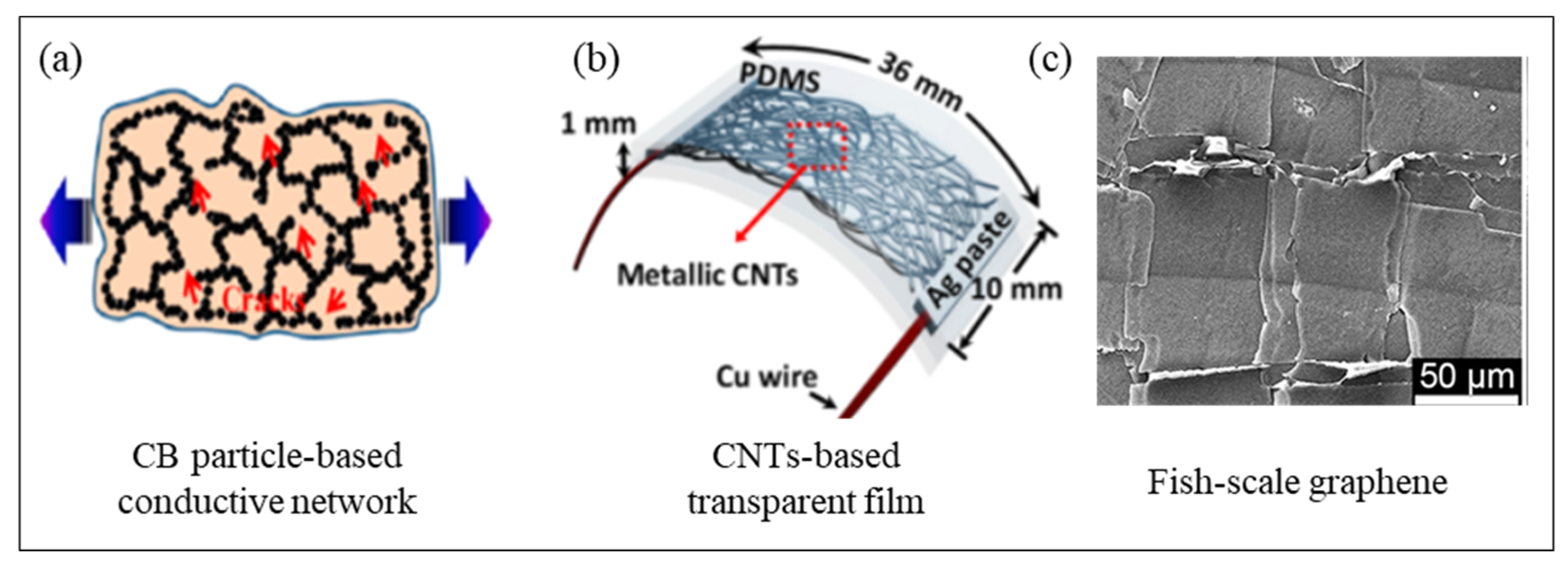

3.1.2. Carbon-Type Materials

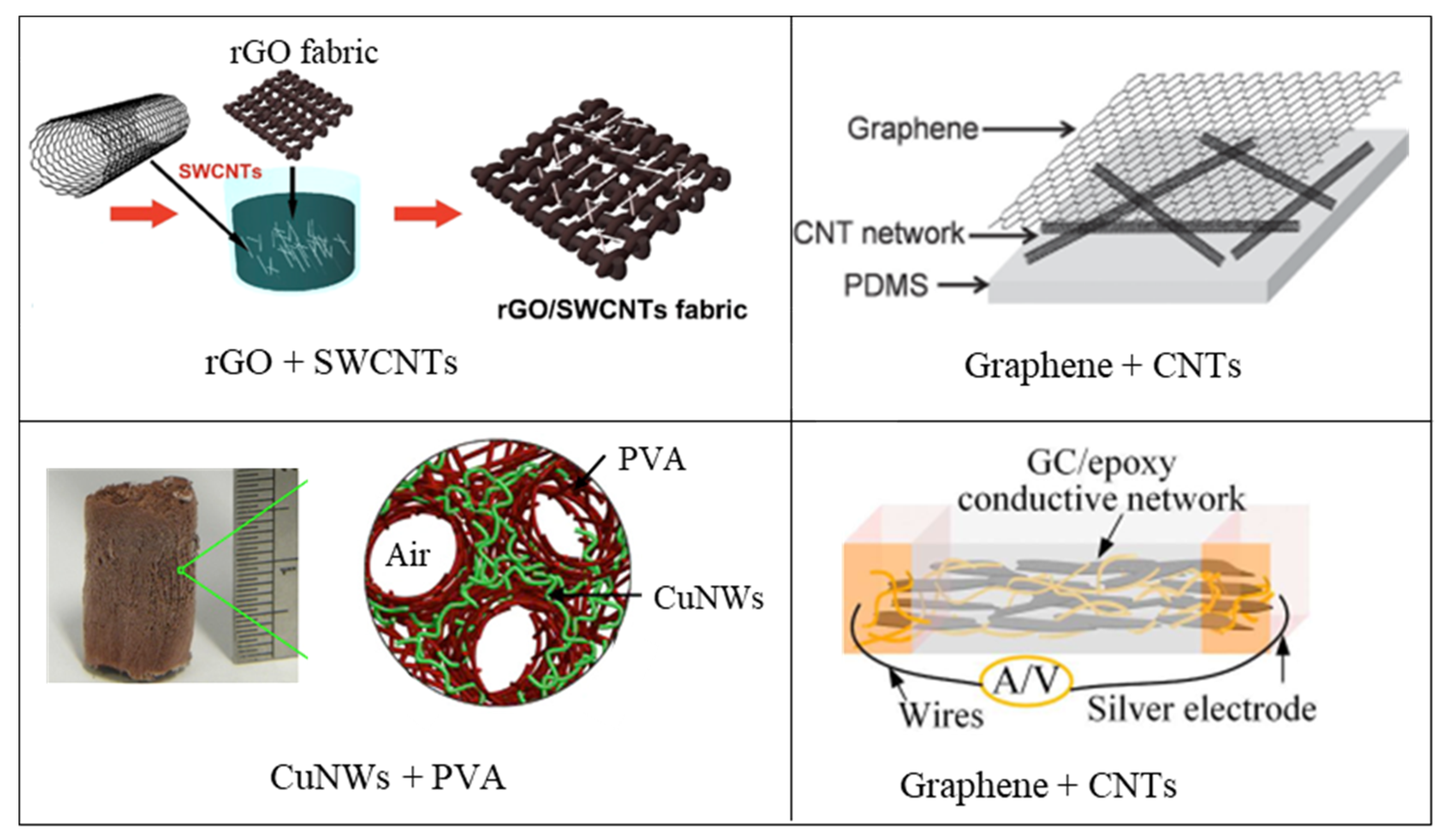

3.1.3. Hybrid Materials

3.2. Flexible Substrates

3.3. Electrodes

4. Optimization of Sensor Performance

4.1. Improvement of Sensitivity

4.2. Improvement of Stretchability

4.3. Improvement of Linearity

4.4. Improvement of Hysteresis and Durability

5. Applications and Prospects in Civil SHM

