Research on Design Method of Product Functional Hybridization for Integrated Innovation

Abstract

1. Introduction

2. Related Research

2.1. Product Hybridization Design

2.2. Functional Integration

2.3. Product Gene

2.4. Summary of the Literature Review

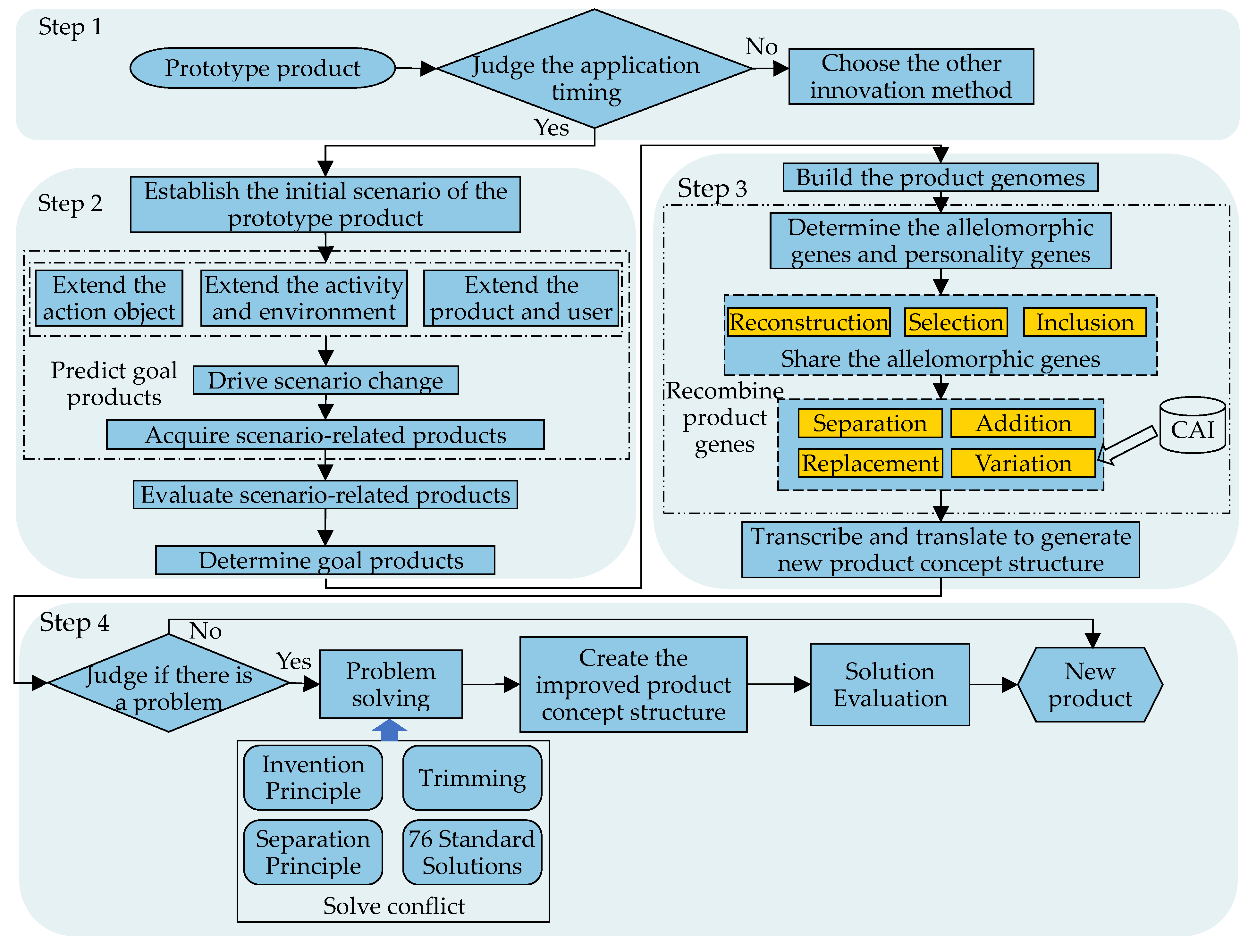

3. Proposed Methods

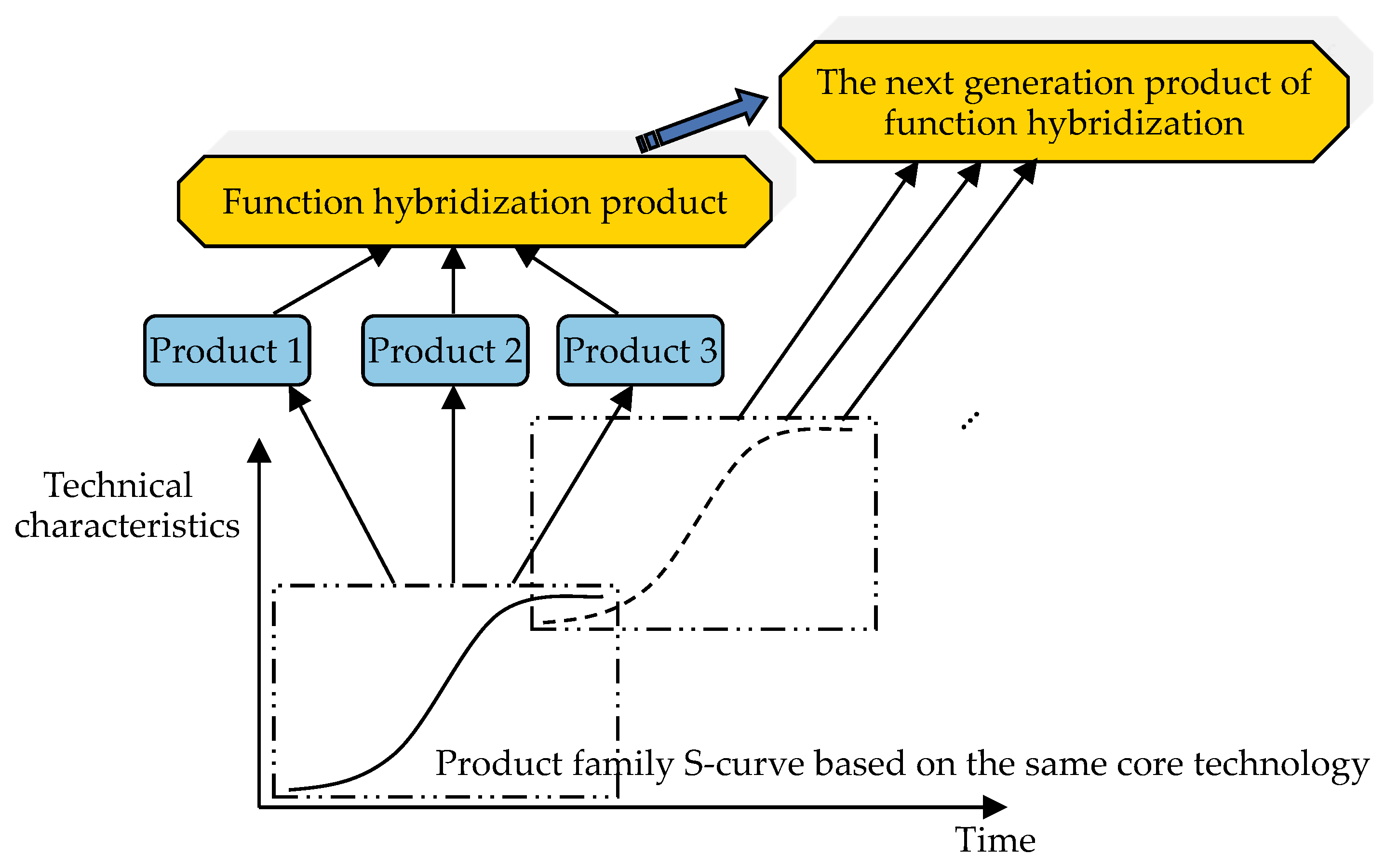

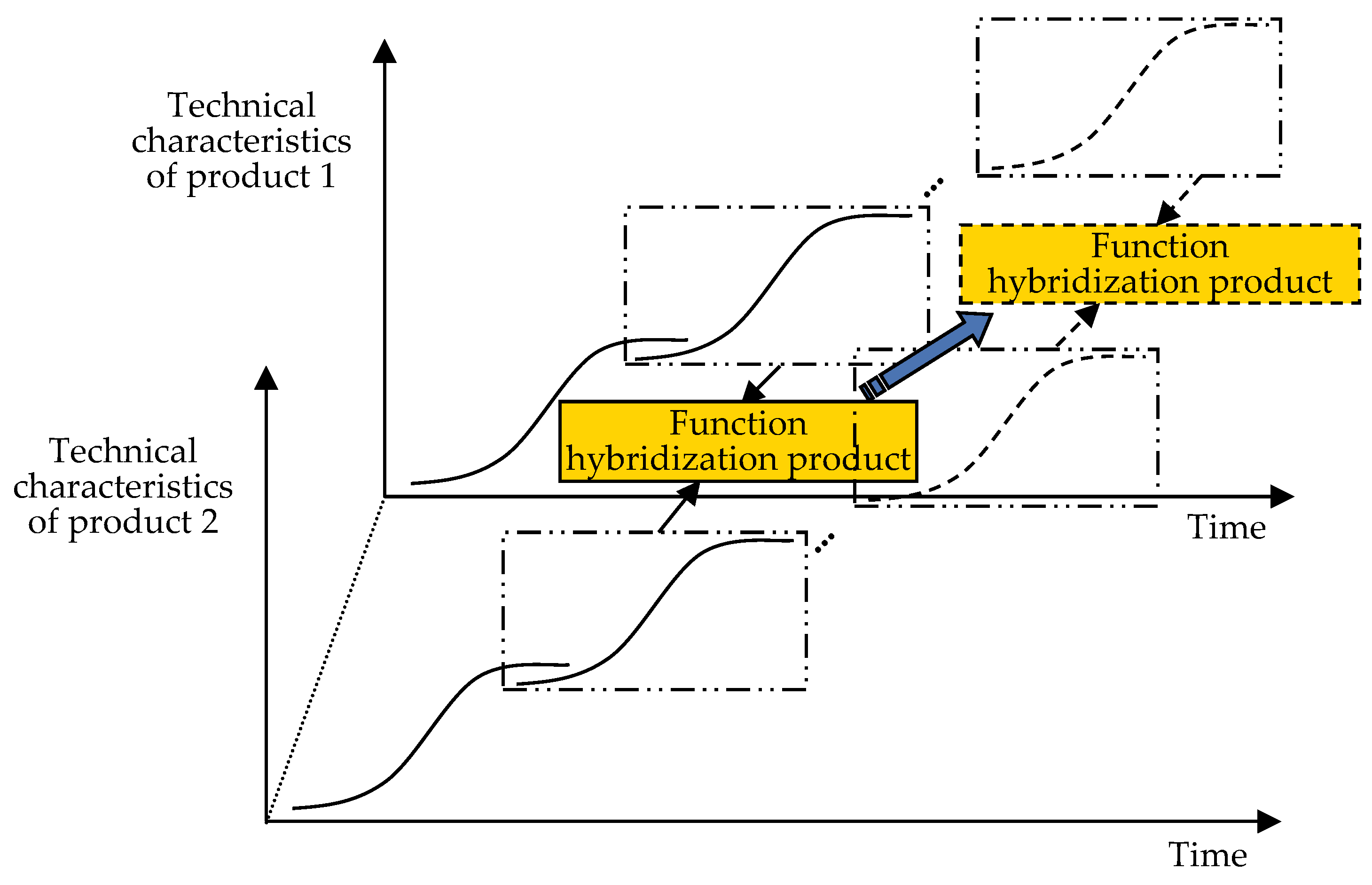

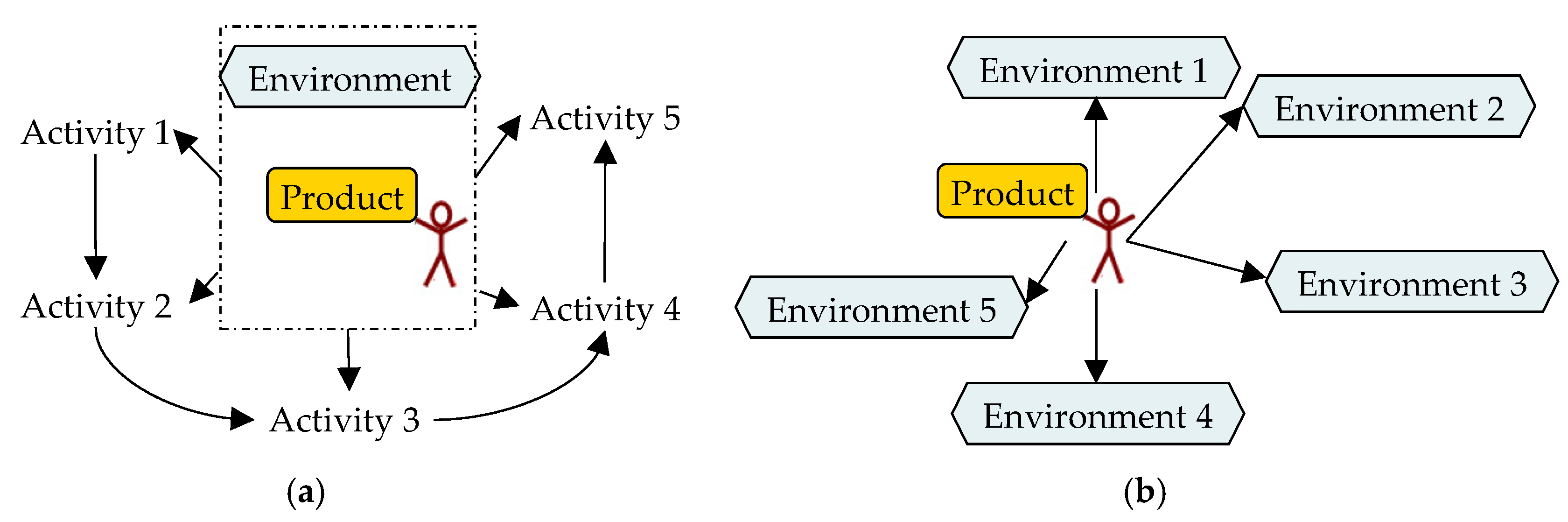

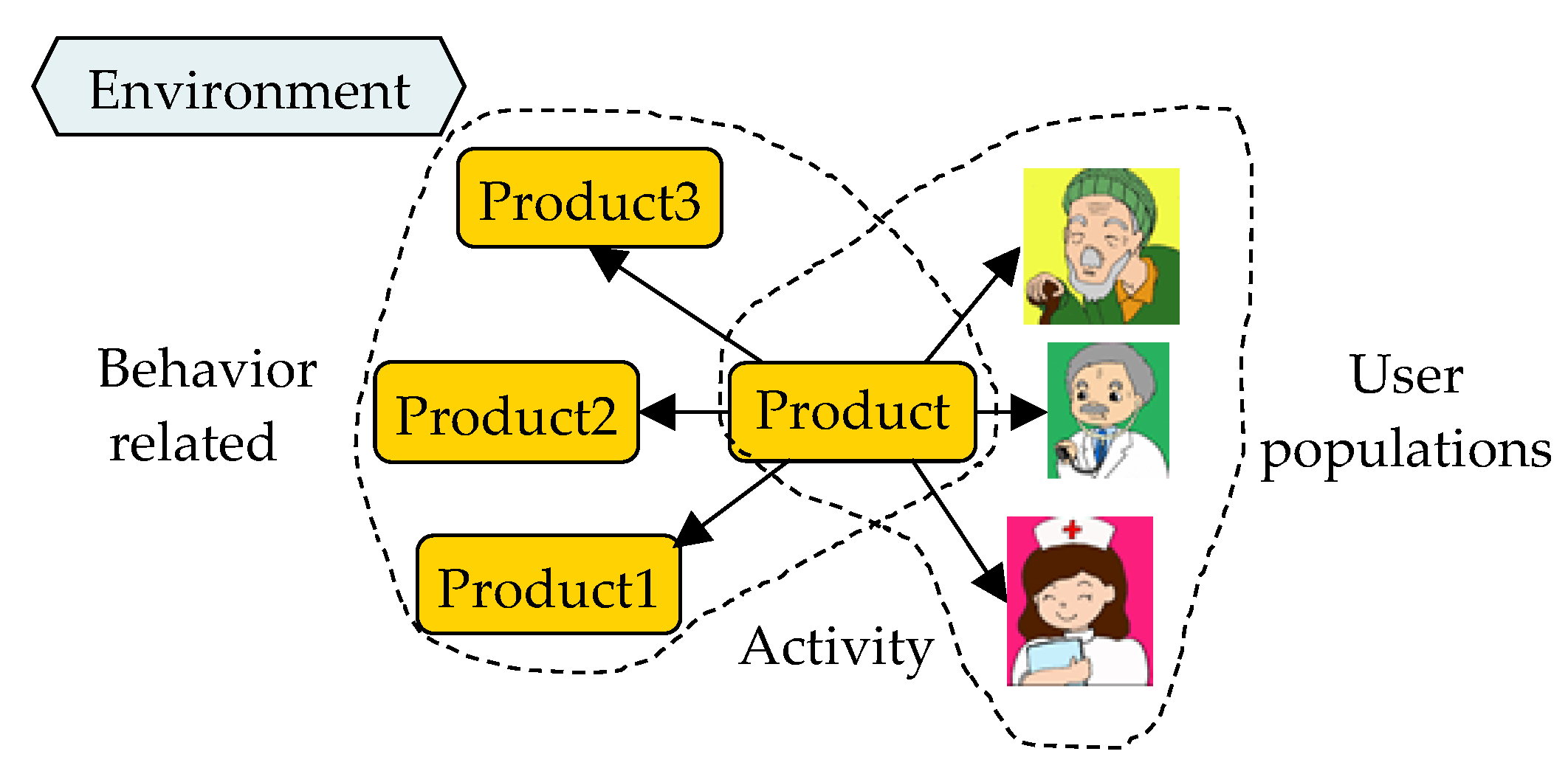

3.1. Concept of Product Functional Hybridization

3.2. Method of Acquiring Goal Products Based on Scenario Analysis and the Divergence Tree

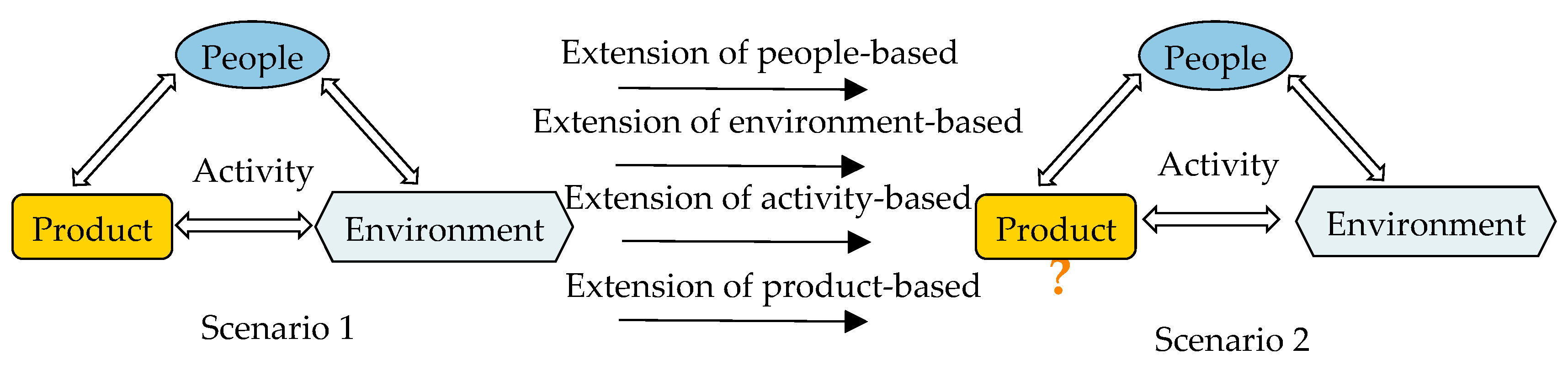

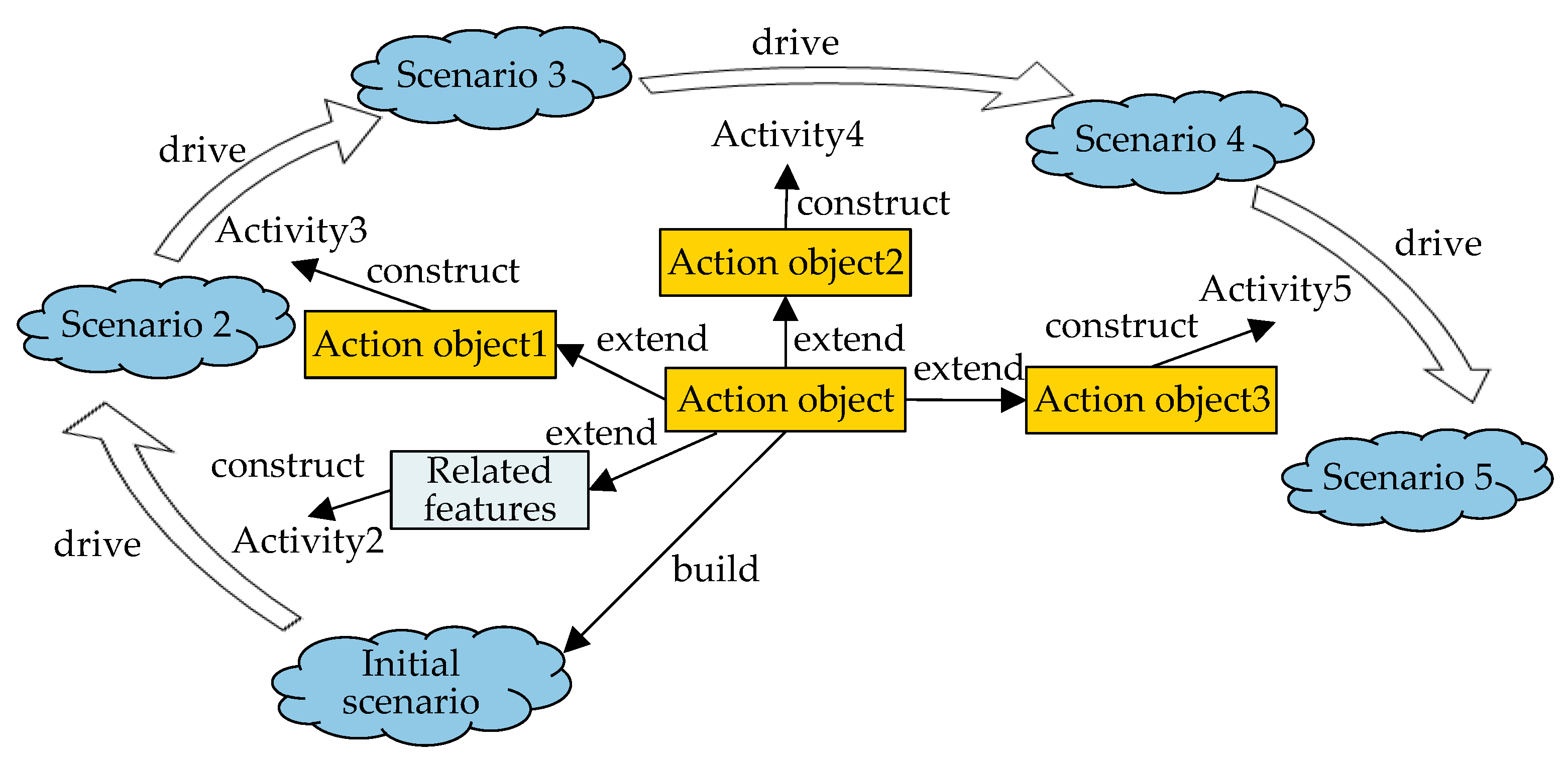

3.2.1. Goal Product Prediction Based on Extending the Action Object

3.2.2. Goal Product Prediction Based on People

3.2.3. Goal Product Prediction Based on the Object

