The Use of Carbon-Containing Compounds to Prepare Functional and Structural Composite Materials: A Review

Abstract

:1. Introduction

2. Carbon-Containing Compounds: Their Synthesis and Application in the Technology of Obtaining Composite Functional and Structural Materials

2.1. Carbon-Containing Functional Composites Based on Graphene

2.2. Carbon Nanotubes and Nanofibers Are Promising Solids for the Preparation of Structural Composite Materials with a Metal Matrix

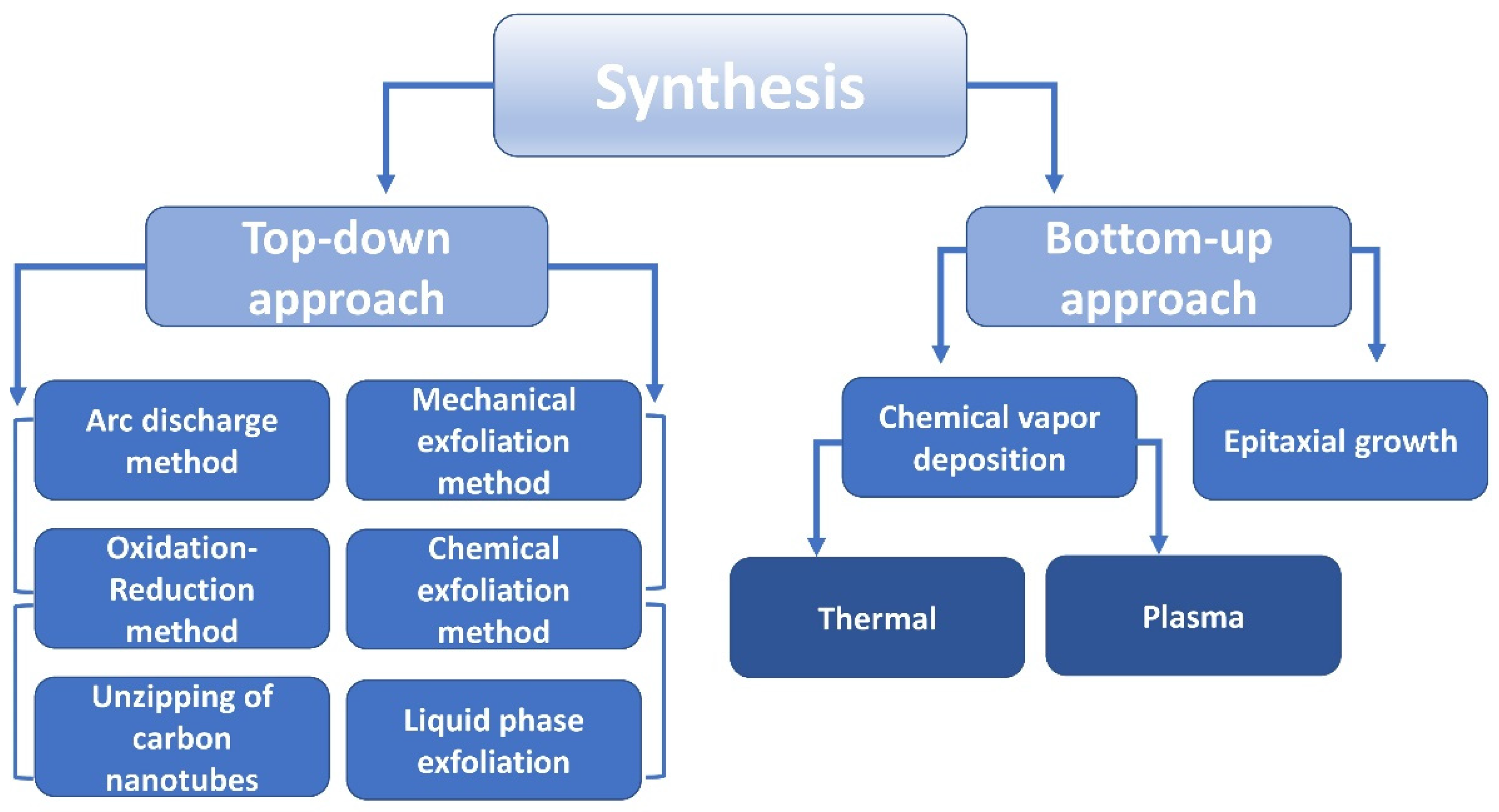

2.3. Basic Methods for the Synthesis of Carbon Nanotubes

3. Advantages of Composites over Traditional Materials

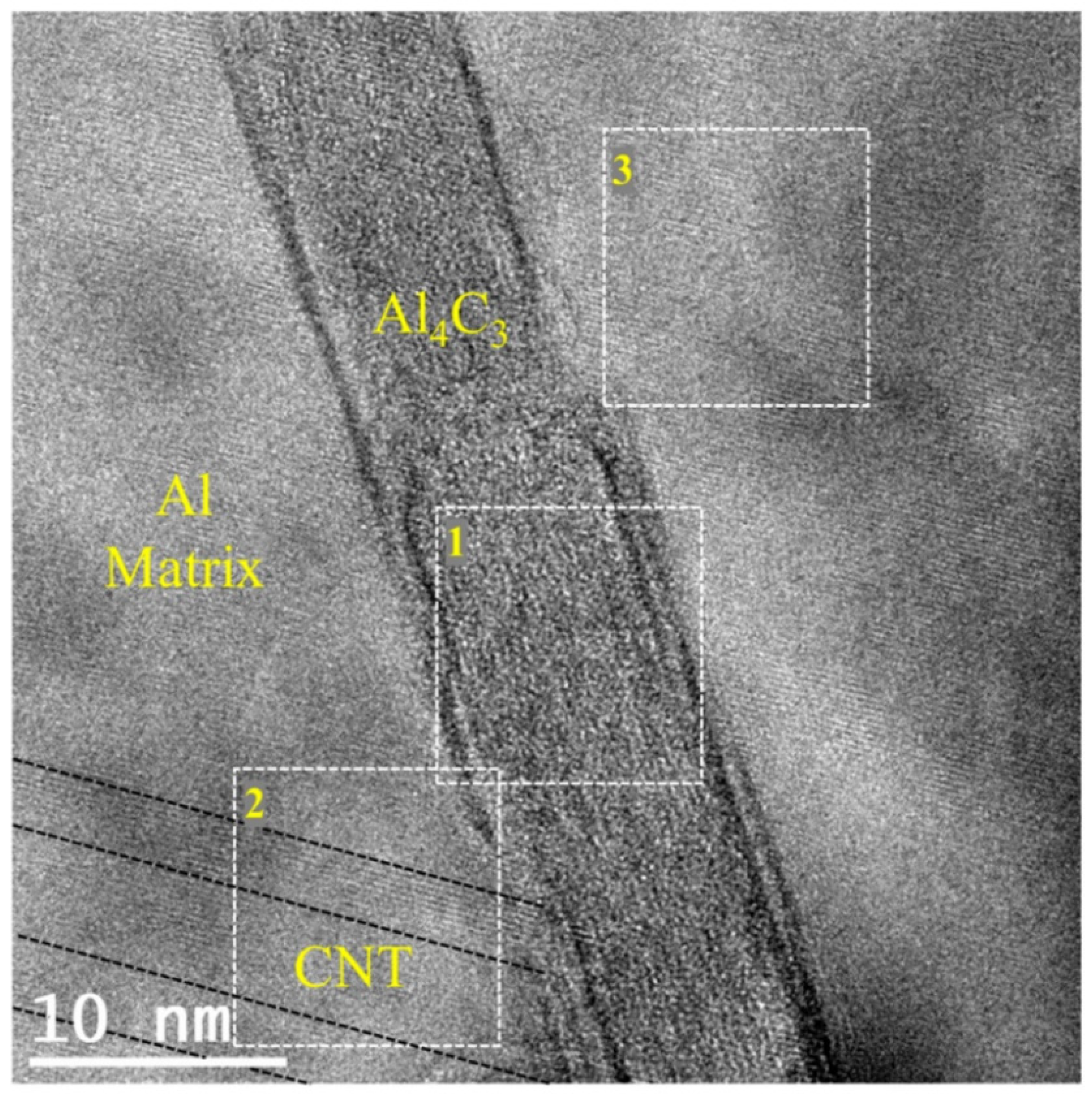

The Influence of Interfacial Interaction of Components in Carbon-Containing Composites on Their Physical and Mechanical Properties

- (1)

- Mechanical bonding due to friction forces. Such materials have low strength in transverse tension and longitudinal compression (composites of the first class).

- (2)

- Bond due to surface tension forces. It is typical for materials formed during wetting and dissolution without a chemical reaction. When wetting, a slight dissolution of the components occurs when the fibers are impregnated with a molten matrix (composites of the first and second classes).

- (3)

- Reactive bond during a chemical reaction at the interface, which results in the formation of other chemical compounds (composites of the third class).

- (4)

- Exchange-reaction bond. A kind of reaction bond in which a chemical reaction does not occur simultaneously but in several stages.

- (5)

- Oxide bond. A kind of reactive bond characteristic of composites reinforced with fibers or oxide particles. In composite materials with metal matrices, bonding is achieved through the formation of spinels at interphase boundaries or through an oxide film through which bonding occurs. The interaction between the metal and SWCNTs can lead to MWCNTs with open ends occurring [109,110].