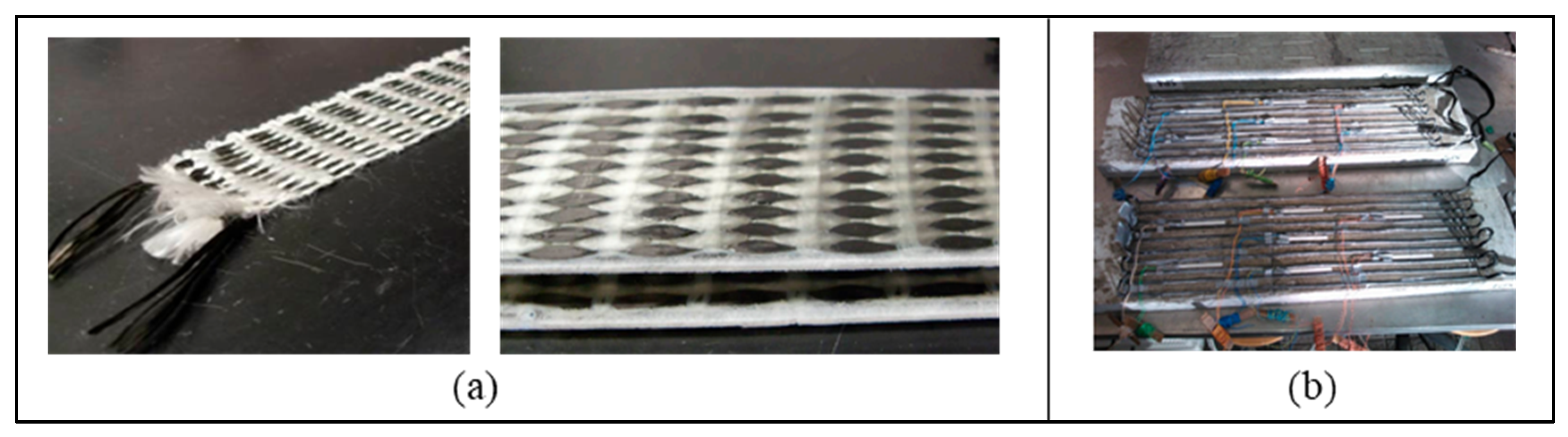

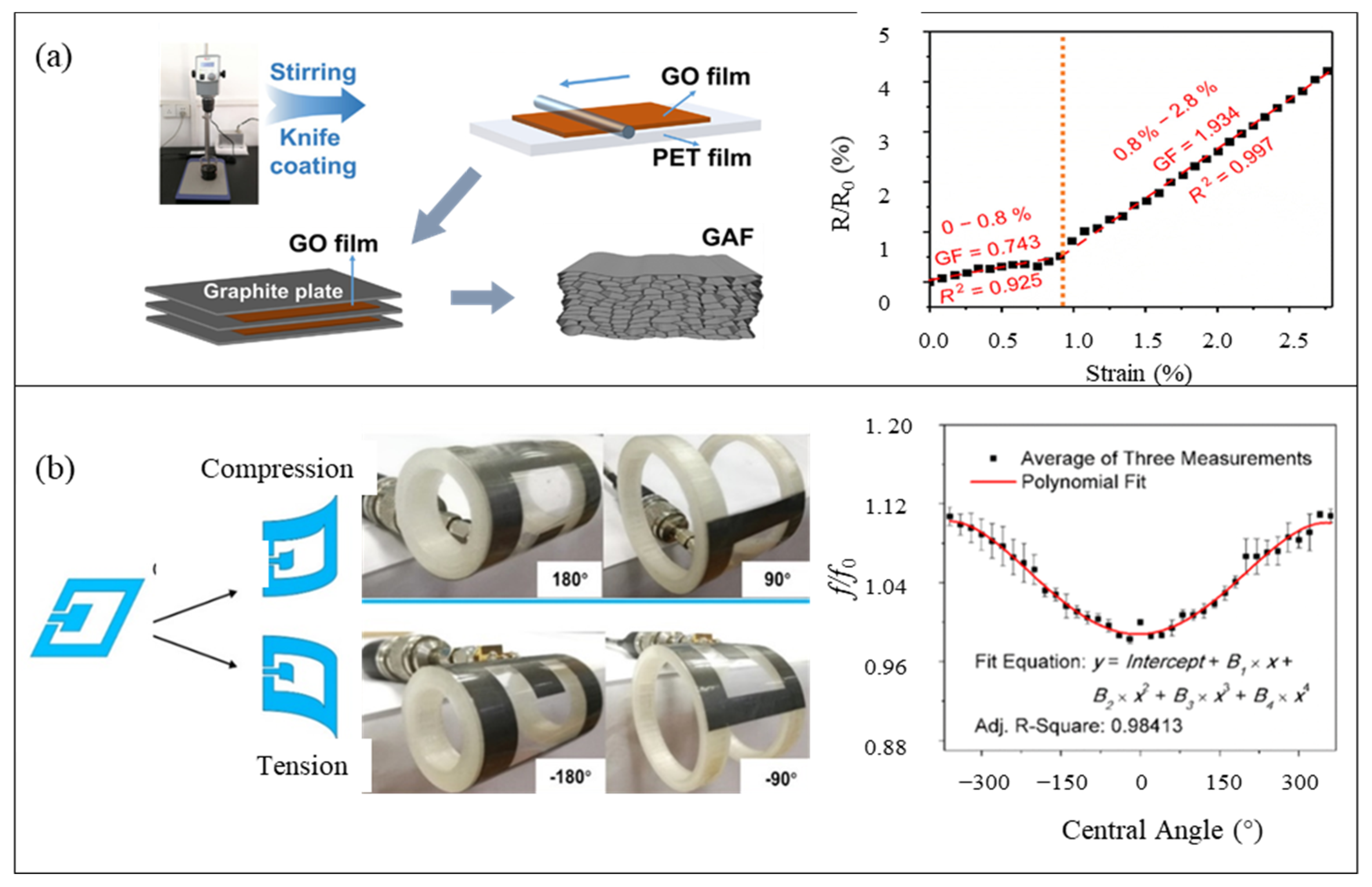

5.1. Steel Structures

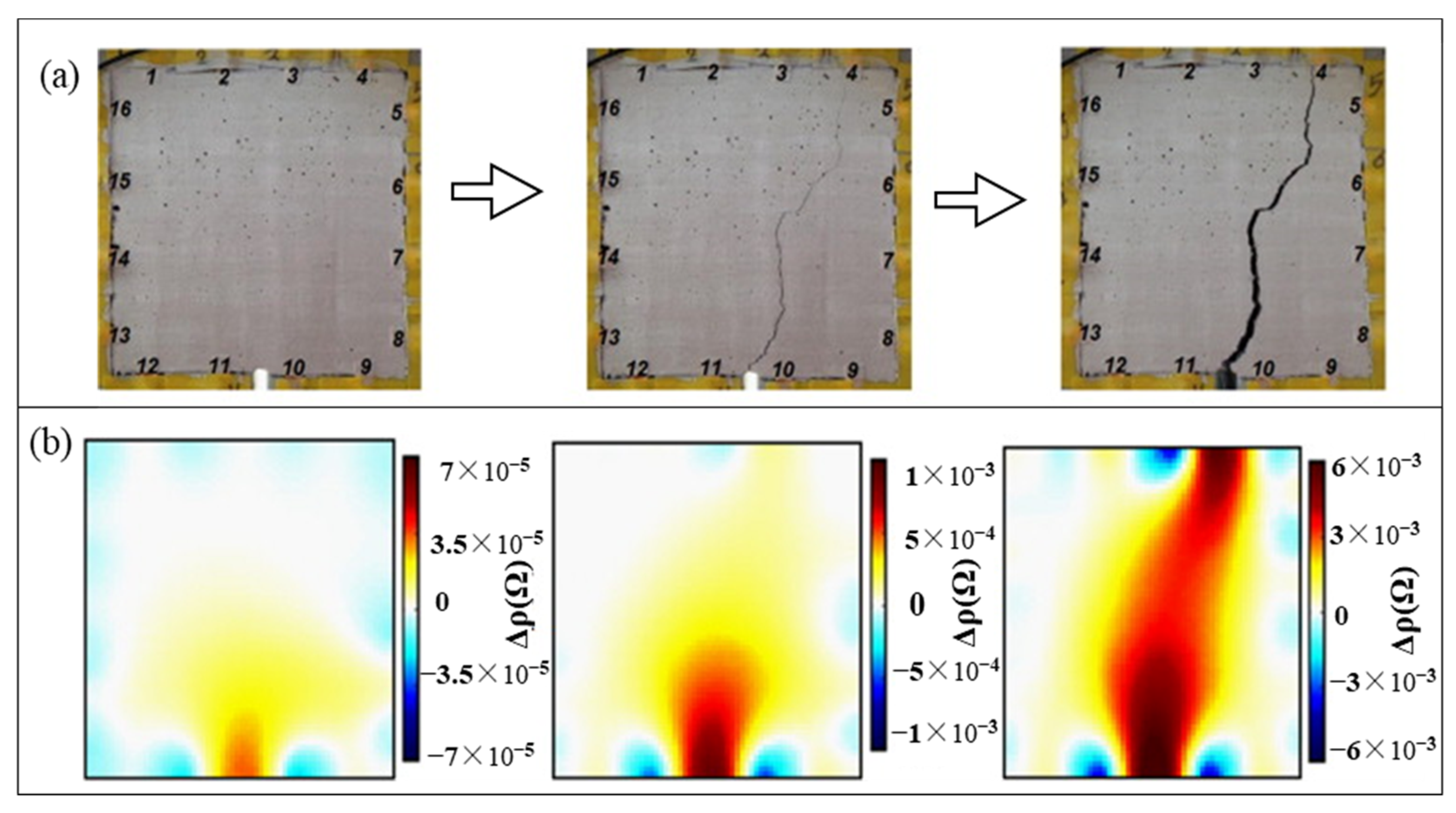

5.2. Concrete Structures

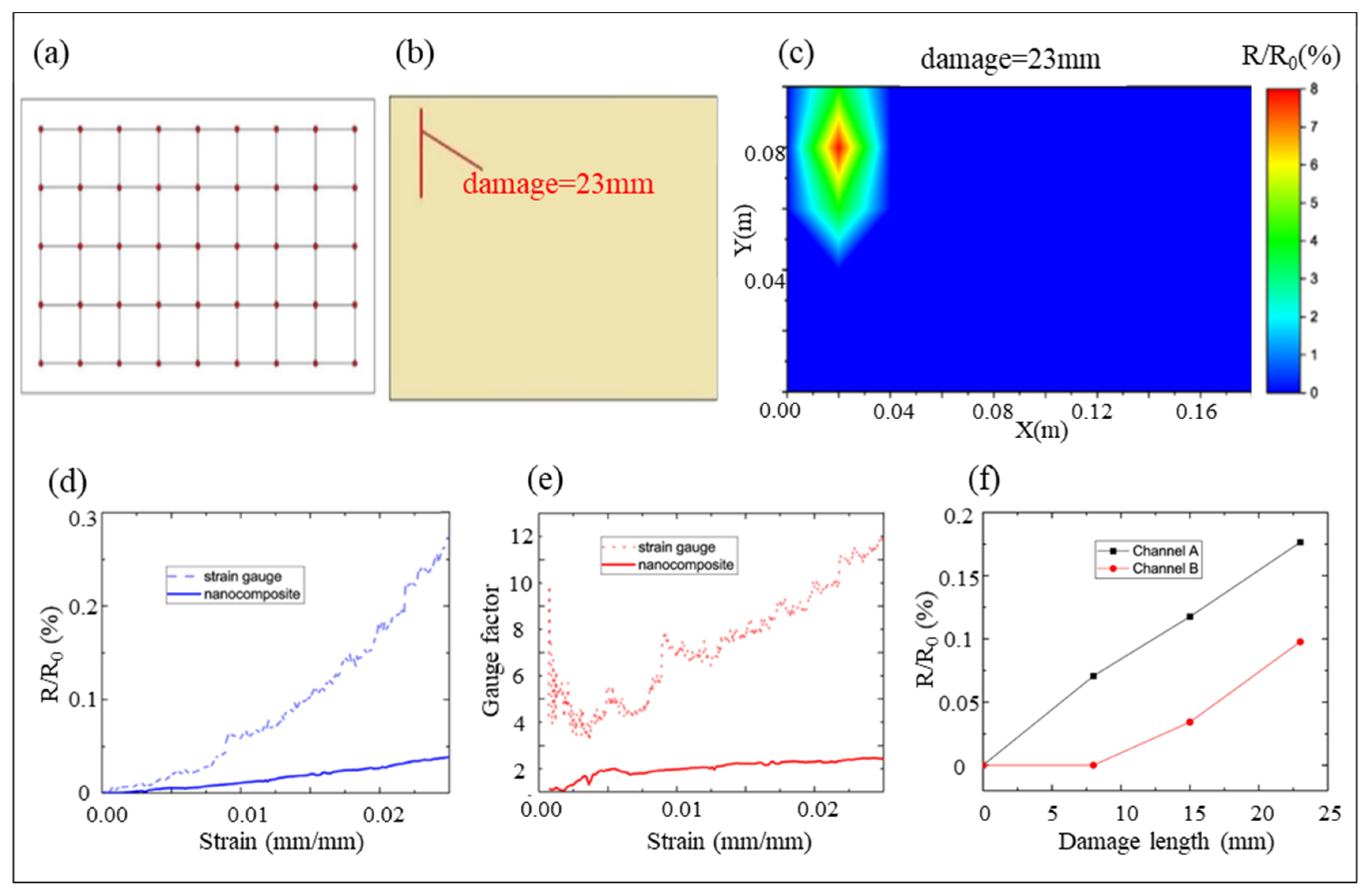

5.3. Fiber Reinforced Composite Structures

| Ref. | Materials Filler + Substrate | Maximum Detectable Range | Gauge Factor (Sensing Range) | Linearity (Strain Range) | Cyclic Times for Durability |