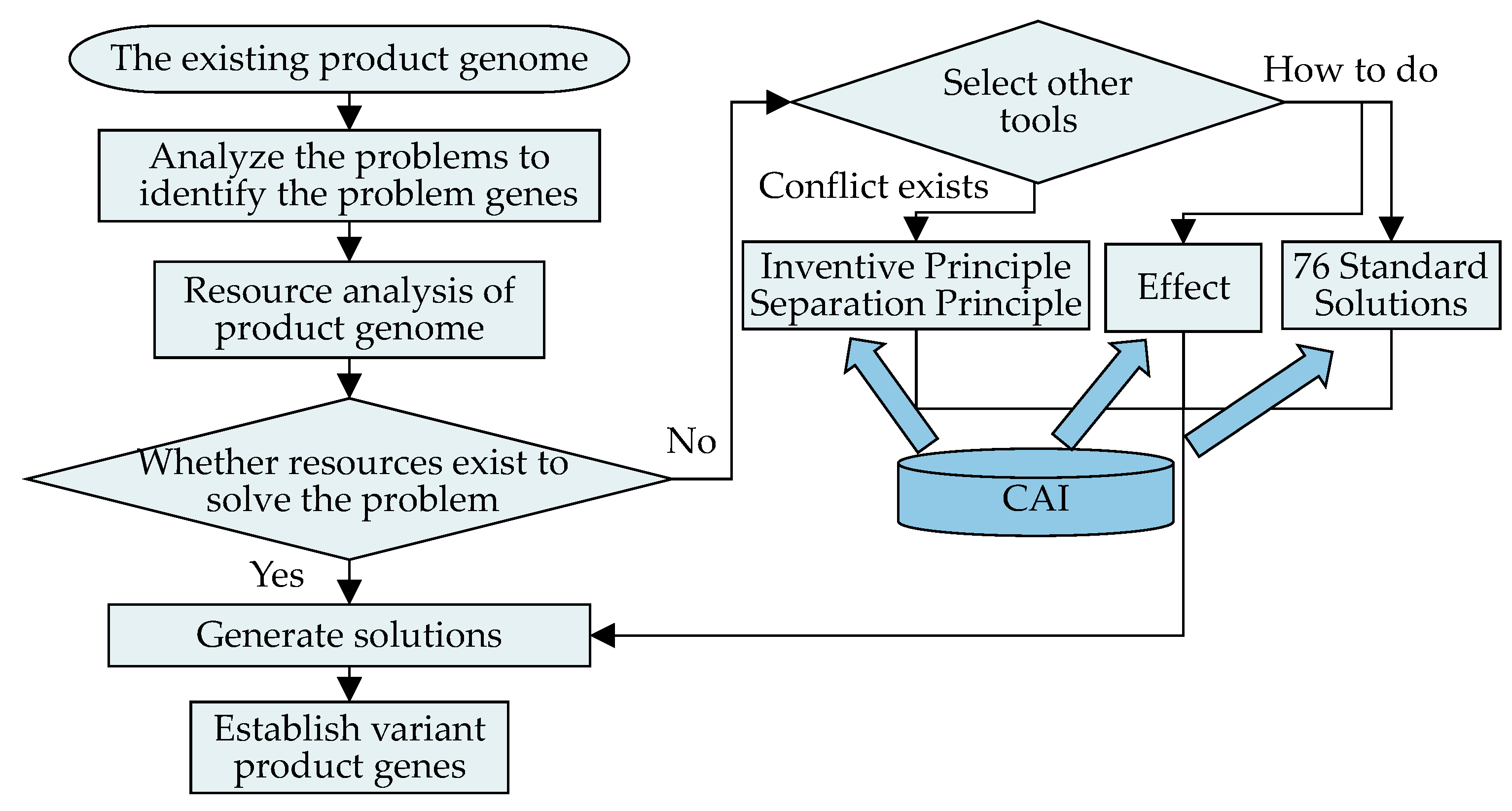

3.3. A Method of Establishing a Product Concept Structure Based on Product Gene Recombination and TRIZ

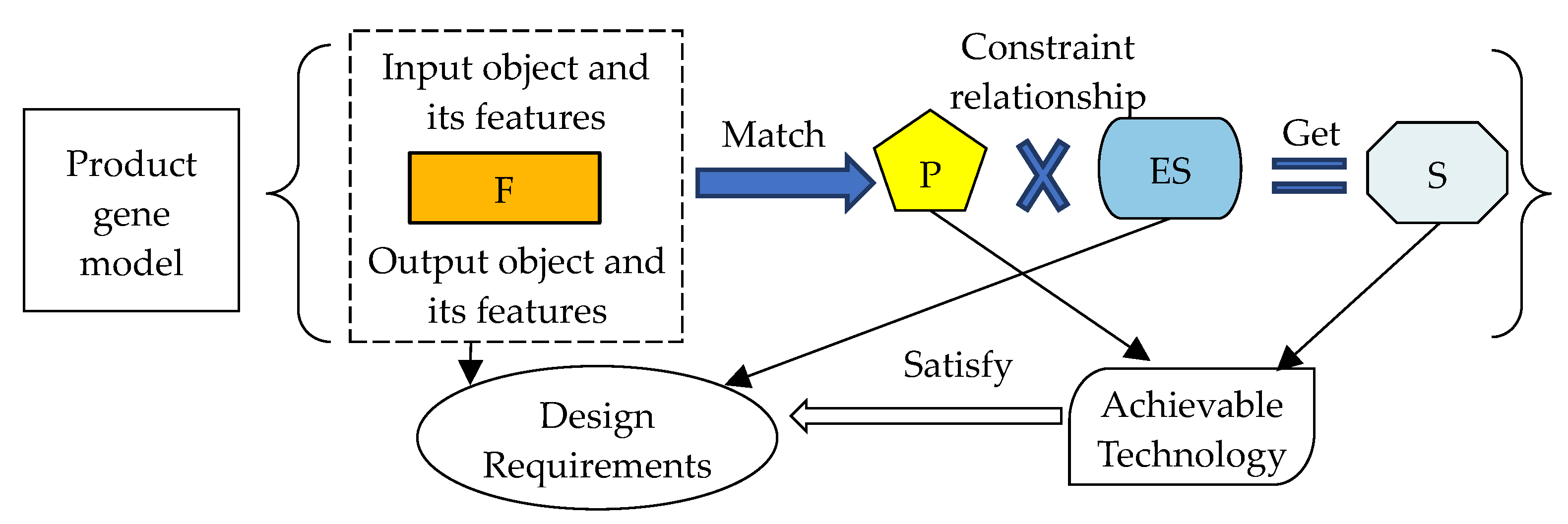

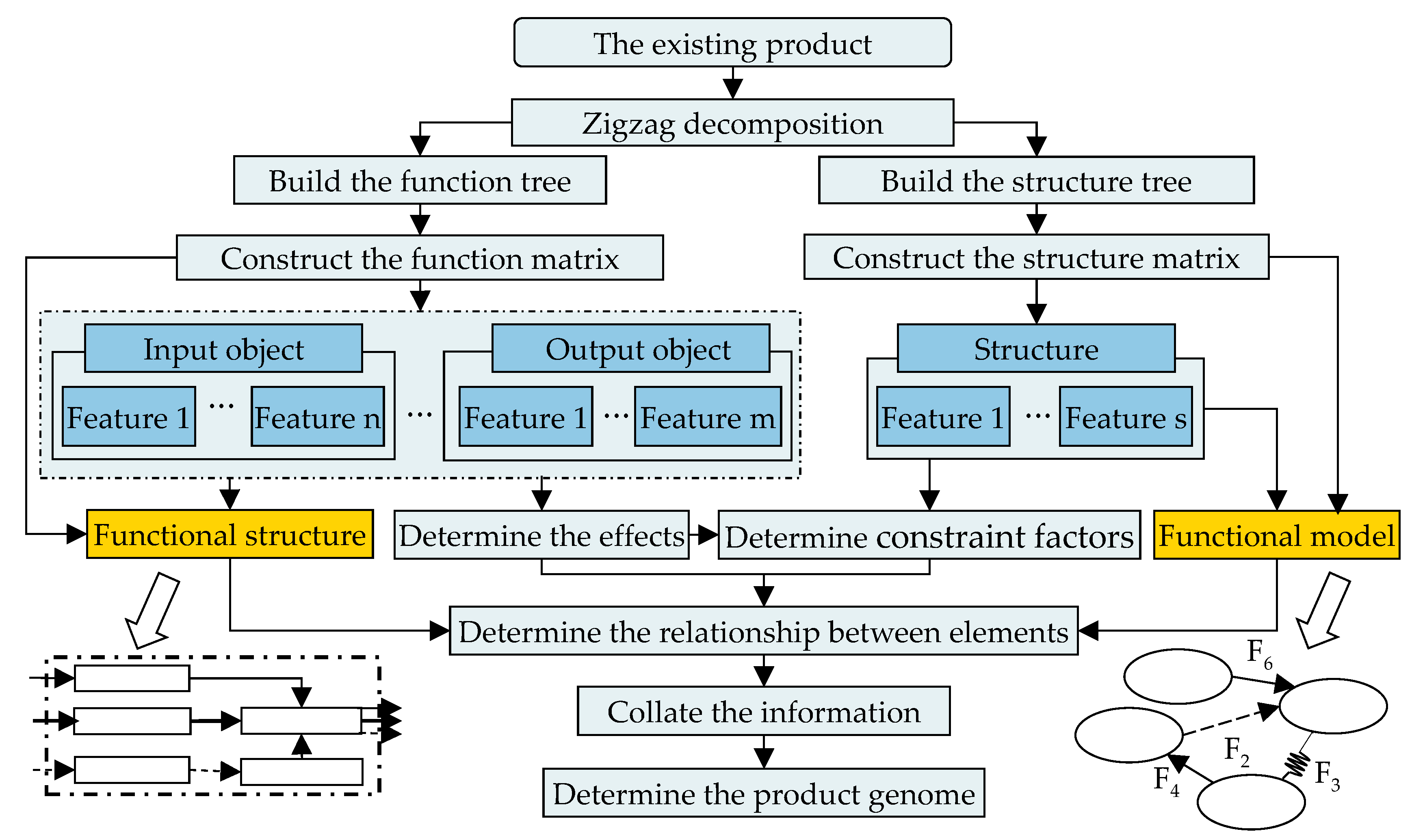

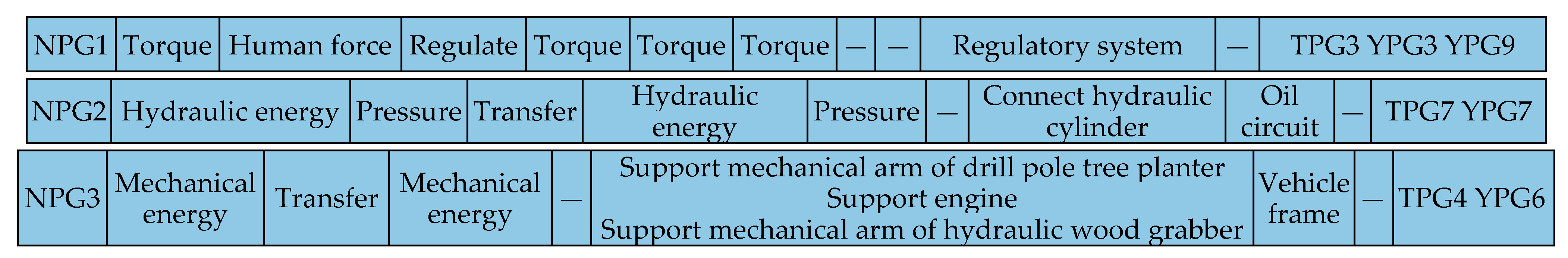

3.3.1. Product Gene Model

3.3.2. Construction Process of Product Genome

3.3.3. Product Gene Recombination

- (1)

- Sharing

- (2)

- Separation. Based on the existing product genome, redundant or problematic genes are removed to form a new product genome. The operation process involves separating a product gene PGi or a segment of product genes PGiPGi+1PGi+2 from the existing product genome and then reconnecting the product genome to form a new product genome.

- (3)

- Adding. Based on the existing product genome, the required product genes are added to form the new product genome. The process involves adding an external