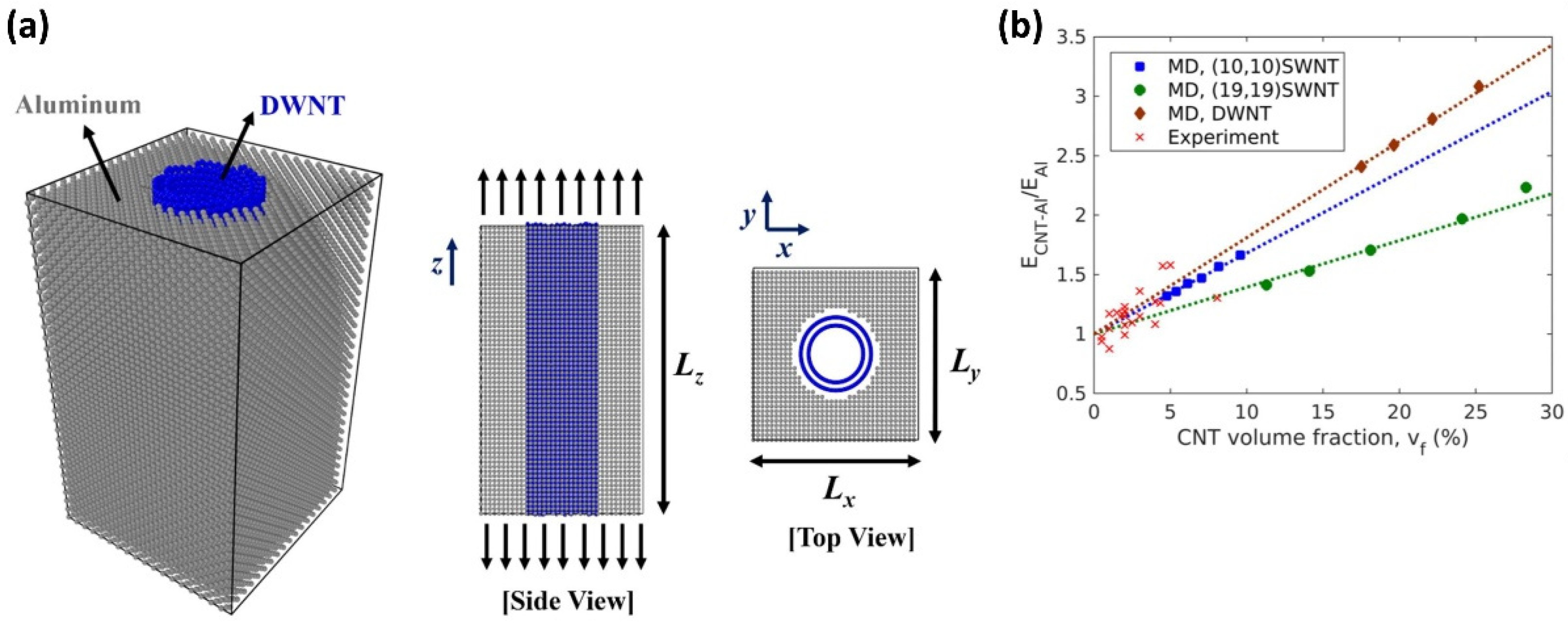

4. Modeling of the Hardening of an Aluminum Metal Matrix Composite Reinforced with CNTs

- (1)

- Due to the effective transfer of the load between the matrix and the reinforcing elements;

- (2)

- Due to the internal thermal stresses caused by a mismatch in the coefficients of thermal expansion between the matrix and carbide particles;

- (3)

- By grinding the grain of the matrix (Hall-Petch law);

- (4)

- Due to a mismatch between the elastic moduli of the matrix materials and the inclusion;

- (5)

- Hardening caused by the dispersed phase, according to Orowan;

- (6)

- Hardening caused by the appearance of an interfacial layer between the reinforcing particle and the matrix.

- Micromechanical modeling based on empirical or semi-empirical models of hardening mechanisms.

- Computer modeling, including modeling by molecular dynamics methods, finite element modeling, and multiscale modeling, representing some combination of molecular dynamics and finite element modeling.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chawla, K.K. Composite Materials: Science and Engineering, 3rd ed.; Springer Science + Business Media: New York, NY, USA, 2013; p. 542. ISBN 978-0-387-74364-6. [Google Scholar]

- Kumar, V.M.; Venkatesha, C.V. Effect of ceramic reinforcement on mechanical properties of aluminum matrix composites produced by stir casting process. Mater. Today Proc. 2018, 5, 2466–2471. [Google Scholar] [CrossRef]

- Kablov, E.N. Innovative developments of FSUE "VIAM" of the State Research Center of the Russian Federation on the implementation of "Strategic directions for the development of materials and technologies of their processing for the period up to 2030. Aviat. Mater. Technol. 2015, 34, 3–33. [Google Scholar]

- Yufeng, W.; Gap-Yong, K.; Alan, M.R. Mechanical alloying of carbon nanotube and Al6061 powder for metal matrix composites. Mater. Sci. Eng. A 2012, 532, 558–566. [Google Scholar]

- Bakshi, S.R.; Lahiri, D.; Argaval, A. Carbon nanotube reinforced metal matrix composites-a review. Int. Mater. Rev. 2013, 55, 41–64. [Google Scholar] [CrossRef]

- Matthews, F.L.; Rawlings, R.D. Composite Materials: Engineering and Science; CRS Press: Boca Raton, FL, USA, 1999; ISBN 0-8493-0621-3. [Google Scholar]

- Bayda, S.; Adeel, M.; Tuccinardi, T.; Cordani, M.; Rizzolio, F. The History of Nanoscience and Nanotechnology: From Chemical–Physical Applications to Nanomedicine. Molecules 2020, 25, 112. [Google Scholar] [CrossRef] [Green Version]

- Rogov, V.A. Technology of structural materials. Nanotechnologies, 2nd ed.; Urait: Moscow, Russia, 2022; p. 190. [Google Scholar]

- Chang, L.; Zhang, Z.; Ye, L.; Friedrich, K. Tribological properties of high temperature resistant polymer composites with fine particles. Tribol. Int. 2007, 40, 1170–1178. [Google Scholar] [CrossRef]

- Liao, X.Z.; Serquis, A.; Jia, Q.; Peterson, D.; Zhu, Y.; Xu, H. Effect of catalyst composition on carbon nanotube growth. Appl. Phys. Lett. 2003, 82, 2694–2696. [Google Scholar] [CrossRef] [Green Version]

- Gleiter, H. Nanostructured materials. Basic Concepts and Microstructure. Acta Mater. 2000, 48, 1–29. [Google Scholar] [CrossRef] [Green Version]

- Suzdalev, I.P. Nanotechnology: Physico-Chemistry of Nanoclusters, Nanostructures and Nanomaterials; ComKniga: Moscow, Russia, 2006; p. 592. [Google Scholar]

- Agarwal, A.; Bakshi, S.R.; Lahiri, D. Carbon Nanotubes: Reinforced Metal Matrix Composites; CRC Press: Boca Raton, FL, USA, 2011; 305p. [Google Scholar]

- Nolan, P.E.; Schabel, M.J.; Lynch, D.C.; Cutler, A.H. Hydrogen control of carbon deposit morphology. Carbon 1995, 33, 79–85. [Google Scholar] [CrossRef]

- Romero, A.; Garrido, A.; Nieto-Márquez, A.; Sánchez, P.; de Lucas, A.; Valverde, J.L. Synthesis and structural characteristics of highly graphitized carbon nanofibers produced from the catalytic decomposition of ethylene: Influence of the active metal (Co, Ni, Fe) and the zeolite type support. Microporous Mesoporous Mater. 2008, 110, 318–329. [Google Scholar] [CrossRef]

- Verfssimo, C.; Moshkalyo, S.A.; Ramos, A.C.S.; Gonçalves, J.L.; Alves, O.L.; Swart, J.W. Different Carbon Nanostructured Materials Obtained in Catalytic Chemical Vapor Deposition. J. Braz. Chem. Soc. 2006, 17, 1124–1132. [Google Scholar] [CrossRef]

- Osawa, E. Perspectives of Fullerene Nanotechnology, 1st ed.; Springer Dordrecht: Dordrecht, The Netherlands, 2002; ISBN 978-0-306-47621-1. [Google Scholar]

- Delgado, J.L.; Herranz, M.A.; Martin, N. The nano-forms of carbon. J. Mater. Chem. 2008, 18, 1417–1426. [Google Scholar]

- Neitzel, I.; Mochalin, V.; Bares, J.A.; Carpick, R.W.; Erdemir, A.; Gogotsi, Y. Tribological properties of nanodiamond-epoxy composites. Tribol. Lett. 2012, 47, 195–202. [Google Scholar] [CrossRef]