|---|---|---|---|---|---|

| [137] | Carbon Particle + PI | 0.6% | 25 | Near linear (ε < 0.6%) | |

| [138] | MWCNTs + Resins | 20% | 2.6 (ε < 1%) | Linear (ε < 1%) | 10 (ε < 1%) |

| [139] | MWCNTs + Epoxy | 0.14% | Linear (ε < 0.14%) | 1000 (ε < 0.14%) | |

| [140] | CB + Epoxy | 1.2% | 11~42 (Depend on filler content) | Nonlinear | |

| [142] | MWCNTs + PDMS | 50% | 1.5~6 | Nonlinear | |

| [143] | rGO/Cellulose nanofiber + Epoxy | 55% | 34~71 | Nonlinear | 100 (ε < 4%) |

| [144] | RGO-CNF + WEP | 4% | 16~52 (Depend on filler content) | Near linear (ε < 4%) | 4 (ε < 4%) |

| [146] | Gold nanoparticles + PDMS | 30% | 0.04 | Near linear | |

| [151] | MWCNT/FRP + Epoxy | 1.23% | 5~6 | Nonlinear | |

| [154] | CNTs/Glass fiber + Epoxy | 1.2% | 2.25 | Linear (0.5% < ε < 1%) | |

| [155] | MWCNTs/Glass Fibers + Epoxy | 2.5% | 3.8 (ε < 0.2%) | Near linear (ε < 0.2%) | |

| [156] | CNT/Glass Fibers + Epoxy | 2.2% | Nonlinear | ||

| [157] | Graphene nanoplate + Glass fiber | 2% | 840~16,400 | Nonlinear | |

| [158] | Carbon fibers + Epoxy | 3.5% | 10 | ||

| [159] | Carbon fibers + Epoxy | 1% | 0~0.25 | Nonlinear | |

| [53] | CNT + Epoxy resin | 2.5% | 3~12 | Nonlinear |

5.4. Challenges and Prospects of Large-Scale Application

5.5. Strategy for Selection of Piezoresistive Sensor in Civil SHM

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brownjohn, J.M. Structural health monitoring of civil infrastructure. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2007, 365, 589–622. [Google Scholar] [CrossRef]

- Lynch, J.P. An overview of wireless structural health monitoring for civil structures. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2007, 365, 345–372. [Google Scholar] [CrossRef]

- Lu, X.; Guan, H.; Sun, H.; Li, Y.; Zheng, Z.; Fei, Y.; Yang, Z.; Zuo, L. A preliminary analysis and discussion of the condominium building collapse in surfside, Florida, US, June 24, 2021. Front. Struct. Civ. Eng. 2021, 15, 1097–1110. [Google Scholar] [CrossRef]

- Bao, Y.Q.; Chen, Z.C.; Wei, S.Y.; Xu, Y.; Tang, Z.Y.; Li, H. The State of the Art of Data Science and Engineering in Structural Health Monitoring. Engineering 2019, 5, 234–242. [Google Scholar] [CrossRef]

- Wu, R.T.; Jahanshahi, M.R. Data fusion approaches for structural health monitoring and system identification: Past, present, and future. Struct. Health Monit. 2020, 19, 552–586. [Google Scholar] [CrossRef]

- Su, J.Z.; Xia, Y.; Weng, S. Review on field monitoring of high-rise structures. Struct. Control. Health Monit. 2020, 27, e2629. [Google Scholar] [CrossRef]

- Moon, H.S.; Ok, S.; Chun, P.J.; Lim, Y.M. Artificial Neural Network for Vertical Displacement Prediction of a Bridge from Strains (Part 1): Girder Bridge under Moving Vehicles. Appl. Sci. 2019, 9, 2881. [Google Scholar] [CrossRef]

- Zhu, H.P.; Gao, K.; Xia, Y.; Gao, F.; Weng, S.; Sun, Y.; Hu, Q. Multi-rate data fusion for dynamic displacement measurement of beam-like supertall structures using acceleration and strain sensors. Struct. Health Monit. 2020, 19, 520–536. [Google Scholar] [CrossRef]

- Jang, H.L.; Han, D.H.; Hwang, M.Y.; Kang, D.; Kang, L.H. Displacement, Strain and Failure Estimation for Multi-Material Structure Using the Displacement-Strain Transformation Matrix. Materials 2020, 13, 190. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, J.; Li, Y.; Shi, G. High-Performance Strain Sensors with Fish-Scale-Like Graphene-Sensing Layers for Full-Range Detection of Human Motions. ACS Nano 2016, 10, 7901–7906. [Google Scholar] [CrossRef]

- Zhang, H.; Bilotti, E.; Peijs, T. The use of carbon nanotubes for damage sensing and structural health monitoring in laminated composites: A review. Nanocomposites 2015, 1, 167–184. [Google Scholar] [CrossRef]

- Trung, T.Q.; Lee, N.E. Flexible and Stretchable Physical Sensor Integrated Platforms for Wearable Human-Activity Monitoring and Personal Healthcare. Adv. Mater. 2016, 28, 4338–4372. [Google Scholar] [CrossRef]

- Wang, X.W.; Liu, Z.; Zhang, T. Flexible Sensing Electronics for Wearable/Attachable Health Monitoring. Small 2017, 13, 1602790. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Ma, X.H.; Hao, Y. Electronic Devices for Human-Machine Interfaces. Adv. Mater. Interfaces 2017, 4, 1600709. [Google Scholar] [CrossRef]

- Park, J.; Lee, Y.; Ha, M.; Cho, S.; Ko, H. Micro/nanostructured surfaces for self-powered and multifunctional electronic skins. J. Mater. Chem. B 2016, 4, 2999–3018. [Google Scholar] [CrossRef] [PubMed]

- United Nations Environment Programme. Global Status Report for Buildings and Construction; Global Alliance for Building and Construction: Paris, France, 2021. [Google Scholar]

- Li, H.-N.; Ren, L.; Jia, Z.-G.; Yi, T.-H.; Li, D.-S. State-of-the-art in structural health monitoring of large and complex civil infrastructures. J. Civ. Struct. Health 2015, 6, 3–16. [Google Scholar] [CrossRef]

- Kranabitl, P.; Faustmann, C.; Hick, H. Decision Making for Sustainable Technical Applications with the SMH Approach. Sustainability 2021, 13, 8702. [Google Scholar] [CrossRef]

- Fan, J.H.; Lu, X.Y.; Cao, W.W. Phase transitions and piezoelectricity enhancement around MC → O phase transition in PMN-0.34PT single crystals. J. Alloys Compd. 2020, 835, 155171. [Google Scholar] [CrossRef]

- Yang, J.; Luo, S.; Zhou, X.; Li, J.L.; Fu, J.T.; Yang, W.D.; Wei, D.P. Flexible, Tunable, and Ultrasensitive Capacitive Pressure Sensor with Microconformal Graphene Electrodes. ACS Appl. Mater. Interfaces 2019, 11, 14997–15006. [Google Scholar] [CrossRef]

- Luo, N.Q.; Dai, W.X.; Li, C.L.; Zhou, Z.Q.; Lu, L.Y.; Poon, C.C.Y.; Chen, S.C.; Zhang, Y.T.; Zhao, N. Flexible Piezoresistive Sensor Patch Enabling Ultralow Power Cuffless Blood Pressure Measurement. Adv. Funct. Mater. 2016, 26, 1178–1187. [Google Scholar] [CrossRef]

- Nauman, S. Piezoresistive Sensing Approaches for Structural Health Monitoring of Polymer Composites—A Review. Eng 2021, 2, 197–226. [Google Scholar] [CrossRef]

- Duan, L.Y.; D’hooge, D.R.; Cardon, L. Recent progress on flexible and stretchable piezoresistive strain sensors: From design to application. Prog. Mater. Sci. 2020, 114, 100617. [Google Scholar] [CrossRef]

- Zeng, W.; Shu, L.; Li, Q.; Chen, S.; Wang, F.; Tao, X.M. Fiber-Based Wearable Electronics: A Review of Materials, Fabrication, Devices, and Applications. Adv. Mater. 2014, 26, 5310–5336. [Google Scholar] [CrossRef] [PubMed]

- Gao, F.; Zhou, H.; Liang, H.J.; Weng, S.; Zhu, H.P. Structural deformation monitoring and numerical simulation of a supertall building during construction stage. Eng. Struct. 2020, 209, 110033. [Google Scholar] [CrossRef]

- Su, J.Z.; Xia, Y.; Zhu, L.D.; Zhu, H.P.; Ni, Y.Q. Typhoon- and temperature-induced quasi-static responses of a supertall structure. Eng. Struct. 2017, 143, 91–100. [Google Scholar] [CrossRef]

- Chen, Z.S.; Zhou, X.; Wang, X.; Dong, L.L.; Qian, Y.H. Deployment of a Smart Structural Health Monitoring System for Long-Span Arch Bridges: A Review and a Case Study. Sensors 2017, 17, 2151. [Google Scholar] [CrossRef]

- Xia, Y.; Ni, Y.Q.; Zhang, P.; Liao, W.Y.; Ko, J.M. Stress Development of a Supertall Structure during Construction: Field Monitoring and Numerical Analysis. Comput. Aided Civ. Infrastruct. Eng. 2011, 26, 542–559. [Google Scholar] [CrossRef]