product gene PGi or an external segment of product genes PGiPGi+1PGi+2 to the product genome and then reconnecting them to form a new product genome.

- (4)

- Replacement. Superior product genes replace product genes with harmful or insufficient functions. The operation process involves replacing product gene PGi or a segment of product genes PGiPGi+1PGi+2 with the product gene PGj or a segment of product genes PGjPGj+1PGj+2 to re-form the product genome.

- (5)

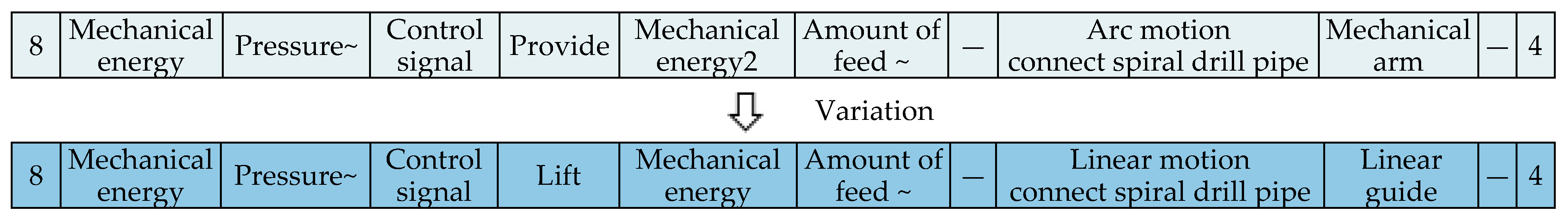

- Variation. Variation is used to improve the existing product genome based on the design requirements. The elements in the product genes are changed through variation. The operation process involves changing the internal elements of gene PGi to produce gene PGi′ based on problem analysis and solution, and then reforming the product genome GP′ = { PG1, PG2, ⋯, PGi′⋯, PGn}.