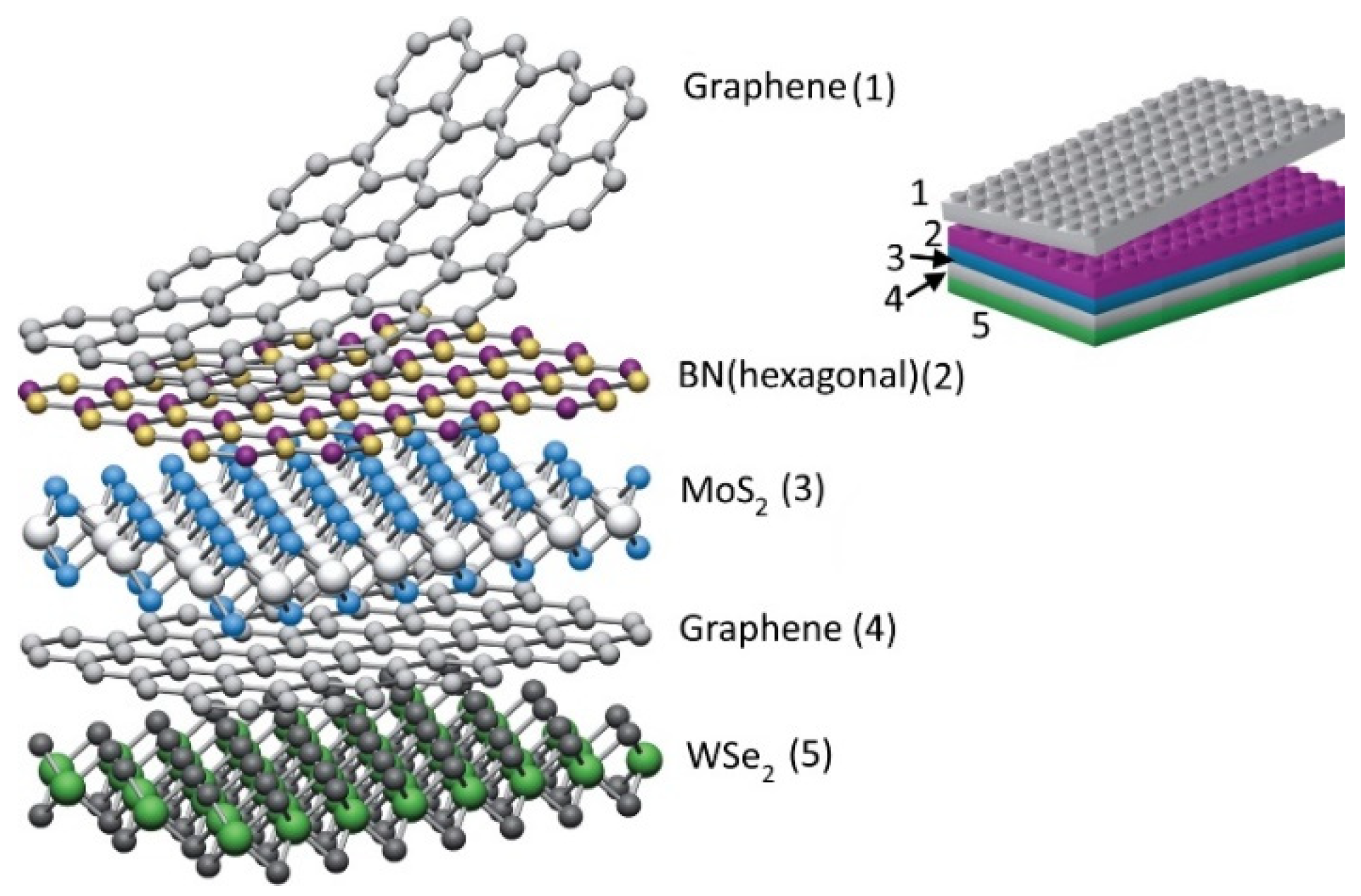

- Geim, A.K.; Grigorieva, I.V. Van der Waals heterostructures. Nature 2013, 499, 419–425. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Korusenko, P.M.; Nesov, S.N.; Iurchenkova, A.A.; Fedorovskaya, E.O.; Bolotov, V.V.; Povoroznyuk, S.N.; Smirnov, D.A.; Vinogradov, A.S. Comparative Study of the Structural Features and Electrochemical Properties of Nitrogen-Containing Multi-Walled Carbon Nanotubes after Ion-Beam Irradiation and Hydrochloric Acid Treatment. Nanomaterials 2021, 11, 2163. [Google Scholar] [CrossRef]

- Kis, A.; Csányi, G.; Salvetat, J.-P.; Lee, T.-N.; Couteau, E.; Kulik, A.J.; Benoit, W.; Brugger, J.; Forró, L. Reinforcement of single-walled carbon nanotube bundles by intertube bridging. Nat. Mater. 2004, 3, 153–157. [Google Scholar]

- Trofimov, N.A. Technology based on nanotubes: Industrial application and product market. Sci. Abroad. 2012, 3, 2–23. [Google Scholar]

- Lau, K. Interfacial bonding characteristics of nanotube/polymer. Chem. Phys. Lett. 2003, 370, 399–405. [Google Scholar] [CrossRef]

- Zhang, H. Introduction: 2D Materials Chemistry. Chem. Rev. 2018, 118, 6089–6090. [Google Scholar] [CrossRef] [Green Version]

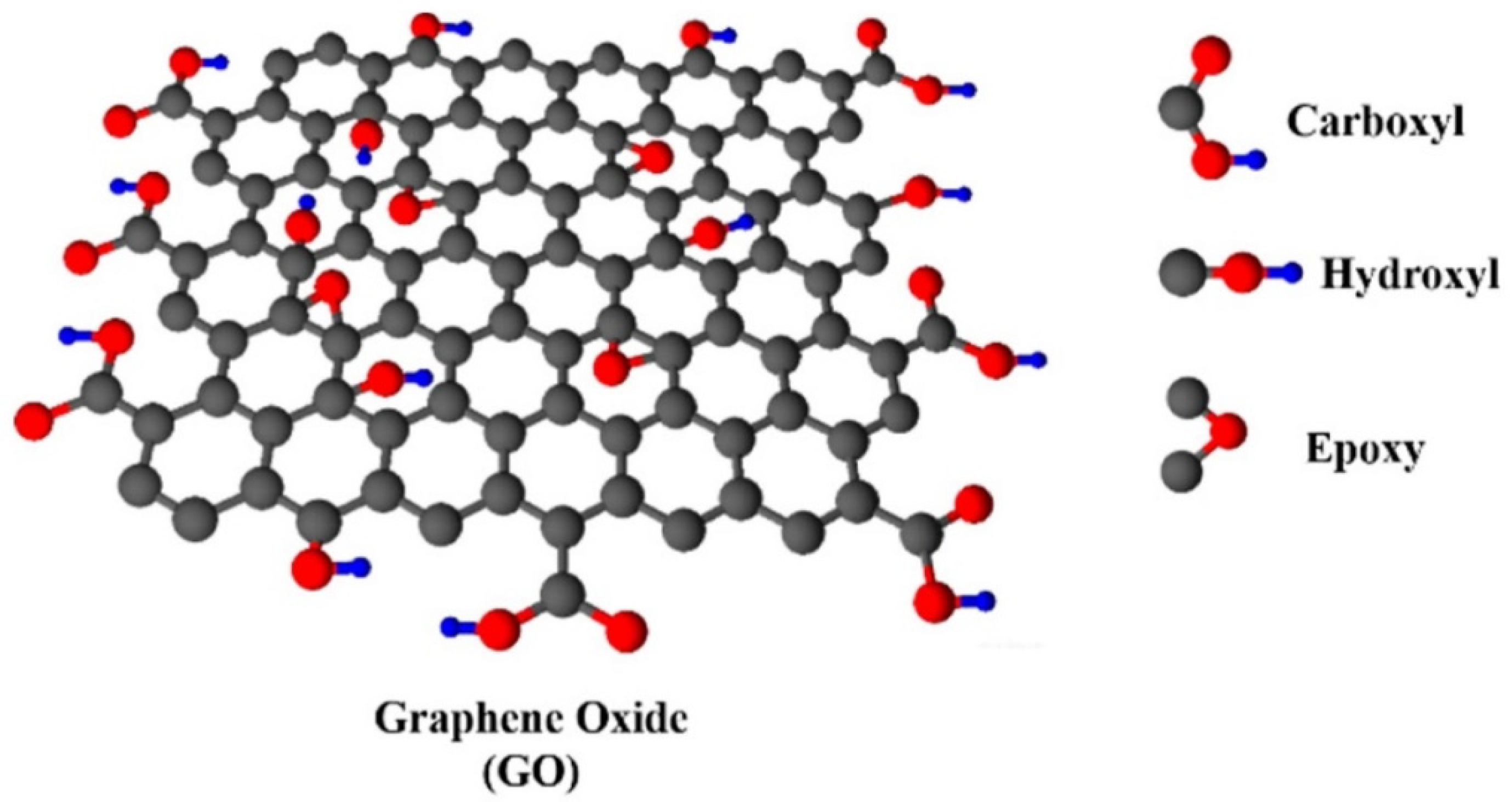

- Li, F.; Jiang, X.; Zhao, J.; Zhang, S. Graphene oxide: A promising Nanomaterial for energy and environmental applications. Nano Energy 2015, 16, 488–515. [Google Scholar] [CrossRef] [Green Version]

- Yao, X.; Niu, X.; Ma, K.; Huang, P.; Grothe, J.; Kaskel, S.; Zhu, Y. Graphene Quantum Dots-Capped Magnetic Mesoporous Silica Nanoparticles as a Multifunctional Platform for Controlled Drug Delivery, Magnetic Hyperthermia and Photothermal Therapy. Small 2017, 13, 1602225. [Google Scholar]