- Gao, K.; Chen, Z.D.; Weng, S.; Zhu, H.P.; Wu, L.Y. Detection of multi-type data anomaly for structural health monitoring using pattern recognition neural network. Smart Struct. Syst. 2022, 29, 129–140. [Google Scholar] [CrossRef]

- Naghashpour, A.; Hoa, S.V. A technique for real-time detecting, locating, and quantifying damage in large polymer composite structures made of carbon fibers and carbon nanotube networks. Struct. Health Monit. 2015, 14, 35–45. [Google Scholar] [CrossRef]

- Qiu, D.; Peng, L.; Yi, P.; Lai, X. A micro contact model for electrical contact resistance prediction between roughness surface and carbon fiber paper. Int. J. Mech. Sci. 2017, 124–125, 37–47. [Google Scholar] [CrossRef]

- Higashisaka, T.; Nagato, K.; Tomizawa, M.; Tanaka, E.; Watanabe, H.; Nakao, M. Small and sensitive force sensors based on contact resistance. Microelectron. Eng. 2019, 216, 111058. [Google Scholar] [CrossRef]

- Gao, L.; Zhu, C.X.; Li, L.; Zhang, C.W.; Liu, J.H.; Yu, H.D.; Huang, W. All Paper-Based Flexible and Wearable Piezoresistive Pressure Sensor. ACS Appl. Mater. Interfaces 2019, 11, 25034–25042. [Google Scholar] [CrossRef] [PubMed]

- Doshi, S.M.; Thostenson, E.T. Thin and Flexible Carbon Nanotube-Based Pressure Sensors with Ultrawide Sensing Range. ACS Sens. 2018, 3, 1276–1282. [Google Scholar] [CrossRef]

- Hu, N.; Karube, Y.; Yan, C.; Masuda, Z.; Fukunaga, H. Tunneling effect in a polymer/carbon nanotube nanocomposite strain sensor. Acta Mater. 2008, 56, 2929–2936. [Google Scholar] [CrossRef]

- Park, J.; Lee, Y.; Hong, J.; Ha, M.; Jung, Y.D.; Lim, H.; Kim, S.Y.; Ko, H. Giant Tunneling Piezoresistance of Composite Elastomers with Interlocked Microdome Arrays for Ultrasensitive and Multimodal Electronic Skins. ACS Nano 2014, 8, 4689–4697. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Yuan, L.; Yao, X.F.; Fang, D.N. Piezoresistive response of graphene rubber composites considering the tunneling effect. J. Mech. Phys. Solids 2020, 139, 103943. [Google Scholar] [CrossRef]

- Haniff, M.A.S.M.; Hafiz, S.M.; Huang, N.M.; Rahman, S.A.; Wahid, K.A.A.; Syono, M.I.; Azid, I.A. Piezoresistive Effect in Plasma-Doping of Graphene Sheet for High-Performance Flexible Pressure Sensing Application. ACS Appl. Mater. Interfaces 2017, 9, 15192–15201. [Google Scholar] [CrossRef] [PubMed]

- Pereira, V.M.; Castro Neto, A.H.; Peres, N.M.R. Tight-binding approach to uniaxial strain in graphene. Phys. Rev. B 2009, 80, 045401. [Google Scholar] [CrossRef]

- Lipomi, D.J.; Lee, J.A.; Vosgueritchian, M.; Tee, B.C.K.; Bolander, J.A.; Bao, Z.A. Electronic Properties of Transparent Conductive Films of PEDOT:PSS on Stretchable Substrates. Chem. Mater. 2012, 24, 373–382. [Google Scholar] [CrossRef]

- Chen, Z.; Ming, T.; Goulamaly, M.M.; Yao, H.M.; Nezich, D.; Hempel, M.; Hofmann, M.; Kong, J. Enhancing the Sensitivity of Percolative Graphene Films for Flexible and Transparent Pressure Sensor Arrays. Adv. Funct. Mater. 2016, 26, 5061–5067. [Google Scholar] [CrossRef]

- Amjadi, M.; Kyung, K.U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Chen, S.; Wei, Y.; Wei, S.M.; Lin, Y.; Liu, L. Ultrasensitive Cracking-Assisted Strain Sensors Based on Silver Nanowires/Graphene Hybrid Particles. ACS Appl. Mater. Interfaces 2016, 8, 25563–25570. [Google Scholar] [CrossRef]

- Park, B.; Kim, J.; Kang, D.; Jeong, C.; Kim, K.S.; Kim, J.U.; Yoo, P.J.; Kim, T.I. Dramatically Enhanced Mechanosensitivity and Signal-to-Noise Ratio of Nanoscale Crack-Based Sensors: Effect of Crack Depth. Adv. Mater. 2016, 28, 8130–8137. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.J.; Park, K.H.; Han, C.J.; Oh, M.S.; You, B.; Kim, Y.S.; Kim, J.W. Crack-induced Ag nanowire networks for transparent, stretchable, and highly sensitive strain sensors. Sci. Rep. 2017, 7, 7959. [Google Scholar] [CrossRef]

- Kang, D.; Pikhitsa, P.V.; Choi, Y.W.; Lee, C.; Shin, S.S.; Piao, L.F.; Park, B.; Suh, K.Y.; Kim, T.I.; Choi, M. Ultrasensitive mechanical crack-based sensor inspired by the spider sensory system. Nature 2014, 516, 222–226. [Google Scholar] [CrossRef] [PubMed]

- Hoang, P.T.; Salazar, N.; Porkka, T.N.; Joshi, K.; Liu, T.; Dickens, T.J.; Yu, Z.B. Engineering Crack Formation in Carbon Nanotube-Silver Nanoparticle Composite Films for Sensitive and Durable Piezoresistive Sensors. Nanoscale Res. Lett. 2016, 11, 422. [Google Scholar] [CrossRef]

- Zhou, J.; Yu, H.; Xu, X.Z.; Han, F.; Lubineau, G. Ultrasensitive, Stretchable Strain Sensors Based on Fragmented Carbon Nanotube Papers. ACS Appl. Mater. Interfaces 2017, 9, 4835–4842. [Google Scholar] [CrossRef]

- Liao, X.Q.; Zhang, Z.; Kang, Z.; Gao, F.F.; Liao, Q.L.; Zhang, Y. Ultrasensitive and stretchable resistive strain sensors designed for wearable electronics. Mater. Horiz. 2017, 4, 502–510. [Google Scholar] [CrossRef]

- Amjadi, M.; Turan, M.; Clementson, C.P.; Sitti, M. Parallel Microcracks-based Ultrasensitive and Highly Stretchable Strain Sensors. ACS Appl. Mater. Interfaces 2016, 8, 5618–5626. [Google Scholar] [CrossRef]

- Jin, H.; Abu-Raya, Y.S.; Haick, H. Advanced Materials for Health Monitoring with Skin-Based Wearable Devices. Adv. Healthc. Mater. 2017, 6, 1700024. [Google Scholar] [CrossRef]

- Melnykowycz, M.; Tschudin, M.; Clemens, F. Piezoresistive Soft Condensed Matter Sensor for Body-Mounted Vital Function Applications. Sensors 2016, 16, 326. [Google Scholar] [CrossRef] [PubMed]

- Sanchez-Romate, X.F.; Moriche, R.; Jimenez-Suarez, A.; Sanchez, M.; Prolongo, S.G.; Guemes, A.; Urena, A. Highly sensitive strain gauges with carbon nanotubes: From bulk nanocomposites to multifunctional coatings for damage sensing. Appl. Surf. Sci. 2017, 424, 213–221. [Google Scholar] [CrossRef]

- Li, X.; Zhang, R.; Yu, W.; Wang, K.; Wei, J.; Wu, D.; Cao, A.; Li, Z.; Cheng, Y.; Zheng, Q. Stretchable and highly sensitive graphene-on-polymer strain sensors. Sci. Rep. 2012, 2, 870. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.B.; Witomska, S.; Aliprandi, A.; Stoeckel, M.A.; Bonini, M.; Ciesielski, A.; Samori, P. Molecule-Graphene Hybrid Materials with Tunable Mechanoresponse: Highly Sensitive Pressure Sensors for Health Monitoring. Adv. Mater. 2019, 31, e1804600. [Google Scholar] [CrossRef] [PubMed]

- Schlicke, H.; Kunze, S.; Rebber, M.; Schulz, N.; Riekeberg, S.; Trieu, H.K.; Vossmeyer, T. Cross-Linked Gold Nanoparticle Composite Membranes as Highly Sensitive Pressure Sensors. Adv. Funct. Mater. 2020, 30, 2003381. [Google Scholar] [CrossRef]

- Schlicke, H.; Rebber, M.; Kunze, S.; Vossmeyer, T. Resistive pressure sensors based on freestanding membranes of gold nanoparticles. Nanoscale 2016, 8, 183–186. [Google Scholar] [CrossRef]

- Tang, Y.; Gong, S.; Chen, Y.; Yap, L.W.; Cheng, W.L. Manufacturable Conducting Rubber Ambers and Stretchable Conductors from Copper Nanowire Aerogel Monoliths. ACS Nano 2014, 8, 5707–5714. [Google Scholar] [CrossRef]

- Gong, S.; Schwalb, W.; Wang, Y.W.; Chen, Y.; Tang, Y.; Si, J.; Shirinzadeh, B.; Cheng, W.L. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun. 2014, 5, 3132. [Google Scholar] [CrossRef]

- Li, Y.X.; Han, D.Y.; Jiang, C.J.; Xie, E.Q.; Han, W.H. A Facile Realization Scheme for Tactile Sensing with a Structured Silver Nanowire-PDMS Composite. Adv. Mater. Technol. 2019, 4, 1800504. [Google Scholar] [CrossRef]

- Lee, Y.; Kim, J.; Joo, H.; Raj, M.S.; Ghaffari, R.; Kim, D.H. Wearable Sensing Systems with Mechanically Soft Assemblies of Nanoscale Materials. Adv. Mater. Technol. 2017, 2, 1700053. [Google Scholar] [CrossRef]

- Zhu, Y.; Hu, Y.G.; Zhu, P.L.; Zhao, T.; Liang, X.W.; Sun, R.; Wong, C.P. Enhanced oxidation resistance and electrical conductivity copper nanowires-graphene hybrid films for flexible strain sensors. New J. Chem. 2017, 41, 4950–4958. [Google Scholar] [CrossRef]