3.3.4. Transcription and Translation of Product Genome

3.4. Process Model of Product Functional Hybridization Design

4. Case Study

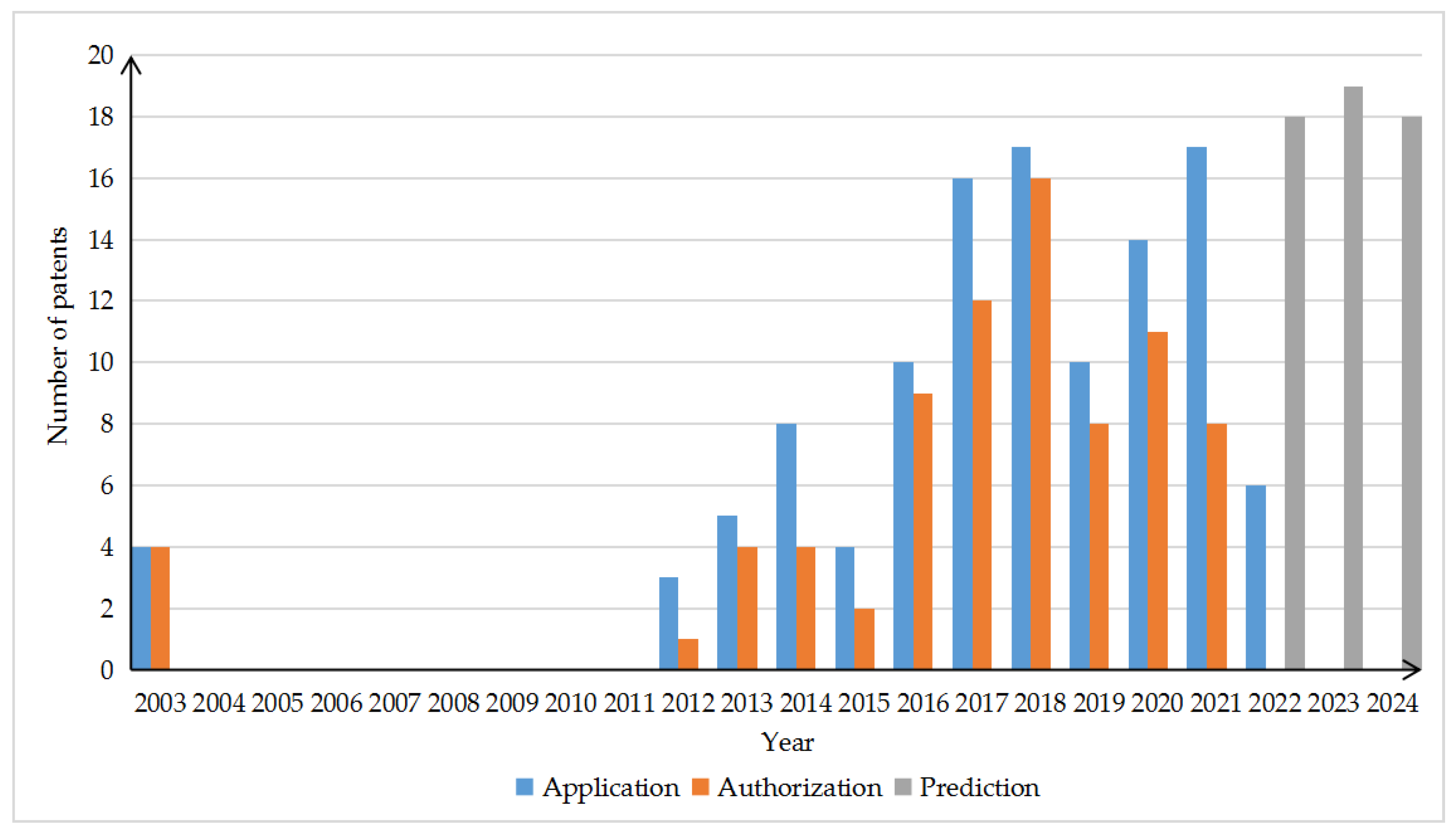

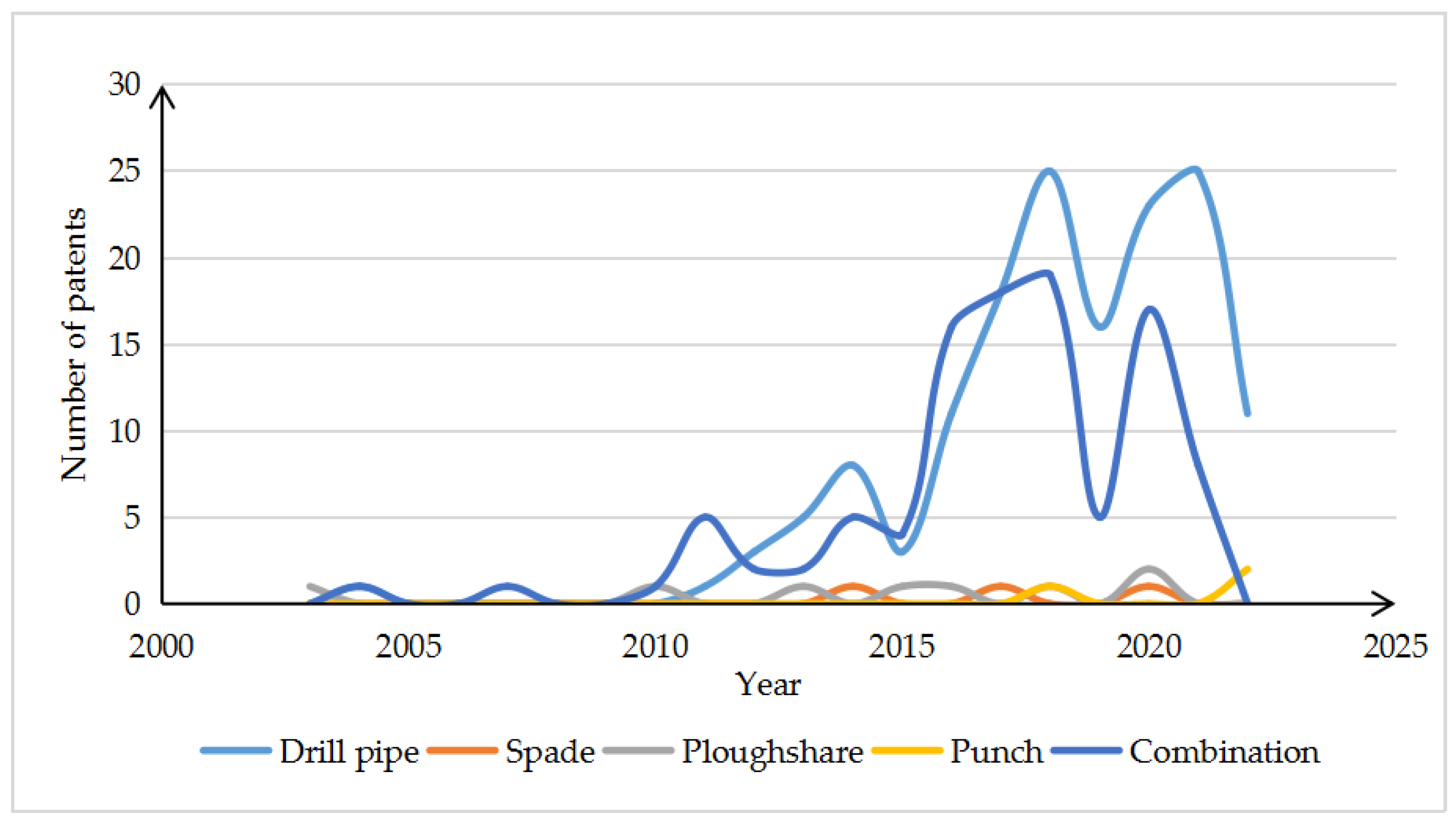

4.1. Preparation Phase

4.2. Acquiring Goal Products

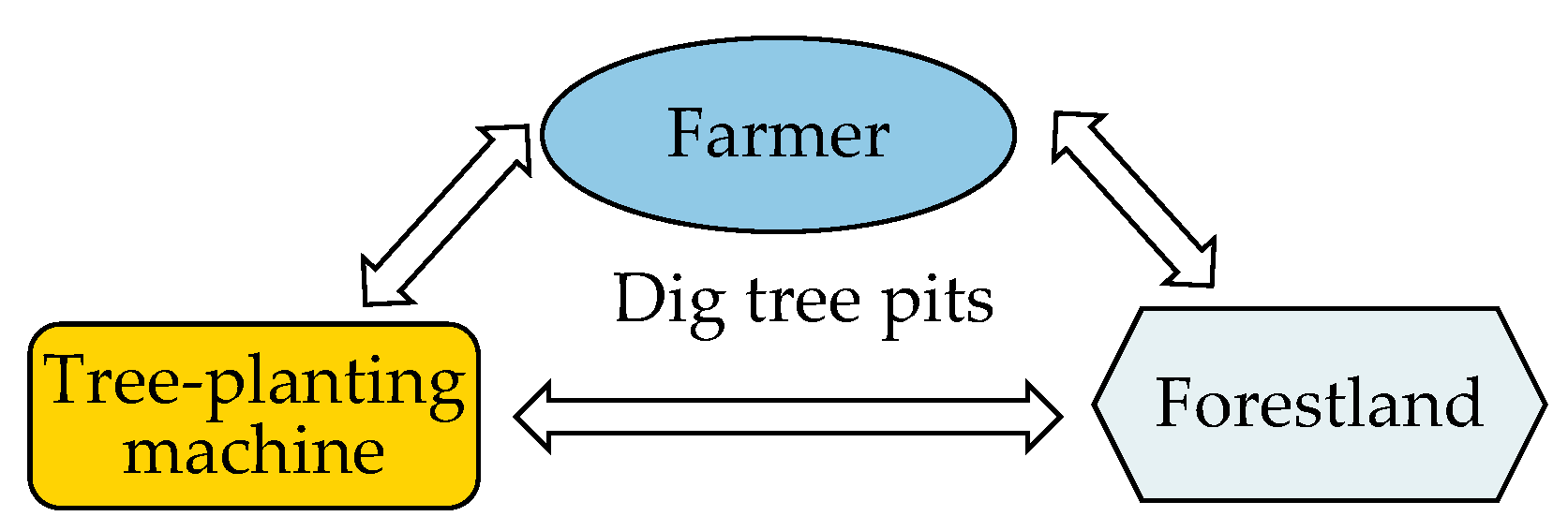

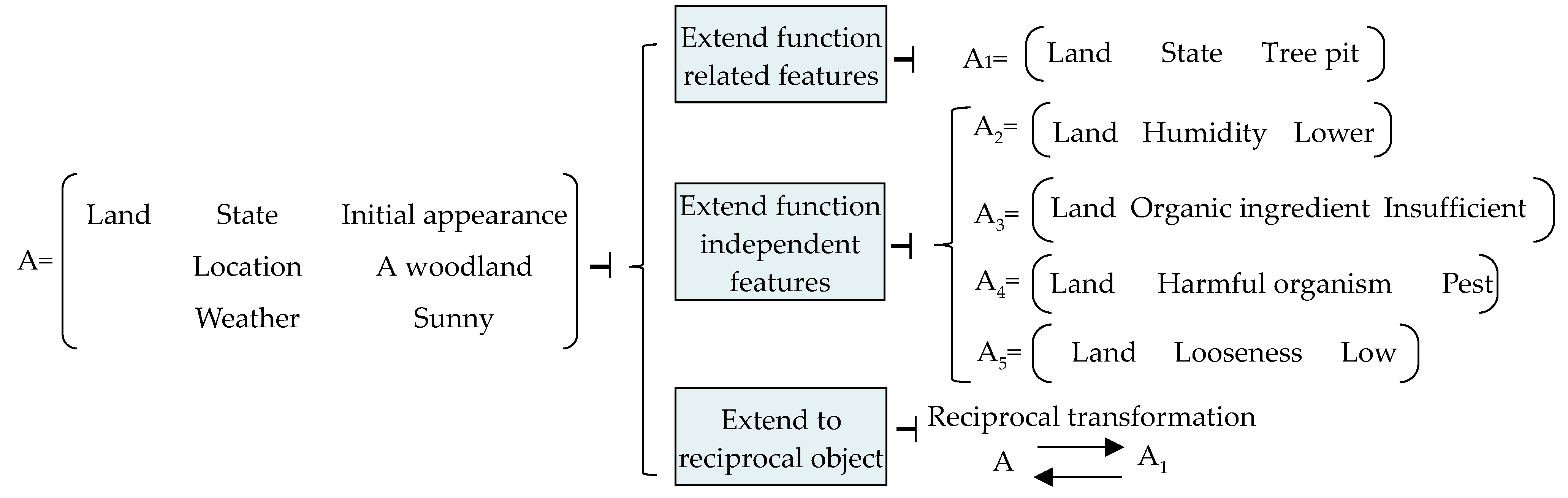

4.2.1. Establishing the Initial Scenario

4.2.2. Predicting Goal Product

- (1)

- Predicting the goal product based on extending the action object

- (2)