- Britnell, L.; Gorbachev, R.V.; Jalil, R.; Belle, B.D.; Schedin, F.; Mishchenko, A.; Georgiou, T.; Katsnelson, M.I.; Eaves, L.; Morozov, S.V.; et al. Field-Effect Tunneling Transistor Based on Vertical Graphene Heterostructures. Science 2012, 335, 947–950. [Google Scholar] [CrossRef] [Green Version]

- Britnell, L.; Gorbachev, R.V.; Geim, A.K.; Ponomarenko, L.A.; Mishchenko, A.; Greenaway, M.T.; Fromhold, T.M.; Novoselov, K.S.; Eaves, L. Resonant tunnelling and negative differential conductance in graphene transistors. Nat. Commun. 2013, 4, 1794. [Google Scholar] [CrossRef] [Green Version]

- Singh, A.; Shishodia, M.S. Graphene vs. silica coated refractory nitrides based core-shell nanoparticles for nanoplasmonic sensing. Physica E Low Dimens. Syst. Nanostruct. 2020, 124, 114288. [Google Scholar] [CrossRef]

- Boehm, H.P.; Clauss, A.; Fischer, G.O.; Hofmann, U. The Adsorption Behavior of Very Thin Carbon Films. Z. Anorg. Allg. Chem. 1962, 316, 119–127. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Shang, L.; Bian, T.; Zhang, B.; Zhang, D.; Wu, L.Z.; Tung, C.H.; Yin, Y.; Zhang, T. Graphene-supported ultrafine metal nanoparticles encapsulated by mesoporous silica: Robust catalysts for oxidation and reduction reactions. Angew. Chem. Int. Ed. Engl. 2014, 53, 250–254. [Google Scholar] [CrossRef]

- Bhuyan, M.d.S.A.; Uddin, M.d.N.; Islam, M.d.M.; Bipasha, F.A.; Hossain, S.S. Synthesis of graphene. Int. Nano Lett. 2016, 6, 65–83. [Google Scholar] [CrossRef] [Green Version]

- Britnell, L.; Ribeiro, R.M.; Eckmann, A.; Jalil, R.; Belle, B.D.; Mishchenko, A.; Kim, Y.-J.; Gorbachev, R.V.; Georgiou, T.; Morozov, S.V.; et al. Strong Light Matter Interactions in Heterostructures of Atomically Thin Films. Science 2013, 340, 1311–1314. [Google Scholar] [CrossRef] [Green Version]

- Stoller, M.D.; Park, S.; Zhu, Y.; An, J.; Ruoff, R.S. Graphene-Based Ultracapacitors. Nano Lett. 2008, 8, 3498–3502. [Google Scholar] [CrossRef]

- Gong, Y.; Lin, J.; Wang, X.; Shi, G.; Lei, S.; Lin, Z.; Zou, X.; Ye, G.; Vajtai, R.; Yakobson, B.I.; et al. Vertical and in-plane heterostructures from WS2/MoS2 monolayers. Nat. Mater. 2014, 13, 1135–1142. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Eizenberg, M.; Blakely, J.M. Carbon interaction with nickel surfaces: Monolayer formation and structural stability. J. Chem. Phys. 1979, 71, 3467–3477. [Google Scholar] [CrossRef]

- Lang, B.A. LEED study of the deposition of carbon on platinum crystal surfaces. Surf. Sci. 1975, 53, 317–329. [Google Scholar] [CrossRef]

- Morozov, S.V.; Novoselov, K.S.; Katsnelson, M.I.; Schedin, F.; Elias, D.C.; Jaszczak, J.A.; Geim, A.K. Giant Intrinsic Carrier Mobilities in Graphene and Its Bilayer. Phys. Rev. Lett. 2008, 100, 016602. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, C.; Wei, X.D.; Kysar, J.W.; Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385–3858. [Google Scholar] [CrossRef] [PubMed]

- Balandin, A.A.; Ghosh, S.; Bao, W.Z.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior Thermal Conductivity of Single-Layer Graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, S.; Calizo, I.; Teweldebrhan, D.; Pokatilov, E.P.; Nika, D.L.; Balandin, A.A.; Bao, W.; Miao, F.; Lau, C.N. Extremely high thermal conductivity of graphene: Prospects for thermal management applications in nanoelectronic circuits. Appl. Phys. Lett. 2008, 92, 151911. [Google Scholar] [CrossRef] [Green Version]

- Feng, W.; Long, P.; Feng, Y.; Li, Y. Two-dimensional fluorinated graphene: Synthesis, structures, properties and applications. Adv. Sci. 2016, 3, 1500413. [Google Scholar] [CrossRef]

- Ponomarenko, L.A.; Geim, A.K.; Zhukov, A.A.; Jalil, R.; Morozov, S.V.; Novoselov, K.S.; Grigorieva, I.V.; Hill, E.H.; Cheianov, V.V.; Fal’ko, V.I.; et al. Tunable metal–insulator transition in double-layer graphene heterostructures. Nat. Phys. 2011, 7, 958–961. [Google Scholar] [CrossRef]

- Eizenberg, M.; Blakely, J.M. Carbon monolayer phase condensation on Ni(111). Surf. Sci. 1979, 82, 228–236. [Google Scholar] [CrossRef]

- Jirickova, A.; Jankovsky, O.; Sofer, Z.; Sedmidubsky, D. Synthesis and Applications of Graphene Oxide. Materials 2022, 15, 920. [Google Scholar] [CrossRef]

- Kang, J.; Tongay, S.; Zhou, J.; Li, J.; Wu, J. Band offsets and heterostructures of two-dimensional semiconductors. Appl. Phys. Lett. 2013, 102, 012111. [Google Scholar] [CrossRef] [Green Version]

- Vincent, T.; Liang, J.; Singh, S.; Castanon, E.G.; Zhang, X.; McCreary, A.; Jariwala, D.; Kazakova, O.; Al Balushi, Z.Y. Opportunities in electrically tunable 2D materials beyond graphene: Recent progress and future outlook. Appl. Phys. Rev. 2021, 8, 041320. [Google Scholar] [CrossRef]

- Novoselov, K.S. Graphene: Materials in the Flatland. Int. J. Mod. Phys. B 2011, 25, 4081–4106. [Google Scholar] [CrossRef]

- Datye, I.M.; Gabourie, A.J.; English, C.D.; Smithe, K.K.H.; McClellan, C.J.; Wang, N.C.; Pop, E. Reduction of hysteresis in MoS2 transistors using pulsed voltage measurements. 2D Mater. 2019, 6, 011004. [Google Scholar] [CrossRef]

- Antonova, I.V. Vertical heterostructures based on graphene and other 2D materials. Semiconductors 2016, 50, 66–82. [Google Scholar] [CrossRef]

- Fiori, G.; Bruzzone, S.; Iannaccone, G. Very Large Current Modulation in Vertical Heterostructure Graphene/hBN Transistors. IEEE Trans. Electron Devices 2013, 60, 268–273. [Google Scholar] [CrossRef]

- Stylianakis, M.M.; Viskadouros, G.; Polyzoidis, C.; Veisakis, G.; Kenanakis, G.; Kornilios, N.; Petridis, K.; Kymakis, E. Updating the Role of Reduced Graphene Oxide Ink on Field Emission Devices in Synergy with Charge Transfer Materials. Nanomaterials 2019, 9, 137. [Google Scholar] [CrossRef] [Green Version]

- Fiori, G.; Betti, A.; Bruzzone, S.; Iannaccone, G. Lateral Graphene–hBCN Heterostructures as a Platform for Fully Two-Dimensional Transistors. ACS Nano 2012, 6, 2642–2648. [Google Scholar] [CrossRef]

- Paussa, A.; Fiori, G.; Palestri, P.; Geromel, M.; Esseni, D.; Iannaccone, G.; Selmi, L. Simulation of the Performance of Graphene FETs With a Semiclassical Model, Including Band-to-Band Tunneling. IEEE Trans. Electron Devices 2014, 61, 1567–1574. [Google Scholar] [CrossRef]

- Georgakilas, V.; Otyepka, M.; Bourlinos, A.B.; Chandra, V.; Kim, N.; Kemp, K.C.; Hobza, P.; Zboril, R.; Kim, K.S. Functionalization of Graphene: Covalent and Non-Covalent Approaches, Derivatives and Applications. Chem. Rev. 2012, 112, 6156–6214. [Google Scholar] [CrossRef]

- Zemtsova, E.G.; Yurchuk, D.V.; Smirnov, V.M. Creation of heterogeneity on the basis of carbide nanostructures in the volume of metal (iron) matrix for regulation of mechanical properties. Mater. Phys. Mech. 2013, 18, 42–52. [Google Scholar]

- Pham, X.H.; Hahm, E.; Kim, H.M.; Son, B.S.; Jo, A.; An, J.; Tran Thi, T.A.; Nguyen, D.Q.; Jun, B.H. Silica-Coated Magnetic Iron Oxide Nanoparticles Grafted onto Graphene Oxide for Protein Isolation. Nanomaterials 2020, 10, 117. [Google Scholar] [CrossRef] [Green Version]

- An, X.; Simmons, T.; Shah, R.; Wolfe, C.; Lewis, K.M.; Washington, M.; Nayak, S.K. Talapatca Si, Ka Si Stable Aqueous Dispersions of Noncovalently Functionalized Graphene from Graphite and their Multifunctional High-Performance Applications. Nano Lett. 2010, 10, 4295–4301. [Google Scholar] [CrossRef] [PubMed]