- Wu, J.J.; Li, H.Q.; Lai, X.J.; Chen, Z.H.; Zeng, X.R. Conductive and superhydrophobic F-rGO@CNTs/chitosan aerogel for piezoresistive pressure sensor. Chem. Eng. J. 2020, 386, 123998. [Google Scholar] [CrossRef]

- Azhari, S.; Yousefi, A.T.; Tanaka, H.; Khajeh, A.; Kuredemus, N.; Bigdeli, M.M.; Hamidon, M.N. Fabrication of piezoresistive based pressure sensor via purified and functionalized CNTs/PDMS nanocomposite: Toward development of haptic sensors. Sens. Actuators A Phys. 2017, 266, 158–165. [Google Scholar] [CrossRef]

- Wang, X.; Tao, X.M.; So, R.C.H.; Shu, L.; Yang, B.; Li, Y. Monitoring elbow isometric contraction by novel wearable fabric sensing device. Smart Mater. Struct. 2016, 25, 125022. [Google Scholar] [CrossRef]

- Wang, F.; Liu, S.; Shu, L.; Tao, X.M. Low-dimensional carbon based sensors and sensing network for wearable health and environmental monitoring. Carbon 2017, 121, 353–367. [Google Scholar] [CrossRef]

- Slobodian, P.; Riha, P.; Saha, P. A highly-deformable composite composed of an entangled network of electrically-conductive carbon-nanotubes embedded in elastic polyurethane. Carbon 2012, 50, 3446–3453. [Google Scholar] [CrossRef]

- Duan, L.Y.; Fu, S.R.; Deng, H.; Zhang, Q.; Wang, K.; Chen, F.; Fu, Q. The resistivity-strain behavior of conductive polymer composites: Stability and sensitivity. J. Mater. Chem. A 2014, 2, 17085–17098. [Google Scholar] [CrossRef]

- Shi, J.D.; Li, X.M.; Cheng, H.Y.; Liu, Z.J.; Zhao, L.Y.; Yang, T.T.; Dai, Z.H.; Cheng, Z.G.; Shi, E.Z.; Yang, L.; et al. Graphene Reinforced Carbon Nanotube Networks for Wearable Strain Sensors. Adv. Funct. Mater. 2016, 26, 2078–2084. [Google Scholar] [CrossRef]

- Haniff, M.A.S.M.; Hafiz, S.M.; Wahid, K.A.A.; Endut, Z.; Lee, H.W.; Bien, D.C.S.; Azid, I.A.; Abdullah, M.Z.; Huang, N.M.; Rahman, S.A. Piezoresistive effects in controllable defective HFTCVD graphene-based flexible pressure sensor. Sci. Rep. 2015, 5, 14751. [Google Scholar] [CrossRef]

- Mattevi, C.; Kim, H.; Chhowalla, M. A review of chemical vapour deposition of graphene on copper. J. Mater. Chem. 2011, 21, 3324–3334. [Google Scholar] [CrossRef]

- Hao, D.P.; Yang, R.X.; Yi, N.; Cheng, H.Y. Highly sensitive piezoresistive pressure sensors based on laser-induced graphene with molybdenum disulfide nanoparticles. Sci. China Technol. Sci. 2021, 64, 2408–2414. [Google Scholar] [CrossRef]

- Ho, M.D.; Ling, Y.; Yap, L.W.; Wang, Y.; Dong, D.; Zhao, Y.; Cheng, W. Percolating Network of Ultrathin Gold Nanowires and Silver Nanowires toward “Invisible” Wearable Sensors for Detecting Emotional Expression and Apexcardiogram. Adv. Funct. Mater. 2017, 27, 1700845. [Google Scholar] [CrossRef]

- Lin, L.; Liu, S.Y.; Zhang, Q.; Li, X.Y.; Ji, M.Z.; Deng, H.; Fu, Q. Towards Tunable Sensitivity of Electrical Property to Strain for Conductive Polymer Composites Based on Thermoplastic Elastomer. ACS Appl. Mater. Interfaces 2013, 5, 5815–5824. [Google Scholar] [CrossRef] [PubMed]

- Ning, N.Y.; Wang, S.S.; Zhang, L.Q.; Lu, Y.L.; Tian, M.; Chan, T.W. Synchronously Tailoring Strain Sensitivity and Electrical Stability of Silicone Elastomer Composites by the Synergistic Effect of a Dual Conductive Network. Polymers 2016, 8, 100. [Google Scholar] [CrossRef]

- Ke, K.; Potschke, P.; Wiegand, N.; Krause, B.; Voit, B. Tuning the Network Structure in Poly(vinylidene fluoride)/Carbon Nanotube Nanocomposites Using Carbon Black: Toward Improvements of Conductivity and Piezoresistive Sensitivity. ACS Appl. Mater. Interfaces 2016, 8, 14190–14199. [Google Scholar] [CrossRef]

- Liu, H.; Gao, J.C.; Huang, W.J.; Dai, K.; Zheng, G.Q.; Liu, C.T.; Shen, C.Y.; Yan, X.R.; Guo, J.; Guo, Z.H. Electrically conductive strain sensing polyurethane nanocomposites with synergistic carbon nanotubes and graphene bifillers. Nanoscale 2016, 8, 12977–12989. [Google Scholar] [CrossRef]

- Gao, Y.J.; Ota, H.; Schaler, E.W.; Chen, K.; Zhao, A.; Gao, W.; Fahad, H.M.; Leng, Y.G.; Zheng, A.Z.; Xiong, F.R.; et al. Wearable Microfluidic Diaphragm Pressure Sensor for Health and Tactile Touch Monitoring. Adv. Mater. 2017, 29, 1701985. [Google Scholar] [CrossRef]

- Lee, J.; Lim, M.; Yoon, J.; Kim, M.S.; Choi, B.; Kim, D.M.; Kim, D.H.; Park, I.; Choi, S.J. Transparent, Flexible Strain Sensor Based on a Solution-Processed Carbon Nanotube Network. ACS Appl. Mater. Interfaces 2017, 9, 26279–26285. [Google Scholar] [CrossRef]

- Amjadi, M.; Yoon, Y.J.; Park, I. Ultra-stretchable and skin-mountable strain sensors using carbon nanotubes-Ecoflex nanocomposites. Nanotechnology 2015, 26, 375501. [Google Scholar] [CrossRef]

- Chen, Y.J.; Li, Y.; Xu, D.H.; Zhai, W.T. Fabrication of stretchable, flexible conductive thermoplastic polyurethane/graphene composites via foaming. RSC Adv. 2015, 5, 82034–82041. [Google Scholar] [CrossRef]

- Gan, X.P.; Wang, J.Z.; Wang, Z.H.; Zheng, Z.; Lavorgna, M.; Ronca, A.; Fei, G.X.; Xia, H.S. Simultaneous realization of conductive segregation network microstructure and minimal surface porous macrostructure by SLS 3D printing. Mater. Des. 2019, 178, 107874. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, J.-G.; Ryu, G.H.; Ko, K.Y.; Woo, W.J.; Kim, Y.; Kim, D.; Lim, J.H.; Lee, S.; Lee, Z. Low-temperature synthesis of 2D MoS2 on a plastic substrate for a flexible gas sensor. Nanoscale 2018, 10, 9338–9345. [Google Scholar] [CrossRef]

- Vuorinen, T.; Niittynen, J.; Kankkunen, T.; Kraft, T.M.; Mantysalo, M. Inkjet-Printed Graphene/PEDOT:PSS Temperature Sensors on a Skin-Conformable Polyurethane Substrate. Sci. Rep. 2016, 6, 35289. [Google Scholar] [CrossRef]

- Hassan, G.; Khan, M.U.; Bae, J.; Shuja, A. Inkjet printed self-healable strain sensor based on graphene and magnetic iron oxide nano-composite on engineered polyurethane substrate. Sci. Rep. 2020, 10, 18234. [Google Scholar] [CrossRef] [PubMed]

- Htwe, Y.Z.N.; Chow, W.S.; Suriati, G.; Thant, A.A.; Mariatti, M. Properties enhancement of graphene and chemical reduction silver nanoparticles conductive inks printed on polyvinyl alcohol (PVA) substrate. Synth. Met. 2019, 256, 116120. [Google Scholar] [CrossRef]

- Zheng, M.Y.; Li, W.Y.; Xu, M.J.; Xu, N.; Chen, P.; Han, M.; Xie, B. Strain sensors based on chromium nanoparticle arrays. Nanoscale 2014, 6, 3930–3933. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Liu, M.M.; Dou, S.; Sun, J.M.; Cong, Z.F.; Jiang, C.Y.; Du, C.H.; Pu, X.; Hu, W.G.; Wang, Z.L. Triboelectric-Nanogenerator-Based Soft Energy-Harvesting Skin Enabled by Toughly Bonded Elastomer/Hydrogel Hybrids. ACS Nano 2018, 12, 2818–2826. [Google Scholar] [CrossRef]

- Wu, H.G.; Liu, Q.; Du, W.C.; Li, C.; Shi, G.Q. Transparent Polymeric Strain Sensors for Monitoring Vital Signs and Beyond. ACS Appl. Mater. Interfaces 2018, 10, 3895–3901. [Google Scholar] [CrossRef]

- Yeo, W.H.; Kim, Y.S.; Lee, J.; Ameen, A.; Shi, L.K.; Li, M.; Wang, S.D.; Ma, R.; Jin, S.H.; Kang, Z.; et al. Multifunctional Epidermal Electronics Printed Directly onto the Skin. Adv. Mater. 2013, 25, 2773–2778. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Qi, D.P.; Guo, P.Z.; Liu, Y.; Zhu, B.W.; Yang, H.; Liu, Y.Q.; Li, B.; Zhang, C.G.; Yu, J.C.; et al. Thickness-Gradient Films for High Gauge Factor Stretchable Strain Sensors. Adv. Mater. 2015, 27, 6230–6237. [Google Scholar] [CrossRef]

- Choi, D.Y.; Kim, M.H.; Oh, Y.S.; Jung, S.H.; Jung, J.H.; Sung, H.J.; Lee, H.W.; Lee, H.M. Highly Stretchable, Hysteresis-Free Ionic Liquid-Based Strain Sensor for Precise Human Motion Monitoring. ACS Appl. Mater. Interfaces 2017, 9, 1770. [Google Scholar] [CrossRef] [PubMed]