- Predicting goal product based on the object

4.2.3. Evaluating Scenario-Related Products

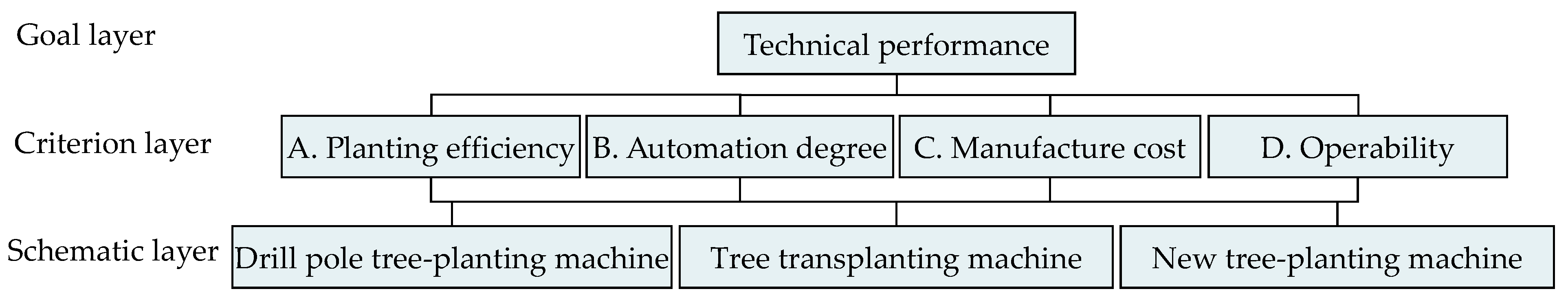

4.2.4. Determining the Goal Product

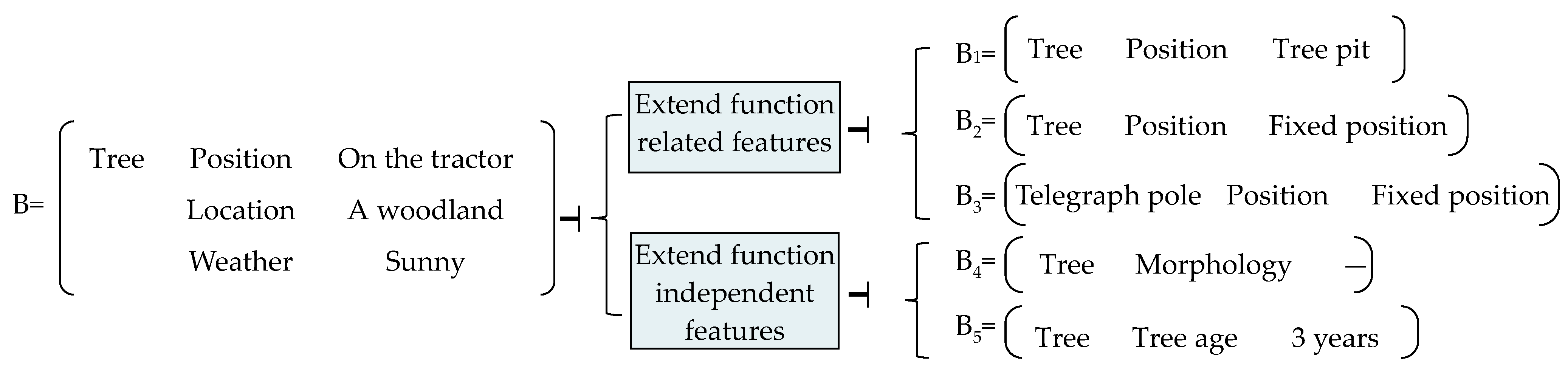

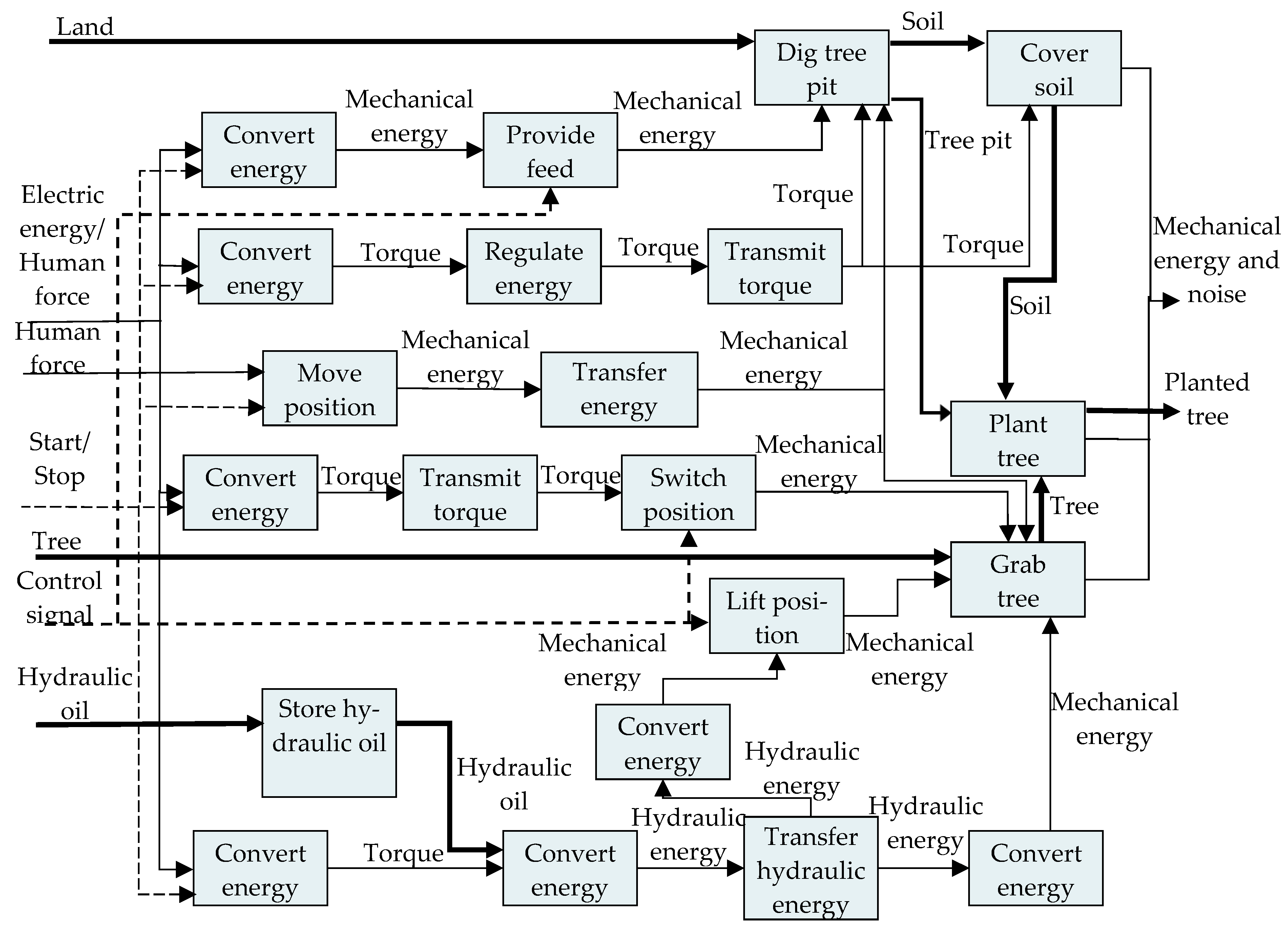

4.3. Establishing a New Product Concept Structure

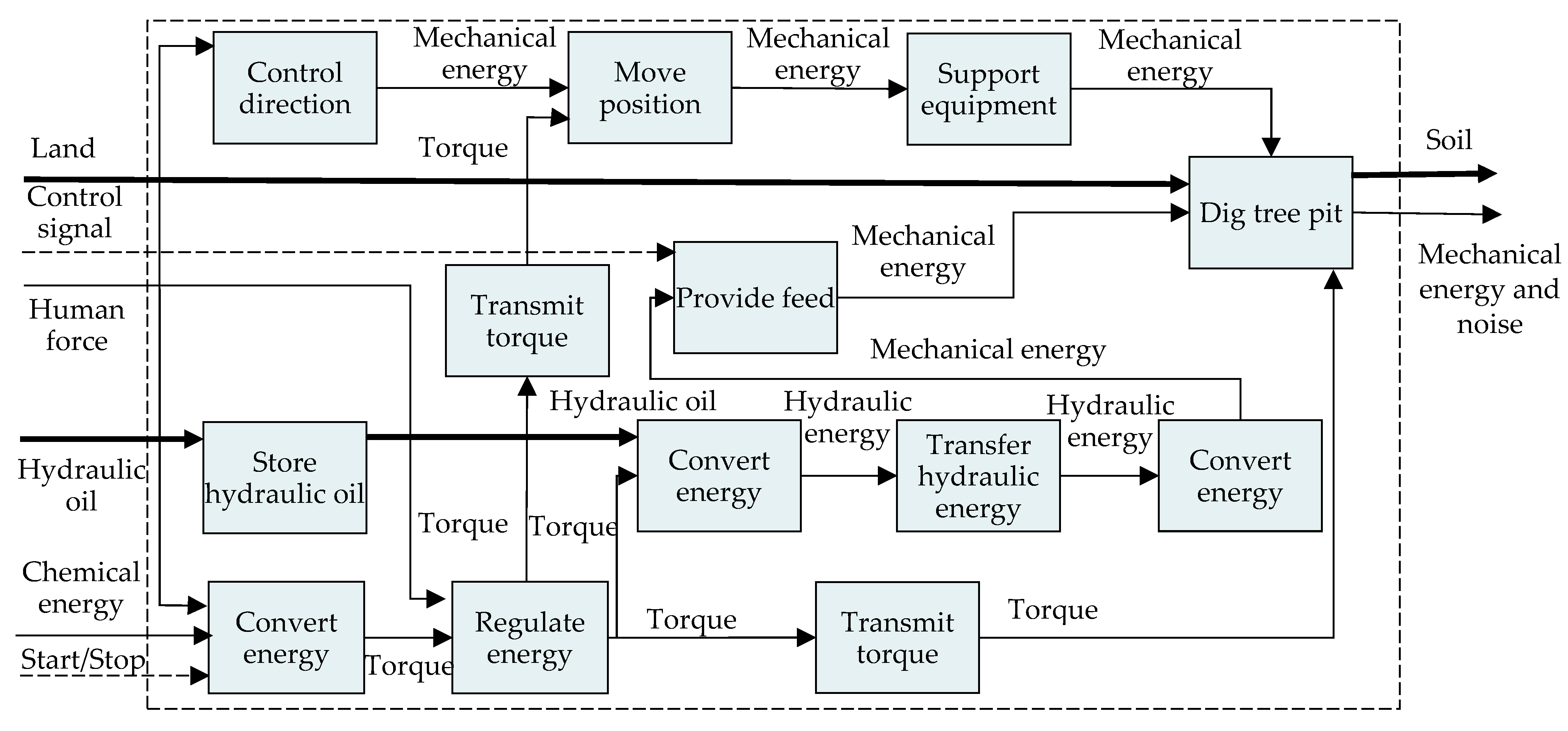

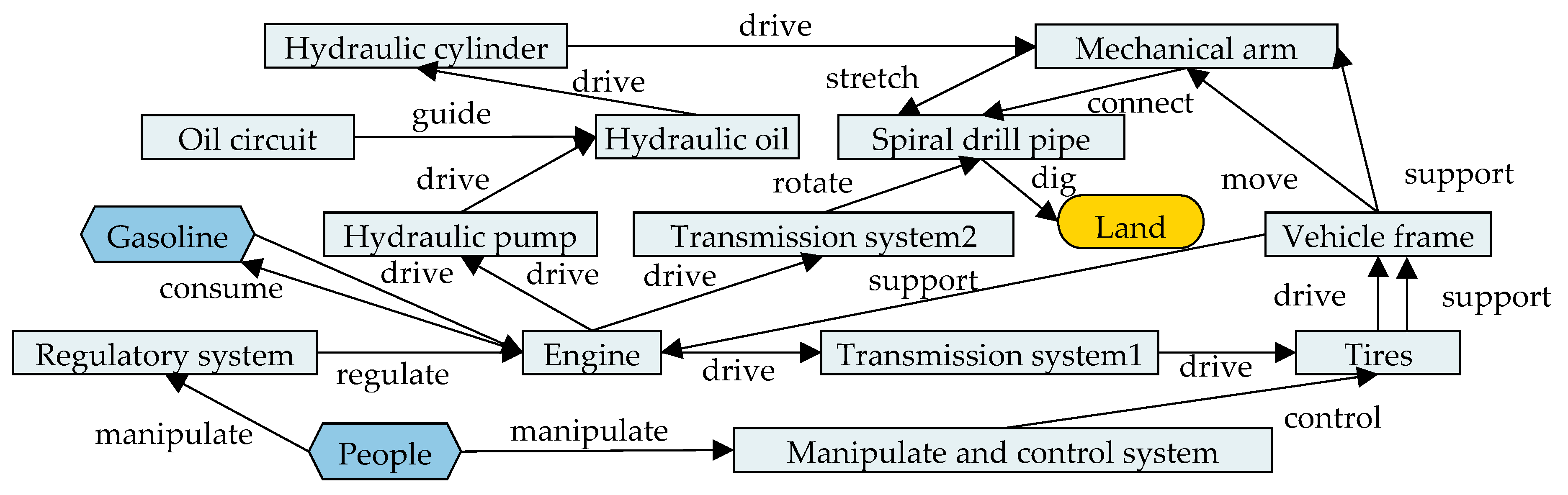

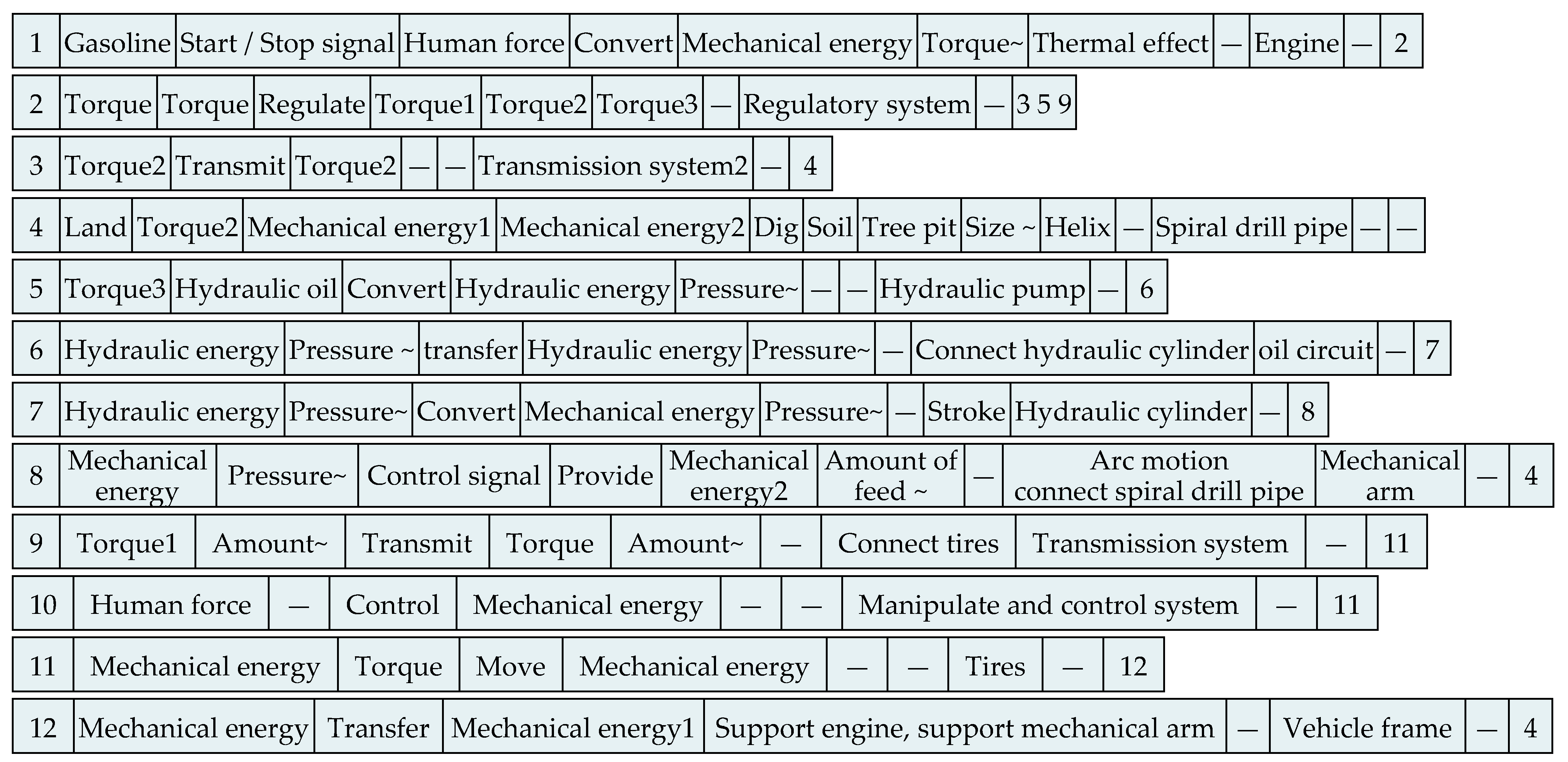

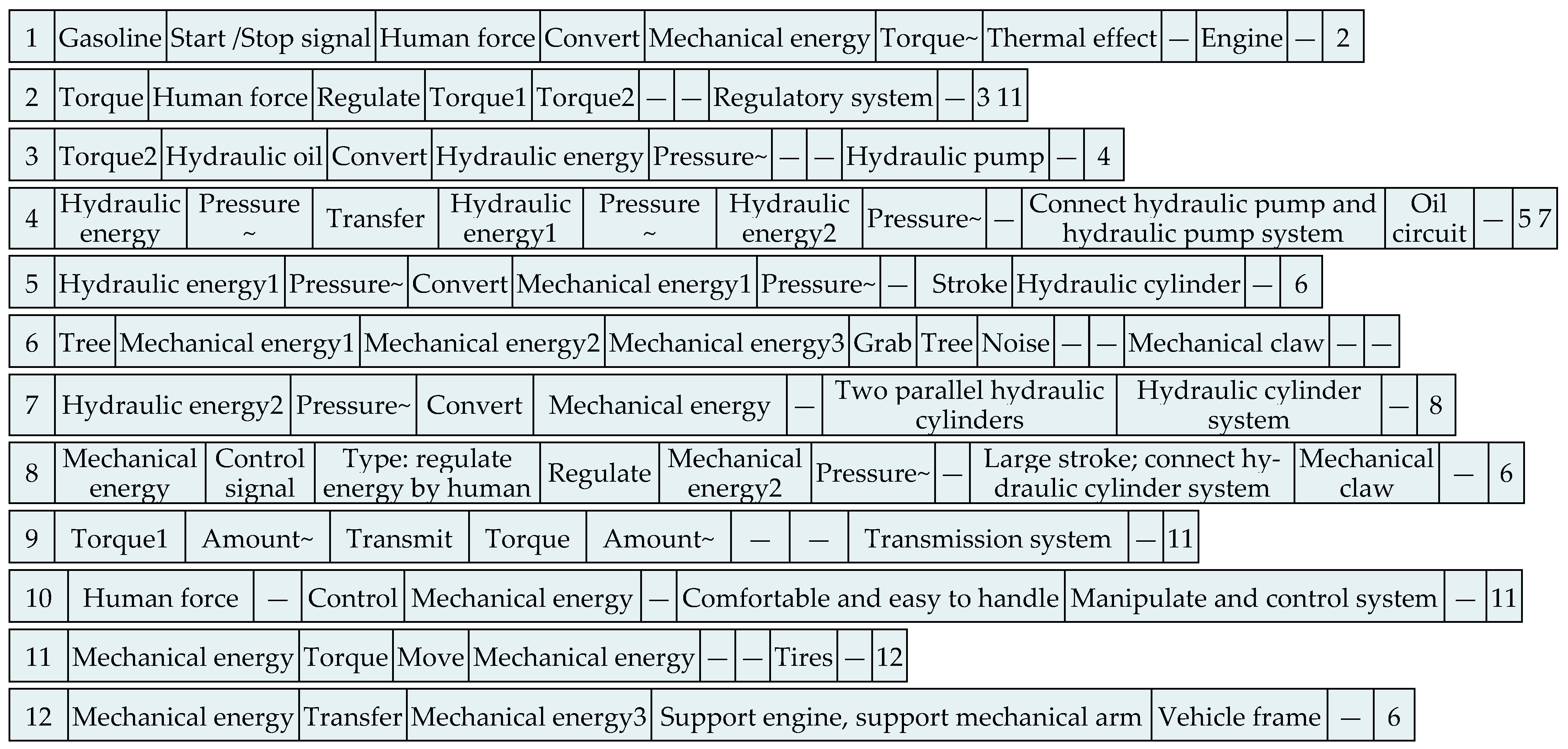

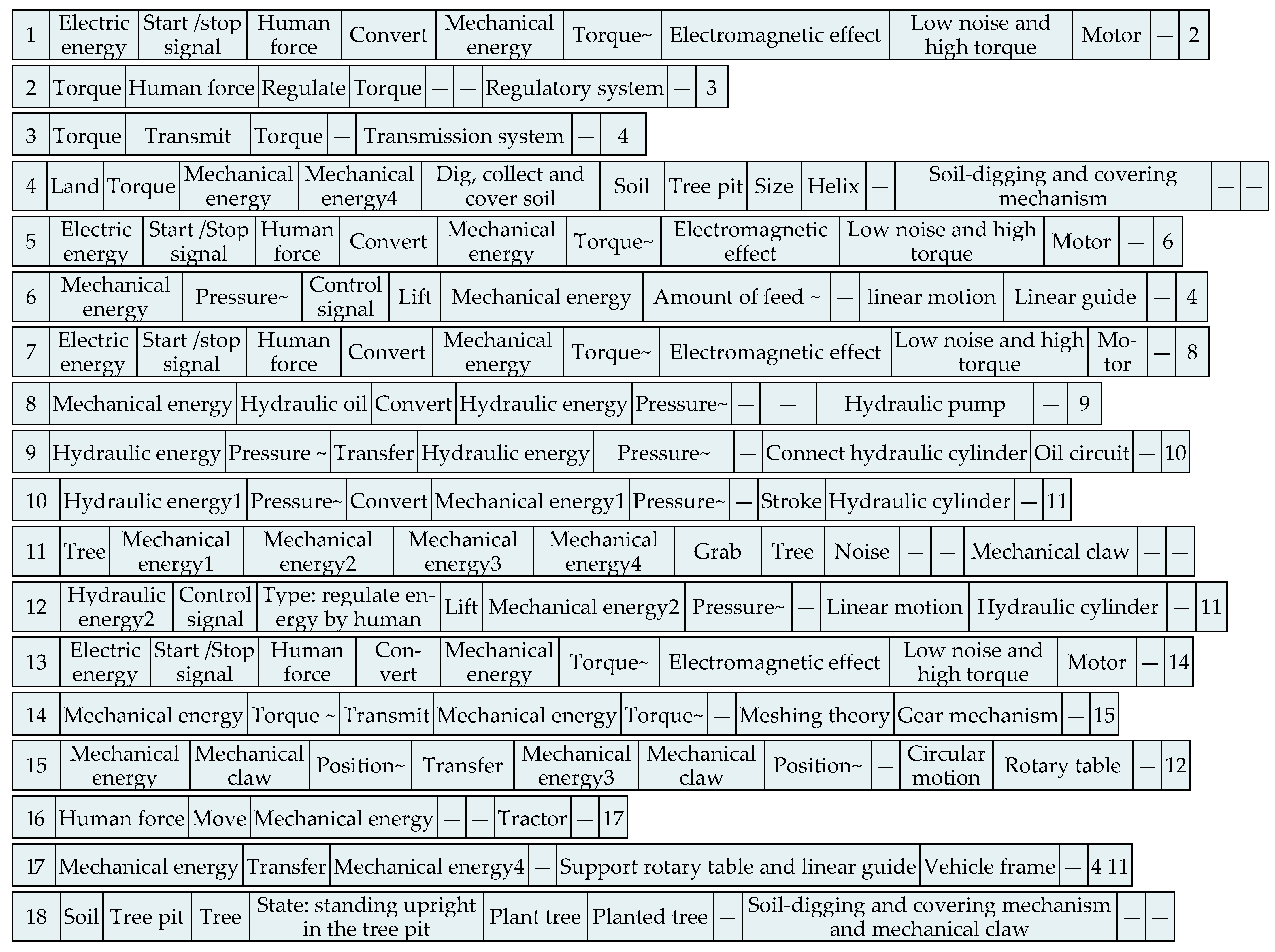

4.3.1. Establishing the Product Genome for the Drill Pole Tree-Planting Machine and the Hydraulic Wood Grabber

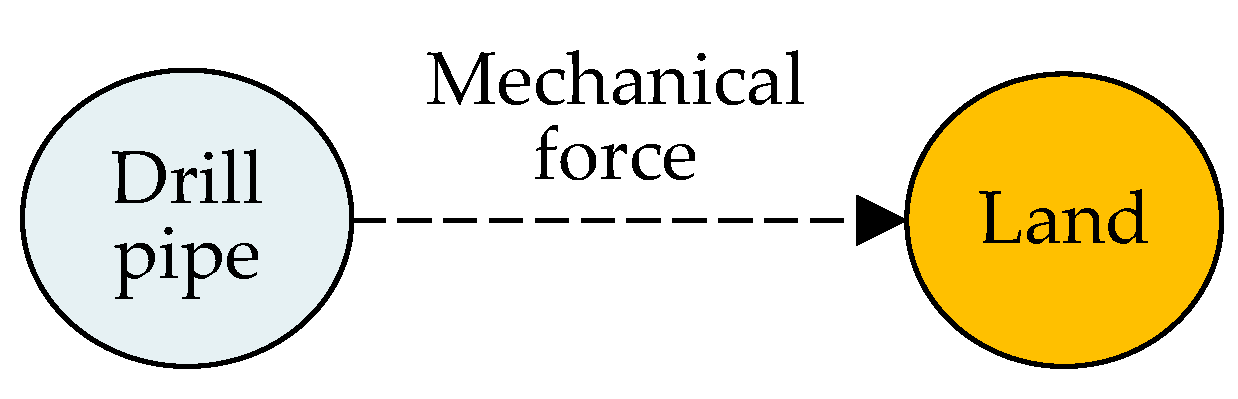

4.3.2. Recombining the Product Genes of the Drill Pole Tree-Planting Machine and Hydraulic Wood Grabber

- (1)

- Sharing of product genes between the drill pole tree-planting machine and hydraulic wood grabber

- (2)

- Recombining product genes

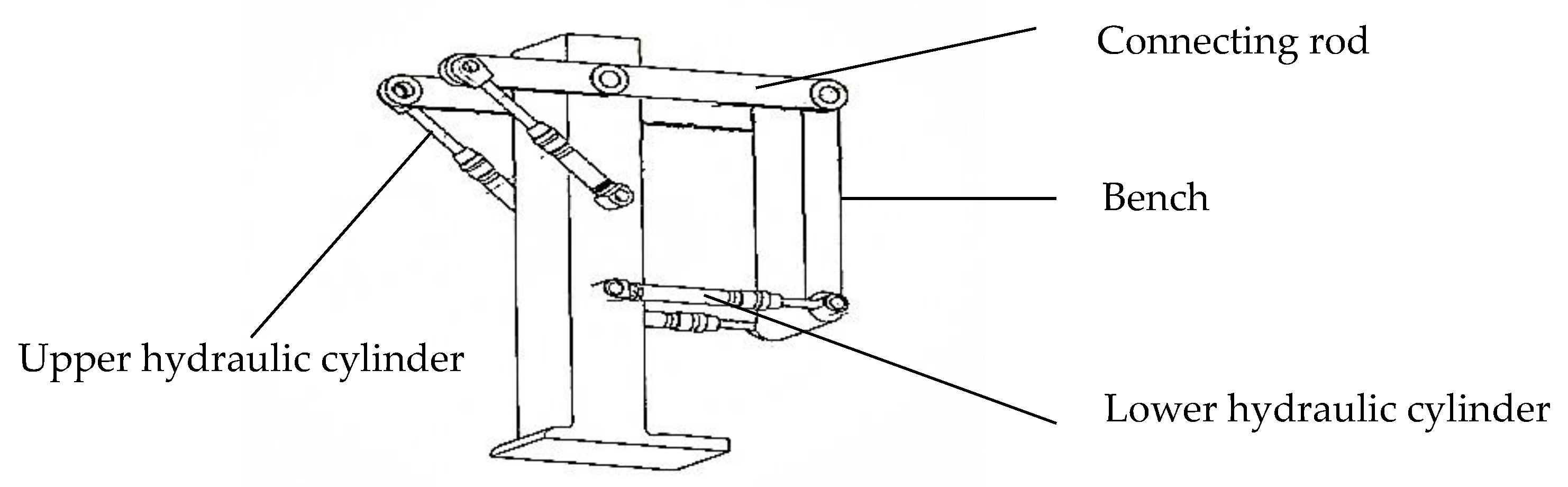