- Tolochko, O.V.; Koltsova, T.S.; Bobrynina, E.V.; Rudskoy, A.I.; Zemtsova, E.G.; Kirichenko, S.O.; Smirnov, V.M. Conditions for Production of Composite Material Based on Aluminum and Carbon Nanofibers and Its Physic-Mechanical Properties. Nanomaterials 2019, 9, 550. [Google Scholar] [CrossRef] [Green Version]

- Casati, R.; Vedani, M. Metal matrix composites reinforced by nano-particles. a review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef] [Green Version]

- Zemtsova, E.G.; Morozov, P.E.; Semenov, B.N.; Morozov, N.F.; Smirnov, V.M. Chemical Preparation of the Surface of a Porous Nickel Matrix for Conducting the Synthesis of TiC Nanolayer. Russ. J. Gen. Chem. 2019, 89, 169–171. [Google Scholar] [CrossRef]

- Zemtsova, E.G.; Yurchuk, D.V.; Morozov, P.E.; Kudymov, V.K.; Smirnov, V.M. Features of the synthesis of the dispersed TiC phase with nickel nanostructures on the surface to create an aluminum-based metal composite. Nanomaterials 2021, 11, 2499. [Google Scholar] [CrossRef] [PubMed]

- Robertson, D.H.; Brenner, D.W.; Mintmire, J.W. Progress on mechanics of carbon nanotubes and derived materials. Phys. Rev. B 1992, 45, 12592. [Google Scholar]

- Sanchez-Portal, D.; Artacho, E.; Soler, J.M.; Rubio, A.; Ordejón, P. Ab initio structural, elastic and vibrational properties of carbon nanotubes. Phys. Rev. B. 1999, 59, 12678. [Google Scholar]

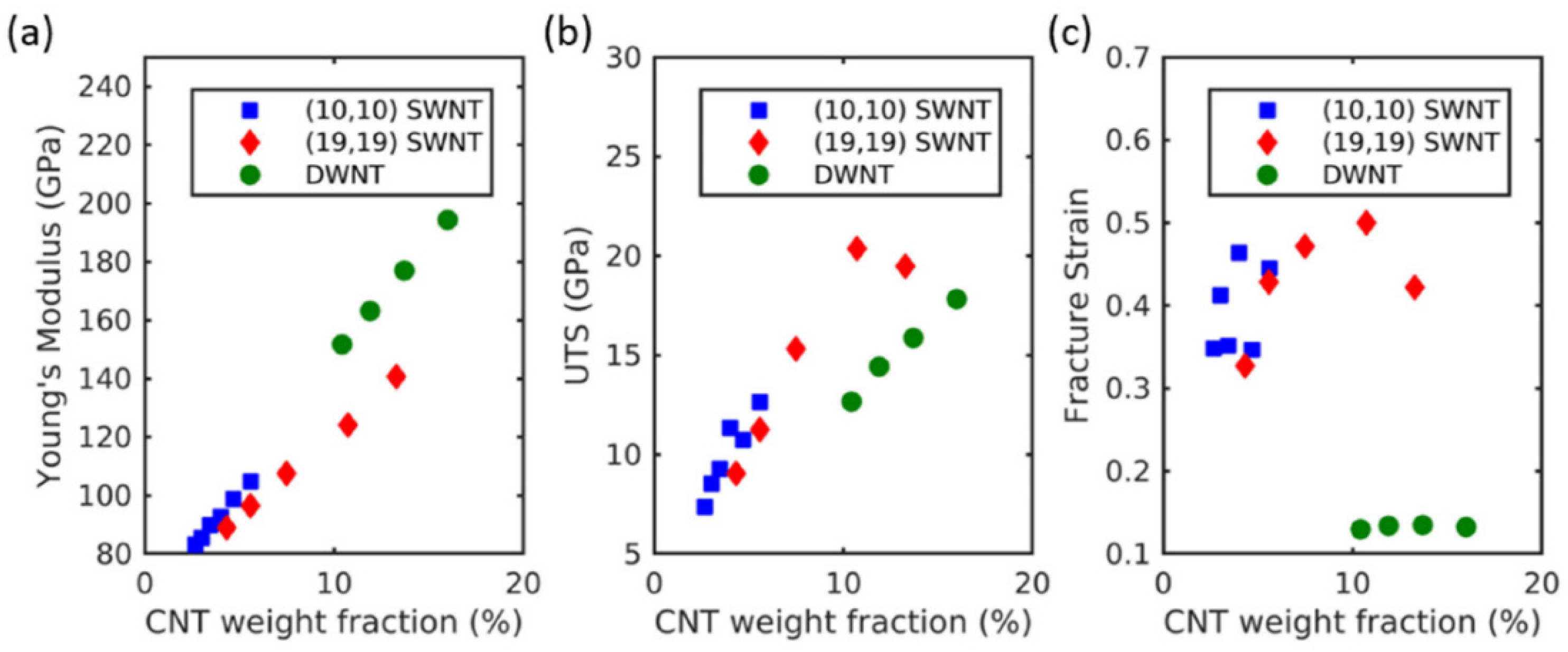

- Suk, M.E. Effect of the Nanotube Radius and the Volume Fraction on the Mechanical Properties of Carbon Nanotube-Reinforced Aluminum Metal Matrix Composites. Molecules 2021, 26, 3947. [Google Scholar] [CrossRef] [PubMed]

- Melezhik, A.V.; Romantsova, I.V.; Dyachkova, T.P.; Bychkov, O.N.; Shlykova, A.; Smykov, M.A.; Tkachev, A.; Golovin, Y. Effect of the Matrix Composition on Activity of Metal Oxide Catalysts in CVD Syntesis of Carbon Nanotubes. Russ. J. Appl. Chem. 2012, 85, 782–787. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Sabaruddin, F.A.; Harussani, M.M.; Kamarudin, S.H.; Rayung, M.; Asyraf, M.R.M.; Aisyah, H.A.; Norrrahim, M.N.F.; Ilyas, R.A.; Abdullah, N.; et al. Mechanical Performance and Applications of CNTs Reinforced Polymer Composites—A Review. Nanomaterials 2021, 11, 2186. [Google Scholar] [CrossRef]

- Khandoker, N.; Hawkins, S.C.; Ibrahim, R.; Huynh, C.P.; Deng, F. Tensile Strength of Spinnable Multiwall Carbon Nanotubes. Procedia Eng. 2011, 10, 2572–2578. [Google Scholar] [CrossRef] [Green Version]

- Fan, M.; Zhao, F.; Liu, Y.; Yin, S.; Peng, S.; Zhang, Z. Zinc Matrix Composites Reinforced with Partially Unzipped Carbon Nanotubes as Biodegradable Implant Materials. Crystals 2022, 12, 1110. [Google Scholar] [CrossRef]

- Rukhov, A.V.; Dyachkova, T.P.; Tugolukov, E.; Besperstova, G. Macrokinetics of carbon nanotubes synthesis by the chemical vapor deposition method. AIP Conf. Proc. 2017, 1899, 020019. [Google Scholar]

- Mwesigye, A.; Yılmaz, İ.H.; Meyer, J.P. Numerical analysis of the thermal and thermodynamic performance of a parabolic trough solar collector using SWCNTs-Therminol®VP-1 nanofluid. Renew. Energy 2018, 119, 844–862. [Google Scholar] [CrossRef] [Green Version]

- Angadi, M.A.; Watanabe, T.; Bodapati, A.; Xiao, X.; Auciello, O.; Carlisle, J.A.; Eastman, J.A.; Keblinski, P.; Schelling, P.K.; Phillpot, S.R. Thermal transport and grain boundary conductance in ultrananocrystalline diamond thin films. J. Appl. Phys. 2006, 99, 114301. [Google Scholar] [CrossRef] [Green Version]

- So, K.P.; Jeong, J.C.; Park, J.G.; Park, H.K.; Choi, Y.H.; Noh, D.H.; Keum, D.H.; Jeong, H.Y.; Biswas, C.; Hong, C.H.; et al. SiC formation on carbon nanotube surface for improving wettability with aluminum. Compos. Sci. Technol. 2013, 74, 6–13. [Google Scholar] [CrossRef]

- Samani, M.K.; Khosravian, N.; Chen, G.C.K.; Shakerzadeh, M.; Baillargeat, D.; Tay, B.K. Thermal conductivity of individual multiwalled carbon nanotubes. Int. J. Therm. Sci. 2012, 62, 40–43. [Google Scholar]

- Rakov, E.G. Nanotubes and Fullerenes, 1st ed.; Logos: Moscow, Russia, 2006; ISBN 5-98699-0009-9. [Google Scholar]

- Moseenkov, S.I.; Kuznetsov, V.L.; Zavorin, A.V.; Golubtsov, G.V.; Ishchenko, A.V.; Serkova, A.N.; Korovin, E.Y.; Suslyaev, V.I.; Sergeenko, D.I.; Velikanov, D.A. Electrophysical properties of composites based on polyethylene modified with multi-walled carbon nanotubes with high content of Fe–Co-catalyst. Russ. J. Appl. Chem. 2020, 93, 586–594. [Google Scholar] [CrossRef]

- Rakov, E.G. Methods for preparation of carbon nanotubes. Russ. Chem. Rev. 2000, 69, 35–52. [Google Scholar] [CrossRef]