- Yang, T.T.; Xie, D.; Li, Z.H.; Zhu, H.W. Recent advances in wearable tactile sensors: Materials, sensing mechanisms, and device performance. Mat. Sci. Eng. R Rep. 2017, 115, 1–37. [Google Scholar] [CrossRef]

- Li, S.; Park, J.G.; Wang, S.; Liang, R.; Zhang, C.; Wang, B. Working mechanisms of strain sensors utilizing aligned carbon nanotube network and aerosol jet printed electrodes. Carbon 2014, 73, 303–309. [Google Scholar] [CrossRef]

- Kang, D.; Shin, Y.E.; Jo, H.J.; Ko, H.; Shin, H.S. Mechanical Properties of Poly(dopamine)-Coated Graphene Oxide and Poly(vinyl alcohol) Composite Fibers Coated with Reduced Graphene Oxide and Their Use for Piezoresistive Sensing. Part. Part. Syst. Charact. 2017, 34, 1600382. [Google Scholar] [CrossRef]

- Park, J.; Lee, Y.; Hong, J.; Lee, Y.; Ha, M.; Jung, Y.; Lim, H.; Kim, S.Y.; Ko, H. Tactile-Direction-Sensitive and Stretchable Electronic Skins Based on Human-Skin-Inspired Interlocked Microstructures. ACS Nano 2014, 8, 12020–12029. [Google Scholar] [CrossRef] [PubMed]

- Pang, C.; Lee, G.Y.; Kim, T.I.; Kim, S.M.; Kim, H.N.; Ahn, S.H.; Suh, K.Y. A flexible and highly sensitive strain-gauge sensor using reversible interlocking of nanofibres. Nat. Mater. 2012, 11, 795–801. [Google Scholar] [CrossRef]

- Wang, C.F.; Zhao, J.; Ma, C.; Sun, J.L.; Tian, L.; Li, X.Y.; Li, F.T.; Han, X.; Liu, C.T.; Shen, C.Y.; et al. Detection of non-joint areas tiny strain and anti-interference voice recognition by micro-cracked metal thin film. Nano Energy 2017, 34, 578–585. [Google Scholar] [CrossRef]

- Wang, D.Y.; Tao, L.Q.; Liu, Y.; Zhang, T.Y.; Pang, Y.; Wang, Q.; Jiang, S.; Yang, Y.; Ren, T.L. High performance flexible strain sensor based on self-locked overlapping graphene sheets. Nanoscale 2016, 8, 20090–20095. [Google Scholar] [CrossRef]

- Li, J.H.; Zhao, S.F.; Zeng, X.L.; Huang, W.P.; Gong, Z.Y.; Zhang, G.P.; Sun, R.; Wong, C.P. Highly Stretchable and Sensitive Strain Sensor Based on Facilely Prepared Three-Dimensional Graphene Foam Composite. ACS Appl. Mater. Interfaces 2016, 8, 18954–18961. [Google Scholar] [CrossRef]

- Liu, X.; Tang, C.; Du, X.H.; Xiong, S.A.; Xi, S.Y.; Liu, Y.F.; Shen, X.; Zheng, Q.B.; Wang, Z.Y.; Wu, Y.; et al. A highly sensitive graphene woven fabric strain sensor for wearable wireless musical instruments. Mater. Horiz. 2017, 4, 477–486. [Google Scholar] [CrossRef]

- Jang, H.; Park, Y.J.; Chen, X.; Das, T.; Kim, M.S.; Ahn, J.H. Graphene-Based Flexible and Stretchable Electronics. Adv. Mater. 2016, 28, 4184–4202. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.F.; Li, J.H.; Cao, D.X.; Gao, Y.J.; Huang, W.P.; Zhang, G.P.; Sun, R.; Wong, C.P. Percolation threshold-inspired design of hierarchical multiscale hybrid architectures based on carbon nanotubes and silver nanoparticles for stretchable and printable electronics. J. Mater. Chem. C 2016, 4, 6666–6674. [Google Scholar] [CrossRef]

- Lin, Y.; Liu, S.Q.; Chen, S.; Wei, Y.; Dong, X.C.; Liu, L. A highly stretchable and sensitive strain sensor based on graphene-elastomer composites with a novel double-interconnected network. J. Mater. Chem. C 2016, 4, 6345–6352. [Google Scholar] [CrossRef]

- Suzuki, K.; Yataka, K.; Okumiya, Y.; Sakakibara, S.; Sako, K.; Mimura, H.; Inoue, Y. Rapid-Response, Widely Stretchable Sensor of Aligned MWCNT/Elastomer Composites for Human Motion Detection. ACS Sens. 2016, 1, 817–825. [Google Scholar] [CrossRef]

- Trung, T.Q.; Lee, N.E. Recent Progress on Stretchable Electronic Devices with Intrinsically Stretchable Components. Adv. Mater. 2017, 29, 1603167. [Google Scholar] [CrossRef]

- Xu, J.S.; Chen, J.; Zhang, M.; Hong, J.D.; Shi, G.Q. Highly Conductive Stretchable Electrodes Prepared by In Situ Reduction of Wavy Graphene Oxide Films Coated on Elastic Tapes. Adv. Electron. Mater. 2016, 2, 1600022. [Google Scholar] [CrossRef]

- Wei, Y.; Chen, S.; Yuan, X.; Wang, P.P.; Liu, L. Multiscale Wrinkled Microstructures for Piezoresistive Fibers. Adv. Funct. Mater. 2016, 26, 5078–5085. [Google Scholar] [CrossRef]

- Liu, Z.F.; Fang, S.; Moura, F.A.; Ding, J.N.; Jiang, N.; Di, J.; Zhang, M.; Lepro, X.; Galvao, D.S.; Haines, C.S.; et al. Hierarchically buckled sheath-core fibers for superelastic electronics, sensors, and muscles. Science 2015, 349, 400–404. [Google Scholar] [CrossRef]

- Guo, F.M.; Cui, X.; Wang, K.L.; Wei, J.Q. Stretchable and compressible strain sensors based on carbon nanotube meshes. Nanoscale 2016, 8, 19352–19358. [Google Scholar] [CrossRef]

- Zhao, Y.C.; Huang, X. Mechanisms and Materials of Flexible and Stretchable Skin Sensors. Micromachines 2017, 8, 69. [Google Scholar] [CrossRef]

- Kim, K.; Kim, J.; Hyun, B.G.; Ji, S.; Kim, S.Y.; Kim, S.; An, B.W.; Park, J.U. Stretchable and transparent electrodes based on in-plane structures. Nanoscale 2015, 7, 14577–14594. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.F.; Li, J.H.; Cao, D.X.; Zhang, G.P.; Li, J.; Li, K.; Yang, Y.; Wang, W.; Jin, Y.F.; Sun, R.; et al. Recent Advancements in Flexible and Stretchable Electrodes for Electromechanical Sensors: Strategies, Materials, and Features. ACS Appl. Mater. Interfaces 2017, 9, 12147–12164. [Google Scholar] [CrossRef] [PubMed]

- Tao, L.Q.; Wang, D.Y.; Tian, H.; Ju, Z.Y.; Liu, Y.; Pang, Y.; Chen, Y.Q.; Yang, Y.; Ren, T.L. Self-adapted and tunable graphene strain sensors for detecting both subtle and large human motions. Nanoscale 2017, 9, 8266–8273. [Google Scholar] [CrossRef] [PubMed]

- Li, X.T.; Hua, T.; Xu, B.G. Electromechanical properties of a yarn strain sensor with graphene-sheath/polyurethane-core. Carbon 2017, 118, 686–698. [Google Scholar] [CrossRef]

- Atalay, A.; Sanchez, V.; Atalay, O.; Vogt, D.M.; Haufe, F.; Wood, R.J.; Walsh, C.J. Batch Fabrication of Customizable Silicone-Textile Composite Capacitive Strain Sensors for Human Motion Tracking. Adv. Mater. Technol. 2017, 2, 1700136. [Google Scholar] [CrossRef]

- Tadakaluru, S.; Thongsuwan, W.; Singjai, P. Stretchable and Flexible High-Strain Sensors Made Using Carbon Nanotubes and Graphite Films on Natural Rubber. Sensors 2014, 14, 868–876. [Google Scholar] [CrossRef]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly Stretchable and Sensitive Strain Sensor Based on Silver Nanowire-Elastomer Nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef]

- Kim, T.; Park, J.; Sohn, J.; Cho, D.; Jeon, S. Bioinspired, highly stretchable, and conductive dry adhesives based on 1D–2D hybrid carbon nanocomposites for all-in-one ECG electrodes. ACS Nano 2016, 10, 4770–4778. [Google Scholar] [CrossRef]

- Moriche, R.; Sanchez, M.; Jimenez-Suarez, A.; Prolongo, S.G.; Urena, A. Strain monitoring mechanisms of sensors based on the addition of graphene nanoplatelets into an epoxy matrix. Compos. Sci. Technol. 2016, 123, 65–70. [Google Scholar] [CrossRef]

- Selvan, N.T.; Eshwaran, S.B.; Das, A.; Stockelhuber, K.W.; Wiessner, S.; Potschke, P.; Nando, G.B.; Chervanyov, A.I.; Heinrich, G. Piezoresistive natural rubber-multiwall carbon nanotube nanocomposite for sensor applications. Sens. Actuators A Phys. 2016, 239, 102–113. [Google Scholar] [CrossRef]

- Yang, T.T.; Jiang, X.; Zhong, Y.J.; Zhao, X.L.; Lin, S.Y.; Li, J.; Li, X.M.; Xu, J.L.; Li, Z.H.; Zhu, H.W. A Wearable and Highly Sensitive Graphene Strain Sensor for Precise Home-Based Pulse Wave Monitoring. ACS Sens. 2017, 2, 967–974. [Google Scholar] [CrossRef] [PubMed]

- Benchirouf, A.; Muller, C.; Kanoun, O. Electromechanical Behavior of Chemically Reduced Graphene Oxide and Multi-walled Carbon Nanotube Hybrid Material. Nanoscale Res. Lett. 2016, 11, 4. [Google Scholar] [CrossRef] [PubMed]