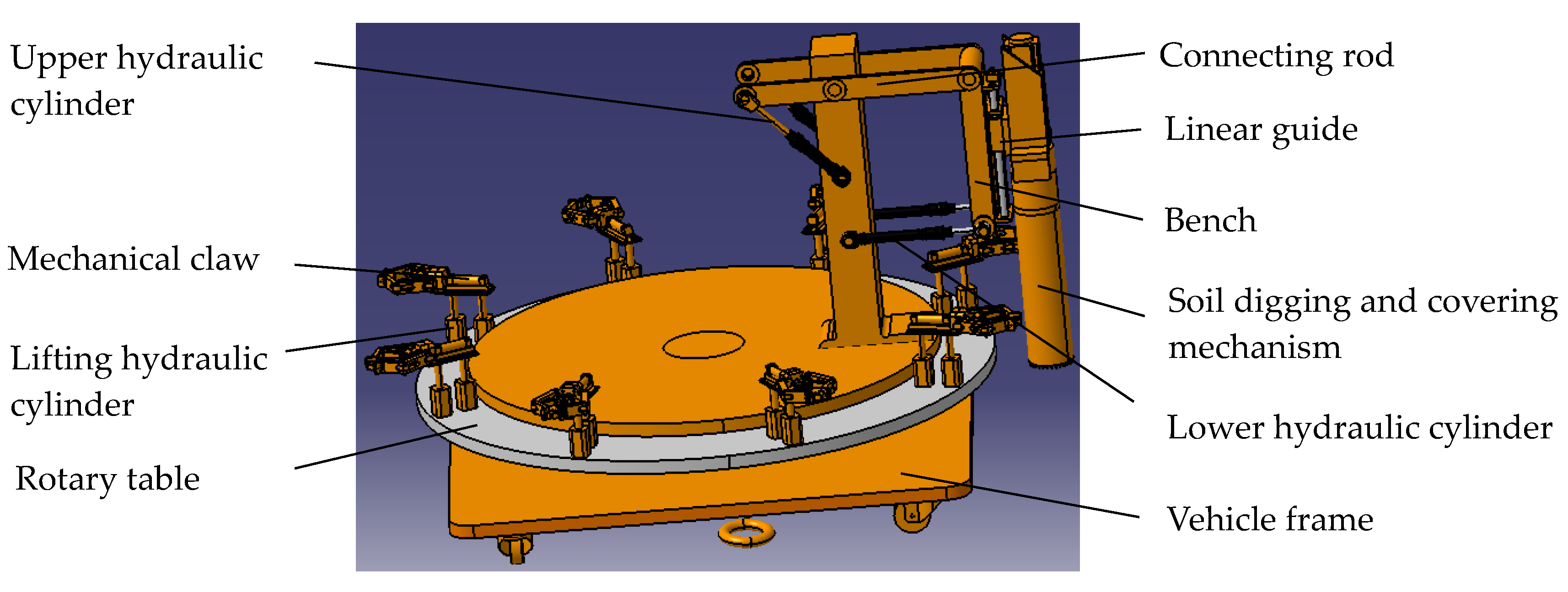

4.3.3. Transcribing and Translating the New Product Genome

4.4. Problem-Solving and Evaluation of the New Product Concept Structure

4.4.1. Solving the Problems of the New Product Concept Structure

4.4.2. Solution Evaluation

5. Discussion and Conclusions

- Acquiring goal products is the key to successfully implementing product functional hybridization. The acquisition method proposed in this paper can accurately acquire the goal products of functional hybridization. However, the extended elements need to be analyzed one by one based on the divergence tree in the acquisition process, which makes the acquisition less efficient.

- A new product concept structure can be effectively formed in the product functional hybridization design process with product genes. However, the establishment and reorganization of product genes are completed with the experience of designers.