- Klimov, E.S.; Buzaeva, M.V.; Davydova, O.A.; Makarova, I.A.; Svetukhin, V.V.; Kozlov, D.V.; Pchelintseva, E.S.; Bunakov, N.A. Some aspects of the synthesis of multi-walled carbon nanotubes by chemical vapor deposition and characteristics of the resulting material. Russ. J. Appl. Chem. 2014, 87, 1128–1132. [Google Scholar] [CrossRef]

- Ob’edkov, A.M.; Kaverin, B.S.; Gusev, S.A.; Ezerskii, A.B.; Semenov, N.M.; Zaytsev, A.A.; Egorov, V.A.; Domrachev, G.A. MOCVD modification of the surface of multiwalled carbon nanotubes to impart to them necessary physicochemical properties. J. Synch. Investig. 2009, 3, 61–66. [Google Scholar] [CrossRef]

- Sun, Y.; Chen, Q. Diameter dependent strength of carbon nanotube reinforced composite. Appl. Phys. Lett. 2009, 95, 021901–021903. [Google Scholar] [CrossRef] [Green Version]

- Bolotov, V.V.; Kan, V.E.; Biryukov, M.Y.; Knyazev, E.V.; Shelyagin, R.V.; Korusenko, P.M.; Nesov, S.N.; Sten’kin, Y.A. Origin of the low-frequency band in Raman spectra of multi-walled carbon nanotubes synthesized by the CVD method. Phys. Solid State 2013, 55, 1459–1462. [Google Scholar] [CrossRef]

- Spitalsky, Z.; Tasis, D.; Papagelis, K.; Galiotis, C. Carbon nanotube–polymer composites: Chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

- Potschke, P.; Fornes, T.D.; Paul, D.R. Rheological behaviour of multiwalled carbon nanotubes/polycarbonate composites. Polymer 2002, 43, 3247–3255. [Google Scholar] [CrossRef]

- Nesov, S.N.; Korusenko, P.M.; Sachkov, V.A.; Bolotov, V.V.; Povoroznyuk, S.N. Effects of preliminary ion beam treatment of carbon nanotubes on structures of interfaces in MOx/multi-walled carbon nanotube (M =Ti,Sn) composites: Experimental and theoretical study. J. Phys. Chem. Solids 2022, 169, 110831. [Google Scholar] [CrossRef]

- Bolotov, V.V.; Nesov, S.N.; Korusenko, P.M.; Povoroznyuk, S.N. Transformation of the electronic structure of the SnO2 − x /MWCNT nanocomposite under high-vacuum annealing conditions. Phys. Solid State 2014, 56, 1899–1903. [Google Scholar] [CrossRef]

- Jiang, L.; Li, Z.; Fan, G.; Cao, L.; Zhang, D. The use of flake powder metallurgy to produce carbon nanotube (CNT)/aluminum composites with a homogenous CNT distribution. Carbon 2012, 50, 1993–1998. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Xiao, B.L.; Wang, W.G.; Ma, Z.Y. Developing high-performance aluminum matrix composites with directionally aligned carbon nanotubes by combining friction stir processing and subsequent rolling. Carbon 2013, 62, 35–42. [Google Scholar] [CrossRef]

- Zhang, T.; Kumari, L.; Du, G.H.; Li, W.Z.; Wang, Q.W.; Balani, K.; Agarwal, A. Mechanical properties of carbon nanotube-alumina nanocomposites synthesized by chemical vapor deposition and spark plasma sintering. Compos. Part A Appl. Sci. Manuf. 2009, 40, 86–93. [Google Scholar] [CrossRef]

- Zhu, X.; Zhao, Y.-G.; Wu, M.; Wang, H.-Y.; Jiang, Q.-C. Fabrication of 2014 aluminum matrix composites reinforced with untreated and carboxyl-functionalized carbon nanotubes. J. Alloys Compd. 2016, 674, 145–152. [Google Scholar] [CrossRef]

- Abu Al-Rub, R.K.; Ashour, A.I.; Tyson, B.M. On the Aspect Ratio Effect of Multi-Walled Carbon Nanotube Reinforcements on the Mechanical Properties of Cementitious Nanocomposites. Constr. Build Mater. 2012, 35, 647–655. [Google Scholar] [CrossRef]

- Arsecularatne, J.A.; Zhang, L.C. Carbon Nanotube Reinforced Ceramic Composites and their Performance. Recent Pat. Nanotechnol. 2007, 1, 176–185. [Google Scholar]

- Klimov, E.S.; Buzaeva, M.V.; Davydova, O.A.; Isaev, A.V.; Nishchev, K.N.; Pynenkov, A.A.; Kalashnikov, E.G.; Fomin, A.N.; Svetukhin, V.V. Changing the surface and properties of multi-walled carbon nanotubes during physico-chemical modification. Russ. J. Appl. Chem. 2015, 88, 1105–1110. [Google Scholar] [CrossRef]

- Datsyuk, V.; Kalyva, M.; Papagelis, K.; Parthenios, J.; Tasis, D.; Siokou, A.; Kallitsis, I.; Galiotis, C. Chemical Oxidation of Multiwalled Carbon Nanotubes. Carbon 2008, 46, 833–840. [Google Scholar]

- Mazov, I.; Kuznetsov, V.L.; Simonova, I.A.; Stadnichenko, A.I.; Ishchenko, A.V.; Romanenko, A.I.; Tkachev, E.N.; Anikeeva, O.B. Oxidation Behavior of Multiwall Carbon Nanotubes with Different Diameters and Morphology. Appl. Surf. Sci. 2012, 258, 6272–6280. [Google Scholar]

- Kobets, A.A.; Iurchenkova, A.A.; Asanov, I.P.; Okotrub, A.V.; Fedorovskaya, E.O. Redox Processes in Reduced Graphite Oxide Decorated by Carboxyl Functional Groups. Phys. Status Solidi B 2019, 256, 1800700. [Google Scholar] [CrossRef]

- Rasheed, A.; Howe, J.Y.; Dadmun, M.D.; Britt, P.F. The Efficiency of the Oxidation of Carbon Nanofibers with Various Oxidizing Agents. Carbon 2007, 45, 1072–1080. [Google Scholar]

- Worsley, K.A.; Kalinina, I.; Bekyarova, E.; Haddon, R.C. Functionalization and Dissolution of Nitric Acid Treated Single-Walled Carbon Nanotubes. J. Am. Chem. Soc. 2009, 131, 18153–18158. [Google Scholar]

- Deng, C.F.; Wang, D.Z.; Zhang, X.X.; Ma, Y.X. Damping Characteristics of Carbon Nanotube Reinforced Aluminum Composite. Mater. Lett. 2007, 61, 3229–3231. [Google Scholar] [CrossRef]

- Jafari, M.; Abbasi, M.H.; Enayati, M.H.; Karimzadeh, F. Mechanical Properties of Nanostructured Al2024–MWCNT Composite Prepared by Optimized Mechanical Milling and Hot Pressing Methods. Adv. Powder Technol. 2012, 23, 205–210. [Google Scholar] [CrossRef]

- Rino, J.J.; Chandramohan, D.; Sucitharan, K.S. An overview on development of aluminium metal matrix composites with hybrid reinforcement. IJSR 2012, 1, 196–203. [Google Scholar]

- Song, S.; Billah, M.; Zhou, Q.; Ren, L.; Zheng, L.; Chen, Q.; Bai, Y. Study on Plastic Strengthening Mechanisms of Aluminum Matrix Nano-Composites Reinforced by Nickel Coated CNTs. Compos. Interfaces 2020, 28, 1015–1036. [Google Scholar] [CrossRef]

- Kondoh, K.; Threrujirapapong, T.; Imai, H.; Umeda, J.; Fugetsu, B. Characteristics of powder metallurgy pure titanium matrix composite reinforced with multi-wall carbon nanotubes. Compos. Sci. Technol. 2009, 69, 1077–1081. [Google Scholar] [CrossRef]

- Saravanan, C.; Subramanian, K.; Krishnan, V.A.; Narayanan, R.S. Effect of particulate reinforced aluminium metal matrix composite–a review. Mech. Mech. Eng. 2015, 19, 23–30. [Google Scholar]

- Kwon, H.; Estili, M.; Takagi, K.; Miyazaki, T.; Kawasaki, A. Combination of hot extrusion and spark plasma sintering or producing carbon nanotube reinforced aluminum matrix composites. Carbon 2009, 47, 570–577. [Google Scholar] [CrossRef]

- Maxwell, A.J. Electronic and geometric structure of C60 and Al 111 and Al 110. Phys. Rev. B. 1998, 57, 7312–7326. [Google Scholar]

- Kim, K.T.; Cha, S.I.; Gemming, T. The role of interfacial oxygen atoms in the enhanced mechanical properties of carbon nanotube reinforced metal matrix nanocomposites. Small 2008, 4, 1936–1940. [Google Scholar]

- Park, M.; Kim, B.-H.; Kim, S. Improved binding between copper and carbon nanotubes in a composite using oxygen-cantaining functional groups. Carbon 2011, 49, 811–818. [Google Scholar]

- Bittencourt, C.; Ke, X.; Tendeloo, G.V.; Thiess, S.; Drube, W.; Ghijsen, J.; Ewels, C.P. Study of the interaction between copper and carbon nanotubes. Chem. Phys. Lett. 2012, 535, 80–83. [Google Scholar]

- Katin, K.P.; Kaya, S.; Maslov, M.M. Graphene nanoflakes and fullerenes doped with aluminum: Features of Al-C interaction and adsorption characteristics of carbon shell. Lett. Mater. 2022, 12, 148–152. [Google Scholar] [CrossRef]