- Xin, Y.Y.; Zhou, J.; Xu, X.Z.; Lubineau, G. Laser-engraved carbon nanotube paper for instilling high sensitivity, high stretchability, and high linearity in strain sensors. Nanoscale 2017, 9, 10897–10905. [Google Scholar] [CrossRef] [PubMed]

- Giffney, T.; Bejanin, E.; Kurian, A.S.; Travas-Sejdic, J.; Aw, K. Highly stretchable printed strain sensors using multi-walled carbon nanotube/silicone rubber composites. Sens. Actuators A Phys. 2017, 259, 44–49. [Google Scholar] [CrossRef]

- Kim, J.Y.; Ji, S.; Jung, S.; Ryu, B.H.; Kim, H.S.; Lee, S.S.; Choi, Y.; Jeong, S. 3D printable composite dough for stretchable, ultrasensitive and body-patchable strain sensors. Nanoscale 2017, 9, 11035–11046. [Google Scholar] [CrossRef]

- Wang, R.; Jiang, N.; Su, J.; Yin, Q.; Zhang, Y.; Liu, Z.S.; Lin, H.B.; Moura, F.A.; Yuan, N.Y.; Roth, S.; et al. A Bi-Sheath Fiber Sensor for Giant Tensile and Torsional Displacements. Adv. Funct. Mater. 2017, 27, 1702134. [Google Scholar] [CrossRef]

- Lozano-Perez, C.; Cauich-Rodriguez, J.V.; Aviles, F. Influence of rigid segment and carbon nanotube concentration on the cyclic piezoresistive and hysteretic behavior of multiwall carbon nanotube/segmented polyurethane composites. Compos. Sci. Technol. 2016, 128, 25–32. [Google Scholar] [CrossRef]

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Izadi-Najafabadi, A.; Futaba, D.N.; Hata, K. A stretchable carbon nanotube strain sensor for human-motion detection. Nat. Nanotechnol. 2011, 6, 296–301. [Google Scholar] [CrossRef]

- Foroughi, J.; Spinks, G.M.; Aziz, S.; Mirabedini, A.; Jeiranikhameneh, A.; Wallace, G.G.; Kozlov, M.E.; Baughman, R.H. Knitted Carbon-Nanotube-Sheath/Spandex-Core Elastomeric Yarns for Artificial Muscles and Strain Sensing. ACS Nano 2016, 10, 9129–9135. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, Y.; Sun, J.; Huang, Y.; Hu, H.; Jiang, R.; Gai, W.; Li, G.; Zhi, C. Polyurethane/Cotton/Carbon Nanotubes Core-Spun Yarn as High Reliability Stretchable Strain Sensor for Human Motion Detection. ACS Appl. Mater. Interfaces 2016, 8, 24837–24843. [Google Scholar] [CrossRef]

- Song, H.L.; Zhang, J.Q.; Chen, D.B.; Wang, K.J.; Niu, S.C.; Han, Z.W.; Ren, L.Q. Superfast and high-sensitivity printable strain sensors with bioinspired micron-scale cracks. Nanoscale 2017, 9, 1166–1173. [Google Scholar] [CrossRef] [PubMed]

- Flandin, L.; Chang, A.; Nazarenko, S.; Hiltner, A.; Baer, E. Effect of strain on the properties of an ethylene-octene elastomer with conductive carbon fillers. J. Appl. Polym. Sci. 2000, 76, 894–905. [Google Scholar] [CrossRef]

- Zhao, J.H.; Dai, K.; Liu, C.G.; Zheng, G.Q.; Wang, B.; Liu, C.T.; Chen, J.B.; Shen, C.Y. A comparison between strain sensing behaviors of carbon black/polypropylene and carbon nanotubes/polypropylene electrically conductive composites. Compos. Part A Appl. Sci. Manuf. 2013, 48, 129–136. [Google Scholar] [CrossRef]

- Sreenatha Reddy, S.; Dhanasekaran, R.; Kumar, S.; Kanwar, S.S.; Shruthi, R.; Navaneetha, T. Studies on Application and Mechanism of Self-Healing Polymer and Nanocomposite Materials. In Recent Trends in Mechanical Engineering; Springer: Singapore, 2020; pp. 487–497. [Google Scholar]

- Banshiwal, J.K.; Tripathi, D.N. Self-Healing Polymer Composites for Structural Application. In Functional Materials; IntechOpen: London, UK, 2019. [Google Scholar]

- Terada, T.; Shiba, K.; Suzuki, M.; Sugita, M.; Matsubara, H. Film Sensor Using Carbon Particles for Monitoring Integrity of Steel Structures. In Proceedings of the Smart Structures and Materials 2004: Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems, San Diego, CA, USA, 14–18 March 2004; Volume 5391, pp. 202–210. [Google Scholar] [CrossRef]

- Ku-Herrera, J.J.; Aviles, F. Cyclic tension and compression piezoresistivity of carbon nanotube/vinyl ester composites in the elastic and plastic regimes. Carbon 2012, 50, 2592–2598. [Google Scholar] [CrossRef]

- Lundberg, A.; Zhao, X.; Kanoun, O. Investigation of Stability and Dynamic Behavior of a Carbon Nanotube/Epoxy Composite Strain Sensor. In Proceedings of the 2019 16th International Multi-Conference on Systems, Signals & Devices, Istanbul, Turkey, 21–24 March 2019; pp. 149–153. [Google Scholar]

- Ji, X. Epoxy Matrix Composites Filled with Nano-Carbon Black and Their Strain and Crack Monitoring. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2009. [Google Scholar]

- Zhang, Y. Research on Properties of CNT/PDMS Flexible Sensing Material and Its Monitoring of Structural Crack. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2017. [Google Scholar]

- Zhang, Y.Q.; Ge, Y.; Du, Y.B.; Yang, L.L. Monitoring of Compression and Bending Process of Reactive Powder Concrete Using MWCNTs/PDMS Composite Sensors. IEEE Sens. J. 2017, 17, 6153–6159. [Google Scholar] [CrossRef]

- Wu, Z.Q.; Wei, J.; Dong, R.Z.; Chen, H. Epoxy Composites with Reduced Graphene Oxide-Cellulose Nanofiber Hybrid Filler and Their Application in Concrete Strain and Crack Monitoring. Sensors 2019, 19, 3963. [Google Scholar] [CrossRef]

- Wu, Z.Q.; Wei, J.; Dong, R.Z.; Chen, H. A Three-Dimensional Strain Rosette Sensor Based on Graphene Composite with Piezoresistive Effect. J. Sens. 2019, 2019, 2607893. [Google Scholar] [CrossRef]

- Zhang, B.N.; Wang, S.L.; Li, X.X.; Zhang, X.; Yang, G.; Qiu, M.F. Crack width monitoring of concrete structures based on smart film. Smart Mater. Struct. 2014, 23, 45031. [Google Scholar] [CrossRef]

- Ryu, D.; Loh, K.J.; Ireland, R.; Karimzada, M.; Yaghmaie, F.; Gusman, A.M. In Situ reduction of gold nanoparticles in PDMS matrices and applications for large strain sensing. Smart Struct. Syst. 2011, 8, 471–486. [Google Scholar] [CrossRef]

- Hallaji, M.; Pour-Ghaz, M. A new sensing skin for qualitative damage detection in concrete elements: Rapid difference imaging with electrical resistance tomography. NDT E Int. 2014, 68, 13–21. [Google Scholar] [CrossRef]

- Nie, X.F.; Zhang, S.S.; Teng, J.G. Strengths of RC beams with a fibre-reinforced polymer (FRP)-strengthened web opening. Compos. Struct. 2021, 258, 113380. [Google Scholar] [CrossRef]

- Zhang, S.S.; Yu, T. Fibre-reinforced polymer strengthening and fibre Bragg grating-based monitoring of reinforced concrete cantilever slabs with insufficient anchorage length of steel bars. Adv. Struct. Eng. 2017, 20, 1684–1698. [Google Scholar] [CrossRef]

- Nag-Chowdhury, S.; Bellegou, H.; Pillin, I.; Castro, M.; Longrais, P.; Feller, J.F. Non-intrusive health monitoring of infused composites with embedded carbon quantum piezo-resistive sensors. Compos. Sci. Technol. 2016, 123, 286–294. [Google Scholar] [CrossRef]

- Park, J.M.; Kwon, D.J.; Wang, Z.J.; DeVries, K.L. Review of self-sensing of damage and interfacial evaluation using electrical resistance measurements in nano/micro carbon materials-reinforced composites. Adv. Compos. Mater. 2015, 24, 197–219. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Y.; Huang, M.L.; Bilotti, E.; Peijs, T. Dissolvable thermoplastic interleaves for carbon nanotube localization in carbon/epoxy laminates with integrated damage sensing capabilities. Struct. Health Monit. 2018, 17, 59–66. [Google Scholar] [CrossRef]

- Gallo, G.J.; Thostenson, E.T. Electrical characterization and modeling of carbon nanotube and carbon fiber self-sensing composites for enhanced sensing of microcracks. Mater. Today Commun. 2015, 3, 17–26. [Google Scholar] [CrossRef]

- Ku-Herrera, J.D.; La Saponara, V.; Aviles, F. Selective damage sensing in multiscale hierarchical composites by tailoring the location of carbon nanotubes. J. Intel. Mat. Syst. Str. 2018, 29, 553–562. [Google Scholar] [CrossRef]

- He, D.L.; Fan, B.H.; Zhao, H.; Lu, X.X.; Yang, M.H.; Liu, Y.; Bai, J.B. Design of Electrically Conductive Structural Composites by Modulating Aligned CVD-Grown Carbon Nanotube Length on Glass Fibers. ACS Appl. Mater. Interfaces 2017, 9, 2948–2958. [Google Scholar] [CrossRef]

- Moriche, R.; Jiménez-Suárez, A.; Sánchez, M.; Prolongo, S.G.; Ureña, A. Graphene nanoplatelets coated glass fibre fabrics as strain sensors. Compos. Sci. Technol. 2017, 146, 59–64. [Google Scholar] [CrossRef]