- During the case study, a concept structure of the new tree-planting machine was established according to the process model for product functional hybridization design. Although the overall performance of this new concept structure was improved compared with the prototype product, the specific extent of improvement is to be considered.

- The product knowledge base will be established based on three paths of goal product prediction for functional hybridization. Thus, scenario-related products can be obtained by searching the knowledge base to improve the acquisition efficiency of function hybridization goal products.

- The software will be developed to establish and recombine product genes through computer assistance, which can make product functional hybridization design more efficient.

- The prototype will be produced through detailed design. Meanwhile, quantitative evaluation criteria will be set up to analyze the specific performance parameters of the prototype. The quantitative and objective evaluation of the overall performance of products can be carried out through the comparison and analysis of data.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ramadani, V.; Hisrich, R.D.; Abazi-Alili, H.; Dana, L.-P.; Panthi, L.; Abazi-Bexheti, L. Product innovation and firm performance in transition economies: A multi-stage estimation approach. Technol. Forecast. Soc. Chang. 2019, 140, 271–280. [Google Scholar] [CrossRef]

- Zhang, L.L.; Tan, R.H.; Peng, Q.J.; Shao, P.; Dong, Y.F.; Wang, K. Construction and Application of Enterprise Knowledge Base for Product Innovation Design. Appl. Sci. 2022, 12, 6358. [Google Scholar] [CrossRef]

- Boavida, R.; Navas, H.; Godina, R.; Carvalho, H.; Hasegawa, H. A Combined Use of TRIZ Methodology and Eco-Compass tool as a Sustainable Innovation Model. Appl. Sci. 2020, 10, 3535. [Google Scholar] [CrossRef]

- Chen, Y.B.; Zhang, H.; Yu, D.J. Design of City Main Battle Fire Engine Based on the Integrated Innovation Theory. Packag. Eng. 2019, 40, 118–122. [Google Scholar] [CrossRef]

- Meng, H.; He, X. Research on mine lifesaving cabin design based on integrated innovation theory. Ind. Des. 2020, 162, 151–152. [Google Scholar] [CrossRef]

- Shang, H.; Yan, Y.H. Natural hybridization and biodiversity conservation. Biodivers. Sci. 2017, 25, 683–688. [Google Scholar] [CrossRef][Green Version]

- Seehausen, O. Hybridization and adaptive radiation. Trends Ecol. Evol. 2004, 19, 198–207. [Google Scholar] [CrossRef]

- Tan, R.H. TRIZ and Applications: The Process and Methods of Technological Innovation; Higher Education Press: Beijing, China, 2010. [Google Scholar]

- Fournier, D.; Aron, S. Hybridization and invasiveness in social insects—The good, the bad and the hybrid. Curr. Opin. Insect Sci. 2021, 46, 1–9. [Google Scholar] [CrossRef]

- Schumpeter, J.A. The Theory of Economic Development; The Commercial Press: Beijing, China, 1999. [Google Scholar]

- Moro, S.R.; Cauchick-Miguel, P.A.; Mendes, G.H.S. Product-service systems benefits and barriers: An overview of literature review papers. Int. J. Ind. Eng. Manag. 2020, 11, 61–70. [Google Scholar] [CrossRef]

- Zivlak, N.; Rakic, S.; Marjanovic, U.; Ciric, D.; Bogojevic, B. The role of digital servitization in transition economy: An SNA approach. Tehnički Vjesnik 2021, 28, 1912–1919. [Google Scholar] [CrossRef]

- Paschou, T.; Rapaccini, M.; Adrodegari, F.; Saccani, N. Digital servitization in manufacturing: A systematic literature review and research agenda. Ind. Mark. Manag. 2020, 89, 278–292. [Google Scholar] [CrossRef]

- Paiola, M.; Gebauer, H. Internet of things technologies, digital servitization and business model innovation in BtoB manufacturing firms. Ind. Mark. Manag. 2020, 89, 245–264. [Google Scholar] [CrossRef]

- Szucs, M.; Clark, E.I.; Schaffner, U.; Littlefield, J.L.; Hoover, C.; Hufbauer, R.A. The effects of intraspecific hybridization on the host specificity of a weed biocontrol agent. Biol. Control 2021, 157, 8. [Google Scholar] [CrossRef]

- Leighton, G.M.; Lu, L.J.Y.; Holop, E.; Dobler, J.; Ligon, R.A. Sociality and migration predict hybridization across birds. Proc. R. Soc. B-Biol. Sci. 2021, 288, 7. [Google Scholar] [CrossRef]

- Fiorineschi, L.; Frillici, F.S.; Rotini, F. Enhancing functional decomposition and morphology with TRIZ: Literature review. Comput. Ind. 2018, 94, 1–15. [Google Scholar] [CrossRef]

- Zhou, M.L. Hybrid integrated design for similarity mechanical and electrical products systems. J. Mech. Eng. 2002, 38, 96–99. [Google Scholar] [CrossRef]

- Prushinskiy, V.; Zainiev, G.; Gerasimov, V. Hybridization: The New Warfare in the Battle for the Market; Ideation International, Incorporated: Reston, VA, USA, 2005. [Google Scholar]

- Fayemi, P.-E.; Vitoux, C.; Schöfer, M.; Bersano, G. Using TRIZ to Combine Advantages of Different Concepts in an Eco-Design Process. In Proceedings of the International Conference on Sustainable Design and Manufacturing, Chania, Greece, 4–6 April 2016; pp. 513–523. [Google Scholar] [CrossRef]

- Litvin, S.S. TRIZ Tools for Disruptive Cost Reduction. In Proceedings of the MATRIZ TRIZfest 2019 International Conference, Heilbronn, Germany, 14 September 2019; pp. 399–411. [Google Scholar]

- Liu, F.; Jiang, P.; Tan, R.H. Product Integrated Innovation Based on the Technological Hybridization. J. Mech. Eng. 2011, 47, 123–132. [Google Scholar] [CrossRef]

- Luo, S.; Weng, J.; Chen, S.; Zheng, L. Scenario-based product family design styling DNA. J. Zhejiang Univ. Eng. Sci. 2009, 43, 1112–1117. [Google Scholar] [CrossRef]

- Gunasekaran, S.; Mancini, N.; El-Khaja, R.; Sheu, E.; Mitsos, A.J.E. Solar–thermal hybridization of advanced zero emissions power cycle. Energy 2014, 65, 152–165. [Google Scholar] [CrossRef]

- Prushinskiy, V. Applying of hybridization for development of flexible display device. In Proceedings of the MATRIZ TRIZfest 2019 International Conference, Heilbronn, Germany, 14 September 2019; pp. 60–69. [Google Scholar]

- Steinbuch, M.; Shepshelovich, M. Development of UAV Wings-Transonic Designs. In Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 10–13 January 2005; p. 42. [Google Scholar] [CrossRef]

- Wang, X.L.; Zhu, Z.Q. Hybrid Optimization Design of High Performance Unmanned Aerial Vehicle Airfoil. Acta Aeronaut. Et Astronaut. Sin. 2007, 28, 839–844. [Google Scholar] [CrossRef]

- Yang, Y.S.; Xu, B.W.; Qin, S.L. Hybrid configuration design based on backcross theory for large scale container crane product. J. Shanghai Marit. Univ. 2013, 34, 35–40. [Google Scholar] [CrossRef]

- Cao, X.Y.; Teng, R.M.; Wang, X.; Gao, S.D. Integrated hybrid design and product gene-base construction for mechanical products. Chin. J. Constr. Mach. 2012, 10, 1–7. [Google Scholar] [CrossRef]

- He, Y.X.; Yu, S.H.; Jiang, C. Product morphological gene hybridization technology in industrial design. Sci. Tech. Engrg. 2017, 17, 60–66. [Google Scholar] [CrossRef]

- Liu, F.; Li, X.P.; Yu, F.; Ping, E.S. Method for product integrated innovation based on functional combination and TRIZ. In Proceedings of the 2014 IEEE International Conference on Management of Innovation and Technology, Singapore, 23–25 September 2014; pp. 268–272. [Google Scholar] [CrossRef]

- Liu, F. Research on functional global ideal solution design method based on multi-domain knowledge fusion. Master’s Thesis, Hebei University of Technology, Tianjin, China, 2020. [Google Scholar] [CrossRef]

- Kalyanasundaram, V.; Lewis, K. A Function Based Approach for Product Integration. In Proceedings of the ASME 2011 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Washington, DC, USA, 28–31 August 2011; pp. 263–279. [Google Scholar] [CrossRef]

- Jiang, W.W.; Xie, Z.B. Research of design method of product function analysis and combination. Proc. Appl. Mech. Mater. 2012, 886–889. [Google Scholar] [CrossRef]

- Cao, G.Z.; Guo, H.X.; Tan, R.H.; Zhang, C.Y.; Li, Q.H. Research on Function Evolution, Combination and Failure Mode for Product Function Innovation. Chin. J. Mech. Eng. 2012, 48, 29–38. [Google Scholar] [CrossRef]

- Lu, C.F.; Chai, H.; Tian, M.Y.; Peng, X.; Jiang, S.F. Product function combination design based on functional redundancy analysis. Concurr. Eng. 2017, 25, 229–244. [Google Scholar] [CrossRef]

- Hou, X.T.; Liu, W.; Cao, G.Z.; Wu, Z.F.; Guo, Z.B. Research on design method of function combination product based on multi biological effects. Chin. J. Eng. Des. 2017, 24, 18–26. [Google Scholar] [CrossRef]

- Wang, J.H. Research on integrated innovation design based on biology and product characteristics. Master’s Thesis, Fuzhou University, Fuzhou, China, 2018. [Google Scholar]

- Klaiber, D.; Frohlich, T.; Vietor, T. Strategies for function integration in engineering design: From differential design to function adoption. In Proceedings of the 29th CIRP Design Conference (CIRP Design), Povoa de Varzim, Portugal, 8–10 May 2019; pp. 599–604. [Google Scholar] [CrossRef]

- Frohlich, T.; Klaiber, D.; Turck, E.; Vietor, T. Function in a box: An approach for multi-functional design by function integration and separation. In Proceedings of the 29th CIRP Design Conference (CIRP Design), Povoa de Varzim, Portugal, 8–10 May 2019; pp. 611–617. [Google Scholar] [CrossRef]

- Chen, Y.; Feng, P.E.; Lin, Z.Q. A genetics-based approach for the principle conceptual design of mechanical products. Int. J. Adv. Manuf. Technol. 2005, 27, 225–233. [Google Scholar] [CrossRef]

- Chen, K.Z.; Feng, X.A. Virtual genes of manufacturing products and their reforms for product innovative design. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2004, 218, 557–574. [Google Scholar] [CrossRef]

- Chen, K.Z.; Feng, X.A.; Chen, X.C. Reverse deduction of virtual chromosomes of manufactured products for their gene-engineering-based innovative design. Comput. Aided Des. 2005, 37, 1191–1203. [Google Scholar] [CrossRef]

- Tai, L.G.; Zhong, T.X.; Miao, Z.H.; Cui, Q.F. Product gene representation and acquisition method based on population of product cases. Chin. J. Mech. Eng. 2007, 20, 114–119. [Google Scholar] [CrossRef]

- Li, P.; Ren, Y.Z.; Yan, Y.; Wang, G.X. Intelligent product-gene acquisition method based on K -means clustering and mutual information-based feature selection algorithm. Artif. Intell. Eng. Des. Anal. Manuf. 2019, 33, 1–15. [Google Scholar] [CrossRef]

- Gu, X.J.; Tan, J.R.; Qi, G.N. Information Gene Model of Mechanical Products. China Mech. Eng. 1997, 77–79+124–125. [Google Scholar]

- Feng, P.E.; Chen, Y.; Zhang, S.; Pan, S.X. Product gene based conceptual design. J. Mech. Eng. 2002, 38, 1–6. [Google Scholar] [CrossRef]

- Liu, W.; Cao, G.Z.; Tan, R.H.; Li, M.L. Variant design based on products genes and physical description. Comput. Integr. Manuf. Syst. 2015, 21, 381–391. [Google Scholar] [CrossRef]

- Li, P.; Ren, Y.Z.; Wang, G.X. A Genetics-Based Conceptual Design Methodology of Unmanned Probe Cars. Trans. Beijing Inst. Technol. 2019, 39, 454–459. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Chen, J.; Li, L.; Tao, M.; Zhang, C.; Qin, Q.B.; Xiao, J.; Liu, Y.; Liu, S.J. Research progress of animal distant hybridization. Sci. Sin. Vitae 2014, 44, 161–174. [Google Scholar]

- Guo, Z.J. Investigation on the formation and genetic traits of hybrids derived from female koi carp (Cyprinus carpio haematopterus, ♀) × male rare minnow (Gobiocypris rarus, ♀). Master’s Thesis, Hunan Normal University, Changsha, China, 2021. [Google Scholar]

- Chen, J.; Luo, M.; Li, S.N.; Tao, M.; Ye, X.L.; Duan, W.; Zhang, C.; Qin, Q.B.; Xiao, J.; Liu, S.J. A comparative study of distant hybridization in plants and animals. Sci. China Life Sci. 2018, 61, 285–309. [Google Scholar] [CrossRef]

- Tan, K.; Fu, W.J.; Zhang, H.K.; Ma, H.Y.; Li, S.K.; Zheng, H.P. Intraspecific hybridization as a mitigation strategy of low salinity in marine bivalve noble scallop Chlamys nobilis. Aquaculture 2022, 552, 9. [Google Scholar] [CrossRef]

- Tan, R.H.; Yuan, C.Y.; Zhang, R.H.; Cao, D.X. Study on product design process based on technology evolution. J. Mech. Eng. 2002, 38, 60–65. [Google Scholar] [CrossRef]

- Kahn, H.; Wiener, A. The next thirty-three years: A framework for speculation. Daedalus 1967, 96, 705–732. [Google Scholar] [CrossRef]

- Carroll, J.M. Scenario-based design. In Handbook of Human-Computer Interaction; Marting, G., Helander, T.K.L., Prabhu, P.V., Eds.; Elsevier: Amsterdam, The Netherlands, 1997; pp. 383–406. [Google Scholar] [CrossRef]

- Uchitel, S.; Kramer, J.; Magee, J. Incremental elaboration of scenario-based specifications and behavior models using implied scenarios. ACM Trans. Softw. Eng. Methodol. 2004, 13, 37–85. [Google Scholar] [CrossRef]

- Culot, G.; Orzes, G.; Sartor, M.; Nassimbeni, G. The future of manufacturing: A Delphi-based scenario analysis on Industry 4.0. Technol. Forecast. Soc. Change 2020, 157, 120092. [Google Scholar] [CrossRef] [PubMed]

- Postma, T.; Broekhuizen, T.; Bosch, F.J.F. The contribution of scenario analysis to the front-end of new product development. Futures 2012, 44, 642–654. [Google Scholar] [CrossRef]

- Li, M.; Hu, M.Y.; Yu, J.X.; Zhao, T.L. Scenario-based innovation design of mobile Internet products. In Proceedings of the 2nd International Conference for Information Systems and Design (ICID), Xi’an, China, 3–7 September 2021; pp. 282–287. [Google Scholar] [CrossRef]

- Zhang, H.G.; Li, Y.C.; Gao, S.S.; Li, M.; Li, H.J. Product Technology Foresight Method Guided by Environmental Profile Transformation Scenario Analysis. Mach. Des. Res. 2021, 37, 163–167+172. [Google Scholar] [CrossRef]

- Liu, L.M.; Tan, R.H.; Liu, W.; Zhang, H.G.; Zhang, J.P. Identification of innovation opportunities in fuzzy front end based on scenario. Comput. Integr. Manuf. Syst. 2022, 1–20. Available online: https://kns.cnki.net/kcms/detail/11.5946.TP.20210618.0946.010.html (accessed on 12 July 2022).