- Aditya, I.D.; Matsunaka, D.; Shibutani, Y.; Yamamoto, G. First-principles study of interfacial interaction between carbon nanotube and Al2O3(0001). J. Appl. Phys. 2017, 121, 025304. [Google Scholar] [CrossRef]

- Deng, C.F.; Wang, D.Z.; Zhang, X.X.; Li, A.B. Processing and properties of carbon nanotubes reinforced aluminum composites. Mater. Sci. Eng. A 2007, 444, 138–145. [Google Scholar] [CrossRef]

- Ci, L.; Ryu, Z.; Yun Jin-Phillipp, N.; Rühle, M. Investigation of the interfacial reaction between multi-walled carbon nanotubes and aluminum. Acta Mater. 2006, 54, 5367–5375. [Google Scholar]

- Kwon, H.; Kawasaki, A. Chapter 7—Effесt оf Sраrk Plаsmа Sintеring in Fаbriсаting Cаrbоn Nаnоtubе Rеinfоrсеd Аluminum Mаtrix Cоmроsitе Mаtеriаls. In Аdvаnсеs in Cоmроsitе Mаtеriаls fоr Mеdiсinе аnd Nаnоtесhnоlоgy; Attaf, B., Ed.; IntechOpen Limited: London, UK, 2011; pp. 431–444. [Google Scholar]

- Shadakshari, R.; Mahesha, K.; Niranjan, H.B. Carbon Nanotube Reinforced Aluminium Matrix Composites–A Review. IJIRSET 2012, 1, 206–2013. [Google Scholar]

- Zhou, W.; Bang, S.; Kurita, H.; Miyazaki, T.; Fan, Y.; Kawasaki, A. Interface and interfacial reactions in multi-walled carbon nanotube reinforced aluminum matrix composites. Carbon 2016, 96, 919–928. [Google Scholar]

- Rudskoy, A.I.; Koltsova, T.S.; Shakhov, F.M.; Tolochko, O.V.; Mikhailov, V.G. Effect of hot pressing modes on the structure and properties of an ‘aluminum–carbon nanofibers’ composite material. Met. Sci. Heat Treat. 2015, 56, 525–530. [Google Scholar] [CrossRef]

- Yang, X.; Liu, E.; Shi, C.; He, C.; Li, J.; Zhao, N.; Kondoh, K. Fabrication of carbon nanotube reinforced Al composites with well-balanced strength and ductility. J. Alloys Compd. 2013, 563, 216–220. [Google Scholar] [CrossRef]

- He, C.; Zhao, N.; Shi, C.; Du, X.; Li, J.; Li, H.; Cui, Q. An approach to obtaining homogeneously dispersed carbon nanotubes in Al powders for preparing reinforced Al-matrix composites. Adv.Mater. 2007, 19, 1128–1132. [Google Scholar]

- Liao, J.Z.; Tan, M.J.; Sridhar, I. Sраrk рlаsmа sintеrеd multi-wаll саrbоn nаnоtubе rеinfоrсеd аluminum mаtrix соmроsitеs. Mater. Des. 2009, 31, 96–100. [Google Scholar]

- Feng, Y.; Yuan, H.L.; Zhang, M. Fаbriсаtiоn аnd рrореrtiеs оf silvеrmаtrix соmроsitеs rеinfоrсеd by саrbоn nаnоtubеs. Mater. Char. 2005, 55, 211–218. [Google Scholar]

- Zhong, R.; Cong, H.; Hou, P. Fаbriсаtiоn оf nаnо-Аl bаsеd соmроsitеs rеinfоrсеd by singlе-wаllеd саrbоn nаnоtubеs. Carbon 2003, 41, 848–851. [Google Scholar]

- Liu, Z.Y.; Xu, S.J.; Xiao, B.L.; Xue, P.; Wang, W.G.; Ma, Z.Y. Effесt оf bаll-milling timе оn mесhаniсаl рrореrtiеs оf саrbоn nаnоtubеs rеinfоrсеd аluminum mаtrix соmроsitеs. Compos. Part A Appl. Sci. Manuf. 2012, 43, 2161–2168. [Google Scholar] [CrossRef]

- Pеrеz-Bustаmаntе, R.; Gómez-Esparza, C.D.; Estrada-Guel, I.; Miki-Yoshida, M.; Licea-Jiménez, L.; Pérez-García, S.A.; Martínez-Sánchez, R. Miсrоstruсturаl аnd mесhаniсаl сhаrасtеrizаtiоn оf Аl-MWCNT соmроsitеs рrоduсеd by mесhаniсаl milling. Mater. Sci. Eng. A 2009, 502, 159–163. [Google Scholar]

- Liao, J.Z.; Tan, M.J.; Sridhar, I. Spark Plasma Sintered Multi-Wall Carbon Nanotube Reinforced Aluminum Matrix Composites. Mater. Des. 2010, 31, 96–100. [Google Scholar] [CrossRef]

- Suarez, M.; Fernández, A.; Menéndez, J.L.; Torrecillas, R.; Kessel, H.U.; Hennicke, J.; Kirchner, R.; Kessel, T. Chapter 13—Chаllеngеs аnd Oрроrtunitiеs fоr Sраrk Plаsmа Sintеring: А Kеy Tесhnоlоgy fоr а Nеw Gеnеrаtiоn оf Mаtеriаls. In Sintering Applications; Ertug, B., Ed.; IntechOpen Limited: London, UK, 2013; pp. 319–342. [Google Scholar]

- Nisar, A.; Zhang, C.; Boesl, B.; Agarwal, A. Unconventional Materials Processing Using Spark Plasma Sintering. Ceramics 2021, 4, 20–39. [Google Scholar] [CrossRef]

- Carneiro, Í.; Fernandes, J.V.; Simões, S. Strengthening Mechanisms of Aluminum Matrix Nanocomposites Reinforced with CNTs Produced by Powder Metallurgy. Metals 2021, 11, 1711. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Agarwal, A. An Analysis of the Factors Affecting Strengthening in Carbon Nanotube Reinforced Aluminum Composites. Carbon 2011, 49, 533–544. [Google Scholar] [CrossRef]

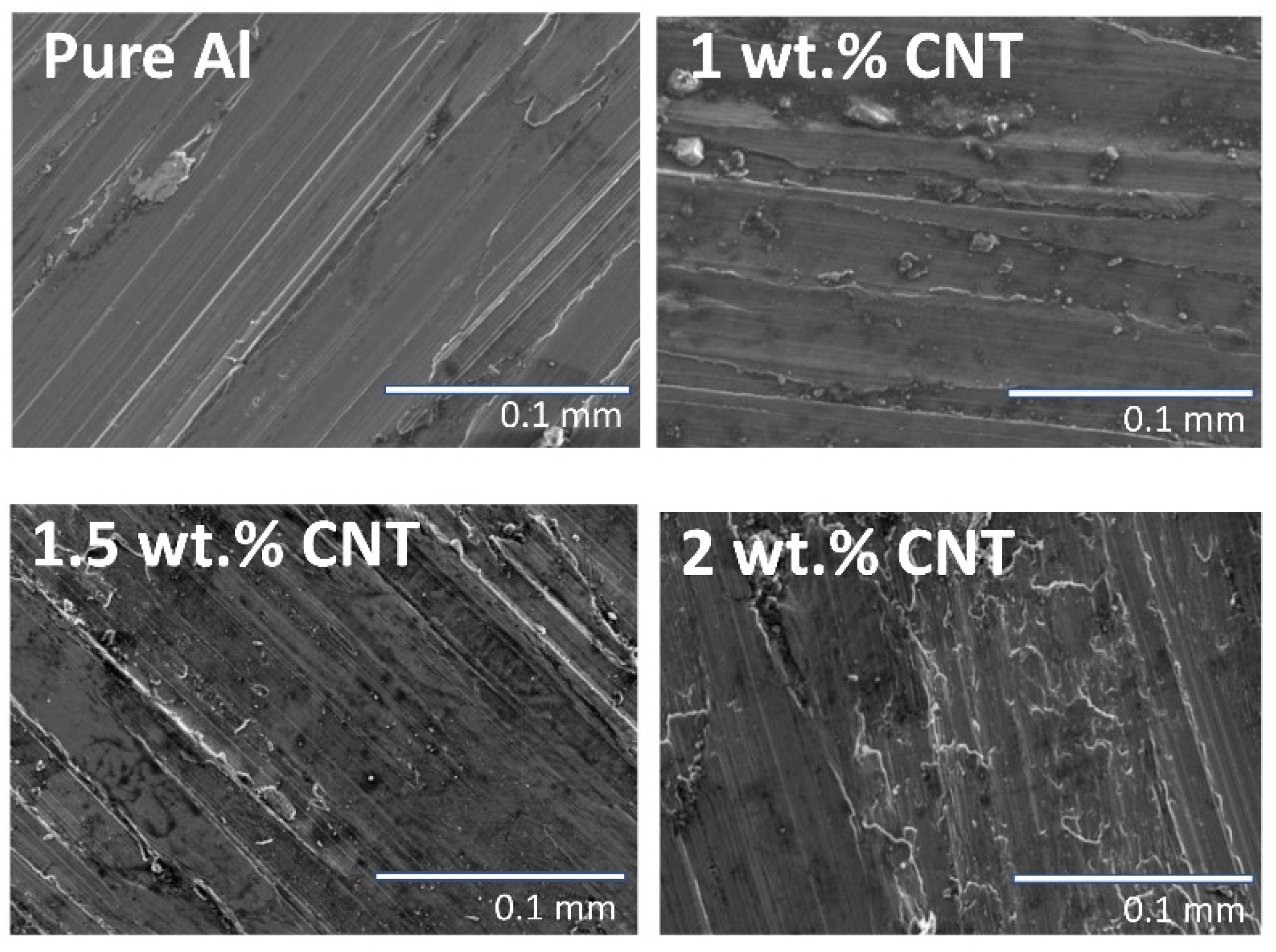

- Padmavathia, K.R.; Ramakrishnan, R. Tribological Behaviour of Aluminium Hybrid Metal Matrix Composite. Procedia Eng. 2014, 97, 660–667. [Google Scholar] [CrossRef] [Green Version]