- Salvado, R.; Lopes, C.; Szojda, L.; Araujo, P.; Gorski, M.; Velez, F.J.; Castro-Gomes, J.; Krzywon, R. Carbon Fiber Epoxy Composites for Both Strengthening and Health Monitoring of Structures. Sensors 2015, 15, 10753–10770. [Google Scholar] [CrossRef]

- Park, J.M.; Kwon, D.J.; Shin, P.S.; Kim, J.H.; DeVries, K.L. New Sensing Method of Dispersion and Damage Detection of Carbon Fiber/Polypropylene-Polyamide Composites via Two-Dimensional Electrical Resistance Mapping. In Proceedings of the Behavior and Mechanics of Multifunctional Materials and Composites, Portland, OR, USA, 26–28 March 2017; Volume 10165. [Google Scholar] [CrossRef]

- Kwon, D.J.; Shin, P.S.; Kim, J.H.; Wang, Z.J.; DeVries, K.L.; Park, J.M. Detection of damage in cylindrical parts of carbon fiber/epoxy composites using electrical resistance (ER) measurements. Compos. Part B Eng. 2016, 99, 528–532. [Google Scholar] [CrossRef]

- Wang, Z.; Li, P.; Song, R.G.; Qian, W.; Zhou, H.; Wang, Q.L.; Wang, Y.; Zeng, X.C.; Ren, L.; Yan, S.L.; et al. High conductive graphene assembled films with porous micro-structure for freestanding and ultra-low power strain sensors. Sci. Bull. 2020, 65, 1363–1370. [Google Scholar] [CrossRef]

- Zhang, J.B.; Song, R.G.; Zhao, X.; Fang, R.; Zhang, B.; Qian, W.; Zhang, J.W.; Liu, C.G.; He, D.P. Flexible Graphene-Assembled Film-Based Antenna for Wireless Wearable Sensor with Miniaturized Size and High Sensitivity. ACS Omega 2020, 5, 12937–12943. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Wang, Z.; Song, R.G.; Qian, W.; Wen, P.; Yang, Z.G.; He, D.P. Customizable fabrication for auxetic graphene assembled macrofilms with high conductivity and flexibility. Carbon 2020, 162, 545–551. [Google Scholar] [CrossRef]

- Zhang, J.J.; Wu, B.; Zhao, Y.T.; Song, L.; Zu, H.R.; Song, R.G.; He, D.P. Two-Dimensional Highly Sensitive Wireless Displacement Sensor with Bilayer Graphene-Based Frequency Selective Surface. IEEE Sens. J. 2021, 21, 23889–23897. [Google Scholar] [CrossRef]

| Abbreviations | Material | Abbreviations | Material |

|---|---|---|---|

| AFM | Atomic Force Microscope | PDMS | Polydimethylsiloxane |

| AgNPs | Silver Nanoparticles | PEDOT: PSS | Polyethylenedioxythiophene: Polystyrene Sulfonate |

| AgNWs | Silver Nanowires | PET | Polyethylene terephthalate |

| AuNWs | Gold Nanowires | PI | Polyimide |

| CB | Carbon Black | PMVS | Polymethylvinylsiloxane |

| CNTs | Carbon Nanotubes | POE | Polyolefin Elastomer |

| CPCs | Conductive Polymer Composites | PP | Polypropylene |

| CSF | Carbonized Silk Fabric | PPy | Polypyrrole |

| CuNWs | Copper Nanowires | PU | Polyurethane |

| DI | Deionized Water | PVA | Polyvinyl Alcohol |

| EG | Ethylene Glycol | PVC | Polyvinyl Chloride |

| FBGs | Fiber Bragg Gratings | PVDF | Polyvinylidene Fluoride |

| FDM | Fused Deposition Modelling | rGO | Reduced Graphene Oxide |

| FGS | Fragmentized Graphene Sponges | SBCs | Styrenic Block Copolymers |

| FSG | Fish-Scale-Like Graphene | SBR | Styrene-Butadiene Rubber |

| GWF | Graphene Woven Fabric | SBS | Polystyrene-Block-Butadiene-Block-Styrene |

| IL | Ionic Liquid | SEBS | Styrene-Ethylene/Butylene-Styrene Triblock Copolymer |

| ILBW | Ionic-Liquid-Based Wavy | SEM | Scanning Electron Microscopy |

| MWCNTs | Multi-Walled Carbon Nanotubes | SPX | Spandex |

| LPG | Laser Patterned Graphene | SWCNTs | Single-Walled Carbon Nanotubes |

| NaCl | Sodium Chloride | TPU | Thermoplastic Polyurethane |

| NR | Natural Rubber | TPV | Thermoplastic Vulcanizate |

| OBC | Olefin Block Copolymer | WEP | Waterborne Epoxy |

| PANI | Polyaniline |

| No. | Materials Filler + Substrate | Maximum Detectable Range | Gauge Factor/GF (Strain Range) | Linearity (Strain Range) | Cyclic Times for Durability |

|---|---|---|---|---|---|

| [58] | CuNWs + PDMS | 7.5% | Nonlinear | ||

| [65] | CB + Knitted Fabric | 60% | 1~100 | Nonlinear | 100,000 (ε < 60%) |

| [67] | CNT + TPU | 400% | 4~69 | Nonlinear | 1000 |

| [68] | MWCNT + SBC | 45% | 5.39~8.58 × 107 | Nonlinear | 600 |

| [69] | CNT/Graphene + PDMS | 10% | 0.4 | Linear (ε < 10%) | 3000 (ε < 10%) |

| [73] | AuNWs/AgNWs + PDMS | 70% | 236 (ε < 5%) | Nonlinear | 1000 (ε < 10%) |

| [74] | MWCNT + PU | 200% | 5~1.4 × 105 | Nonlinear | |

| [75] | CNT/CB + PMVS | 60% | 1~192 | Nonlinear | 10,000 (ε < 30%) |

| [76] | CNT/CB + PVDF | 10% | 0.6 | Nonlinear | |

| [77] | CNT/Graphene + TPU | 30% | 152 | Nonlinear | |

| [79] | CNT + PDMS | 30% | 3 | Linear (ε < 30%) | 600 |

| [80] | CNT + Ecoflex | 500% | 2.4 | Linear (ε < 100%) | 2000 (ε < 300%) |

| [82] | SWCNT + TPU | 25% | 0.2 | Linear (ε < 25%) | 1000 (ε < 20%) |

| [85] | Graphene + PVA | 55% | 271 (ε < 35%) | Nonlinear | 10,000 (ε < 55%) |

| [87] | CrNP + PET | 3% | 20 (ε < 0.36%) | Nonlinear |

| Ref. | Materials Filler + Substrate | Maximum Detectable Range | Gauge Factor (Sensing Range) | Linearity (Strain Range) | Cyclic Times for Durability |

|---|---|---|---|---|---|

| [91] | SWCNT+ PDMS | 150% | 161 (ε < 2%), 9.8 (2% < ε < 15%), 0.58 (ε > 15%) | Multi-stage linear | 100,000 (ε < 60%) |

| [94] | CNT + PI | 1% | 40 | Near linear (ε < 0.8%) | 500 (ε < 0.8%) |

| [95] | Graphene + PVA | 1% | 2.3 (ε < 1%) | Linear | 1800 |

| [96] | CNT + PDMS | 120% | 27.8 (ε < 40%), 1084 (40% < ε < 90%) | Multi-stage linear | |

| [97] | Pt + PDMS | 4% | 0.75 (ε < 4%) | Linear | |

| [99] | Graphene + PDMS | 7.5% | 3.4 (ε < 2.5%), 100 (2.5% < ε < 5%), 400 (5% < ε < 7.5%) | Multi-stage linear | |

| [101] | Graphene + PDMS | 3% | 223 (ε < 3%) | Linear | 1000 |

| [105] | MWCNTs + PDMS | 200% | 10.5 | Linear (ε < 100%) | 180,000 (ε < 30%) |

| [110] | CNTs + PDMS | 11% | 1 (ε < 30%), 2 (30% < ε < 50%) | Multi-stage linear | 1000 (ε < 20%) |

| [114] | Graphene + Ecoflex | 100% | 457 (ε < 35%), 268 (35% < ε < 100%) | Multi-stage linear | 180 |

| [123] | GO/MWCNTs + Kapton HN | 0.6% | 8.5 | Near linear (ε < 0.5%) | |

| [124] | CNT +PDMS | 150% | 2.2 × 103 (ε < 15%), 4.2 × 104 (22% < ε < 150%) | Multi-stage linear | 5000 |

| [125] | MWCNTs + Ecoflex | 300% | 1.5 | Near linear (ε < 300%) | |

| [127] | CNT sheets + Rubber | 600% | 0.5 (ε < 200%), 0.14 (200% < ε < 600%) | Near linear (ε < 1%) | 5000 (ε < 100%) |

| [130] | CNT + SPX | 80% | 0.2~0.3 | Nonlinear | 270,000 (ε < 40%) |

| [132] | CB + paper | 0.22% | 647 (ε < 0.14%), 33 (ε < 0.22%) | Multi-stage linear | 70,000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, K.; Zhang, Z.; Weng, S.; Zhu, H.; Yu, H.; Peng, T. Review of Flexible Piezoresistive Strain Sensors in Civil Structural Health Monitoring. Appl. Sci. 2022, 12, 9750. https://doi.org/10.3390/app12199750

Gao K, Zhang Z, Weng S, Zhu H, Yu H, Peng T. Review of Flexible Piezoresistive Strain Sensors in Civil Structural Health Monitoring. Applied Sciences. 2022; 12(19):9750. https://doi.org/10.3390/app12199750

Chicago/Turabian StyleGao, Ke, Zhiyue Zhang, Shun Weng, Hongping Zhu, Hong Yu, and Tingjun Peng. 2022. "Review of Flexible Piezoresistive Strain Sensors in Civil Structural Health Monitoring" Applied Sciences 12, no. 19: 9750. https://doi.org/10.3390/app12199750

APA StyleGao, K., Zhang, Z., Weng, S., Zhu, H., Yu, H., & Peng, T. (2022). Review of Flexible Piezoresistive Strain Sensors in Civil Structural Health Monitoring. Applied Sciences, 12(19), 9750. https://doi.org/10.3390/app12199750