- Yang, C.; Cai, W. Extenics; Science Press: Beijing, China, 2014; p. 381. [Google Scholar]

- Cai, W.; Yang, C.Y. Basic theory and methodology on Extenics. Chin. Sci. Bull. 2013, 58, 1190–1199. [Google Scholar] [CrossRef]

- Liu, F.Y.; Li, X.S.; Shi, Y. Scientific Breakthrough Study of Extenics. In Proceedings of the 4th International Conference on Information Technology and Quantitative Management (ITQM)—Promoting Business Analytics and Quantitative Management of Technology, Asan, Korea, 16–18 August 2016; pp. 526–531. [Google Scholar] [CrossRef]

- Waldman, A.S. Genetic Recombination:Reviews and Protocols; Humana Press: Totowa, NJ, USA, 2004. [Google Scholar]

- Xiong, Y.F. Recombination in the first generation of grass carp (♀)× blunt snout bream (♂) hybrids strain. Master’s Thesis, Hunan Normal University, Changsha, China, 2015. [Google Scholar]

- Altshuller, G.S. The Innovation Algorithm: TRIZ, Systematic Innovation and Technical Creativity; Technical Innovation Center: Worchester, MA, USA, 1999. [Google Scholar]

- Chou, J.R. A TRIZ-based product-service design approach for developing innovative products. Comput. Ind. Eng. 2021, 161, 19. [Google Scholar] [CrossRef]

- Lu, S.Z.; Guo, Y.Q.; Huang, W.; Shen, M. Product Form Evolutionary Design Integrated with TRIZ Contradiction Matrix. Math. Probl. Eng. 2022, 2022, 12. [Google Scholar] [CrossRef]

- Shao, P.; Tan, R.H.; Peng, Q.J.; Zhang, L.L.; Wang, K.; Dong, Y.F. Problem-Solving in Product Innovation Based on the Cynefin Framework-Aided TRIZ. Appl. Sci. 2022, 12, 4157. [Google Scholar] [CrossRef]

- Lei, C.G. The Process of Function-Structure Mapping Driven by CAI Technique. Master’s Thesis, Hebei University of Technology, Tianjin, China, 2016. [Google Scholar]

- Wan, Y.J.; Wang, J.; Wang, Y.W.; Du, X.F.; Xie, S.L.; Chen, Z.L. Research on the process planning and multi-method integration strategy of product conceptual design with cognitive mechanisms. Sci. Prog. 2021, 104, 17. [Google Scholar] [CrossRef]

- Zhang, P.; Li, X.D.; Nie, Z.F.; Yu, F.; Liu, W. A Trimming Design Method Based on Bio-Inspired Design for System Innovation. Appl. Sci. 2021, 11, 4060. [Google Scholar] [CrossRef]

- Yang, M.; Xia, Y.M.; Jia, L.H.; Wang, D.J.; Ji, Z.Y. A modular design method based on TRIZ and AD and its application to cutter changing robot. Adv. Mech. Eng. 2021, 13, 18. [Google Scholar] [CrossRef]

- Lin, S.Y.; Wu, C.T. Application of TRIZ inventive principles to innovate recycling machine. Adv. Mech. Eng. 2016, 8, 8. [Google Scholar] [CrossRef]

- Zhang, B.J. Analytic Hierarchy Process and its Application Cases; Publishing House of Electronics Industry: Beijing, China, 2014. [Google Scholar]

| Number | Function | Scenario-Related Product | Occurrence Probability | Weight | Score |

|---|---|---|---|---|---|

| ··· | ··· | ··· | ··· | ··· | ··· |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| RI | 0.00 | 0.00 | 0.52 | 0.89 | 1.12 | 1.24 | 1.36 | 1.41 | 1.46 | 1.49 |

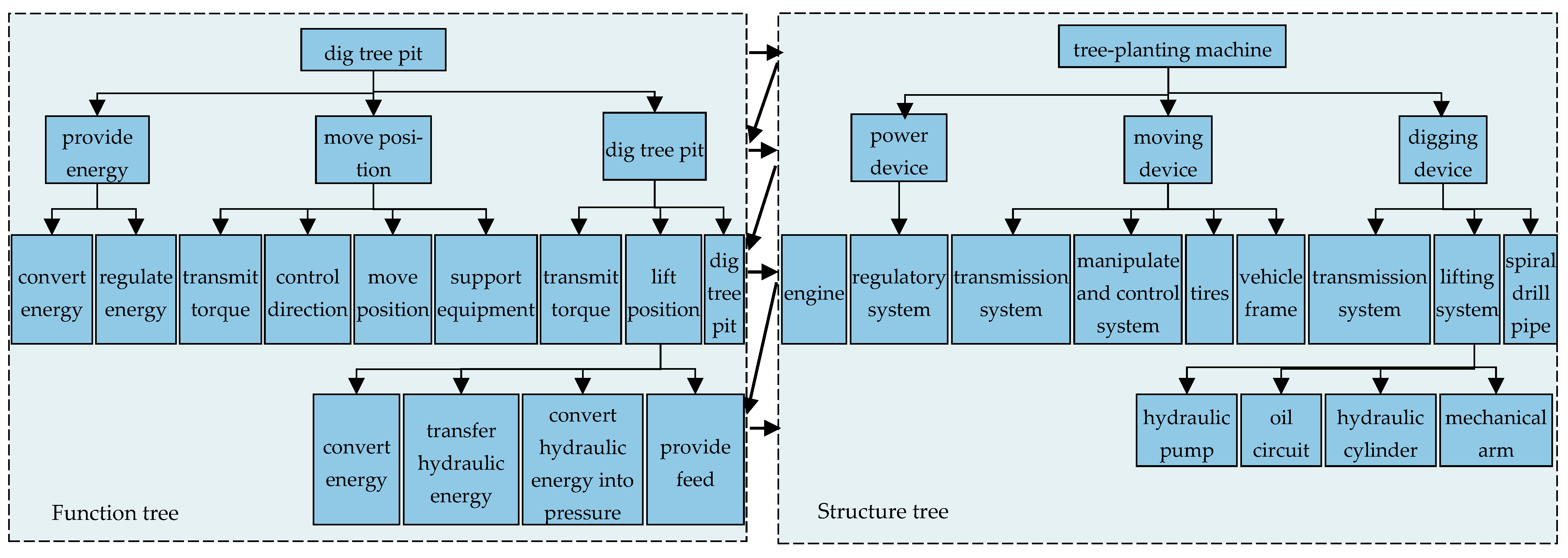

| Environmental Characteristics | Object (O) | Characteristics (C) | Value (V) | Activity | Scenario |

|---|---|---|---|---|---|

| Location: woodland Weather: sunny | Land | State | Tree pit | Dig tree pit | Workers operate tree planter to dig tree pit |

| Humidity | Lower | Irrigate land | Workers irrigate land through motor-pumped well | ||

| Organic ingredient | Insufficient | Apply fertilizer | Workers apply fertilizer by hand | ||

| Harmful organism | Pest | Kill pests | Workers kill pests with spray. | ||

| Looseness | Low | Plow land | Workers loosen the land with plow car | ||

| Similar objects | — | — | — | — | |

| Tree | Position | Tree pit | Move position | Workers move trees and insert them into tree pits | |

| Fixed | Fix trees | Workers cover and compact soil with shovel | |||

| Morphology | — | Prune branches | Workers prune branches with scissors or saws | ||

| Tree age | 3 years | Transplant trees | Workers transplant trees of different ages with different tree planters | ||

| Telegraph pole | Position | Fixed | Fix telegraph pole | Workers dig pit with drill pipe machine | |

| Scenario-related products | Motor-pumped well, spray, plow car, shovel, scissors, electric saw, and drill pipe machine | ||||

| Environment Characteristic | Product (O) | Characteristics (C) | Value (V) | Activity | Scenario |

|---|---|---|---|---|---|

| Location: woodland Weather: sunny Activity: planting trees | Tree planter | Function | Dig pit | Dig tree pit | Workers operate tree planter to dig tree pits |

| — | Function | Carry trees | Move trees | Workers insert trees into tree pits | |

| Shovel | Function | Cover soil | Fill soil | Workers use the shovel to fill the tree pits with soil | |

| — | Function | Compact soil | Compact soil | Workers compact soil with their feet | |

| Motor-pumped well | Function | Draw water | Water trees | Workers irrigate land through motor-pumped well | |

| Scenario-related products | Shovel and motor-pumped well | ||||

| Number | Function | Scenario-Related Product | Occurrence Probability | Weight | Score |

|---|---|---|---|---|---|

| 1 | Dig pit | Tree planter | 1 | 1 | 1 |

| 2 | Carry trees | — | 1 | 1 | 1 |

| 3 | Cover soil | Shovel | 1 | 1 | 1 |

| 4 | Compact soil | — | 0.8 | 0.6 | 0.48 |

| 5 | Draw water | Motor-pumped well | 0.5 | 0.5 | 0.25 |

| 6 | Prune branches | Scissors | 0.6 | 0.5 | 0.3 |

| 7 | Apply fertilizer | — | 0.5 | 0.6 | 0.3 |

| 8 | Kill pests | Spray | 0.4 | 0.5 | 0.2 |

| 9 | Plow land | Plow car | 0.4 | 0.5 | 0.2 |

| 10 | Fix telegraph pole | Drill pipe machine | 0.1 | 0.1 | 0.1 |

| Drill Pole Tree-Planting Machine | Hydraulic Wood Grabber | Sharing Operation | Results of Gene Sharing | |

|---|---|---|---|---|

| Allelomorphic gene | TPG1 | YPG1 | Selection | YPG1 |

| TPG2 | YPG2 | Reconstruction | NPG1 | |

| TPG5 | YPG3 | Selection | YPG3 | |

| TPG6 | YPG4 | Reconstruction | NPG2 | |

| TPG7 | YPG7 | Inclusion | TPG7 and YPG7 | |

| TPG8 | YPG8 | Inclusion | TPG8 and YPG8 | |

| TPG9 | YPG9 | Selection | YPG9 | |

| TPG10 | YPG10 | Selection | YPG10 | |

| TPG11 | YPG11 | Selection | YPG11 | |

| TPG12 | YPG12 | Reconstruction | NPG3 |

| Indicator A | Indicator B | Indicator C | Indicator D | Weight | |

|---|---|---|---|---|---|

| Indicator A | 1 | 3 | 1 | 5 | 0.4094 |

| Indicator B | 1/3 | 1 | 1/3 | 1/3 | 0.0913 |

| Indicator C | 1 | 3 | 1 | 3 | 0.3603 |

| Indicator D | 1/5 | 3 | 1/3 | 1 | 0.1391 |

| Indicator A | Drill Pole Tree-Planting Machine | Tree Transplanting Machine | New Tree-Planting Machine | Weight |

|---|---|---|---|---|

| Drill pole tree-planting machine | 1 | 2 | 1/2 | 0.2970 |

| Tree transplanting machine | 1/2 | 1 | 1/3 | 0.1634 |

| New tree-planting machine | 2 | 3 | 1 | 0.5396 |

| Product | Planting Efficiency (0.4094) | Automation Degree (0.0913) | Manufacturing Cost (0.3603) | Operability (0.1391) | Score |

|---|---|---|---|---|---|

| Drill pole tree-planting machine | 0.2970 | 0.1094 | 0.5396 | 0.1112 | 0.3414 |

| Tree transplanting machine | 0.1634 | 0.5816 | 0.1634 | 0.4444 | 0.2407 |

| New tree-planting machine | 0.5396 | 0.3090 | 0.2970 | 0.4444 | 0.4179 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, F.; Jing, Y.; Shao, P.; Zhang, Y. Research on Design Method of Product Functional Hybridization for Integrated Innovation. Appl. Sci. 2022, 12, 10302. https://doi.org/10.3390/app122010302

Liu F, Jing Y, Shao P, Zhang Y. Research on Design Method of Product Functional Hybridization for Integrated Innovation. Applied Sciences. 2022; 12(20):10302. https://doi.org/10.3390/app122010302

Chicago/Turabian StyleLiu, Fang, Yingchao Jing, Peng Shao, and Yazhen Zhang. 2022. "Research on Design Method of Product Functional Hybridization for Integrated Innovation" Applied Sciences 12, no. 20: 10302. https://doi.org/10.3390/app122010302

APA StyleLiu, F., Jing, Y., Shao, P., & Zhang, Y. (2022). Research on Design Method of Product Functional Hybridization for Integrated Innovation. Applied Sciences, 12(20), 10302. https://doi.org/10.3390/app122010302