- Razzaq, A.M.; Majid, D.L.; Basheer, U.M.; Aljibori, H.S.S. Research Summary on the Processing, Mechanical and Tribological Properties of Aluminium Matrix Composites as Effected by Fly Ash Reinforcement. Crystals 2021, 11, 1212. [Google Scholar] [CrossRef]

- Evdokimov, I.A.; Chernyshova, T.A.; Pivovarov, G.I.; Bykov, P.A.; Ivanov, L.A.; Vaganov, V.E. Tribological behavior of aluminum-matrix composites reinforced with carbon nanostructures. Inorg. Mater. Appl. Res. 2014, 5, 255–262. [Google Scholar] [CrossRef]

- Srinivasan, R.; Shivananad, H.K. Studies on Tribological characterization of Carbon Nanotube reinforced with 6061 Aluminium Alloy Metal Matrix Composites coated with Nickel. Int. J. Appl. Eng. Res. 2019, 14, 3721–3729. [Google Scholar]

- Kumar, H.G.P.; Xavior, M.A. Chapter 7—Tribological Aspects of Graphene-Aluminum Nanocomposites. In Book Graphene Materials-Structure, Properties and Modifications, 2nd ed.; Kyzas, G., Mitropoulos, A., Eds.; IntechOpen Limited: London, UK, 2017; pp. 154–173. [Google Scholar]

- Nasiri, S.; Wang, K.; Yang, M.; Li, Q.; Zaiser, M. Nickel coated carbon nanotubes in aluminum matrix composites: A multiscale simulation study. Eur. Phys. J. B 2019, 92, 186. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.; Song, S.; Li, L.; Zhang, R. Molecular dynamics simulation for mechanical properties of magnesium matrix composites reinforced with nickel-coated single-walled carbon nanotube. J. Compos. Mater. 2016, 50, 191–200. [Google Scholar] [CrossRef]

- Kun, X.; Guopeng, Z.; Hai, H.; Jianjian, Z.; Zhongxia, L.; Bin, C. Investigation of the main strengthening mechanism of carbon nanotube reinforced aluminum composites. Mater. Sci. Eng. A 2021, 804, 140780. [Google Scholar]

- Xu, R.; Tan, Z.; Fan, G.; Ji, G.; Li, Z.; Guo, Q.; Li, Z.; Zhang, D. Microstructure-based modeling on structure-mechanical property relationships in carbon nanotube/aluminum composites. Int. J. Plasticity 2019, 120, 278–295. [Google Scholar] [CrossRef]

- Dong, S.; Zhou, J.; Hui, D.; Pang, X.; Wang, Q.; Zhang, S.; Wang, L. Interaction between edge dislocations and amorphous interphase in carbon nanotubes reinforced metal matrix nanocomposites incorporating interface effect. Int. J. Solids Struct. 2014, 51, 1149–1163. [Google Scholar] [CrossRef] [Green Version]

- Sahoo, B.P.; Das, D.; Chaubey, A.K. Strengthening mechanisms and modelling of mechanical properties of submicron-TiB2 particulate reinforced Al 7075 metal matrix composites. Mater. Sci. Eng. A 2021, 825, 141873. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Xiao, B.L.; Wang, W.G.; Ma, Z.Y. Modelling of carbon nanotube dispersion and strengthening mechanisms in Al matrix composites prepared by high energy ball milling-powder metallurgy method. Compos. Part A Appl. Sci. Manuf. 2017, 94, 189–198. [Google Scholar] [CrossRef]

- Dong, S.; Zhou, J.; Hui, D.; Wang, Y.; Zhang, S. Size dependent strengthening mechanisms in carbon nanotube reinforced metal matrix composites. Compos. Part A Appl. Sci. Manuf. 2015, 68, 356–364. [Google Scholar] [CrossRef]

- Chen, B.; Shen, J.; Ye, X.; Jia, L.; Li, S.; Umeda, J.; Takahashi, M.; Kondoh, K. Length Effect of Carbon Nanotubes on the Strengthening Mechanisms in Metal Matrix Composites. Acta Mater. 2017, 140, 317–325. [Google Scholar] [CrossRef]

- Zeeshan, B.; Othman, M.; Mazli, M. Recent Progress on the Dispersion and the Strengthening Effect of Carbon Nanotubes and Graphene- Reinforced Metal Nanocomposites: A Review. Crit Rev Solid State 2018, 43, 1–46. [Google Scholar]

- Zhou, M.Y.; Ren, L.B.; Fan, L.L.; Tun, K.S.; Gupta, M.; Zhang, Y.W.X.; Lu, T.H.; Quan, G.F. Achieving ultra-high strength and good ductility in AZ61 alloy composites containing hybrid micron SiC and carbon nanotubes reinforcements. Mater. Sci. Eng. A 2019, 768, 138447. [Google Scholar] [CrossRef]

- Choi, B.K.; Yoon, G.H.; Lee, S. Molecular dynamics studies of CNT-reinforced aluminum composites under uniaxial tensile loading. Compos. Part B-Eng. 2016, 91, 119–125. [Google Scholar] [CrossRef]

- Meguid, S.A.; Al Jahwari, F. Modeling the pullout test of nanoreinforced metallic matrices using molecular dynamics. Acta Mech. 2014, 225, 1267–1275. [Google Scholar] [CrossRef]

- Zhang, J.F.; Zhang, X.X.; Wang, Q.Z.; Xiao, B.L.; Ma, Z.Y. Simulations of deformation and damage processes of SiCp/Al composites during tension. J. Mater. Sci. Technol. 2018, 34, 627–634. [Google Scholar] [CrossRef]

- Jagannatham, M.; Chandran, P.; Sankaran, S.; Haridoss, P.; Nayan, N.; Bakshi, S.R. Tensile properties of carbon nanotubes reinforced aluminum matrix composites: A review. Carbon 2020, 160, 14–44. [Google Scholar] [CrossRef]

- Ahmadi, M.; Ansari, R.; Hassanzadeh-Aghdam, M.K. Micromechanical analysis of elastic modulus of carbon nanotube-aluminum nanocomposites with random microstructures. J. Alloys Compd. 2019, 779, 433–439. [Google Scholar] [CrossRef]

- Pérez, L.; Cabrera, I.; Santiago, A.A.; Vargas, J.; Beltrán, A.; Alfonso, I. Effect of the Al-CNT interlayer on the tensile elastic modulus of Al matrix composites with random dispersion of CNTs. J. Braz. Soc. Mech. Sci. 2018, 40, 550. [Google Scholar] [CrossRef]

- Dong, S.; Zhou, J.; Liu, H.; Qi, D. Computational prediction of waviness and orientation effects in carbon nanotube reinforced metal matrix composites. Comp. Mater. Sci. 2015, 101, 8–15. [Google Scholar] [CrossRef]

- Su, Y.; Li, Z.; Jiang, L.; Gong, X.; Fan, G.; Zhang, D. Computational structural modeling and mechanical behavior of carbon nanotube reinforced aluminum matrix composites. Mater. Sci. Eng. A 2014, 614, 273–283. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zemtsova, E.G.; Arbenin, A.Y.; Sidorov, Y.V.; Morozov, N.F.; Korusenko, P.M.; Semenov, B.N.; Smirnov, V.M. The Use of Carbon-Containing Compounds to Prepare Functional and Structural Composite Materials: A Review. Appl. Sci. 2022, 12, 9945. https://doi.org/10.3390/app12199945

Zemtsova EG, Arbenin AY, Sidorov YV, Morozov NF, Korusenko PM, Semenov BN, Smirnov VM. The Use of Carbon-Containing Compounds to Prepare Functional and Structural Composite Materials: A Review. Applied Sciences. 2022; 12(19):9945. https://doi.org/10.3390/app12199945

Chicago/Turabian StyleZemtsova, Elena G., Andrey Yu. Arbenin, Yuri V. Sidorov, Nikita F. Morozov, Petr M. Korusenko, Boris N. Semenov, and Vladimir M. Smirnov. 2022. "The Use of Carbon-Containing Compounds to Prepare Functional and Structural Composite Materials: A Review" Applied Sciences 12, no. 19: 9945. https://doi.org/10.3390/app12199945

APA StyleZemtsova, E. G., Arbenin, A. Y., Sidorov, Y. V., Morozov, N. F., Korusenko, P. M., Semenov, B. N., & Smirnov, V. M. (2022). The Use of Carbon-Containing Compounds to Prepare Functional and Structural Composite Materials: A Review. Applied Sciences, 12(19), 9945. https://doi.org/10.3390/app12199945